R&E International

A Subsidiary of Microchip Technology Inc.

RE46C108

Piezoelectric Horn Driver and Voltage Regulator

Product Specification

General Description

The RE46C108 is a piezoelectric horn driver with a

voltage regulator that can operate at 3.3V or 5V. It

is intended for applications requiring a 9V horn

driver with a low voltage logic supply. The horn

feedback control pin is designed for use with self-

oscillating piezoelectric horn but can also be used in

direct drive applications.

Applications

Smoke detectors

CO Detectors

Personal Security Products

Electronic Toys

Features

• Low Quiescent Current

• Low Horn Driver Ron

• Voltage Regulation to 3.3V or 5V

• Available in DIP and SOIC packaging

•

Available in Standard Packaging or RoHS

Compliant Pb Free Packaging

Pin Configuration

REGSEL

VDD

REGOUT

FEED

HRNEN

HORNS

HORNB

VSS

1

8

Absolute maximum ratings

Supply Voltage Vdd ........………………………………….......-.5V to +14V

Input voltage Range Vin ...…………………………………..... -.3V to VDD+.3V, except FEED

FEED Input Voltage Range Vinf …………………………...… -10V to +22V

Input Current Iin ..............…………………………………..... 10mA, except FEED

Operating Temperature .......………………………………….. -40 to 85

°C

Continuous Output Current (HornS, HornB) .……………….. 30mA

Continuous Output Current (REGOUT) .…………………….. 55mA

Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These

are stress ratings only and operation at these conditions for extended periods may affect device reliability.

This product utilizes CMOS technology with static protection; however proper ESD prevention procedures should be

used when handling this product. Damage can occur when exposed to extremely high static electrical charges

© 2009 Microchip Technology Inc.

DS22165A-page 1

RE46C108

Piezoelectric Horn Driver and Voltage Regulator

R&E International

Product Specification

A Subsidiary of Microchip Technology

Inc.

© 2009 Microchip Technology Inc.

