2016 Microchip Technology Inc.

DS20005640A-page

1

HV98100/HV98101

Features

• Good LED Current Regulation

- Better than 5% accuracy

• Valley Switching Buck-Boost Converter with

Power Factor Correction (PFC)

- 0.97 Power Factor (typical)

- 5% Total Harmonic Distortion (THD) (typical)

• Uses a Standard Off-the-Shelf Inductor

- No auxiliary winding required

• Single Input Voltage Range

- HV98100: 110

V

AC

±15%

- HV98101: 230

V

AC

±15%

• Supports 5W-15W Output Power

• Space-saving SOT-23-6L Package

Applications

• LED Lamps

• LED Lighting Fixtures

Description

The HV98100/HV98101 LED driver integrated circuit

(IC) is an off-line, high-power factor, buck-boost

controller targeted at general LED lighting products,

such as LED lamps and LED lighting fixtures with a

maximum power rating of about 15W.

Valley-switching buck-boost converters are preferred in

off-line applications since they reduce switching losses.

A typical solution is to pair a constant on-time control

scheme with valley switching to achieve both a

high-power factor and good efficiency. However, this

control scheme results in a higher total harmonic distor-

tion, and the actual value is dependent on the input and

output voltages. The HV98100/HV98101 uses a unique

control scheme to achieve a high-power factor and low

THD simultaneously under all line and load conditions,

while maximizing efficiency utilizing valley switching.

The average LED current is also controlled in a closed-

loop manner to achieve high LED accuracy.

Other unique features of the ICs are the bootstrap of

the IC supply voltage from the output, as well as the

unique valley-sensing scheme that allows the use of a

standard off-the-shelf inductor to minimize the overall

system cost.

Applications with low-output voltage can be

accommodated using a coupled inductor.

Package Types

4

1

2

3

6 GATE

CS

IND

GND

COMP

5 PV

DD

HV98100/HV98101

6-Lead SOT-23

See

Table

3-1

for pin description.

