© 2006 Microchip Technology Inc.

DS21904C-page 1

PS810

H

ardware Features

• Highly accurate fuel gauge for single cell Li Ion

applications

• Algorithms are implemented using an embedded

PIC18 low-power microcontroller with 16-bit

instruction set

• Reports current, voltage and temperature utilizing a

programmable 8 to15-bit + sign, sigma-delta ADC

• Host communication accomplished through an

industry standard SMBus interface or an

alternative single pin serial interface

• I/O pins are available to provide functions such as

digital GPIO, coin cell voltage measurement and

thermistor input

• Integrated temperature sensor and regulator

minimize external components

• Embedded fuel gauge algorithms and application

specific parameters are stored in a 4K x 16 Flash

memory

• 512 bytes of RAM are available for temporary

storage of battery parameters

Software Features

• Provides battery status, such as average time to empty,

relative State-Of-Charge and battery State-Of-Health

• In-system offset calibration compensates for

offset error in current measurement

Package Features

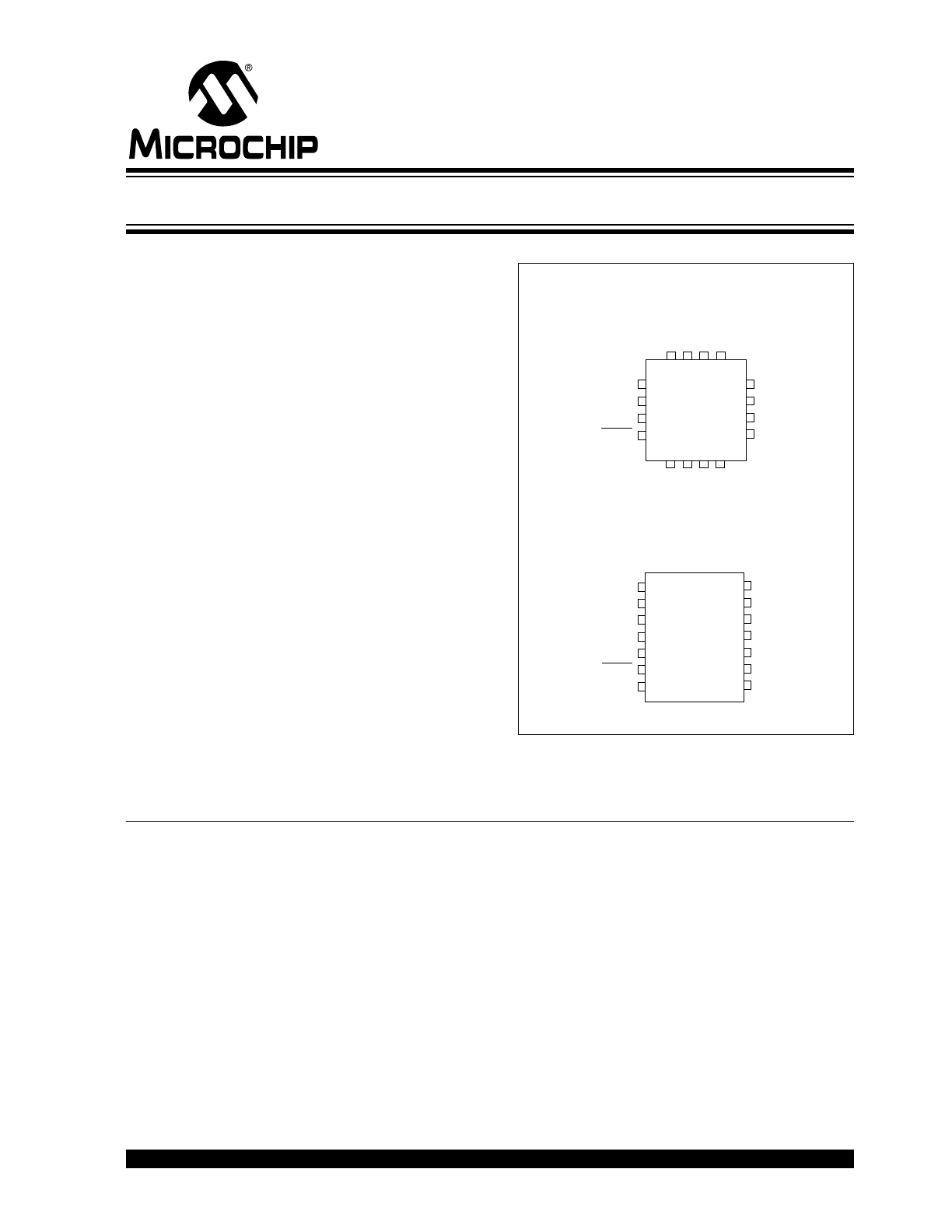

• 16-pin QFN package or 14-pin TSSOP package

• -20°C to +85°C operating temperature range

Pin Description

1.0

PRODUCT OVERVIEW

The PS810 is a fuel gauge for one-cell Li Ion or Li Poly-

mer applications. The device provides the host and the

system user with critical battery information, such as

voltage, current, temperature, run time, State-Of-Charge

and State-Of-Health. This information is available

through an industry standard SMBus or an alternative

Single Pin Serial interface. Advanced fuel gauge

algorithms are stored in on-board Flash memory and

executed by the industry recognized PIC18 micro-

controller. These algorithms include compensation

factors which optimize the performance of the battery for

a specific application and operating environment.

Compensation is included for the effects of temperature,

discharge rate, charge rate and battery aging.

To provide precise measurements of current, voltage and

temperature, the PS810 integrates a highly accurate

15-bit + sign, sigma-delta A/D converter. Based upon

operating conditions, this programmable converter can be

configured to measure specific battery parameters with a

resolution of 8 to 15 bits + sign. Precision measurements

combined with advanced algorithms provide accurate

indications of capacity, run time, State-Of-Health and

safety and charge/discharge conditions.

The ability to operate directly from a single Li Ion or Li

Polymer cell minimizes the need for external compo-

nents, such as a voltage regulator and voltage divider.

To further limit external circuitry and enhance accuracy,

the PS810 provides an integrated temperature sensor

and oscillator.

