S E M I C O N D U C T O R

8-103

November 1996

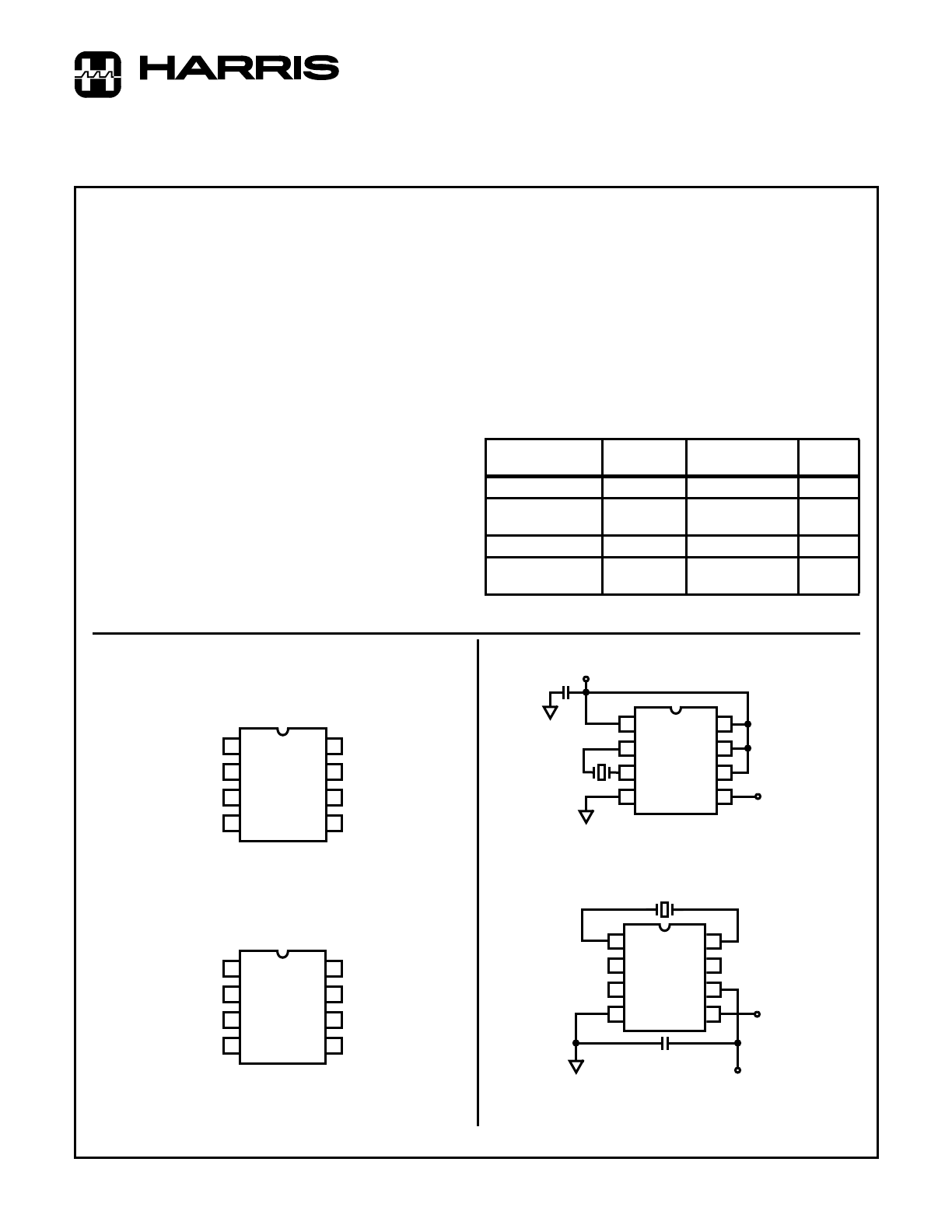

HA7210, HA7211

10kHz to 10MHz, Low Power Crystal Oscillator

Features

• Single Supply Operation at 32kHz . . . . . . . . . . 2V to 7V

• Operating Frequency Range. . . . . . . . 10kHz to 10MHz

• Supply Current at 32kHz . . . . . . . . . . . . . . . . . . . . . .5

µ

A

• Supply Current at 1MHz . . . . . . . . . . . . . . . . . . . .130

µ

A

• Drives 2 CMOS Loads

• Only Requires an External Crystal for Operation

• Two Pinouts Available

Applications

• Battery Powered Circuits

• Remote Metering

• Embedded Microprocessors

• Palm Top/Notebook PC

• Related Literature

- AN9334, Improving HA7210 Start-Up Time

Description

The HA7210 and HA7211 are very low power crystal-controlled

oscillators that can be externally programmed to operate

between 10kHz and 10MHz. For normal operation it requires

only the addition of a crystal. The part exhibits very high stabil-

ity over a wide operating voltage and temperature range.

The HA7210 and HA7211 also feature a disable mode that

switches the output to a high impedance state. This feature

is useful for minimizing power dissipation during standby and

when multiple oscillator circuits are employed.

Pinouts

HA7210

(PDIP, SOIC)

TOP VIEW

HA7211

(SOIC)

TOP VIEW

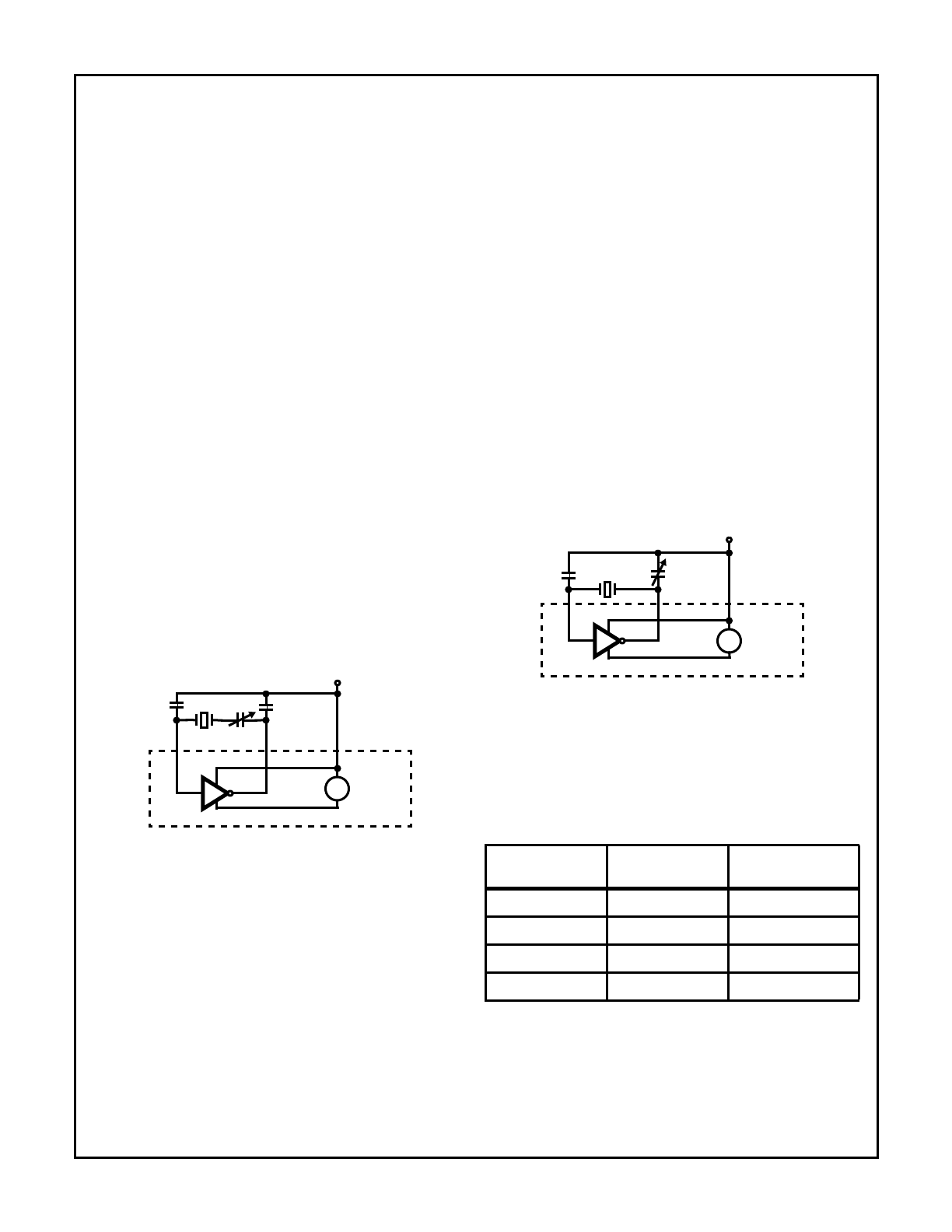

Typical Application Circuits

32.768kHz MICROPOWER CLOCK OSCILLATOR

NOTE:

1. Internal pull-up resistors provided for both HA7210 and HA7211.

Ordering Information

PART NUMBER

(BRAND)

TEMP.

RANGE (

o

C)

PACKAGE

PKG.

NO.

HA7210IP

-40 to 85

8 Ld PDIP

E8.3

HA7210IB

(H7210I)

-40 to 85

8 Ld SOIC

M8.15

HA7210Y

-40 to 85

DIE

HA7211IB

(H7211I)

-40 to 85

8 Ld SOIC

M8.15

V

DD

OSC IN

OSC OUT

V

SS

1

2

3

4

8

7

6

5

ENABLE

FREQ 2

FREQ 1

OUTPUT

OSC OUT

ENABLE

FREQ 1

V

SS

1

2

3

4

8

7

6

5

OSC IN

FREQ 2

V

DD

OUTPUT

V

DD

1

2

3

4

8

7

6

5

HA7210

32.768kHz

CLOCK

32.768kHz

CRYSTAL

0.1

µ

F

1

2

3

4

8

7

6

5

32.768kHz

CLOCK

NC (NOTE 1)

0.1

µ

F

NC (NOTE 1)

V

DD

NC (NOTE 1)

32.768kHz CRYSTAL

HA7211

CAUTION: These devices are sensitive to electrostatic discharge. Users should follow proper IC Handling Procedures.