Non-Dimmable, Off-Line, LED Driver with Low Total

Harmonic Distortions

HV98100/HV98101

DS20005640A-page

2

2016 Microchip Technology Inc.

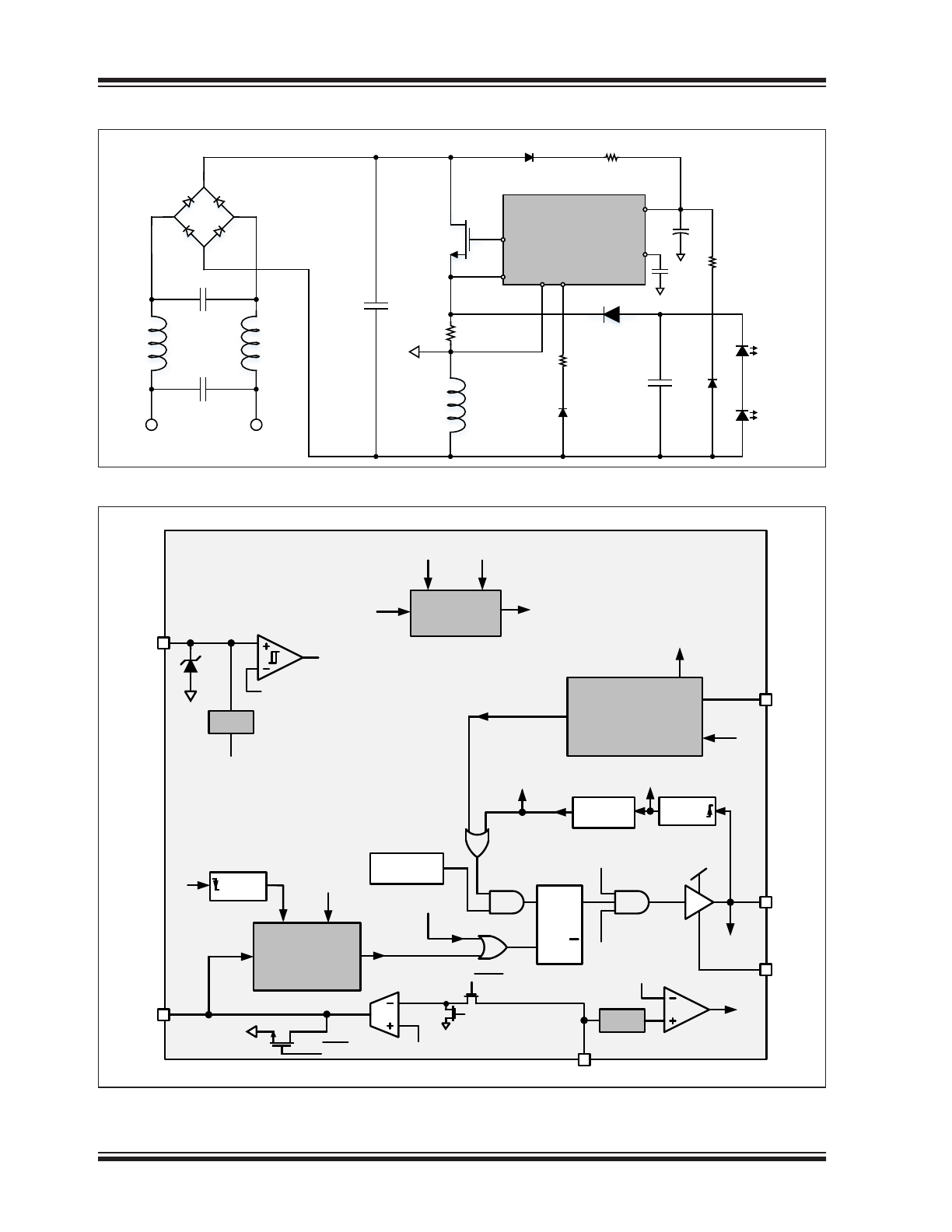

Typical Application Circuit

HV98100/1

GT

GN

D

CS

IN

D

COMP

P

VDD

M

BBT

L

BBT

R

CS

D

BBT

LED

C

COMP

C

REC

D

PVDD

R

PVDD

C

O

C

PVDD

R

HV

D

HV

R

VD

D

VD

V

AC

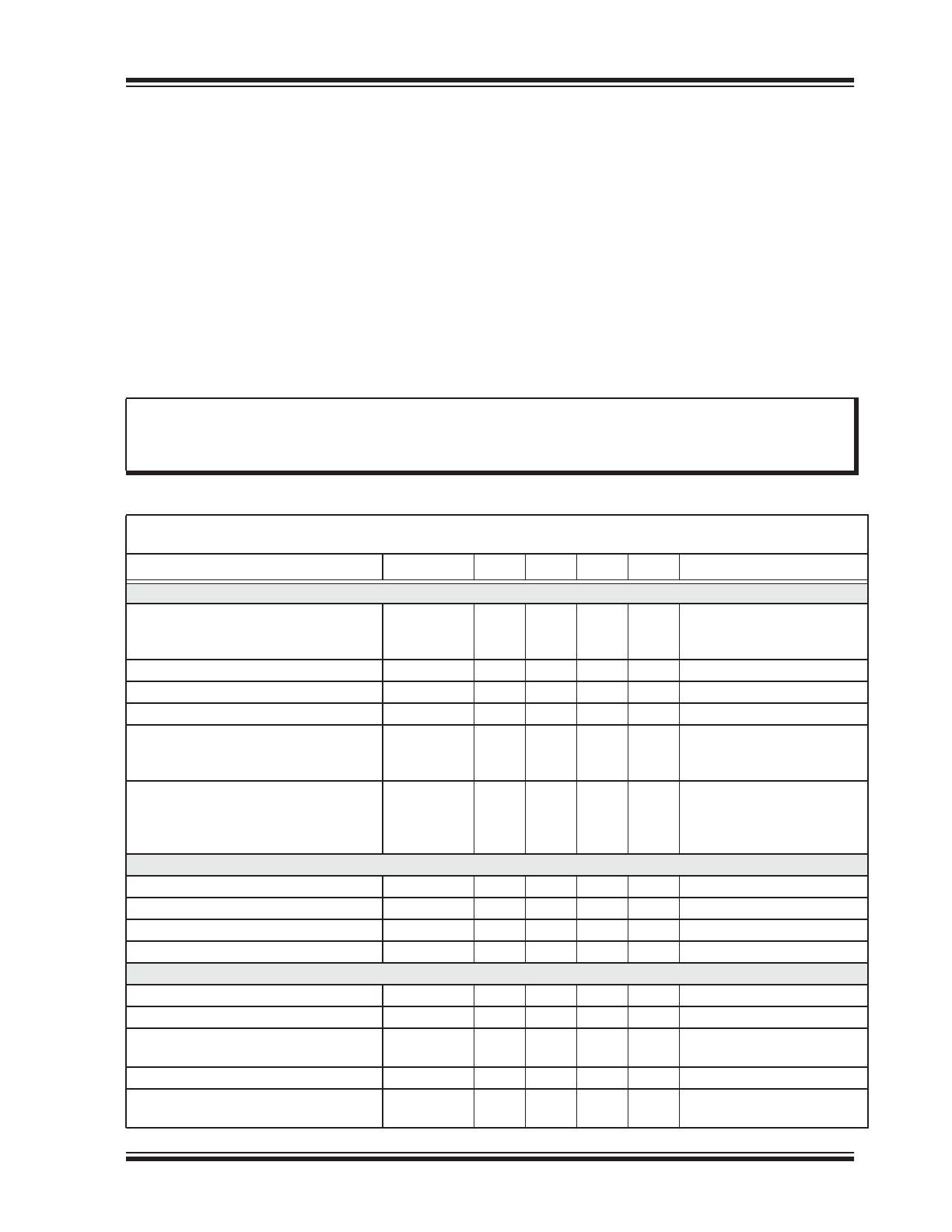

Internal Block Diagram

Monos hot

COMP

S

R

Q

Q

GATE

P

VDD

P

VDD

Startup

clock

V

al

ley

_

D

et

GT_ON

Gate

VDD

on

/VDD

of f

THD

control

POR

GND

P

VDD

IND

Valley Detect

RE

F

GT

_

R

RES E T

Monos hot

Gate

RE

S

E

T

Gate

IN

DE

T

_

V

A

L

GATE

I_V O

f

sta rt

POR

FLT

I_VO

CS

CS_REF

Fault

Pr otection

I_VO

FLT

Gate

Reg

ST RT_UP

Vton_ref

V_TON

POR

Max F req

Clock

A

VDD

Gate

Gate

LEB

OCP_REF

OCP

OCP

2016 Microchip Technology Inc.

DS20005640A-page

3

HV98100/HV98101

1.0

ELECTRICAL CHARACTERISTICS

Absolute Maximum Ratings†

Supply Voltage PV

DD

to GND .....................................................................................................................-0.3V to +20V

GATE

to GND.................................................................................................................................-0.3V to (PV

DD

+0.5V)

CS, COMP, IND

to GND............................................................................................................................... -0.3V to 4.5V

Operating Junction Temperature.............................................................................................................-40°C to +125°C

Storage Temperature ..............................................................................................................................-65°C to +150°C

Power Dissipation at +25°C for 6L-SOT-23 .........................................................................................................800

mW

ESD Protection on all pins (HBM) ..............................................................................................................................2

kV

ESD Protection on all pins (MM) ...............................................................................................................................175V

* Based on JEDEC JESD51 testing and reporting standards

†

Notice:

Stresses above those listed under “Maximum Ratings” may cause permanent damage to the device. This is

a stress rating only and functional operation of the device at those or any other conditions above those indicated in

the operational sections of this specification is not intended. Exposure to maximum rating conditions for extended

periods may affect device reliability.

