LM2672

SIMPLE SWITCHER

®

Power Converter High Efficiency

1A Step-Down Voltage Regulator with Features

General Description

The LM2672 series of regulators are monolithic integrated

circuits built with a LMDMOS process. These regulators pro-

vide all the active functions for a step-down (buck) switching

regulator, capable of driving a 1A load current with excellent

line and load regulation. These devices are available in fixed

output voltages of 3.3V, 5.0V, 12V, and an adjustable output

version.

Requiring a minimum number of external components, these

regulators are simple to use and include patented internal

frequency compensation (Patent Nos. 5,382,918 and

5,514,947), fixed frequency oscillator, external shutdown,

soft-start, and frequency synchronization.

The LM2672 series operates at a switching frequency of

260 kHz, thus allowing smaller sized filter components than

what would be needed with lower frequency switching regu-

lators. Because of its very high efficiency (

>

90%), the cop-

per traces on the printed circuit board are the only heat sink-

ing needed.

A family of standard inductors for use with the LM2672 are

available from several different manufacturers. This feature

greatly simplifies the design of switch-mode power supplies

using these advanced ICs. Also included in the datasheet

are selector guides for diodes and capacitors designed to

work in switch-mode power supplies.

Other features include a guaranteed

±

1.5% tolerance on

output voltage within specified input voltages and output

load conditions, and

±

10% on the oscillator frequency. Ex-

ternal shutdown is included, featuring typically 50 µA

stand-by current. The output switch includes current limiting,

as well as thermal shutdown for full protection under fault

conditions.

To simplify the LM2672 buck regulator design procedure,

there exists computer design software,

LM267X Made

Simple

version 6.0.

Features

n

Efficiency up to 96%

n

Available in SO-8 and 8-pin DIP packages

n

Computer Design Software

LM267X Made Simple

version 6.0

n

Simple and easy to design with

n

Requires only 5 external components

n

Uses readily available standard inductors

n

3.3V, 5.0V, 12V, and adjustable output versions

n

Adjustable version output voltage range: 1.21V to 37V

n

±

1.5% max output voltage tolerance over line and load

conditions

n

Guaranteed 1A output load current

n

0.25

Ω

DMOS Output Switch

n

Wide input voltage range: 8V to 40V

n

260 kHz fixed frequency internal oscillator

n

TTL shutdown capability, low power standby mode

n

Soft-start and frequency synchronization

n

Thermal shutdown and current limit protection

Typical Applications

n

Simple High Efficiency (

>

90%) Step-Down (Buck)

Regulator

n

Efficient Pre-Regulator for Linear Regulators

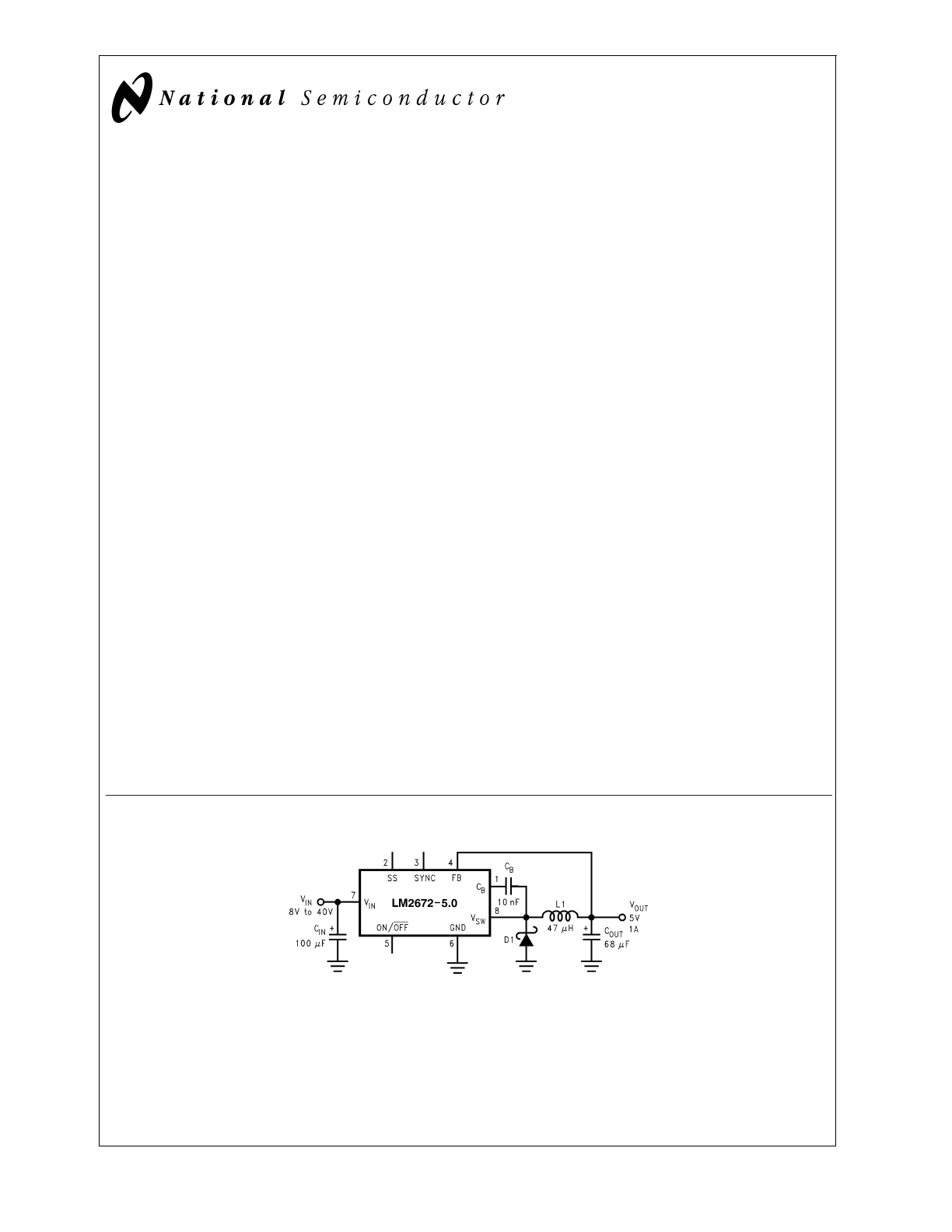

Typical Application

(Fixed Output Voltage Versions)

SIMPLE SWITCHER

®

is a registered trademark of National Semiconductor Corporation.

Windows

®

is a registered trademark of Microsoft Corporation.

DS012934-1

August 2000

LM2672

SIMPLE

SWITCHER

Power

Converter

High

Efficiency

1A

Step-Down

V

oltage

Regulator

with

Features

© 2000 National Semiconductor Corporation

DS012934

www.national.com

Absolute Maximum Ratings

(Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Supply Voltage

45V

ON/OFF Pin Voltage

−0.1V

≤

V

SH

≤

6V

Switch Voltage to Ground

−1V

Boost Pin Voltage

V

SW

+ 8V

Feedback Pin Voltage

−0.3V

≤

V

FB

≤

14V

ESD Susceptibility

Human Body Model (Note 2)

2 kV

Power Dissipation

Internally Limited

Storage Temperature Range

−65˚C to +150˚C

Lead Temperature

M Package

Vapor Phase (60s)

+215˚C

Infrared (15s)

+220˚C

N Package (Soldering, 10s)

+260˚C

Maximum Junction Temperature

+150˚C

Operating Ratings

Supply Voltage

6.5V to 40V

Temperature Range

−40˚C

≤

T

J

≤

+125˚C

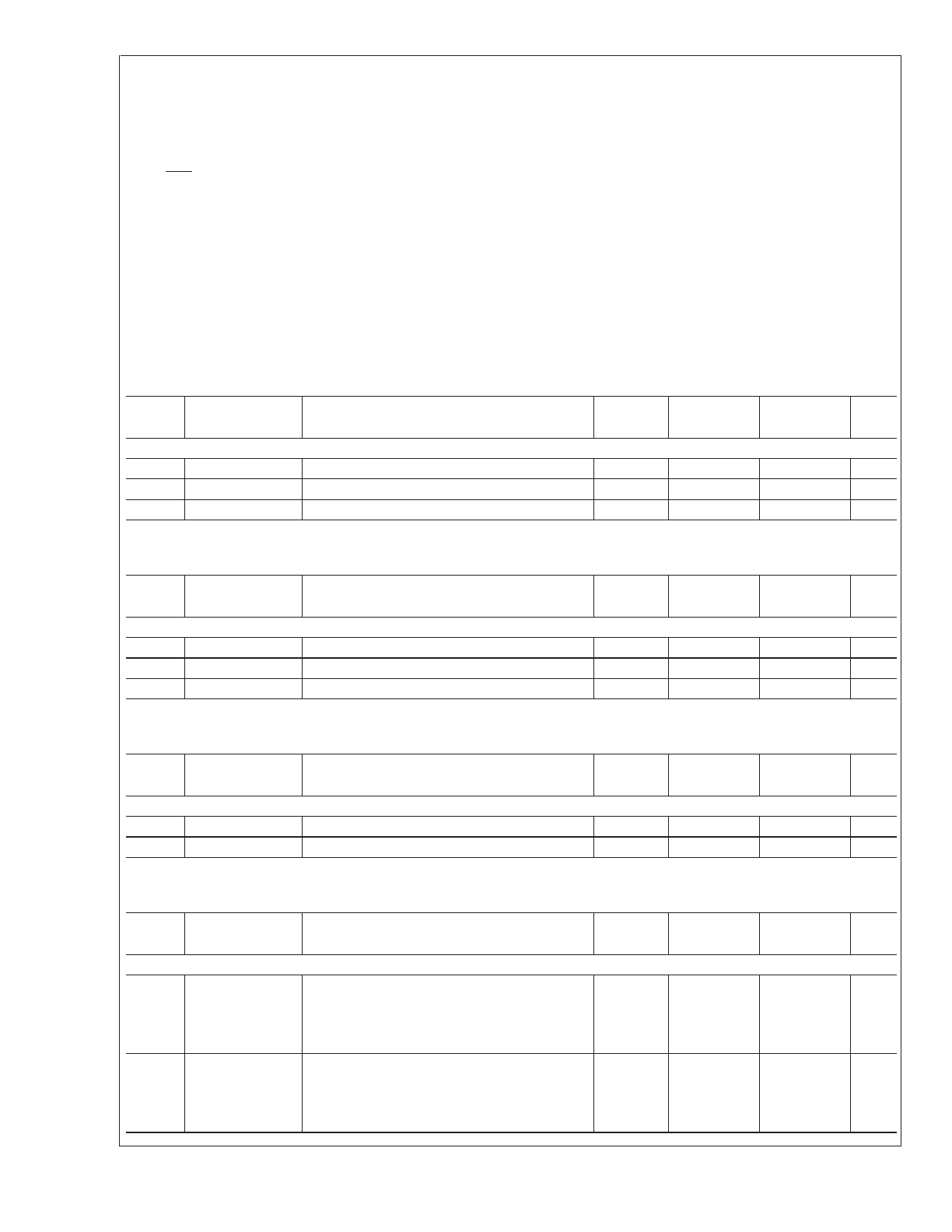

Electrical Characteristics

Specifications with standard type face are for T

J

= 25˚C, and those in bold type

face apply over full Operating Temperature Range.

LM2672-3.3

Symbol

Parameter

Conditions

Typical

Min

Max

Units

(Note 4)

(Note 5)

(Note 5)

SYSTEM PARAMETERS Test Circuit

Figure 2

(Note 3)

V

OUT

Output Voltage

V

IN

= 8V to 40V, I

LOAD

= 20 mA to 1A

3.3

3.251/3.201

3.350/3.399

V

V

OUT

Output Voltage

V

IN

= 6.5V to 40V, I

LOAD

= 20 mA to 500 mA

3.3

3.251/3.201

3.350/3.399

V

η

Efficiency

V

IN

= 12V, I

LOAD

= 1A

86

%

LM2672-5.0

Symbol

Parameter

Conditions

Typical

Min

Max

Units

(Note 4)

(Note 5)

(Note 5)

SYSTEM PARAMETERS Test Circuit

Figure 2

(Note 3)

V

OUT

Output Voltage

V

IN

= 8V to 40V, I

LOAD

= 20 mA to 1A

5.0

4.925/4.850

5.075/5.150

V

V

OUT

Output Voltage

V

IN

= 6.5V to 40V, I

LOAD

= 20 mA to 500 mA

5.0

4.925/4.850

5.075/5.150

V

η

Efficiency

V

IN

= 12V, I

LOAD

= 1A

90

%

LM2672-12

Symbol

Parameter

Conditions

Typical

Min

Max

Units

(Note 4)

(Note 5)

(Note 5)

SYSTEM PARAMETERS Test Circuit

Figure 2

(Note 3)

V

OUT

Output Voltage

V

IN

= 15V to 40V, I

LOAD

= 20 mA to 1A

12

11.82/11.64

12.18/12.36

V

η

Efficiency

V

IN

= 24V, I

LOAD

= 1A

94

%

LM2672-ADJ

Symbol

Parameter

Conditions

Typ

Min

Max

Units

(Note 4)

(Note 5)

(Note 5)

SYSTEM PARAMETERS Test Circuit

Figure 3

(Note 3)

V

FB

Feedback

Voltage

V

IN

= 8V to 40V, I

LOAD

= 20 mA to 1A

1.210

1.192/1.174

1.228/1.246

V

V

OUT

Programmed for 5V

(see Circuit of

Figure 3

)

V

FB

Feedback

Voltage

V

IN

= 6.5V to 40V, I

LOAD

= 20 mA to 500 mA

1.210

1.192/1.174

1.228/1.246

V

V

OUT

Programmed for 5V

(see Circuit of

Figure 3

)

LM2672

www.national.com

2

LM2672-ADJ

(Continued)

Symbol

Parameter

Conditions

Typ

Min

Max

Units

(Note 4)

(Note 5)

(Note 5)

SYSTEM PARAMETERS Test Circuit

Figure 3

(Note 3)

η

Efficiency

V

IN

= 12V, I

LOAD

= 1A

90

%

All Output Voltage Versions

Electrical Characteristics

Specifications with standard type face are for T

J

= 25˚C, and those in bold type face apply over full Operating Temperature

Range. Unless otherwise specified, V

IN

= 12V for the 3.3V, 5V, and Adjustable versions and V

IN

= 24V for the 12V version,

and I

LOAD

= 100 mA.

