2010-2012 Microchip Technology Inc.

DS22263B-page 1

Features

• Position Sensorless BLDC Drivers (No Hall

Sensor Required)

• 180° Sinusoidal Drive, for High Efficiency and Low

Acoustic Noise

• Support 2V to 14V Power Supplies

• Speed Control Through PAM and/or PWM

• Built-in Frequency Generator (FG Output Signal)

• Built-in Lock-up Protection and Automatic

Recovery Circuit (External Capacitor not

Necessary)

• Built-in Over Current Limitation and Short Circuit

Protection

• Built-in Thermal Shutdown Protection

• Thermally Enhanced SOP-8 Package for

MTD6501C and MTD6501G (Maximum Output

Current – 800 mA);

• MSOP-10L Package for MTD6501D (Maximum

Output Current – 500 mA)

• 20 kHz PWM Output Frequency for MTD6501C/D

and 23 kHz for MTD6501G

• Boost Mode (Optional Back Electromotive Force

(BEMF) Pre-amplification in MTD6501D)

• No External Tuning Required

Description

The MTD6501C/D/G devices are 3-phase, full-wave

drivers for brushless sensorless DC motors. They

feature 180° sinusoidal drive, high torque output, and

silent drive. Due to their adaptive features and wide

power-supply range capabilities (2V to 14V), they are

intended to cover a wide range of motor characteristics,

while requiring no external tuning from the user. Speed

control can be achieved through either power supply

modulation or pulse-width modulation (using the PWM

digital input pin).

Due to the compact packaging and minimum bill of

materials (power transistors incorporated, no Hall

sensor, no external tuning), they are best suited for low-

cost fan applications requiring high efficiency and low

acoustic noise, such as CPU cooling fans. Frequency

generator output enables precision speed control in

closed-loop applications. The MTD6501C/D/G drivers

include a Lock-up Protection mode, which turns off the

output current when the motor is under lock condition,

and an automatic recovery that enables the fan to run

when the lock condition is removed. Motor overcurrent

limitation, short-circuit protection and thermal-

shutdown protection are also included.

The MTD6501C and the MTD6501G are available in a

compact thermally-enhanced SOP-8 package, while

the MTD6501D is available in the MSOP-10L package.

