2004 Microchip Technology Inc.

DS21760F-page 1

PS700

Features

• Measures, maintains and reports all critical

rechargeable battery parameters with high

accuracy

• Supports Lithium (1-cell and 2-cell) battery packs

• Current measurement with 16-bit integrating A/D

accurate to less than ±0.5% error

• Temperature measurement accurate to within

±2°C absolute, using on-chip temperature sensor

or external thermistor

• Accumulation of charge current, discharge

current, temperature and voltage in independent

32-bit registers

• 512-byte nonvolatile EEPROM stores factory

programmed, measured and user-defined

parameters

• In-system offset calibration compensates for

offset error in current measurement

• Industry standard SMBus/I

2

C™ compatible 2-wire

communications interface

• 8-pin TSSOP package

• -20°C to +85°C operating temperature range

• NTC pin can be configured as a thermistor input

or GPIO

• VC2 pin can be configured as a cell input or a

GPIO

• Flexible power operating modes allow low-power

monitoring of battery conditions during system full

operating and standby conditions:

- Run: Continuous Conversion; 80

µ

A typ.

- Sample: Sample interval from

0.5-64s @ 45

µ

A typ.

- Sample-Sleep: Sample interval from

0.5-138s min. @ 20

µ

A typ.

• Shelf-Sleep mode reduces power consumption

during pack storage conditions to 300 nA typ.,

with automatic wake-up upon pack insertion

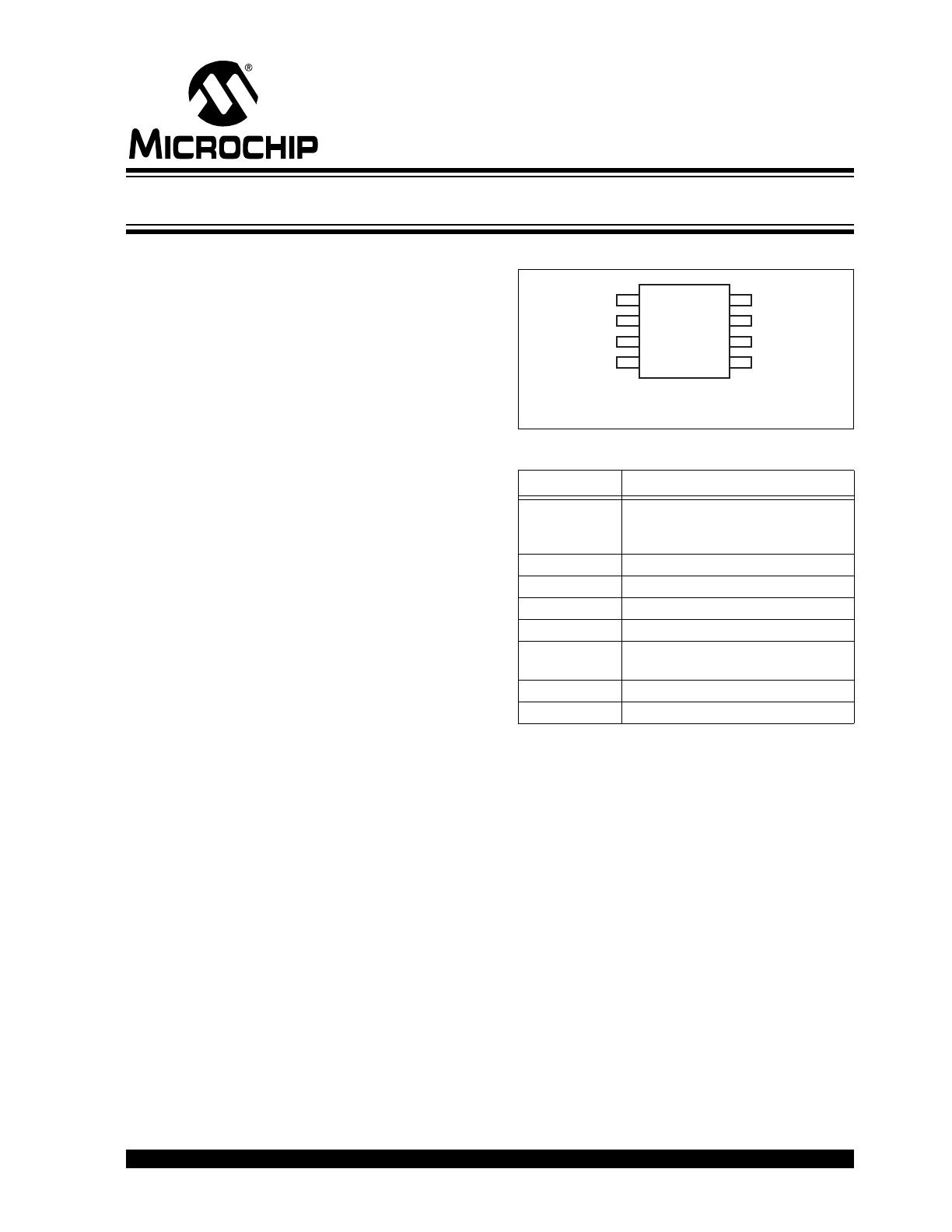

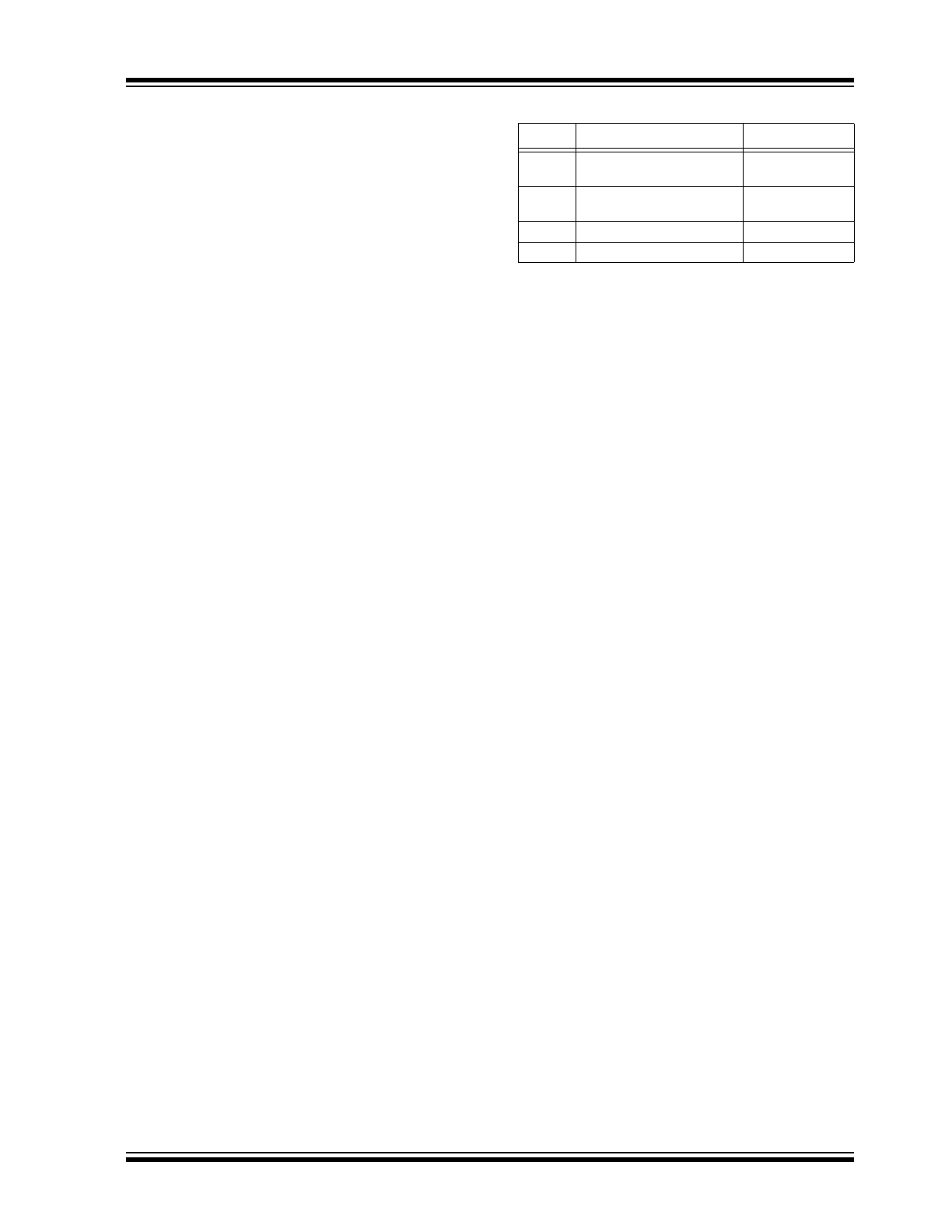

Pin Description

Pin Summary

Pin Name

Description

VC2/IO1

Cell voltage input for cell 2 in a

2-series Li Ion pack or general

purpose I/O #1

VC1

Cell voltage input for cell 1

SCL

SMBus clock line

SDA

SMBus data l/O

R

OSC

Oscillator bias resistor

NTC/IO0

External thermistor connection or

general purpose I/O #0

GND

