L6219

STEPPER MOTOR DRIVER

ABLE TO DRIVE BOTH WINDINGS OF BIPO-

LAR STEPPER MOTOR

OUTPUT CURRENT UP TO 750mA EACH

WINDING

WIDE VOLTAGE RANGE 10V TO 46V

HALF-STEP, FULL-STEP AND MICROSTEPP-

ING MODE

BUILT-IN PROTECTION DIODES

INTERNAL PWM CURRENT CONTROL

LOW OUTPUT SATURATION VOLTAGE

DESIGNED FOR UNSTABILIZED MOTOR

SUPPLY VOLTAGE

INTERNAL THERMAL SHUTDOWN

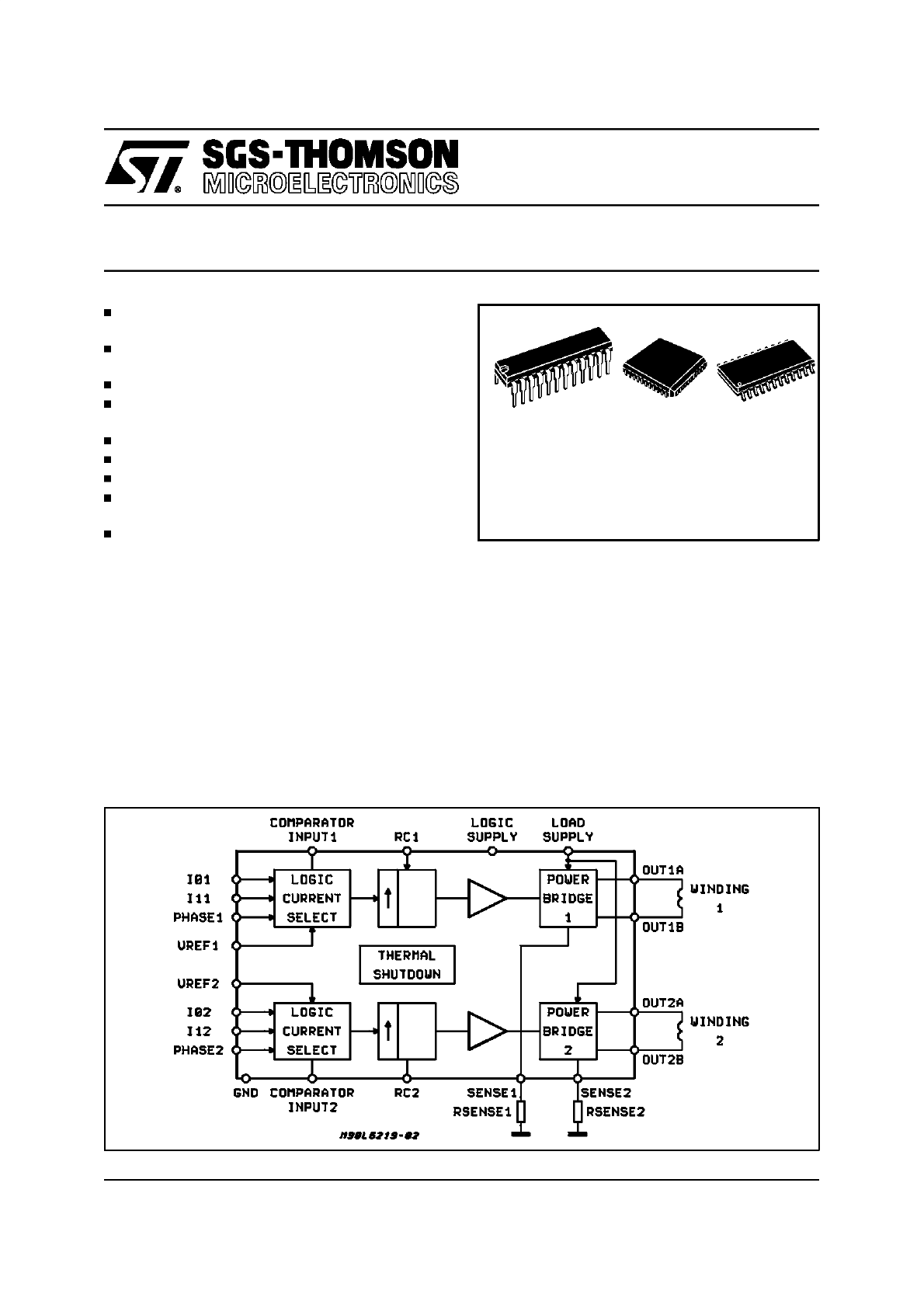

DESCRIPTION

The L6219 is a bipolar monolithic integrated cir-

cuits intended to control and drive both winding of

a bipolar stepper motor or bidirectionally control

two DC motors.

The L6219 with a few external components form

a complete control and drive circuit for LS-TTL or

microprocessor controlled stepper motor system.

The power stage is a dual full bridge capable of

sustaining 46V and including four diodes for cur-

rent recirculation.

A cross conduction protection is provided to avoid

simultaneous cross conduction during switching

current direction.

An internal pulse-width-modulation (PWM) con-

trols the output current to 750mA with peak start-

up current up to 1A.

Wide range of current control from 750mA (each

bridge) is permitted by means of two logic inputs

and an external voltage reference. A phase input

to each bridge determines the load current direc-

tion.

A thermal protection circuitry disables the outputs

if the chip temperature exceeds safe operating

limits.