Symbol

Parameters

Conditions

Typ

Min

Max

Units

DEVICE PARAMETERS

I

Q

Quiescent Current

V

FEEDBACK

= 8V

2.5

3.6

mA

For 3.3V, 5.0V, and ADJ Versions

V

FEEDBACK

= 15V

2.5

mA

For 12V Versions

I

STBY

Standby Quiescent Current

ON/OFF Pin = 0V

50

100/150

µA

I

CL

Current Limit

1.55

1.25/1.2

2.1/2.2

A

I

L

Output Leakage Current

V

IN

= 40V, ON/OFF Pin = 0V

1

25

µA

V

SWITCH

= 0V

V

SWITCH

= −1V, ON/OFF Pin = 0V

6

15

mA

R

DS(ON)

Switch On-Resistance

I

SWITCH

= 1A

0.25

0.30/0.50

Ω

f

O

Oscillator Frequency

Measured at Switch Pin

260

225

275

kHz

D

Maximum Duty Cycle

95

%

Minimum Duty Cycle

0

%

I

BIAS

Feedback Bias

V

FEEDBACK

= 1.3V

85

nA

Current

ADJ Version Only

V

S/D

ON/OFF Pin

1.4

0.8

2.0

V

Voltage Thesholds

I

S/D

ON/OFF Pin Current

ON/OFF Pin = 0V

20

7

37

µA

F

SYNC

Synchronization Frequency

V

SYNC

= 3.5V, 50% duty cycle

400

kHz

V

SYNC

Synchronization Threshold

Voltage

1.4

V

V

SS

Soft-Start Voltage

0.63

0.53

0.73

V

I

SS

Soft-Start Current

4.5

1.5

6.9

µA

θ

JA

Thermal Resistance

N Package, Junction to Ambient (Note 6)

95

˚C/W

M Package, Junction to Ambient (Note 6)

105

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is in-

tended to be functional, but device parameter specifications may not be guaranteed under these conditions. For guaranteed specifications and test conditions, see

the Electrical Characteristics.

Note 2: The human body model is a 100 pF capacitor discharged through a 1.5 k

Ω

resistor into each pin.

Note 3: External components such as the catch diode, inductor, input and output capacitors, and voltage programming resistors can affect switching regulator per-

formance. When the LM2672 is used as shown in

Figure 2 and Figure 3 test circuits, system performance will be as specified by the system parameters section of

the Electrical Characteristics.

Note 4: Typical numbers are at 25˚C and represent the most likely norm.

Note 5: All limits guaranteed at room temperature (standard type face) and at temperature extremes (bold type face). All room temperature limits are 100% pro-

duction tested. All limits at temperature extremes are guaranteed via correlation using standard Statistical Quality Control (SQC) methods. All limits are used to cal-

culate Average Outgoing Quality Level (AOQL).

Note 6: Junction to ambient thermal resistance with approximately 1 square inch of printed circuit board copper surrounding the leads. Additional copper area will

lower thermal resistance further. See Application Information section in the application note accompanying this datasheet and the thermal model in

LM267X Made

Simple version 6.0 software.

LM2672

www.national.com

3

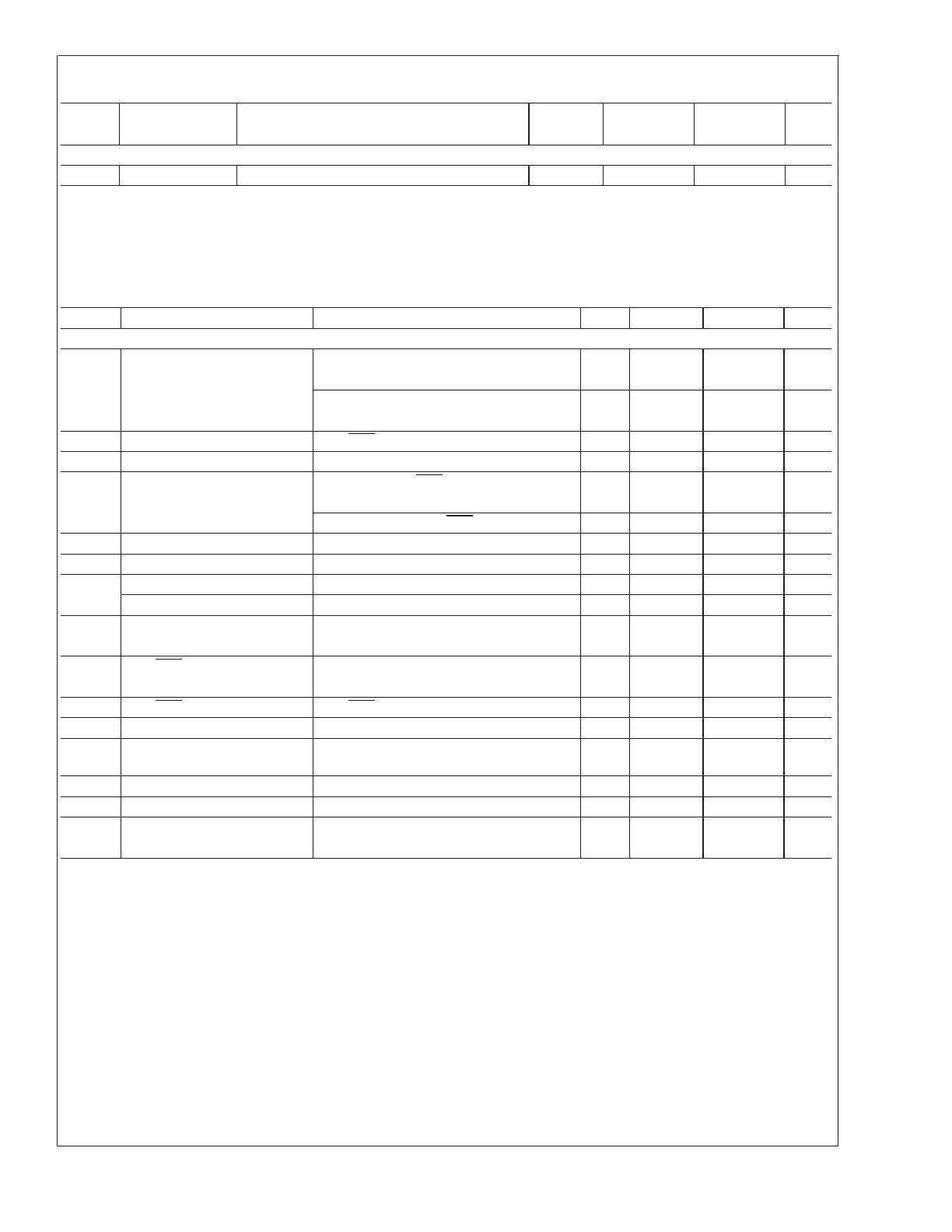

Connection Diagram

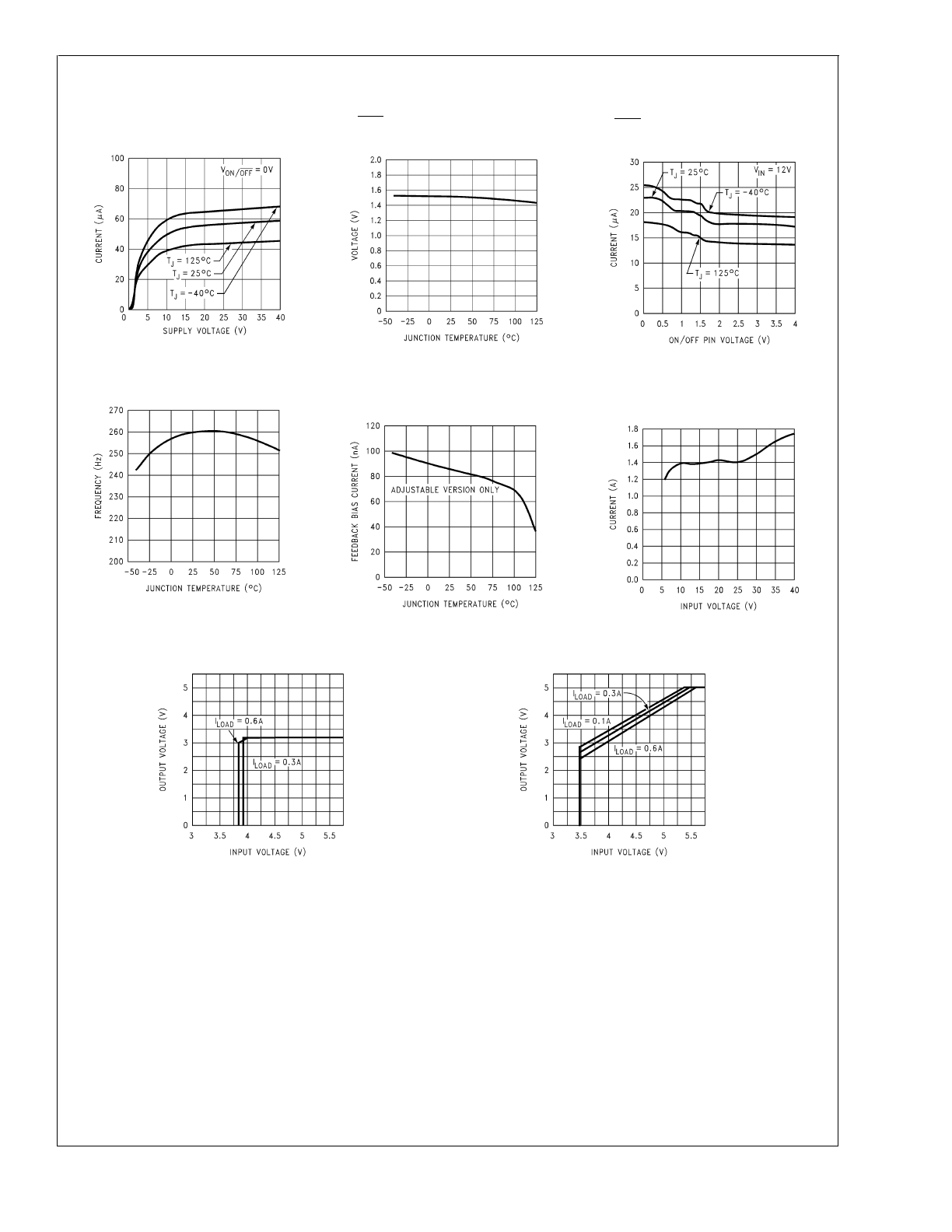

Typical Performance Characteristics

8-Lead Package

Top View

DS012934-2

For Surface Mount Package

Order Number

LM2672M-3.3, LM2672M-5.0,

LM2672M-12 or LM2672M-ADJ

See NSC Package Number M08A

For DIP Package

Order Number

LM2672N-3.3, LM2672N-5.0,

LM2672N-12 or LM2672N-ADJ

See NSC Package Number N08E

Normalized

Output Voltage

DS012934-3

Line Regulation

DS012934-4

Efficiency

DS012934-5

Drain-to-Source

Resistance

DS012934-6

Switch Current Limit

DS012934-7

Operating

Quiescent Current

DS012934-8

LM2672

www.national.com

4

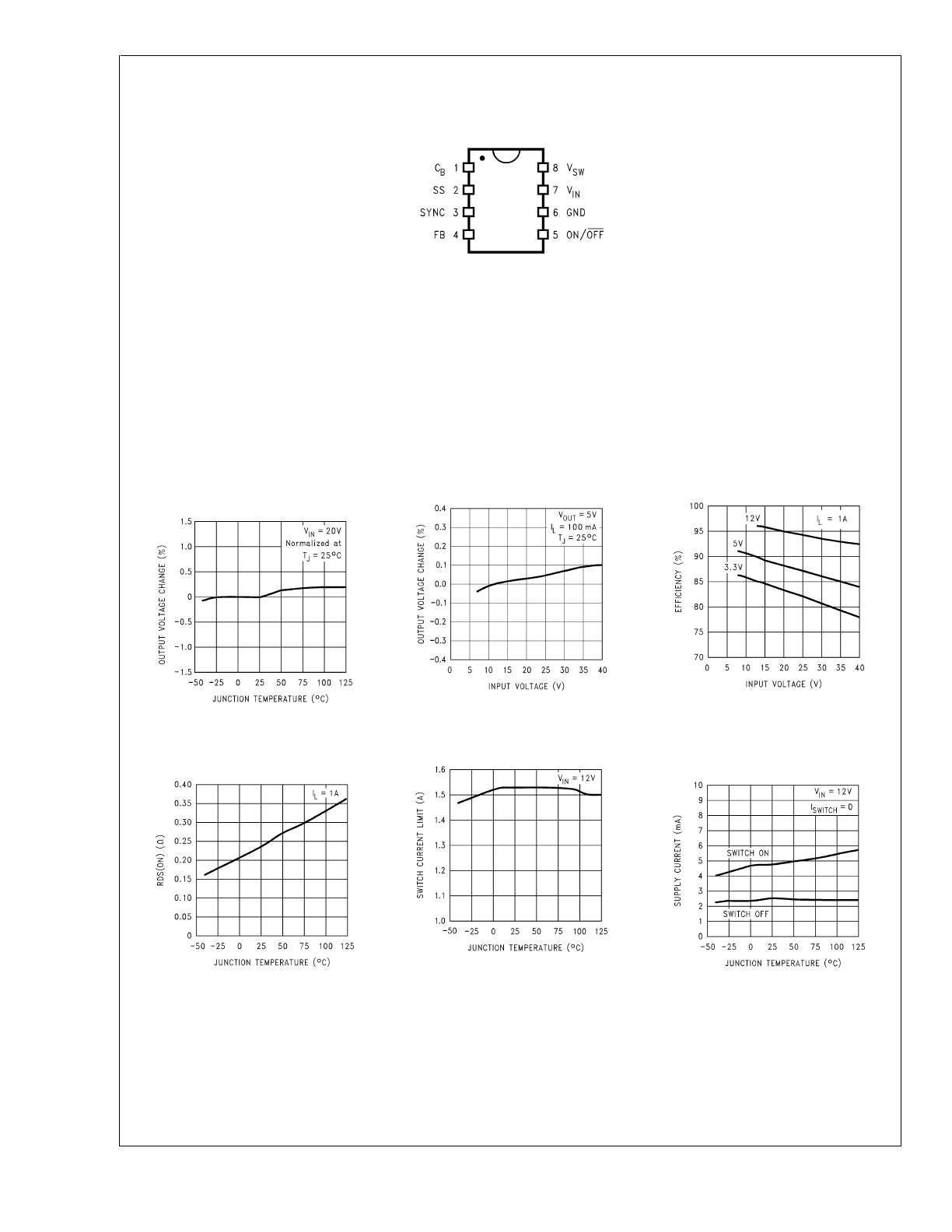

Typical Performance Characteristics

(Continued)

Standby

Quiescent Current

DS012934-9

ON/OFF Threshold

Voltage

DS012934-10

ON/OFF Pin

Current (Sourcing)