Power supply ground

SR

Sense resistor input

R

OSC

PS700

1

SCL

2

3

GND

4

8

7

6

5

VC1

VC2/IO1

NTC/IO0

SR

SDA

8-pin 150 mil

TSSOP Package

Battery Monitor

PS700

DS21760F-page 2

2004 Microchip Technology Inc.

1.0

PRODUCT OVERVIEW

The PS700 is a cost-effective, highly accurate IC that

measures, stores and reports all of the critical

parameters required for rechargeable battery monitor-

ing with a minimum of external components. It precisely

measures charge/discharge current as well as voltage

and temperature of a battery pack. In addition, the

PS700 accurately accumulates both charge and

discharge current as independent parameters.

Temperature history can also be maintained for

calculating self-discharge effects.

The PS700 integrates a highly accurate 16-bit integrat-

ing A/D converter that performs current measurement

to within ±0.5% error. On-chip counters precisely track

battery charge/discharge and temperature history. Also

included are an on-chip voltage regulation circuit, non-

crystal time base and on-chip temperature sensor. The

operating voltage range of the PS700 is optimized to

allow a direct interface to 1 or 2-series Li Ion/Li Poly

battery packs. 512 bytes of general purpose nonvolatile

EEPROM storage are provided to store factory

programmed, measured and user defined parameters.

Efficient communication is provided through an

industry standard SMBus/I

2

C™ compatible 2-wire

communications interface. This interface allows the

host to determine accurate battery status for effective

system power management and for communication to

the end user. A battery management solution utilizing

the PS700 delivers both space and total system

component cost savings for a wide variety of battery

operated applications.

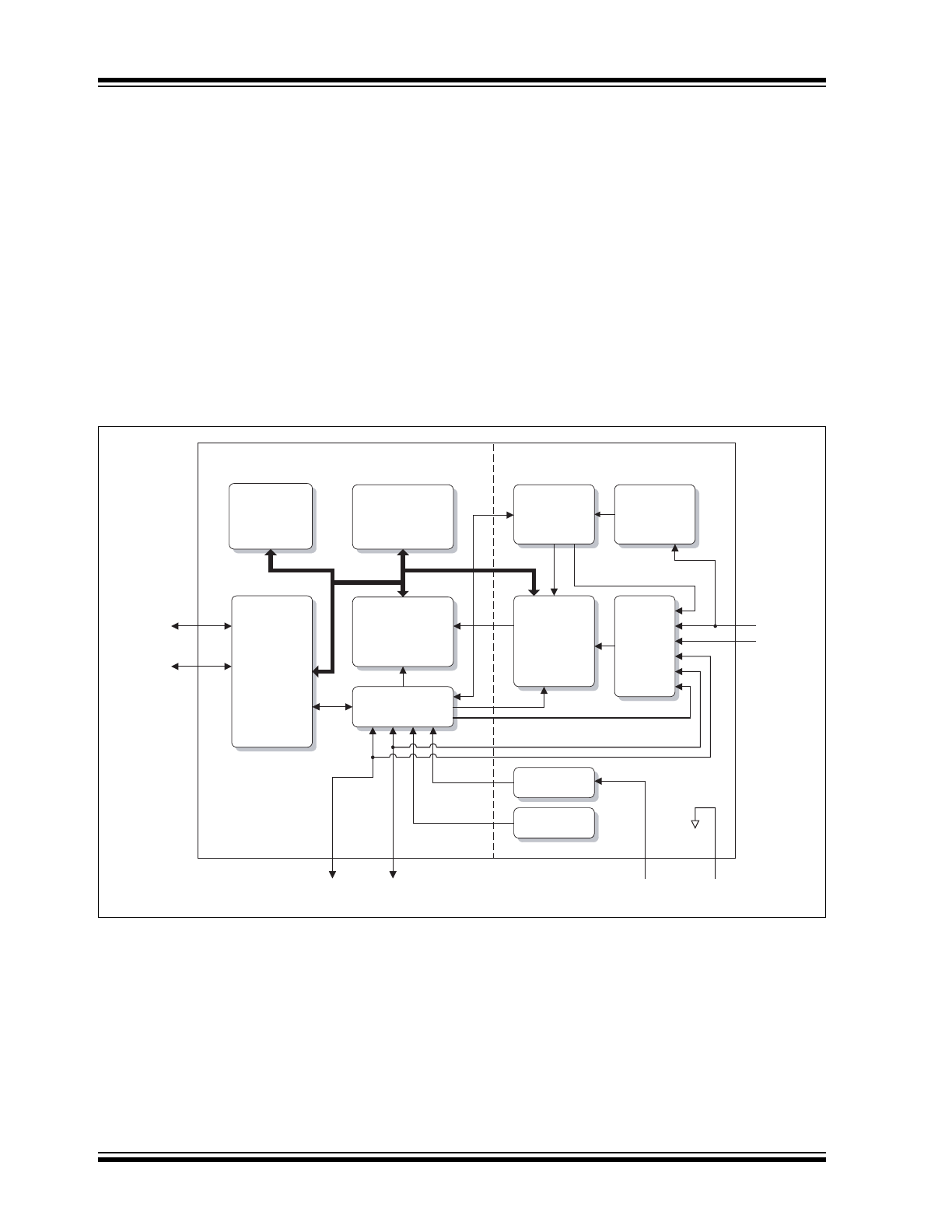

FIGURE 1-1:

PS700 INTERNAL BLOCK DIAGRAM

512

EEPROM

512

EEPROM

32-bit

Accumulators /

Timers

32-bit

Accumulators/

Timers

Voltage

Reference and

Temp Sensor

Voltage

Reference and

Temp Sensor

Voltage

Regulator

Voltage

Regulator

Comm

Interface

Comm

Interface

Registers

Registers

16-Bit

Sigma-Delta

Integrating

A/D Converter

16-Bit

Sigma-Delta

Integrating

A/D Converter

Analog

Input Mux

Analog

Input Mux

Run

Oscillator

Run

Oscillator

VC1

R

OSC

GND

Digital Section

Analog Section

Control and Status

Control and Status

SCL

SR

SDA

Sleep

Oscillator

Sleep

Oscillator

VC2/IO1

NTC/IO0

2004 Microchip Technology Inc.

DS21760F-page 3

PS700

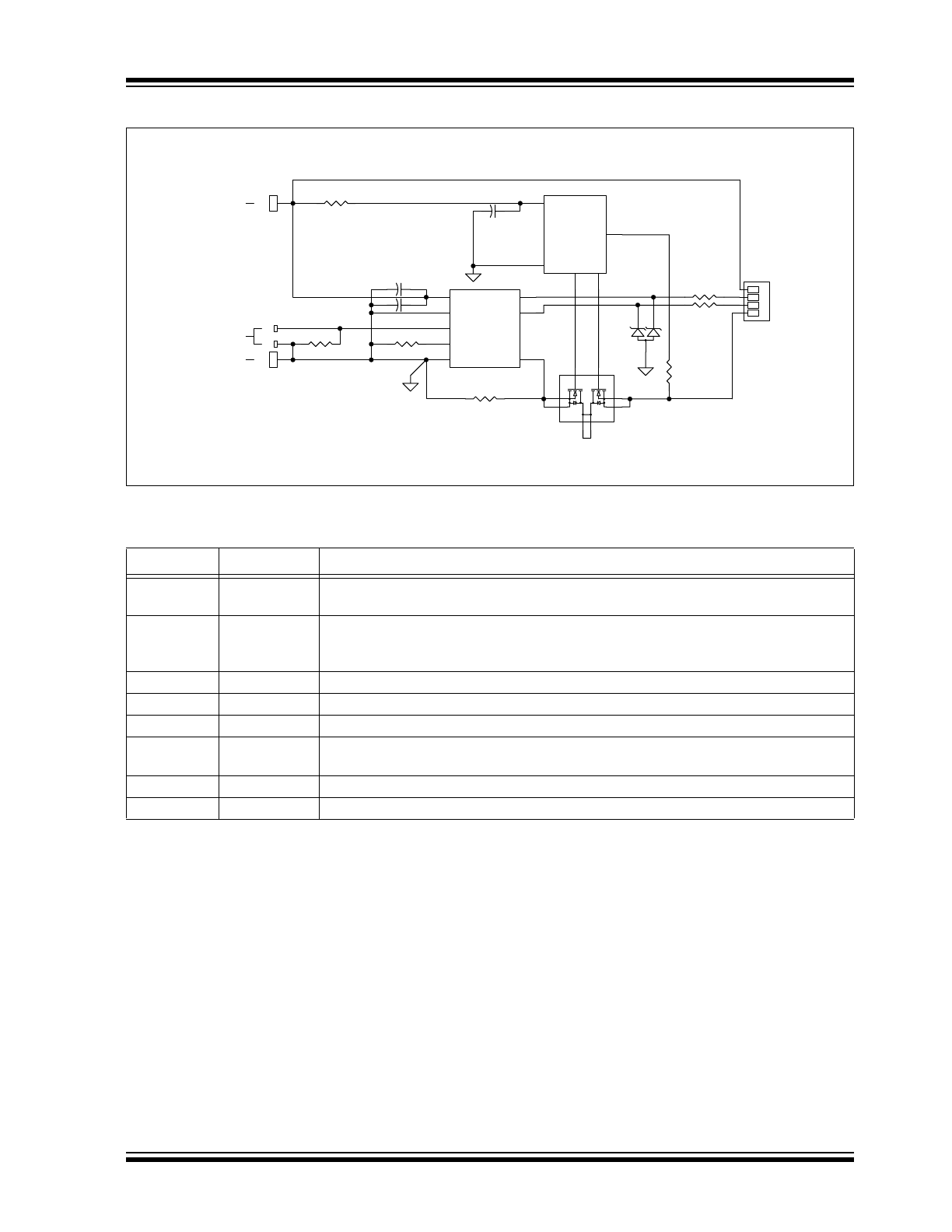

FIGURE 1-2:

APPLICATION SCHEMATIC – PS700-BASED BATTERY PACK

TABLE 1-1:

PIN DESCRIPTIONS

R15

1.0K

R3

221K

R4

680

R5

680

V

CELL

1

2

V

CELL

2

1

NTC

6

SR

8

GND

7

SMB-CLK

3

SMB-DTA

4

R

OSC

5

U1

PS700

R11

470

VR

V1

NTC1

NTC2

PACK CONNECTION

CELL POSITIVE (+)

CELL NEGATIVE (-)

THERMISTOR CONNECTIONS

B+

C

D

B-

R8

0.020

C11

100 nF

C1

100 nF

R7

6.49K

3

1

2

D1

CMSZDA5V6

CONNECTION

GROUND PLANE

C3

1.0 nF

3

4

2

1

5

6

8

7

Q1

SI6880EDQ

V

DD

2

V

SS

3

VM

1

CO

5

DO

4

U2

S8241A

Pin No.

Pin Name

Description

1

VC2/IO1

Cell input connection for lowest cell in a 2-cell series Li Ion pack. Can also be

configured as an open-drain general purpose input/output.

2

VC1

Cell input connection for highest cell in a 2-cell series Li Ion pack. Connects to the

positive terminal of 1-cell series packs. VC1 serves as the power supply input for the

PS700.

3

SCL

SMBus/I

2

C clock line connection.

4

SDA

SMBus/I

2

C data line connection.

5

R

OSC

External bias resistor.

6

NTC/IO0

Input for an external temperature sensor using a 103ETB-type thermistor. Can also

be configured as a general purpose input/output pin.

7

GND

Analog and digital ground.

8

SR

Current measurement A/D input from positive side of the current sense resistor.

PS700

DS21760F-page 4

2004 Microchip Technology Inc.

2.0

ARCHITECTURAL OVERVIEW

The PS700 contains a complete analog “front-end” for

battery monitoring as well as digital logic for control, mea-

surement accumulation, timing and communications.

Major functions within the PS700 include:

• Voltage Regulator

• Precision Time Base

• Temperature Sensor

• 512-Byte EEPROM Memory

• 32-Byte RAM Memory

• Analog-to-Digital (A/D) Converter

• 32-bit Accumulators/Timers

• SMBus/I

2

C Communications Interface

Figure 1-1 is a block diagram of the internal circuitry of

the PS700. Figure 1-2 is a schematic diagram that

depicts the PS700 in a typical single cell Lithium Ion

application. The function of each of the blocks listed

above is summarized in the following sections.

2.1

Internal Voltage Regulator

The PS700 incorporates an internal voltage regulator

that supports 1 or 2-cell series lithium pack configura-

tions. The internal regulator draws power directly from

the VC1 input. No other external components are

required to regulate internal supply voltage.

2.2

Precision Time Base

The integrated precision time base is a highly accurate

RC oscillator that provides precise timing for the sigma-

delta A/D and for the on-chip elapsed time counters

without the need for an external crystal. This time base

is trimmed during manufacturing to a nominal

frequency of 131,072 Hz.

2.3

Temperature Sensor

An integrated temperature sensor is provided that can

eliminate the need for an external thermistor. As an

option, a connection is provided for an external

thermistor for applications where the battery pack is

physically located at a distance away from the PS700.

