2010-2013 Microchip Technology Inc.

DS22260C-page 1

Features

• 750 mA Continuous Output Current

• Load Voltage Supply: 10V to 40V

• Full Bipolar Stepper Motor Drive Capability

• Bidirectional DC Motor Capability

• Internal Fixed T

OFF

Time PWM Current Control

• Internal Protection Diodes

• Internal Thermal Shutdown

• Under Voltage Lockout

• LS-TTL Compatible Logic Inputs with Pull-Up

Resistors

• Low R

ON

Output Resistance

• Low Quiescent Current

• Operating Temperature Range: -40°C to +105°C

• Pin Compatible with Allegro 6219

Applications

• Stepper Motor Actuators

• DC Motor Actuators

• Automotive HVAC Ventilation

• Automotive Power Seats

Description

The MTS62C19A motor driver is a CMOS device capa-

ble of driving both windings of a bipolar stepper motor

or bidirectionally control two DC motors. Each of the

two independent H-bridge outputs is capable of sus-

taining 40V and delivering up to 750 mA of continuous

current. The output current level is controlled by an

internal pulse-width modulation (PWM) circuit that is

configured using two logic inputs, a current sense

resistor, and a selectable reference voltage. The

H-bridge outputs have been optimized to provide a low

output saturation voltage drop.

Full, half and micro-stepping operations are possible

with the PWM current control and logic inputs. The

maximum output current is set by a sensing resistor

and a user-selectable reference voltage. The output

current limit is selected using two logic level inputs. The

selectable output current limits are 0%, 33%, 67% or

100% of the maximum output current. Each bridge has

a PHASE input signal which is used to control the

direction of current flow through the H-bridge and the

load.

The H-bridge power stage is controlled by non-overlap-

ping signals which prevent current cross conduction

when switching the direction of the current flow. Internal

clamp diodes protect against inductive transients.

Thermal protection circuitry disables the outputs when

the junction temperature exceeds the safe operating

limit. No special power-up sequencing is required.

Undervoltage Lockout circuitry prevents the chip from

operating when the load supply is applied prior to the

logic supply.

The device is supplied in a 24-pin SOP Package.

Package Types

Note:

The MTS62C19A device is formerly a

product of Advanced Silicon.

GND

1

2

3

4

24

23

22

21

20

19

18

17

5

6

7

8

I01

V

LOAD

OUT1A

OUT2A

SENSE2

COMPIN2

OUT2B

GND

16

9

V

REF1

I11

PHASE1

GND

GND

I02

SENSE1

15

10

I12

PHASE2

OUT1B

COMPIN1

MTS62C19A

SOP-24

V

REF2

RC2

RC1

V

LOGIC

11

12

14

13

Dual Full-Bridge Motor Driver

MTS62C19A

MTS62C19A

DS22260C-page 2

2010-2013 Microchip Technology Inc.