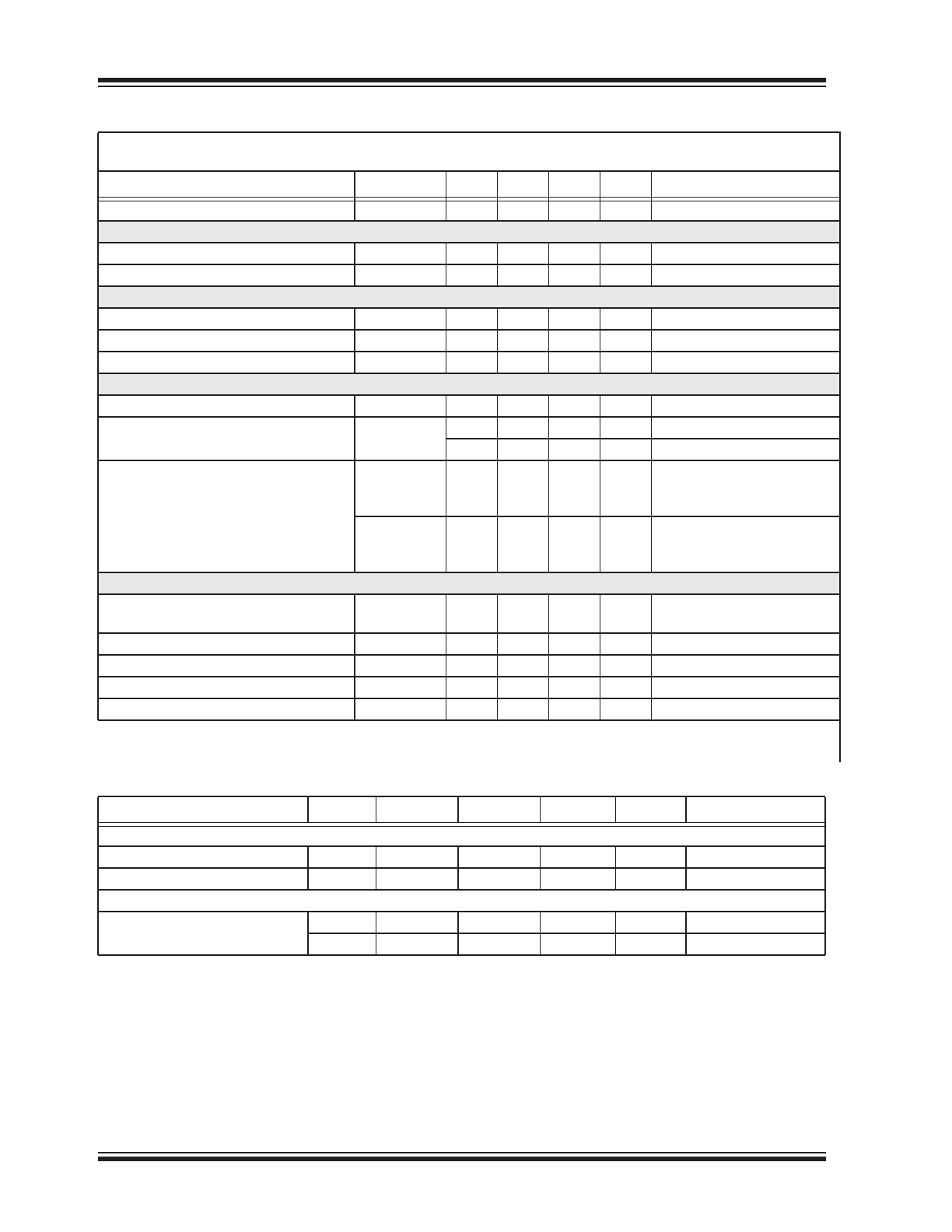

ELECTRICAL CHARACTERISTICS

Electrical Specifications

: Unless otherwise specified, all specifications are for T

A

=

T

J

=

+25°C, PV

DD

=

12V. Boldface

specifications apply over the full temperature range T

A

=

T

J

=

-40°C to +125°C.

Parameter

Symbol

Min.

Typ.

Max.

Units

Conditions

Power Supply (PV

DD

)

PV

DD

Clamp Voltage

PV

DD,clamp

15.5

17

18.5

V

Current into PV

DD

= 4.0

mA;

C

GATE

=

500

pF;

f

sw

=

100

kHz;

V

DD

Start Voltage

V

DD,ON

14.5

16

17.5

V

GATE starts switching

V

DD

Stop Voltage

V

DD,OFF

6.5

8

9.5

V

GATE stops switching

Current into clamp

I

DD,max

—

—

5

mA

Note

1

Current drawn by IC before start

I

DD,Q

—

—

200

μA

Measured at PV

DD

=

12V

after PV

DD

rises from 0V to

12V

Current drawn by IC during operation

I

DD,OP

—

—

4.3

mA

C

GATE

=

500

pF;

f

sw

=

100

kHz; COMP

=

3V;

I_IND

SINK

=

200

μA;

I_IND

SOURCE

=

250

μA

Gate Driver

GATE Driver Sourcing Current

I

SOURCE

0.3

—

—

A

Note

2

Gate Driver Sinking Current

I

SINK

0.6

—

—

A

Note

2

Gate Rise Time (10%-90%)

