2011 Microchip Technology Inc.

DS22275A-page 1

RE46C180

Features

• 6 – 12V Operation

• Low Quiescent Current Consumption

• Programmable Standby Sensitivity

• Programmable HUSH Sensitivity

• Programmable Hysteresis

• Programmable Chamber Voltage for Push-to-Test

(PTT) and Chamber Test

• Programmable ±150 mV Low Battery Set Point

• Internal Ionization Chamber Test

• Internal Low Battery Test

• Internal Power-On Reset and Power-up Low

Battery Test

• Alarm Memory

• Auto Alarm Locate

• Horn Synchronization

• IO Filter and Charge Dump

• Smart Interconnect

• Interconnect up to 40 Detectors

• ±5% All Internal Oscillator

• 9 Minute or 80 Second Timer for Sensitivity

Control

• Temporal or Continuous Horn Pattern

• Guard Outputs for Ion Detector Input

• ±0.75 pA Detect Input Current

• 10-year End-of-Life Indication

Description

The RE46C180 is a next generation low power, CMOS

ionization-type, smoke detector IC. With minimal exter-

nal components, this circuit will provide all the required

features for an ionization-type smoke detector.

An on-chip oscillator strobes power to the smoke

detection circuitry for 5 ms every 10 seconds to keep

the standby current to a minimum.

A check for a Low Battery condition is performed every

80s and an ionization chamber test is performed once

every 320s when in Standby. The temporal horn pattern

complies with the National Fire Protection Association

NFPA 72

®

National Fire Alarm and Signaling Code

®

for

emergency evacuation signals.

An interconnect pin allows multiple detectors to be con-

nected, such that when one unit alarms, all units will

sound. A charge dump feature quickly discharges the

interconnect line when exiting a Local Alarm condition.

The interconnect input is also digitally filtered.

An internal 9 minute or 80s timer can be used for a

Reduced Sensitivity mode.

An alarm memory feature allows the user to determine

whether the unit has previously entered a Local Alarm

condition.

Utilizing low-power CMOS technology, the RE46C180

is designed for use in smoke detectors that comply with

the Standard for Single and Multiple Station Smoke

Alarms, UL217 and the Standard for Smoke Detectors

for Fire Alarm Systems, UL268.

Package Types

RE46C180

PDIP, SOIC

TEST

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

IO

GLED

CHAMBER

RLED

V

DD

TESTOUT

FEED

GUARD2

DETECT

GUARD1

T3

T2

HS

HB

V

SS

CMOS Programmable Ionization Smoke Detector ASIC with

Interconnect, Timer Mode and Alarm Memory

RE46C180

DS22275A-page 2

2011 Microchip Technology Inc.

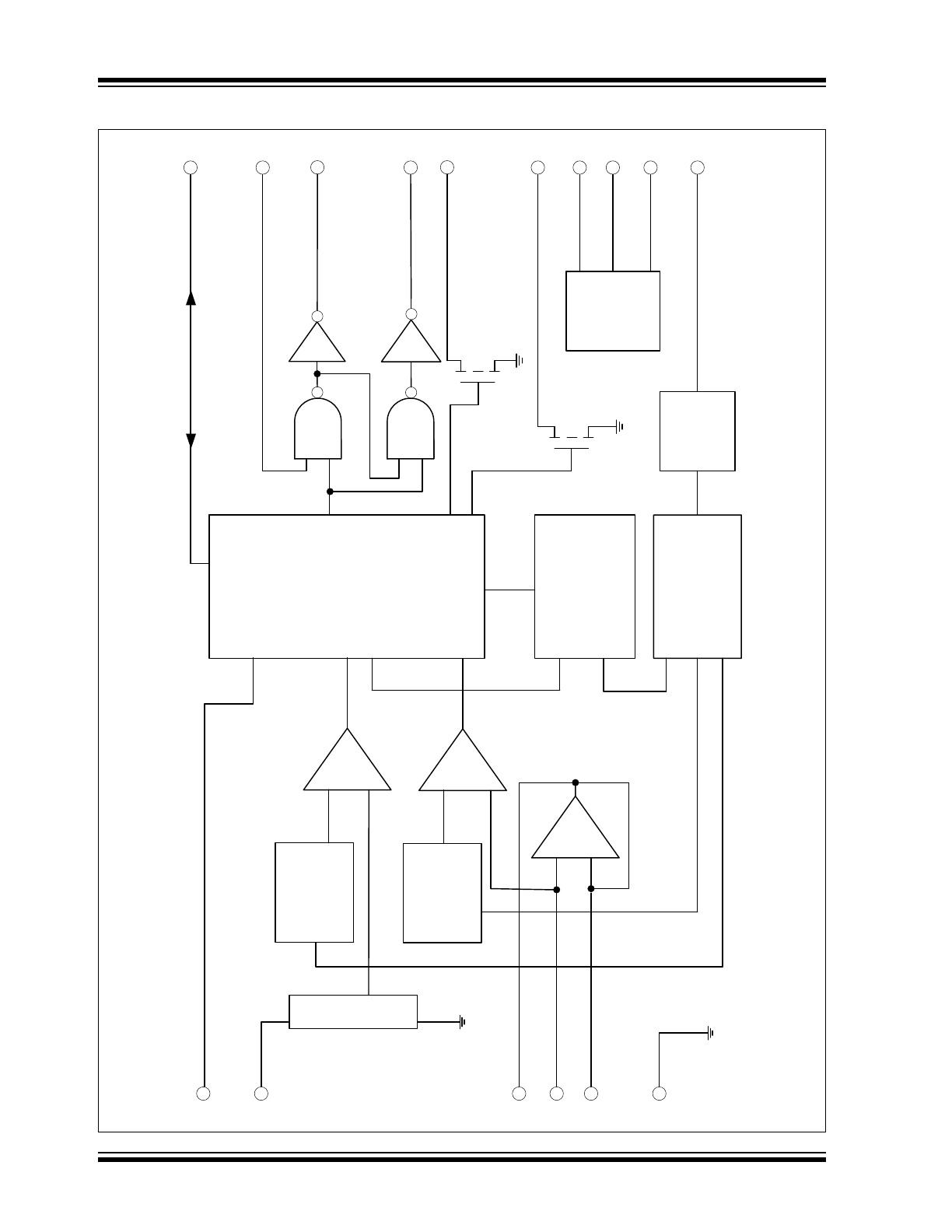

Functional Block Diagram

+

-

+

-

+

-

V

DD

(6)

TEST

(1)

GUARD1

(14)

DETECT

(15)

GUARD2

(16)

V

SS

(9)

IO

(2)

FEED

(8)

HS

(11)

RLED

(5)

HB

(10)

CHAMBER

(4)

T3

(13)

Logic

and

Timing

BIAS,

P

ower

Reset

and

Trimmable

Oscillator

Programmable

Trim

Trimmable

Low

B

att

Reference

Trimmable

Smoke

Reference

GLED

(3)

Chamber

Voltage

T2

(12)

