L295

DUAL SWITCH-MODE SOLENOID DRIVER

PRELIMINARY DATA

HIGH CURRENT CAPABILITY (up to 2.5A per

channel)

HIGH VOLTAGE OPERATION (up to 46V for

power stage)

HIGH EFFICIENCY SWITCHMODE OPERATION

REGULATED OUTPUT CURRENT (adjustable)

FEW EXTERNAL COMPONENTS

SEPARATE LOGIC SUPPLY

THERMAL PROTECTION

DESCRIPTION

The L295 is a monolithic integrated circuit in a 15 -

lead Multiwatt ® package; it incorporates all the

functions for direct interfacing between digital cir-

cuitry and inductive loads. The L295 is designed to

accept standard microprocessor logic levels at the

inputs and can drive 2 solenoids. The output current

is completely controlled by means of a switch-

March 1993

Symbol

Parameter

Value

Unit

V

s

Supply voltage

50

V

V

ss

Logic supply voltage

12

V

V

EN

, V

i

Enable and input voltage

7

V

V

ref

Reference voltage

7

V

Io

Peak output current (each channel)

- non repetitive (t = 100

µ

sec)

3

A

- repetitive (80% on - 20% off; T

on

= 10 ms)

2.5

A

- DC operation

2

A

Ptot

Total power dissipation (at Tcase = 75

°

C

25

W

Tstg, Tj

Storage and junction temperature

- 40 to 150

°

C

ABSOLUTE MAXIMUM RATINGS

ing technique allowing very efficient operation.

Furthermore, it includes an enable input and dual

supplies (for interfacing with peripherals running at

a higher voltage than the logic).

The L295 is particularly suitable for applications

such as hammer driving in matrix printers, step

motor driving and electromagnet controllers.