Copyright

©

Harris Corporation 1996

File Number

3389.6

8-104

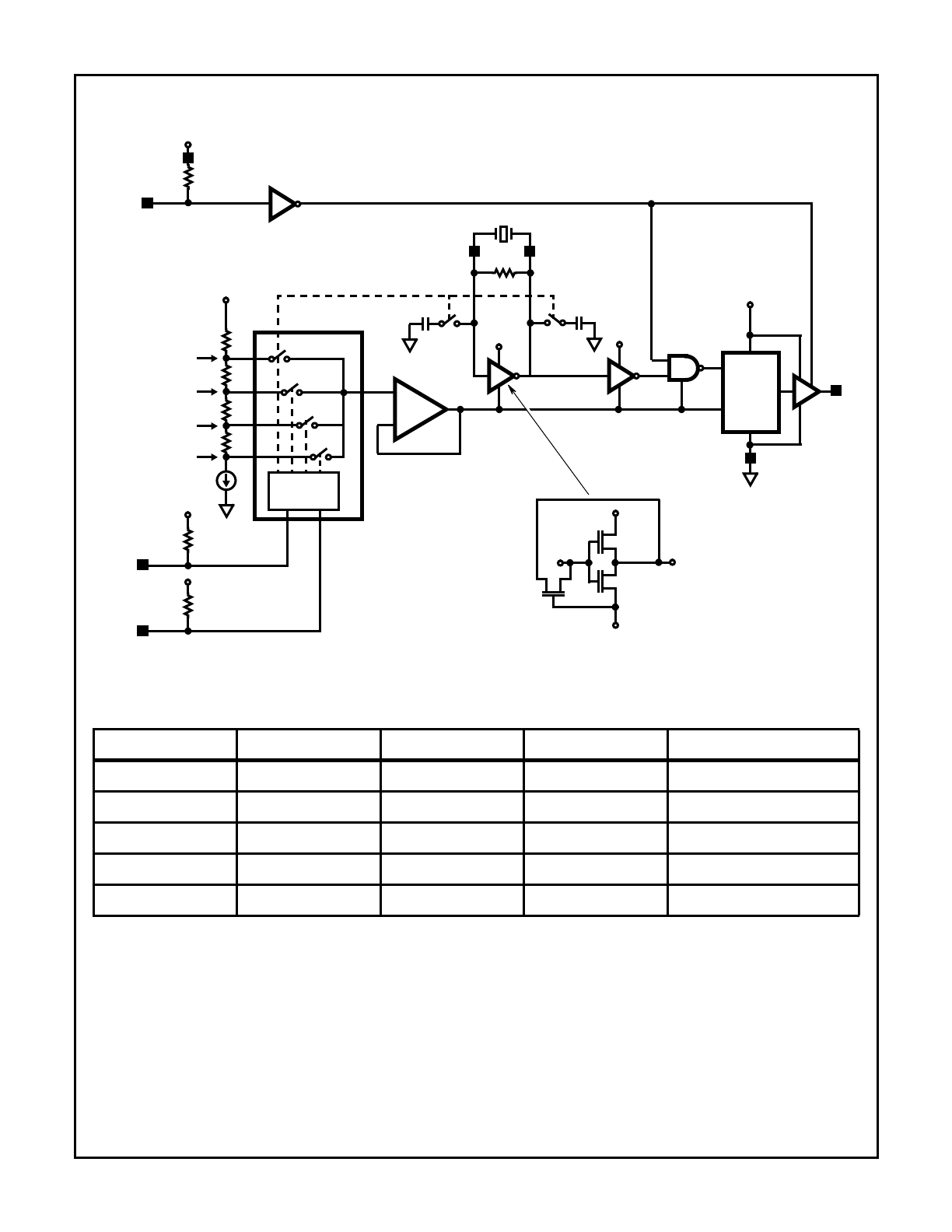

Simplified Block Diagram

(HA7210)

+

-

LEVEL

SHIFTER

BUFFER

BUFFER AMP

OSC IN 2

3 OSC OUT

EXTERNAL CRYSTAL

V

DD

V

DD

I

BIAS

V

DD

- 1.4V

V

DD

- 2.2V

V

DD

- 3.0V

V

DD

- 3.8V

FREQ 1

FREQ 2

7

6

ENABLE

8

V

DD

15pF

S

1B

S

1C

15pF

V

DD

R

F

V

DD

V

RN

V

RN

S

1A

S

2

S

3

S

4

V

DD

4

V

SS

5

OUTPUT

V

DD

1

N

P

V

DD

V

RN

P

IN

R

F

OUT

OSCILLATOR

(NOTE 2)

(NOTE 2)

(NOTE 2)

1 OF 4

DECODE

FREQUENCY SELECTION TRUTH TABLE

ENABLE

FREQ 1

FREQ 2

SWITCH

OUTPUT RANGE

1

1

1

S

1A

, S

1B

, S

1C

10kHz - 100kHz

1

1

0

S

2

100kHz - 1MHz

1

0

1

S

3

1MHz - 5MHz

1

0

0

S

4

5MHz - 10MHz+

0

X

X

X

High Impedance

NOTE:

2. Logic input pull-up resistors are constant current source of 0.4

µ

A.

HA7210, HA7211

8-105

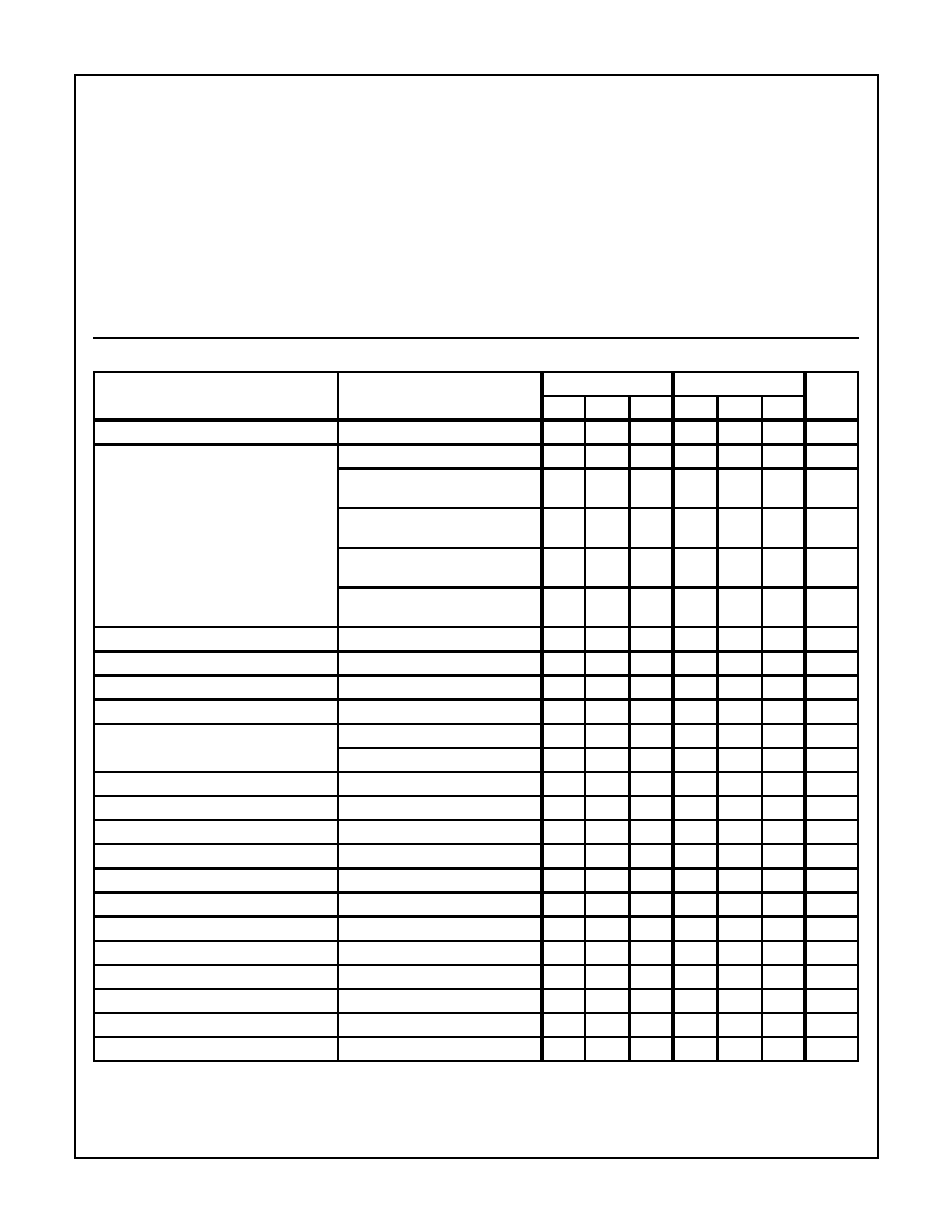

Absolute Maximum Ratings

Thermal Information

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10V

Voltage (any pin). . . . . . . . . . . . . . . . . . . . . . V

SS

-0.3V to V

DD

+0.3V

ESD Rating

Human Body Model (Per MIL-STD-883 Method 3015.7) . . 4000V

Operating Conditions

Temperature Range (Note 3) . . . . . . . . . . . . . . . . . . -40

o

C to 85

o

C

Thermal Resistance (Typical, Note 4)

θ

JA

(

o

C/W)

PDIP Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

125

SOIC Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

170

Maximum Junction Temperature (Plastic Package) . . . . . . . . 150

o

C

Maximum Storage Temperature Range . . . . . . . . . -65

o

C to 150

o

C

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . 300

o

C

(SOIC - Lead Tips Only)

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation

of the device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTES:

3. This product is production tested at 25

o

C only.

4.

θ

JA

is measured with the component mounted on an evaluation PC board in free air.

Electrical Specifications

V

SS

= GND, T

A

= 25

o

C, Unless Otherwise Specified

PARAMETER

TEST CONDITIONS

V

DD

= 5V

V

DD

= 3V

UNITS

MIN

TYP

MAX

MIN

TYP

MAX

V

DD

Supply Range

f

OSC

= 32kHz

2

5

7

-

-

-

V

I

DD

Supply Current

f

OSC

= 32kHz, EN = 0 (Standby)

-

5.0

9.0

-

-

-

µ

A

f

OSC

= 32kHz, C

L

= 10pF (Note 5),

EN = 1, Freq1 = 1, Freq2 = 1

-

5.2

10.2

-

3.6

6.1

µ

A

f

OSC

= 32kHz, C

L

= 40pF, EN = 1,

Freq1 = 1, Freq2 = 1

-

10

15

-

6.5

9

µ

A

f

OSC

= 1MHz, C

L

= 10pF (Note 5),

EN = 1, Freq1 = 0, Freq2 = 1

-

130

200

-

90

180

µ

A

f

OSC

= 1MHz, C

L

= 40pF, EN = 1,

Freq1 = 0, Freq2 = 1

-

270

350

-

180

270

µ

A

V

OH

Output High Voltage

I

OUT

= -1mA

4.0

4.9

-

-

2.8

-

V

V

OL

Output Low Voltage

I

OUT

= 1mA

-

0.07

0.4

-

0.1

-

V

I

OH

Output High Current

V

OUT

≥

4V

-

-10

-5

-

-

-

mA

I

OL

Output Low Current

V

OUT

≤

0.4V

5.0

10.0

-

-

-

-

mA

Three-State Leakage Current

V

OUT

= 0V, 5V, T

A

= 25

o

C, -40

o

C

-

0.1

-

-

-

-

nA

V

OUT

= 0V, 5V, T

A

= 85

o

C

-

10

-

-

-

-

nA

I

IN

Enable, Freq1, Freq2 Input Current

V

IN

= V

SS

to V

DD

-

0.4

1.0

-

-

-

µ

A

V

IH

Input High Voltage Enable, Freq1, Freq2

2.0

-

-

-

-

-

V

V

IL

Input Low Voltage Enable, Freq1, Freq2

-

-

0.8

-

-

-

V

Enable Time

C

L

= 18pF, R

L

= 1k

Ω

-

800

-

-

-

-

ns

Disable Time

C

L

= 18pF, R

L

= 1k

Ω

-

90

-

-

-

-

ns

t

R

Output Rise Time

10% - 90%, f

OSC

= 32kHz, C

L

= 40pF

-

12

25

-

12

-

ns

t

F

Output Fall Time

10% - 90%, f

OSC

= 32kHz, C

L

= 40pF

-

12

25

-

14

-

ns

Duty Cycle, Packaged Part Only (Note 6)