TESTOUT

(7)

Test

and

Program

Mode

Sel

Low

B

att

Comp

Smoke

Comp

Guard

Amp

Trimmable

Low

B

att

Setting

2011 Microchip Technology Inc.

DS22275A-page 3

RE46C180

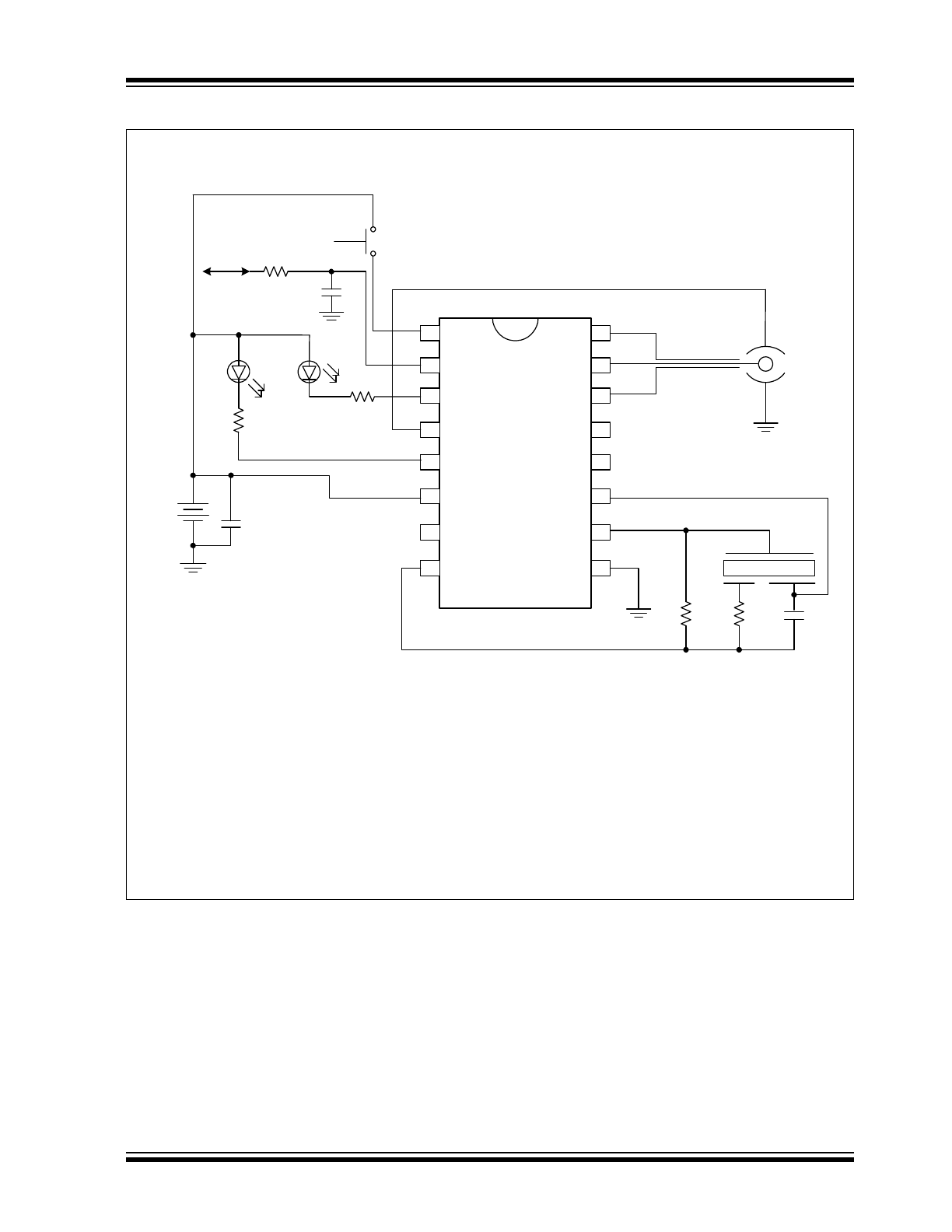

Typical Application

Note 1:

R3, R4 and C1 are typical values, and may be adjusted to maximize sound pressure.

2:

C2 should be located as close as possible to the device power pins.

3:

Route the pin 8 PC board trace away from pin 4 to avoid coupling.

4:

No internal reverse battery protection. External reverse battery protection circuitry required.

9V

Battery

+

-

1 µF

C2

R1

390

R5

100

To Other

Units

TEST and HUSH

R4

220K

R3

1.5M

C1

.001 µF

Rled

TEST

IO

GLED

CHAMBER

RLED

V

DD

TESTOUT

FEED

GUARD2

DETECT

GUARD1

T3

T2

HS

HB

V

SS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Gled

R2

390

RE46C180

C3

10 µF

RE46C180

DS22275A-page 4

2011 Microchip Technology Inc.

1.0

ELECTRICAL

CHARACTERISTICS

1.1

Absolute Maximum Ratings†

V

DD

.................................................................................12.5V

Input Voltage Range Except FEED, IO .......... V

IN

= -.3V to V

DD

+.3V

FEED Input Voltage Range ..................... V

INFD

=-10 to +22V

IO Input Voltage Range................................. V

IO1

= -.3 to 15V

Input Current except FEED ...................................I

IN

= 10 mA

Operating Temperature ................................T

A =

-10 to +60°C

Storage Temperature............................ T

STG

= -55 to +125°C

Maximum Junction Temperature ............................T

J

= +150°

† Notice:

Stresses above those listed under “Maximum

ratings” may cause permanent damage to the device.

This is a stress rating only and functional operation of

the device at these or any other conditions above those

indicated in the operation listings of this specification is

not implied. Exposure to maximum rating conditions for

extended periods may affect device reliability.