T

RISE

—

—

45

ns

C

GATE

=

500

pF

Gate Fall Time (10%-90%)

T

FALL

—

—

23

ns

C

GATE

=

500

pF

Output Current Control

Internal Reference Voltage

CS

REF

194

204

214

mV

Note

2

OTA Offset Voltage

V

OFFSET

-7.5

—

7.5

mV

Note

2

Open Loop DC Gain

A

V

55

—

—

dB

1V

COMP

4V; Output

open

Note

1

Small Signal Transconductance

g

m

160

230

300

μA/V 1V

COMP 4V;

Note

1

Gain Bandwidth Product

GBW

0.16

0.24

—

MHz

CCOMP = 150

pF

(

Note

2

)

HV98100/HV98101

DS20005640A-page

4

2016 Microchip Technology Inc.

R

ON

of COMP Reset FET

R

COMP

300

400

500

Internal Clocks

Start-up Clock

F

start

6.25

10

15

kHz

Maximum Frequency Limit

F

max

217

320

480

kHz

Note

1

Valley Detect

Current into IND pin

I

IND

—

—

600

μA

Note

2

Voltage at IND pin

V

IND

3.87

4.3

4.73

V

I

IND

=

250

μA

Comparator Delay Time

T

delay

—

—

50

ns

Note

2

Control Circuit

Internal Timing Constant

K

T

—

1.25

—

μs

Internal Voltage for Timing

V

Tref

—

2

—

V

HV98100

—

2.5

—

V

HV98101

GATE On-time

T

ON

6.83

7.35

7.89

μs

HV98100

Ext Clk = 50

kHz

COMP = 2V

T

ON

6.11

6.7

7.05

μs

HV98101

Ext CSlk = 50

kHz

COMP = 2V

Protection

Over Voltage Protection Current

Threshold

I

OVP

350

450

550

μA

GATE

=

LOW

Over Current Protection Reference

OCP

REF

2.2

2.35

2.5

V

Over Current Protection Blanking Time

T

BLNKOCP

150

—

250

ns

Note

2

Detect time for Over Current Protection

T

DETOCP

150

—

250

ns

After TBLNKOCP (

Note

2

)

Over Current Comparator Delay

OCP

DLY

—

50

100

ns

100

mV overdrive (

Note

2

)

Note 1:

Obtained by Design and Characterization; not 100% tested in production.

2:

Design Guidance only.

TABLE 1-1:

TEMPERATURE SPECIFICATIONS

Parameter

Symbol

Min.

Typ.

Max.

Units

Conditions

Temperature Ranges

Storage Temperature

T

A

-65

—

+150

°C

Operating Junction Temperature

T

J

-40

—

+125

°C

Thermal Package Resistance

Thermal Resistance, 6L-SOT-23

JA

—

124

—

°C/W

JC

—

74

—

°C/W

ELECTRICAL CHARACTERISTICS (CONTINUED)

Electrical Specifications

: Unless otherwise specified, all specifications are for T

A

=

T

J

=

+25°C,

PV

DD

=

12V.

Boldface

specifications apply over the full temperature range T

A

=

T

J

=

-40°C to +125°C.

Parameter

Symbol

Min.

Typ.

Max.

Units

Conditions

2016 Microchip Technology Inc.

DS20005640A-page

5

HV98100/HV98101

2.0

TYPICAL OPERATING CURVES

Note:

The graphs and tables provided following this note are a statistical summary based on a limited number of

samples and are provided for informational purposes only. The performance characteristics listed herein

are not tested or guaranteed. In some graphs or tables, the data presented may be outside the specified

operating range (e.g., outside specified power supply range) and therefore outside the warranted range.

Note:

Unless otherwise indicated, T

A

=

T

J

=

+25°C, PV

DD

=

12V. Boldface specifications apply over the full temperature

range T

A

=

T

J

=

-40°C to +125°C.