C

L

= 40pF, f

OSC

= 1MHz

40

54

60

-

-

-

%

Duty Cycle, (See Typical Curves)

C

L

= 40pF, f

OSC

= 32kHz

-

41

-

-

44

-

%

Frequency Stability vs Supply Voltage

f

OSC

= 32kHz, V

DD

= 5V, C

L

=10pF

-

1

-

-

-

-

ppm/V

Frequency Stability vs Temperature

f

OSC

= 32kHz, V

DD

= 5V, C

L

=10pF

-

0.1

-

-

-

-

ppm/

o

C

Frequency Stability vs Load

f

OSC

= 32kHz, V

DD

= 5V, C

L

=10pF

-

0.01

-

-

-

-

ppm/pF

NOTES:

5. Calculated using the equation I

DD

= I

DD

(No Load) + (V

DD

) (f

OSC

)(C

L

)

6. Duty cycle will vary with supply voltage, oscillation frequency, and parasitic capacitance on the crystal pins.

HA7210, HA7211

8-106

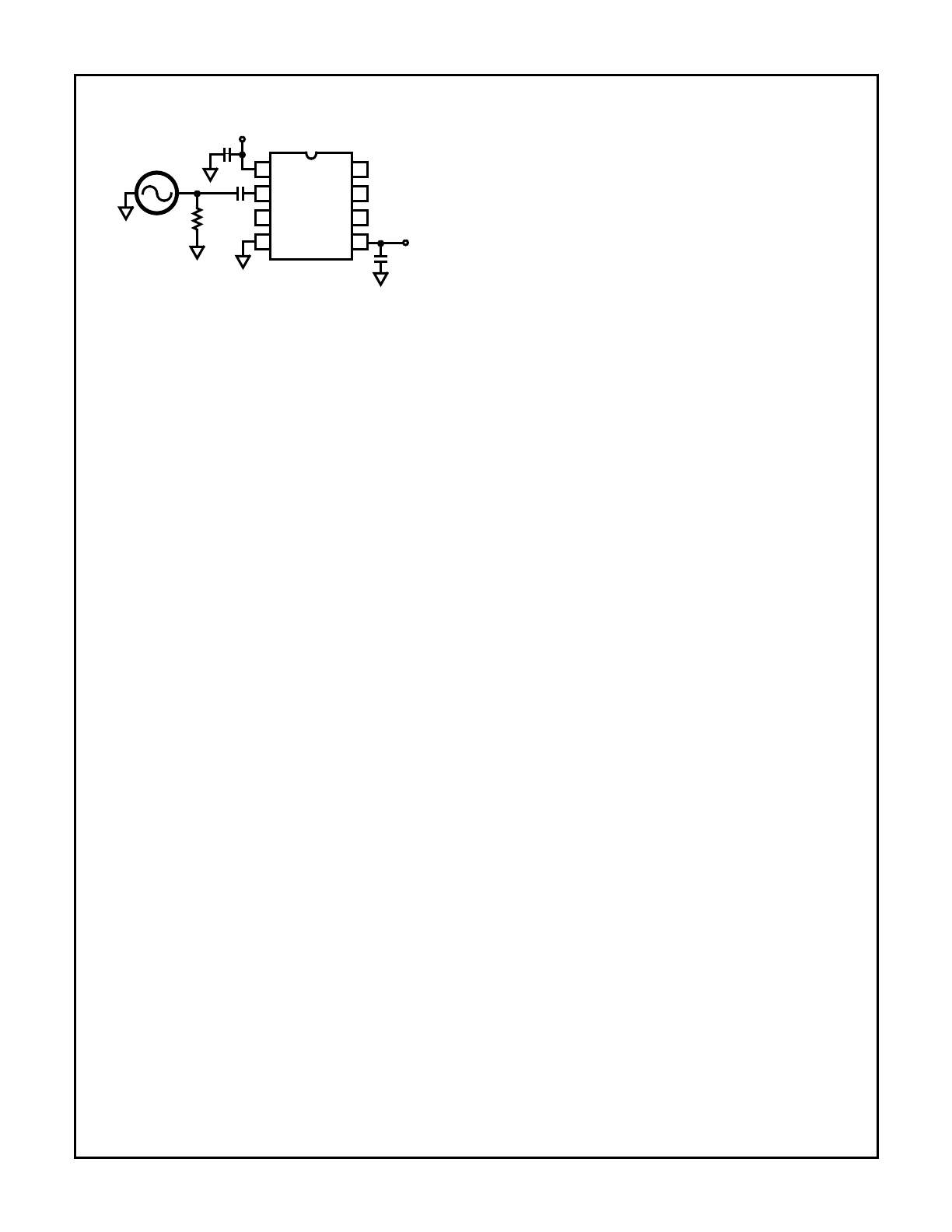

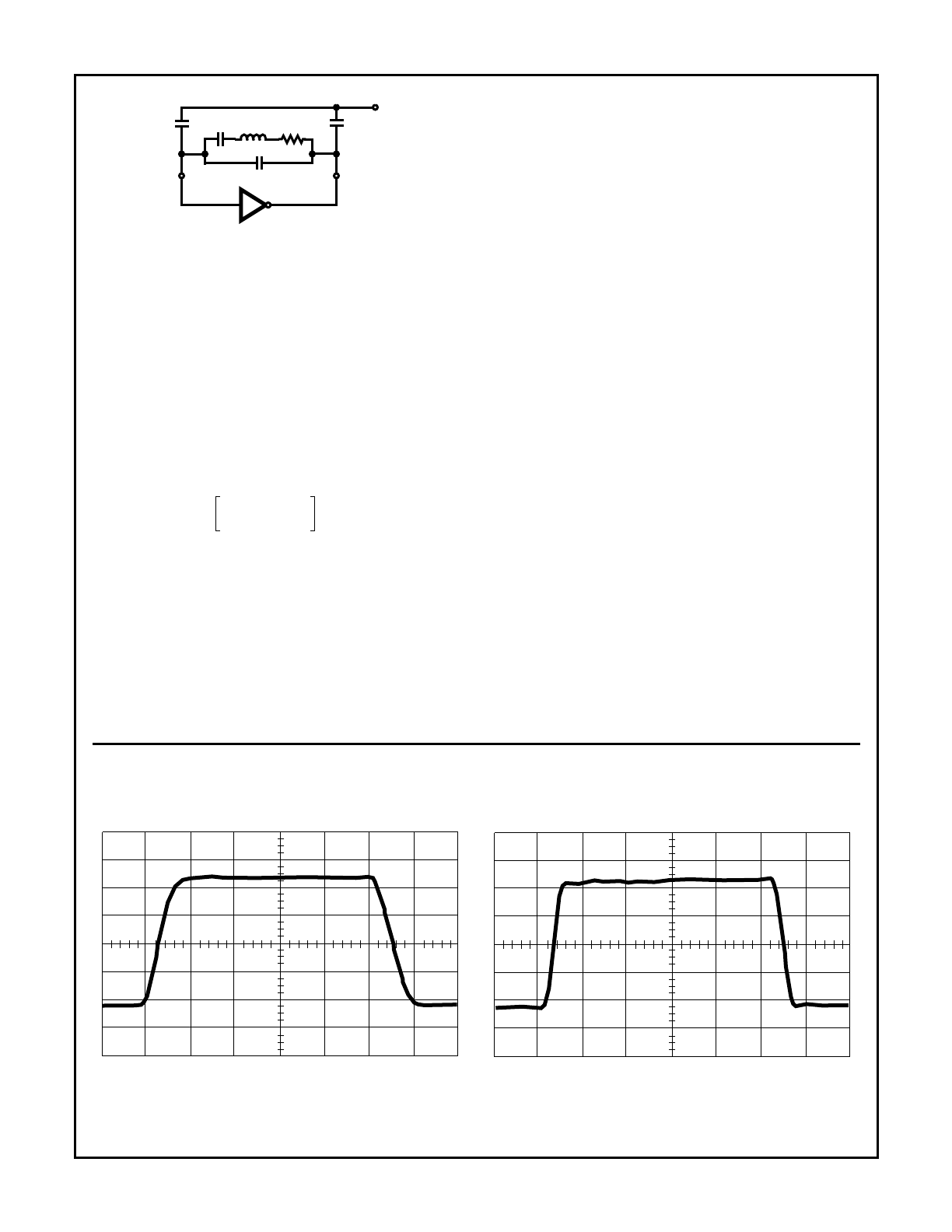

Test Circuit

In production the HA7210 is tested with a 32kHz and a

1MHz crystal. However for characterization purposes data

was taken using a sinewave generator as the frequency

determining element, as shown in Figure 1. The 1V

P-P

input

is a smaller amplitude than what a typical crystal would gen-

erate so the transitions are slower. In general the Generator

data will show a “worst case” number for I

DD

, duty cycle, and

rise/fall time. The Generator test method is useful for testing

a variety of frequencies quickly and provides curves which

can be used for understanding performance trends. Data for

the HA7210 using crystals has also been taken. This data

has been overlaid onto the generator data to provide a refer-

ence for comparison.

Application Information

Theory Of Operation

The HA7210 and HA7211 are Pierce Oscillators optimized

for low power consumption, requiring no external compo-

nents except for a bypass capacitor and a Parallel Mode

Crystal. The Simplified Block Diagram shows the Crystal

attached to pins 2 and 3, (HA7210) the Oscillator input and

output. The crystal drive circuitry is detailed showing the

simple CMOS inverter stage and the P-channel device being

used as biasing resistor R

F

. The inverter will operate mostly

in its linear region increasing the amplitude of the oscillation

until limited by its transconductance and voltage rails, V

DD

and V

RN

. The inverter is self biasing using R

F

to center the

oscillating waveform at the input threshold. Do not interfere

with this bias function with external loads or excessive leak-

age on pin 2 for HA7210, pin 8 for HA7211. Nominal value

for R

F

is 17M

Ω

in the lowest frequency range to 7M

Ω

in the

highest frequency range.