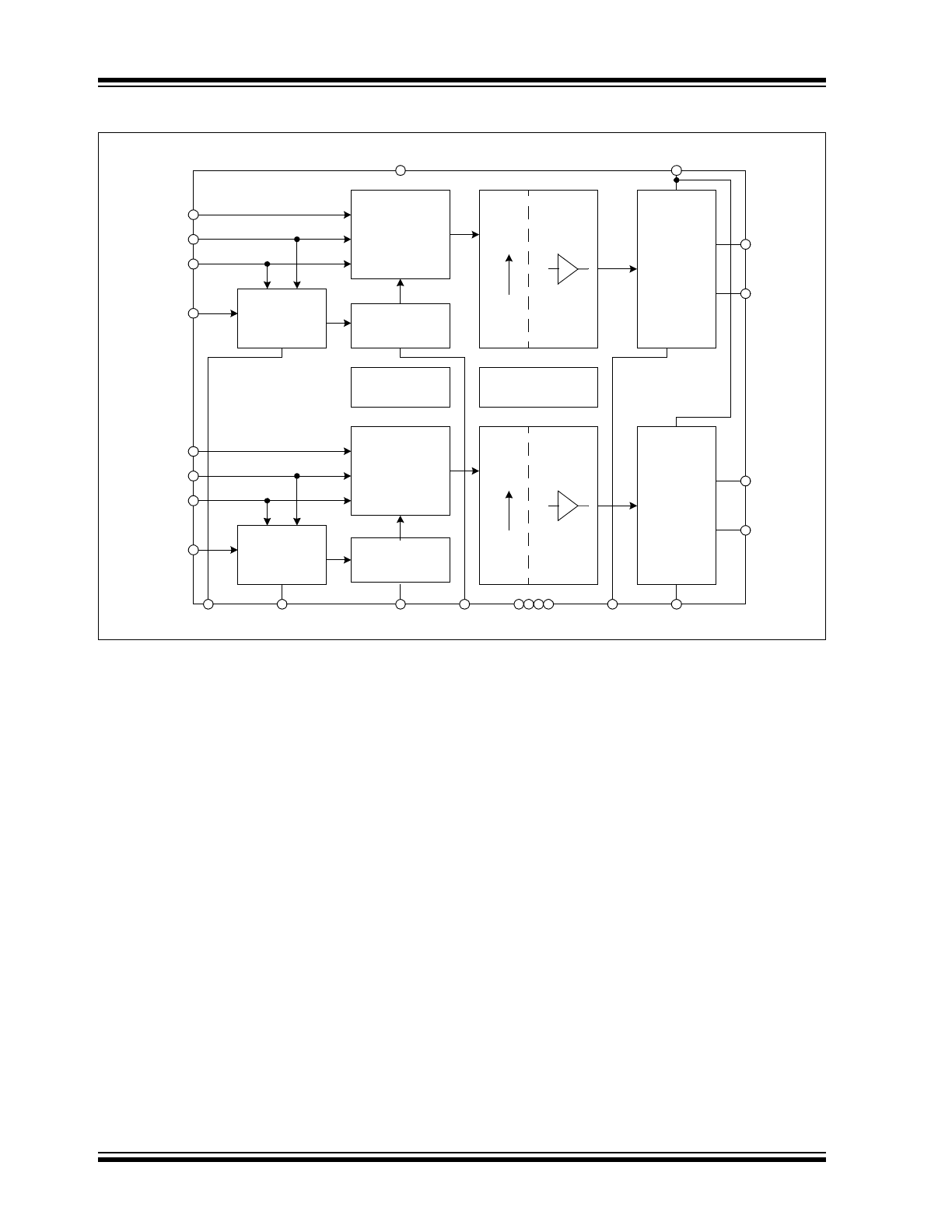

Functional Block Diagram

V

LOGIC

Logic

Shift

Drivers

Power

Bridge

Power

Bridge

Shift

Drivers

Thermal

Shutdown

One-shot

Logic

Current

Sense

Comparator

Current

Sense

Comparator

One-shot

Under-V

Lockout

COMPIN1

COMPIN2

RC2

RC1

GND

SENSE1

SENSE2

OUT2B

OUT2A

OUT1B

OUT1A

V

LOAD

V

REF1

V

REF2

PHASE1

PHASE2

I01

I11

I02

I12

2010-2013 Microchip Technology Inc.

DS22260C-page 3

MTS62C19A

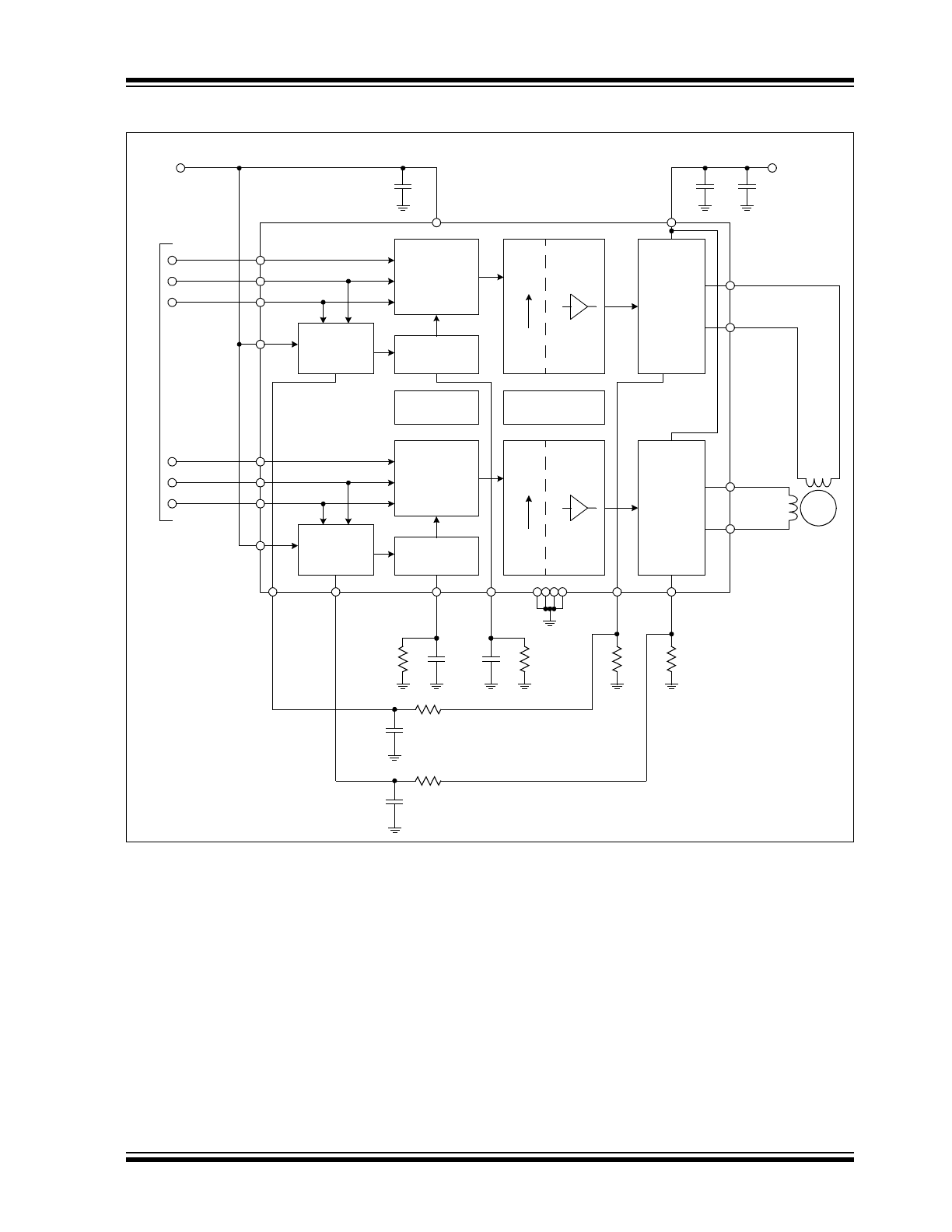

Typical Application

5V

V

LOGIC

V

LOAD

10 to 30V

V

REF1

V

REF2

100 nF

PHASE1

PHASE2

I01

I11

I02

I12

100 nF

100 µF

Logic

Logic

Current

Sense

Comparator

Current

Sense

Comparator

M

One-shot

One-shot

Under-V

Lockout

Thermal

Shutdown

Shift

Drivers

Shift

Drivers

OUT1A

OUT1B

OUT2A

OUT2B

COMPIN1

COMPIN2

RC2

RC1

GND

SENSE1

SENSE2

R

S

R

S

C

t

R

t

R

t

R

C

R

C

C

t

C

C

C

C

Logic/

µP

Power

Bridge

Power

Bridge

MTS62C19A

DS22260C-page 4

2010-2013 Microchip Technology Inc.