December 1996

Powerdip 20+2+2

PLCC44

SO20+2+2

ORDERING NUMBERS:

L6219

L6219D

L6219DS

BLOCK DIAGRAM

1/10

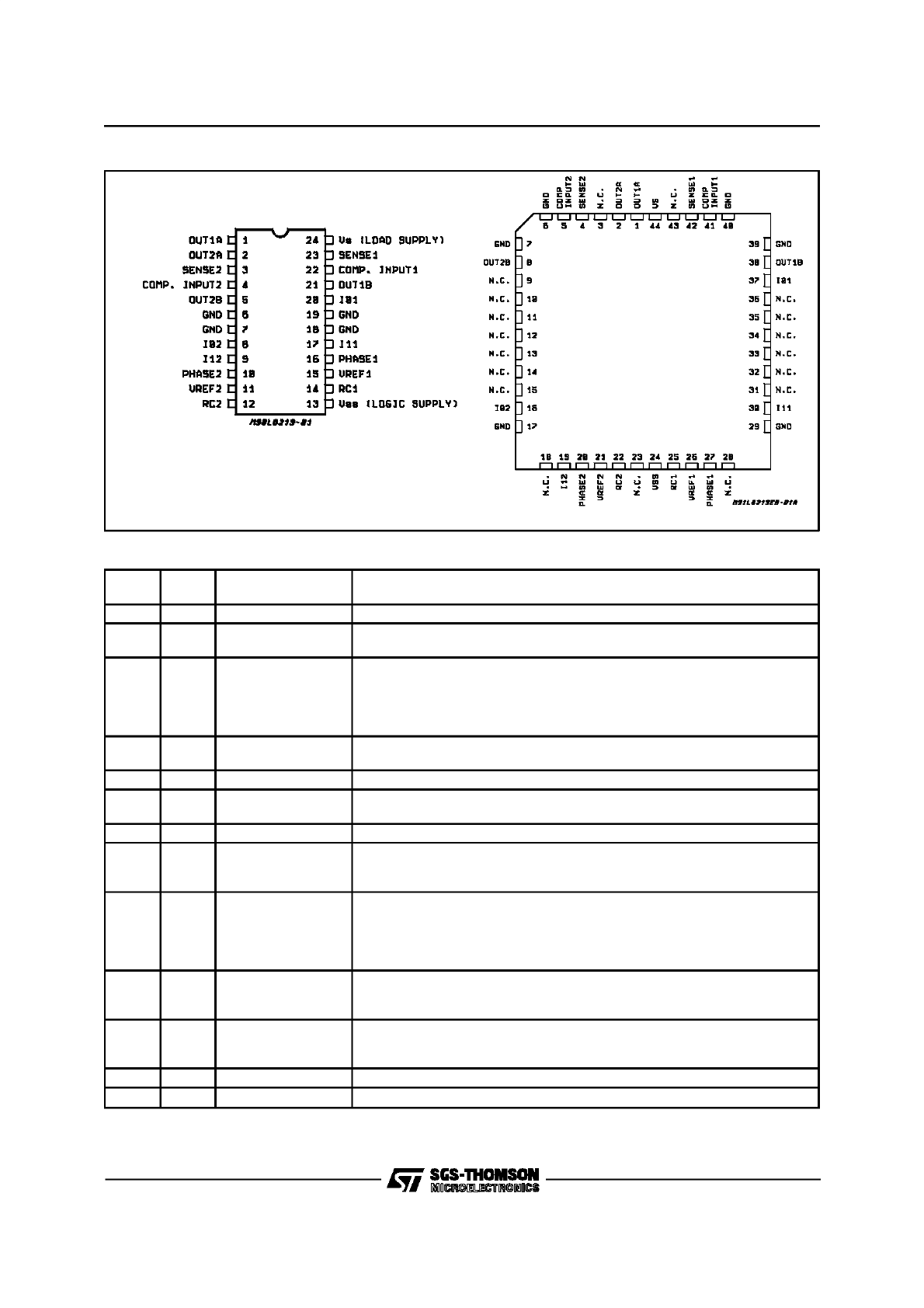

PIN FUNCTIONS

PLCC

(*)

PDIP &

SO

Name

Function

1;2

1;2

OUTPUT A

See pins 5;21

4;42

3;23

SENSE RESISTOR

Connection to Lower Emitters of Output Stage for Insertion of Current Sense

Resistor

5;41

4;22

COMPARATOR

INPUT

Input connected to the comparators. The voltage across the sense resistor is

feedback to this input throught the low pass filter RC CC. The higher power

transistors are disabled when the sense voltage exceeds the reference

voltage of the selected comparator. When this occurs the current decays for

a time set by R

T

C

T

(t

off

= 1.1 R

T

C

T

). See fig. 1.

8;38

5;21

OUTPUT B

Output Connection. The output stage is a ”H” bridge formed by four

transistors and four diodes suitable for switching applications.

6;7;17

6;19

GROUND

See pins 7;18

29;39;

40

7;18

GROUND

Ground Connection. With pins 6 and 19 also conducts heat from die to

printed circuit copper.

16;37

8;20

INPUT 0

See INPUT 1 (pins 9;17)

19;30

9;17

INPUT 1

These pins and pins 8;20 (INPUT 0) are logic inputs which select the outputs

of the comparators to set the current level. Current also depends on the

sensing resistor and reference voltage. See Funcional Description.

20;27

10;16

PHASE

This TTL-compatible logic inputs sets the direction of current flow through

the load. A high level causes current to flow from OUTPUT A (source) to

OUTPUT B (sink). A schmitt trigger on this input provides good noise

immunity and a delay circuit prevents output stage short circuits during

switching.

21;26

11;15

REFERENCE

VOLTAGE

A voltage applied to this pin sets the reference voltage of the comparators,

this determining the output current (also thus depending on R

s

and the two

inputs INPUT 0 and INPUT 1).

22;25

12;14

RC

A parallel RC network connected to this pin sets the OFF time of the higher

power transistors. The pulse generator is a monostable triggered by the

output of the comparators (t

off

= 1.1 R

T

C

T

).

24

13

V

ss

- LOGIC SUPPLY Supply Voltage Input for Logic Circuitry

44

24

Vs - LOAD SUPPLY Supply Voltage Input for the Output Stages.

(*) Pins: 3, 9,10,11,12,13,14,15,18,23,28,31,32,33,34,35,36,43 are Not Connected.

Note: ESD on GND, V

S

, V

SS

, OUT 1A and OUT 2A is guaranteed up to 1.5KV (Human Body Model, 1500

Ω

, 100pF).

PIN CONNECTIONS (Top view)

Powerdip and SO

PLCC44

L6219

2/10

ABSOLUTE MAXIMUM RATINGS

Symbol

Parameter

Value

Unit

V

S

Supply Voltage

50

V

I

o

Output Current (peak)

±

1

A

I

o

Output Current (continuous)

±

0.75

A

V

SS

Logic Supply Voltage

7

V

V

IN

Logic Input Voltage Range

-0.3 to +7

V

V

sense

Sense Output Voltage

1.5

V

T

J

Junction Temperature

+150

°

C

T

op

Operating Temperature Range

0 to 70

°

C

T

stg

Storage Temperature Range

-55 to +150

°

C

THERMAL DATA

Symbol

Description

PLCC

PDIP

SO

Unit

R

thj-case

R

thj-amb

Thermal Resistance Junction-case

Max.