IO4

GND

N/C

VC1

IO1

NTC/IO2

1

2

3

4

5

6

7

16 15 14 13

12

11

10

PS810

8

9

IO5

R

OSC

16-pin QFN (4 mm x 4 mm)

V

COIN

/IO3

V

FILTER

MCLR

N/C

S

C

L/IO

0

IO6

SDA/

SP

S

SR

2

NTC/IO2

SDA/SPS

GND

SR

MCLR

VC1

IO6

IO5

V

COIN

/IO3

V

FILTER

1

2

3

4

5

6

7

14

13

12

11

10

9

8

PS810

IO4

R

OSC

SCL/IO0

IO1

14-pin TSSOP

Li Ion Single Cell Fuel Gauge

PS810

DS21904C-page 2

© 2006 Microchip Technology Inc.

TABLE 1-1:

PS810 QFN PIN SUMMARY

TABLE 1-2:

PS810 TSSOP PIN SUMMARY

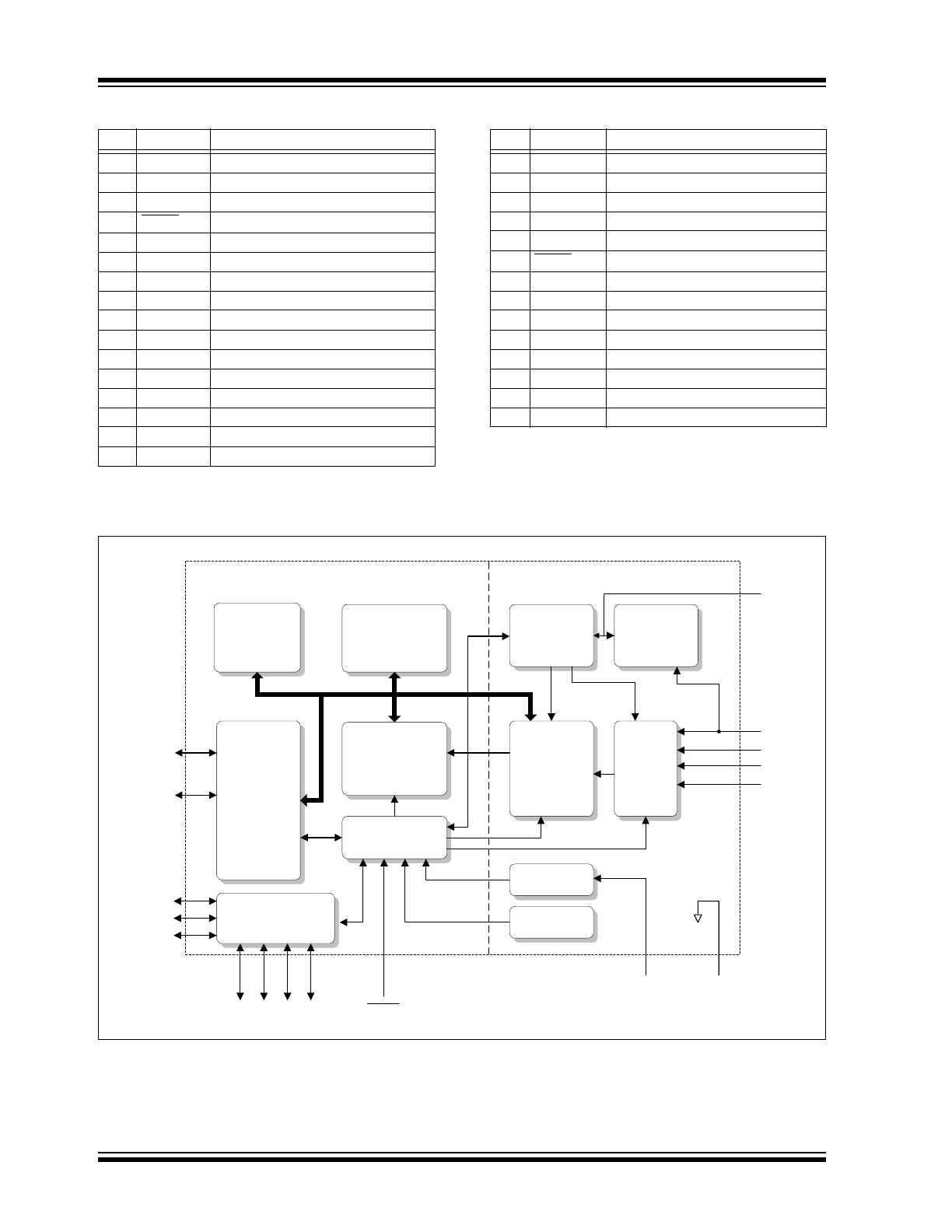

FIGURE 1-1:

PS810 INTERNAL BLOCK DIAGRAM

Pin#

Pin Name

Description

1

NTC/IO2

External NTC input or GPIO

2

V

COIN

/IO3

Coin cell monitor input or GPIO

3

V

FILTER

Power supply filter cap

4

MCLR

Master Clear

5

VC1

Cell voltage input

6

N/C

No connect

7

N/C

No connect

8

R

OSC

Oscillator bias resistor

9

SR

Sense resistor input

10

GND

Power supply ground

11

IO4

General purpose IO

12

IO5

General purpose IO

13

IO6

General purpose IO

14

SDA/SPS

SMBus data/one-wire serial line

15

SCL/IO0

SMBus clock or GPIO0

16

IO1

General purpose IO

Pin#

Pin Name

Description

1

SCL/IO0

SMBus clock or GPIO

2

IO1

General purpose IO

3

NTC/IO2

External NTC input or GPIO

4

V

COIN

/IO3

Coin cell monitor input or GPIO

5

V

FILTER

Power supply filter cap

6

MCLR

Master Clear

7

VC1

Cell voltage input

8

R

OSC

Oscillator bias resistor

9

SR

Sense resistor input

10

GND

Power supply ground

11

IO4

General purpose IO

12

IO5

General purpose IO

13

IO6

General purpose IO

14

SDA/SPS

SMBus data/one-wire serial line

4K x 16 Flash

4K x 16 Flash

512-byte RAM/

Registers

512-byte RAM/

Registers

Voltage

Reference and

Temp Sensor

Voltage

Reference and

Temp Sensor

Voltage

Regulator

Voltage

Regulator

Comm

Interface

Comm

Interface

PIC18F

Microcontroller

PIC18F

Microcontroller

15-bit + sign

Sigma-Delta

Integrating

A/D Converter

15-bit + sign

Sigma-Delta

Integrating

A/D Converter

Analog

Input Mux

Analog

Input Mux

Run

Oscillator

Run

Oscillator

VC1

R

OSC

GND

Digital Section

Analog Section

Control and Status

Control and Status

SCL

V

COIN

SDA/SPS

Sleep

Oscillator

Sleep

Oscillator

IO0

Input/Output

Input/Output

NTC

SR

IO1

IO2

IO5

IO4

IO3

IO6

MCLR

V

FILTER

© 2006 Microchip Technology Inc.