1.0

ELECTRICAL

CHARACTERISTICS

Absolute Maximum Ratings †

Logic Supply Voltage (V

LOGIC

)

......................... -0.3 to +5.5V

Load Supply Voltage (V

LOAD

) .......................... -0.3 to +40.0V

Logic Input Voltage Range (V

IN

) ....... -0.3 to VLOGIC + 0.3V

V

REF

Voltage Range (V

REF

) ............................. -0.3 to +10.0V

Output Current (Peak) ..................................................... ±1A

Output Current (Continuous) ...................................... ±0.75A

Sense Output Voltage ...................................... -0.3V to 1.5V

Junction Temperature (T

J

).............................-40°C to +150°C

Operating Temperature Range (T

OPR

)..........-40°C to +105°C

Storage Temperature Range (T

STG

) .............-55°C to +150°C

† Notice: Stresses above those listed under “Maximum

Ratings” may cause permanent damage to the device.

This is a stress rating only and functional operation of

the device at those or any other conditions above those

indicated in the operational listings of this specification

is not implied. Exposure to maximum rating conditions

for extended periods may affect device reliability.

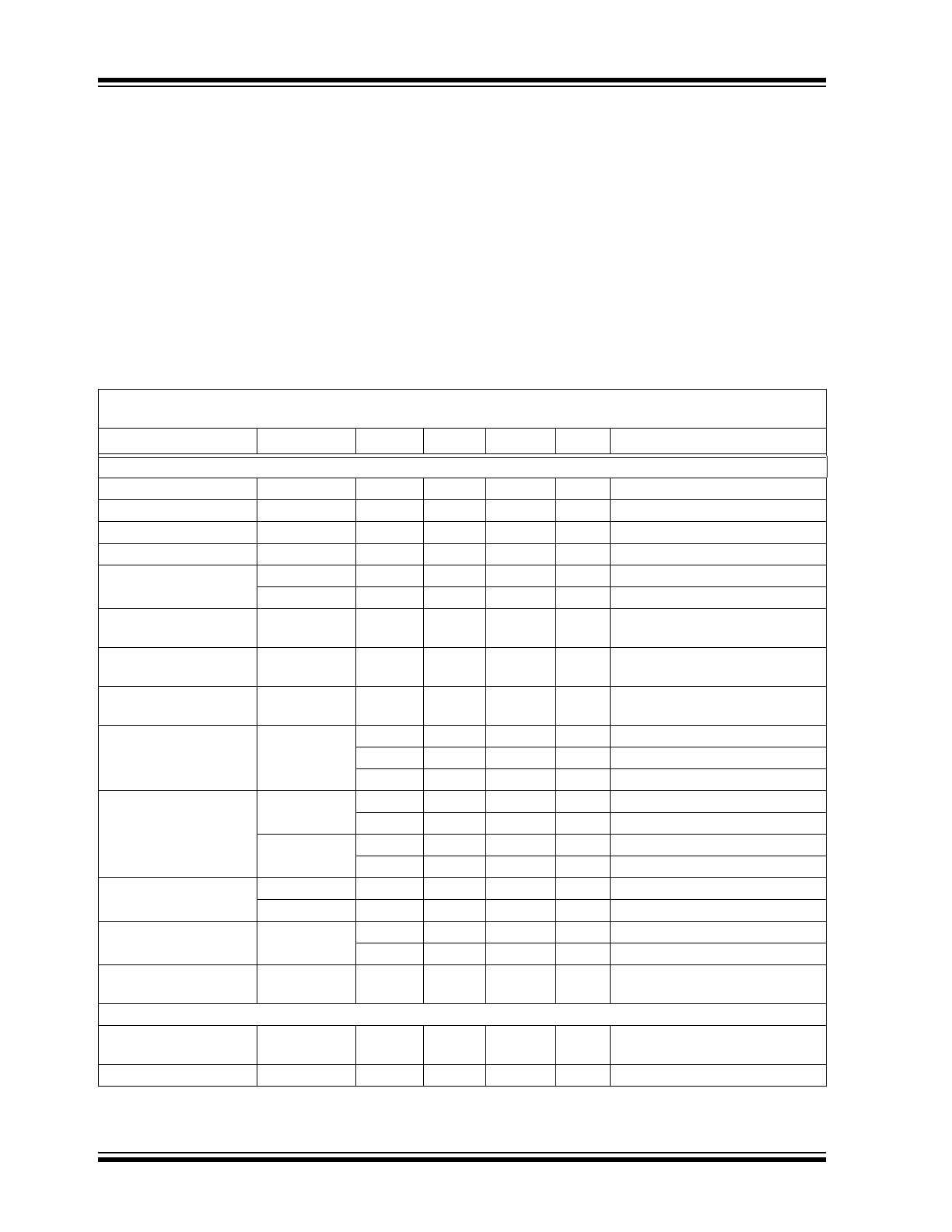

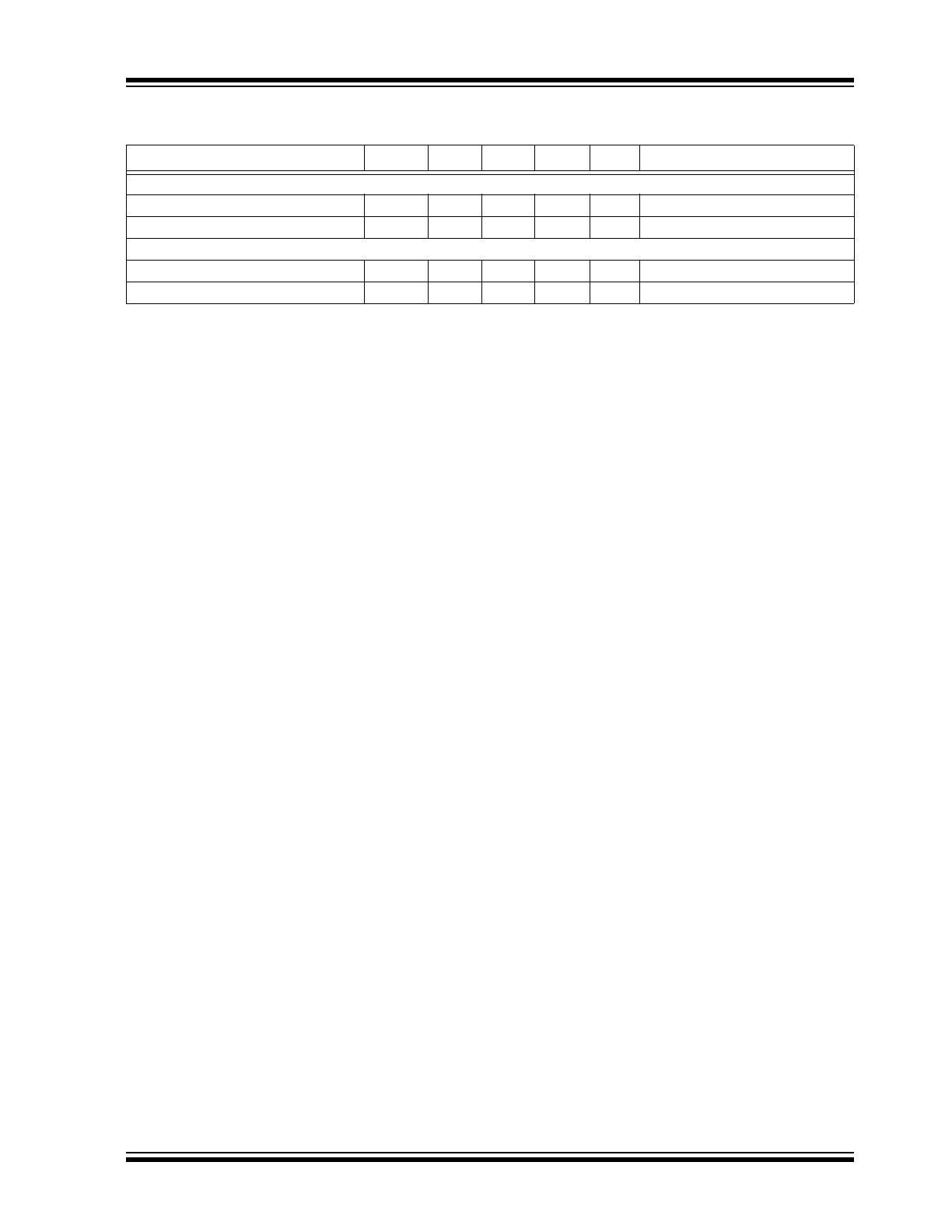

ELECTRICAL CHARACTERISTICS

Electrical Specifications: Unless otherwise specified, all limits are established for V

LOGIC

= 4.5V to 5.5V,

V

LOAD

= 30V,V

REF

= 5V, T

A

= +25°C

Parameters

Sym

Min

Typ

Max

Units

Conditions

DC Characteristics

Logic Supply Voltage

V

LOGIC

4.5

5.0

5.5

V

Load Supply Voltage

V

LOAD

10

30

40

V

Logic Supply Current

I

VLOGIC

—

0.8

1.0

mA

V

REF

Voltage Range

V

REF

1.5

5.0

7.0

V

Driver Supply Current

I

VLOAD_ON

—

0.55

1.0

mA

Both Bridges ON, No Load

I

VLOAD_OFF

—

0.55

1.0

mA

Both Bridges Off

Control Logic

Input Current (V