Thermal Resistance Junction-ambient

Max.

12

45 (*)

14

60 (*)

18

75 (*)

°

C/W

°

C/W

(*) With minimized copper area.

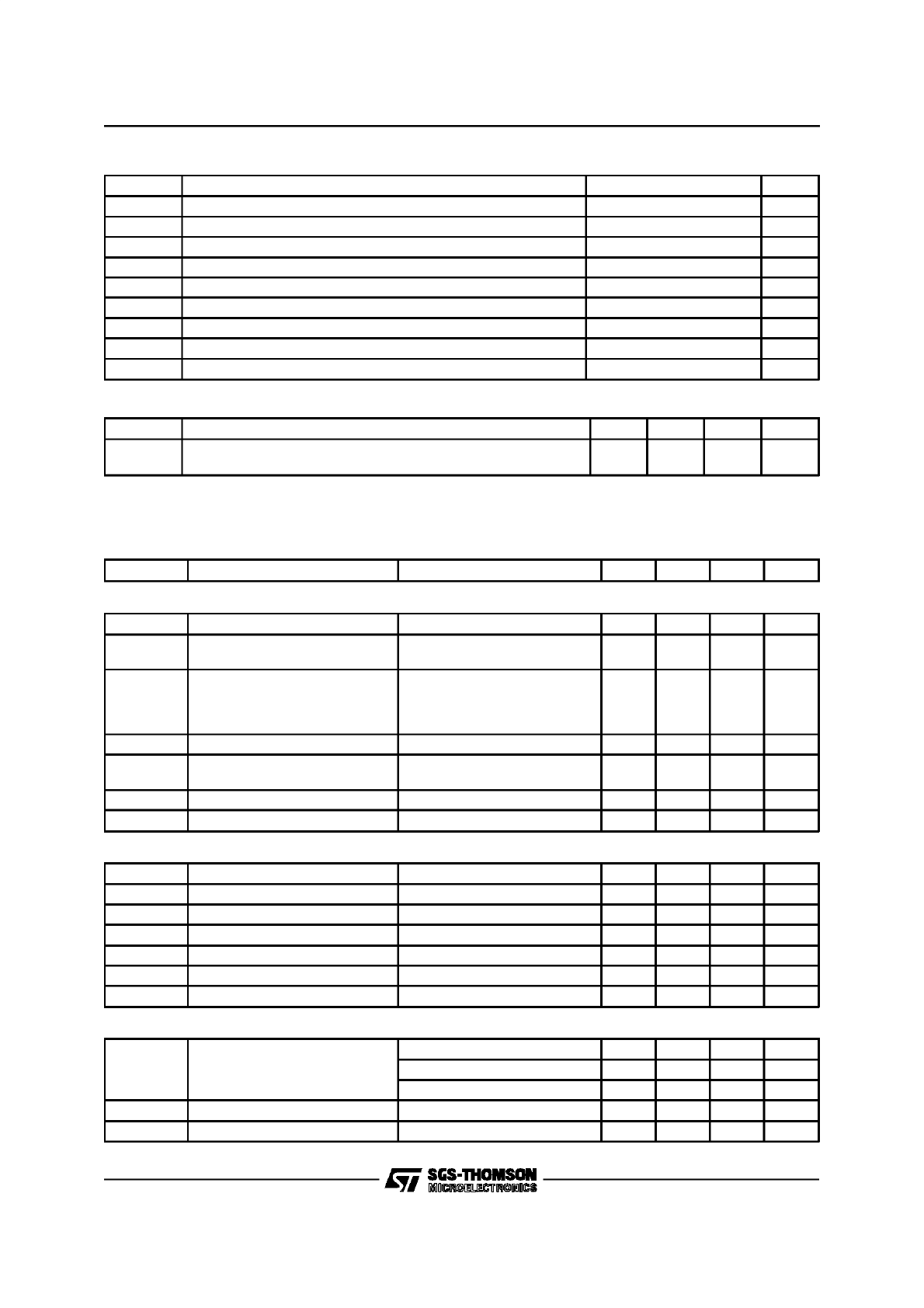

ELECTRICAL CHARACTERISTICS (T

j

= 25

°

C, V

S

= 46V, V

SS

= 4.75V to 5.25V, V

REF

= 5V; unless oth-

erwise specified) See fig. 3.

Symbol

Parameter

Test Condition

Min.

Typ.

Max.

Unit

OUTPUT DRIVERS (OUT

A

or OUT

B

)

V

S

Motor Supply Range

10

46

V

I

CEX

Output Leakage Current

V

OUT

= Vs

V

OUT

= 0

-

-

<1

<-1

50

-50

µ

A

µ

A

V

CE(sat)

Output Saturation Voltage

Sink Driver, I

OUT

= +500mA

Sink Driver, I

OUT

= +750mA

Source Driver, I

OUT

= -500mA

Source Driver, I

OUT

= -750mA

-

-

-

-

0.3

0.7

1.1

1.3

0.6

1

1.4

1.6

V

V

V

V

I

R

Clamp Diode Leakage Current

V

R

= 50V

-

<1

50

µ

A

V

F

Clamp Diode Forward Voltage

Sink Diode

Source Diode I

F

=750mA

1

1

1.5

1.5

V

V

I

S(on)

Driver Supply Current

Both Bridges ON, No Load

-

8

15

mA

I

S(off)

Driver Supply Current

Both Bridges OFF

-

6

10

mA

CONTROL LOGIC

V

IN(H)

Input Voltage

All Inputs

2.4

-

-

V

V

IN(L)

Input Voltage

All Inputs

-

-

0.8

V

I

IN(H)

Input Current

VIN = 2.4V

-

<1

20

µ

A

I

IN(L)

Input Current

VIN = 0.84V

-

-3

-200

µ

A

V

REF

Reference Voltage

Operating

1.5

-

7.5

V

I

SS(ON)

Total Logic Supply Current

I

o

= I

1

= 0.8V, No Load

-

64

74

mA

I

SS(OFF)