The HA7210 and HA7211 optimizes its power for 4 fre-

quency ranges selected by digital inputs Freq1 and Freq2 as

shown in the Block Diagram. Internal pull up resistors (con-

stant current 0.4

µ

A) on Enable, Freq1 and Freq2 allow the

user simply to leave one or all digital inputs not connected

for a corresponding “1” state. All digital inputs may be left

open for 10kHz to 100kHz operation.

A current source develops 4 selectable reference voltages

through series resistors. The selected voltage, V

RN

, is buff-

ered and used as the negative supply rail for the oscillator

section of the circuit. The use of a current source in the refer-

ence string allows for wide supply variation with minimal

effect on performance. The reduced operating voltage of the

oscillator section reduces power consumption and limits

transconductance and bandwidth to the frequency range

selected. For frequencies at the edge of a range, the higher

range may provide better performance.

The OSC OUT waveform on pin 3 for HA7210 (pin 1 for

HA7211) is squared up through a series of inverters to the

output drive stage. The Enable function is implemented with

a NAND gate in the inverter string, gating the signal to the

level shifter and output stage. Also during Disable the output

is set to a high impedance state useful for minimizing power

during standby and when multiple oscillators are OR’ed to a

single node.

Design Considerations

The low power CMOS transistors are designed to consume

power mostly during transitions. Keeping these transitions

short requires a good decoupling capacitor as close as pos-

sible to the supply pins 1 and 4 for HA7210, pins 4 and 6 for

HA7211. A ceramic 0.1

µ

F is recommended. Additional sup-

ply decoupling on the circuit board with 1

µ

F to 10

µ

F will fur-

ther reduce overshoot, ringing and power consumption. The

HA7210, when compared to a crystal and inverter alone, will

speed clock transition times, reducing power consumption of

all CMOS circuitry run from that clock.

Power consumption may be further reduced by minimizing the

capacitance on moving nodes. The majority of the power will

be used in the output stage driving the load. Minimizing the

load and parasitic capacitance on the output, pin 5, will play

the major role in minimizing supply current. A secondary

source of wasted supply current is parasitic or crystal load

capacitance on pins 2 and 3 for HA7210, pins 1 and 8 for

HA7211. The HA7210 is designed to work with most available

crystals in its frequency range with no external components

required. Two 15pF capacitors are internally switched onto

crystal pins 2 and 3 on the HA7210 to compensate the oscilla-

tor in the 10kHz to 100kHz frequency range.

The supply current of the HA7210 and HA7211 may be

approximately calculated from the equation:

I

DD

= I

DD

(Disabled) + V

DD

×

f

OSC

×

C

L

where:

I

DD

= Total supply current

V

DD

= Total voltage from V

DD

(pin1) to V

SS

(pin4)

f

OSC

= Frequency of Oscillation

C

L

= Output (pin5) load capacitance

Example #1:

V

DD

= 5V, f

OSC

= 100kHz, C

L

= 30pF

I

DD

(Disabled) = 4.5

µ

A (Figure 10)

I

DD

= 4.5

µ

A + (5V)(100kHz)(30pF) = 19.5

µ

A

Measured I

DD

= 20.3

µ

A

Example #2:

V

DD

= 5V, f

OSC

= 5MHz, C

L

= 30pF

I

DD

(Disabled) = 75

µ

A (Figure 9)

I

DD

= 75

µ

A + (5V)(5MHz)(30pF) = 825

µ

A

Measured I

DD

= 809

µ

A

1

2

3

4

8

7

6

5

HA7210

V

OUT

C

L

+5V

18pF

0.1

µ

F

1000pF

50

Ω

ENABLE

FREQ 2

FREQ 1

1V

P-P

FIGURE 1.

HA7210, HA7211

8-107

Crystal Selection

For general purpose applications, a Parallel Mode Crystal is

a good choice for use with the HA7210 or HA7211. However

for applications where a precision frequency is required, the

designer needs to consider other factors.

Crystals are available in two types or modes of oscillation,

Series and Parallel. Series Mode crystals are manufactured

to operate at a specified frequency with zero load capaci-

tance and appear as a near resistive impedance when oscil-

lating. Parallel Mode crystals are manufactured to operate

with a specific capacitive load in series, causing the crystal

to operate at a more inductive impedance to cancel the load

capacitor. Loading a crystal with a different capacitance will

“pull” the frequency off its value.

The HA7210 and HA7211 has 4 operating frequency ranges.

The higher three ranges do not add any loading capacitance

to the oscillator circuit. The lowest range, 10kHz to 100kHz,

automatically switches in two 15pF capacitors onto OSC IN

and OSC OUT to eliminate potential start-up problems.

These capacitors create an effective crystal loading capaci-

tor equal to the series combination of these two capacitors.

For the HA7210 and HA7211, in the lowest range, the effec-

tive loading capacitance is 7.5pF. Therefore the choice for a

crystal, in this range, should be a Parallel Mode crystal that

requires a 7.5pF load.

In the higher 3 frequency ranges, the capacitance on OSC

IN and OSC OUT will be determined by package and layout

parasitics, typically 4 to 5pF. Ideally the choice for crystal

should be a Parallel Mode set for 2.5pF load. A crystal man-

ufactured for a different load will be “pulled” from its nominal

frequency (see Crystal Pullability).

Frequency Fine Tuning

Two Methods will be discussed for fine adjustment of the

crystal frequency. The first and preferred method (Figure 2),

provides better frequency accuracy and oscillator stability

than method two (Figure 3). Method one also eliminates

start-up problems sometimes encountered with 32kHz tun-

ing fork crystals.

For best oscillator performance, two conditions must be met:

the capacitive load must be matched to both the inverter and

crystal to provide ideal conditions for oscillation, and the fre-

quency of the oscillator must be adjustable to the desired

frequency. In Method two these two goals can be at odds

with each other; either the oscillator is trimmed to frequency

by de-tuning the load circuit, or stability is increased at the

expense of absolute frequency accuracy.

Method one allows these two conditions to be met indepen-

dently. The two fixed capacitors, C

1

and C

2

, provide the opti-

mum load to the oscillator and crystal. C

3

adjusts the

frequency at which the circuit oscillates without appreciably

changing the load (and thus the stability) of the system.

Once a value for C

3

has been determined for the particular

type of crystal being used, it could be replaced with a fixed

capacitor. For the most precise control over oscillator fre-

quency, C

3

should remain adjustable.

This three capacitor tuning method will be more accurate

and stable than method two and is recommended for 32kHz

tuning fork crystals; without it they may leap into an overtone

mode when power is initially applied.

Method two has been used for many years and may be pre-

ferred in applications where cost or space is critical. Note

that in both cases the crystal loading capacitors are con-

nected between the oscillator and V

DD

; do not use V

SS

as

an AC ground. The Simplified Block Diagram shows that the

oscillating inverter does not directly connect to V

SS

but is

referenced to V

DD

and V

RN

. Therefore V

DD

is the best AC

ground available.

Typical values of the capacitors in Figure 2 are shown below.

Some trial and error may be required before the best combi-

nation is determined. The values listed are total capacitance

including parasitic or other sources. Remember that in the

10kHz to 100kHz frequency range setting the HA7210

switches in two internal 15pF capacitors.

CRYSTAL PULLABILITY

Figure 4 shows the basic equivalent circuit for a crystal and

its loading circuit.

HA7210

+5V

V

REG

C

1

C

2

XTAL

C

3

2

OSC IN

3

OSC OUT

1

V

DD

FIGURE 2.

+

-

CRYSTAL

FREQUENCY

LOAD CAPS

C

1

, C

2

TRIMMER CAP

C

3

32kHz

33pF

5pF to 50pF

1MHz

33pF

5pF to 50pF

2MHz

25pF

5pF to 50pF

4MHz

22pF

5pF to 100pF

HA7210

+

-

+5V

V

REG

C

1

C

2

XTAL

2

OSC IN

3

OSC OUT

1

V

DD

FIGURE 3.

HA7210, HA7211

8-108

Where:

C

M

= Motional Capacitance

L

M

= Motional Inductance

R

M

= Motional Resistance

C

0

= Shunt Capacitance

If loading capacitance is connected to a Series Mode Crys-

tal, the new Parallel Mode frequency of resonance may be

calculated with the following equation:

Where:

f

P

= Parallel Mode Resonant Frequency

f

S

= Series Mode Resonant Frequency

In a similar way, the Series Mode resonant frequency may

be calculated from a Parallel Mode crystal and then you may

calculate how much the frequency will “pull” with a new load.

Layout Considerations

Due to the extremely low current (and therefore high imped-

ance) the circuit board layout of the HA7210 or HA7211

must be given special attention. Stray capacitance should be

minimized. Keep the oscillator traces on a single layer of the

PCB. Avoid putting a ground plane above or below this layer.

The traces between the crystal, the capacitors, and the OSC

pins should be as short as possible. Completely surround

the oscillator components with a thick trace of V

DD

to mini-

mize coupling with any digital signals. The final assembly

must be free from contaminants such as solder flux, mois-

ture, or any other potential source of leakage. A good solder

mask will help keep the traces free of moisture and contami-

nation over time.

Further Reading

Al Little “HA7210 Low Power Oscillator: Micropower Clock

Oscillator and Op Amps Provide System Shutdown for Battery

Circuits”. Harris Semiconductor Application Note AN9317.

Robert Rood “Improving Start-Up Time at 32KHz for the

HA7210 Low Power Crystal Oscillator”. Harris Semiconductor

Application Note AN9334.

S. S. Eaton “Timekeeping Advances Through COS/MOS

Technology”. Harris Semiconductor Application Note

ICAN-6086.

E. A. Vittoz, et. al. “High-Performance Crystal Oscillator cir-

cuits: Theory and Application”. IEEE Journal of Solid-State

Circuits, Vol. 23, No3, June 1988, pp774-783.

M. A. Unkrich, et. al. “Conditions for Start-Up in Crystal

Oscillators”. IEEE Journal of Solid-State Circuits, Vol. 17,

No1, Feb. 1982, pp87-90.

Marvin E. Frerking “Crystal Oscillator Design and Tempera-

ture Compensation”. New York: Van Nostrand-Reinhold,

1978. Pierce Oscillators Discussed pp56-75.

C

1

C

2

2

OSC IN

3

OSC OUT

V

DD

C

0

C

M

L

M

R

M

FIGURE 4.

C

CL

1

1

C

1

-------

1

C

2

-------

+

--------------------------

Equivalent Crystal Load

=

=

f

P

f

S

1

C

M

2 C

0

C

CL

+

(

)

----------------------------------

+

=

Typical Performance Curves

FIGURE 5. OUTPUT WAVEFORM (C

L

= 40pF)

FIGURE 6. OUTPUT WAVEFORM (C

L

= 18pF)

NOTE: Refer to Test Circuit (Figure 1).