IN

= 0V)

I

IN

—

—

-70

µA

I01, I11, I02, I12, PHASE1,

PHASE2, (

Note 1

)

Logic-Low

Input Voltage

V

IL

—

—

0.8

V

I01, I11, I02, I12, PHASE1,

PHASE2

Logic-High

Input Voltage

V

IH

2.4

—

—

V

I01, I11, I02, I12, PHASE1,

PHASE2

Current Limit Threshold

Ratio (V

REF

÷ V

SENSE

)

V

REF

_V

SENSE

9.5

10

10.5

—

I0 = L, I1 = L

13.5

15

16.5

—

I0 = H, I1 = L

25.5

30

34.5

—

I0 = L, I1 = H

Driver Output Satura-

tion Voltage V

CE(SAT)

V

ONN

(Low Side)

—

0.55

0.65

V

(Sink) I

OUT

= +500 mA

—

0.90

1.00

V

(Sink) I

OUT

= +750 mA

V

ONP

(High Side)

—

1.05

1.40

V

(Source) I

OUT

= -500 mA

—

1.85

2.10

V

(Source) I

OUT

= -750 mA

Clamp Diode Forward

Voltage (

Note 2

)

V

F_NDIODE

—

0.95

1.30

V

I

F

= 750 mA

V

F_PDIODE

—

1.00

1.30

V

I

F

= 750 mA

Driver Output

Leakage Current

I

LEAK

—

—

-50

µA

V

OUT

= 0V

—

—

50

µA

V

OUT

= V

LOAD

Thermal Shutdown

Temperature

T

J_SHDN

—

170

—

°C

AC Characteristics

Cut-off Time

(one-shot pulse)

T

OFF

—

50

58

µs

R

s

= 1

, R

C

= 1 k

, C

C

= 820 pF,

R

t

= 56 k

, C

t

= 820 pF

Turn-off Delay

T

D

—

1.5

10

µs

Note

1:

V

IN

= 5.0V input current given by internal pull-up to Logic Supply.

2:

Clamp/Freewheel diode is the intrinsic body-drain diode of the NMOS and PMOS transistors.

2010-2013 Microchip Technology Inc.

DS22260C-page 5

MTS62C19A

TEMPERATURE SPECIFICATIONS

Parameters

Sym

Min

Typ

Max

Units

Conditions

Recommended Temperature Ranges

Junction Temperature Range

T

J

-40

+125

°C

Operating Temperature Range

T

A

-40

+105

°C

Thermal Package Resistance

Thermal Resistance, SOP-24

JA

—

76

—

°C/W

EIA/JEDEC JESD51-10

Thermal Resistance, SOP-24

JC

—

16

—

°C/W

EIA/JEDEC JESD51-10

MTS62C19A

DS22260C-page 6

2010-2013 Microchip Technology Inc.