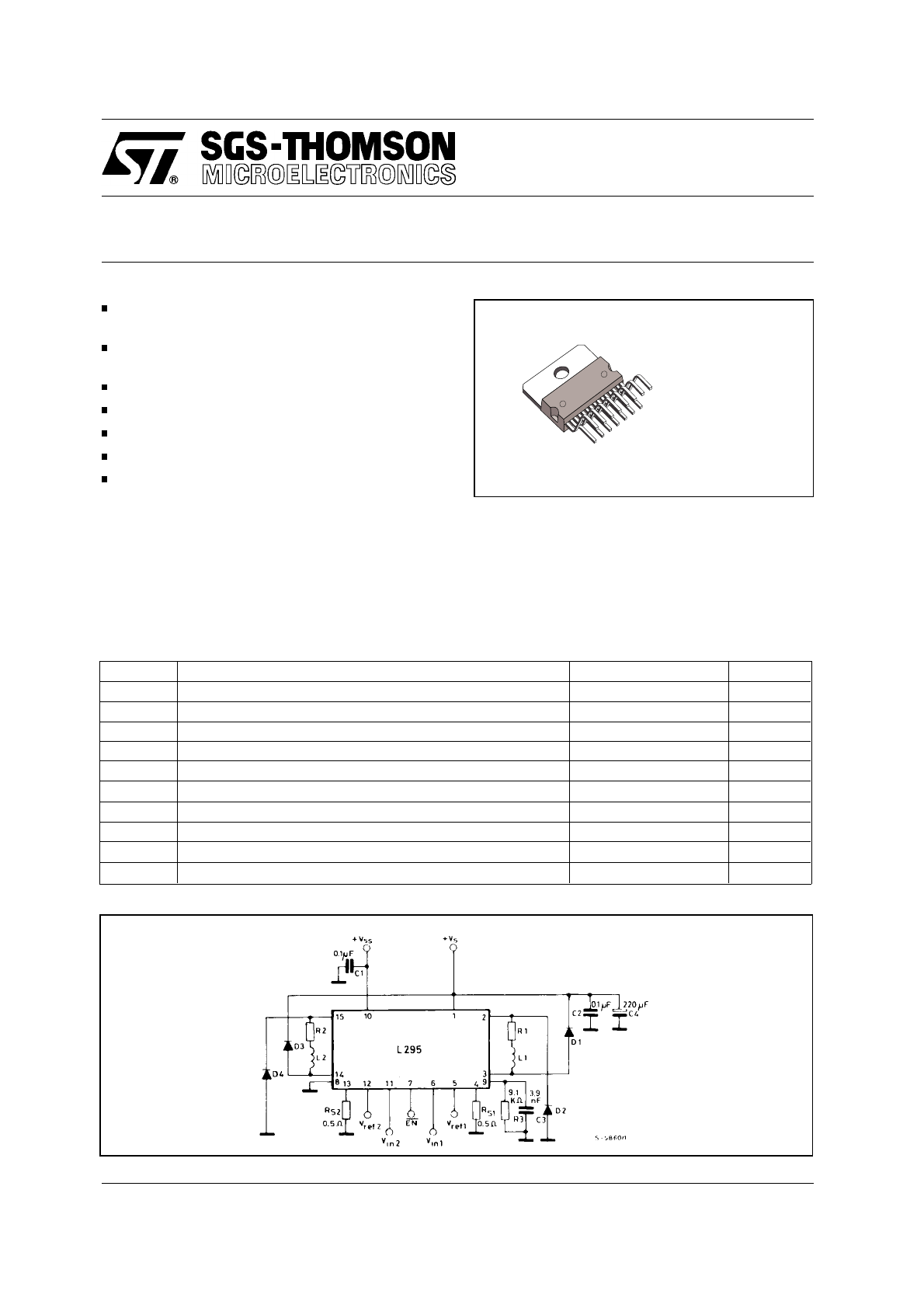

APPLICATION CIRCUIT

Multiwatt 15

ORDER CODE : L295

1/8

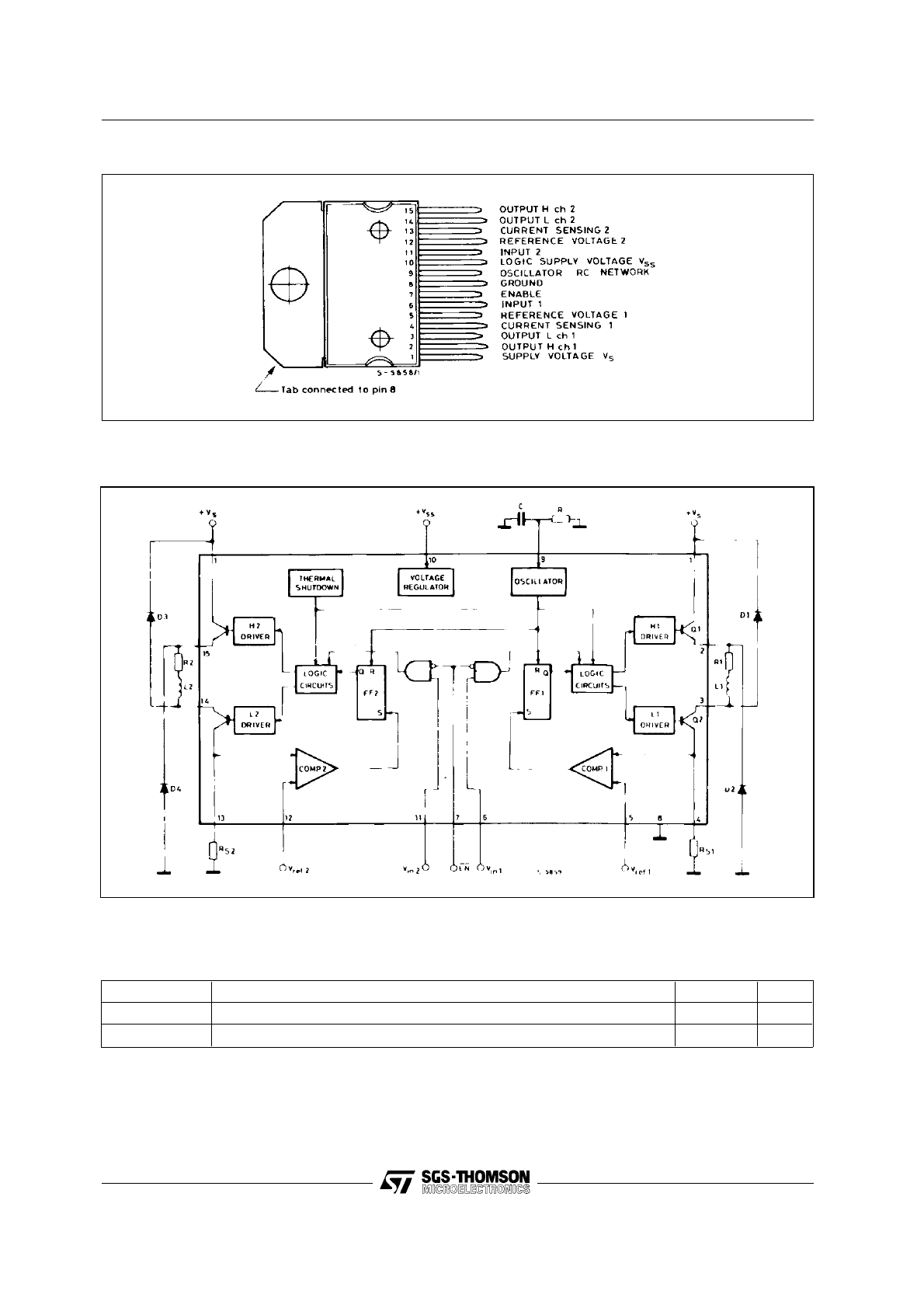

CONNECTION DIAGRAM (top view)