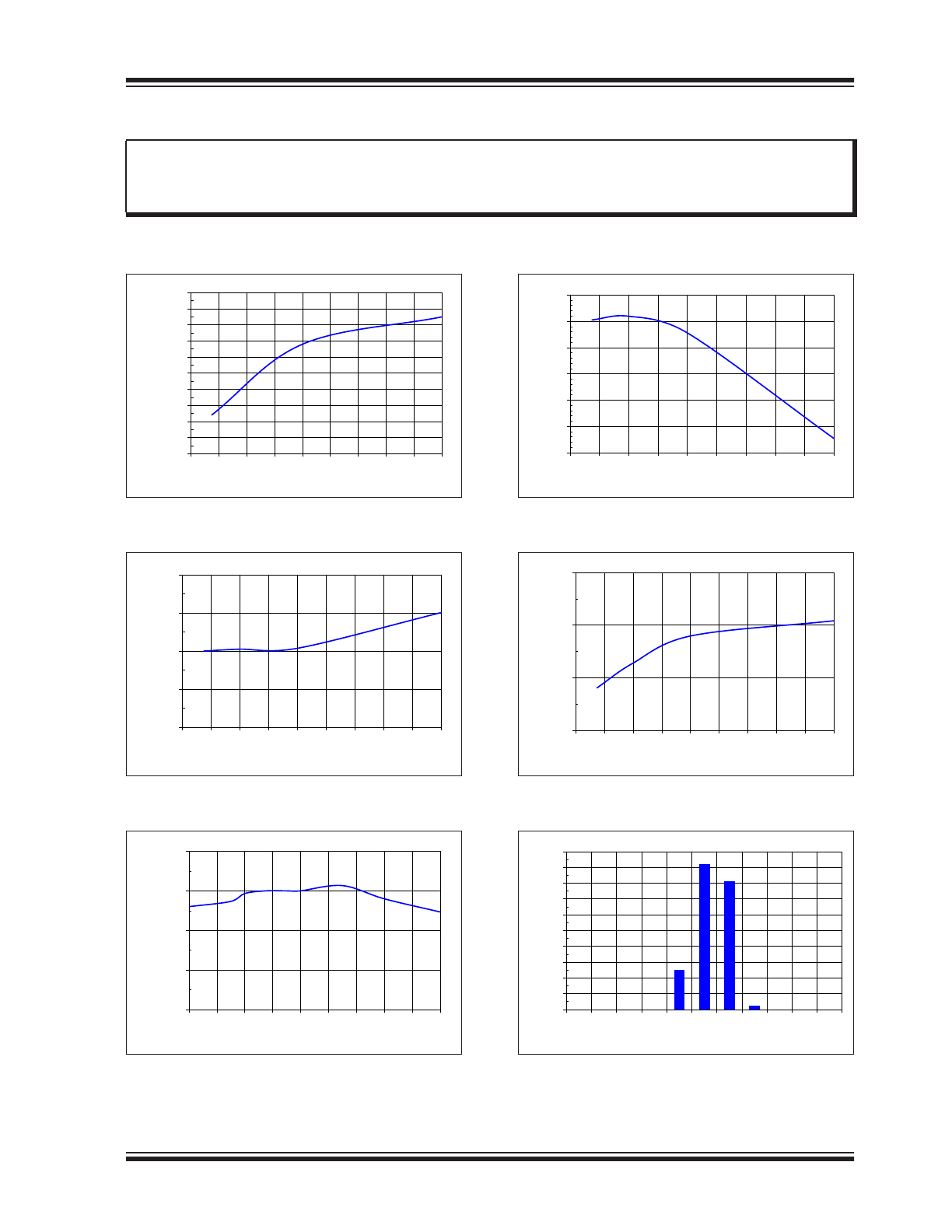

15.6

15.65

15.7

15.75

15.8

15.85

15.9

15.95

16

16.05

16.1

-55 -35 -15

5

25

45

65

85 105 125

V

DD,ON

(V)

Temperature (°C)

FIGURE 2-1:

V

DD

Start Voltage vs.

Junction Temperature.

7.9

7.95

8

8.05

8.1

-55 -35 -15

5

25

45

65

85

105 125

V

DD,ON

(V)

Temperature (°C)

FIGURE 2-2:

V

DD

Stop Voltage vs.

Junction Temperature.

199

199.5

200

200.5

201

-55 -35 -15

5

25

45

65

85 105 125

CS

REF

(mV)

Temperature (°C)

FIGURE 2-3:

Internal Reference Voltage

vs. Junction Temperature.

430

435

440

445

450

455

460

-55 -35 -15

5

25

45

65

85

105 125

I

OVP

(uA)

Temperature (°C)

FIGURE 2-4:

Over Voltage Protection

Current Threshold vs. Junction Temperature.

2.37

2.38

2.39

2.4

-55 -35 -15

5

25

45

65

85 105 125

OCP

REF

(V)

Temperature (°C)

FIGURE 2-5:

Over Current Protection

Reference vs. Junction Temperature.

0

5

10

15

20

25

30

35

40

45

50

7

7.5

8

8.5

9

9.5 10 10.5 11 11.5 12

%

of

Units

F

START

(kHz)

FIGURE 2-6:

Startup Clock Frequency

Histogram.