Total Logic Supply Current

I

o

= I

1

= 2.4V, No Load

-

10

14

mA

COMPARATORS

V

REF

/ V

sense

Current Limit Threshold (at trip

point

I

o

= I

1

= 0.8V

9.5

10

10.5

-

I

o

= 2.4V, I

1

= 0.8V

13.5

15

16.5

-

I

o

= 0.8V, I

1

= 2.4V

25.5

30

34.5

-

t

off

Cutoff Time

Rt = 56K

Ω

C

t

= 820pF

-

50

s

t

d

Turn Off Delay

Fig. 1

-

1

s

µ

µ

L6219

3/10

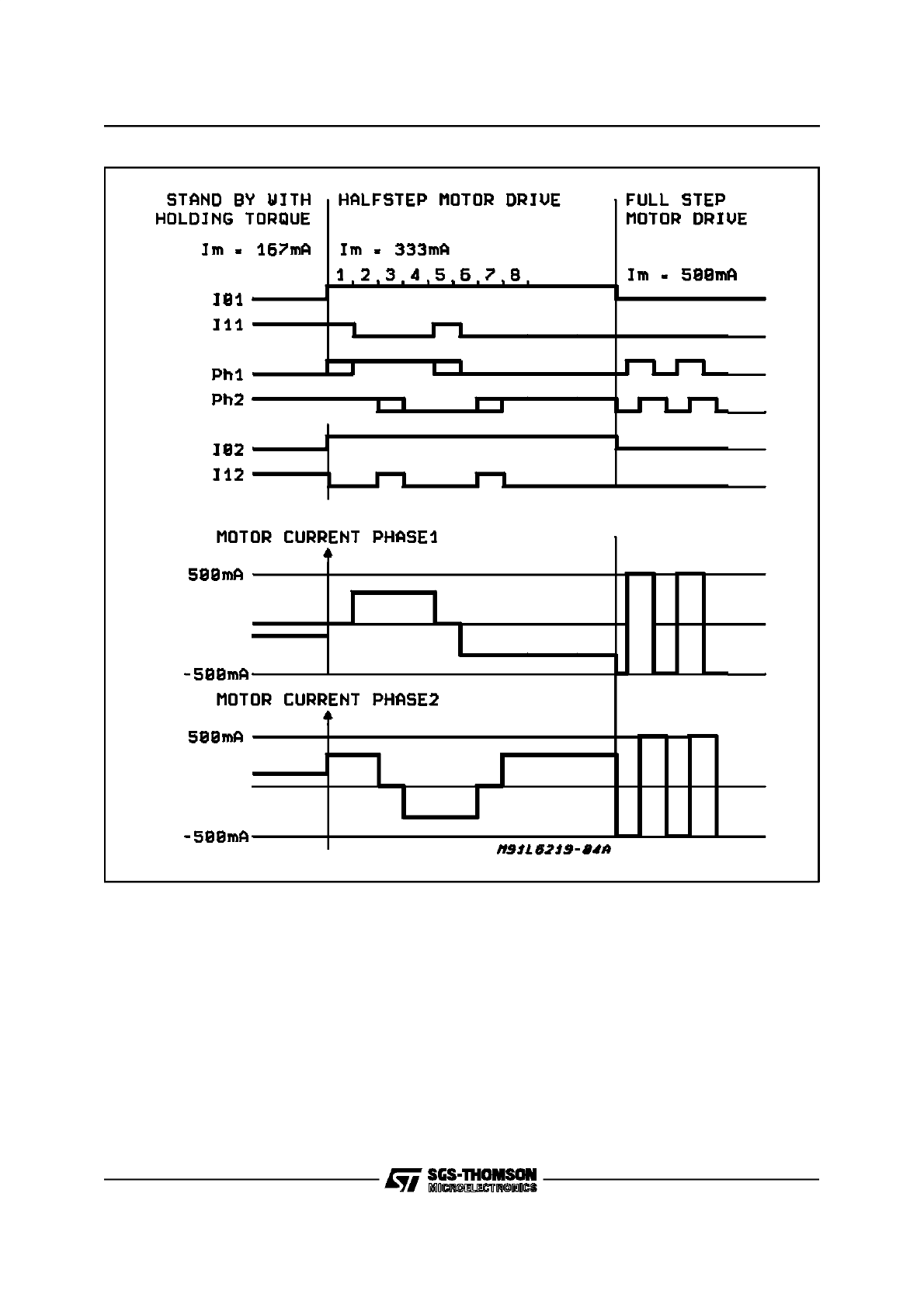

FUNCTIONAL DESCRIPTION

The circuit is intended to drive both windings of a

bipolar stepper motor.

The peak current control is generated through

switch mode regulation.

There is a choice of three different current levels

with the two logic inputs I

01

- I

11

for winding 1 and

I

02

- I

12

for winding 2.

The current can also be switched off completely

Input Logic (I

0

and I

1

)

The current level in the motor winding is selected

with these inputs. (See fig. 2)

If any of the logic inputs is left open, the circuit will

treat it has a high level input.

I

o

I

1

Current Level

H

L

H

L

H

H

L

L

No Current

Low Current 1/3 I

o

max

Medium Current 2/3 I

o

max

Maximum Current I

o

max

Phase

This input determines the direction of current flow

in the windings, depending on the motor connec-

tions. The signal is fed through a Schmidt-trigger

for noise immunity, and through a time delay in

order to guarantee that no short-circuit occurs in

the output stage during phase-shift.

High level on the PHASE input causes the motor

current flow from Out A through the winding to

Out B

Current Sensor

This part contains a current sensing resistor (R

S

),

a low pass filter (R

C

, C

C

) and three comparators.

Only one comparator is active at a time. It is acti-

vated by the input logic according to the current

level chosen with signals I

o

and I

1

.

The motor current flows through the sensing re-

sistor R

S

.

When the current has increased so that the volt-

age across R

S

becomes higher than the refer-

ence voltage on the other comparator input, the

comparator goes high, which triggers the pulse

generator.