BLOCK DIAGRAM

Symbol

Parameter

Value

Unit

R

th-j-case

Thermal resistance junction-case

max

3

°

C/W

R

th-j-amb

Thermal resistance junction-ambient

max

35

°

C/W

THERMAL DATA

2/8

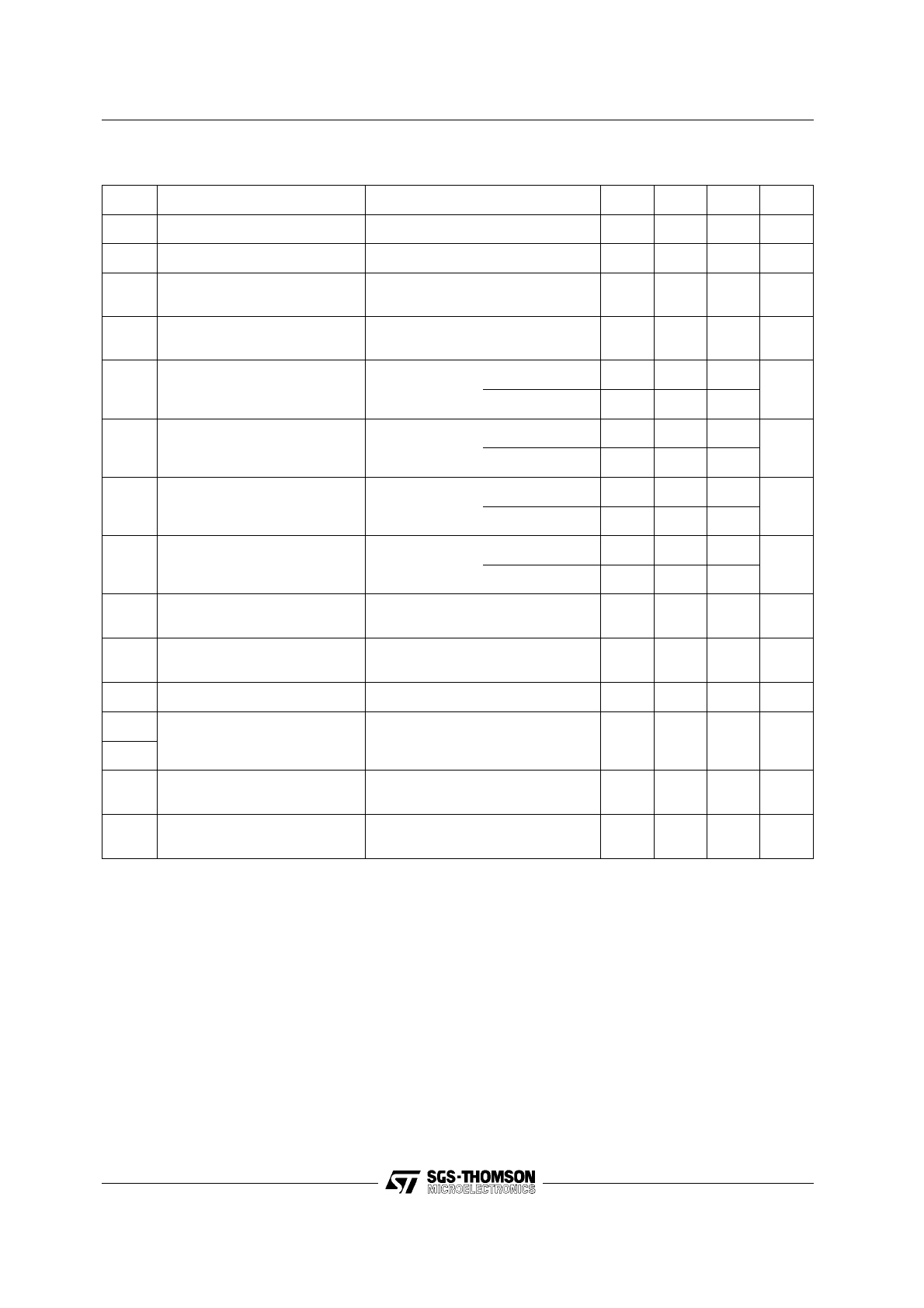

L295

Symbol

Parameter

Test conditions

Min.

Typ.

Max.