2.0

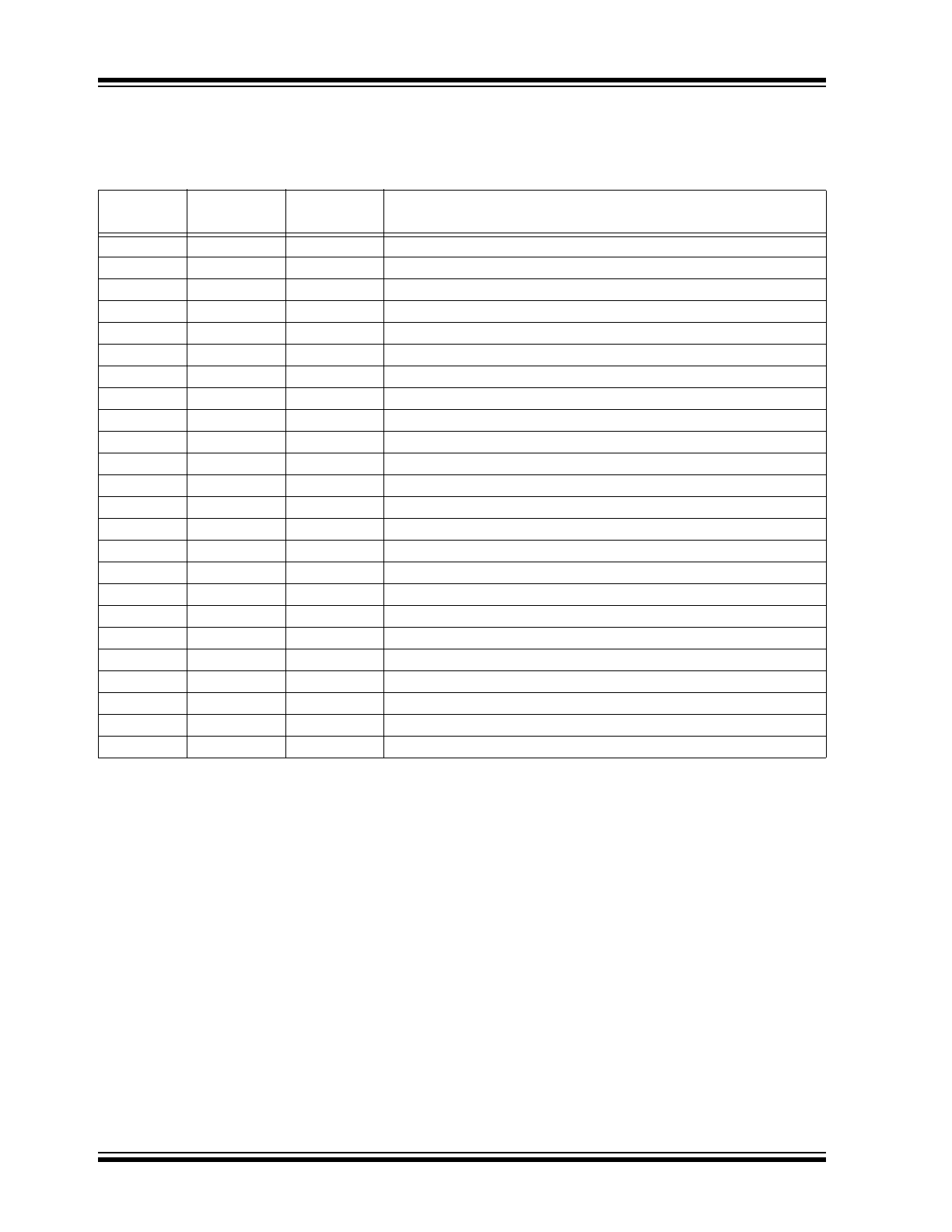

PIN DESCRIPTIONS

The descriptions of the pins are listed in

Table 2-1

.

TABLE 2-1:

MTS62C19A PIN FUNCTION TABLE

Pin No.

SOP-24

Type

Name

Function

1

Output

OUT1A

Output 1 ‘A’ Side of Motor Winding

2

Output

OUT2A

Output 2 ‘A’ Side of Motor Winding

3

Input

SENSE2

Current Sense for Output 2

4

Input

COMPIN2

Current Sense Comparator Input for Output 2

5

Output

OUT2B

Output 2 ‘B’ Side of Motor Winding

6

Power

GND

Negative Logic Supply (Ground)

7

Power

GND

Negative Logic Supply (Ground)

8

Input

I02

Output 2 Current Selection Bit 0

9

Input

I12

Output 2 Current Selection Bit 1

10

Input

PHASE2

Output 2 Phase

11

Input

V

REF2

Output 2 Current Reference

12

Input

RC2

Output 2 RC Time Constant

13

Power

V

LOGIC

Positive Logic Supply Voltage

14

Input

RC1

Output 1 RC Time Constant

15

Input

V

REF1

Output 1 Current Reference

16

Input

PHASE1

Output 1 Phase

17

Input

I11

Output 1 Current Selection Bit 1

18

Power

GND

Negative Logic Supply (Ground)

19

Power

GND

Negative Logic Supply (Ground)

20

Input

I01

Output 1 Current Selection Bit 0

21

Output

OUT1B

Output 1 ‘B’ Side of Motor Winding

22

Input

COMPIN1

Current Sense Comparator Input for Output 1

23

Input

SENSE1

Current Sense for Output 1

24

Power

V

LOAD

Positive Load Supply Voltage

2010-2013 Microchip Technology Inc.

DS22260C-page 7

MTS62C19A

2.1

Output Stage (OUT1A, OUT2A,

OUT1B, OUT2B)

Output connection to “A” side and “B” side of motor

windings.

2.2

Current Sense Input (SENSE1,

SENSE2)

Connection to lower sources of output stage for

insertion of current sense resistor.

2.3

Current Sense Comparator Input

(COMPIN1, COMPIN2)

Current sense comparator input.

2.4

Ground Terminal (GND)

Logic supply ground. Only the driver current flows out

of this pin; there is no high current. Minimize voltage

drops between this pin and the logic inputs.

2.5

Current Detection Selection

(I01, I02, I11, I12)

Comparator input for current threshold detection. The

voltage across the sense resistor is fed back to this

input through the low-pass filter R

c

C

c

. The power tran-

sistors are disabled when the sense voltage exceeds

the reference voltage of the selected comparator.