The max peak current I

max

can be defined by:

I

max

=

V

ref

10 R

s

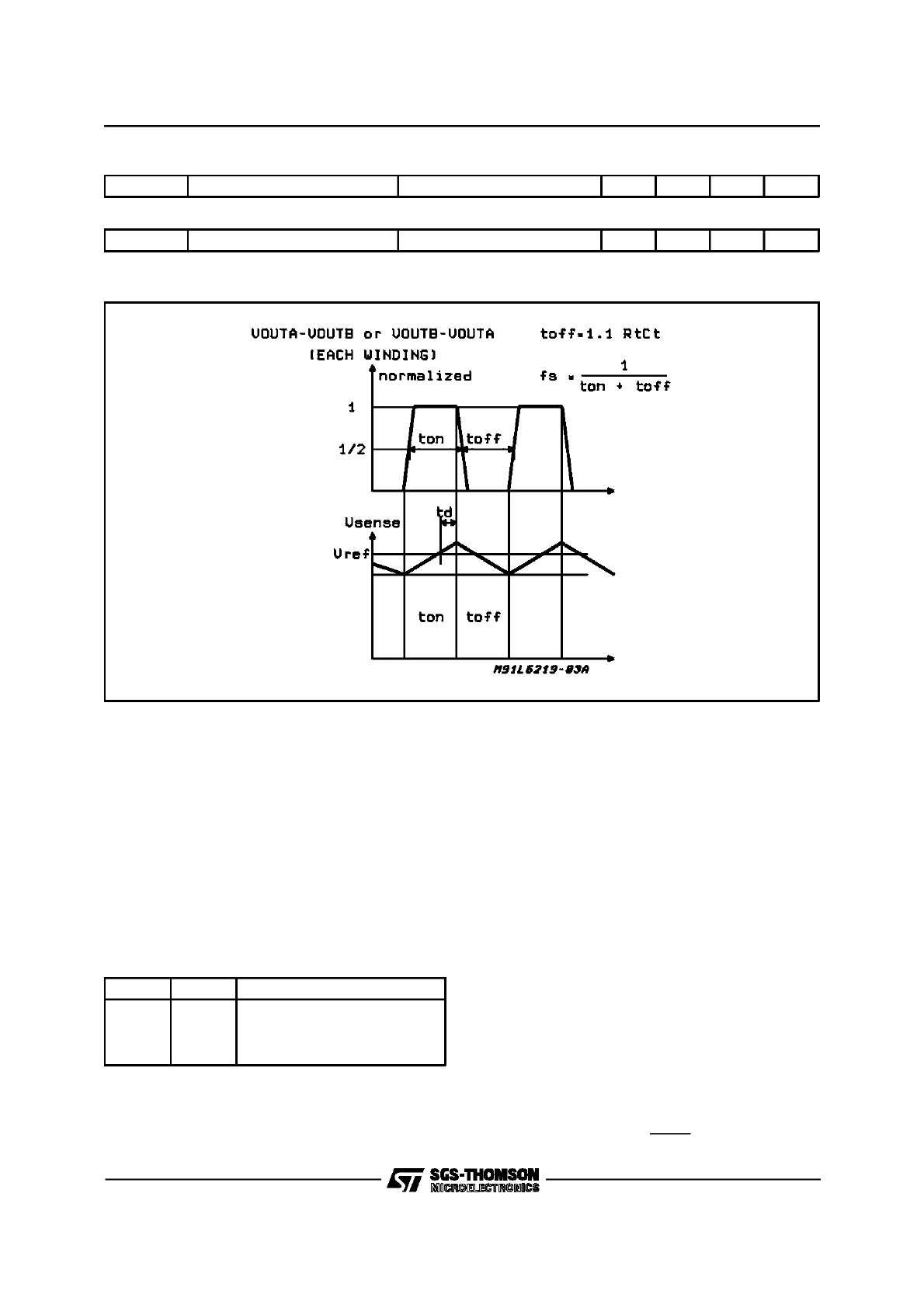

Figure 1

ELECTRICAL CHARACTERISTICS (Continued)

Symbol

Parameter

Test Condition

Min.

Typ.

Max.

Unit

PROTECTION

T

J

Thermal Shutdown Temperature

-

170

-

°

C

L6219

4/10

Single-pulse Generator

The pulse generator is a monostable triggered on

the positive going edge of the comparator output.

The monostable output is high during the pulse

time, t

off

, which is determined by the time compo-

nents R

t

and C

t

.

t

off

= 1.1

•

R

t

C

t

The single pulse switches off the power feed to

the motor winding, causing the winding current to

decrease during t

off

.

If a new trigger signal should occur during t

off

, it is

ignored.

Output Stage

The output stage contains four Darlington transis-

tors (source drivers) four saturated transistors

(sink drivers) and eight diodes, connected in two

H bridge.

The source transistors are used to switch the

power supplied to the motor winding, thus driving

a constant current through the winding.

It should be noted however, that is not permitted

to short circuit the outputs.

Internal circuitry is added in order to increase the

accuracy of the motor current particularly with low

current levels.

Figure 2: Principle Operating Sequence

L6219

5/10

V

S

, V

SS

, V

Ref

The circuit will stand any order of turn-on or turn-

off the supply voltages V

S

and V

SS

. Normal dV/dt

values are then assumed.

Preferably, V

Ref

should be tracking V

SS

during

power-on and power-off if V

S

is established.