DS012934-11

Switching Frequency

DS012934-12

Feedback Pin

Bias Current

DS012934-13

Peak Switch Current

DS012934-14

Dropout Voltage — 3.3V Option

DS012934-15

Dropout Voltage — 5.0V Option

DS012934-16

LM2672

www.national.com

5

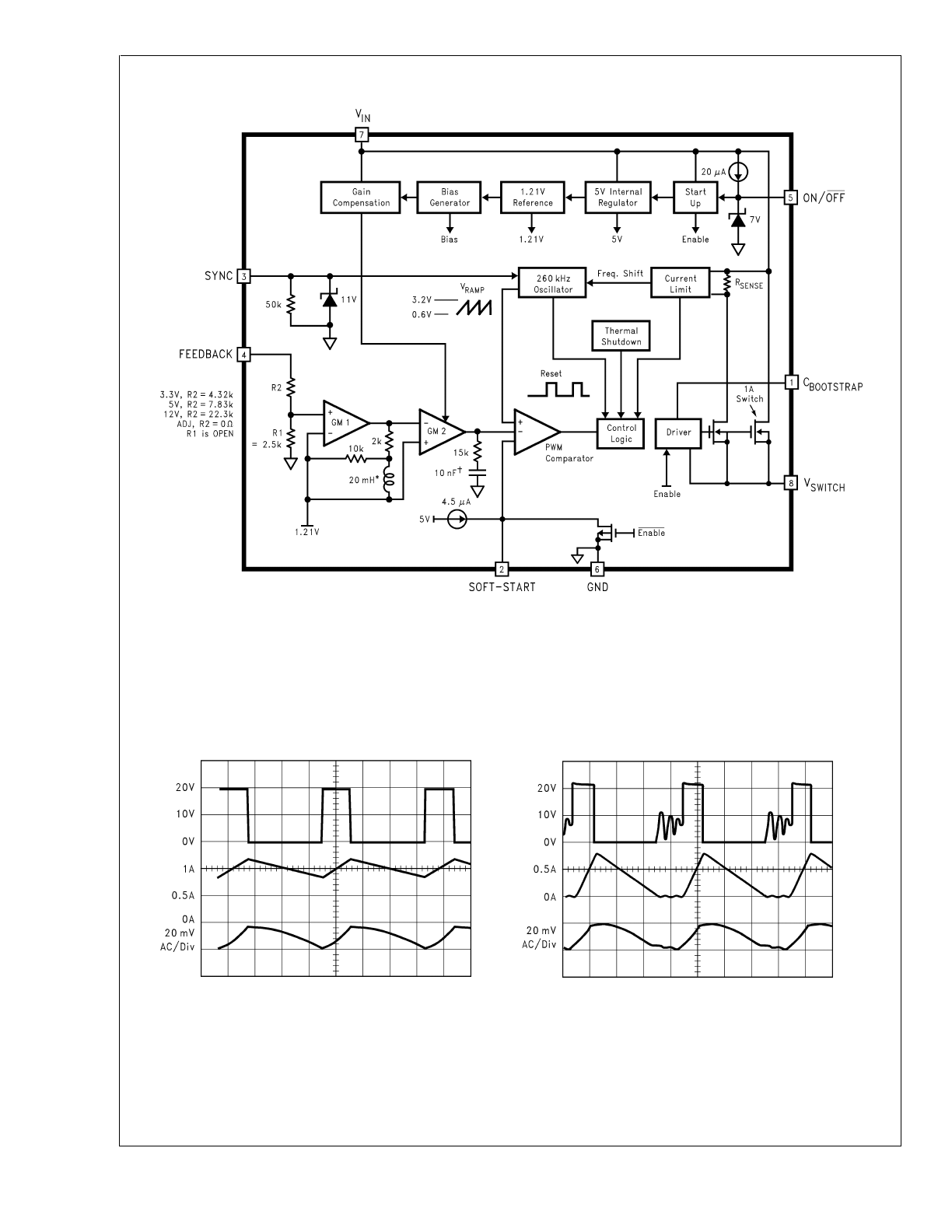

Block Diagram

Typical Performance Characteristics

(Circuit of

Figure 2

)

DS012934-17

* Patent Number 5,514,947

†

Patent Number 5,382,918

FIGURE 1.

Continuous Mode Switching Waveforms

V

IN

= 20V, V

OUT

= 5V, I

LOAD

= 1A

L = 47 µH, C

OUT

= 68 µF, C

OUT

ESR = 50 m

Ω

DS012934-18

A: V

SW

Pin Voltage, 10 V/div.

B: Inductor Current, 0.5 A/div

C: Output Ripple Voltage, 20 mV/div AC-Coupled

Horizontal Time Base: 1 µs/div

Discontinuous Mode Switching Waveforms

V

IN

= 20V, V

OUT

= 5V, I

LOAD

= 300 mA

L = 15 µH, C

OUT

= 68 µF (2x), C

OUT

ESR = 25 m

Ω

DS012934-19

A: V

SW

Pin Voltage, 10 V/div.

B: Inductor Current, 0.5 A/div

C: Output Ripple Voltage, 20 mV/div AC-Coupled

Horizontal Time Base: 1 µs/div

LM2672

www.national.com

6

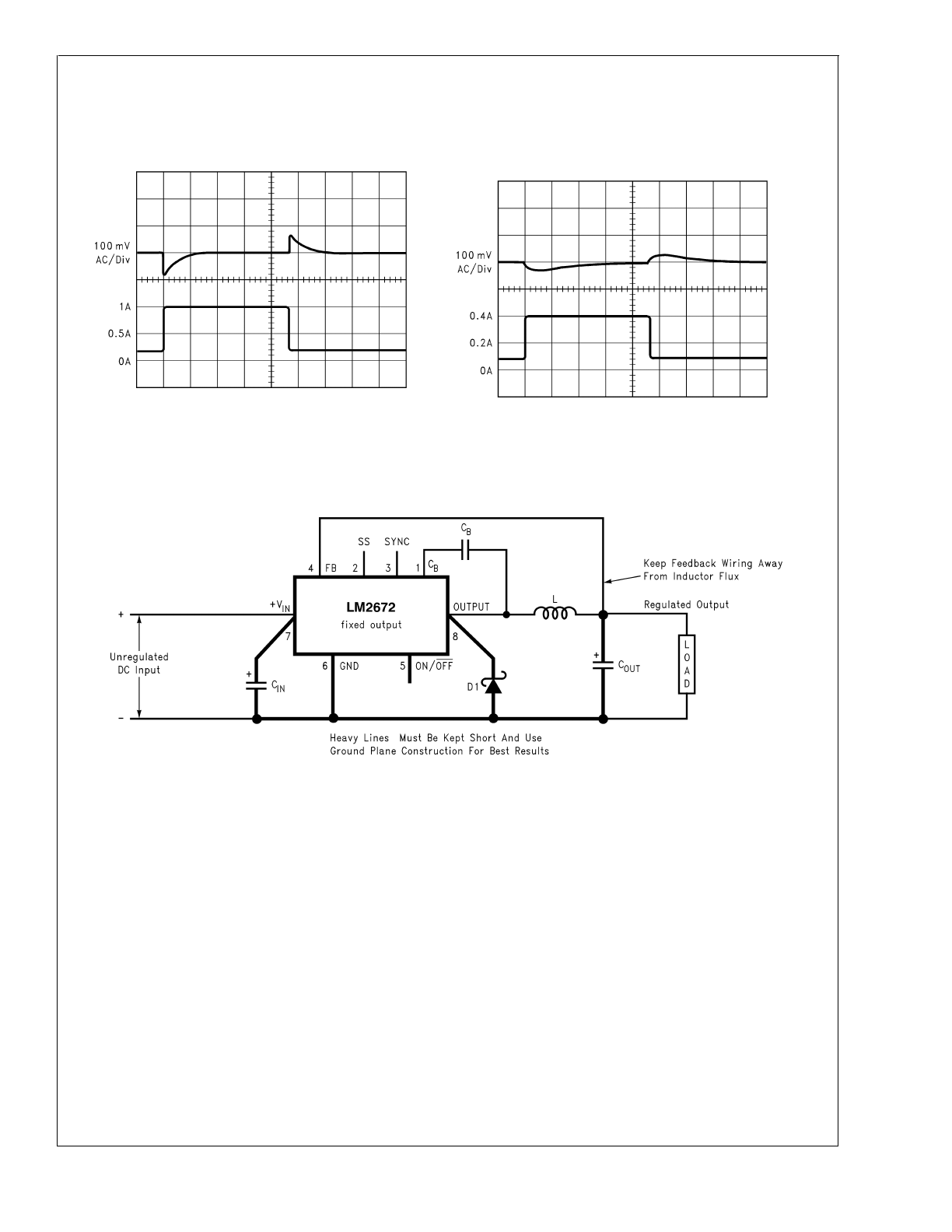

Typical Performance Characteristics

(Circuit of

Figure 2

) (Continued)

Test Circuit and Layout Guidelines

Load Transient Response for Continuous Mode

V

IN

= 20V, V

OUT

= 5V, I

LOAD

= 1A

L = 47 µH, C

OUT

= 68 µF, C

OUT

ESR = 50 m

Ω

DS012934-20

A: Output Voltage, 100 mV/div, AC-Coupled

B: Load Current: 200 mA to 1A Load Pulse

Horizontal Time Base: 50 µs/div

Load Transient Response for Discontinuous Mode

V

IN

= 20V, V

OUT

= 5V,

L = 47 µH, C

OUT

= 68 µF, C

OUT

ESR = 50 m

Ω

DS012934-21

A: Output Voltage, 100 mV/div, AC-Coupled

B: Load Current: 100 mA to 300 mA Load Pulse

Horizontal Time Base: 200 µs/div

DS012934-22

C

IN

- 22 µF, 50V Tantalum, Sprague “199D Series”

C

OUT

- 47 µF, 25V Tantalum, Sprague “595D Series”

D1 - 3.3A, 50V Schottky Rectifier, IR 30WQ05F

L1 - 68 µH Sumida #RCR110D-680L

C

B

- 0.01 µF, 50V Ceramic

FIGURE 2. Standard Test Circuits and Layout Guides

Fixed Output Voltage Versions

LM2672

www.national.com

7

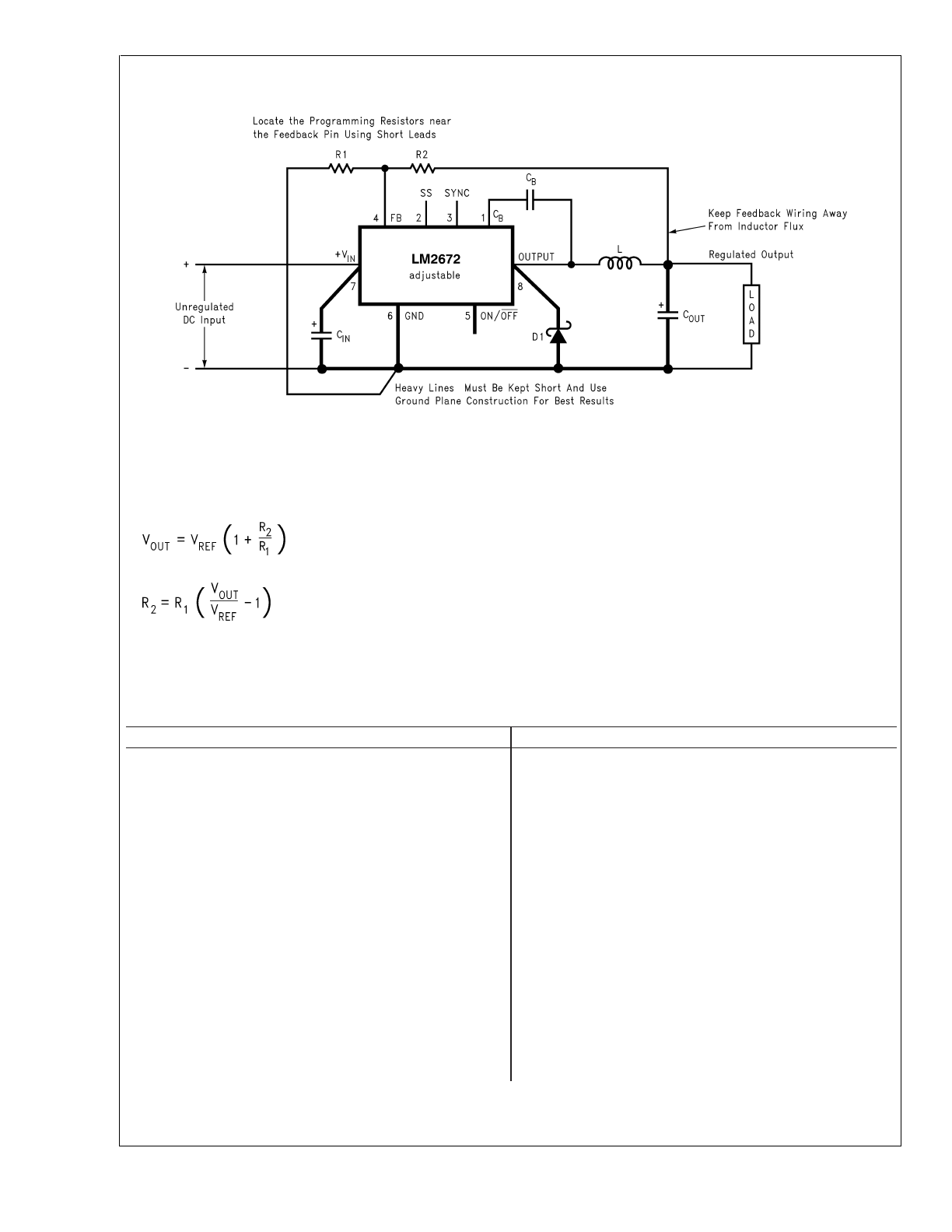

Test Circuit and Layout Guidelines

(Continued)

LM2672 Series Buck Regulator Design Procedure (Fixed Output)

PROCEDURE (Fixed Output Voltage Version)

EXAMPLE (Fixed Output Voltage Version)

To simplify the buck regulator design procedure, National

Semiconductor is making available computer design software

to be used with the

SIMPLE SWITCHER

line of switching

regulators. LM267X Made Simple

version 6.0 is available on

Windows

®

3.1, NT, or 95 operating systems.

Given:

Given:

V

OUT

= Regulated Output Voltage (3.3V, 5V, or 12V)

V

OUT

= 5V

V

IN

(max) = Maximum DC Input Voltage

V

IN

(max) = 12V

I

LOAD

(max) = Maximum Load Current

I

LOAD

(max) = 1A

1. Inductor Selection (L1)

A. Select the correct inductor value selection guide from

Figure

4

and

Figure 5

or

Figure 6

(output voltages of 3.3V, 5V, or 12V

respectively). For all other voltages, see the design procedure

for the adjustable version.

1. Inductor Selection (L1)

A. Use the inductor selection guide for the 5V version shown

in

Figure 5

.

B. From the inductor value selection guide, identify the

inductance region intersected by the Maximum Input Voltage

line and the Maximum Load Current line. Each region is

identified by an inductance value and an inductor code (LXX).

B. From the inductor value selection guide shown in

Figure 5

,

the inductance region intersected by the 12V horizontal line

and the 1A vertical line is 33 µH, and the inductor code is L23.

DS012934-23

C

IN

- 22 µF, 50V Tantalum, Sprague “199D Series”

C

OUT

- 47 µF, 25V Tantalum, Sprague “595D Series”

D1 - 3.3A, 50V Schottky Rectifier, IR 30WQ05F

L1 - 68 µH Sumida #RCR110D-680L

R1 - 1.5 k

Ω

, 1%

C

B

- 0.01 µF, 50V Ceramic

For a 5V output, select R2 to be 4.75 k

Ω

, 1%

where V

REF

= 1.21V

Use a 1% resistor for best stability.

FIGURE 3. Standard Test Circuits and Layout Guides

Adjustable Output Voltage Versions

LM2672

www.national.com

8

LM2672 Series Buck Regulator Design Procedure (Fixed Output)

(Continued)

PROCEDURE (Fixed Output Voltage Version)

EXAMPLE (Fixed Output Voltage Version)

C. Select an appropriate inductor from the four manufacturer’s

part numbers listed in

Figure 8

. Each manufacturer makes a

different style of inductor to allow flexibility in meeting various

design requirements. Listed below are some of the

differentiating characteristics of each manufacturer’s inductors:

C. The inductance value required is 33 µH. From the table in

Figure 8

, go to the L23 line and choose an inductor part

number from any of the four manufacturers shown. (In most

instances, both through hole and surface mount inductors are

available.)