When this occurs, the current decays for a time set by

R

t

C

t

(T

OFF

= 1.1 R

t

C

t

).

2.6

Current Flow Direction Selection

(PHASE1, PHASE2)

Logic input to select the direction of the current flow

through the load. A “HIGH” logic signal level causes

load current to flow from OUTxA to OUTxB. A “LOW”

logic level causes load current to flow from OUTxB to

OUTxA.

2.7

Current Sense Reference

(V

REF1

, V

REF2

)

Reference voltage for current sense comparator.

Determines the level of output current detection

together with sensing resistor and inputs I0x, I1x.

2.8

Output Stage OFF Time

(RC1, RC2)

A parallel R

t

C

t

network connected to this pin sets the

OFF time of the power transistors. The monostable

pulse generator is triggered by the output of the current

sense comparator.

2.9

Logic Supply Voltage (V

LOGIC

)

Connect V

LOGIC

to the logic source voltage. Decouple

the supply with a 0.1 µF ceramic capacitor mounted

close to the V

LOGIC

and GND terminals.

2.10

Load Supply Voltage (V

LOAD

)

Connect V

LOAD

to the motor positive voltage supply.

The motor current is supplied through this pin and the

selected output transistors.

MTS62C19A

DS22260C-page 8

2010-2013 Microchip Technology Inc.

3.0

FUNCTIONAL DESCRIPTION

The circuit is designed to drive the two windings of a

bipolar stepper motor, and can be divided in two identi-

cal channels (channel 1 and channel 2) and protection

circuitry for overtemperature and undervoltage. The

functionality of a channel and protection circuitry is

presented in the following sections.

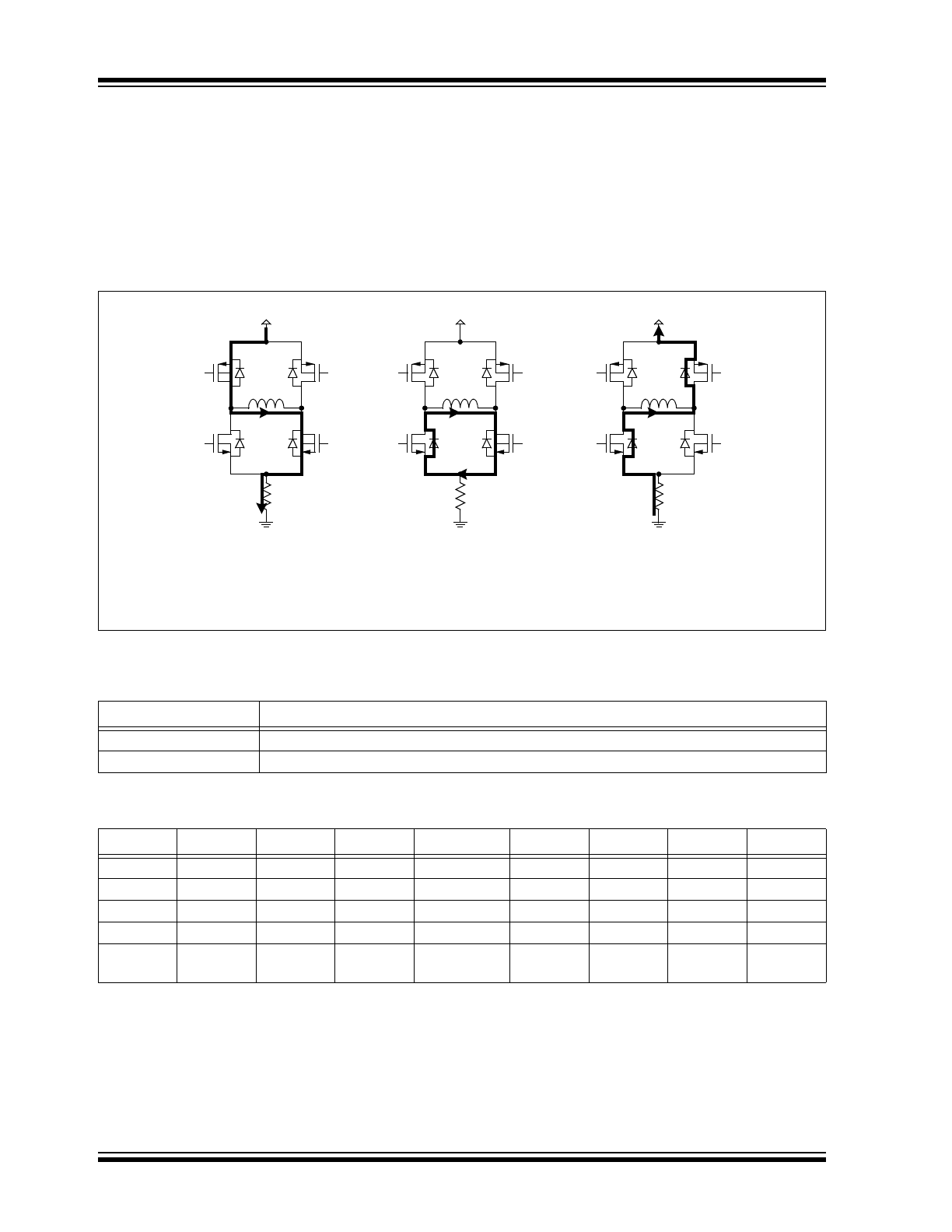

3.1

Power Bridge Operation

Each motor winding is driven by an H-type bridge

consisting of two N and two P transistors that allow the

current to flow in both winding directions depending on

the value of the PHASE signal (

Table 3-1

). The

H-bridge can be set in five configurations that are

related to the digital inputs PHASE, I0 and I1 and to the

current sensed. These configurations are shown in

Table 3-2

.

FIGURE 3-1:

Power Bridge Control (PHASE = H/forward).

Legend: a) Bridge ON, b) Source OFF, c) All OFF/Coasting

Note: For PHASE = L/Reverse, invert A and B in drawings.