Unit

V

s

Supply Voltage

12

46

V

V

ss

Logic Supply Voltage

4.75

10

V

I

d

Quiescent drain current

(from VSS)

V

S

= 46V; V

i1

= V

i2

= V

EN

= L

4

mA

I

ss

Quiescent drain current

(from VS)

V

SS

= 10 V

46

mA

V

i1

,,V

i2

Input Voltage

Low

-0.3

0.8

V

High

2.2

7

V

EN

Enable Input Voltage

Low

-0.3

0.8

V

High

2.2

7

I

i1

, I

i2

Input Current

V

i1

= V

i2

= L

-100

µ

A

V

i1

= V

i2

= H

10

I

EN

Enable Input Current

V

EN

= L

-100

µ

A

V

EN

= H

10

V

ref1

,

V

ref2

Input Reference Voltage

0.2

2

V

I

ref1

,

I

ref2

m

Input Reference Voltage

-5

µ

A

F

osc

Oscillation Frequency

C = 3.9 nF;

R = 9.1 K

Ω

25

KHz

I

p

Transconductance (each ch.)

V

ref

= 1V

1.9

2

2.1

A/V

V

ref

V

drop

Total output voltage drop

(each channel) (*)

I

o

= 2 A

2.8

3.6

V

V

sens1

V

sens2

External sensing resistors

voltage drop

2

V

(*) V

drop

= V

CEsat

Q1

+ V

CEsat Q2.

ELECTRICAL CHARACTERISTICS (Refer to the application circuit, V

ss

= 5V, V

s

= 36V; T

j

= 25

°

C; L =

Low; H = High; unless otherwise specified)