DS21904C-page 3

PS810

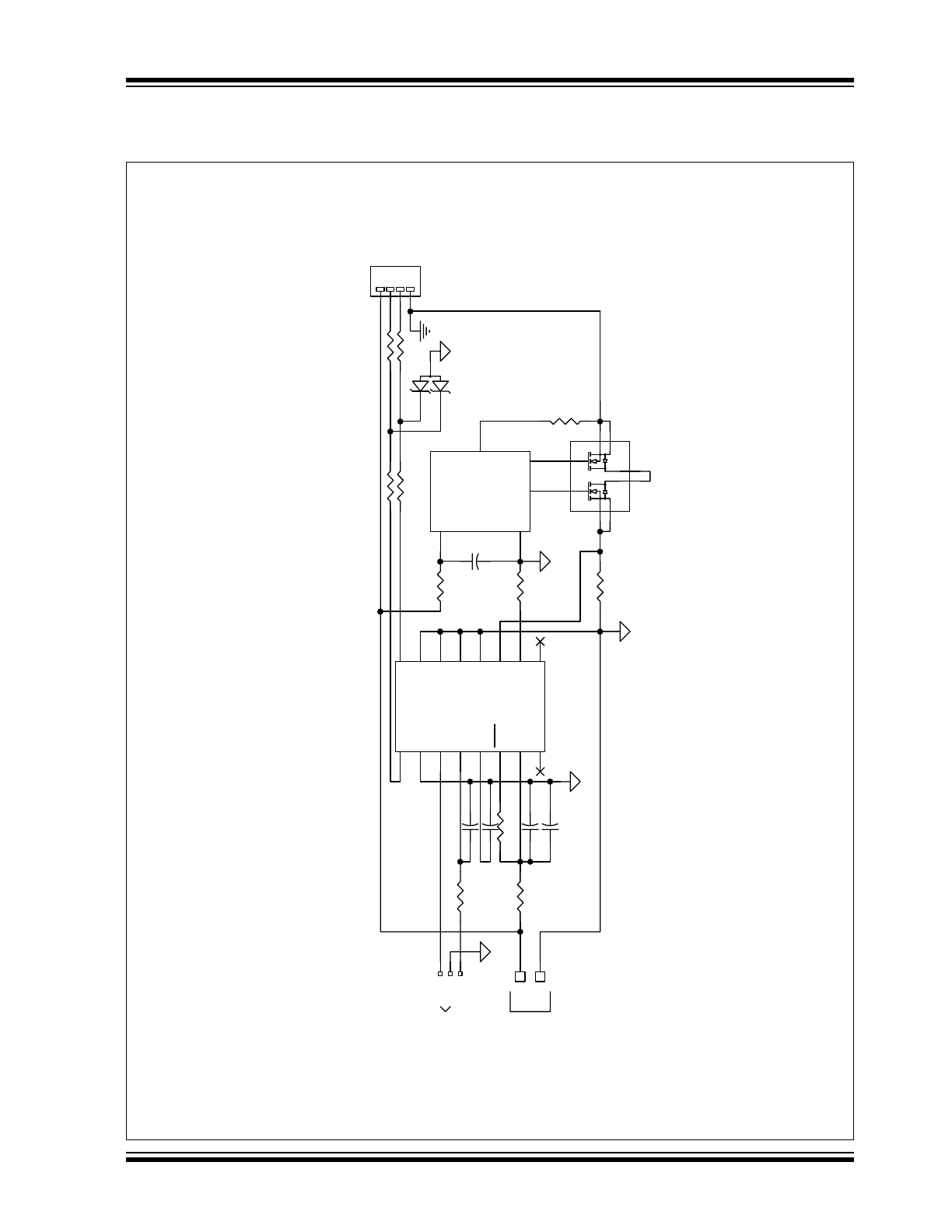

1.1

Schematic

FIGURE 1-2:

PS810 APPLICATION SCHEMATIC – PS810-BASED BATTERY PACK

R3

1

1.

0K

R8

232K

R2

1

240

R2

0

240

PACK CONNECTI

ON

R9

0.

020

3

1

2

D1

CMSZDA5

V6

CONNECTI

ON

GROUND PLANE

C1

0

1.

0 nF

3

4

2

1

5

6

8

7

Q1

TPC

S8209

R5

20

C5 100 nF

R

4

20K

CEL

L CONNECTI

ONS

R1

5

20

R1

4

20

V1

VR

B+ C D B-

QFN PACKAGE

VC1

5

V

COIN

/IO3

2

NTC/IO2

1

SR

9

GND

10

SCL/IO0

15

SDA/SPS

14

R

OSC

8

IO1

16

IO4

11

IO6

13

V

FILTER

3

MCLR

4

IO5

12

NC

6

NC

7

U1

PS810Q

R3

2

470

C3

2

100 nF

V

DD

2

V

SS

3

VM

1

CO

5

DO

4

U

2

S8241A

SAFETY

IC

NTC NVR V

COIN

R2

240

C3 100 nF

C2 100 nF

EXT.

THERMI

STOR I

N

PUT

COI

N CELL

IN

PUT

* GROUND I

F NOT USED

*

*

PS810

DS21904C-page 4

© 2006 Microchip Technology Inc.