1.0V/DIV.

20.0ns/DIV.

C

L

= 40pF, f

OSC

= 5MHz, V

DD

= 5V, V

SS

= GND

1.0V/DIV.

20.0ns/DIV.

C

L

= 18pF, f

OSC

= 5MHz, V

DD

= 5V, V

SS

= GND

HA7210, HA7211

8-109

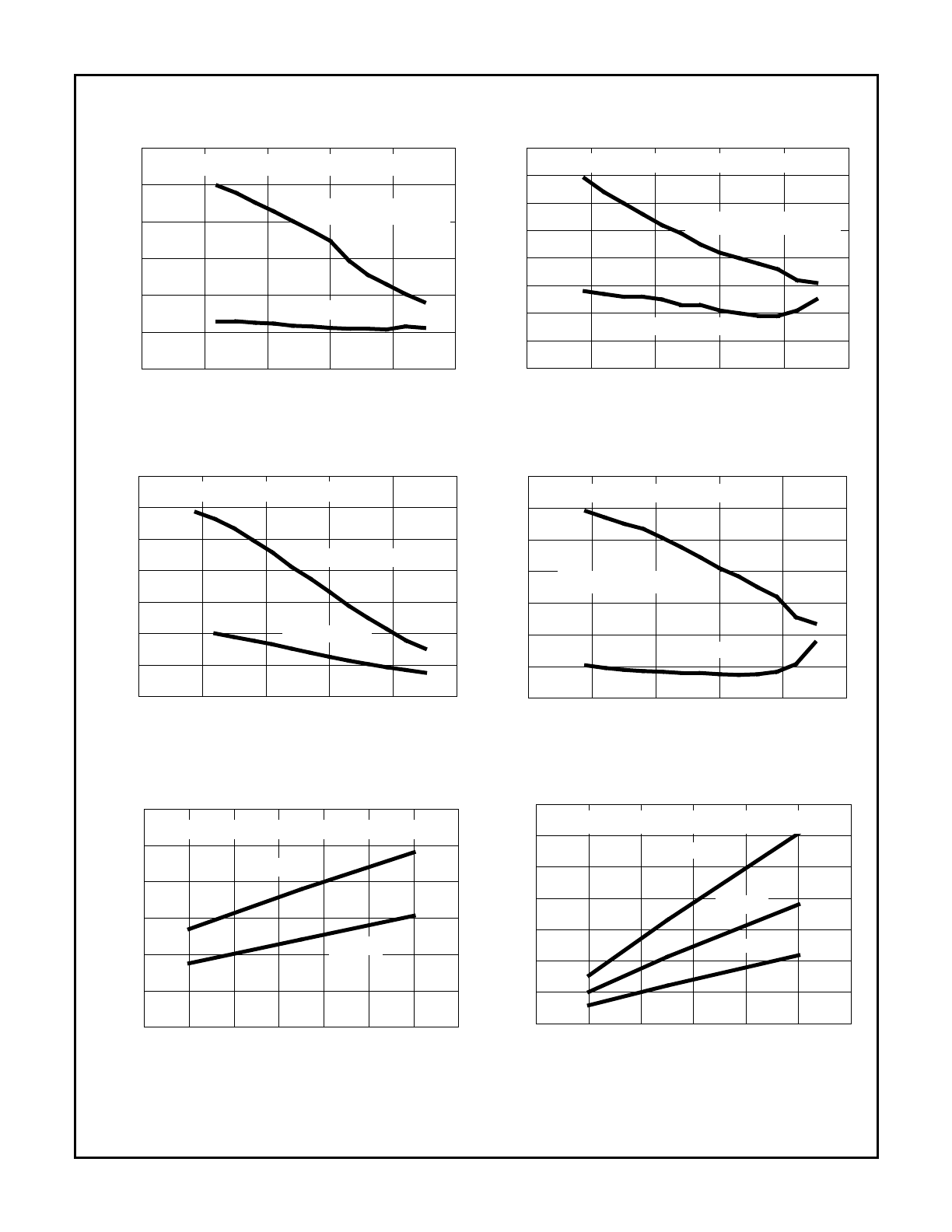

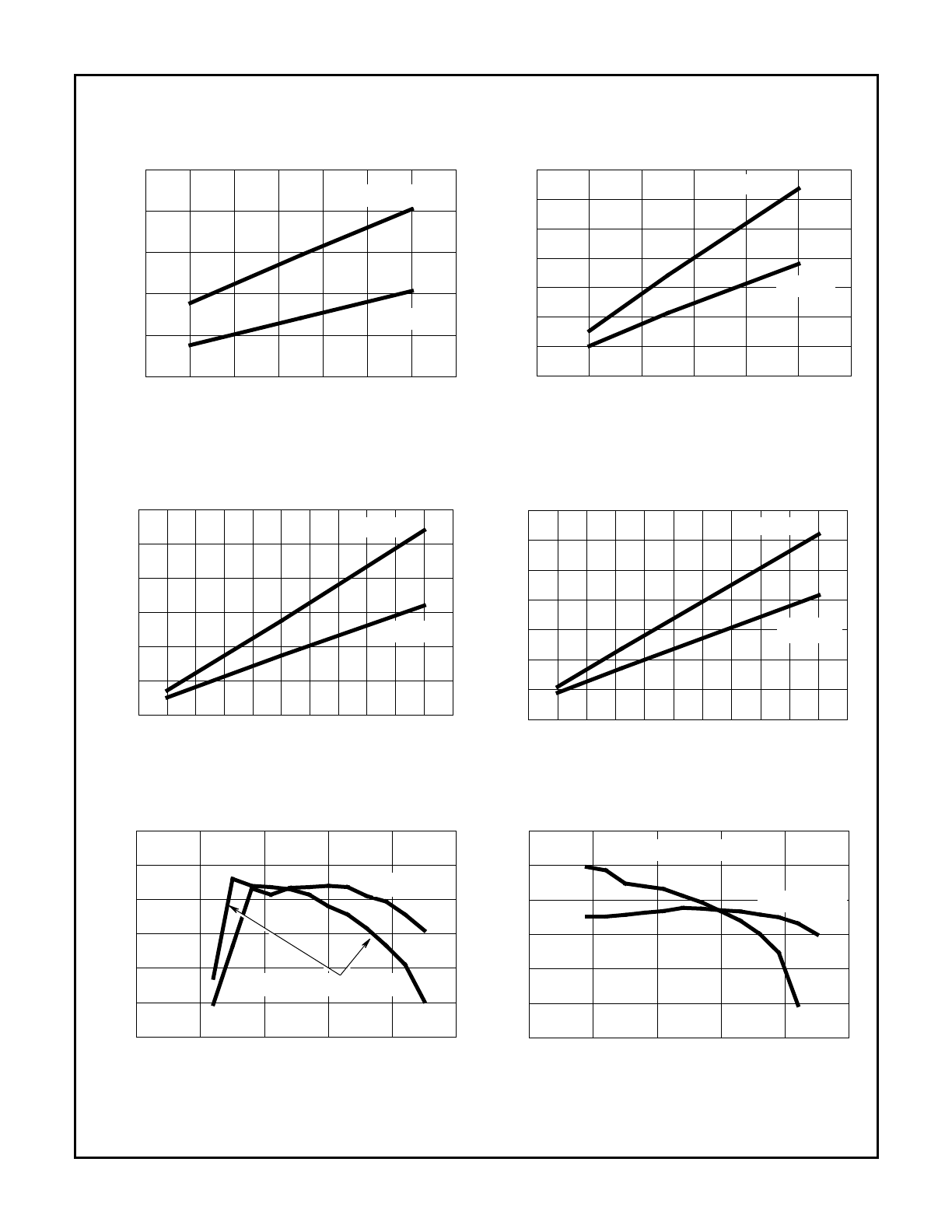

FIGURE 7. SUPPLY CURRENT vs TEMPERATURE

FIGURE 8. SUPPLY CURRENT vs TEMPERATURE

FIGURE 9. DISABLE SUPPLY CURRENT vs TEMPERATURE

FIGURE 10. DISABLE SUPPLY CURRENT vs TEMPERATURE

FIGURE 11. SUPPLY CURRENT vs FREQUENCY

FIGURE 12. SUPPLY CURRENT vs FREQUENCY

Typical Performance Curves

(Continued)

NOTE: Refer to Test Circuit (Figure 1).

-100

-50

0

50

100

150

750

800

850

900

950

1000

1050

TEMPERATURE (

o

C)

f

IN

= 5MHz, EN = 1, F1 = 0, F2 = 0, C

L

= 30pF, V

DD

= 5V

X

TAL

AT 25

o

C

SUPPL

Y CURRENT (

µ

A)

GENERATOR (1V

P-P

) (NOTE)

-100

-50

0

50

100

150

18

19

20

21

22

23

24

25

26

TEMPERATURE (

o

C)

EN = 1, F1 = 1, F2 = 1, f

IN

= 100kHz, C

L

= 30pF, V

DD

= 5V

X

TAL

AT 25

o

C

SUPPL

Y CURRENT (

µ

A)

GENERATOR (1V

P-P

) (NOTE)

-100

-50

0

50

100

150

0

50

100

150

200

250

300

350

TEMPERATURE (

o

C)

SUPPL

Y CURRENT (

µ

A)

f

IN

= 5MHz, EN = 0, F1 = 0, F2 = 0, V

DD

= 5V

GENERATOR (1V

P-P

) (NOTE)

X

TAL

AT 25

o

C

-100

-50

0

50

100

150

4

4.5

5

5.5

6

6.5

7

7.5

TEMPERATURE (

o

C)

GENERATOR (1V

P-P

) (NOTE)

X

TAL

AT 25

o

C

EN = 0, F1 = 1, F2 = 1, f

IN

= 100kHz, V

DD

= 5V

SUPPL

Y CURRENT (

µ

A)

4

5

6

7

8

9

10

11

0

500

1000

1500

2000

2500

3000

FREQUENCY (MHz)

EN = 1, F1 = 0, F2 = 0, C

L

= 18pF, GENERATOR (1V

P-P

) (NOTE)

V

DD

= +8V

V

DD

= +5V

SUPPL

Y CURRENT (

µ

A)

0

1

2

3

4

5

6

0

200

400

600

800

1000

1200

1400

FREQUENCY (MHz)

V

DD

= +8V

EN = 1, F1 = 0, F2 =1, C

L

= 18pF, GENERATOR (1V

P-P

) (NOTE)

V

DD

= +5V

V

DD

= +3V

SUPPL

Y CURRENT (

µ

A)