Schott:

ferrite EP core inductors; these have very low leakage

magnetic fields to reduce electro-magnetic interference (EMI)

and are the lowest power loss inductors

Renco:

ferrite stick core inductors; benefits are typically lowest

cost inductors and can withstand E

•

T and transient peak

currents above rated value. Be aware that these inductors

have an external magnetic field which may generate more EMI

than other types of inductors.

Pulse:

powered iron toroid core inductors; these can also be

low cost and can withstand larger than normal E

•

T and

transient peak currents. Toroid inductors have low EMI.

Coilcraft:

ferrite drum core inductors; these are the smallest

physical size inductors, available only as SMT components. Be

aware that these inductors also generate EMI — but less than

stick inductors.

Complete specifications for these inductors are available from

the respective manufacturers. A table listing the manufacturers’

phone numbers is located in

Figure 9

.

2. Output Capacitor Selection (C

OUT

)

A. Select an output capacitor from the output capacitor table in

Figure 10

. Using the output voltage and the inductance value

found in the inductor selection guide, step 1, locate the

appropriate capacitor value and voltage rating.

2. Output Capacitor Selection (C

OUT

)

A. Use the 5.0V section in the output capacitor table in

Figure

10

. Choose a capacitor value and voltage rating from the line

that contains the inductance value of 33 µH. The capacitance

and voltage rating values corresponding to the 33 µH inductor

are the:

The capacitor list contains through-hole electrolytic capacitors

from four different capacitor manufacturers and surface mount

tantalum capacitors from two different capacitor manufacturers.

It is recommended that both the manufacturers and the

manufacturer’s series that are listed in the table be used. A

table listing the manufacturers’ phone numbers is located in

Figure 11

.

Surface Mount:

68 µF/10V

Sprague 594D Series.

100 µF/10V

AVX TPS Series.

Through Hole:

68 µF/10V

Sanyo OS-CON SA Series.

220 µF/35V

Sanyo MV-GX Series.

220 µF/35V

Nichicon PL Series.

220 µF/35V

Panasonic HFQ Series.

3. Catch Diode Selection (D1)

A. In normal operation, the average current of the catch diode

is the load current times the catch diode duty cycle, 1-D (D is

the switch duty cycle, which is approximately the output

voltage divided by the input voltage). The largest value of the

catch diode average current occurs at the maximum load

current and maximum input voltage (minimum D). For normal

operation, the catch diode current rating must be at least 1.3

times greater than its maximum average current. However, if

the power supply design must withstand a continuous output

short, the diode should have a current rating equal to the

maximum current limit of the LM2672. The most stressful

condition for this diode is a shorted output condition.

3. Catch Diode Selection (D1)

A. Refer to the table shown in

Figure 12

. In this example, a

1A, 20V Schottky diode will provide the best performance. If

the circuit must withstand a continuous shorted output, a

higher current Schottky diode is recommended.

B. The reverse voltage rating of the diode should be at least

1.25 times the maximum input voltage.

C. Because of their fast switching speed and low forward

voltage drop, Schottky diodes provide the best performance

and efficiency. This Schottky diode must be located close to

the LM2672 using short leads and short printed circuit traces.

LM2672

www.national.com

9

LM2672 Series Buck Regulator Design Procedure (Fixed Output)

(Continued)

PROCEDURE (Fixed Output Voltage Version)

EXAMPLE (Fixed Output Voltage Version)

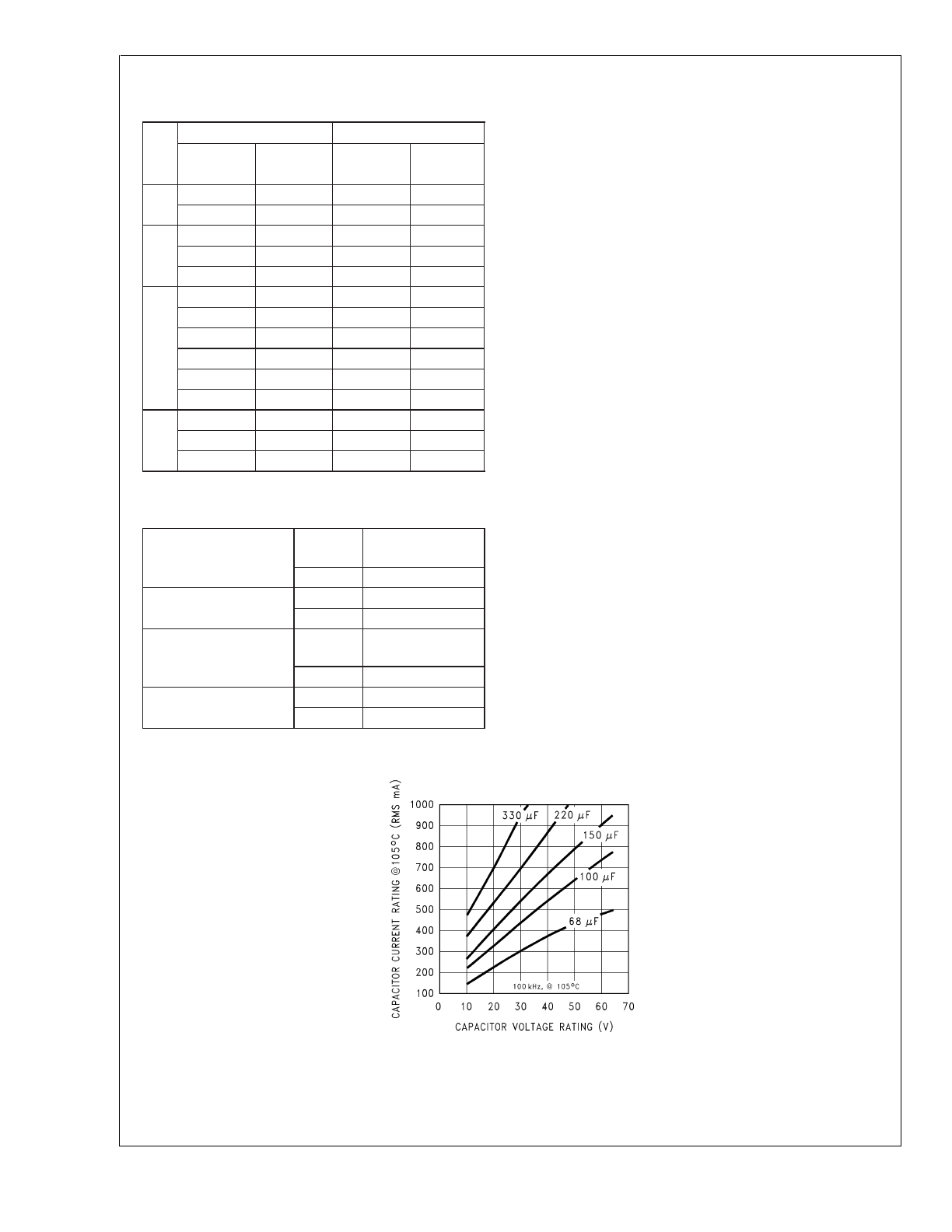

4. Input Capacitor (C

IN

)

A low ESR aluminum or tantalum bypass capacitor is needed

between the input pin and ground to prevent large voltage

transients from appearing at the input. This capacitor should

be located close to the IC using short leads. In addition, the

RMS current rating of the input capacitor should be selected to

be at least

1

⁄

2

the DC load current. The capacitor manufacturer

data sheet must be checked to assure that this current rating

is not exceeded. The curves shown in

Figure 14

show typical

RMS current ratings for several different aluminum electrolytic

capacitor values. A parallel connection of two or more

capacitors may be required to increase the total minimum RMS

current rating to suit the application requirements.

For an aluminum electrolytic capacitor, the voltage rating

should be at least 1.25 times the maximum input voltage.

Caution must be exercised if solid tantalum capacitors are

used. The tantalum capacitor voltage rating should be twice

the maximum input voltage. The tables in

Figure 15

show the

recommended application voltage for AVX TPS and Sprague

594D tantalum capacitors. It is also recommended that they be

surge current tested by the manufacturer. The TPS series

available from AVX, and the 593D and 594D series from

Sprague are all surge current tested. Another approach to

minimize the surge current stresses on the input capacitor is to

add a small inductor in series with the input supply line.

Use caution when using ceramic capacitors for input

bypassing, because it may cause severe ringing at the V

IN

pin.

4. Input Capacitor (C

IN

)

The important parameters for the input capacitor are the input

voltage rating and the RMS current rating. With a maximum

input voltage of 12V, an aluminum electrolytic capacitor with a

voltage rating greater than 15V (1.25 x V

IN

) would be needed.

The next higher capacitor voltage rating is 16V.

The RMS current rating requirement for the input capacitor in a

buck regulator is approximately

1

⁄

2

the DC load current. In this

example, with a 1A load, a capacitor with a RMS current rating

of at least 500 mA is needed. The curves shown in

Figure 14

can be used to select an appropriate input capacitor. From the

curves, locate the 16V line and note which capacitor values

have RMS current ratings greater than 500 mA.

For a through hole design, a 330 µF/16V electrolytic capacitor

(Panasonic HFQ series, Nichicon PL, Sanyo MV-GX series or

equivalent) would be adequate. Other types or other

manufacturers’ capacitors can be used provided the RMS

ripple current ratings are adequate. Additionally, for a complete

surface mount design, electrolytic capacitors such as the

Sanyo CV-C or CV-BS and the Nichicon WF or UR and the

NIC Components NACZ series could be considered.

For surface mount designs, solid tantalum capacitors can be

used, but caution must be exercised with regard to the

capacitor surge current rating and voltage rating. In this

example, checking

Figure 15

, and the Sprague 594D series

datasheet, a Sprague 594D 15 µF, 25V capacitor is adequate.

5. Boost Capacitor (C

B

)

This capacitor develops the necessary voltage to turn the

switch gate on fully. All applications should use a 0.01 µF, 50V

ceramic capacitor.

5. Boost Capacitor (C

B

)

For this application, and all applications, use a 0.01 µF, 50V

ceramic capacitor.

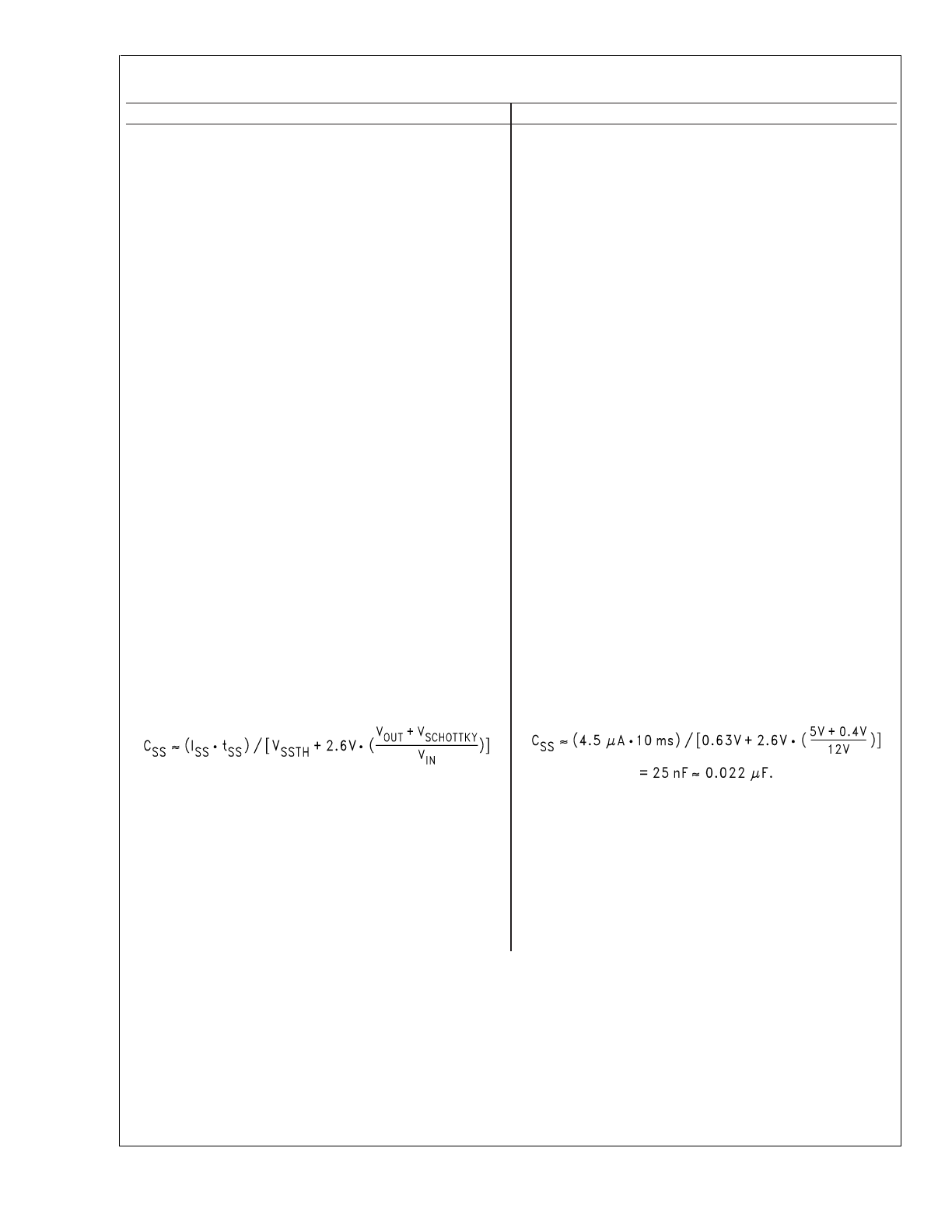

6. Soft-Start Capacitor (C

SS

- optional)

This capacitor controls the rate at which the device starts up.

The formula for the soft-start capacitor C

SS

is:

6. Soft-Start Capacitor (C

SS

- optional)

For this application, selecting a start-up time of 10 ms and

using the formula for C

SS

results in a value of:

where:

I

SS

= Soft-Start Current

:4.5 µA typical.

t

SS

= Soft-Start Time

:Selected.

V

SSTH

= Soft-Start Threshold Voltage

:0.63V typical.

V

OUT

= Output Voltage

:Selected.

V

SCHOTTKY

= Schottky Diode Voltage Drop

:0.4V typical.

V

IN

= Input Voltage

:Selected.

If this feature is not desired, leave this pin open.

LM2672

www.national.com

10

LM2672 Series Buck Regulator Design Procedure (Fixed Output)

(Continued)

PROCEDURE (Fixed Output Voltage Version)

EXAMPLE (Fixed Output Voltage Version)

7. Frequency Synchronization (optional)

The LM2672 (oscillator) can be synchronized to run with an

external oscillator, using the sync pin (pin 3). By doing so, the

LM2672 can be operated at higher frequencies than the

standard frequency of 260 kHz. This allows for a reduction in

the size of the inductor and output capacitor.

As shown in the drawing below, a signal applied to a RC filter

at the sync pin causes the device to synchronize to the

frequency of that signal. For a signal with a peak-to-peak

amplitude of 3V or greater, a 1 k

Ω

resistor and a 100 pF

capacitor are suitable values.

7. Frequency Synchronization (optional)

For all applications, use a 1 k

Ω

resistor and a 100 pF capacitor

for the RC filter.