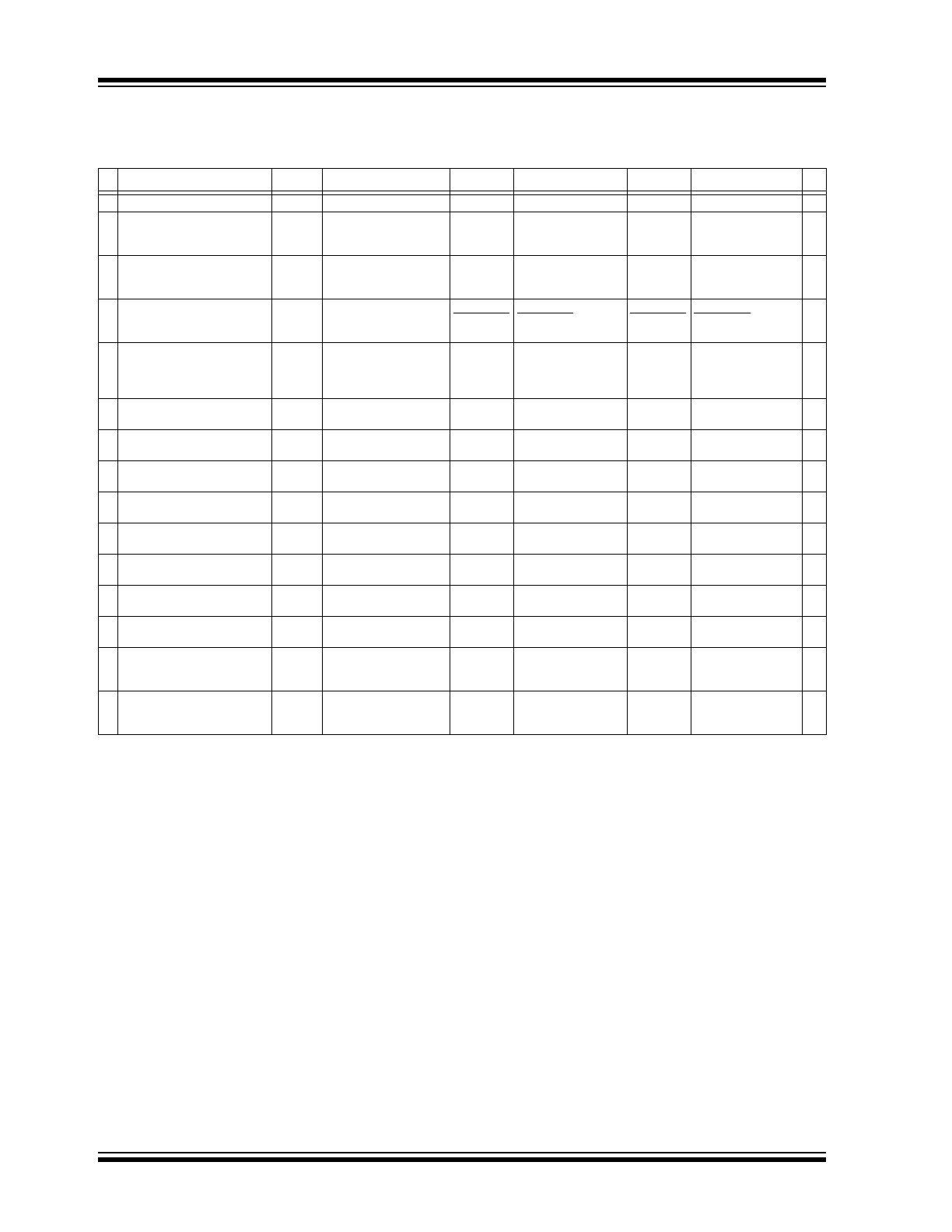

1.2

Bill of Materials

TABLE 1-3:

PS810 BILL OF MATERIALS

ID

Part Number

Symbol

Description

Mftr.

Mftr. PN

Supplier

Supplier PN

Qty

1

04-826197 Rev. 1.1

Raw PCB, PS8110

Microchip

04-826197 Rev. 1.1

Microchip

04-826197 Rev. 1.1

1

2

CC-0402-10X7R25-1.0NF-01

C10

Capacitor, Ceramic, 1.0 nF,

25V, +/-10%, X7R dielectric,

0402

Panasonic

ECJ-0EB1E102K

Digikey

PCC102BQCT-ND

1

3

CC-0603-10X7R16-100NF-01

C2, C3,

C5, C32

Capacitor, Ceramic, 100 nF,

16V, +/-10%, X7R dielectric,

0603

Panasonic

ECJ-1VB1C104K

Digikey

PCC1762CT-ND

4

4

DZ-SOT323-10D-CMSZDA5V6-01 D1

Dual Zener Diode, 5.6V,

+/-10%, 200 mW,

common anode, SOT-323

Central Semi.

Diodes Inc.

CMSZDA5V6

AZ23C5V6W-7

Central Semi.

Diodes Inc.

CMSZDA5V6

AZ23C5V6W-7

1

5

QM-TSSOP844-DN-TPCS8209-01 Q1

MOSFET, dual N-channel

Enhancement mode, 20V,

5A, TSSOP-8/4.4 mm body

width package

Toshiba

TPCS8209(TE12L)

Digikey

TPCS8209CT-ND

1

6

RF-0402-5-20-01 (Note 1)

R14, R15

Resistor, film, 0402, 5%,

20 ohms

Panasonic

ERJ-2GEJ200X

Digikey

P20JCT-ND

2

7

RF-0402-5-20K-01 (Note 1)

R4

Resistor, film, 0402, 5%,

20 kOhms

Panasonic

ERJ-2GEJ203X

Digikey

P20KJCT-ND

1

8

RF-0603-ITC25-221K-01 (Note 1)

R8

Resistor, film, 0603, 1%,

232 kOhms, 25 ppm TC

Susumu Co.

Ltd.