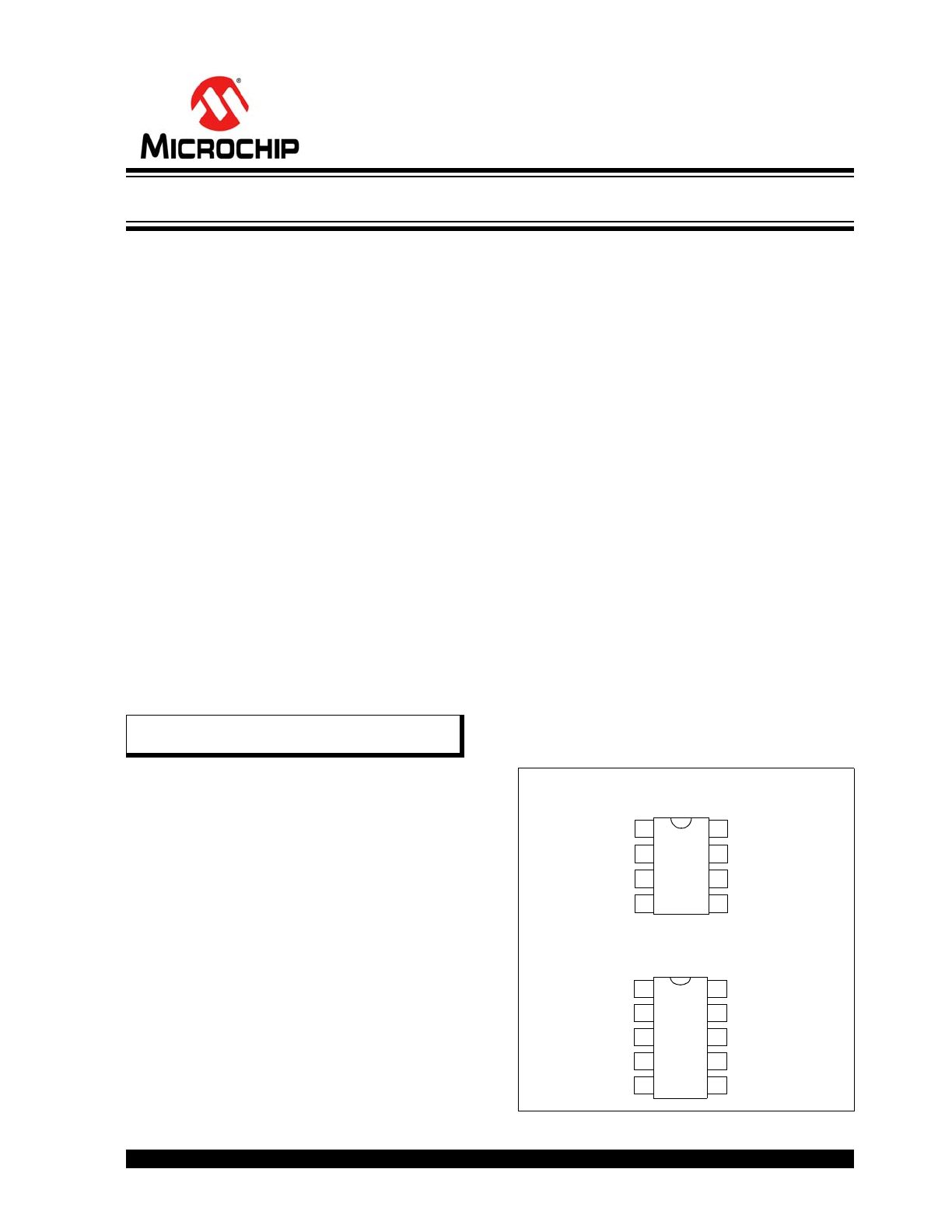

Package Types

The MTD6501C/D/G devices are formerly products of

Advanced Silicon.

MTD6501D

MSOP

V

DD

GND

OUT1

1

2

3

4

10

9

8

7

FG

PWM

BOOST

V

CC

OUT3

OUT2 5

6 GND

MTD6501C, MTD6501G

SOP-8

OUT1

V

DD

OUT2

1

2

3

4

8

7

6

5

FG

PWM

V

CC

OUT3

GND

3-Phase Brushless DC Sinusoidal Sensorless Fan Motor Driver

MTD6501C/D/G

MTD6501C/D/G

DS22263B-page 2

2010-2012 Microchip Technology Inc.