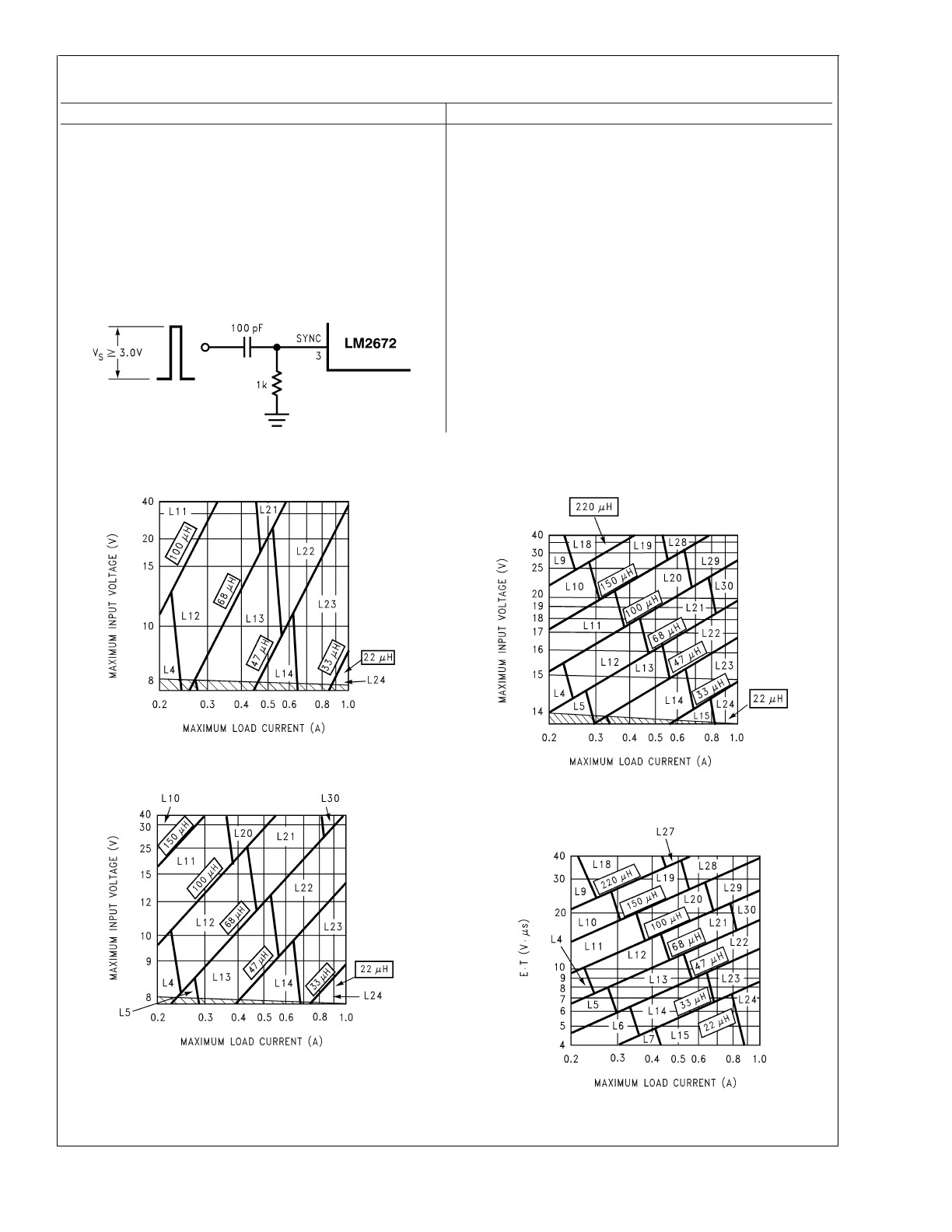

INDUCTOR VALUE SELECTION GUIDES (For Continuous Mode Operation)

DS012934-29

FIGURE 4. LM2672-3.3

DS012934-30

FIGURE 5. LM2672-5.0

DS012934-31

FIGURE 6. LM2672-12

DS012934-32

FIGURE 7. LM2672-ADJ

LM2672

www.national.com

11

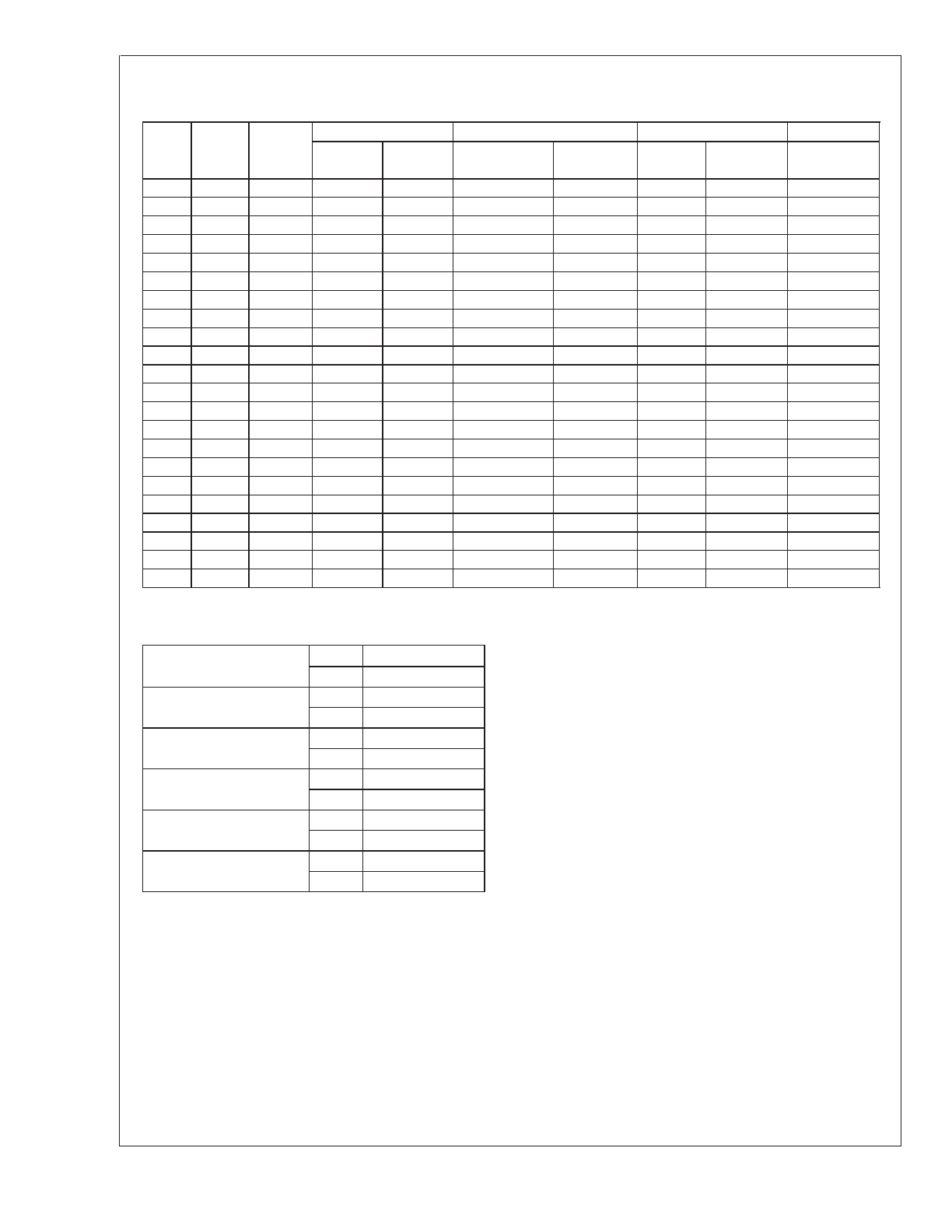

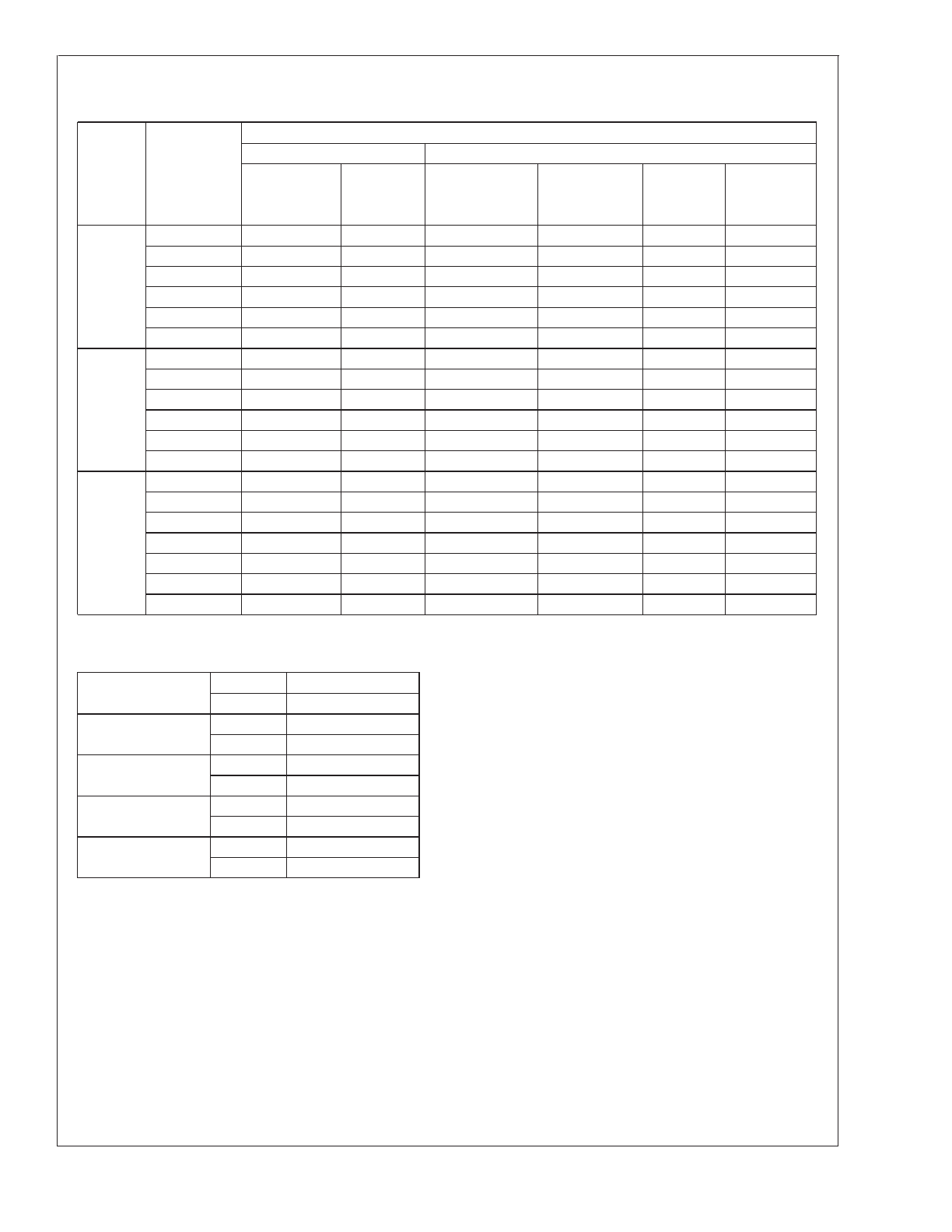

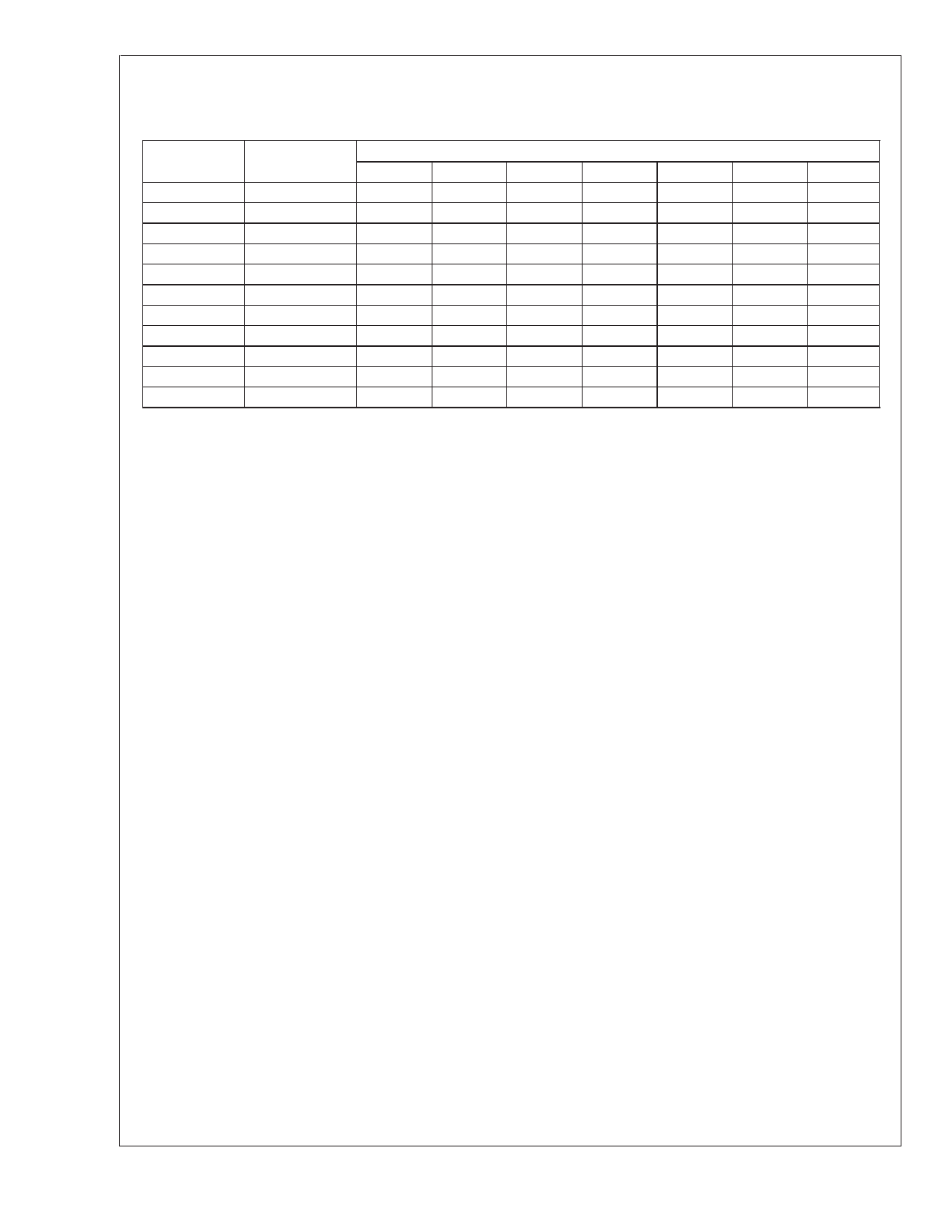

LM2672 Series Buck Regulator Design Procedure (Fixed Output)

(Continued)

Ind.

Ref.

Desg.