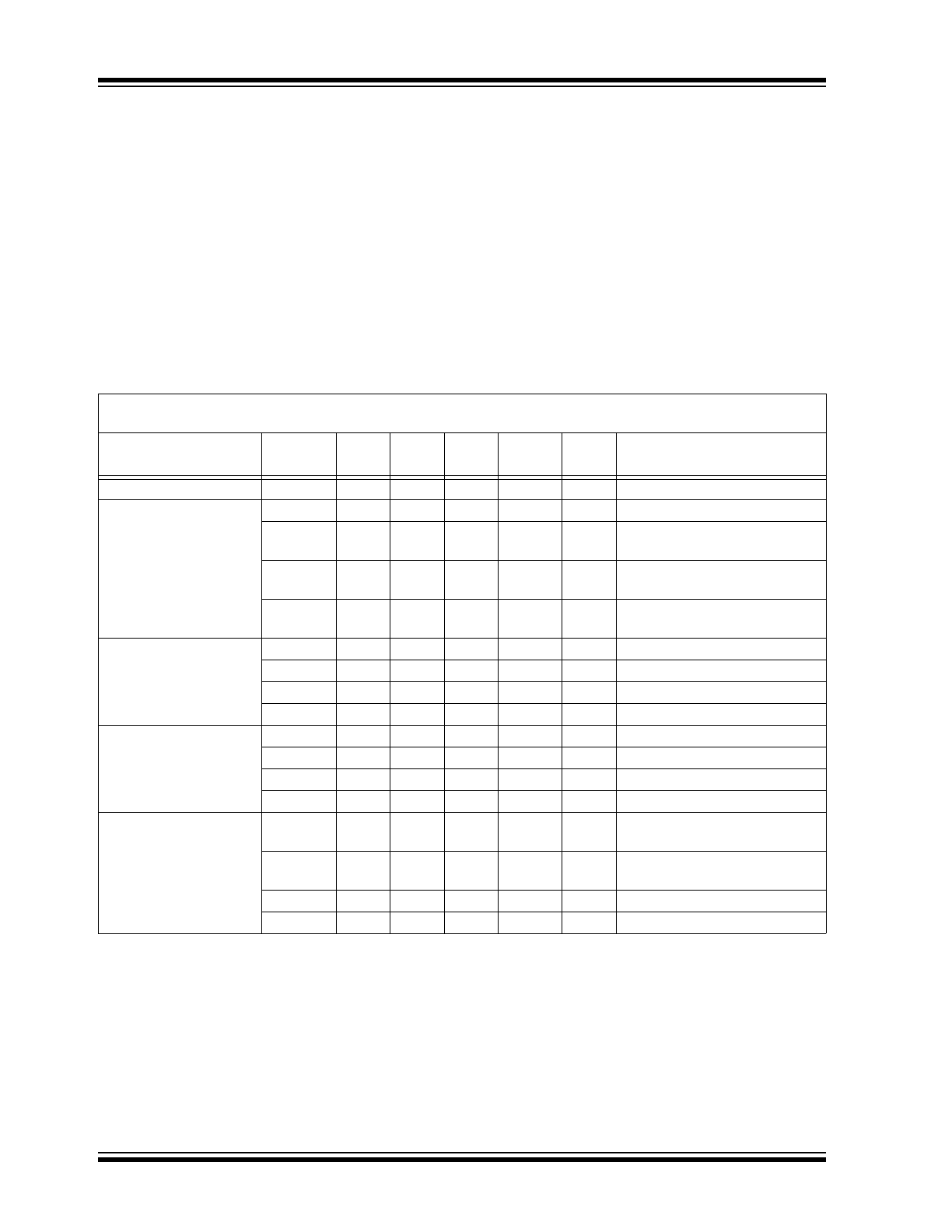

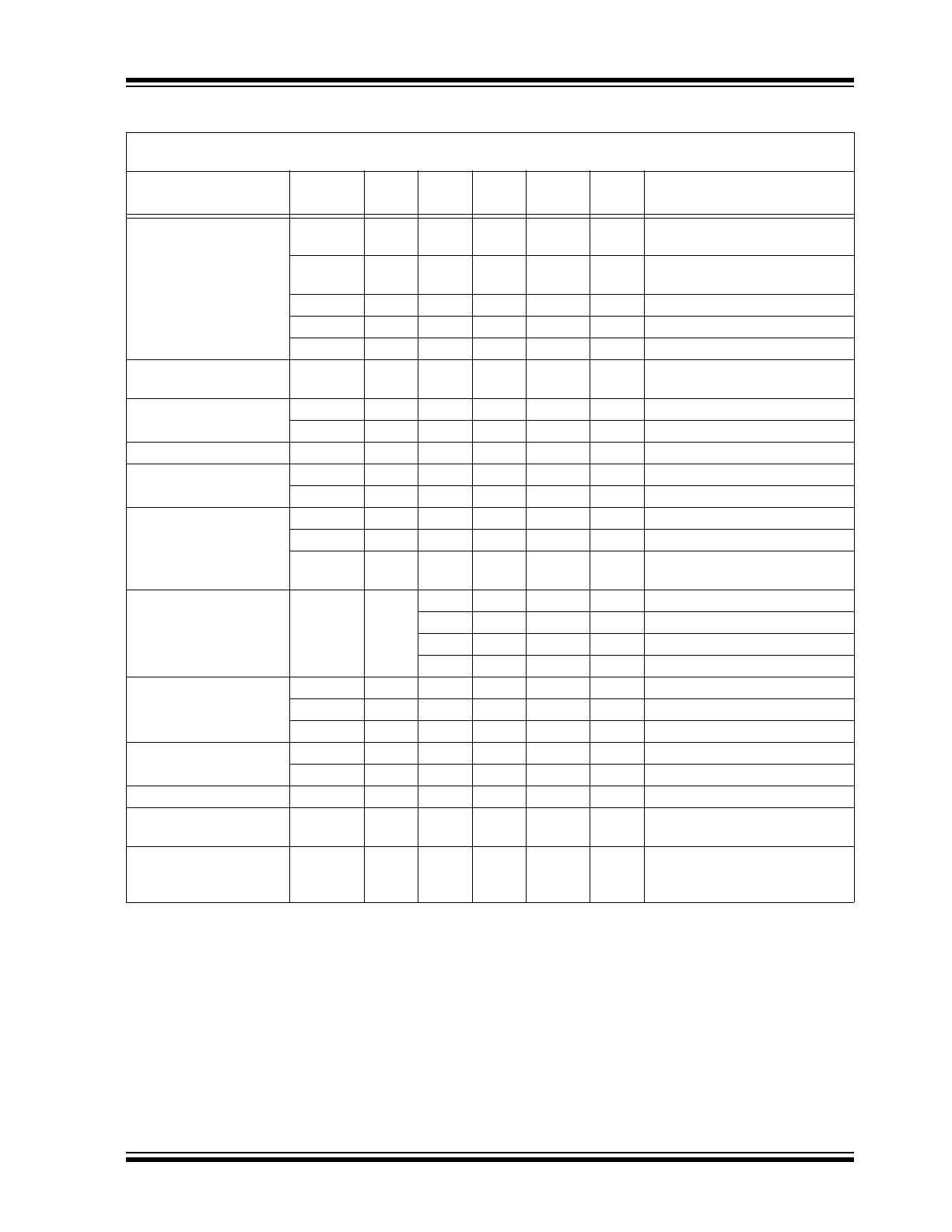

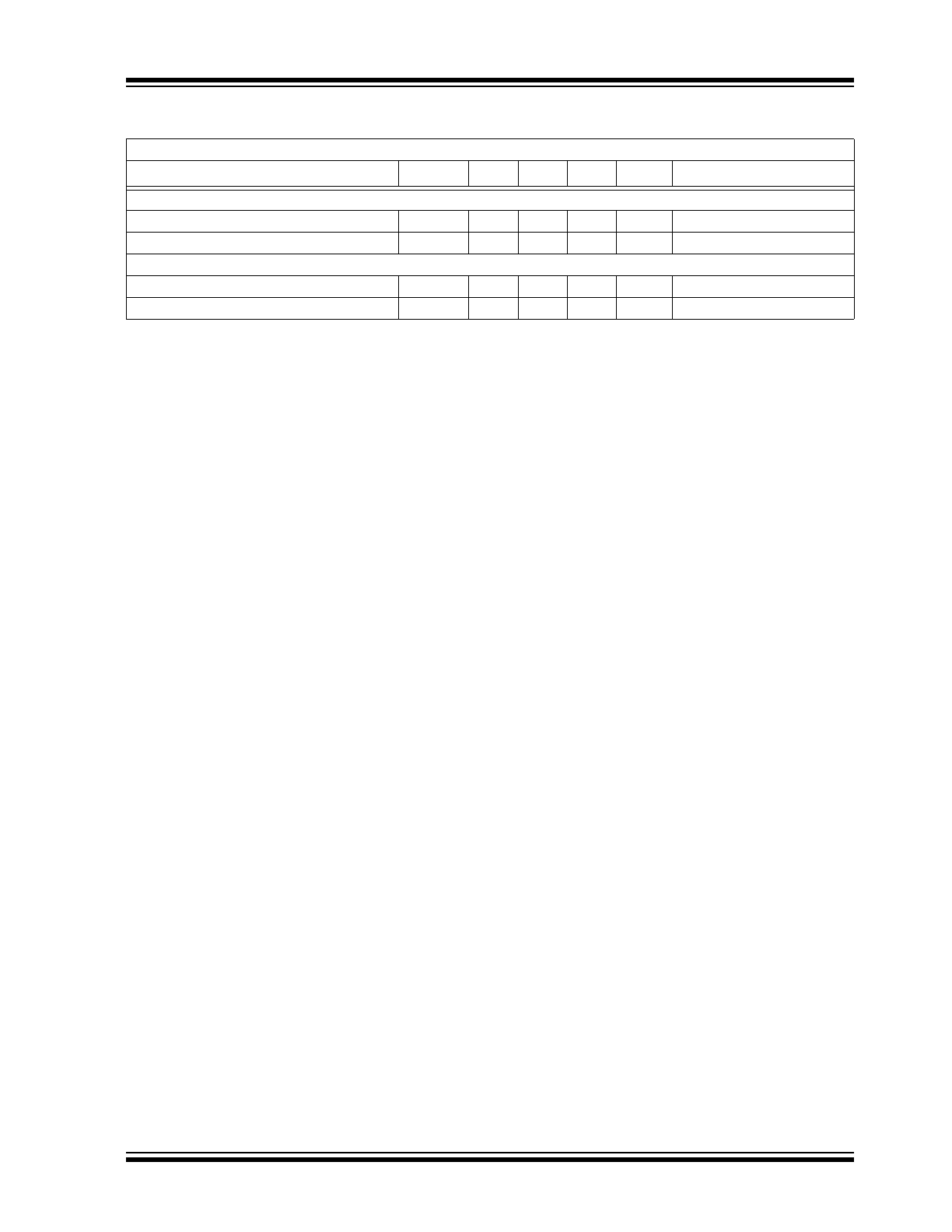

DC ELECTRICAL CHARACTERISTICS

DC Electrical Characteristics:

Unless otherwise indicated, all parameters apply at T

A

= -10°C to +60°C,

V

DD

= 9V, V

SS

= 0V (

Note 1

)

Parameter Symbol

Test

Pin

Min Typ Max Units

Conditions

Supply Voltage

V

DD

6

6

—

12

V

Operating

Supply Current

I

DD1

6

—

3.8

5.3

µA

Operating, RLED off, GLED off

I

DD2

6

—

—

6

µA

Operating, V

DD

= 12V,

RLED off, GLED off

I

DD3

6

—

9.6

13.9

µA

Operating, RLED off,

GLED off, Smoke check

I

DD4

6

—

21.4

30

µA

Operating, RLED off, GLED off,

Low Battery check

Input Voltage High

V

IH1

8

6

—

—

V

V

IH2

2

3

—

—

V

No Local Alarm, IO as an input

V

IH3

1

5.6

—

—

V

V

IH4

12

5.6

—

—

V

Input Voltage Low

V

IL1

8

—

—

2.8

V

V

IL2

2

—

—

1

V

No Local Alarm, IO as an input

V

IL3

1

—

—

3.4

V

V

IL4

12

—

—

3.4

Input Leakage Low

IL

DET1

15

—

—

-0.75

pA

V

DD

= 9V, DETECT = V

SS

,

0-40% RH, T

A

= +25°C

IL

DET2

15

—

—

-1.5

pA

V

DD

= 9V, DETECT = V

SS

,

85% RH, T

A

= +25°C (

Note 2

)

IL

FD1

8

—

—

-50

µA

FEED = -10V

IL

FD2

8

—

—

-100

nA

FEED = V

SS

Note 1:

Production tested at room temperature with temperature guard banded limits.

2:

Sample test only.

3:

Not 100% production tested.

4:

Same limit range at each programmable step, see