2.4

EEPROM Memory

512 bytes of EEPROM memory are incorporated for

storage of nonvolatile parameters, such as

PowerSmart

®

3D cell models for use with host driver

firmware. An initialization block is reserved within the

EEPROM array for values that are loaded into PS700

registers following a power-on condition.

2.5

RAM Memory

32 bytes of general purpose RAM memory are

provided for storage of temporary parameters.

2.6

A/D Converter

The PS700 incorporates an integrating sigma-delta

A/D converter together with an analog mux that has

inputs for charge and discharge current, cell and pack

voltages, the on-chip temperature sensor and an off-

chip thermistor. The converter can be programmed to

perform a conversion with resolutions of 8 to 15 bits plus

sign while utilizing either a ±340 mV or a ±170 mV

reference.

2.7

32-Bit Accumulators/Timers

The PS700 incorporates four 32-bit accumulators and

four 32-bit elapsed time counters. The Discharge

Current Accumulator (DCA) and the Charge Current

Accumulator (CCA) are intended to record discharge

and charge capacity values. The Discharge Time

Counter (DTC) and the Charge Time Counter (CTC)

are intended to maintain the total discharge time and

charge time. Accumulated charge and discharge

values can be used to determine state of charge of the

battery as well as cycle count information. With

information provided by the elapsed time counters,

average charge and discharge currents over an

extended period of time can be calculated.

2.8

SMBus/I

2

C Communications

Interface

The communications port for the PS700 is a 2-wire

industry standard SMBus/I

2

C interface. All commands,

status and data are read or written from the host

system via this interface.

2004 Microchip Technology Inc.

DS21760F-page 5

PS700

3.0

OPERATIONAL DESCRIPTION

3.1

A/D and Accumulator/Timer

Operation

3.1.1

A/D CONVERSION CYCLE

When the A/D converter is enabled and active, it

repeatedly performs a cycle of 1 to 8 conversions as

programmed by the user through 8 A/D Control

registers. These registers determine the input source,

resolution, reference voltage source and sequence of

conversions during an A/D converter cycle. During the

cycle, the A/D logic accesses each register in

sequence and performs the conversion specified by the

bits within the register. This register contains an enable

bit, a resolution field, a select bit for a single-ended or

differential reference and a select field for the analog

input mux. The results from each conversion are stored

in one of eight corresponding16-bit result registers.

If the “enable” bit is set within a control register, a

conversion will be performed. If it is disabled, that

conversion will be skipped and the logic will move on to

the next register. In this manner, the user can specify a

sequence of conversions that will be performed during

each A/D cycle.

As stated above, the input source for each of the

registers is programmable. The 3-bit mux field within

each control register selects one of seven possible

input sources for the A/D conversion. The list of input

sources is as follows:

• Charge/Discharge Current (voltage from SR pin to

GND)

• Internal Temperature Sensor

• External Thermistor (constant current source on

NTC pin)

• Battery Pack Voltage

• VC1 Voltage

• VC2 Voltage

• A/D Offset (conversion performed with input

shorted internally to determine offset error

associated with the converter)

However, the accumulator/timer functions are “hard

wired” to specific A/D Result registers. For this reason,

the control/result registers are given names which

indicate their primary intended usage (see Table 3-1).