DS22165A-page 2

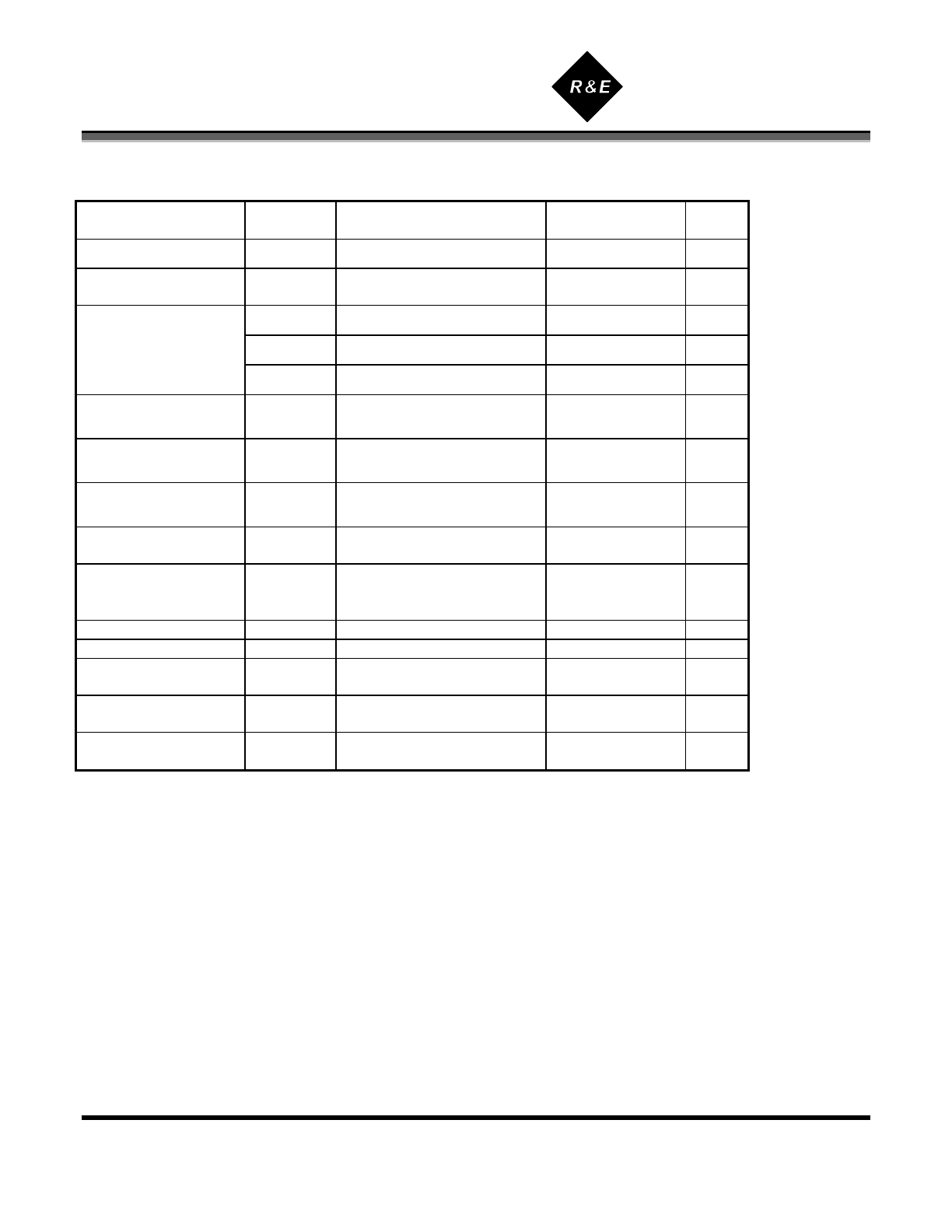

Electrical Characteristics at TA = 25°C, VDD = 9V, Vss = 0V (unless otherwise noted).

Parameter

Test

Pin

Test Conditions

Limits

Min Typ Max

Units

Supply Voltage

Vdd

Operating

6.0 9.0 13.8

V

Standby Supply

Current

Vdd

Hrnen=Vss; No Loads

4

uA

Input Leakage

Hrnen,Resel

Vin=Vdd or Vss

-100 100

nA

FEED

Feed = +22V

20 50

uA

FEED

Feed = -10V

-50 -15

uA

Input Voltage Low

Hrnen,

Regsel

1.0

V

Input Voltage High

Hrnen,

Regsel

2.3

V

Output Low Voltage

Horns or

Hornb

Iout=16mA; Vdd=9V

Vdd=7.2V

0.3 0.5

0.9

V

V

Output High Voltage

Horns or

Hornb

Iout=-16mA; Vdd=9V

Vdd=7.2V

8.5 8.7

6.3

V

V

Regulator Voltage

Regout

Iout<50mA; Regsel=Vdd

Iout<50mA; Regsel=Vss

T

A

=-40 to 85

°C

See note #3

4.75 5.0 5.25

3.10 3.3 3.50

V

V

Line Regulation

Regout

6V<Vdd<12V; No load

30

mV

Load Regulation

Regout

0mA<Iout<20mA

100

mV

Brown-Out Threshold

Voltage

*See note #1

Vdd

Regsel=Vdd or Vss

Falling edge of Vdd

4.5 5.0 5.5

V

Brown-Out Pull Down

Current

Regout

Vdd=4.5V; Regout=2V

15 25

mA

Regout Overvoltage

Clamp

*See note #2

Regout

Regsel=Vdd; Iout > 1mA

Regsel=Vss; Iout > 1mA

5.5 6.0 6.5

3.7 4.0 4.3

V

V

Notes:

1/ The brown-out threshold voltage is the Vdd voltage at which the regulator will be disabled and Regout will be

pulled to Vss.

2/ In normal operation, the regulator will provide high-side current of up to 20mA, but current sinking capability is

typically under 1uA. The overvoltage clamp is intended to limit the voltage at Regout when it is pulled up by an

external source.

3/ The limits shown are 100% tested at 25C only. Test limits are guard-banded based on temperature

characterization to guarantee compliance at temperature extremes.

RE46C108

Piezoelectric Horn Driver and Voltage Regulator

R&E International

Product Specification

A Subsidiary of Microchip Technology

Inc.