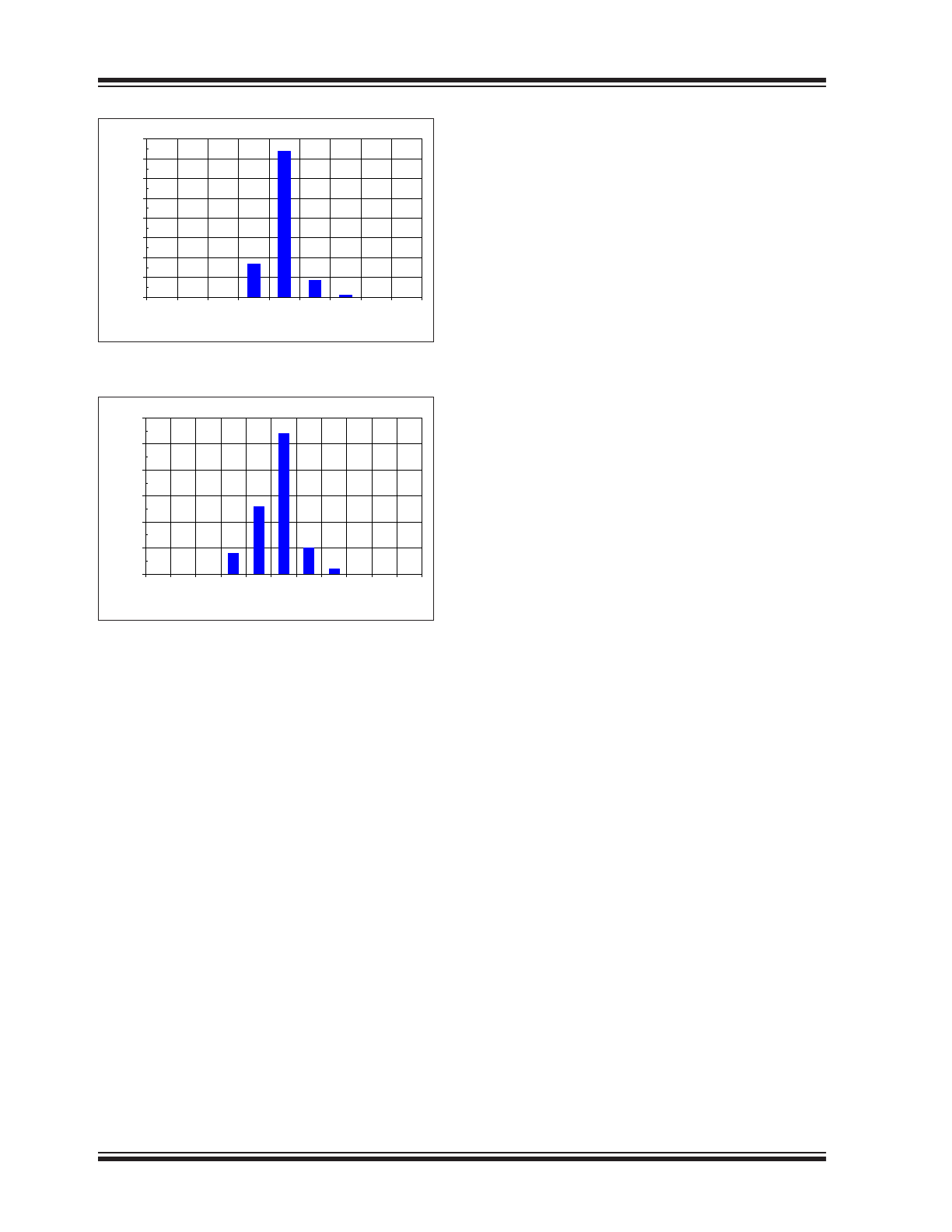

0

10

20

30

40

50

60

70

80

125 135 145 155 165 175 185 195 205

%

of

Units

I

DD,Q

(uA)

HV98100/HV98101

DS20005640A-page

6

2016 Microchip Technology Inc.

FIGURE 2-7:

Quiescent Current

Histogram.

0

10

20

30

40

50

60

90 92 94 96 98 100 102 104 106 108 110

%

of

Units

Output Current (mA)

FIGURE 2-8:

Output Current Accuracy in

Application.

2016 Microchip Technology Inc.

DS20005640A-page

7

HV98100/HV98101

3.0

PIN DESCRIPTION

The description of the pins are listed in

Table

3-1

.

TABLE 3-1:

PIN DESCRIPTION

HV98100/HV98101

SOT-23

Symbol

Description

1

IND

Input from LED String Anode for both valley detection and over-voltage protection

Pin

2

GND

Common connection for all circuits Pin

3

COMP

Loop compensation for stable response Pin

4

CS

Current sense input for sensing inductor current Pin

5

PV

DD

Supply Voltage for the IC Pin

6

GATE

Gate driver for driving the external MOSFET Pin

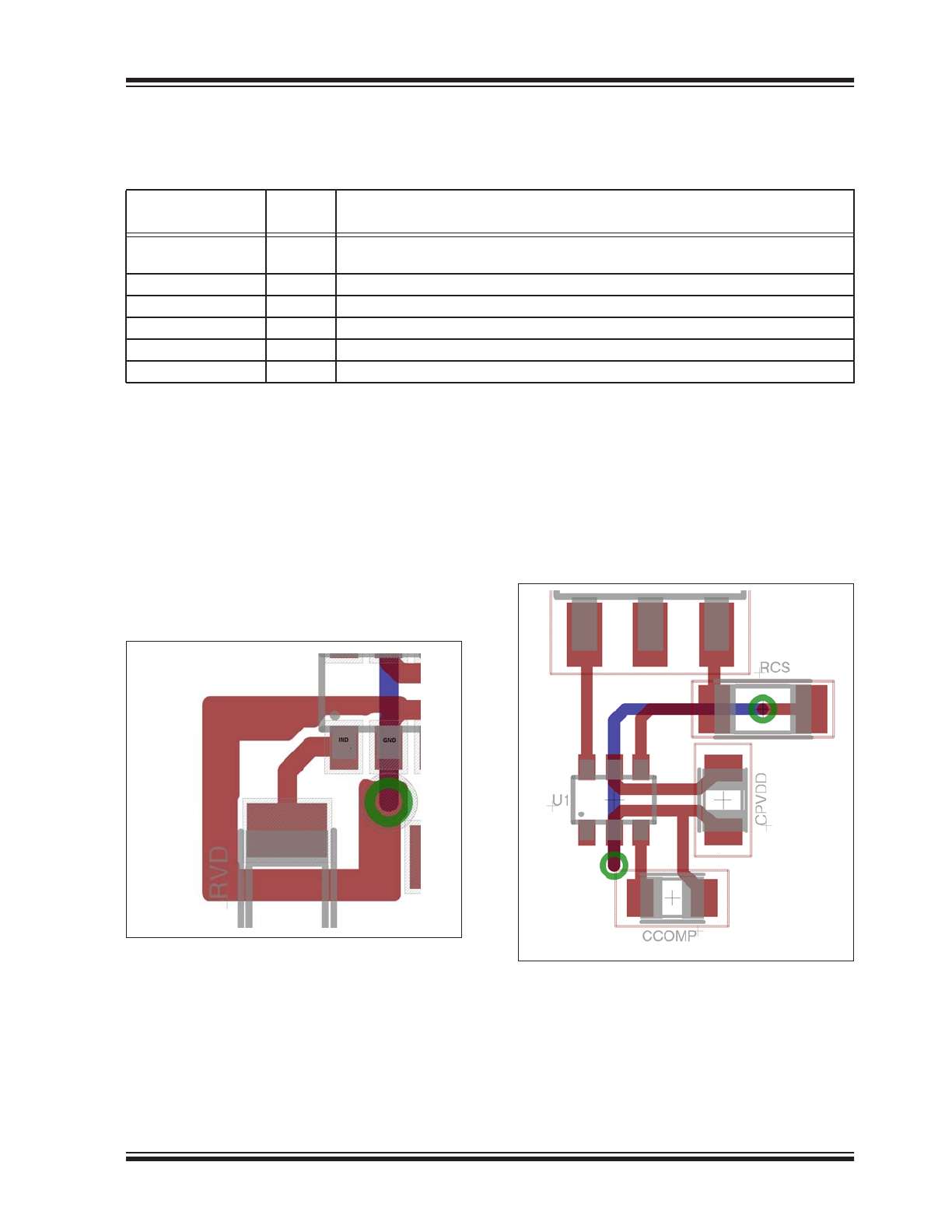

3.1

IND

This pin is used for detecting the valley, as well as for

over-voltage protection. The voltage at pin is main-

tained at approximately 4.3V.