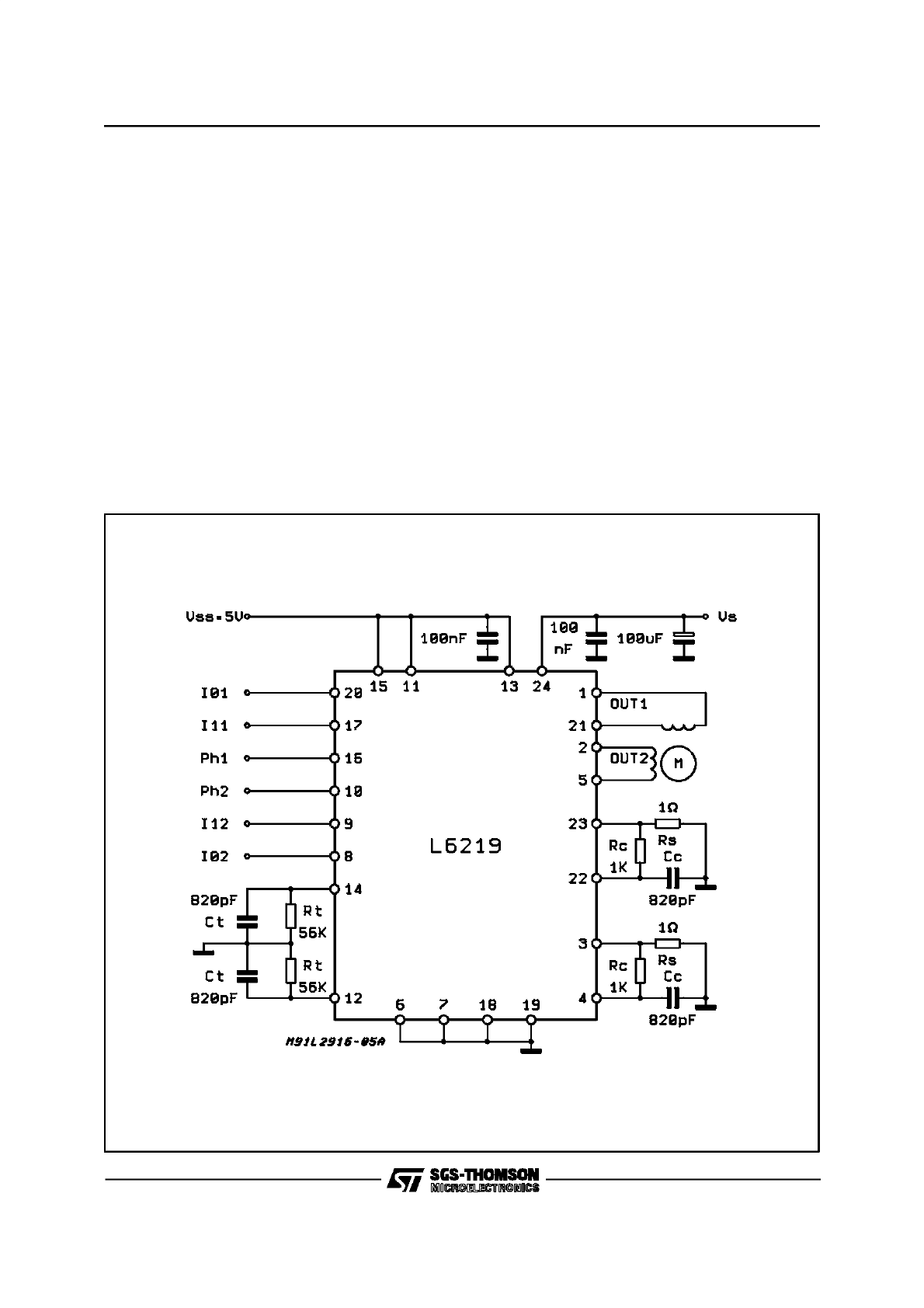

APPLICATION INFORMATIONS (Note 1)

Some stepper motors are not designed for contin-

uous operation at maximum current. As the circuit

drives a constant current through the motor, its

temperature might increase exceedingly both at

low and high speed operation.

Also, some stepper motors have such high core

losses that they are not suited for switch mode

current regulation.

Unused inputs should be connected to proper

voltage levels in order to get the highest noise im-

munity.

As the circuit operates with switch mode current

regulation,

interference

generation

problems

might arise in some applications. A good measure

might then be to decouple the circuit with a 100nF

capacitor, located near the package between

power line and ground.

The ground lead between R

s

, and circuit GND

should be kept as short as possible.

A typical Application Circuit is shown in Fig. 3.

Note that C

t

must be NPO type or similar else.

To sense the winding current, paralleled metal

film resistors are recommended (R

s

)

Note 1 - Other information is available as ”Smart

Power Development System”:

Test board HWL6219 (Stepper driver)

Software SWL6219 (Floppy disc)

Figure 3: Typical Application Circuit. (Pin out referred to DIP24 package)