RR0816P-2213-D-34D

Digikey

RR08P221KDCT-ND

1

9

RF-0603-5-1.0K-01 (Note 1)

R31

Resistor, film, 0603, 5%,

1.0 kOhms

Panasonic

ERJ-3GEYJ102V

Digikey

P1.0KGCT-ND

1

10 RF-0603-5-470-01 (Note 1)

R32

Resistor, film, 0603, 5%,

470 ohms

Panasonic

ERJ-3GEYJ471V

Digikey

P470GCT-ND

1

11 RF-0805-5-20-01 (Note 1)

R5

Resistor, film, 0805, 5%,

20 ohms

Panasonic

ERJ-6GEYJ200V

Digikey

P20ACT-ND

1

12 RF-0805-5-240-01 (Note 1)

R2, R20,

R21

Resistor, film, 0805, 5%,

240 ohms

Panasonic

ERJ-6GEYJ241V

Digikey

P240ACT-ND

3

13 RF-1206-1-0.029-01 (Note 1)

R9

Resistor, metal strip, 1206,

1%, 0.020 ohms

Vishay

WSL1206-0.020-1%-R86 Vishay

WSL1206-0.020-1%-R86

1

14 UM-SOT235-4085-

S8241ABPMCGBPT2-01

U2

IC, Battery Protection Circuit,

Li Ion, 1-cell, -40°C to +85°C,

SOT23-5 package

Seiko

Instruments

S-8241ABPMC-GBP-T2

(Note 2)

Seiko

Instruments

S-8241ABPMC-GBP-T2

(Note 2)

1

15 UM-QFN164X4-2085-PS810-01

U1

IC, Low-Voltage Fuel Gauge,

-20°C to +85°C, QFN-16/

4.0x4.0 mm package

Microchip

PS810

Microchip

PS810

1

Note

1:

Resistor sizes shown are minimum recommended sizes for the application.

2:

Other variants of the S-8241A series, with different trip points, are also available. Consult the S-8241A series data sheet.

© 2006 Microchip Technology Inc.

DS21904C-page 5

PS810

2.0

ARCHITECTURAL OVERVIEW

The PS810 contains a complete analog “front-end” for

battery monitoring as well as an embedded micro-

controller, with supporting memory, for control,

measurement accumulation, calculation and

communications. Major functions within the PS810

include:

• Voltage Regulator

• Precision Time Base

• Temperature Sensor

• 4K x 16 Flash Memory

• 512-byte RAM Memory

• 15-bit plus sign Analog-to-Digital (A/D) Converter

• SMBus/I

2

C™ or Single Pin Serial

Communications Interface

• PIC18 Microcontroller

Figure 1-1 is a block diagram of the internal circuitry of

the PS810. Figure 1-2 is a schematic diagram that

depicts the PS810 in a typical single cell lithium ion

application. The function of each of the blocks listed

above is summarized in the following sections.

2.1

Internal Voltage Regulator

The PS810 incorporates an internal voltage regulator

that supports 1-cell lithium pack configurations. The

internal regulator draws power directly from the VC1

input. No other external components are required to

regulate circuit voltage.

2.2

Precision Time Base

The integrated precision time base is a highly accurate

RC oscillator that provides precise timing for the sigma-

delta A/D and for the on-chip elapsed time counters

without the need for an external crystal. This time base

is trimmed during manufacturing to a nominal

frequency of 512 kHz.

2.3

Temperature Sensor

An integrated temperature sensor is provided that can

eliminate the need for an external thermistor. As an

option, a connection is provided for an external

thermistor for applications where the battery cell is

physically separated from the PS810.

2.4

Flash Memory

4K x 16 of Flash memory is incorporated for storage of

nonvolatile parameters, such as PowerSmart

®

3D cell

models, fuel gauge algorithms and application specific

data.

2.5

RAM Memory

512 bytes of general purpose RAM memory is provided

for storage of temporary parameters.

2.6

A/D Converter

The PS810 incorporates an integrating sigma-delta

A/D converter together with an analog that has inputs

for charge and discharge current, cell voltage, coin cell

voltage, the on-chip temperature sensor and an off-chip

thermistor. The converter can be programmed to per-

form a conversion with resolutions of 8 to 15 bits + sign,

while utilizing either a single-ended +300 mV or a

differential ±150 mV reference.

2.7

SMBus/I

2

C™ or Single Pin Serial

Communications Interface

This communications port for the PS810 is selectable

as a 2-pin industry standard SMBus/I

2

C or a single pin

interface. All commands, status and data are read or

written from the host system via this interface.

2.7.1

SMBus/I

2

C

The two pin communication interface uses one clock

pin and one data pin and is compatible with the industry

standard System Management Bus (SMBus) and the

Inter IC Communication Bus (I

2

C).

2.7.2

SINGLE PIN SERIAL INTERFACE

The Single Pin Serial (SPS) interface consists of one pin

only: the SDA/SPS pin (pin 14). This communication is

an asynchronous return-to-one protocol. The timing of

the driven low pulses defines the communication.

2.8

PIC18 Microcontroller

The PIC18 is a high-performance, CMOS, fully static

8-bit microcontroller. The PIC18 employs an advanced

RISC architecture. This device has enhanced core

features, such as 31 level deep stack and multiple

internal and external interrupt sources. The separate

instruction and data buses of the Harvard architecture

allow a 16-bit wide instruction word with a separate 8-bit

wide data bus. The two-stage instruction pipeline allows

all instructions to execute in a single cycle, except for

program branches, which require two cycles. A total of

75 instructions are available.

PS810

DS21904C-page 6

© 2006 Microchip Technology Inc.

NOTES:

© 2006 Microchip Technology Inc.

DS21904C-page 7

PS810

3.0

OPERATIONAL DESCRIPTION

3.1

A/D Operation

The PS810 A/D converter measures current, voltage

and temperature and integrates the current over time to

calculate State-Of-Charge. Cell voltage is measured

with a direct connection to the battery cell without

requiring an external voltage divider. Using an external

sense resistor, current is monitored during both charge

and discharge and is integrated over time using the on-

chip oscillator as the time base. Temperature is

measured from the on-chip temperature sensor or an

optional external thermistor. Voltage, current and

temperature can be calibrated for accuracy over the

operational range. The A/D converter performs

sampling using a 32 kHz clock.