Table 4-1

.

2011 Microchip Technology Inc.

DS22275A-page 5

RE46C180

Input Leakage High

IH

DET1

15

—

—

0.75

pA

V

DD

= 9V, DETECT = V

DD

,

0–40% RH, T

A

= +25°C

IH

DET2

15

—

—

1.5

pA

V

DD

= 9V, DETECT = V

DD

,

85% RH, T

A

= +25°C (

Note 2

)

IH

FD1

8

—

—

50

µA

FEED = 22V

IH

FD2

8

—

—

100

nA

FEED = V

DD

I

IOL2

2

—

—

150

µA

No

Alarm,

V

IO

= 15V

Output Off Leakage High

I

IOHZ

3, 5

—

—

1

µA

Outputs Off,

V

RLED

= 9V, V

GLED

= 9V

Input Pull Down Current

I

PD1

1

20

50

80

µA

TEST = 9V

I

PD2

12

0.4

0.8

1.3

mA

T2 = 9V

Output High Voltage

V

OH1

10,11

6.3

—

—

V

I

OH

= -16 mA, V

DD

= 7.2V

Output Low Voltage

V

OL1

10,11

—

—

0.9

V

I

OL

= 16 mA, V

DD

= 7.2V

V

OL3

3, 5

—

—

1

V

I

OL

= 10 mA, V

DD

= 7.2V

Output Current

I

IOL1

2

25

—

60

µA

No

Alarm,

V

IO

= V

DD

-2V

I

IOH1

2

-4

—

-16

mA

Alarm,

V

IO

= 4V or V

IO

= 0V

I

IODMP

2

5

—

—

mA

At conclusion of Local Alarm

or PTT, V

IO

= 1V

Low Battery Voltage

V

LB

6

6.75

6.9

7.05

V

LBTR[2:1] = 1 0

7.05

7.2

7.35

V

LBTR[2:1] = 1 1

7.35

7.5

7.65

V

LBTR[2:1] = 0 0

7.65

7.8

7.95

V

LBTR[2:1] = 0 1

Offset Voltage

V

GOS1

14,15

-50

—

50

mV

Guard

amplifier

V

GOS2

15,16

-50

—

50

mV

Guard

amplifier

V

GOS3

15

-50

—

50

mV

Smoke

comparator

Common Mode Voltage

V

CM1

14,15

2

—

V

DD

–.5

V

Guard amplifier (

Note 3

)