When the switching FET

is off, current is sourced out of this pin. If this current

exceeds 450

μA, then

over voltage is detected and the

IC shuts down. This current sourced out of the pin is

also used to detect the valley, using a patented method.

For proper operation, the IND pin should be shielded to

prevent mis-triggering due to the large voltage slew

rates present in application. A recommended layout is

shown in

Figure

3-1

.

FIGURE 3-1:

Shielding the IND Pin.

3.2

Power Ground Pin (GND)

This is the ground pin of the IC. The V

DD

capacitor and

COMP network should be connected to this pin and the

GND pin should be connected to the sense resistor, as

shown in the

Typical Application Circuit

for proper

functioning of the IC.

Figure

3-2

shows a

recommended layout. Red traces in the layout are on

the top layer, whereas blue traces on the layout are on

the bottom layer.

FIGURE 3-2:

Connection to the GND Pin.

HV98100/HV98101

DS20005640A-page

8

2016 Microchip Technology Inc.

3.3

COMP

This pin is the output of the internal transconductance

amplifier. A compensation network connected between

COMP and GND pins is used to stabilize the closed

loop control of the LED current.

3.4

CS

This pin is used to sense the inductor current. The

inductor current information is used to derive the output

LED current, as well as to protect the inductor from

saturation.

3.5

PV

DD

This pin is the power supply pin for the IC. A minimum

of 4.7

μF capacitor needs to be connected between

PV

DD

and GND for stability of the internal shunt regu-

lator. The C

PVDD

capacitor needs to be placed physi-

cally close to the IC to minimize the trace length

between the PV

DD

pin and the capacitor.

3.6

GATE

This pin is the gate drive output of the IC and is used to

control the switching of the external FET.

2016 Microchip Technology Inc.

DS20005640A-page

9

HV98100/HV98101

4.0

FUNCTIONAL DESCRIPTION

4.1

Introduction

The HV98100/HV98101 control ICs provide constant

average LED current for LED lamps and fixtures with a

single-stage, valley-switching, buck-boost power-

supply topology.

The IC is targeted at designs at a single-line voltage,

such as 110

V

AC

(HV98100) or 230

V

AC

(HV98101)

and does not support designs for universal input volt-

age range.

4.2

Principle of Operation

The IC adopts a novel control mechanism to vary both

on-time and switching period at the same instant over

the line cycle in a way that forces the average input cur-

rent to be proportional to the input voltage, realizing

high-power factor and low THD which is independent of

the load voltage (V

O

) (unlike a constant on-time control

where the THD is dependent on the LED string volt-

age).

In order to determine the LED current regulation, power

balancing is used to maintain the mean programmable

LED current (I

O

) in a closed-loop manner by means of

the adaptive V

COMP

swing upon the defined input/out-

put voltage variation, as shown in

Equation

4-1

.

EQUATION 4-1:

I

O

V

2

in,rms

K

T

V

COMP

V

O

---------------------------------------------------------------

=

Assume a V

COMP

variation from 1.2V to 3.8V, an input

voltage (V

IN,rms

) variation of ±15% and the internal tim-

ing constant (K

T

) variation of ±12%. With these

assumptions, the maximum variation in the LED string

voltage (to maintain constant LED current) cannot

exceed ±18% approximately.

HV98100/HV98101

DS20005640A-page

10

2016 Microchip Technology Inc.

5.0

APPLICATION INFORMATION

5.1

Introduction

This section describes the operation of the various

blocks in the IC. Detailed design information, along with

a design example, is provided in

Section

6.0 “Design

Example”

.

5.2

PV

DD

Regulator

The supply current is initially fed from the rectified AC

input directly via an external start-up resistor (R

HV

) to

peak charge a hold-up capacitor (C

PVDD

) connected at

this pin. Note that a switching diode (D

HV

) is required in

series to prevent the capacitor from discharging when

the buck-boost converter FET (M

BBT

) turns on. As the

voltage on the V

DD

capacitor increases, the IC is held

in a Stand-by mode and draws minimum current

(200

μA max.). Once the voltage at V

DD

reaches

V

DD,ON

, the IC turns on and starts switching at an inter-

nally fixed switching frequency of 10

kHz, until the val-

ley can be detected. Once the valley is detected, the

converter starts working in the normal Valley-Switching

mode

and tries to regulate the LED current. In this

mode, the current drawn by the IC from V

DD

increases

causing the voltage across the V

DD

capacitor to start

dropping (since the current supplied by the external

start-up resistor is not sufficient).

If the V

DD

voltage drops below V

DD,OFF

, the IC enters

into Stand-by mode and the process starts again. If the

bootstrap from the output capacitor (C

O

) is available to

prevent the V

DD

voltage from going below V

DD,OFF

,

then the LED driver operates normally. In this way, as

shown in

Figure

5-1

, the PV

DD

voltage bounces

between V

DD,ON

and V

DD,OFF

within a hysteresis band

for the IC to start GATE switching, until the energy

stored in the output capacitor can be partially delivered

to PV

DD

through the bootstrapping resistor-diode net-

work (R

PVDD

-D

PVDD

).