3.1.1

CURRENT MEASUREMENT

The A/D input channels for current measurement are the

SR and GND pins. The voltage drop across the sense

resistor is measured and converted mathematically into

a current measurement. The current is also integrated

over time to get the amount of charge entering or leaving

the battery.

A sense resistor is connected to SR and GND. The

maximum input voltage that can be measured at SR is

+/-150 mV. The sense resistor should be properly sized

to accommodate the lowest and highest expected

charge and discharge currents, including suspend and/

or standby currents.

The parameter NullCurr represents the zero-zone

current of the battery. This is provided as a calibration

guardband for reading zero current. Currents below

+/- NullCurr (in mA) limit are read as zero and not

included in the capacity algorithm calculations. A

typical value for NullCurr is 3 mA, therefore, currents

between -3 mA and +3 mA will be reported as zero and

not included in the capacity calculations. This feature is

provided so that electrical noise on the battery module

current path is not interpreted as actual charge entering

or leaving the battery.

3.1.1.1

Sense Resistor Selection and

Current Measurement Range

The current resolution is based on the smallest amount

of voltage the A/D converter can measure across the

sense resistor. Since this measurement uses 13 bits

(plus sign) and the reference used is the internal

150 mV reference, the smallest voltage across the

sense resistor that can be measured is:

EQUATION 3-1:

3.1.1.2

Current Calibration

In-circuit calibration of the current is done using the

communication interface (SMBus/I

2

C or SPS) at time

of manufacture to obtain optimal accuracy. A correction

is calculated and stored for both offset and slope.

COD is a constant that is measured at calibration time

and contains the offset due to external PCB

components.

CFCurr is the “Correction Factor for Current” which

compensates the A/D gain and any variances in the

actual sense resistance over varying currents. It is

multiplied against the raw A/D measurement.

COCurr is the “Correction Offset for Current” which is

updated in real time by the A/D shorting the inputs and

comparing any result to zero. This is added to COD and

compensates for any offset that varies over time, such

as temperature dependent offsets.

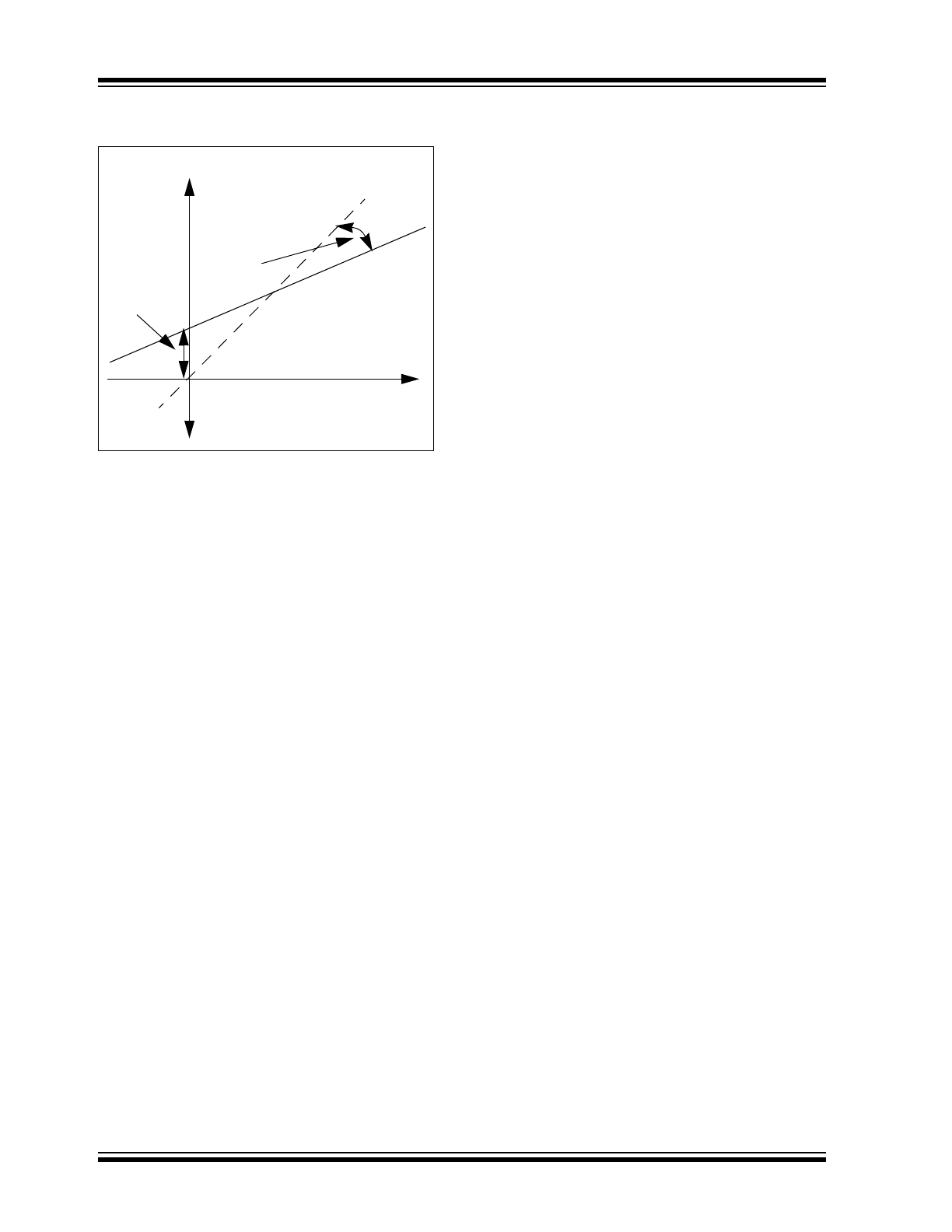

Figure 3-1 shows the relationship of the COCurr and

CFCurr values.

150 mV/(2 ^ 13

– 1) = 150 mV/32767 = 18.3

μV

Thus, the smallest current that can be measured is:

18.3

μV/R

SENSE

(m

Ω)

The largest current that can be measured is:

150 mV/R

SENSE

(m

Ω)

Example: a 20 milliohm sense resistor will measure

from:

18.3

μV/20 mΩ = 0.915 mA

(though will be recorded as zero if < NullCurr)

up to:

150 mV/20 m

Ω = 7.5 Amps

PS810

DS21904C-page 8

© 2006 Microchip Technology Inc.