V

CM2

15

0.5

—

V

DD

–2

V

Smoke comparator (

Note 3

)

Output Impedance

Z

OUT

14,16

—

10

—

k

Guard amplifier outputs (

Note 3

)

Chamber Voltage in

PTT/Chamber Test

V

CHAMBER

4

4.49

4.5

4.51

V

User programmable

(2.1V to 6.75V) (

Note 4

)

Hysteresis V

HYS

13

140

150

160

mV

No Alarm to Alarm condition,

user programmable

(50 to 225 mV) (

Note 4

)

DC ELECTRICAL CHARACTERISTICS (CONTINUED)

DC Electrical Characteristics:

Unless otherwise indicated, all parameters apply at T

A

= -10°C to +60°C,

V

DD

= 9V, V

SS

= 0V (

Note 1

)

Parameter Symbol

Test

Pin

Min Typ Max Units

Conditions

Note 1:

Production tested at room temperature with temperature guard banded limits.

2:

Sample test only.

3:

Not 100% production tested.

4:

Same limit range at each programmable step, see

Table 4-1

.

RE46C180

DS22275A-page 6

2011 Microchip Technology Inc.

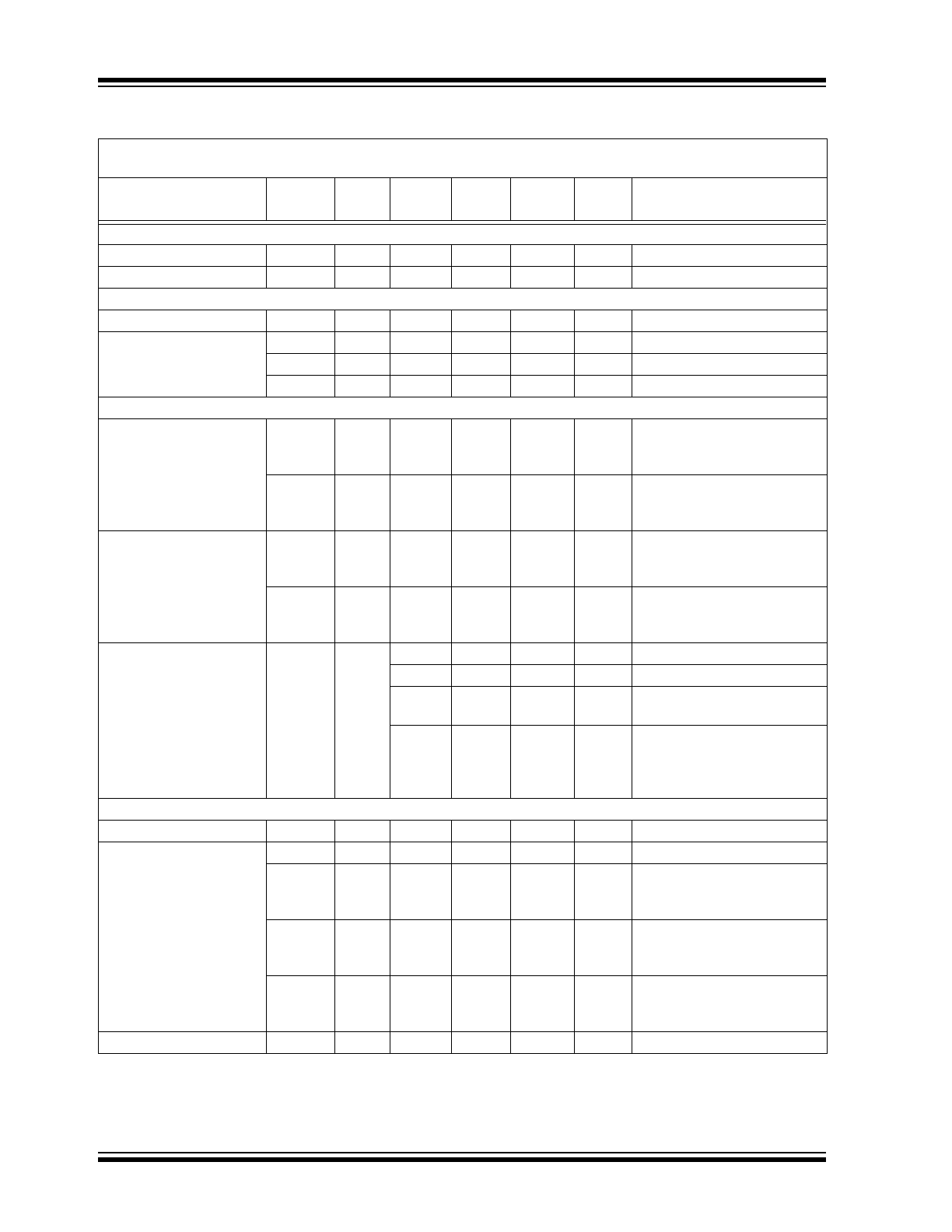

AC ELECTRICAL CHARACTERISTICS

AC Electrical Characteristics:

Unless otherwise indicated, all parameters apply at T

A

= -10°C to +60°C,

V

DD

= 9V, V

SS

= 0V.

Parameter Symbol

Test

Pin

Min Typ Max

Units

Conditions

Time Base

Internal Oscillator Period

T

POSC

7

593

625

657

µs

Test mode (

Note 1

)

Internal Clock Period

T

PCLK

9.5

10

10.5

ms

Operating

RLED Indicator

On Time

T

ON1

5

9.5

10

10.5

ms

Operating

Period

T

PLED1

5

304

320

336

s

Standby

T

PLED2

5

0.95

1

1.05

s

Local alarm

T

PLED3

5

9.5

10

10.5

s

HUSH mode, No Local Alarm

GLED Indicator

Period

T

PLED4

3

38

40

42

s

Alarm Memory Indication

GLED period, No Alarm,

no PTT

T

PLED5

3

237

250

263

ms

Alarm Memory Indication

GLED period upon PTT,

AMLEDEn = 1

Off Time

T

OFLED1

3

0.95

1

1.05

s

Alarm Memory Indication

GLED off time between

pulses

T

OFLED2

3

36

38

40

s

Alarm Memory Indication

GLED off time between pulse

trains (3x)

Alarm Memory Indication

Timeout Period

T

AMTO

3

22.8

24

25.2

Hour

AMTO[2:1] = 0 0

45.6

48

50.4

Hour

AMTO[2:1] = 0 1

0

0

0

Hour

AMTO[2:1] = 1 0,

No Alarm Memory Indication

—

—

—

—

AMTO[2:1] = 1 1,

Alarm Memory Indication

never times out, as long as

Alarm Memory Latch is set

Smoke Check

Smoke Check Time

T

SCT

—

4.7

5

5.3

ms

Operating

Smoke Check Period

T

PER0

—

9.5

10

10.5

s

Standby, No Alarm

T

PER1

—

0.95

1

1.05

s

Standby, after one valid

smoke sample and before

entering Local Alarm, no PTT

T

PER2

—

237

250

263

ms

Standby, upon start of PTT

and before entering Local

Alarm

T

PER3

—

0.95

1

1.05

s

Local Alarm (after three con-

secutive valid smoke

samples) or Remote Alarm

Chamber Test Period

T

PCT1

—

304

320

336

s

Operating

Note 1:

T

POSC

is 100% production tested. All other timing is verified by functional testing.