V

LOAD

Pb

Pa

H

H

L

L

Nb

Na

SENSE

OUTA

OUTB

V

LOAD

Pb

Pa

H

H

L

L

Nb

Na

SENSE

OUTA

OUTB

V

LOAD

Pb

Pa

H

H

L

L

Nb

Na

SENSE

OUTA

OUTB

R

S

R

S

R

S

a)

b)

c)

TABLE 3-1:

CURRENT DIRECTION CONTROL

Phase

Output Current

L

Current flows from OUTxB to OUTxA

H

Current flows from OUTxA to OUTxB

TABLE 3-2:

POWER BRIDGE GATE CONTROL TRUTH TABLE

I0I1

PHASE

Overi

T

OFF

Case/Mode

gna

gpa

gnb

gpb

00/01/10

1

0

0

Forward ON

L

L

H

H

00/01/10

1

x

1

Forward OFF

L

H

H

H

00/01/10

0

0

0

Reverse ON

H

H

L

L

00/01/10

0

x

1

Reverse OFF

H

H

L

H

11

x

x

x

No Current/

Coasting

L

H

L

H

Legend: Bold = Active MOS Transistors, Overi = Overcurrent flag, T

OFF

= Channel T

OFF

State Flag

2010-2013 Microchip Technology Inc.

DS22260C-page 9

MTS62C19A

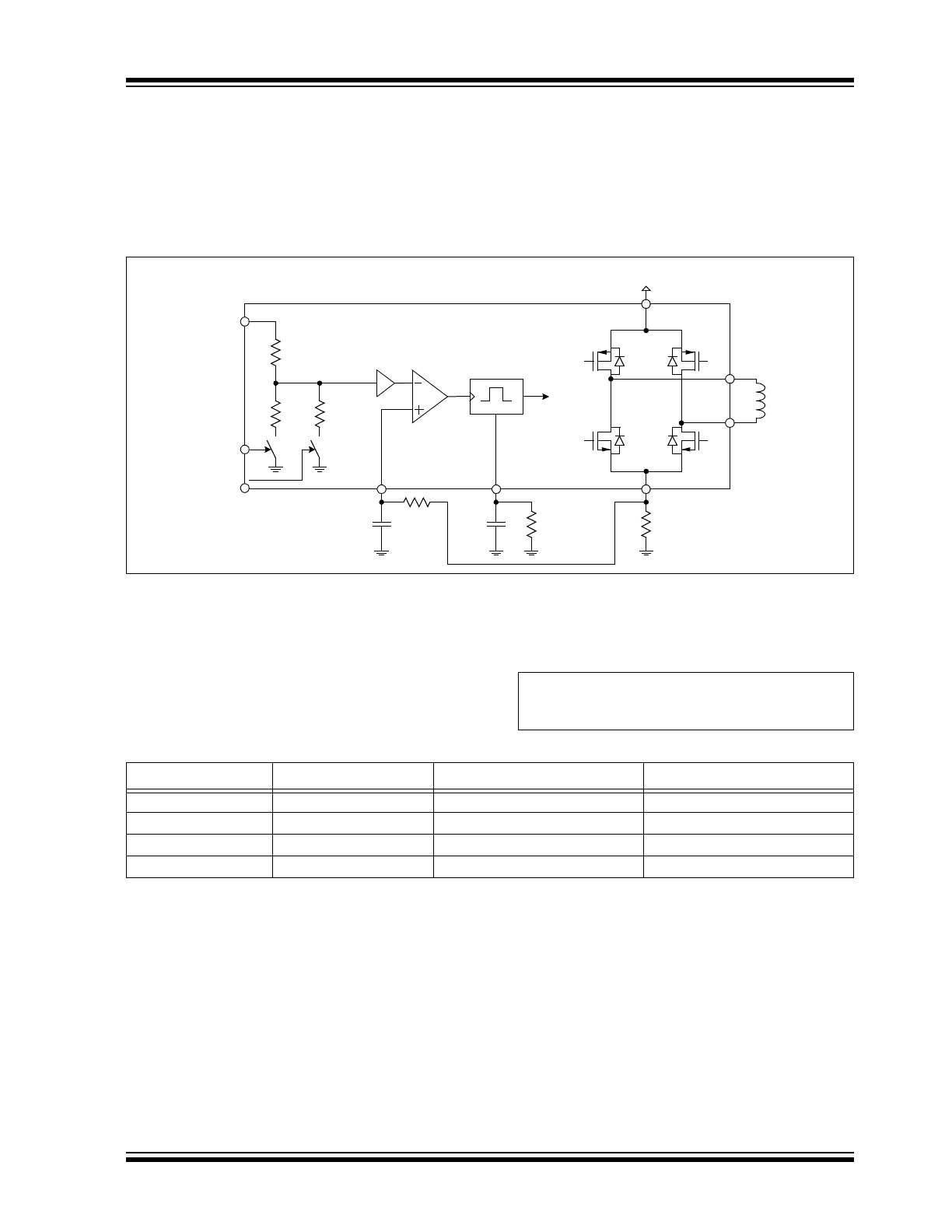

3.2

PWM Current Control

The current level in each motor winding is controlled by

a PWM circuit with a fixed T

OFF

time. The load current

flowing in the winding is sensed through an external

sensing resistor R

S

, connected between the power

bridge's source pin SENSE (sources of transistors Na

and Nb) and GND.

FIGURE 3-2:

PWM Current Control Circuit Principle (Channel 1 Shown).

The voltage across R

S

is compared to a fraction of the

reference voltage V

REF

, chosen with the logic input bits

I0 and I1 (

Table 3-3

). The power bridge, and thus the

load current, can also be switched off completely when

both logic inputs are high. Note that any logic input left

unconnected will be treated as a high level (pull-up

resistor).

The maximum trip current for regulation, given for

I0 I1 = 00 is calculated in

Equation 3-1

.