L6219

6/10

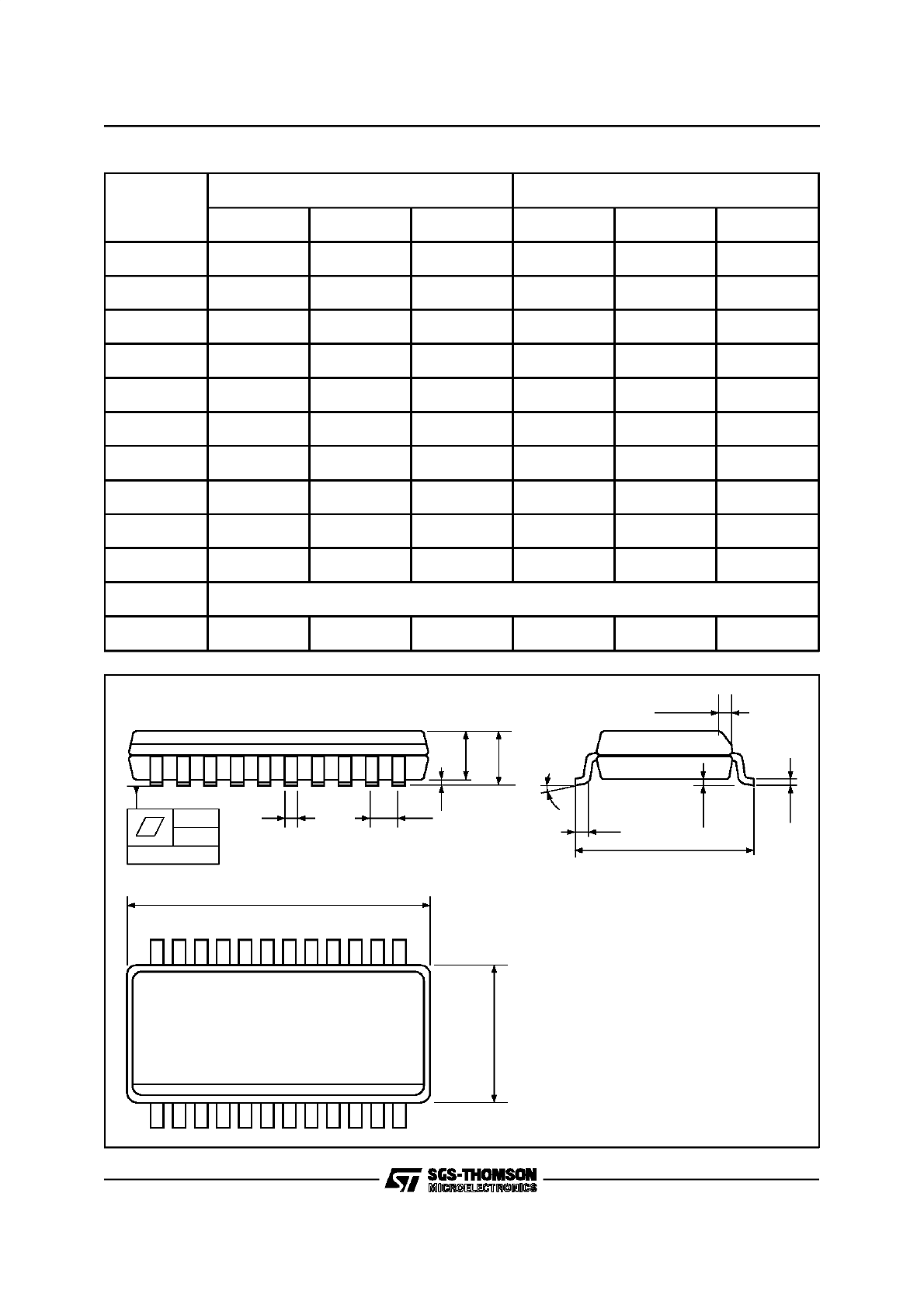

DIM.

mm

inch

MIN.

TYP.

MAX.

MIN.

TYP.

MAX.

A

4.320

0.170

A1

0.380

0.015

A2

3.300

0.130

B

0.410

0.460

0.510

0.016

0.018

0.020

B1

1.400

1.520

1.650

0.055

0.060

0.065

c

0.200

0.250

0.300

0.008

0.010

0.012

D

31.62

31.75

31.88

1.245

1.250

1.255

E

7.620

8.260

0.300

0.325

e

2.54

0.100

E1

6.350

6.600

6.860

0.250

0.260

0.270

e1

7.620

0.300

L

3.180

3.430

0.125

0.135

M

0

°

min, 15

°

max.