Induc-

tance

(µH)

Current

(A)

Schott

Renco

Pulse Engineering

Coilcraft

Through

Surface

Through

Surface

Through

Surface

Surface

Hole

Mount

Hole

Mount

Hole

Mount

Mount

L4

68

0.32

67143940

67144310

RL-1284-68-43

RL1500-68

PE-53804

PE-53804-S

DO1608-683

L5

47

0.37

67148310

67148420

RL-1284-47-43

RL1500-47

PE-53805

PE-53805-S

DO1608-473

L6

33

0.44

67148320

67148430

RL-1284-33-43

RL1500-33

PE-53806

PE-53806-S

DO1608-333

L7

22

0.52

67148330

67148440

RL-1284-22-43

RL1500-22

PE-53807

PE-53807-S

DO1608-223

L9

220

0.32

67143960

67144330

RL-5470-3

RL1500-220

PE-53809

PE-53809-S

DO3308-224

L10

150

0.39

67143970

67144340

RL-5470-4

RL1500-150

PE-53810

PE-53810-S

DO3308-154

L11

100

0.48

67143980

67144350

RL-5470-5

RL1500-100

PE-53811

PE-53811-S

DO3308-104

L12

68

0.58

67143990

67144360

RL-5470-6

RL1500-68

PE-53812

PE-53812-S

DO3308-683

L13

47

0.70

67144000

67144380

RL-5470-7

RL1500-47

PE-53813

PE-53813-S

DO3308-473

L14

33

0.83

67148340

67148450

RL-1284-33-43

RL1500-33

PE-53814

PE-53814-S

DO3308-333

L15

22

0.99

67148350

67148460

RL-1284-22-43

RL1500-22

PE-53815

PE-53815-S

DO3308-223

L18

220

0.55

67144040

67144420

RL-5471-2

RL1500-220

PE-53818

PE-53818-S

DO3316-224

L19

150

0.66

67144050

67144430

RL-5471-3

RL1500-150

PE-53819

PE-53819-S

DO3316-154

L20

100

0.82

67144060

67144440

RL-5471-4

RL1500-100

PE-53820

PE-53820-S

DO3316-104

L21

68

0.99

67144070

67144450

RL-5471-5

RL1500-68

PE-53821

PE-53821-S

DO3316-683

L22

47

1.17

67144080

67144460

RL-5471-6

—

PE-53822

PE-53822-S

DO3316-473

L23

33

1.40

67144090

67144470

RL-5471-7

—

PE-53823

PE-53823-S

DO3316-333

L24

22

1.70

67148370

67148480

RL-1283-22-43

—

PE-53824

PE-53824-S

DO3316-223

L27

220

1.00

67144110

67144490

RL-5471-2

—

PE-53827

PE-53827-S

DO5022P-224

L28

150

1.20

67144120

67144500

RL-5471-3

—

PE-53828

PE-53828-S

DO5022P-154

L29

100

1.47

67144130

67144510

RL-5471-4

—

PE-53829

PE-53829-S

DO5022P-104

L30

68

1.78

67144140

67144520

RL-5471-5

—

PE-53830

PE-53830-S

DO5022P-683

FIGURE 8. Inductor Manufacturers’ Part Numbers

Coilcraft Inc.

Phone

(800) 322-2645

FAX

(708) 639-1469

Coilcraft Inc., Europe

Phone

+44 1236 730 595

FAX

+44 1236 730 627

Pulse Engineering Inc.

Phone

(619) 674-8100

FAX

(619) 674-8262

Pulse Engineering Inc.,

Phone

+353 93 24 107

Europe

FAX

+353 93 24 459

Renco Electronics Inc.

Phone

(800) 645-5828

FAX

(516) 586-5562

Schott Corp.

Phone

(612) 475-1173

FAX

(612) 475-1786

FIGURE 9. Inductor Manufacturers’ Phone Numbers

LM2672

www.national.com

12

LM2672 Series Buck Regulator Design Procedure (Fixed Output)

(Continued)

Output

Voltage

(V)

Inductance

(µH)

Output Capacitor

Surface Mount

Through Hole

Sprague

AVX TPS

Sanyo OS-CON

Sanyo MV-GX

Nichicon

Panasonic

594D Series

Series

SA Series

Series

PL Series

HFQ Series

(µF/V)

(µF/V)

(µF/V)

(µF/V)

(µF/V)

(µF/V)

3.3

22

120/6.3

100/10

100/10

330/35

330/35

330/35

33

120/6.3

100/10

68/10

220/35

220/35

220/35

47

68/10

100/10

68/10

150/35

150/35

150/35

68

120/6.3

100/10

100/10

120/35

120/35

120/35

100

120/6.3

100/10

100/10

120/35

120/35

120/35

150

120/6.3

100/10

100/10

120/35

120/35

120/35

5.0

22

100/16

100/10

100/10

330/35

330/35

330/35

33

68/10

10010

68/10

220/35

220/35

220/35

47

68/10

100/10

68/10

150/35

150/35

150/35

68

100/16

100/10

100/10

120/35

120/35

120/35

100

100/16

100/10

100/10

120/35

120/35

120/35

150

100/16

100/10

100/10

120/35

120/35

120/35

12

22

120/20

(2x) 68/20

68/20

330/35

330/35

330/35

33

68/25

68/20

68/20

220/35

220/35

220/35

47

47/20

68/20

47/20

150/35

150/35

150/35

68

47/20

68/20

47/20

120/35

120/35

120/35

100

47/20

68/20

47/20

120/35

120/35

120/35

150

47/20

68/20

47/20

120/35

120/35

120/35

220

47/20

68/20

47/20

120/35

120/35

120/35

FIGURE 10. Output Capacitor Table

Nichicon Corp.

Phone

(847) 843-7500

FAX

(847) 843-2798

Panasonic

Phone

(714) 373-7857

FAX

(714) 373-7102

AVX Corp.

Phone

(803) 448-9411

FAX

(803) 448-1943

Sprague/Vishay

Phone

(207) 324-4140

FAX

(207) 324-7223

Sanyo Corp.

Phone

(619) 661-6322

FAX

(619) 661-1055

FIGURE 11. Capacitor Manufacturers’ Phone Numbers

LM2672

www.national.com

13

LM2672 Series Buck Regulator Design Procedure (Fixed Output)

(Continued)

V

R

1A Diodes

3A Diodes

Surface

Through

Surface

Through

Mount

Hole

Mount

Hole

20V

SK12

1N5817

SK32

1N5820

B120

SR102

SR302

30V

SK13

1N5818

SK33

1N5821

B130

11DQ03

30WQ03F

31DQ03

MBRS130

SR103

40V

SK14

1N5819

SK34

1N5822

B140

11DQ04

30BQ040

MBR340

MBRS140

SR104

30WQ04F

31DQ04

10BQ040

MBRS340

SR304

10MQ040

MBRD340

15MQ040

50V

SK15

MBR150

SK35

MBR350

B150

11DQ05

30WQ05F

31DQ05

10BQ050

SR105

SR305

FIGURE 12. Schottky Diode Selection Table

International Rectifier

Corp.

Phone

(310) 322-3331

FAX

(310) 322-3332

Motorola, Inc.

Phone

(800) 521-6274

FAX

(602) 244-6609

General Instruments

Corp.

Phone

(516) 847-3000

FAX

(516) 847-3236

Diodes, Inc.

Phone

(805) 446-4800

FAX

(805) 446-4850

FIGURE 13. Diode Manufacturers’ Phone Numbers

DS012934-33

FIGURE 14. RMS Current Ratings for Low ESR Electrolytic Capacitors (Typical)

LM2672

www.national.com

14

LM2672 Series Buck Regulator Design Procedure (Fixed Output)

(Continued)

LM2672 Series Buck Regulator Design Procedure (Adjustable Output)

PROCEDURE (Adjustable Output Voltage Version)

EXAMPLE (Adjustable Output Voltage Version)

To simplify the buck regulator design procedure, National

Semiconductor is making available computer design software

to be used with the

SIMPLE SWITCHER

line of switching

regulators. LM267X Made Simple version 6.0 is available on

Windows

3.1, NT, or 95 operating systems.

Given:

Given:

V

OUT

= Regulated Output Voltage

V

OUT

= 20V

V

IN

(max) = Maximum Input Voltage

V

IN

(max) = 28V

I

LOAD

(max) = Maximum Load Current

I

LOAD

(max) = 1A

F = Switching Frequency

(Fixed at a nominal 260 kHz).

F = Switching Frequency

(Fixed at a nominal 260 kHz).

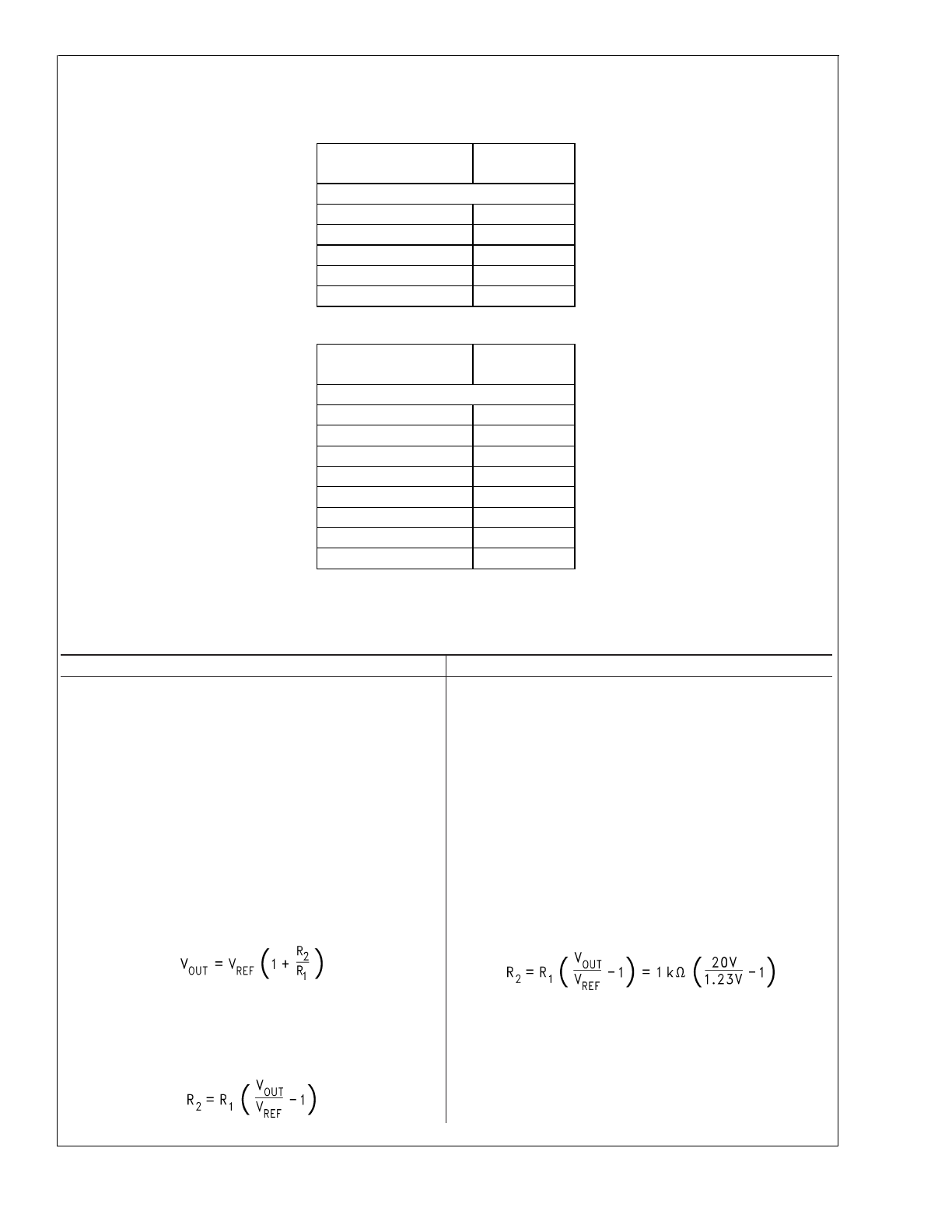

1. Programming Output Voltage (Selecting R

1

and R

2

, as

shown in

Figure 3

)

Use the following formula to select the appropriate resistor

values.

1. Programming Output Voltage (Selecting R

1

and R

2

, as

shown in

Figure 3

)

Select R

1

to be 1 k

Ω

, 1%. Solve for R

2

.

where V

REF

= 1.21V

Select a value for R

1

between 240

Ω

and 1.5 k

Ω

. The lower

resistor values minimize noise pickup in the sensitive feedback

pin. (For the lowest temperature coefficient and the best

stability with time, use 1% metal film resistors.)

R

2

= 1 k

Ω

(16.53 − 1) = 15.53 k

Ω

, closest 1% value is

15.4 k

Ω

.

R

2

= 15.4 k

Ω

.

AVX TPS

Recommended

Application Voltage

Voltage

Rating

+85˚C Rating

3.3

6.3

5

10

10

20

12

25

15

35

Sprague 594D

Recommended

Application Voltage

Voltage

Rating

+85˚C Rating

2.5

4

3.3

6.3

5

10

8

16

12

20

18

25

24

35

29

50

FIGURE 15. Recommended Application Voltage for AVX TPS and

Sprague 594D Tantalum Chip Capacitors Derated for 85˚C.