2:

See timing diagram for CO alarm horn pattern.

3:

See timing diagram for smoke alarm temporal and non-temporal horn pattern.

4:

See timing diagram for horn synchronization and Auto Alarm Locate (AAL).

2011 Microchip Technology Inc.

DS22275A-page 7

RE46C180

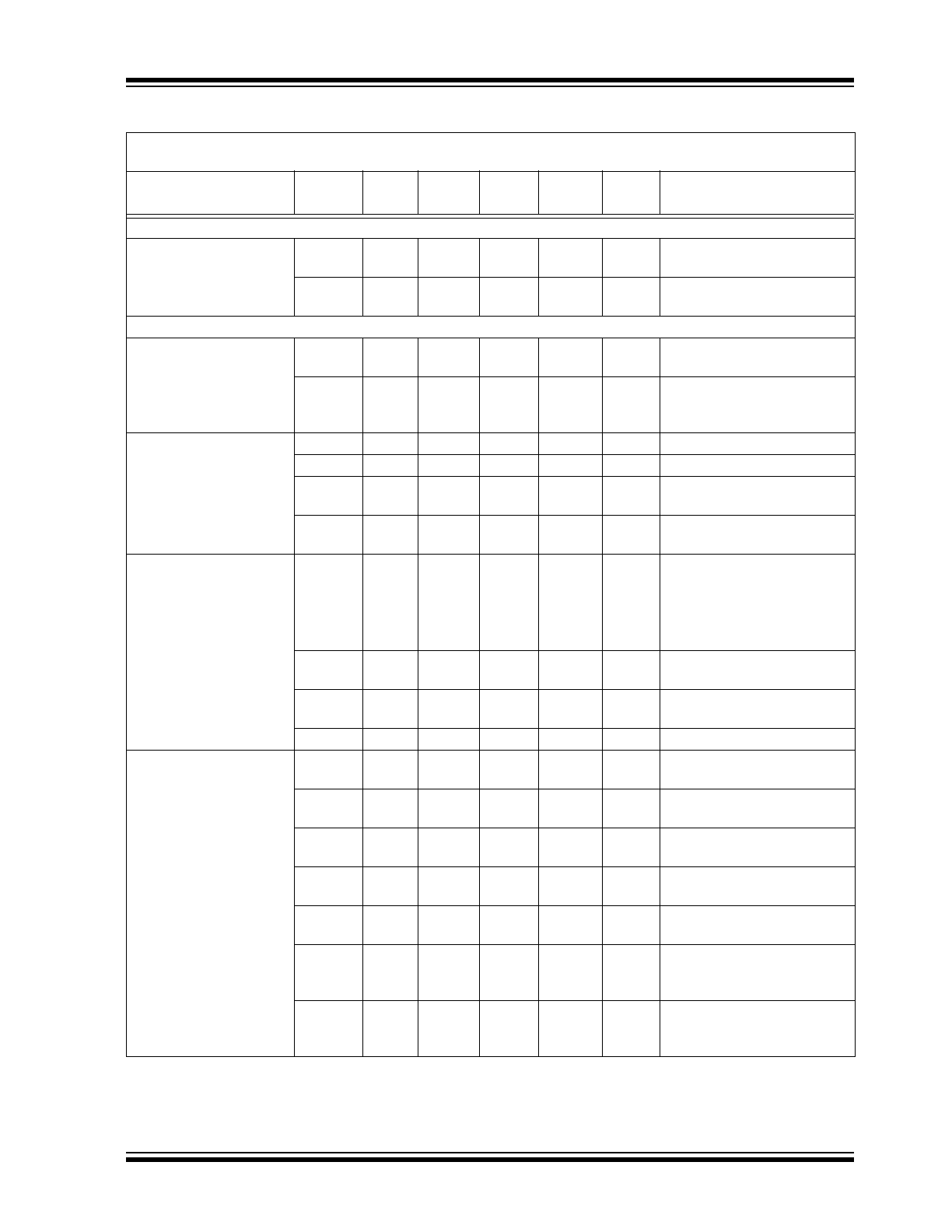

Low Battery

Low Battery Check

Period

T

PLB1

—

76

80

84

s

Standby, No Alarm,

No Low Battery

T

PLB2

—

304

320

336

s

Standby, No Alarm, Low

Battery

Horn Operation

Horn Delay

T

HDLY1

10, 11

475

500

525

ms

From Local Alarm to Horn

Active, temporal horn pattern

T

HDLY2

10, 11

380

400

420

ms

From Local Alarm to Horn

Active, continuous horn

pattern

Horn Period

T

HPER1

10, 11

38

40

42

s

Low Battery, No Alarm

T

HPER2

10, 11

38

40

42

s

Chamber Failure, No Alarm

T

HPER3

10, 11

237

250

263

ms

Alarm Memory Indication

upon PTT, AMHCEn=1

T

HPER4

10, 11

5.5

5.8

6.1

s

CO Alarm horn period

(

Note 2

)

Horn On Time

T

HON1

10, 11

9.5

10

10.5

ms

1.

Low Battery, No Alarm

2.

Chamber Failure

3.

Alarm Memory

Indication upon PTT,

AMHCEn = 1

T

HON2

10, 11

475

500

525

ms

Smoke Alarm, temporal horn

pattern (

Note 3

)

T

HON3

10, 11

332

350

368

ms

Smoke Alarm, continuous

horn pattern (

Note 3

)

T

HON4

10, 11

95

100

105

ms

CO Alarm, COEn = 1

Horn Off Time

T

HOF1

10, 11

475

500

525

ms

Smoke Alarm, temporal horn

pattern (

Note 3

)

T

HOF2

10, 11

1.43

1.5

1.58

s

Smoke Alarm, temporal horn

pattern (

Note 3

)

T

HOF3

10, 11

143

150

158

ms

Smoke Alarm, continuous

horn pattern (

Note 3

)

T

HOF4

10, 11

37

39

41

s

Chamber Fail horn off time

between pulse trains (3x)

T

HOF5

10, 11

465

490

515

ms

Chamber Fail horn off time

between pulses

T

HOF6

10, 11

95

100

105

ms

CO Alarm horn off time

between pulses,

COEn = 1 (

Note 2

)

T

HOF7

10, 11

4.8

5.1

5.4

s

CO alarm horn off time

between pulse trains,

COEn = 1 (

Note 2

)

AC ELECTRICAL CHARACTERISTICS

(CONTINUED)

AC Electrical Characteristics:

Unless otherwise indicated, all parameters apply at T

A

= -10°C to +60°C,

V

DD

= 9V, V

SS

= 0V.