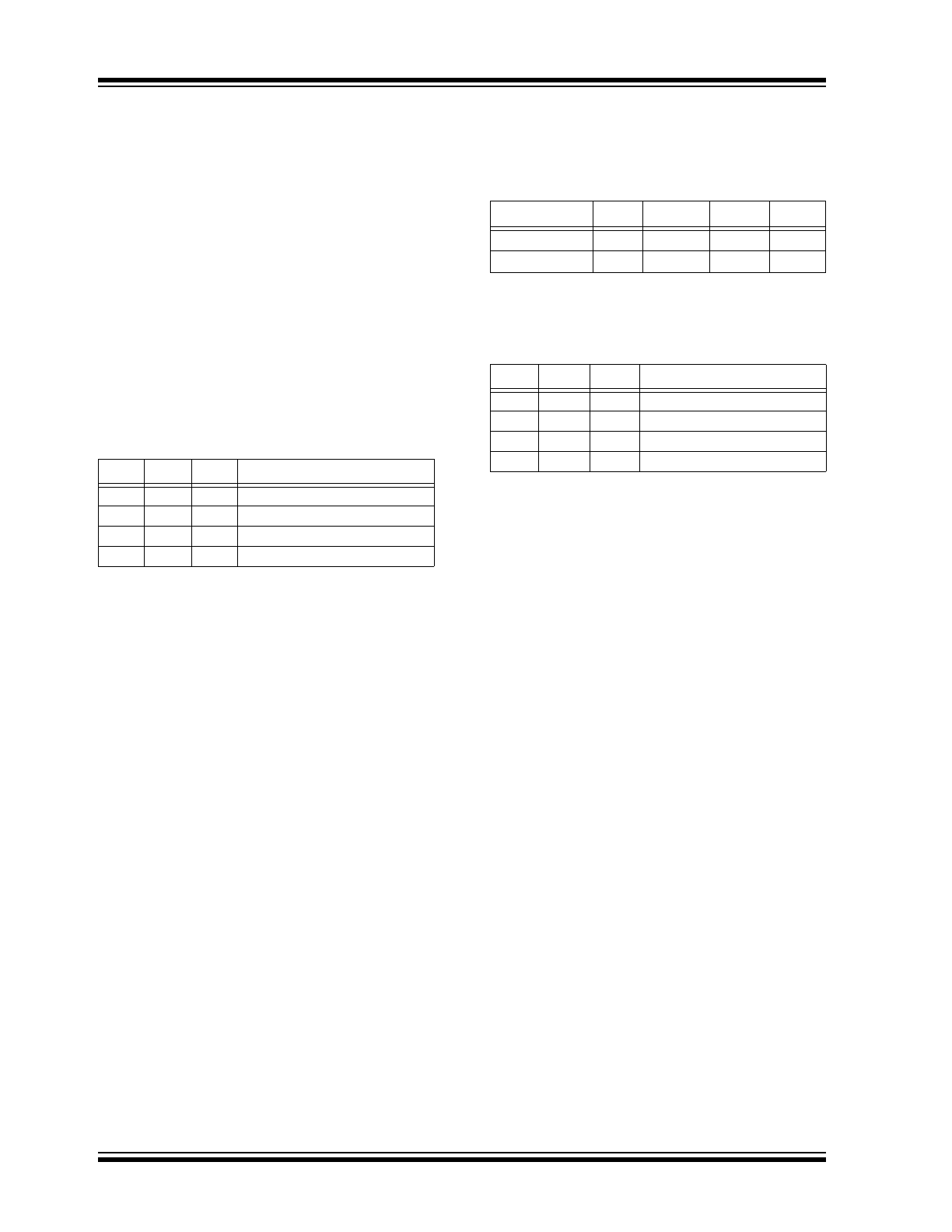

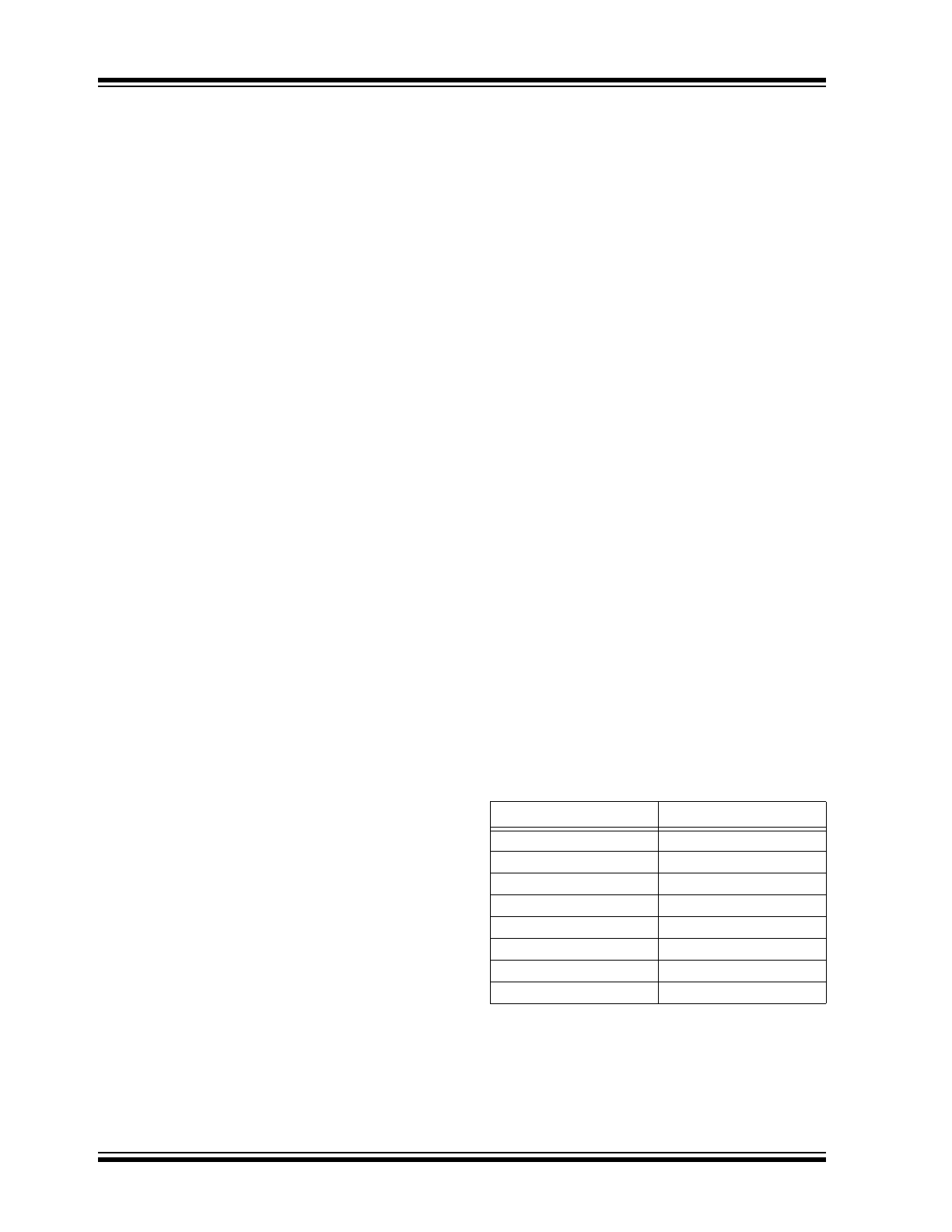

TABLE 3-1:

A/D CONTROL/RESULT REGISTERS

The 3-bit “resolution” field in each A/D Control register

determines the resolution of the conversion, from a

minimum of 9 bits (8 bits plus sign bit) to a maximum of

16 bits (15 bits plus sign bit). The time required to

complete the conversion is a function of the number of

bits of resolution (n) selected. The conversion time can

be calculated as follows:

T

ADC

= 30.52

µs * 2

n

where:

“n” is the number of bits of resolution selected

The “Ref” bit selects the magnitude of the reference

voltage. Either a ±340 mV or a ±170 mV reference is

available. The ±170 mV reference is typically used for

current readings and the ±340 mV reference for all

other measurements.

The value of the LSB can be expressed as a function of

the resolution selected as follows:

A/D LSB = 680/340 mV/2

n

where:

“n” is the number of bits of resolution selected

The result value is given in sign/magnitude format (i.e.,

a sign bit with a 15-bit magnitude).

A/D Register #

Control Register

Result Register

Intended Input Source

0

Ictrl

Ires

Battery Pack Current (via sense resistor)

1

ITctrl

ITres

Internal Temperature Sensor

2

ETctrl

ETres

External Temperature Sensor

3

VPctrl

VPres

Battery Pack Voltage (VC1 to GND)

4

VC1ctrl

VC1res

Battery Cell Voltage (VC1 to VC2)

5

VC2ctrl

VC2res

Battery Cell Voltage (VC2 to GND)

6

OFFSctrl

OFFSres

Internal A/D Offset Voltage (A/D input automatically

internally shorted to GND)

7

AUXctrl

AUXres

Any

15

0

S

Magnitude

PS700

DS21760F-page 6

2004 Microchip Technology Inc.

3.1.2

CURRENT MEASUREMENT

Charge and discharge currents are measured using a

5 to 600 m

Ω

sense resistor that is connected between

the SR and GND pins. The maximum input voltage at

SR is ±150 mV. The sense resistor should be properly

sized to accommodate the systems lowest and highest

expected charge and discharge currents including

suspend and/or standby currents.

In order to perform charge and discharge current

measurements, the Ictrl register must be programmed

with the SR pin as the analog input source. If charge

and discharge accumulation is desired, the Ictrl and

corresponding Ires registers should be used to select

current measurement since the DCA, DTC, CCA and

DCA registers are updated by the measurement results

from the Ires register.

Ictrl programming in a typical application is as follows.

TABLE 3-2:

Ictrl PROGRAMMING

Using the maximum resolution of 16 bits, the voltage

value of the LSB is:

A/D LSB = 340 mV/2

16

= 5.19

µV

Using a sense resistor value of 20 m

Ω

, the value of the

LSB in units of current is:

5.19

µV/20 mΩ = 259 µA

3.1.3

VOLTAGE MEASUREMENTS

Analog mux inputs are provided to support measure-

ment of individual cell and battery pack voltages. A/D

control registers VPctrl, VC1ctrl and VC2ctrl are used

to specify the measurement to be made. In typical

applications, voltage measurement at the cell or pack

level is done using the +340 mV reference and a

resolution of 10 bits plus sign bit.

The value of the LSB in a pack voltage measurement

using a 340 mV reference voltage is given by the formula:

V

PACK

LSB = 10.2V/2

n

Where “n” is the resolution selected. For typical

applications where n = 10:

V

PACK

LSB = 10.2V/2

10

= 10.2V/1024 = 9.96 mV

The value of the LSB in a cell voltage measurement

using a 340 mV reference voltage is given by the

formula:

V

CELL

LSB = 6.23V/2

n

Where “n” is the resolution selected. For typical

applications where n = 10:

V

CELL

LSB = 6.23V/2

10

= 6.23V/1024 = 6.08 mV

The following table shows LSB values for 9-bit plus

sign resolution, so n = 9.

TABLE 3-3:

LSB VALUES FOR 10-BIT

RESOLUTION

VPctrl programming in a typical application is as

follows.

TABLE 3-4:

VPctrl PROGRAMMING

The input source fields for the VPctrl, VC1ctrl and

VC2ctrl registers must be programmed to select pack

voltage (on VC1), VC1 cell voltage and VC2 cell

voltage in order for these registers to control their

intended measurements.

3.1.4

TEMPERATURE MEASUREMENTS

A/D input channels are provided for temperature mea-

surement using either the internal temperature sensor

or an external thermistor.