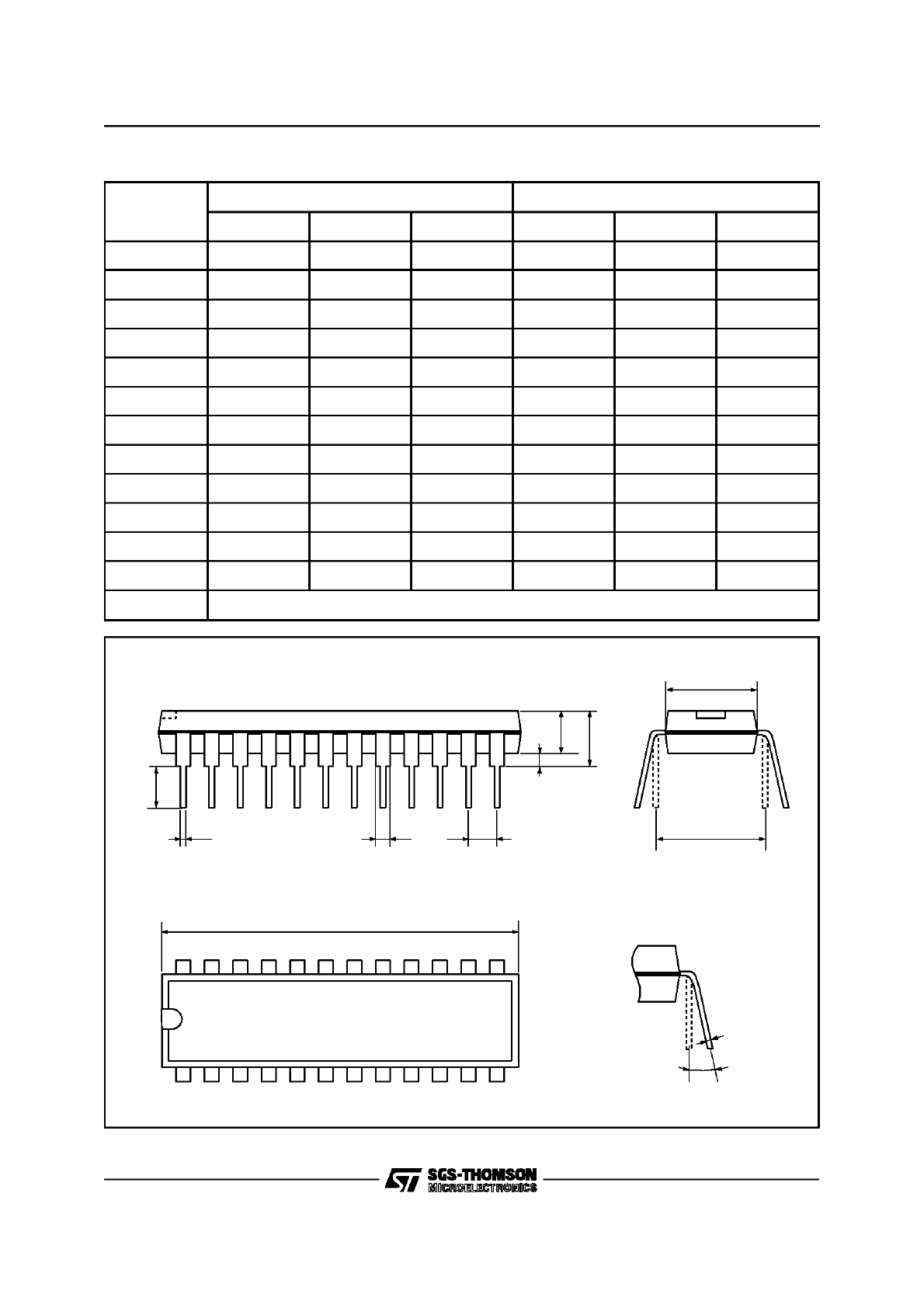

DIP24 PACKAGE MECHANICAL DATA

A1

B

e

B1

D

13

12

24

1

L

A

e1

A2

c

E1

SDIP24L

M

L6219

7/10

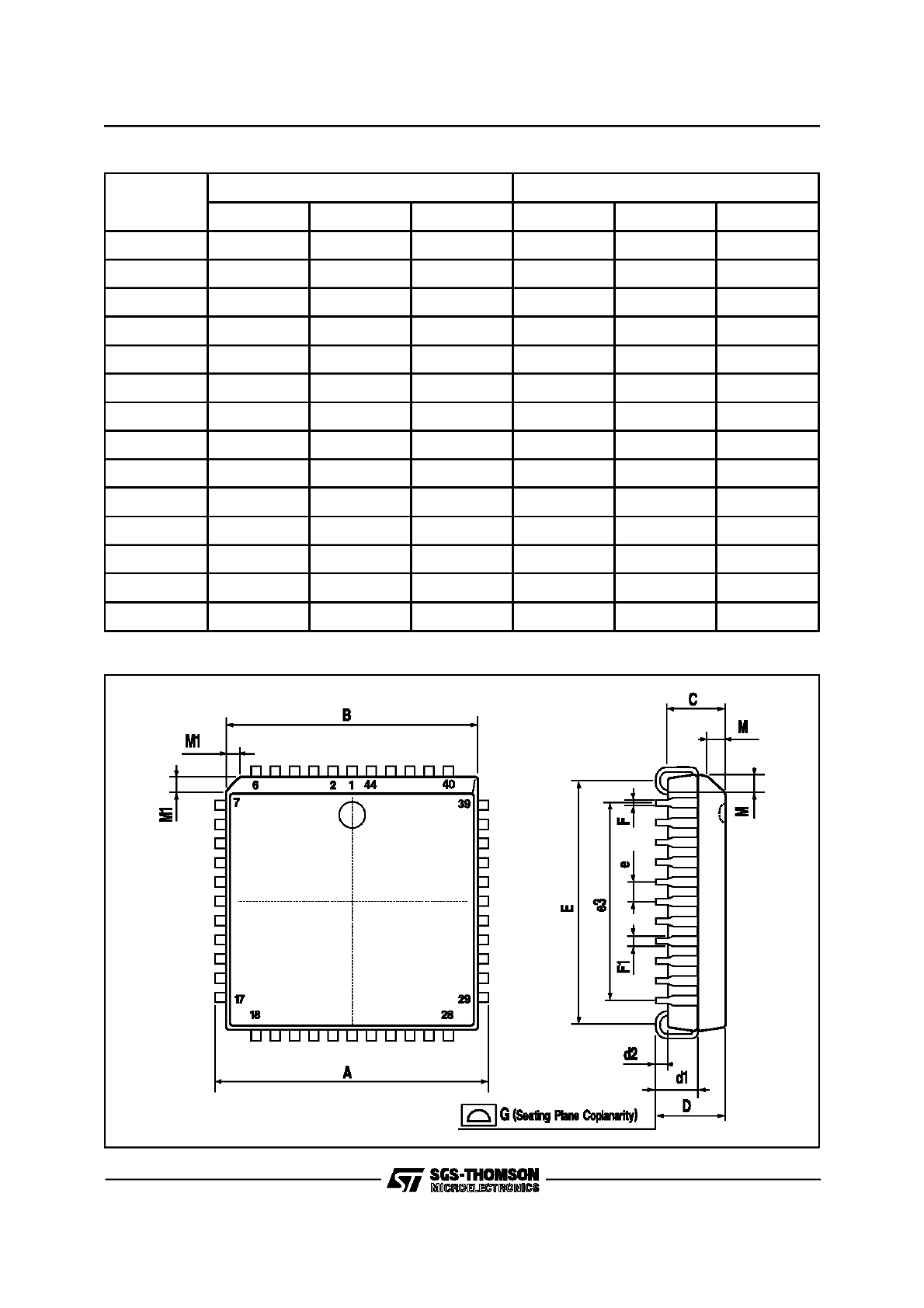

PLCC44 PACKAGE MECHANICAL DATA

DIM.

mm

inch

MIN.

TYP.

MAX.

MIN.

TYP.

MAX.

A

17.4

17.65

0.685

0.695

B

16.51

16.65

0.650

0.656

C

3.65

3.7

0.144

0.146

D

4.2

4.57

0.165

0.180

d1

2.59

2.74

0.102

0.108

d2

0.68

0.027

E

14.99

16

0.590

0.630

e

1.27

0.050

e3

12.7

0.500

F

0.46

0.018

F1

0.71

0.028

G

0.101

0.004

M

1.16

0.046

M1

1.14

0.045

P027B

L6219

8/10

DIM.

mm

inch

MIN.

TYP.

MAX.

MIN.

TYP.

MAX.

A

2.35

2.65

0.093

0.104

A1

0.10

0.30

0.004

0.012

A2

2.55

0.100

B

0.33

0.51

0.013

0.0200

C

0.23

0.32

0.009

0.013

D

15.20

15.60

0.598

0.614

E

7.40

7.60

0.291

0.299

e

1.27

0,050

H

10.0

10.65

0.394

0.419

h

0.25

0.75

0.010

0.030

k

0

°

(min.), 8

°

(max.)

L

0.40

1.27

0.016

0.050

B

e

A2

A

1

12

13

24

D

L

H

A1

C

E

K

h x 45?

SO24

Seating Plane

0.10mm

.004

A1

SO24 PACKAGE MECHANICAL DATA

L6219

9/10

Information furnished is believed to be accurate and reliable. However, SGS-THOMSON Microelectronics assumes no responsibility for the

consequences of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No

license is granted by implication or otherwise under any patent or patent rights of SGS-THOMSON Microelectronics. Specification mentioned

in this publication are subject to change without notice. This publication supersedes and replaces all information previously supplied. SGS-

THOMSON Microelectronics products are not authorized for use as critical components in life support devices or systems without express

written approval of SGS-THOMSON Microelectronics.

1996 SGS-THOMSON Microelectronics – Printed in Italy – All Rights Reserved

SGS-THOMSON Microelectronics GROUP OF COMPANIES

Australia - Brazil - Canada - China - France - Germany - Hong Kong - Italy - Japan - Korea - Malaysia - Malta - Morocco - The Netherlands -

Singapore - Spain - Sweden - Switzerland - Taiwan - Thailand - United Kingdom - U.S.A.

L6219

10/10