Parameter Symbol

Test

Pin

Min Typ Max

Units

Conditions

Note 1:

T

POSC

is 100% production tested. All other timing is verified by functional testing.

2:

See timing diagram for CO alarm horn pattern.

3:

See timing diagram for smoke alarm temporal and non-temporal horn pattern.

4:

See timing diagram for horn synchronization and Auto Alarm Locate (AAL).

RE46C180

DS22275A-page 8

2011 Microchip Technology Inc.

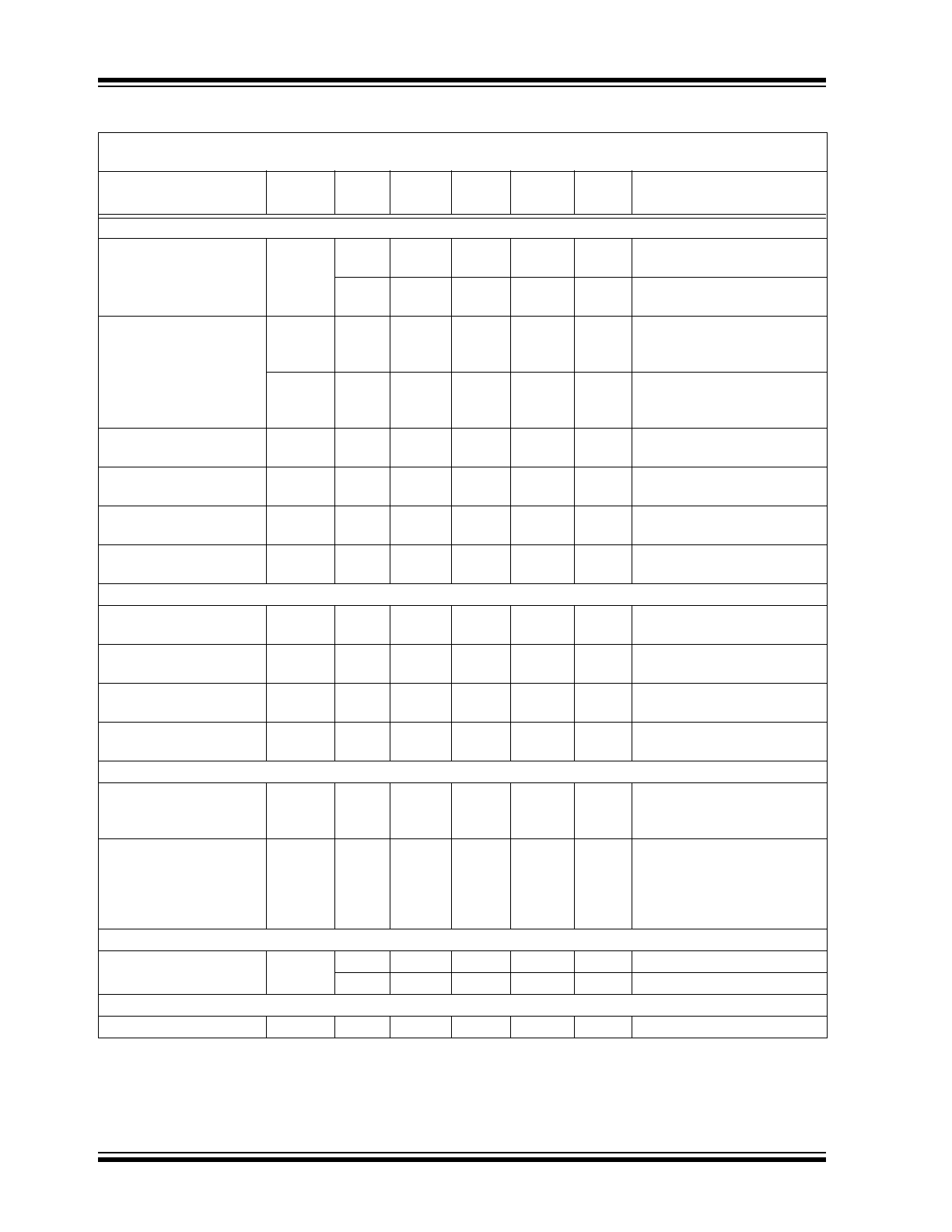

Interconnect

IO Active Delay

T

IODLY1

2

3.5

3.7

3.9

s

From start of Local Alarm

to IO Active. SyncEn = 1

2

3.1

3.3

3.5

s

From start of Local Alarm

to IO Active. SyncEn = 0

Remote Smoke Alarm

Delay

T

IODLY2

2

769

810

851

ms

No Local Alarm,

from IO Active to Alarm,

temporal horn pattern

T

IODLY3

2

299

315

331

ms

No Local Alarm,

from IO Active to alarm,

continuous horn pattern

IO Filter for Remote

Smoke Alarm

T

IOFILT

2

—

—

291

ms

IO pulse-width to be filtered

IO as input, no Local Alarm

IO Pulse On Time

for CO Alarm

T

IOPW1

2

37

—

290

ms

No Local Alarm, 2 valid

pulses required for CO

IO Pulse Off Time

for CO Alarm

T

IOTO1

2

—

—

5.4

s

IO = Low

IO Dump

T

IODMP1

2

475

500

525

ms

At conclusion of Local Alarm

or PTT

Horn Synchronization

IO Pulse Period

T

PIO1

2

3.8

4

4.2

s

Local Alarm, temporal horn

pattern, SyncEn =1 (

Note 4

)

IO Pulse On Time

T

ONIO

2

3.41

3.59

3.77

s

Local Alarm, temporal horn

pattern, SyncEn =1 (

Note 4

)

Horn Sync IO Dump

T

IODMP2

2

95

100

105

ms

Local Alarm,

SyncEn =1 (

Note 4

)

Horn Sync IO Dump

Delay

T

IODLY4

2

285

300

315

ms

Local Alarm,

SyncEn =1 (

Note 4

)

Auto Alarm Locate (AAL)

IO Cycle Period

T

PIO2

2

15.2

16

16.8

s

Local Alarm, temporal horn

pattern, SyncEn =1,

NoAAL = 0 (

Note 4

)

IO Cycle Off Time

T

OFIO

2

4.19

4.41

4.63

s

Local Alarm, temporal horn

pattern, SyncEn = 1,

No AAL = 0, IO off time

between IO pulse trains (3x)

(

Note 4

)

HUSH Timer Operation

HUSH Timer Period

T

TPER

—

8.5

9

9.5

min

No Alarm, ShrtTO = 0

—

76

80

84

s

No Alarm, ShrtTO = 1

EOL

End-of-Life Age Sample

T

EOL

—

346

364

382

Hours Standby, EOLEn = 1

AC ELECTRICAL CHARACTERISTICS

(CONTINUED)

AC Electrical Characteristics:

Unless otherwise indicated, all parameters apply at T

A

= -10°C to +60°C,

V

DD

= 9V, V

SS

= 0V.