LM2672

www.national.com

15

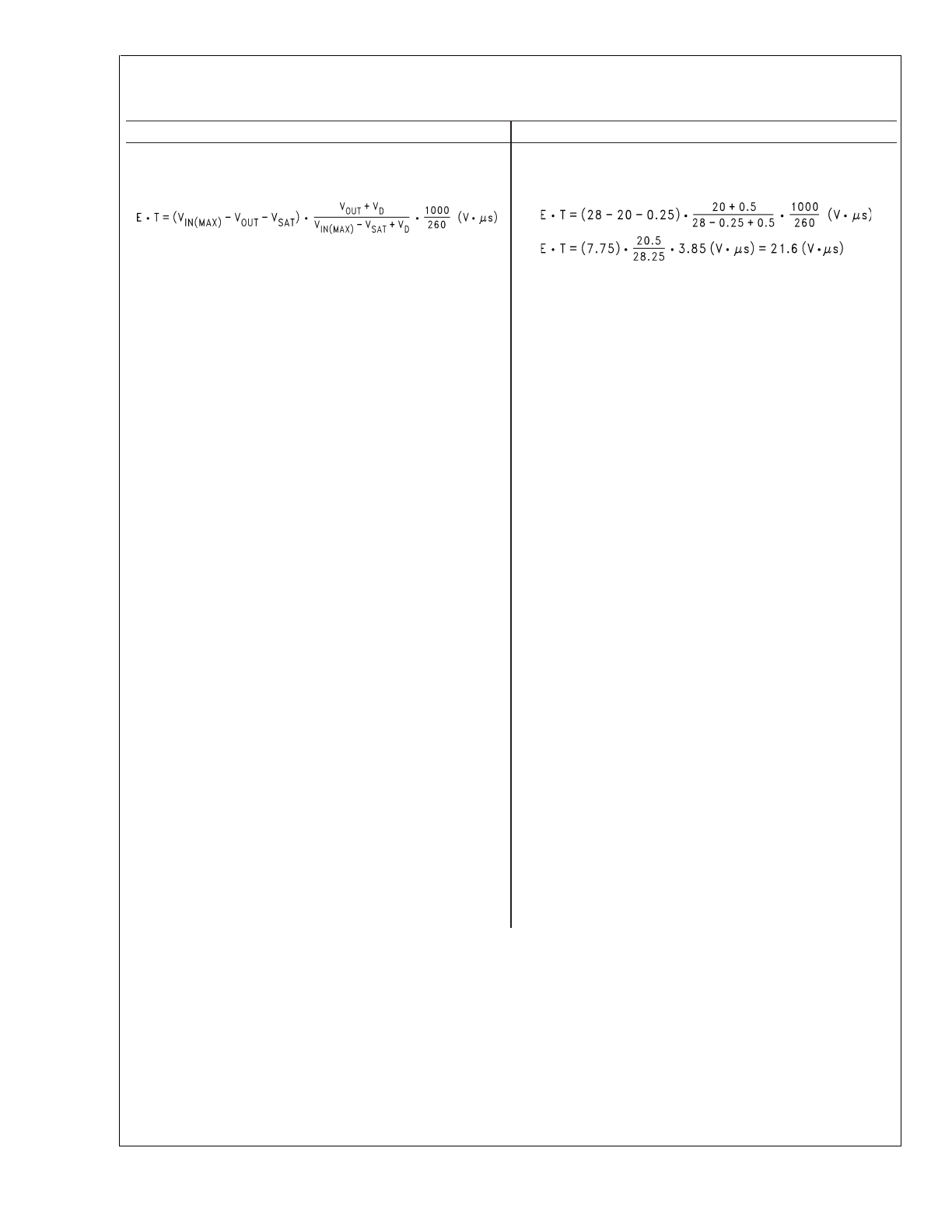

LM2672 Series Buck Regulator Design Procedure (Adjustable Output)

(Continued)

PROCEDURE (Adjustable Output Voltage Version)

EXAMPLE (Adjustable Output Voltage Version)

2. Inductor Selection (L1)

A. Calculate the inductor Volt

•

microsecond constant E

•

T

(V

•

µs), from the following formula:

2. Inductor Selection (L1)

A. Calculate the inductor Volt

•

microsecond constant (E

•

T),

where V

SAT

=internal switch saturation voltage=0.25V and

V

D

= diode forward voltage drop = 0.5V

B. Use the E

•

T value from the previous formula and match it

with the E

•

T number on the vertical axis of the Inductor

Value Selection Guide shown in

Figure 7

.

B. E

•

T = 21.6 (V

•

µs)

C. On the horizontal axis, select the maximum load current.

C. I

LOAD

(max) = 1A

D. Identify the inductance region intersected by the E

•

T value

and the Maximum Load Current value. Each region is identified

by an inductance value and an inductor code (LXX).

D. From the inductor value selection guide shown in

Figure 7

,

the inductance region intersected by the 21.6 (V

•

µs)

horizontal line and the 1A vertical line is 68 µH, and the

inductor code is L30.

E. Select an appropriate inductor from the four manufacturer’s

part numbers listed in

Figure 8

. For information on the different

types of inductors, see the inductor selection in the fixed

output voltage design procedure.

E. From the table in

Figure 8

, locate line L30, and select an

inductor part number from the list of manufacturers’ part

numbers.

3. Output Capacitor SeIection (C

OUT

)

A. Select an output capacitor from the capacitor code selection

guide in

Figure 16

. Using the inductance value found in the

inductor selection guide, step 1, locate the appropriate

capacitor code corresponding to the desired output voltage.

3. Output Capacitor SeIection (C

OUT

)

A. Use the appropriate row of the capacitor code selection

guide, in

Figure 16

. For this example, use the 15–20V row.

The capacitor code corresponding to an inductance of 68 µH is

C20.

B. Select an appropriate capacitor value and voltage rating,

using the capacitor code, from the output capacitor selection

table in

Figure 17

. There are two solid tantalum (surface

mount) capacitor manufacturers and four electrolytic (through

hole) capacitor manufacturers to choose from. It is

recommended that both the manufacturers and the

manufacturer’s series that are listed in the table be used. A

table listing the manufacturers’ phone numbers is located in

Figure 11

.

B. From the output capacitor selection table in

Figure 17

,

choose a capacitor value (and voltage rating) that intersects

the capacitor code(s) selected in section A, C20.

The capacitance and voltage rating values corresponding to

the capacitor code C20 are the:

Surface Mount:

33 µF/25V

Sprague 594D Series.

33 µF/25V

AVX TPS Series.

Through Hole:

33 µF/25V

Sanyo OS-CON SC Series.

120 µF/35V

Sanyo MV-GX Series.

120 µF/35V

Nichicon PL Series.

120 µF/35V

Panasonic HFQ Series.

Other manufacturers or other types of capacitors may also be

used, provided the capacitor specifications (especially the 100

kHz ESR) closely match the characteristics of the capacitors

listed in the output capacitor table. Refer to the capacitor

manufacturers’ data sheet for this information.

LM2672

www.national.com

16

LM2672 Series Buck Regulator Design Procedure (Adjustable Output)

(Continued)

PROCEDURE (Adjustable Output Voltage Version)

EXAMPLE (Adjustable Output Voltage Version)

4. Catch Diode Selection (D1)

A. In normal operation, the average current of the catch diode

is the load current times the catch diode duty cycle, 1-D (D is

the switch duty cycle, which is approximately V

OUT

/V

IN

). The

largest value of the catch diode average current occurs at the

maximum input voltage (minimum D). For normal operation,

the catch diode current rating must be at least 1.3 times

greater than its maximum average current. However, if the

power supply design must withstand a continuous output short,

the diode should have a current rating greater than the

maximum current limit of the LM2672. The most stressful

condition for this diode is a shorted output condition.

4. Catch Diode Selection (D1)

A. Refer to the table shown in

Figure 12

. Schottky diodes

provide the best performance, and in this example a 1A, 40V

Schottky diode would be a good choice. If the circuit must

withstand a continuous shorted output, a higher current (at

least 2.2A) Schottky diode is recommended.

B. The reverse voltage rating of the diode should be at least

1.25 times the maximum input voltage.

C. Because of their fast switching speed and low forward

voltage drop, Schottky diodes provide the best performance

and efficiency. The Schottky diode must be located close to

the LM2672 using short leads and short printed circuit traces.

5. Input Capacitor (C

IN

)

A low ESR aluminum or tantalum bypass capacitor is needed

between the input pin and ground to prevent large voltage

transients from appearing at the input. This capacitor should

be located close to the IC using short leads. In addition, the

RMS current rating of the input capacitor should be selected to

be at least

1

⁄

2

the DC load current. The capacitor manufacturer

data sheet must be checked to assure that this current rating

is not exceeded. The curves shown in

Figure 14

show typical

RMS current ratings for several different aluminum electrolytic

capacitor values. A parallel connection of two or more

capacitors may be required to increase the total minimum RMS

current rating to suit the application requirements.

For an aluminum electrolytic capacitor, the voltage rating

should be at least 1.25 times the maximum input voltage.

Caution must be exercised if solid tantalum capacitors are

used. The tantalum capacitor voltage rating should be twice

the maximum input voltage. The tables in

Figure 15

show the

recommended application voltage for AVX TPS and Sprague

594D tantalum capacitors. It is also recommended that they be

surge current tested by the manufacturer. The TPS series

available from AVX, and the 593D and 594D series from

Sprague are all surge current tested. Another approach to

minimize the surge current stresses on the input capacitor is to

add a small inductor in series with the input supply line.

Use caution when using ceramic capacitors for input

bypassing, because it may cause severe ringing at the V

IN

pin.

5. Input Capacitor (C

IN

)

The important parameters for the input capacitor are the input

voltage rating and the RMS current rating. With a maximum

input voltage of 28V, an aluminum electrolytic capacitor with a

voltage rating of at least 35V (1.25 x V

IN

) would be needed.

The RMS current rating requirement for the input capacitor in a

buck regulator is approximately

1

⁄

2

the DC load current. In this

example, with a 1A load, a capacitor with a RMS current rating

of at least 500 mA is needed. The curves shown in

Figure 14

can be used to select an appropriate input capacitor. From the

curves, locate the 35V line and note which capacitor values

have RMS current ratings greater than 500 mA.

For a through hole design, a 330 µF/35V electrolytic capacitor

(Panasonic HFQ series, Nichicon PL, Sanyo MV-GX series or

equivalent) would be adequate. Other types or other

manufacturers’ capacitors can be used provided the RMS

ripple current ratings are adequate. Additionally, for a complete

surface mount design, electrolytic capacitors such as the

Sanyo CV-C or CV-BS and the Nichicon WF or UR and the

NIC Components NACZ series could be considered.

For surface mount designs, solid tantalum capacitors can be

used, but caution must be exercised with regard to the

capacitor surge current rating and voltage rating. In this

example, checking

Figure 15

, and the Sprague 594D series

datasheet, a Sprague 594D 15 µF, 50V capacitor is adequate.

6. Boost Capacitor (C

B

)

This capacitor develops the necessary voltage to turn the

switch gate on fully. All applications should use a 0.01 µF, 50V

ceramic capacitor.

6. Boost Capacitor (C

B

)

For this application, and all applications, use a 0.01 µF, 50V

ceramic capacitor.

If the soft-start and frequency synchronization features are

desired, look at steps 6 and 7 in the fixed output design

procedure.

LM2672

www.national.com

17

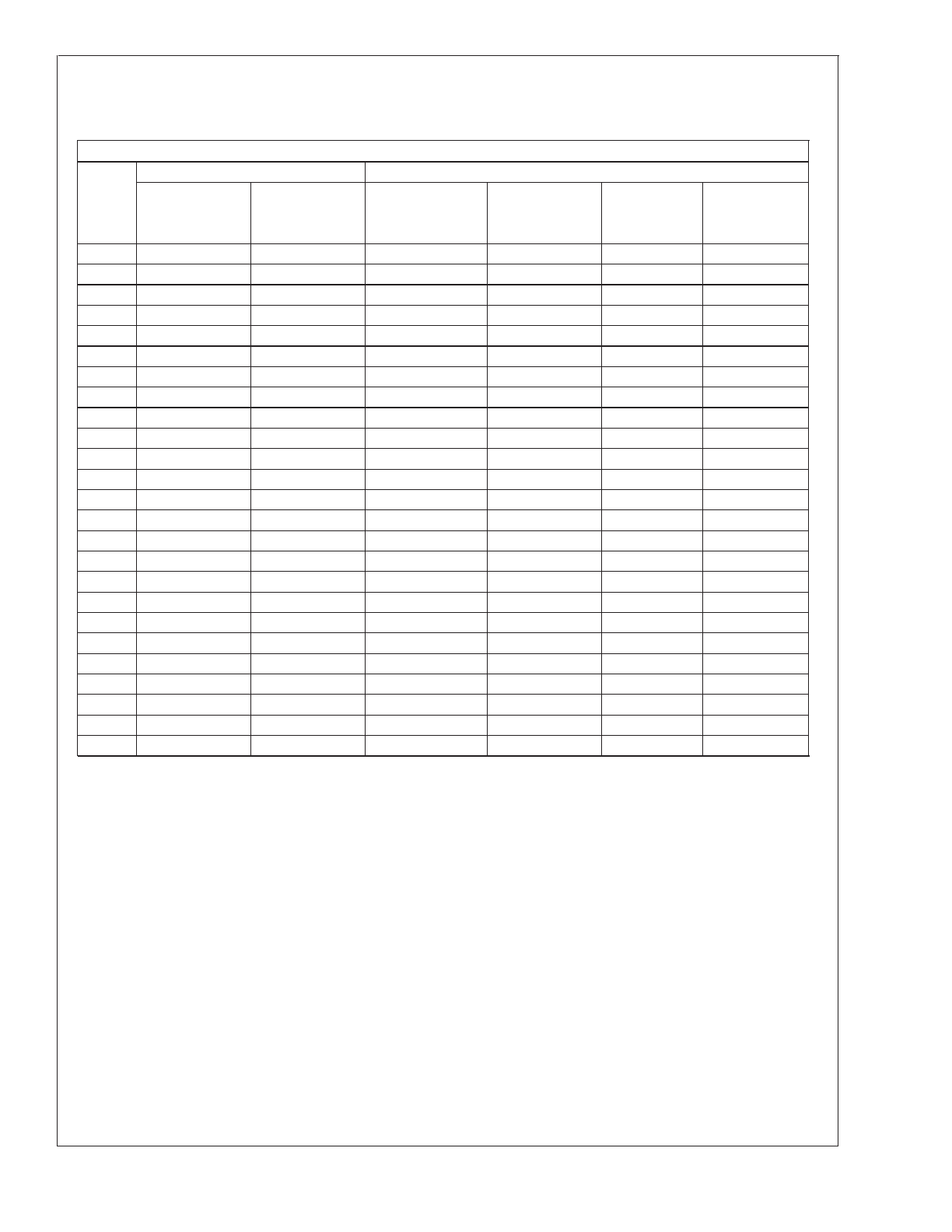

LM2672 Series Buck Regulator Design Procedure (Adjustable Output)

(Continued)

Case

Style (Note 7)

Output

Voltage (V)

Inductance (µH)

22

33

47

68

100

150

220

SM and TH

1.21–2.50

—

—

—

—

C1

C2

C3

SM and TH

2.50–3.75

—

—

—

C1

C2

C3

C3

SM and TH

3.75–5.0

—

—

C4

C5

C6

C6

C6

SM and TH

5.0–6.25

—

C4

C7

C6

C6

C6

C6

SM and TH

6.25–7.5

C8

C4

C7

C6

C6

C6

C6

SM and TH

7.5–10.0

C9

C10

C11

C12

C13

C13

C13

SM and TH

10.0–12.5

C14

C11

C12

C12

C13

C13

C13

SM and TH

12.5–15.0

C15

C16

C17

C17

C17

C17

C17

SM and TH

15.0–20.0

C18

C19

C20

C20

C20

C20

C20

SM and TH

20.0–30.0

C21

C22

C22

C22

C22

C22

C22

TH

30.0–37.0

C23

C24

C24

C25

C25

C25

C25

Note 7: SM - Surface Mount, TH - Through Hole

FIGURE 16. Capacitor Code Selection Guide

LM2672

www.national.com

18

LM2672 Series Buck Regulator Design Procedure (Adjustable Output)

(Continued)

Output Capacitor

Cap.

Ref.

Desg.