3.1.4.1

Internal Temperature

The output of the internal temperature sensor is a volt-

age range with limits that correspond to operating

temperature limits as follows:

-20°C

→

239 mV

+70°C

→

312 mV

The output voltage of the internal sensor as a function

of temperature can be given as:

V

IT

(mV) = 239 + 0.82 * (T + 20)

Defined within the ITctrl registers are the settings for

the reference utilized and the resolution desired for

measurement of temperature using the internal tem-

perature sensor. Because of input voltage range

described above, the 340 mV reference should be

selected. Typically, 10-bit plus sign of resolution are

selected which results in the following temperature

resolution:

LSB (Voltage) = Full Scale Range/# of steps

= 340 mV/2

10

= 332

µV/LSB

LSB (°C)

= 332

µV/LSB * (1 / 820) °C/µV

= 0.404°C/LSB

Bit(s)

Name

Value

Function

7

En

1

Enables A/D conversion

6-4

Res

111

Selects 16-bit resolution

3

Ref

0

Selects ±170 mV reference

2-0

Sel

000

Selects V

SR

as converter input

Measurement

VR

Divider

Bits

LSB

V

PACK

340

1/30

9 + sign

19.92

V

CELL

340

1/18.33

9 + sign

12.17

Bit(s)

Name

Value

Function

7

En

1

Enables A/D conversion

6-4

Res

001

Selects 10-bit resolution

3

Ref

1

Selects ±340 mV reference

2-0

Sel

011

Selects V

SR

as converter input

2004 Microchip Technology Inc.

DS21760F-page 7

PS700

3.1.4.2

External Temperature

For temperature measurement using an external sensor,

the NTC pin supplies a constant current source of

12.5

µ

A. For proper operation, an industry standard

10 kOhm at 25°C negative temperature coefficient

(NTC) device of the 103ETBtype, should be connected

between NTC and GND. The NTC reference output is

only enabled during an external temperature

measurement in order to minimize power consumption.

The output of the current source, connected to the

external thermistor, produces a voltage range with

limits that correspond to operating temperature limits,

as follows:

-20°C

→

263 mV

+70°C

→

317 mV

The output voltage of the external sensor as a function

of temperature can be given as:

V

EX

(mV) = 263 + 0.6 * (T + 20)

Defined within the ETctrl registers are the settings for the

reference utilized and the resolution desired for mea-

surement of temperature using the external temperature

sensor. Again, the 340 mV reference should be

selected. The following temperature results in a 10-bit

conversion:

LSB (Voltage) = Full Scale Range/# of steps

= 340 mV/2

10

= 332

µV/LSB

LSB (°C)

= 332

µV/LSB * (1/600)°C/µV

= 0.553°C/LSB

3.1.5

OFFSET COMPENSATION

The host software can perform offset compensation by

using an offset measurement value read from the

PS700. When the offset calibration is enabled within

the OFFSctrl register, the converter inputs are

internally shorted together and an A/D conversion is

performed at the specified resolution. The offset value

is stored in the OFFSres register.

3.1.6

ACCUMULATION/TIMING

The PS700 incorporates four 32-bit accumulators and

four 32-bit elapsed time counters. The Discharge Current

Accumulator (DCA) and the Charge Current Accumula-

tor (CCA) are intended to record discharge and charge

capacity values. The Discharge Time Counter (DTC) and

the Charge Time Counter (CTC) are intended to maintain

the total discharge time and charge time. Accumulated

charge and discharge values can be used to determine

state of charge of the battery as well as cycle count infor-

mation. With information provided by the elapsed time

counters, average charge and discharge currents over

an extended period of time can be calculated.

Each of the four 32-bit accumulator registers is assigned

a fixed “source” A/D Result register. When the accumu-

lator is enabled, it is updated every 500 ms by adding the

contents of the assigned result register value to the

previous accumulator value. The accumulators are

listed in Table 3-5 with their assigned source registers.

TABLE 3-5:

ACCUMULATOR REGISTERS

The resolution of the accumulated value is equal to the

resolution selected for the associated conversion, up to

a converter resolution of 15-bit plus sign. If a 15-bit plus

sign A/D value is being accumulated, then the

accumulator resolution in microvolt seconds is:

Accumulator LSB (

µVs) = (Full Scale Range/# of steps)

* 0.5s = (340 mV/2

15

) * 0.5s

= 5.19

µVs

3.1.7

CHARGE/DISCHARGE

ACCUMULATORS

The DCA register is intended to accumulate discharge

current and the CCA register is intended to accumulate

charge current. Both use the Ires register as its source.

For this reason, in most applications, current measure-

ment defined in the A/D Control registers should be

programmed to measure current by reading the voltage

across the Sense Resistor pin (SR).

During charging, a negative voltage will exist across

the SR pin to ground. Following a conversion, a

positive voltage measurement results in the sign bit =

0

in the Ires register. When the sign bit =

0

, the measured

result will be added to the CCA register contents and

the sum is returned to CCA.

In this way, the total charge current will be accumulated

in CCA.

Similarly, during discharge, a positive voltage will exist

between the SR pin and ground. In this case, the

conversion will result with sign bit =

1

in the Ires regis-

ter, indicating a negative value or discharge current

condition. Under this condition, the DCA register will be

updated with the discharge current measured during

that conversion.

The value stored in the DCA or CCA register can be

interpreted as illustrated in the following example.

Using a 16-bit signed conversion for current measure-

ment and a 20 m

Ω

sense resistor, the LSB can be

expressed in units of capacity in micro amp seconds as

follows:

Accumulator LSB (

µAs) = Voltage LSB/R

SENSE

=

(2.59

µVs)/20 mΩ = 130 µAs

The “Accum” bit in the Accumctrl register must be

enabled for accumulation to occur in both the CCA and

DCA registers.

Abbr.

Accumulator Name

Source

DCA

Discharge Current

Accumulator

Ires (Sign bit =

1

)

CCA

Charge Current

Accumulator

Ires (Sign bit =

0

)

TA

Temperature Accumulator

ITres or ETres

VC2A

VC2 Accumulator

VC2res

PS700

DS21760F-page 8

2004 Microchip Technology Inc.

3.1.8

CHARGE/DISCHARGE TIME

COUNTERS

The Charge Time Counter (CTC) will increment at the

rate of 2 counts every second as long as a negative

voltage is measured at the SR pin. The CTC can

thereby maintain a time count representing the total

time that charge current has flowed into the battery.

The Discharge Time Counter (DTC) will increment at

the rate of 2 counts every second as long as a positive

voltage is measured at the SR pin. The DTC can

thereby maintain a time count representing the total

time that discharge current has flowed from the battery.

3.1.9

GENERAL PURPOSE

ACCUMULATORS

There are two general purpose accumulators, TA and

VC2A. For typical applications, these accumulators

have been assigned specific functions. The user can

redefine the use of these accumulators to fit the design

requirements.

TA can be used to accumulate results from the ITres or

ETres registers. Accumulation to TA must be enabled

in the Accumctrl register bit “AccT”. The selection for

accumulation of the values represented by the internal

or external thermistor is also determined in the

Accumctrl register bit “tsel”.

VC2A can be used to accumulate results from VC2res.

Accumulation in VC2A must be enabled in the

Accumctrl register bit “AccV”. The value stored in

VC2res corresponds to the measurement as defined in

the A/D Control register VC2ctrl. This function is

utilized if the VC2 pin is configured as an independent

A/D input and not connected to the cell stack.

The “Accum” bit in the Accumctrl register must be

enabled for accumulation to occur in TA and VC2A.

3.1.10

GENERAL PURPOSE TIMERS

There are two general purpose timers that are enabled

by accumulation in the TA and VC2A accumulators.