Parameter Symbol

Test

Pin

Min Typ Max

Units

Conditions

Note 1:

T

POSC

is 100% production tested. All other timing is verified by functional testing.

2:

See timing diagram for CO alarm horn pattern.

3:

See timing diagram for smoke alarm temporal and non-temporal horn pattern.

4:

See timing diagram for horn synchronization and Auto Alarm Locate (AAL).

2011 Microchip Technology Inc.

DS22275A-page 9

RE46C180

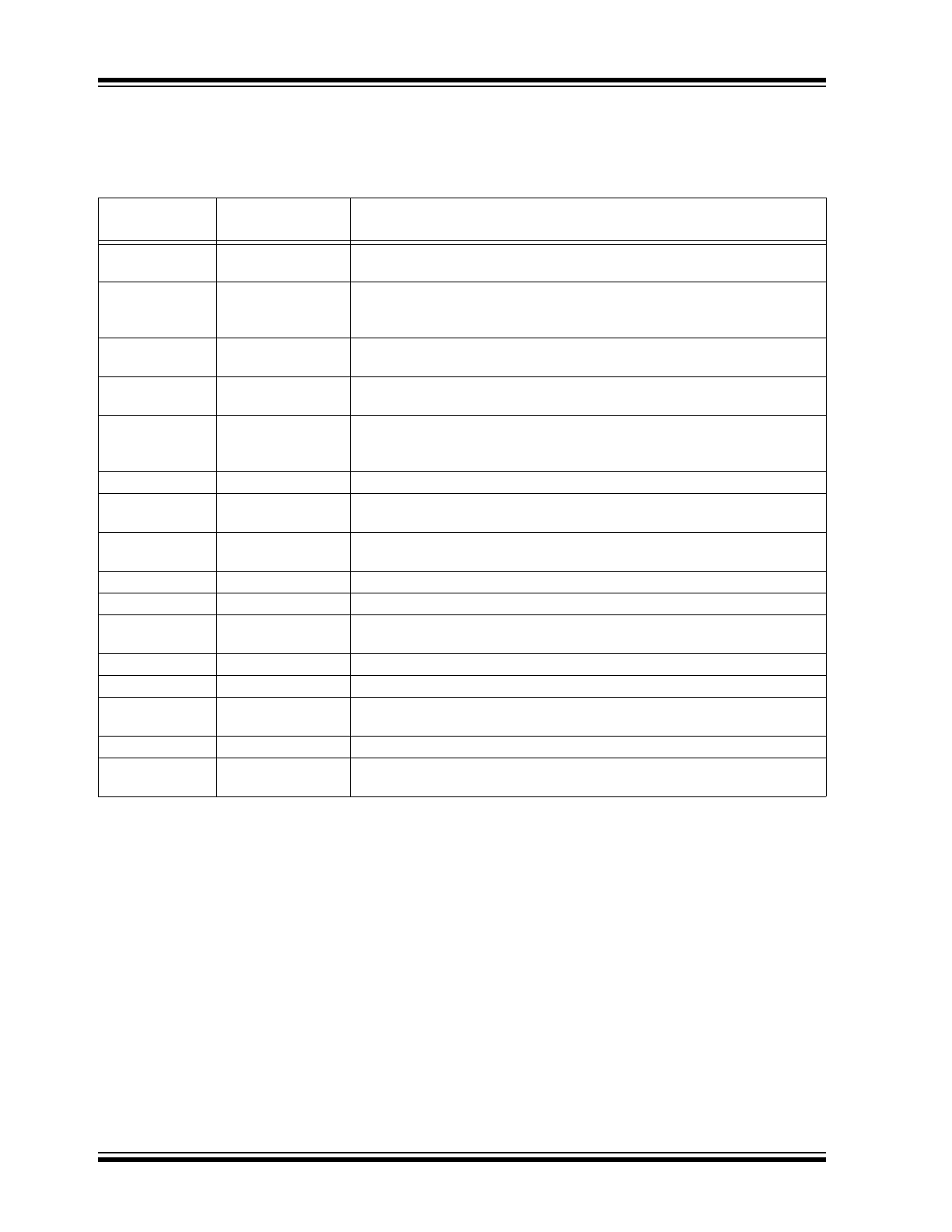

TEMPERATURE CHARACTERISTICS

Electrical Specifications:

Unless otherwise indicated, V

DD

= 9V, V

SS

= 0V

Parameters

Sym

Min

Typ

Max

Units

Conditions

Temperature Ranges

Operating Temperature Range

T

A

-10

—

+60

°C

Storage Temperature Range

T

STG

-55

—

+125

°C

Thermal Package Resistances

Thermal Resistance, 16L-PDIP

θJ

A

—

70

—

°C/W

Thermal Resistance, 16L-SOIC (150 mil.)

θJ

A

—

86.1

—

°C/W

RE46C180

DS22275A-page 10

2011 Microchip Technology Inc.

2.0

PIN DESCRIPTIONS

The descriptions of the pins are listed in

Table 2-1

.

TABLE 2-1:

PIN FUNCTION TABLE

RE46C180

PDIP, SOIC

Symbol

Function

1

TEST

This input is used to invoke Push-to-Test, Timer mode and Alarm Memory

Indication. This input has an internal pull-down.

2

IO

This bidirectional pin provides the capability to interconnect many detectors

in a single system. This pin has an internal pull-down device and a charge

dump device.

3

GLED

Open drain NMOS output, used to drive a visible LED to provide visual

indication of an Alarm Memory condition.

4

CHAMBER

Connect to the ionization smoke chamber. This pin provides power to the

chamber

5

RLED

Open drain NMOS output, used to drive a visible LED. This pin provides the

load current for the Low Battery test, and is a visual indicator for alarm and

HUSH mode.

6

V

DD

Connect to the positive supply voltage

7

TESTOUT

This output is an indicator of the internal IO dump signal. This pin is also

used for Test modes.

8

FEED

Usually connected to the feedback electrode through a current limiting

resistor. If not used, this pin must be connected to V

DD

or V

SS

.

9

V

SS

Connect to the negative supply voltage.

10

HB

This pin is connected to the metal electrode of a piezoelectric transducer.

11

HS

This pin is a complementary output to HB, connected to the ceramic

electrode of the piezoelectric transducer.

12

T2

Test input to invoke Test modes. This pin has an internal pull-down.

13

T3

Test output for Test modes.

14

GUARD1

Output of the guard amplifier. This allows for measurement of the DETECT

input without loading the ionization chamber.

15

DETECT

Connect to the CEV of the ionization smoke chamber.

16

GUARD2

Output of the guard amplifier. This allows for measurement of the DETECT

input without loading the ionization chamber.