#

Surface Mount

Through Hole

Sprague

AVX TPS

Sanyo OS-CON

Sanyo MV-GX

Nichicon

Panasonic

594D Series

Series

SA Series

Series

PL Series

HFQ Series

(µF/V)

(µF/V)

(µF/V)

(µF/V)

(µF/V)

(µF/V)

C1

120/6.3

100/10

100/10

220/35

220/35

220/35

C2

120/6.3

100/10

100/10

150/35

150/35

150/35

C3

120/6.3

100/10

100/35

120/35

120/35

120/35

C4

68/10

100/10

68/10

220/35

220/35

220/35

C5

100/16

100/10

100/10

150/35

150/35

150/35

C6

100/16

100/10

100/10

120/35

120/35

120/35

C7

68/10

100/10

68/10

150/35

150/35

150/35

C8

100/16

100/10

100/10

330/35

330/35

330/35

C9

100/16

100/16

100/16

330/35

330/35

330/35

C10

100/16

100/16

68/16

220/35

220/35

220/35

C11

100/16

100/16

68/16

150/35

150/35

150/35

C12

100/16

100/16

68/16

120/35

120/35

120/35

C13

100/16

100/16

100/16

120/35

120/35

120/35

C14

100/16

100/16

100/16

220/35

220/35

220/35

C15

47/20

68/20

47/20

220/35

220/35

220/35

C16

47/20

68/20

47/20

150/35

150/35

150/35

C17

47/20

68/20

47/20

120/35

120/35

120/35

C18

68/25

(2x) 33/25

47/25 (Note 8)

220/35

220/35

220/35

C19

33/25

33/25

33/25 (Note 8)

150/35

150/35

150/35

C20

33/25

33/25

33/25 (Note 8)

120/35

120/35

120/35

C21

33/35

(2x) 22/25

(Note 9)

150/35

150/35

150/35

C22

33/35

22/35

(Note 9)

120/35

120/35

120/35

C23

(Note 9)

(Note 9)

(Note 9)

220/50

100/50

120/50

C24

(Note 9)

(Note 9)

(Note 9)

150/50

100/50

120/50

C25

(Note 9)

(Note 9)

(Note 9)

150/50

82/50

82/50

Note 8: The SC series of Os-Con capacitors (others are SA series)

Note 9: The voltage ratings of the surface mount tantalum chip and Os-Con capacitors are too low to work at these voltages.

FIGURE 17. Output Capacitor Selection Table

LM2672

www.national.com

19

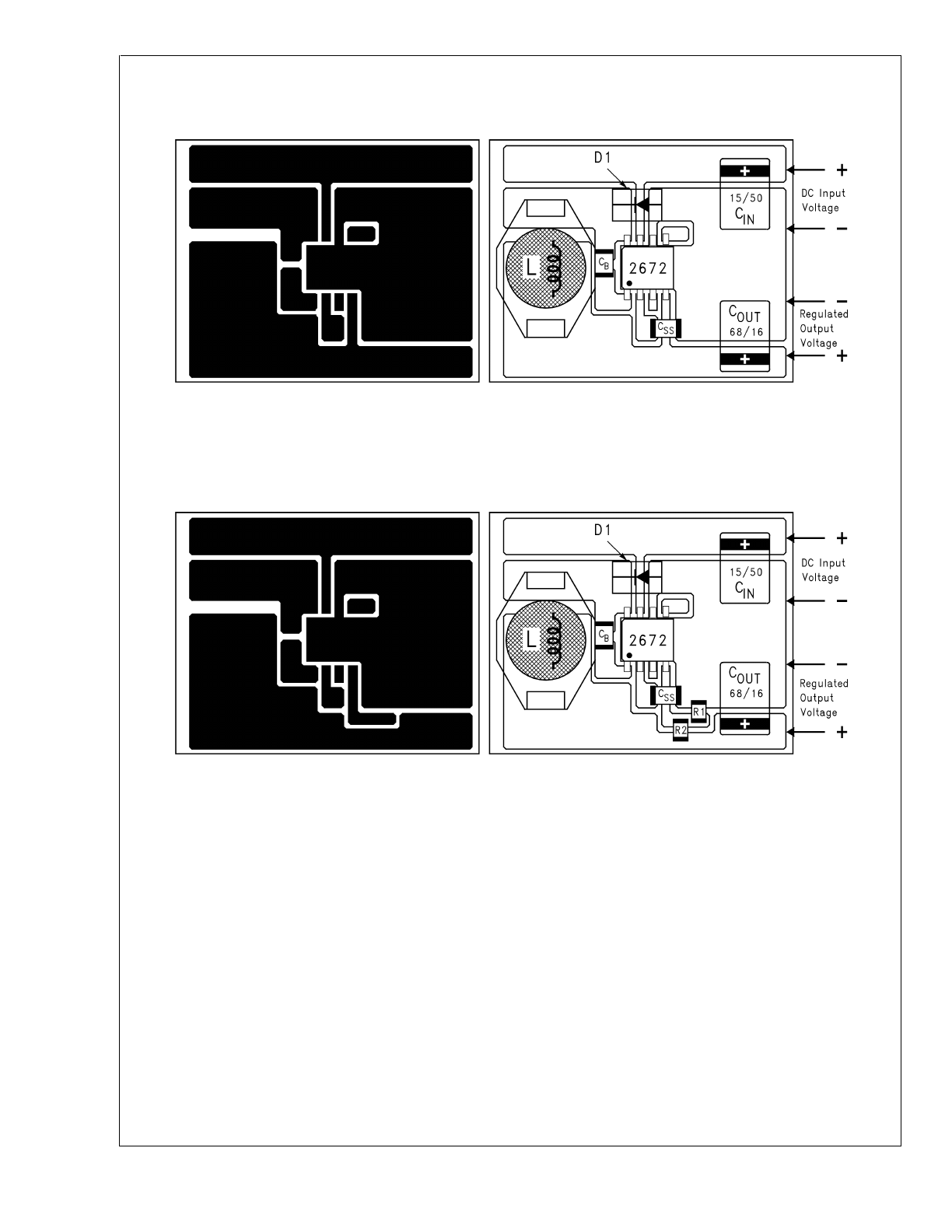

Application Information

TYPICAL SURFACE MOUNT PC BOARD LAYOUT, FIXED OUTPUT (4X SIZE)

TYPICAL SURFACE MOUNT PC BOARD LAYOUT, ADJUSTABLE OUTPUT (4X SIZE)

Layout is very important in switching regulator designs. Rap-

idly switching currents associated with wiring inductance can

generate voltage transients which can cause problems. For

minimal inductance and ground loops, the wires indicated by

heavy lines (in

Figure 2

and

Figure 3

) should be wide

printed circuit traces and should be kept as short as

possible. For best results, external components should be

located as close to the switcher IC as possible using ground

plane construction or single point grounding.

If open core inductors are used, special care must be

taken as to the location and positioning of this type of induc-

tor. Allowing the inductor flux to intersect sensitive feedback,

IC ground path, and C

OUT

wiring can cause problems.

When using the adjustable version, special care must be

taken as to the location of the feedback resistors and the as-

sociated wiring. Physically locate both resistors near the IC,

and route the wiring away from the inductor, especially an

open core type of inductor.

DS012934-39

C

IN

- 15 µF, 50V, Solid Tantalum Sprague, “594D series”

C

OUT

- 68 µF, 16V, Solid Tantalum Sprague, “594D series”

D1 - 1A, 40V Schottky Rectifier, Surface Mount

L1 - 33 µH, L23, Coilcraft DO3316

C

B

- 0.01 µF, 50V, Ceramic

DS012934-40

C

IN

- 15 µF, 50V, Solid Tantalum Sprague, “594D series”

C

OUT

- 33 µF, 25V, Solid Tantalum Sprague, “594D series”

D1 - 1A, 40V Schottky Rectifier, Surface Mount

L1 - 68 µH, L30, Coilcraft DO3316

C

B

- 0.01 µF, 50V, Ceramic

R1 - 1k, 1%

R2 - Use formula in Design Procedure

FIGURE 18. PC Board Layout

LM2672

www.national.com

20

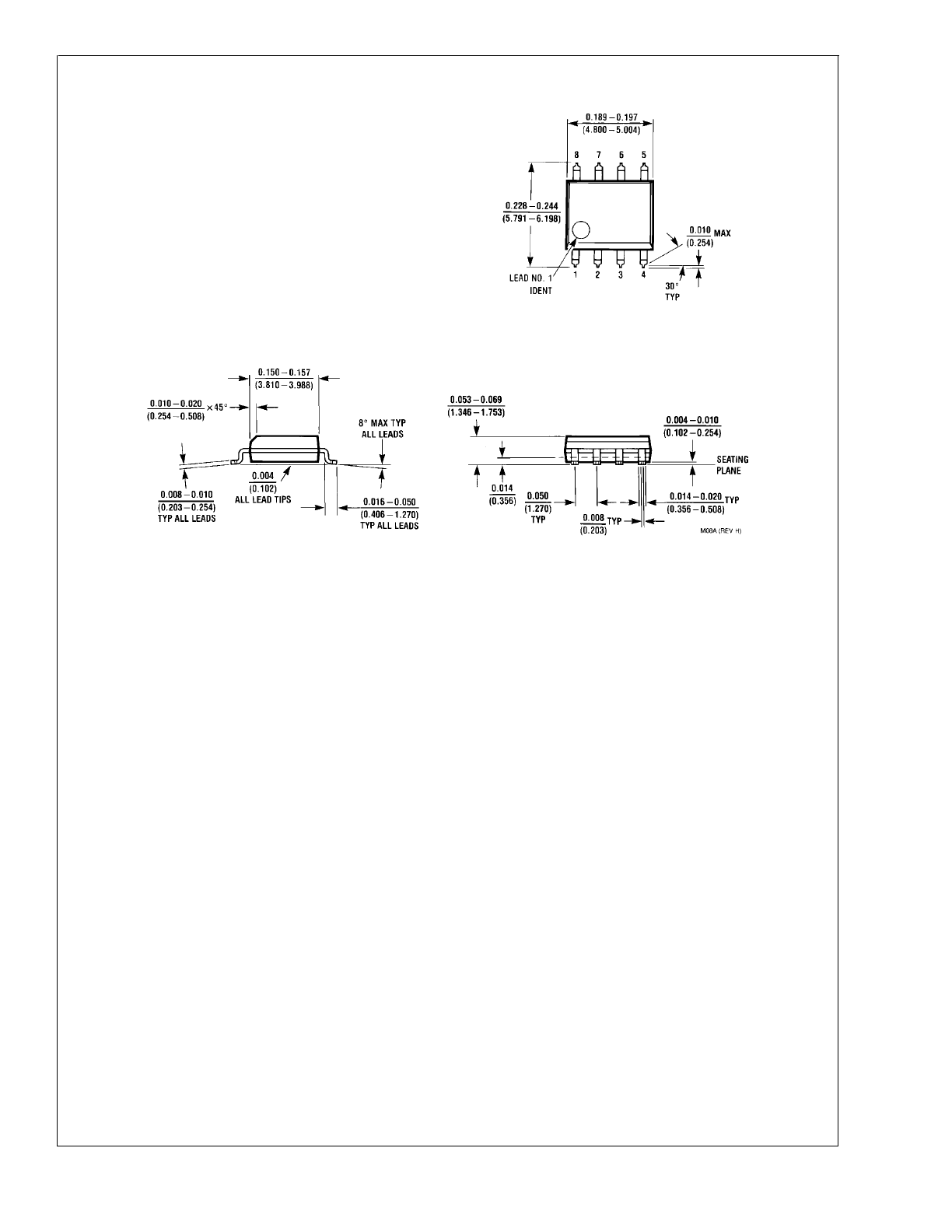

Physical Dimensions

inches (millimeters) unless otherwise noted

8-Lead (0.150" Wide) Molded Small Outline Package, JEDEC

Order Number LM2672M-3.3, LM2672M-5.0,

LM2672M-12 or LM2672M-ADJ

NS Package Number M08A

LM2672

www.national.com

21

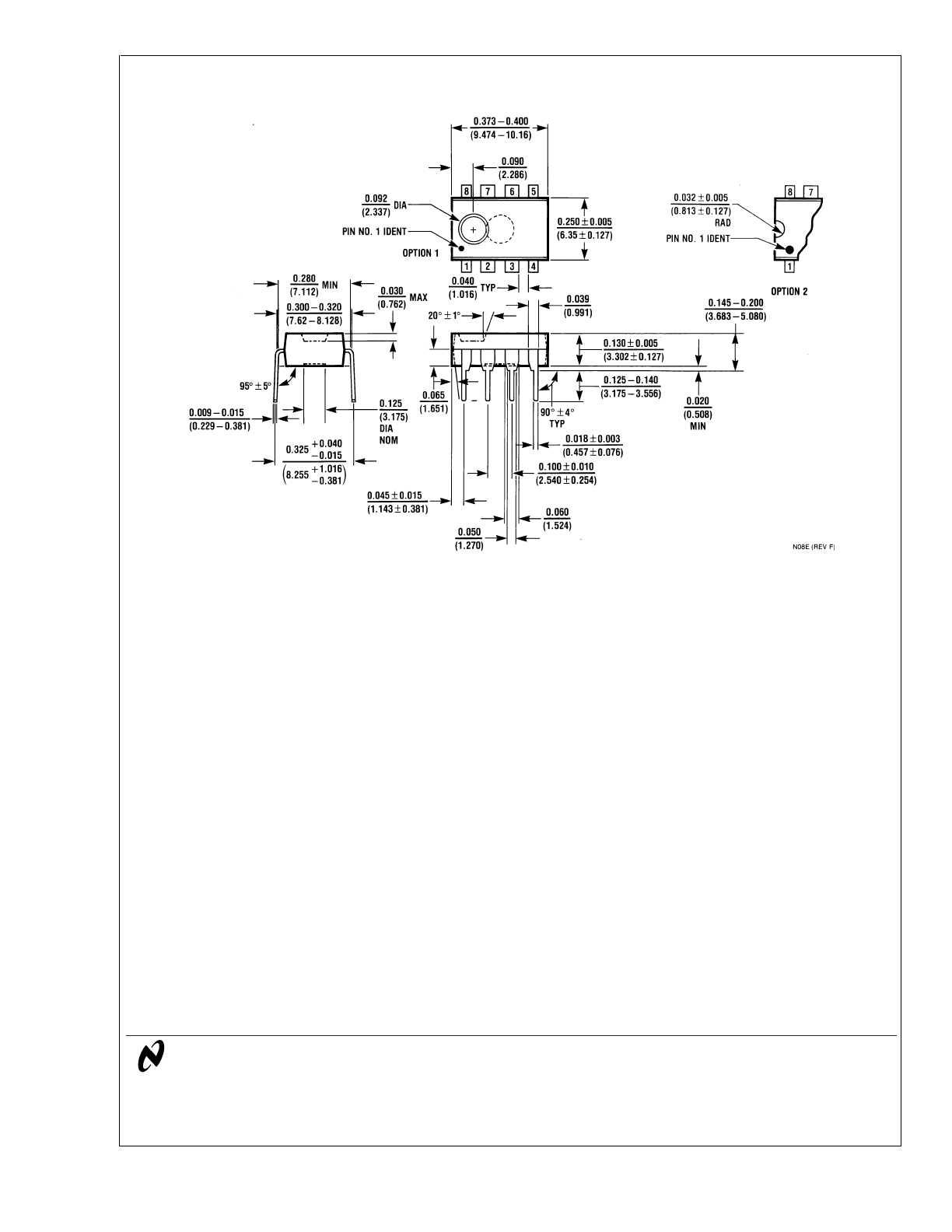

Physical Dimensions

inches (millimeters) unless otherwise noted (Continued)

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

labeling, can be reasonably expected to result in a

significant injury to the user.

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

National Semiconductor

Corporation

Americas

Tel: 1-800-272-9959

Fax: 1-800-737-7018

Email: support@nsc.com

National Semiconductor

Europe

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English

Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: ap.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

www.national.com

8-Lead (0.300" Wide) Molded Dual-In-Line Package

Order Number LM2672N-3.3, LM2672N-5.0,

LM2672N-12 or LM2672N-ADJ

NS Package Number N08E

LM2672

SIMPLE

SWITCHER

Power

Converter

High

Efficiency

1A

Step-Down

V

oltage

Regulator

with

Features

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.