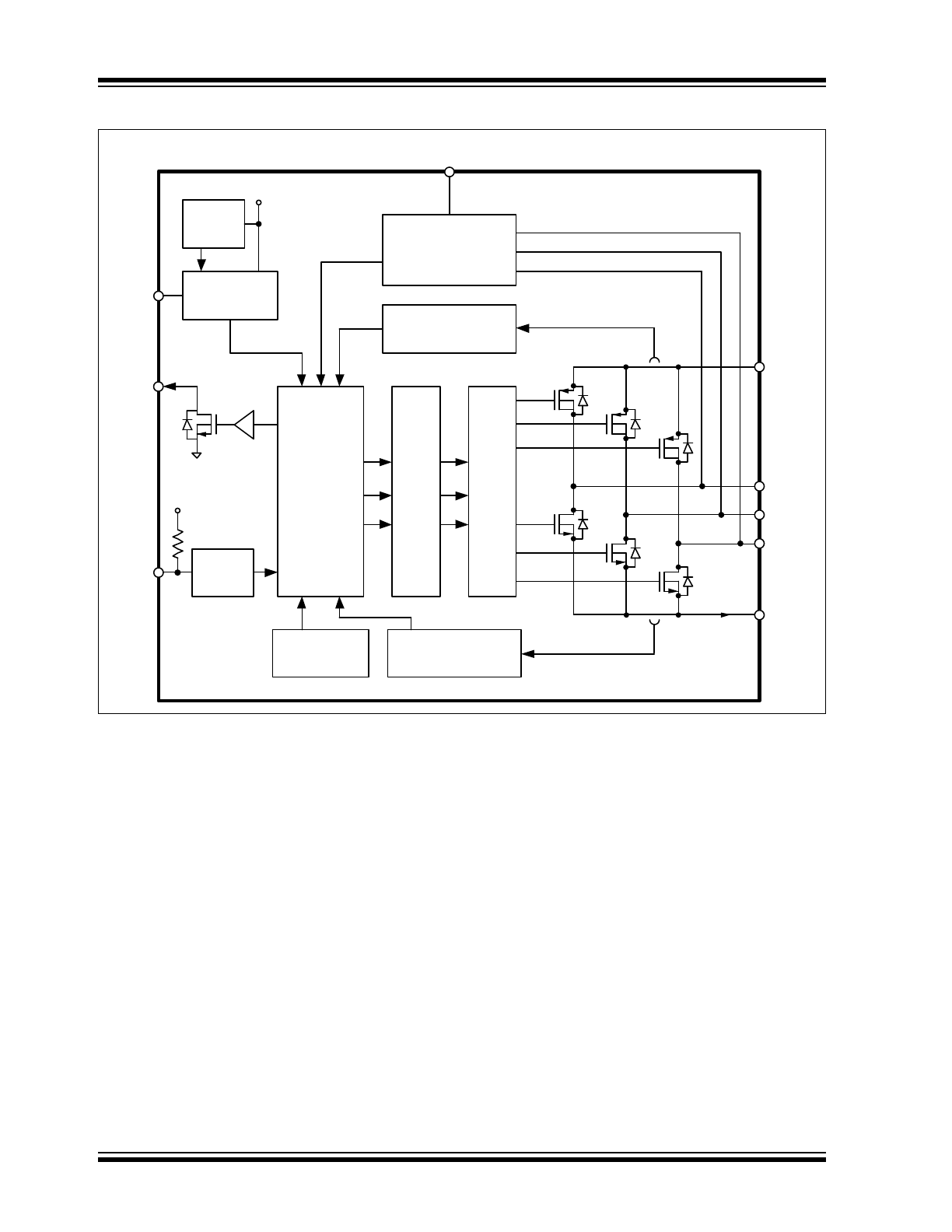

Functional Block Diagram

Thermal

protection

V

DD

OUT1

OUT2

Timing

Controller

PWM

FG

OUT3

V

CC

Short-circuit

protection

Output

Drive

Circuit

Motor Phase

Detection Circuit

Overcurrent

protection

PWM

Input

Soft

Switching

Drive

V

CC

Regulator

V

REF

GND

V

DD

BOOST

*MTD6501D Only

2010-2012 Microchip Technology Inc.