HA7210, HA7211

8-110

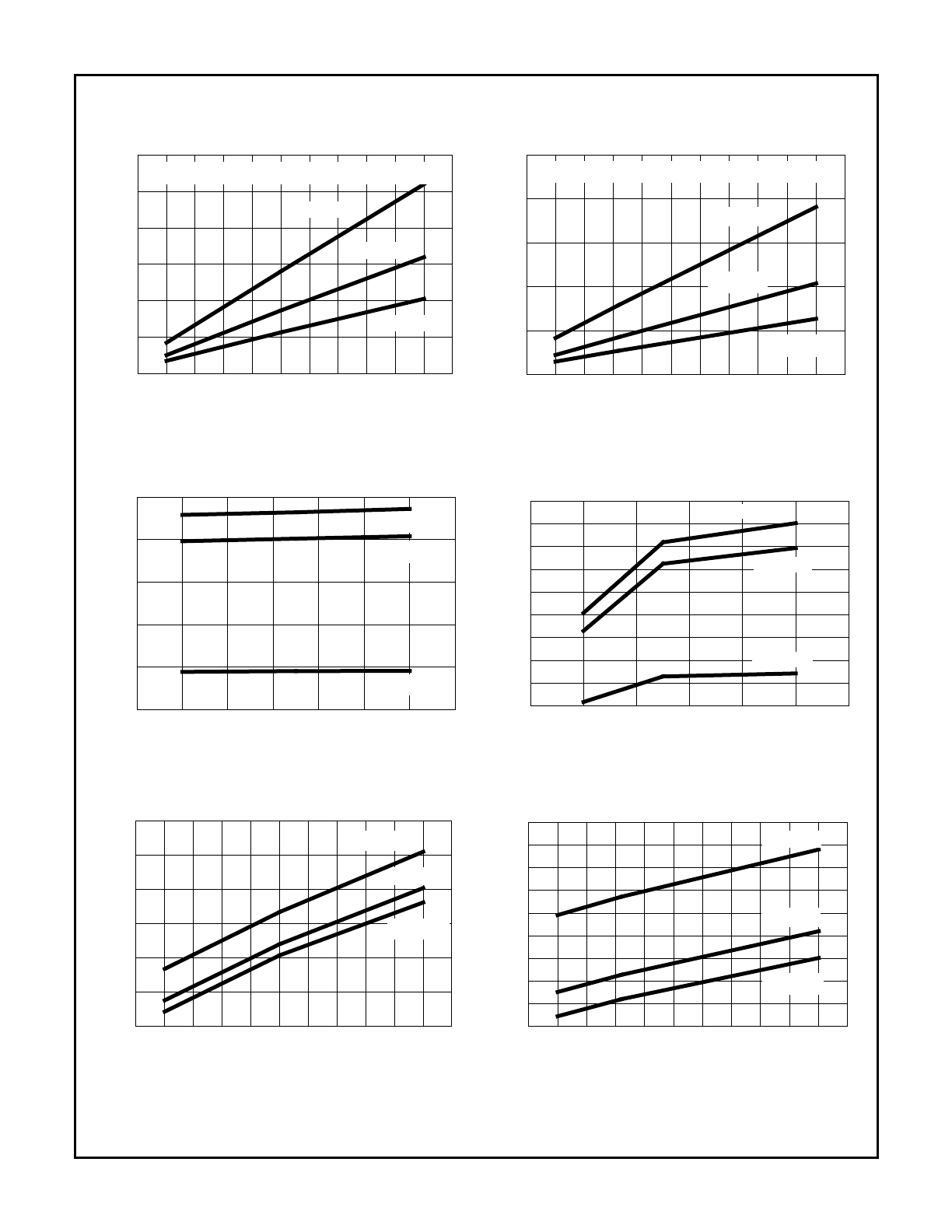

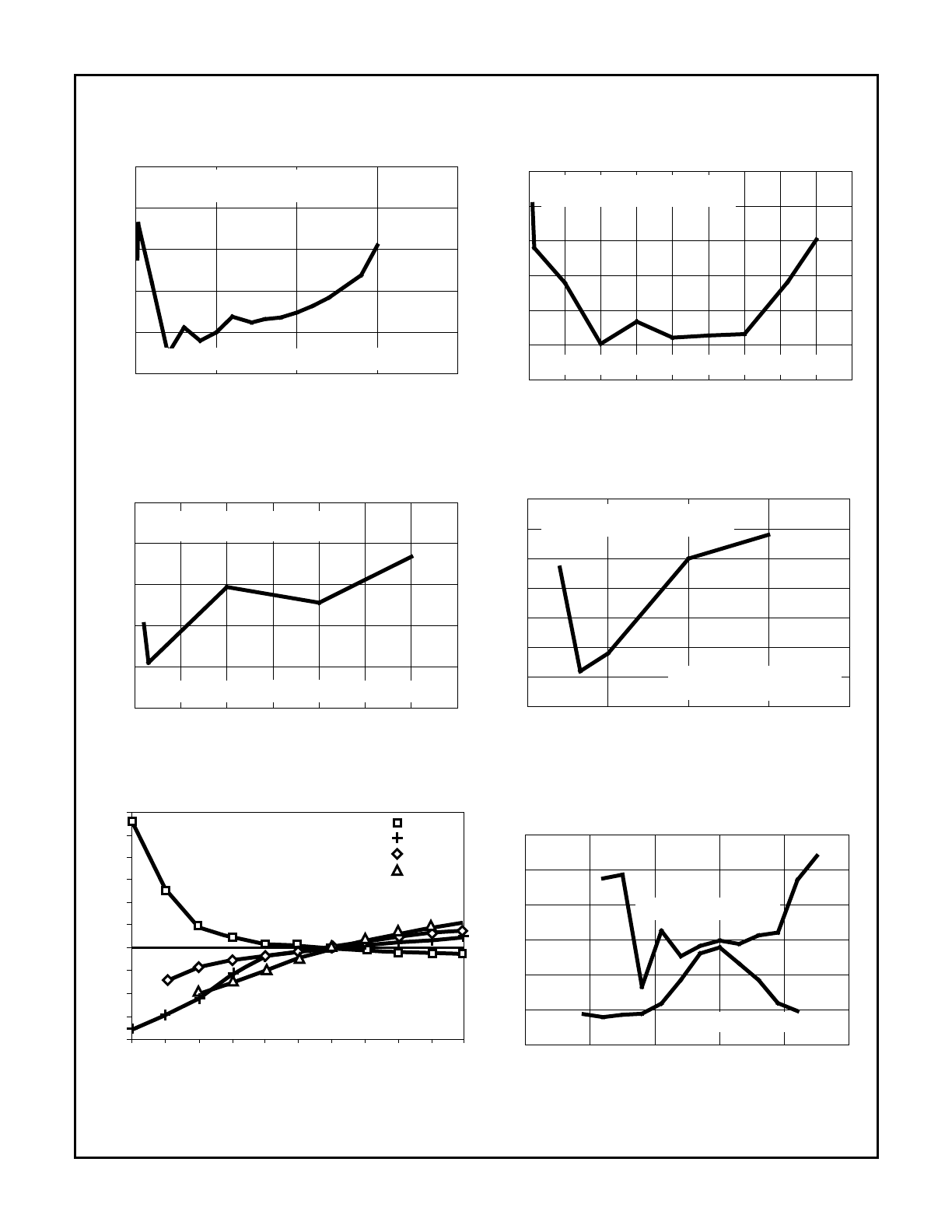

FIGURE 13. SUPPLY CURRENT vs FREQUENCY

FIGURE 14. SUPPLY CURRENT vs FREQUENCY

FIGURE 15. DISABLED SUPPLY CURRENT vs FREQUENCY

FIGURE 16. DISABLE SUPPLY CURRENT vs FREQUENCY

FIGURE 17. DISABLE SUPPLY CURRENT vs FREQUENCY

FIGURE 18. DISABLE SUPPLY CURRENT vs FREQUENCY

Typical Performance Curves

(Continued)

NOTE: Refer to Test Circuit (Figure 1).

0

100

200

300

400

500

600

700

800

900 1000 1100

0

50

100

150

200

250

300

FREQUENCY (kHz)

V

DD

= +8V

V

DD

= +5V

V

DD

= +3V

EN = 1, F1 = 0, F2 = 0, C

L

= 18pF, GENERATOR (1V

P-P

) (NOTE)

SUPPL

Y CURRENT (

µ

A)

0

10

20

30

40

50

60

70

80

90

100

110

0

10

20

30

40

50

FREQUENCY (kHz)

EN = 1, F1 = 0, F2 = 0, C

L

= 18pF, GENERATOR (1V

P-P

) (NOTE)

V

DD

= +8V

V

DD

= +5V

V

DD

= +3V

SUPPL

Y CURRENT (

µ

A)

4

5

6

7

8

9

10

11

0

50

100

150

200

250

EN = 0, F1 = 0, F2 = 0, C

L

= 18pF, GENERATOR (1V

P-P

) (NOTE)

FREQUENCY (MHz)

V

DD

= +8V

V

DD

= +5V

V

DD

= +3V

SUPPL

Y CURRENT (

µ

A)

0

1

2

3

4

5

6

30

40

50

60

70

80

90

100

110

120

EN = 0, F1 = 0, F2 = 1, C

L

= 18pF, GENERATOR (1V

P-P

) (NOTE)

FREQUENCY (MHz)

SUPPL

Y CURRENT (

µ

A)

V

DD

= +8V

V

DD

= +5V

V

DD

= +3V

0

100

200

300

400

500

600

700

800

900 1000 1100

5

10

15

20

25

30

35

EN = 0, F1 = 1, F2 = 0, C

L

= 18pF, GENERATOR (1V

P-P

) (NOTE)

FREQUENCY (kHz)

SUPPL

Y CURRENT (

µ

A)

V

DD

= +8V

V

DD

= +5V

V

DD

= +3V

0

10

20

30

40

50

60

70

80

90

100 110

2

3

4

5

6

7

8

9

10

11

EN = 0, F1 = 1, F2 = 1, C

L

= 18pF, GENERATOR (1V

P-P

) (NOTE)

FREQUENCY (kHz)

SUPPL

Y CURRENT (

µ

A)