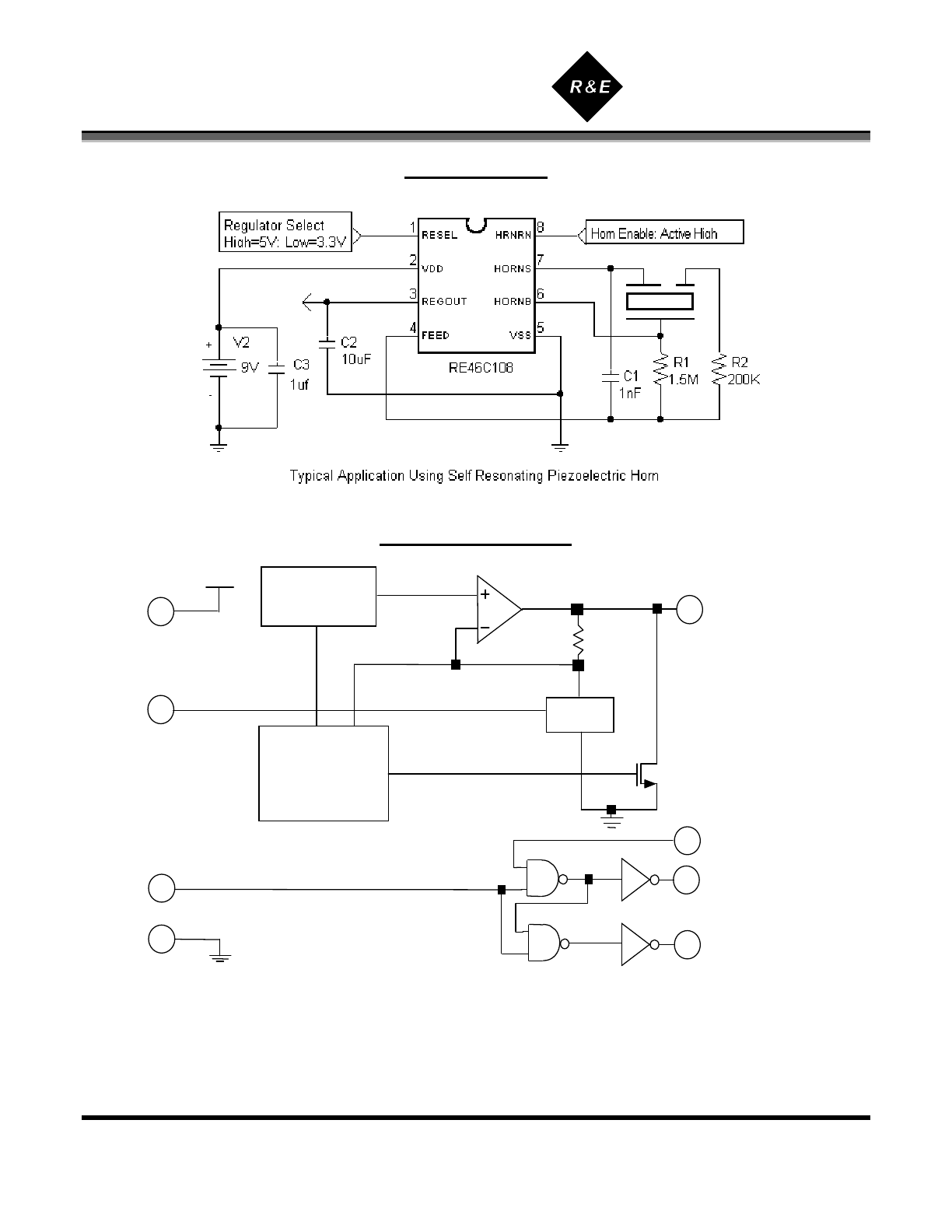

Typical Application

Functional Block Diagram

Bandgap

Reference

© 2009 Microchip Technology Inc.

DS22165A-page 3

Output

Adjust

3

VDD

2

4

1

8

7

6

5

VSS

REGSEL

REGOUT

HRNEN

HORNB

HORNS

FEED

Clamp &

Shutdown

Circuit

RE46C108

Piezoelectric Horn Driver and Voltage Regulator

R&E International

Product Specification

A Subsidiary of Microchip Technology

Inc.

Information contained in this publication regarding device

applications and the like is provided only for your convenience and

may be superseded by updates. It is your responsibility to ensure

that your application meets with your specifications. MICROCHIP

MAKES NO REPRESENTATIONS OR WARRANTIES OF ANY

KIND WHETHER EXPRESS OR IMPLIED, WRITTEN OR ORAL,

STATUTORY OR OTHERWISE, RELATED TO THE

INFORMATION, INCLUDING BUT NOT LIMITED TO ITS

CONDITION, QUALITY, PERFORMANCE, MERCHANTABILITY

OR FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip devices in

life support and/or safety applications is entirely at the buyer’s risk,

and the buyer agrees to defend, indemnify and hold harmless

Microchip from any and all damages, claims, suits, or expenses

resulting from such use. No licenses are conveyed, implicitly or

otherwise, under any Microchip intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, K

EE

L

OQ

, K

EE

L

OQ

logo,

MPLAB, PIC, PICmicro,

PICSTART, rfPIC, SmartShunt and UNI/O are registered

trademarks of Microchip Technology Incorporated in the U.S.A.

and other countries.

FilterLab, Hampshire, Linear Active Thermistor, MXDEV, MXLAB,

SEEVAL, SmartSensor and The Embedded Control Solutions

Company are registered trademarks of Microchip Technology

Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, CodeGuard,

dsPICDEM, dsPICDEM.net, dsPICworks, dsSPEAK, ECAN,

ECONOMONITOR, FanSense, In-Circuit Serial Programming,

ICSP, ICEPIC, Mindi, MiWi, MPASM, MPLAB Certified logo,

MPLIB, MPLINK, mTouch, nanoWatt XLP, PICkit, PICDEM,

PICDEM.net, PICtail, PIC

32

logo, PowerCal, PowerInfo,

PowerMate, PowerTool, REAL ICE, rfLAB, Select Mode, Total

Endurance, TSHARC, WiperLock and ZENA are trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

SQTP is a service mark of Microchip Technology Incorporated in

the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2009, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona; Gresham, Oregon and design centers in California and

India. The Company’s quality system processes and procedures are for its

PIC

®

MCUs and dsPIC

®

DSCs, K

EE

L

OQ

®

code hopping devices, Serial

EEPROMs, microperipherals, nonvolatile memory and analog products. In

addition, Microchip’s quality system for the design and manufacture of

development systems is ISO 9001:2000 certified.

© 2009 Microchip Technology Inc.

DS22165A-page 4