3/8

L295

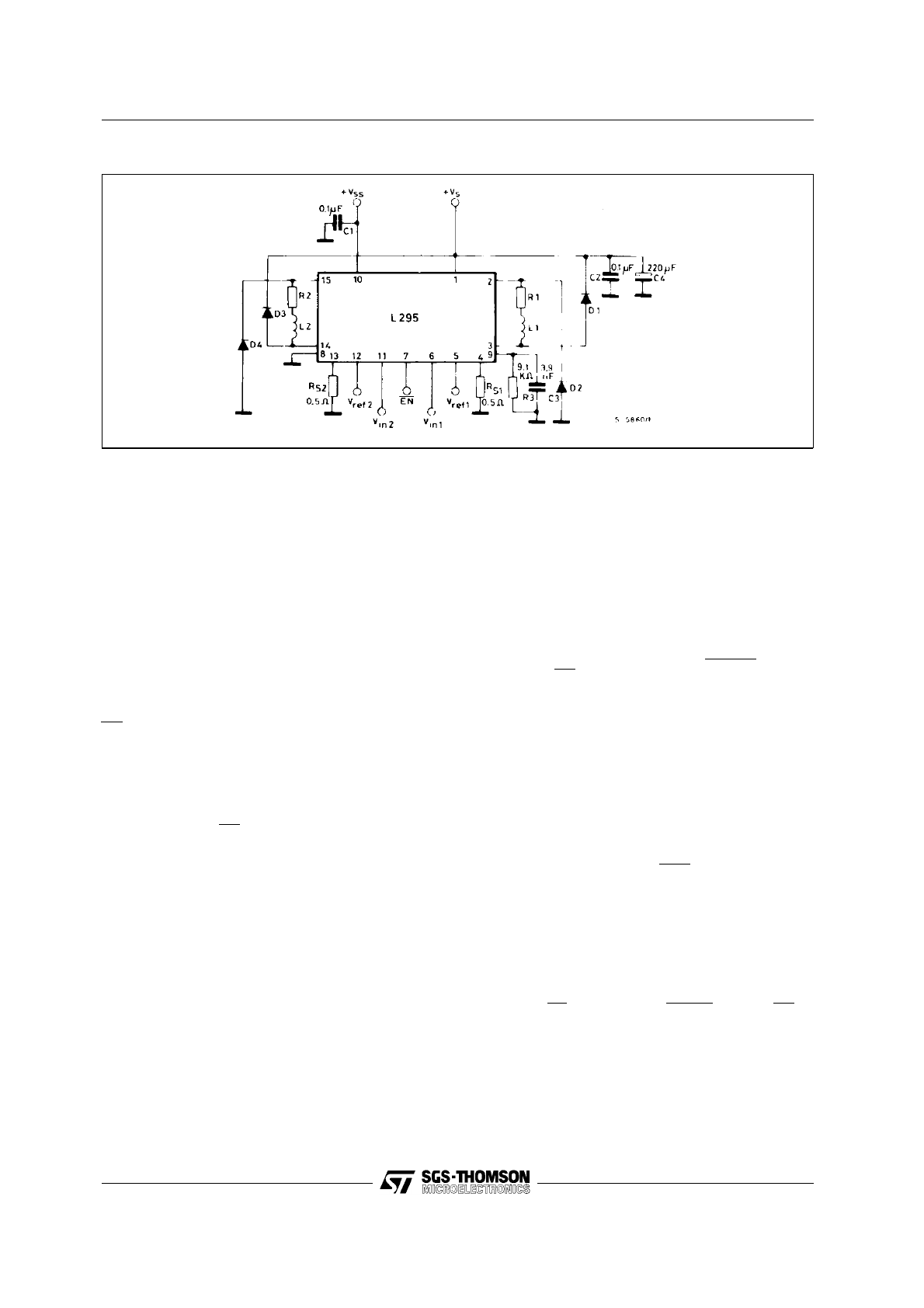

APPLICATION CIRCUIT

D2, D4 = 2A High speed diodes

D1, D3 = 1A High speed diodes

R1 = R2 = 2

Ω

L1 = L2 = 5 mH

)

trr

≤

200 ns

FUNCTIONAL DESCRIPTION

The L295 incorporates two indipendent driver

channals with separate inputs and outputs, each

capable of driving an inductive load (see block

diagram).

The device is controlled by three micriprocessor

compatible digital inputs and two analog inputs.

These inputs are:

EN

chip enable (digital input, active low),

enables both channels when in the low

state.

V

in1

, V

in2

channel inputs (digital inputs, active

high), enable each channel inde-

pendently. A channel is actived when

both EN and the appropriate channel

input are active.

V

ref1

, V

ref2

referce

voltages

(analog

inputs),

used

to program the peak load currents.

Peak load current is proportional to V

ref

.

Since the two channels are identical, only channel

one will be described.

The following description applies also the channel

two, replacing FF2 for FF1, V

ref

for V

ref1

etc.

When the channel is avtivated by low level on the

EN input and a high level on the channel input, V

in2

,

the output transistors Q1 and Q2 switch on and

current flows in the load according to the exponen-

tial law:

I

=

V

R1

(

1

−

e

−

R1 t

L1

)

where:

R1 and R2 are the resistance and in-

ductance of the load and V is the volt-

age available on the load (V

s

- V

drop

-

V

sense

).

The current increases until the voltage on the ex-

ternal sensing resistor, R

S1

, reaches the reference

voltage, V

ref1

. This peak current, I

p1

, is given by:

I

p1

=

V

ref1

R

S1

At this point the comparator output, Vomp1, sete

the RS flip-flop, FF1, that turns off the output tran-

sistor, Q1. The load current flowing through D2, Q2,

R

S1

, decreases according to the law:

I

=

(

V

A

R

1

+

I

p1

)