V

DD

= +8V

V

DD

= +5V

V

DD

= +3V

HA7210, HA7211

8-111

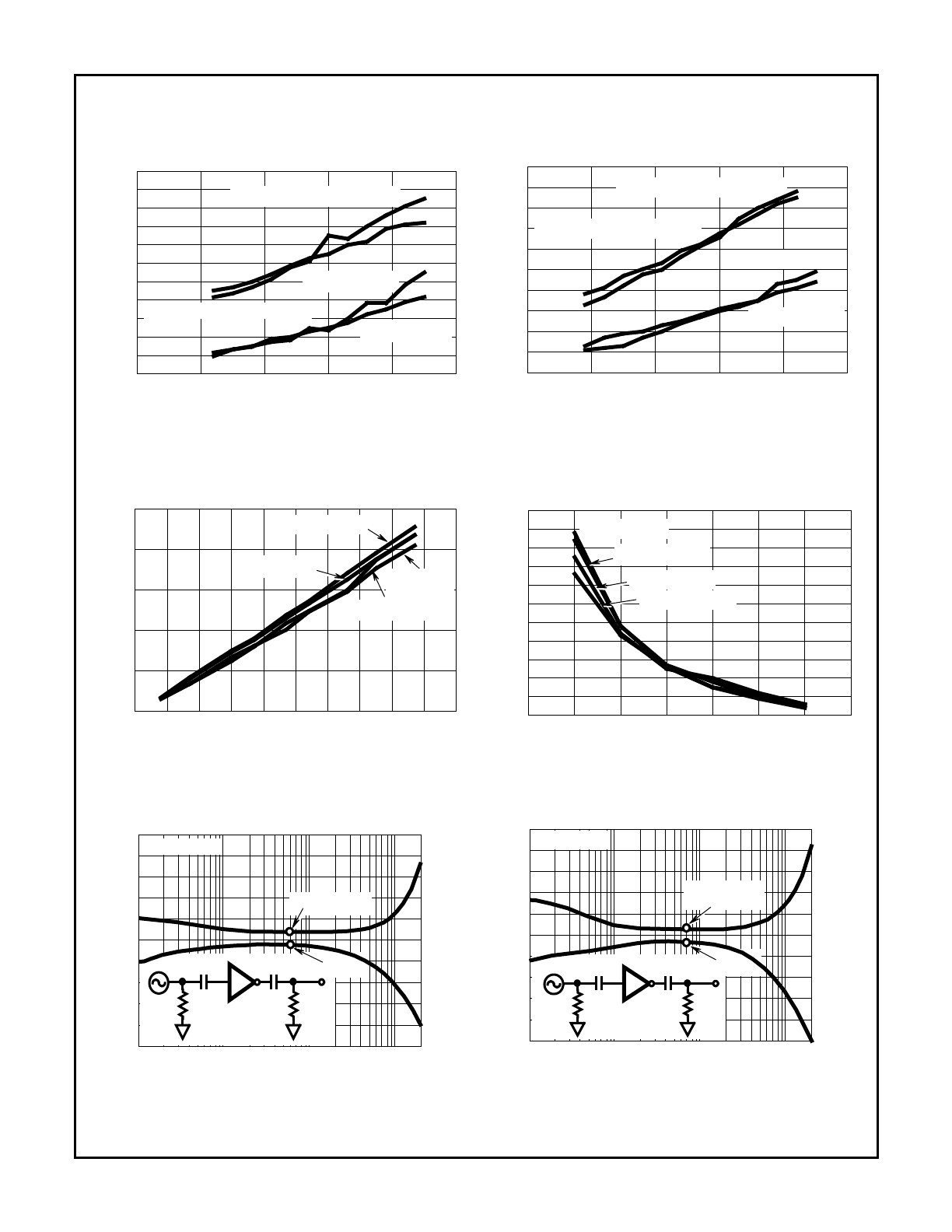

FIGURE 19. SUPPLY CURRENT vs FREQUENCY

FIGURE 20. SUPPLY CURRENT vs FREQUENCY

FIGURE 21. SUPPLY CURRENT vs FREQUENCY

FIGURE 22. SUPPLY CURRENT vs FREQUENCY

FIGURE 23. DUTY CYCLE vs TEMPERATURE

FIGURE 24. DUTY CYCLE vs TEMPERATURE

Typical Performance Curves

(Continued)

NOTE: Refer to Test Circuit (Figure 1).

4

5

6

7

8

9

10

11

500

1000

1500

2000

2500

3000

EN = 1, F1 = 0, F2 = 0, V

DD

= +5V, GENERATOR (1V

P-P

) (NOTE)

FREQUENCY (MHz)

SUPPL

Y CURRENT (

µ

A)

C

L

= 40pF

C

L

= 18pF

0

1

2

3

4

5

6

0

200

400

600

800

1000

1200

1400

EN = 1, F1 = 0, F2 = 1, V

DD

= +5V, GENERATOR (1V

P-P

) (NOTE)

FREQUENCY (MHz)

SUPPL

Y CURRENT (

µ

A)

C

L

= 40pF

C

L

= 18pF

0

100

200

300

400

500

600

700

800

900 1000 1100

0

50

100

150

200

250

300

EN = 1, F1 = 1, F2 = 0, V

DD

= +5V, GENERATOR (1V

P-P

) (NOTE)

FREQUENCY (kHz)

SUPPL

Y CURRENT (

µ

A)

C

L

= 40pF

C

L

= 18pF

0

10

20

30

40

50

60

70

80

90

100 110

0

5

10

15

20

25

30

35

EN = 1, F1 = 1, F2 = 1, V

DD

= +5V, GENERATOR (1V

P-P

) (NOTE)

FREQUENCY (kHz)

SUPPL

Y CURRENT (

µ

A)

C

L

= 18pF

C

L

= 40pF

-100

-50

0

50

100

150

30

35

40

45

50

55

60

f

IN

= 5MHz, F1 = 0, F2 = 0, C

L

= 30pF, V

DD

= 5V

TEMPERATURE (

o

C)

DUTY CYCLE (%)

X

TAL

AT 25

o

C

GENERATOR (1V

P-P

) (NOTE)

-100

-50

0

50

100

150

10

20

30

40

50

60

70

f

IN

= 100kHz, F1 = 1, F2 = 1, C

L

= 30pF, V

DD

= 5V

TEMPERATURE (

o

C)

DUTY CYCLE (%)

GENERATOR (1V

P-P

) (NOTE)

X

TAL

AT 25

o

C

HA7210, HA7211

8-112

FIGURE 25. DUTY CYCLE vs FREQUENCY

FIGURE 26. DUTY CYCLE vs FREQUENCY

FIGURE 27. DUTY CYCLE vs FREQUENCY

FIGURE 28. DUTY CYCLE vs FREQUENCY

FIGURE 29. FREQUENCY CHANGE vs V

DD

FIGURE 30. EDGE JITTER vs TEMPERATURE

Typical Performance Curves

(Continued)

NOTE: Refer to Test Circuit (Figure 1).

0

45

50

55

60

65

70

F1 = F2 = 0, V

DD

= 5V, C

L

= 18pF, C

1

= C

2

= 0

FREQUENCY (MHz)

DUTY CYCLE (%)

15

20

5

10

DATA COLLECTED USING CRYSTALS

AT EACH FREQUENCY

F1 = 0, F2 = 0 RECOMMENDED FOR 5MHz TO 10MHz RANGE

0

45

50

55

60

65

70

F1 = 0, F2 = 1, V

DD

= 5V, C

L

= 18pF, C

1

= C

2

= 0

FREQUENCY (MHz)

DUTY CYCLE (%)

7

9

4

6

1

2

3

5

8

40

DATA COLLECTED USING CRYSTALS

AT EACH FREQUENCY

F1 = 0, F2 = 1 RECOMMENDED FOR 1MHz TO 5MHz RANGE

0

40

45

50

55

60

65

F1 = 1, F2 = 0, V

DD

= 5V, C

L

= 18pF, C

1

= C

2

= 0

FREQUENCY (kHz)

DUTY CYCLE (%)

1500

2000

500

1000

2500

3000

3500

DATA COLLECTED USING CRYSTALS

AT EACH FREQUENCY

F1 = 1, F2 = 0 RECOMMENDED FOR 100kHz TO 1MHz RANGE

0

42

43

44

45

46

47

F1 = F2 = 1, V

DD

= 5V, C

L

= 18pF, C

1

= C

2

= 0

FREQUENCY (kHz)

DUTY CYCLE (%)

150

200

50

100

41

40

DATA COLLECTED USING CRYSTALS

AT EACH FREQUENCY

F1 = 1, F2 = 1 RECOMMENDED

FOR 10kHz TO 100kHz RANGE

2

4

6

-20

-10

0

5

15

20

30

V

DD

SUPPLY VOLTAGE (V)

-5

-15

25

10

32kHz

1MHz

5MHz

10MHz

FREQ

UENCY CHANGE (PPM)

DEVIATION FROM FREQUENCY AT 5.0V

-100

-50

0

50

100

150

0

1

2

3

4

5

6

V

DD

= 5V, C

L

= 30pF, GENERATOR (1V

P-P

) (NOTE)

TEMPERATURE (

o

C)

EDGE JITTER (% OF PERIOD)