EQUATION 3-1:

V

LOAD

SENSE

V

REF

I0

I1

COMPIN

C

C

R

C

C

t

R

t

R

S

RC

÷10

One-Shot

Source

Disable

Power

Bridge

Pa

Pb

Na

Nb

OUTA

OUTB

I

MAX

V

REF

10

R

S

------------------

=

TABLE 3-3:

CURRENT LEVEL CONTROL TRUTH TABLE

I0

I1

Comp. Trip Voltage

Output Current

0

0

V

TRIP

= 1/10 x V

REF

I

MAX

= V

REF

/10R

S

1

0

V

TRIP

= 1/15 x V

REF

2/3 x I

MAX

= V

REF

/15R

S

0

1

V

TRIP

= 1/30 x V

REF

1/3 x I

MAX

= V

REF

/30R

S

1

1

x

0 (no current)

MTS62C19A

DS22260C-page 10

2010-2013 Microchip Technology Inc.

When the maximum allowed current is reached, the

bridge source is turned off during a fixed period T

OFF

(typically 50 µs) given by a non-retriggerable pulse

generator and the external timing components R

t

(20k – 100 k

range) and C

t

(100 pF – 1000 pF

range):

EQUATION 3-2:

During T

OFF

the winding current decreases. When the

driver is re-enabled, the winding current increases

again until it reaches the threshold, and the cycle

repeats itself, maintaining the load current at the

desired level.

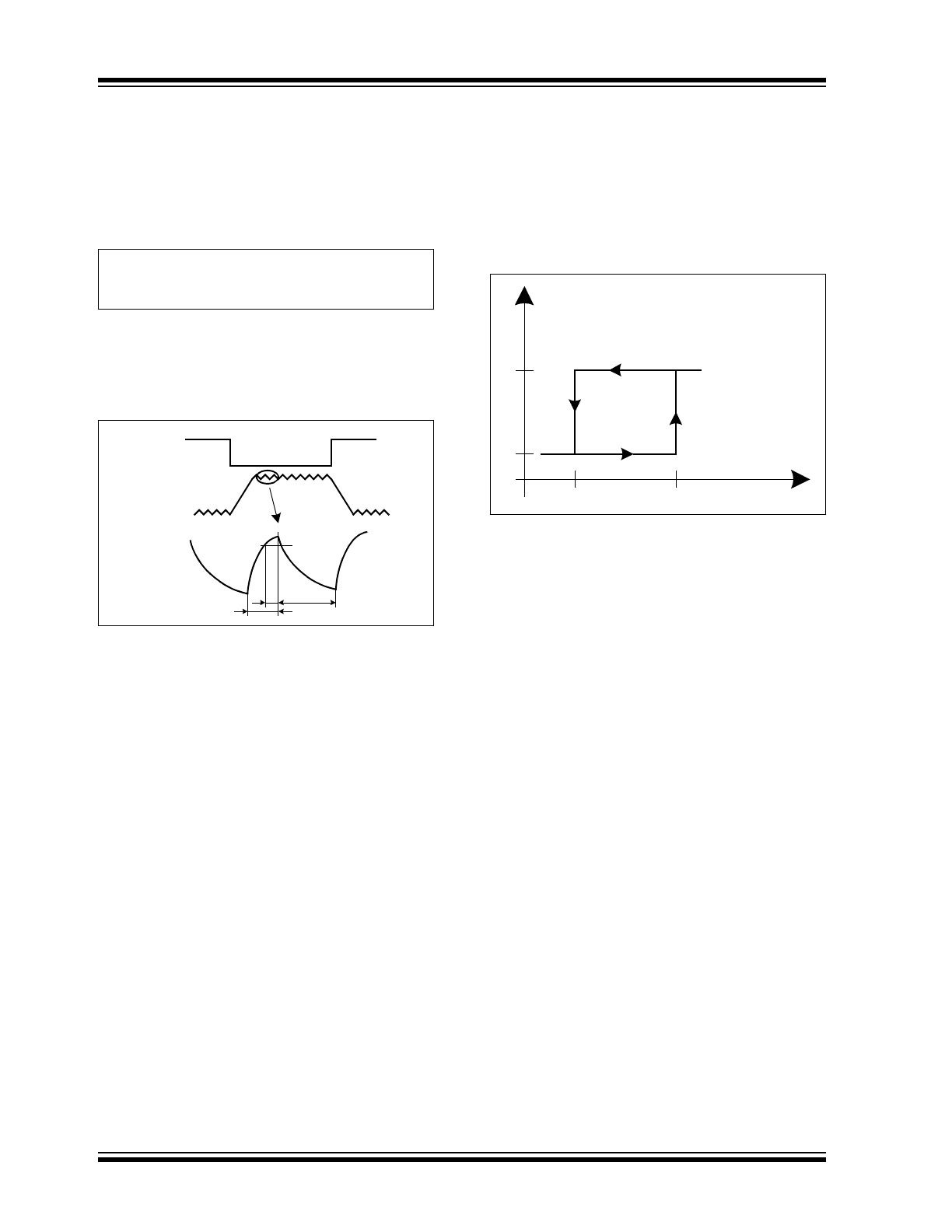

FIGURE 3-3:

PWM Output Current

Waveform.

3.3

Circuit Protection

A thermal protection circuitry turns off all drivers when

the junction temperature exceeds a safe operating limit

of +170°C (typical). This protects the devices from

failure due to excessive heating. Despite this thermal

protection, output short circuits are not permitted. The

output drivers are re-enabled once junction

temperature has dropped below +145°C (typical).

FIGURE 3-4:

Thermal Shutdown Output

vs. Temperature Showing Hysteresis.

An undervoltage lockout circuit protects the

MTS62C19A from potential shoot-through currents

when the load supply voltage is applied prior to the

logic supply voltage. The power bridge and all outputs

are disabled if V

LOGIC

is smaller than 4V.

With this protection feature, the circuit will withstand

any order of turn-on or turn-off of the supply voltages

V

LOGIC

and V

LOAD.

Normal dV/dt values are assumed.

T

OFF

1.1

R

t

C

t

=

PHASE

I

OUT

+

0

-

I

OUT

t

off

t

d

t

on

1

0

+170°C

+145°C

thshtd_en