e

−

R1

t

L1

−

V

A

R1

where V

A

= V

CEsat Q2

+ V

sense

+ V

D2

4/8

L295

If the oscillator pin (9) is connected to ground the

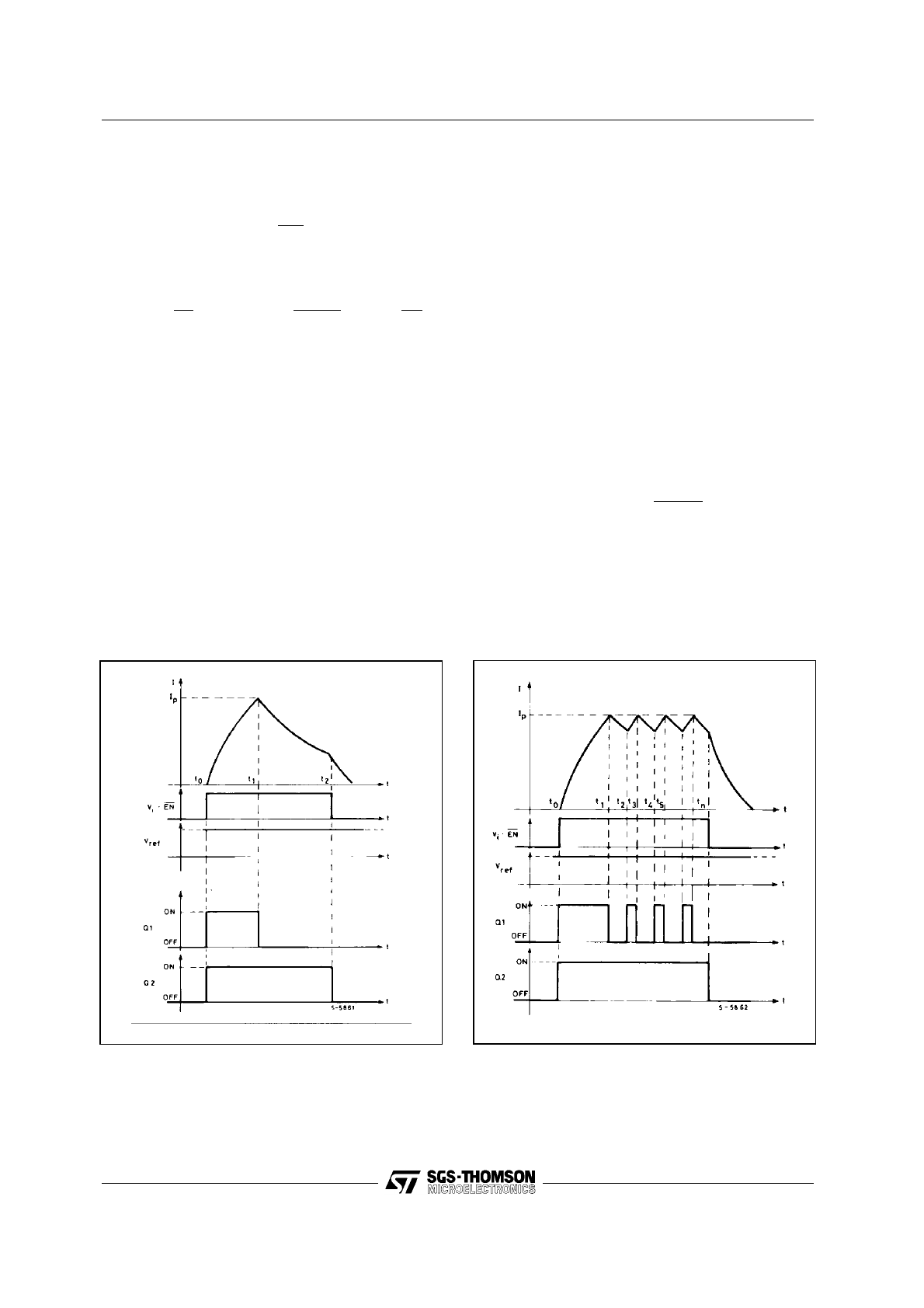

load current falls to zero as shown in fig. 1.

At this time t

2

the channel 1 is disabled, by taking

the inputs V

in1

low and/or EN high, and the output

transistor Q2 is turned off. The load current flows

through D2 and D1 according to the law:

I

=

(

V

B

R

1

+

I

T2

)

e

−

R1

t

L1

−

V

B

R1

where V

B

= V

S

+ V

D1

+ V

D2

I

T2

= current value at the time t

2

.

Fig. 2 in shows the current waveform obtained with

an RC network connected between pin 9 and

ground. From to t

1

the current increases as in fig.

1. A difference exists at the time t

2

because the

current starts to increase again. At this time a pulse

is produced by the oscillator circuit that resets the

flip.flop, FF1, and switches on the outout transistor,

Q1. The current increases until the drop on the

sensing resistor R

S1

is equal to V

ref1

(t

3

) and the

cycle repeats.