f

IN

= 5MHz, F1 = 0, F2 = 0

f

IN

= 100kHz, F1 = 1, F2 = 1

HA7210, HA7211

8-113

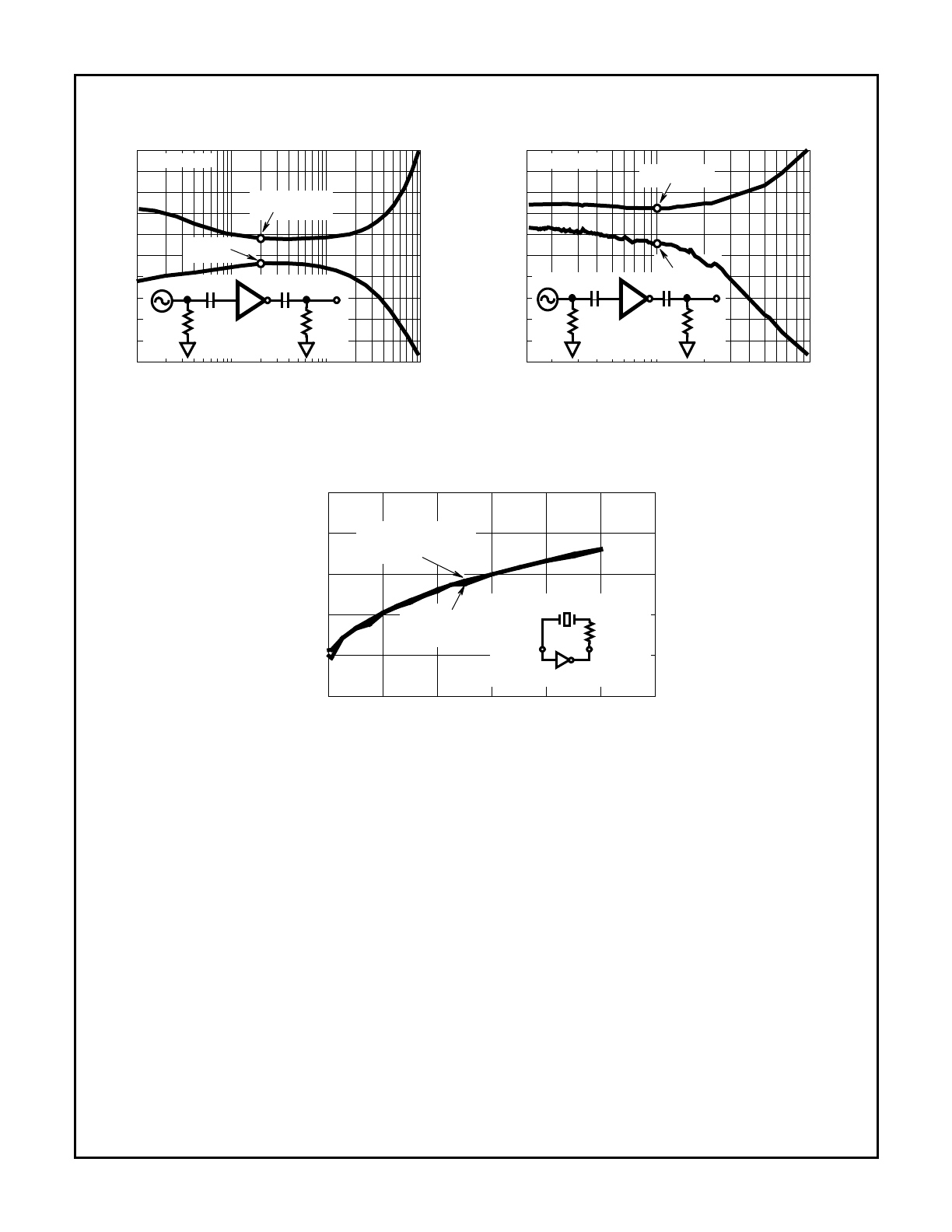

FIGURE 31. RISE/FALL TIME vs TEMPERATURE

FIGURE 32. RISE/FALL TIME vs TEMPERATURE

FIGURE 33. RISE/FALL TIME vs C

L

FIGURE 34. RISE/FALL TIME vs V

DD

FIGURE 35. TRANSCONDUCTANCE vs FREQUENCY

FIGURE 36. TRANSCONDUCTANCE vs FREQUENCY

Typical Performance Curves

(Continued)

NOTE: Refer to Test Circuit (Figure 1).

-100

-50

0

50

100

150

2

3

4

5

6

7

8

9

10

11

12

13

f

IN

= 5MHz, F1 = 0, F2 = 0, C

L

= 30pF, V

DD

= 5V

TEMPERATURE (

o

C)

t

F

GENERATOR (1V

P-P

) (NOTE)

t

R

GENERATOR (1V

P-P

) (NOTE)

t

F

X

TAL

AT 25

o

C

t

R

X

TAL

AT 25

o

C

RISE/F

ALL TIME (ns)

-100

-50

0

50

100

150

2

3

4

5

6

7

8

9

10

11

12

f

IN

= 100kHz, F1 = 1, F2 = 1, C

L

= 30pF, V

DD

= 5V

TEMPERATURE (

o

C)

t

F

GENERATOR (1V

P-P

) (NOTE)

t

R

GENERATOR (1V

P-P

) (NOTE)

t

F

X

TAL

AT 25

o

C

t

R

X

TAL

AT 25

o

C

RISE/F

ALL TIME (ns)

10

20

30

40

50

60

70

80

90

100

110

5

10

15

20

25

30

C

L

(pF)

RISE/F

ALL TIME (ns)

V

DD

= 5V, GENERATOR (1V

P-P

) (NOTE)

t

F

(f

IN

= 100kHz)

t

F

(f

IN

= 5MHz)

t

R

t

R

(f

IN

= 100kHz)

(f

IN

= 5MHz)

2

3

4

5

6

7

8

9

4

5

6

7

8

9

10

11

12

13

14

15

V

DD

(+V)

C

L

= 18pF, GENERATOR (1V

P-P

) (NOTE)

t

F

(f

IN

= 5MHz)

t

F

(f

IN

= 100kHz)

t

R

(f

IN

= 5MHz)

t

R

(f

IN

= 100kHz)

RISE/F

ALL TIME (ns)

580

540

500

460

420

380

340

300

260

10K

100K

1M

10M

140

150

160

170

180

FREQUENCY (Hz)

PHASE (DEGREES)

TRANSCONDUCT

ANCE (

µ

A/V)

V

DD

= 5V, V

SS

= GND

436.5

µ

A/V

2

3

1000pF

1

µ

F

HA7210

100

Ω

50

Ω

178

o

620

F1 = 0, F2 = 0

460

420

380

340

300

260

10K

100K

1M

10M

140

150

160

170

180

FREQUENCY (Hz)

PHASE (DEGREES)

TRANSCONDUCT

ANCE (

µ

A/V)

130

V

DD

= 5V, V

SS

= GND

311.6

µ

A/V

2

3

1000pF

1

µ

F

HA7210

100

Ω

50

Ω

500

177

o

F1 = 0, F2 = 1

HA7210, HA7211

8-114

FIGURE 37. TRANSCONDUCTANCE vs FREQUENCY

FIGURE 38. TRANSCONDUCTANCE vs FREQUENCY

NOTE: Figure 39 (Duty Cycle vs R

S

at 32kHz) should only be used for 32kHz crystals. R

S

may be used at other frequencies to adjust Duty

Cycle but experimentation will be required to find an appropriate value. The R

S

value will be proportional to the effective series resis-

tance of the crystal being used.

FIGURE 39. DUTY CYCLE vs R

S

at 32kHz

Typical Performance Curves

(Continued)

NOTE: Refer to Test Circuit (Figure 1).

220

200

180

160

140

120

100

10K

100K

1M

10M

140

150

160

170

180

FREQUENCY (Hz)

PHASE (DEGREES)

TRANSCONDUCT

ANCE (

µ

A/V)

130

240

V

DD

= 5V, V

SS

= GND

156.7

µ

A/V

176.6

o

2

3

1000pF

1

µ

F

HA7210

100

Ω

50

Ω

F1 = 1, F2 = 0

15

10

5

0

10K

100K

1M

140

150

160

170

180

FREQUENCY (Hz)

PHASE (DEGREES)

TRANSCONDUCT

ANCE (

µ

A/V)

130

120

110

20

V

DD

= 5V, V

SS

= GND

6.56

µ

A/V

2

3

1000pF

1

µ

F

HA7210

100

Ω

50

Ω

166

o

F1 = 1, F2 = 1

0

20

40

60

80

100

120

35

40

45

50

55

60

F1 = F2 = 1, V

DD

= 5V, C

L

= 18pF, T

A

= 25

o

C, f

OSC

= 32.768kHz

R

S

(k

Ω

)

DUTY CYCLE (%)

NDK PART #

MX-38

EPSON PART #

C-001R32.768K-A

HA7210

XTAL

2

OSC IN

3

OSC OUT

R

S

HA7210, HA7211

8-115

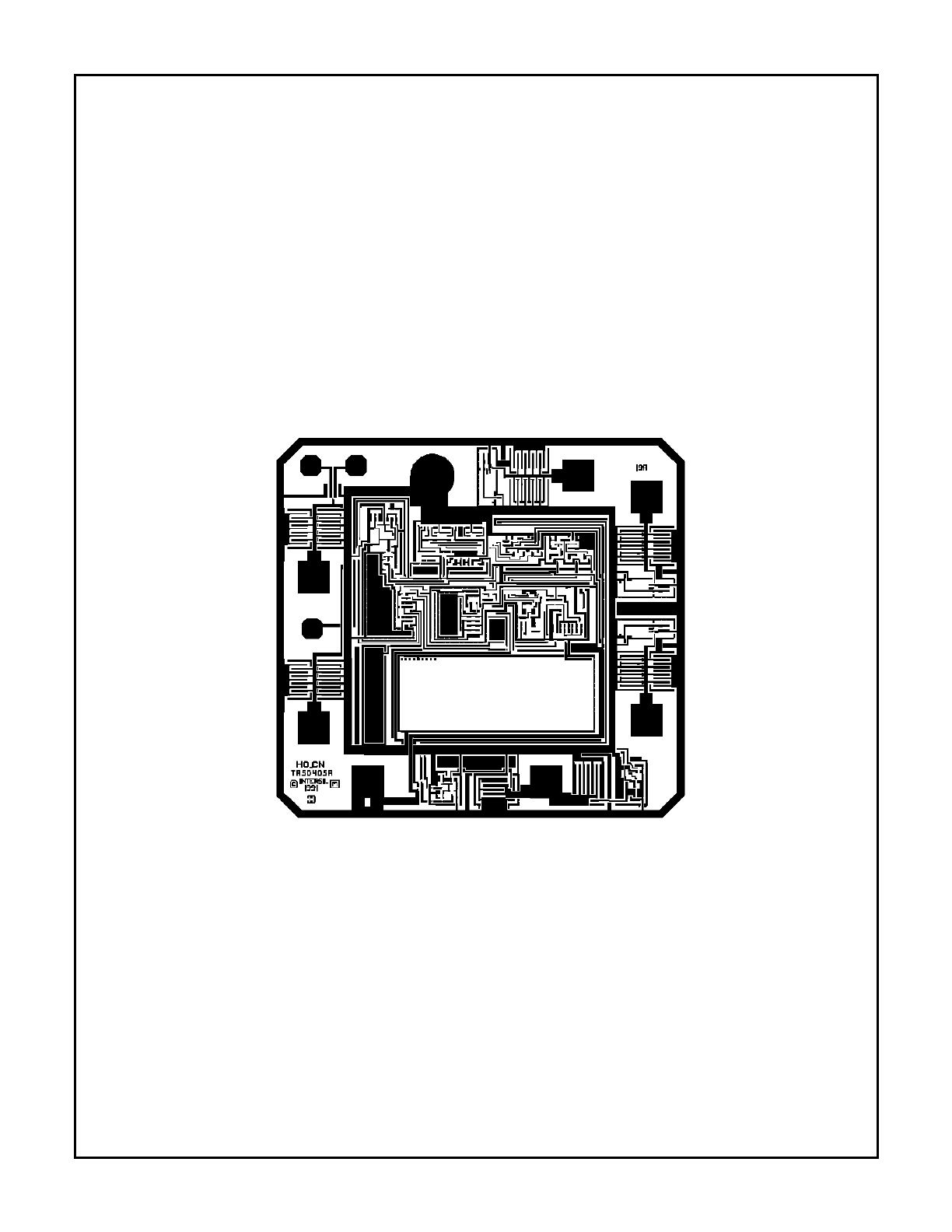

Die Characteristics

DIE DIMENSIONS:

68 mils x 64 mils x 14 mils

METALLIZATION:

Type: Si - Al

Thickness: 10k

Å

±

1k

Å

SUBSTRATE POTENTIAL

V

SS

PASSIVATION:

Type: Nitride (Si

3

N

4

) Over Silox (SiO

2

, 3% Phos)

Silox Thickness: 7k

Å

±

1k

Å

Nitride Thickness: 8k

Å

±

1k

Å

Metallization Mask Layout

HA7210

(1) V

DD

CRYSTAL (2)

CRYSTAL (3)

V

SS

(4)

OUTPUT (5)

(6) FREQ 1

(7) FREQ 2

(8) ENABLE

HA7210, HA7211