V

DDON

V

IN

P

VDD

0

0

GT

V

DDOF F

0

V

O

0

FIGURE 5-1:

Typical Startup Waveforms.

The IC includes an internal V

DD

clamp circuit. The

clamp limits the voltage on the V

DD

supply pin to the

maximum value (PV

DD,clamp

). If the maximum current

supplied through the external resistors minus the cur-

rent consumption of the IC is lower than the maximum

value that the Zener clamp can sustain (I

DD,MAX

), no

external Zener diode is required.

5.3

LED Current Regulator

The LED current (I

O

) is sensed directly using an exter-

nal sense resistor R

CS

and compared to an internal

fixed reference (CS

REF

). An internal transconductance

amplifier is used to close the loop on the LED current

with an external compensation capacitor. The LED cur-

rent can be programmed as in

Equation

5-1

.

EQUATION 5-1:

I

LED

CS

REF

R

CS

--------------------

=

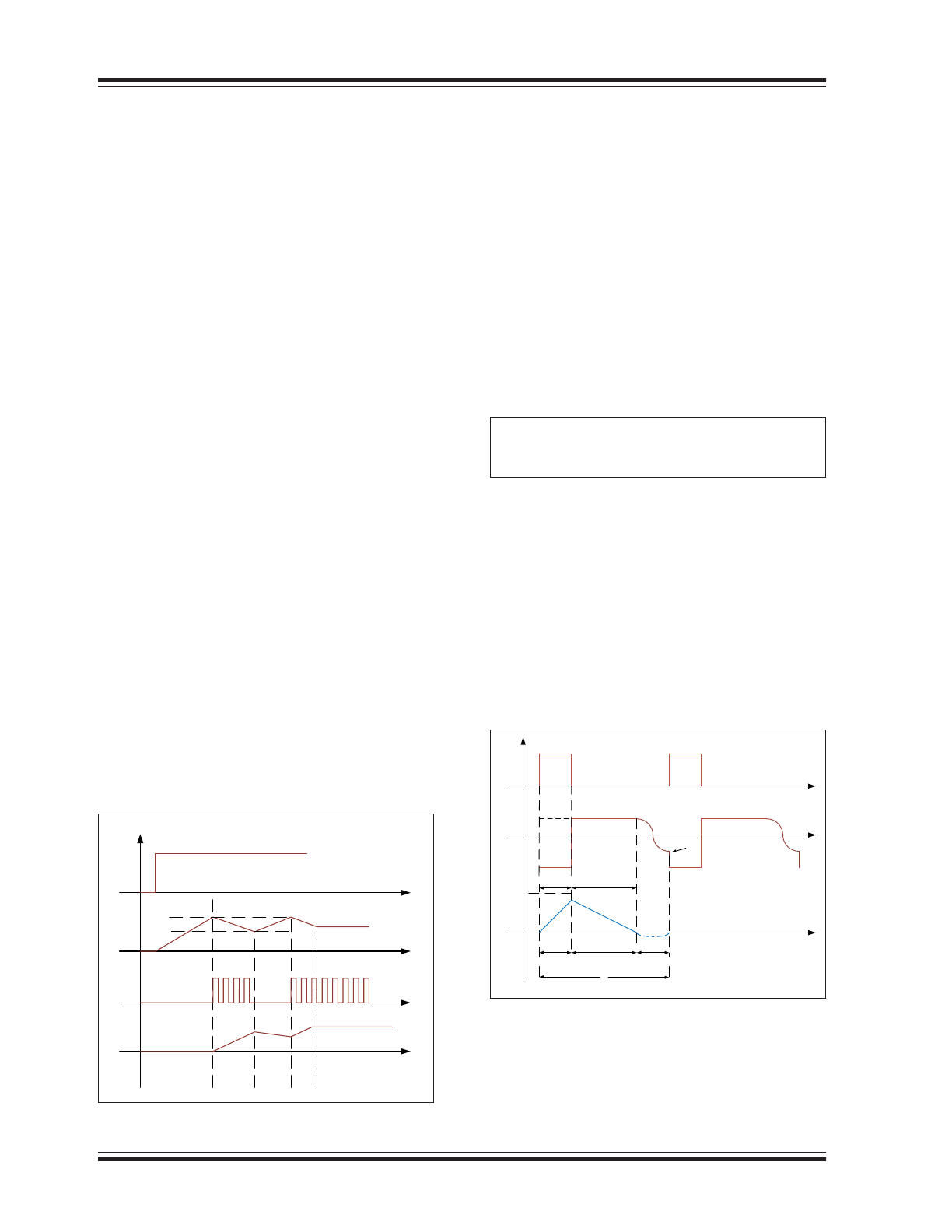

5.4

Valley Switching

The driver incorporates valley switching (quasi-reso-

nant switching), a technique for reducing switching loss

at the turn-on event of the buck-boost converter FET.

Valley detect is accomplished by sensing the current

sunk into the IND pin when the GATE is low. The oper-

ation is illustrated in

Figure

5-2

. When the inductor cur-

rent I

L

has decreased to zero at t

2

, the positive LED

voltage V

L

starts to oscillate around the 0V level (with

respect to the IC GND), with an amplitude V

O

. The

GATE turns on again when the first lowest level (valley)

is detected.

+Vo

-V

IN

Gate

V

L

0

0

0

magne tization

I

L

demag netization

valley

t

0

T

on

t

1

t

2

t

00

T

S

3

T

off

I

L,max

FIGURE 5-2:

Valley Detect Waveforms.

However, in case the valley is not detected (during

startup, output short circuit and input voltage zero

crossings), a 10

kHz internal clock is used to start the

next cycle.