SIGNAL WAVEFORMS

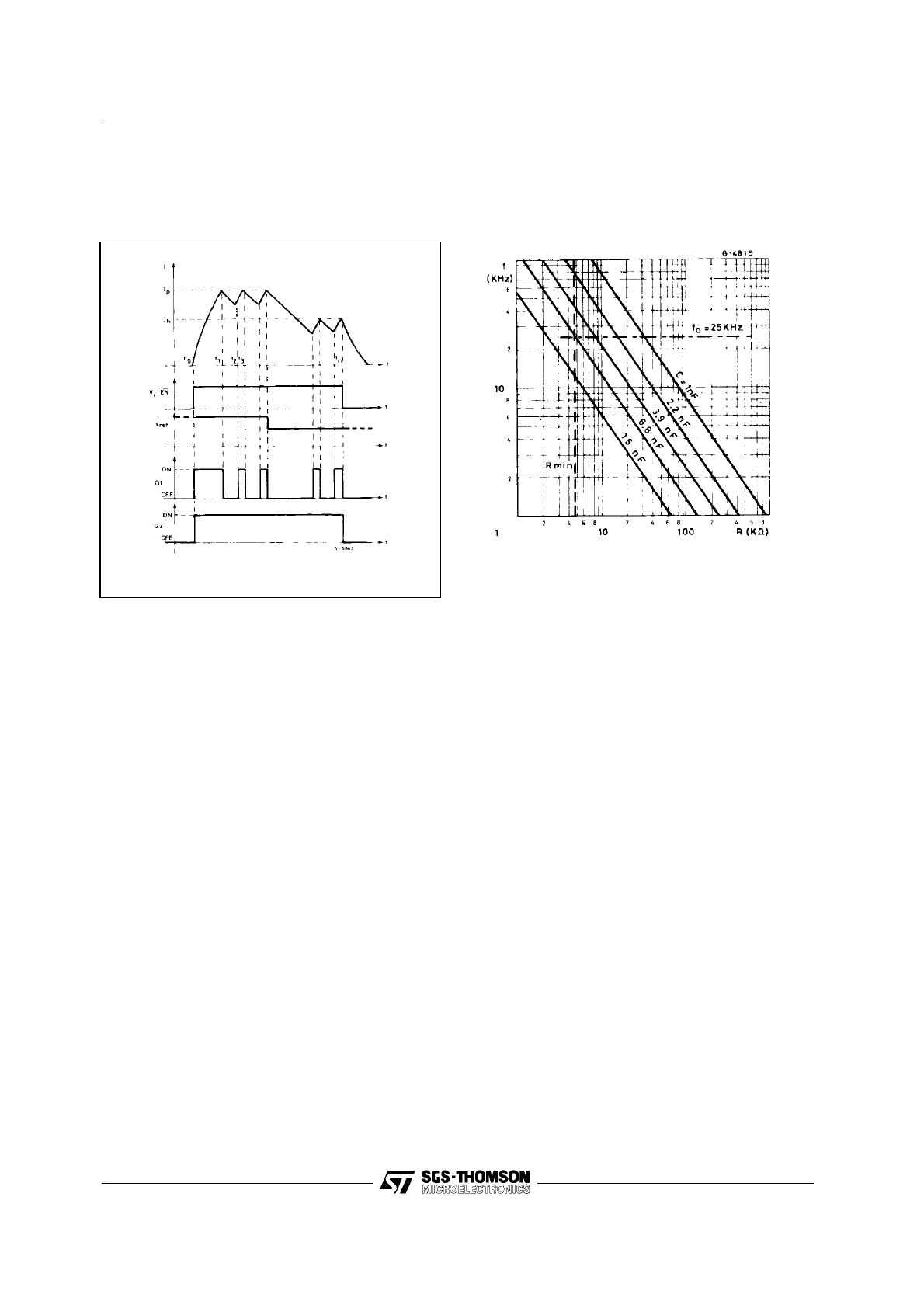

The switching frequency depends on the value R

and C, as shown in fig. 4 and must be chosen in

the range 10 to 30 KHz.

It is possible with external hardware to change the

reference voltage V

ref

in order to obtain a high peak

current I

p

and a lower holding current I

h

(see fig. 3).

The L295 is provided with a thermal protection that

switches off all the output transistors when the

junction temperature exceeds 150

°

C. The pres-

ence of a hysteresis circuit makes the IC work again

aftera fall of the junction temperature of about

20

°

C.

The analog input pins (V

ref1

, V

ref2

) can be left open

or connected to V

ss

; in this case the circuit works

with an internal reference voltage of about 2.5V and

the peak current in the load is fixed only by the value

of R

s

:

I

p

=

2.5

R

S

Figure 1. Load current waveform with pin 9

connected to GND.

Figure 2. Load current waveform with external

R-C network connected between pin 9 and

ground.

5/8

L295

SIGNAL WAVEFORMS (continued)

Figure 3. With V

ref

changed by hardware.

Figure 4. Switching frequency vs. values of R

and C.