FIGURE 3-1:

COCurr AND CFCurr

VALUE RELATIONSHIP

3.1.2

AUTO-OFFSET COMPENSATION

Accuracy drift is prevented using an automatic auto-

zero self-calibration method which zeros the current

measurement circuit periodically at a programmable

rate. This feature can correct for drift in temperature

during operation. The Auto-Offset Compensation

circuit works internally by disconnecting the RS input

and internally shorting it to GND to measure the zero

input offset. Furthermore, the calibration factor, COD,

contains the offset factor external to the IC, offset due

to the circuit board, system, etc. COD is added to the

internal offset calculated by the auto-offset cycle to

determine the full offset, COCurr.

3.1.3

VOLTAGE MEASUREMENTS

The A/D input channel for cell voltage measurement is

the VC1 pin. Measurements are taken each measure-

ment period when the A/D is active. The maximum

voltage at the VC1 pin is 5.5V, but voltages above 4.5V

are not suggested since this will saturate the A/D. The

cell voltage is measured with an integration method to

reduce any sudden spikes or fluctuations. The A/D

uses a default of 11-bit plus sign resolution for these

measurements.

The VC1 input circuit contains an internal resistive

divider to reduce the external voltage input to a range

that the internal A/D circuit can accommodate (300 mV

maximum). The divider is 15 to 1 based on a maximum

cell voltage of 4.5 volts. The voltage divider is only

connected to ground when the actual voltage

measurement is occurring.

CFVoltage is the “Correction Factor for Pack Voltage”

which compensates for any variance in the actual A/D

response versus an ideal A/D response over varying

voltage inputs. In-circuit calibration of the voltage is

done at the time of manufacture to obtain accuracy in

addition to high resolution. Cell voltage measurements

can be accurate to within ±20 mV.

3.1.4

TEMPERATURE MEASUREMENTS

The A/D can measure temperature from the internal

temperature sensor or an external thermistor

connected to the NTC pin. The A/D uses a default of

11-bit plus sign resolution for the temperature

measurements.

A standard 10 kOhms at 25°C Negative-Temperature-

Coefficient (NTC) device of the 103ETB type is

suggested for the optional external thermistor. One leg

of the NTC should be connected to the NTC pin and the

other to ground.

A linearization algorithm is used to convert the voltage

measurement seen at the NTC pin to a temperature

value. The external thermistor should be placed as

close as possible to the battery cells and should be

isolated from any other sources of heat that may affect

its operation.

Calibration of the temperature measurements involves

a correction factor and an offset exactly like the current

measurement. The internal temperature measurement

makes use of correction factor, CFTempI and offset,

COTempI, while the NTC pin for the optional external

thermistor makes use of correction factor, CFTempE.

Ideal A/D Response

Actual A/D

Response

CFCurr

COCurr

Raw Measurement

Actual Current

© 2006 Microchip Technology Inc.

DS21904C-page 9

PS810

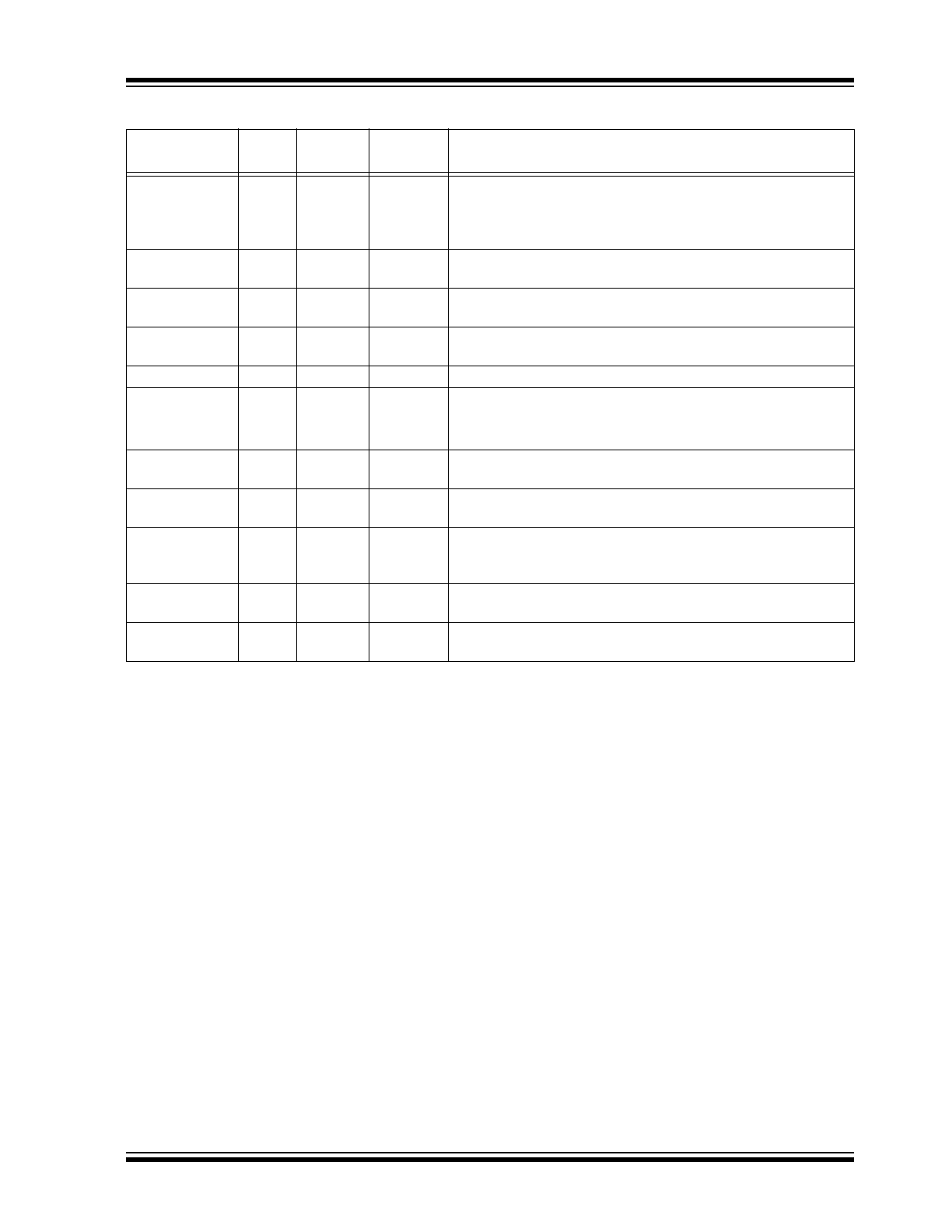

TABLE 3-1:

A/D OPERATION PARAMETERS

Parameter

Name

# of

Bytes

Units

Typical

Value

Operational Description

NullCurr

1

mA

3

Zero zone control is built into the PS810 so that electrical noise

doesn’t actually drain the gas gauge, when in fact the current is

zero. For this reason, current less than NullCurr mA in either

direction will be measured as zero.

CFCurr

2

unsigned

word

4200

Correction Factor for Current. Adjusts the scaling of the sense

resistor current measurements.

COCurr

1

signed

byte

0

Correction Offset for Current. This is the value the A/D reads

when zero current is flowing through the sense resistor.

COD

1

signed

byte

0

Correction Offset Deviation. Offset value for the auto-zero

calibration of the current readings.

AOMInterval

1

op cycles

60

Interval of time between auto-offset calibrations.

AVGIScale

1

coded

b00100000 Time period over which current is averaged to calculate

average current: I

AVG

= I

AVG

+ (I – I

AVG

)/(AVGIScale * 2).

Note: Only Most Significant set bit is used, others are ignored.

CFVoltage

2

integer

2250

Correction Factor for Pack Voltage. Adjusts the scaling of the

VC1 pin measurement.

CFCoin

2

integer

2250

Correction Factor for Coin Cell Measurement. Adjusts the

scaling of the V

COIN

pin measurement.

CFTempE

2

integer

326

Correction Factor for Temperature. Adjusts the scaling of

temperature measured across an external thermistor at the NTC

input pin.

CFTempI

2

integer

2038

Correction Factor for Temperature. Adjusts the scaling of

temperature measured from the internal temperature sensor.

COTempI

2

signed

word

21298

Correction Offset for Temperature. Used for temperature

measurement using internal temperature sensor.

PS810

DS21904C-page 10

© 2006 Microchip Technology Inc.

3.2

Operational Modes

The PS810 operates on a continuous cycle, measuring

current, voltage and temperature, then performing fuel

gauge calculations. There are four power modes: Run

mode, in which the measuring and calculating loop

constantly repeats; Bus Inactive Low-Power mode, in

which only self-discharge is calculated; Low-Voltage

Sleep mode, in which there are no measurements and

only wake-up circuitry is powered; and Shelf-Sleep

mode, in which only communication line sensors are

powered.

3.2.1

RUN MODE

Run mode is the highest power consuming mode.

During Run mode, all measurements and calculations

occur. Current, voltage and temperature measure-

ments are each made sequentially. Run mode is active

until voltage drops below the Sleep voltage, the bus

goes inactive or the Shelf-Sleep command is executed.

3.2.2

BUS INACTIVE LOW-POWER MODE

The PS810 enters Low-Power mode when all of the

following conditions are true:

• Current is zero (optional)

• The communication pins are low for at least

8 periods of 512 ms each

• There is no communication attempt for at least

8 periods of 512 ms each

To enter this mode, typically, there must be no load or

charger present and no communication host. The pack

is out of the system. In this mode, the PS810 will draw

less current from the battery, approximately 25

μA and

will only track self-discharge. Alternatively, if self-

discharge tracking is not required, Ultra Low-Power

mode can be used and the PS810 will draw less than

1 microamp.

3.2.3

LOW-VOLTAGE SLEEP MODE

Entry to Low-Voltage Sleep mode can only occur when

the measured pack voltage at VC1 input is below a

preset limit set by the parameter SleepVoltage (in mV)

and the current is zero (less than NullCurr). Sleep

mode may be exited to Run mode when the voltage at

VC1 is greater than the wake-up voltage, which is

3.2 volts, 10%.

While in 10% Sleep mode, no measurements occur

and no calculations are made. The fuel gauge display

is not operational, no communications are recognized

and only a wake-up condition will permit an exit from

Sleep mode. Sleep mode is one of the lowest power

consuming modes and is used to conserve battery

energy following a complete discharge.

There are two power levels that can be chosen for Low-

Voltage Sleep mode. Low-Power mode draws

approximately 20

μA and will wake-up automatically

when the voltage rises above the wake-up voltage,

which is a constant 3.2 volts above the wake-up volts,

+/-5%. Ultra Low-Power mode draws less than 1

μA

and requires an external source to drive the communi-

cation line high to wake-up, since the voltage wake-up

comparator is powered down.

3.2.4

SHELF-SLEEP MODE

Shelf-Sleep mode can be entered by a battery data

command on the communication bus for conserving

energy while shipping battery packs. It can be exited

only by an external source driving the communication

data line high. This mode uses the Ultra Low-Power

Sleep mode, resulting in current draw less than

1 microamp. This mode is entered by writing a pass-

word to SMBus command code, 0x43. A word write

protocol is used to write the password, 0x5A7A.

TABLE 3-2:

OPERATIONAL MODES

Mode

Entry

Exit

Notes

Run

Voltage > Wake-up voltage

or data line driven high

Voltage less than SleepVoltage, bus Idle or

Shelf-Sleep command issued

Highest power

consumption and

accuracy.

Bus Inactive

Low-Power

Current < NullCurr,

communication lines low

and no communication

attempts

Activity on communication lines

Only self-discharge

calculated.

Low-Voltage

Sleep

VC(1) < SleepVoltage,

Current is not zero

Voltage > Wake-up voltage (Low-Power mode),

Data line driven high (Ultra Low-Power mode)

No measurements

made.

Shelf-Sleep

Can be entered by SMBus

command

Data line driven high

No measurements

made.