TAT is used to maintain a time count during accumula-

tion in the TA register. This timer increments at a

frequency of 2 counts every second.

VC2T is used to maintain a time count during

accumulation in the VC2A register. This timer

increments at a frequency of 2 counts every second.

3.2

Power Modes

The PS700 has four operational power modes: Run,

Sample, Sample-Sleep and Shelf-Sleep. Each con-

sumes power according to the configuration settings as

described in the following sections.

3.2.1

RUN MODE

During Run mode, the PS700 performs continuous A/D

conversion cycles per the programming of the A/D

conversion cycle documented in Section 3.1.1 “A/D

Conversion Cycle”. As described above, during each

cycle, between 1 and 8 conversions are performed and

the accumulators/time counters are updated as

programmed by the user.

Run mode is entered following a Power-on Reset when

the pack voltage (V

PACK

) applied on the VC1 pin rises

above the V

POR

threshold. Run mode can also

be entered from the Sample, Sample-Sleep and

Shelf-Sleep modes as described below.

The PS700 will remain in Run mode as long as the pack

voltage is above the V

POR

threshold and the Sample,

Sample-Sleep and Shelf-Sleep modes are not active.

3.2.2

SAMPLE MODE

In Sample mode, A/D measurements are not continu-

ously performed as in Run mode. Instead, they are

performed at a user selectable rate. The purpose of

Sample mode is to reduce power consumption during

periods of low rate charge or discharge. The power

advantage of Sample mode comes from the reduction

in frequency of A/D measurements.

Sample mode is entered by programming the “Samp”

bit =

1

in the A/D Configuration register. The PS700 will

remain in Sample mode as long as “Samp” bit =

1

and

the VC1 voltage is above the V

POR

threshold and the

Sample-Sleep and Shelf-Sleep modes are not active.

Run mode will be resumed when the Samp bit is

cleared to ‘

0

’.

The Sample mode rate is selected using the “SampDiv”

bits within the A/D Configuration register. The sample

interval is 2**(SampDiv) * 0.5 sec. The possible sample

rate intervals are as follows.

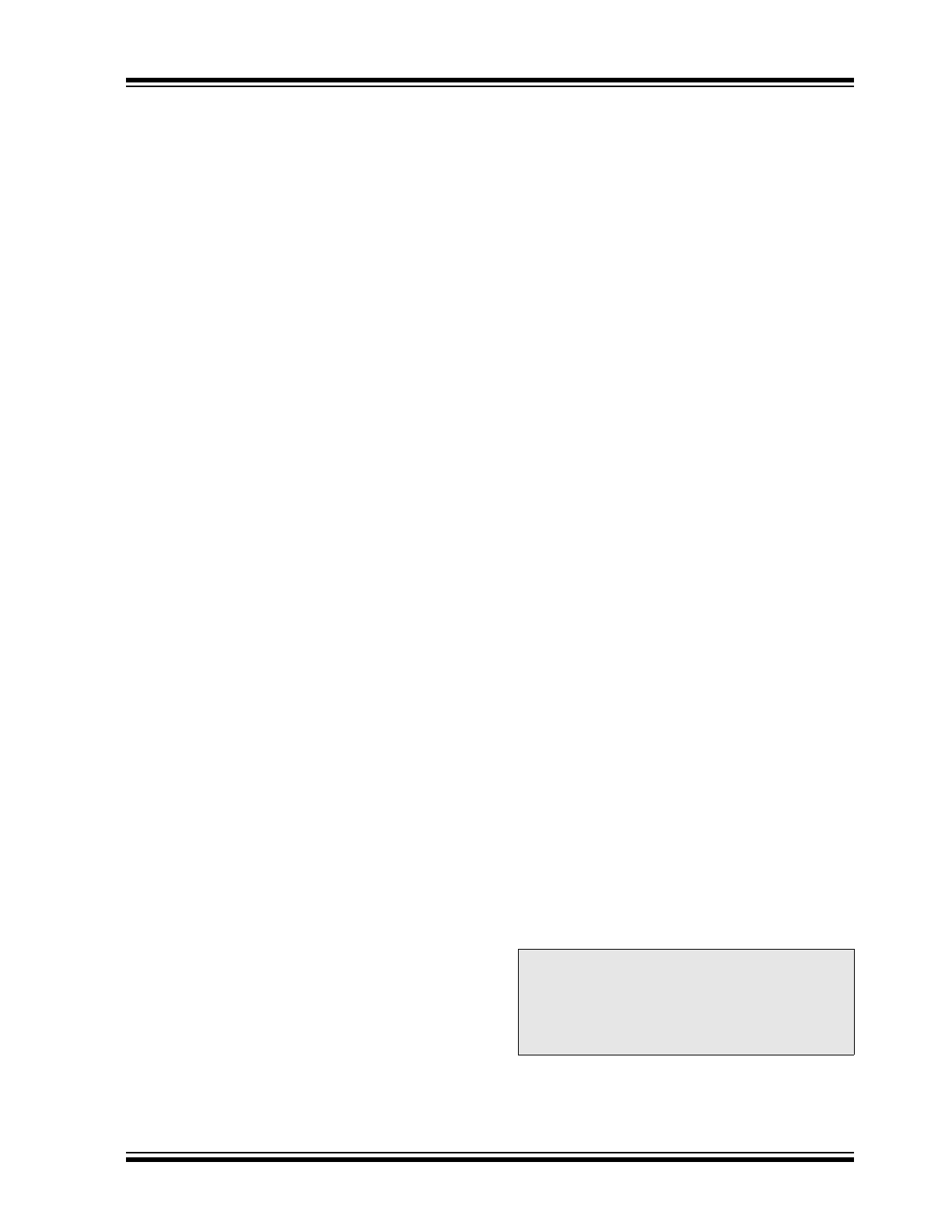

TABLE 3-6:

SAMPLE RATE INTERVALS

In Sample mode, much of the analog circuitry remains

on. Therefore, the power savings are not as great as in

Sample-Sleep mode (described below). Refer to

Section 6.0 “Electrical Characteristics” for a specifi-

cation of the amount of current consumed in Sample

mode.

“SampDiv”

Sample Interval

Value = 0

0.5s

Value = 1

1.0s

Value = 2

2.0s

Value = 3

4.0s

Value = 4

8.0s

Value = 5

16.0s

Value = 6

32.0s

Value = 7

64.0s

2004 Microchip Technology Inc.

DS21760F-page 9

PS700

3.2.3

SAMPLE-SLEEP MODE

In Sample-Sleep mode, the PS700 goes into the Sleep

state and wakes up at user-programmed intervals to

perform a set of conversions as programmed for the

A/D cycle. The purpose of Sample-Sleep is to achieve

the minimum power consumption possible while

periodically measuring specified parameters.

While the PS700 is in the Sleep portion of Sample-

Sleep interval, all of the analog circuitry is shut off. The

Sleep interval time is driven by an independent low-

power on-chip RC oscillator that is separate from the

primary oscillator. The Sleep oscillator consumes much

less power than the primary oscillator, but is less

accurate. While in Sample-Sleep mode, the device

consumes average current in the range of 20

µ

A.

During the active portion of Sample-Sleep mode, a

single set of conversions is performed and a Run mode

current in the range of 85

µ

A will be consumed for the

duration of the measurements.

Sample-Sleep mode is invoked by one of the following

actions:

1.

Cell voltage on VC1 or VC2 drops below the trip

point programmed in the VCtrip register with the

corresponding “VC1ent” or “VC2ent” bit set in

the TRIPctrl register. This action can be used to

prevent excessive battery discharge in the event

of a dangerously low cell voltage. Be aware that

Sample-Sleep will not be entered if the “lex” bit

is set, enabling wake-up based on charge

current and the measured current is above the

threshold set in the I+trip register.