6/8

L295

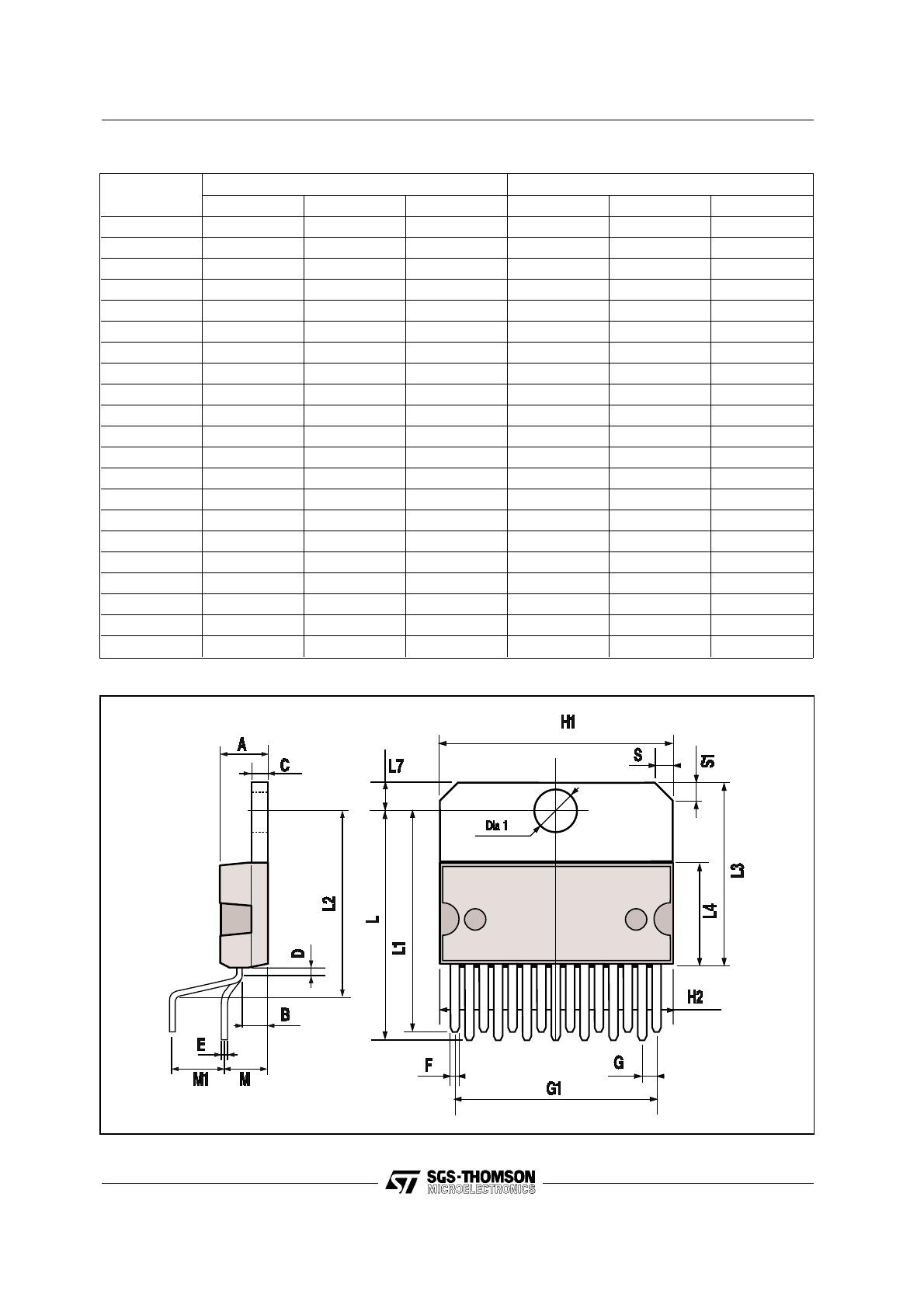

DIM.

mm

inch

MIN.

TYP.

MAX.

MIN.

TYP.

MAX.

A

5

0.197

B

2.65

0.104

C

1.6

0.063

D

1

0.039

E

0.49

0.55

0.019

0.022

F

0.66

0.75

0.026

0.030

G

1.02

1.27

1.52

0.040

0.050

0.060

G1

17.53

17.78

18.03

0.690

0.700

0.710

H1

19.6

0.772

H2

20.2

0.795

L

21.9

22.2

22.5

0.862

0.874

0.886

L1

21.7

22.1

22.5

0.854

0.870

0.886

L2

17.65

18.1

0.695

0.713

L3

17.25

17.5

17.75

0.679

0.689

0.699

L4

10.3

10.7

10.9

0.406

0.421

0.429

L7

2.65

2.9

0.104

0.114

M

4.25

4.55

4.85

0.167

0.179

0.191

M1

4.63

5.08

5.53

0.182

0.200

0.218

S

1.9

2.6

0.075

0.102

S1

1.9

2.6

0.075

0.102

Dia1

3.65

3.85

0.144

0.152

MULTIWATT15 PACKAGE MECHANICAL DATA

7/8

L295

8/8

Information furnished is believed to be accurate and reliable. However, SGS-THOMSON Microelectronics assumes no responsibility for the

consequences of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No

license is granted by implication or otherwise under any patent or patent rights of SGS-THOMSON Microelectronics. Specifications mentioned

in this publication are subject to change without notice. This publication supersedes and replaces all information previously supplied.

SGS-THOMSON Microelectronics products are not authorized for use as critical components in life support devices or systems without express

written approval of SGS-THOMSON Microelectronics.

© 1994 SGS-THOMSON Microelectronics - All Rights Reserved

SGS-THOMSON Microelectronics GROUP OF COMPANIES

Australia - Brazil - France - Germany - Hong Kong - Italy - Japan - Korea - Malaysia - Malta - Morocco - The Netherlands - Singapore -

Spain - Sweden - Switzerland - Taiwan - Thaliand - United Kingdom - U.S.A.

L295