2.

Setting the SSLP bit in the OpMode register.

The host can take this action when the system is

entering a low-power standby condition and it is

desired to periodically measure and accumulate

current, voltage, or temperature.

3.

Current less than the I-trip register value when

“Ient” bit is set in the TRIPctrl register.

The Sample-Sleep interval is determined by the

programming of the “Sampdiv” bits within the A/D Con-

figuration register, together with the “SSLPdiv” bits

within the OpMode register. The sample interval is

2**(Sampdiv) * 2**(SSLPdiv) * 0.5 sec. The possible

Sample-Sleep interval time, therefore, ranges from a

minimum of 0.5 sec to over 136 minutes.

Exit from Sample-Sleep mode to Run mode can be

accomplished by clearing the “SSLP” bit or by program-

ming a wake-up based on pack voltage or current.

Wake-up based on charge current will occur when the

“Iex” bit is set in the TRIPctrl register and the charging

current value is above the threshold programmed in the

I+trip register. Wake-up based on pack voltage will

occur when the “VPex” bit is set in the TRIPctrl register

and the pack voltage rises above the threshold

programmed in the SStrip register.

3.2.4

SHELF-SLEEP MODE

Shelf-Sleep mode is the lowest power mode and is

intended to preserve battery capacity when the battery

pack is shipped or stored or if the battery voltage drops

below a specified threshold. While in Shelf-Sleep

mode, no measurements occur, no accumulation is

performed and no SMBus communications are

recognized. In addition, volatile memory is not

maintained.

Entry to Shelf-Sleep mode is enabled by programming

the “SHent” bit =

1

or if V

PACK

is less than VPtrip. The

Shelf-Sleep mode will then be entered when the

SMBus pins (both SDA and SCL) drop from a high to a

low level for a minimum time period specified by t

SHELF

.

This action will also occur if the battery pack is

physically disconnected from the system.

Exit from the Shelf-Sleep mode back to Run mode will

occur when the SMBus pins (both SDA and SCL) are

both pulled from a low to high condition and remain

high for a minimum time of t

WAKE

, signifying system

activity or the connection of the pack to the host.

3.3

General Purpose Input/Outputs

The NTC and VC2 pins have alternate functions of

general purpose I/O; IO0 and IO1, respectively. These

pins can be configured as digital general purpose

inputs/outputs if their normal application functions of

temperature and cell monitoring are not needed. Their

configuration is controlled in the GPIOctrl register.

The IO0 (NTC) pin may be configured as a push-pull

output, an open-drain driver with internal pull-up, or as

a tri-stated pin. When configured as a push-pull or

open-drain output, the output high voltage is the 3.0V

internally regulated supply. When the output function is

disabled, an external circuit may drive the pin as an

input with a voltage range of 0-3.0V. The input function

may be used whether or not the pin is driven by the

PS700. In addition, the input function may be disabled,

in which case the input buffer is powered down,

preventing current drain if the NTC pin rests at an

intermediate level.

The IO1 (VC2) pin is similar to that of NTC except it is

an open-drain output only. IO1 has no explicit output

enable control; therefore, if the output is set to a logic

‘

1

’, the internal pull-down is turned off which tri-states

the pin. The input function is the same as IO0.

Note:

If the IO0 and/or IO1 pins are being used

for their analog functions, their respective

GPIO output and input functions must be

disabled. The GPIO function may be

totally disabled by clearing the appropriate

GPIOctrl bit.

PS700

DS21760F-page 10

2004 Microchip Technology Inc.

3.4

SMBus/I

2

C Interface

The PS700 supports a 2-wire bidirectional bus and

data transmission protocol that is fully compatible with

the industry standard SMBus V1.1 based on the I

2

C

interface. This interface is used to read and write data

from/to the on-chip registers and EEPROM. The device

responds to the same SMBus slave address for access

to all functions. The following is a brief overview of the

SMBus/I

2

C operational implementation in the PS700.

Please refer to the SMBus v1.1 specification for

complete operational details of this industry standard

interface. This specification can be obtained at the

SMBus Implementer’s Forum web site at

www.smbus.org.

3.4.1

SMBus OVERVIEW

SMBus is a two-wire multi-master bus, meaning that

more than one device capable of controlling the bus

can be connected to it. A master device initiates a bus

transfer and provides the clock signals. A slave device

can receive data provided by the master or can in

return provide data to the master.

Since more than one device may attempt to take

control of the bus as a master, SMBus provides an

arbitration mechanism based on I

2

C and relying on the

wired-AND connection of all SMBus devices residing

on the bus. If two or more masters try to place informa-

tion on the bus, the first to produce a “one” when the

other(s) produce a “zero” loses arbitration and has to

release the bus.

The clock signals during arbitration are a wired-AND

combination of all the clocks provided by SMBus

masters. Bus clock signals from a master can only be

altered by clock stretching or by other masters and only

during a bus arbitration situation. In addition to bus

arbitration, SMBus implements the I

2

C method of clock

low extending in order to accommodate devices of

different speeds on the same bus.

SMBus version 1.1 can be implemented at any voltage

between 3 and 5 Volts ±10%. Devices can be powered

by the bus V

DD

or by their own power source (such as

Smart Batteries) and they will interoperate flawlessly as

long as they adhere to the SMBus electrical

specifications.

3.4.2

SMBus DATA TRANSFERS

A device that sends data onto the SMBus is defined as

a transmitter and a device receiving data as a receiver.

The device that controls the message is called a

“master”. The devices that are controlled by the master

are “slaves”. The SMBus must be controlled by a

master device that generates the serial clock (SCL),

controls the bus access and generates Start and Stop

conditions. The PS700 operates as a slave on the two-

wire bus. Connections to the bus are made via the

open-drain I/O lines SDA and SCL.

SMBus operates according to the following bus

protocol:

• Data transfer may be initiated only when the bus

is not busy.

• During data transfer, the data line must remain

stable whenever the clock line is high. Changes in

the data line while the clock line is high will be

interpreted as control signals.

The SMBus specification defines the following bus

conditions:

Bus Not Busy: Both data and clock lines remain high.

Start Data Transfer: A change in the state of the data

line from high to low, while the clock is high, defines a

Start condition.

Stop Data Transfer: A change in the state of the data

line from low to high, while the clock line is high, defines

the Stop condition.

Data Valid: The state of the data line represents valid

data when, after a Start condition, the data line is stable

for the duration of the high period of the clock signal.

The data on the line must be changed during the low

period of the clock signal. There is one clock pulse per

bit of data. Each data transfer is initiated with a Start

condition and terminated with a Stop condition. The

number of data bytes transferred between Start and

Stop conditions is not limited and is determined by the

master device. The information is transferred byte-wise

and each receiver Acknowledges with a ninth bit.

Acknowledge:

Each receiving device, when

addressed, is obliged to generate an Acknowledge bit

after the reception of each byte. The master device

must generate an extra clock pulse which is associated

with this Acknowledge bit.

A device that Acknowledges must pull down the SDA

line during the Acknowledge clock pulse in such a way

that the SDA line is stable low during the high period of

the Acknowledge related clock pulse. Of course, setup

and hold times must be taken into account. A master

must signal an end of data to the slave by not generat-

ing an Acknowledge bit on the last byte that has been

clocked out of the slave. In this case, the slave must

leave the data line high to enable the master to

generate the Stop condition.