DS22263B-page 3

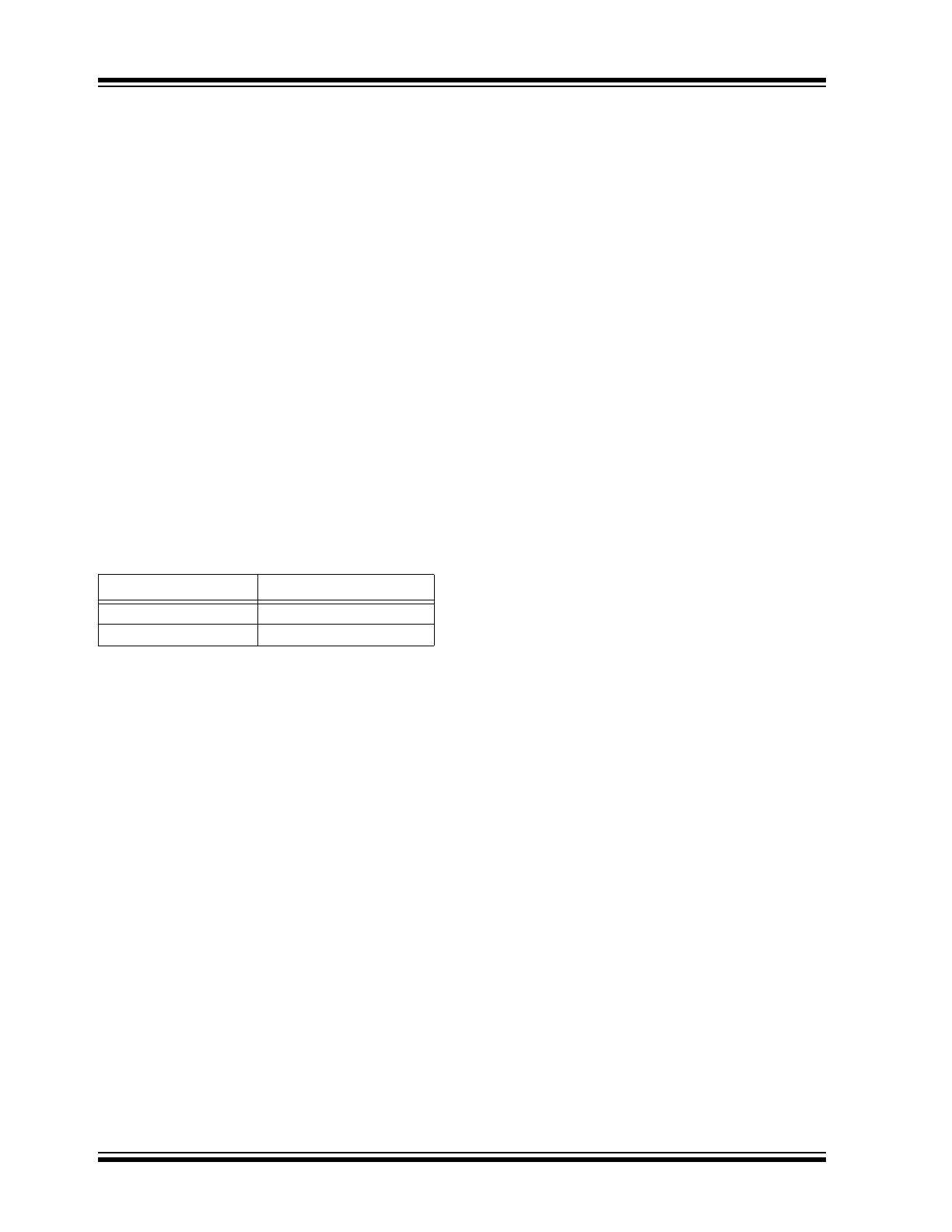

MTD6501C/D/G

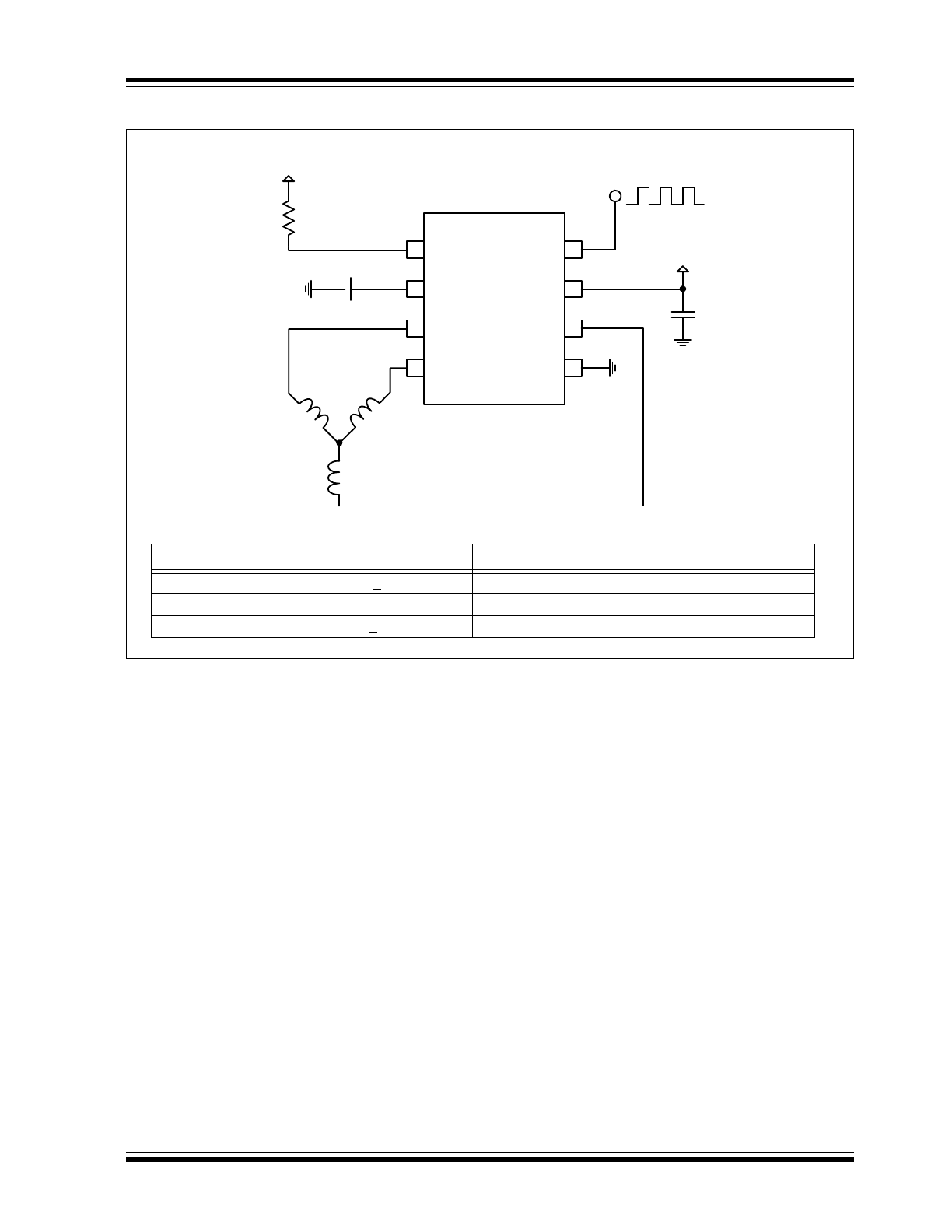

Typical Application – Fan Motor Driver Using the MTD6501C or MTD6501G

Recommended External Components for Typical Application

Element

Type/Value

Comment

C

1

>1 µF

Connect as close as possible to IC input pins

C

2

>1 µF

Connect as close as possible to IC input pins

R

1

>10 kΩ

Connect to V

logic

on controller side

OUT1

FG

V

DD

OUT2

GND

V

CC

PWM

OUT3

1

2

3

4

5

6

7

8

M

T

D6

5

0

1

C/

G

V

CC

PWM input

(0.02-100 kHz)

C

1

C

2

R

1

V

logic

(controller side)

MTD6501C/D/G

DS22263B-page 4

2010-2012 Microchip Technology Inc.

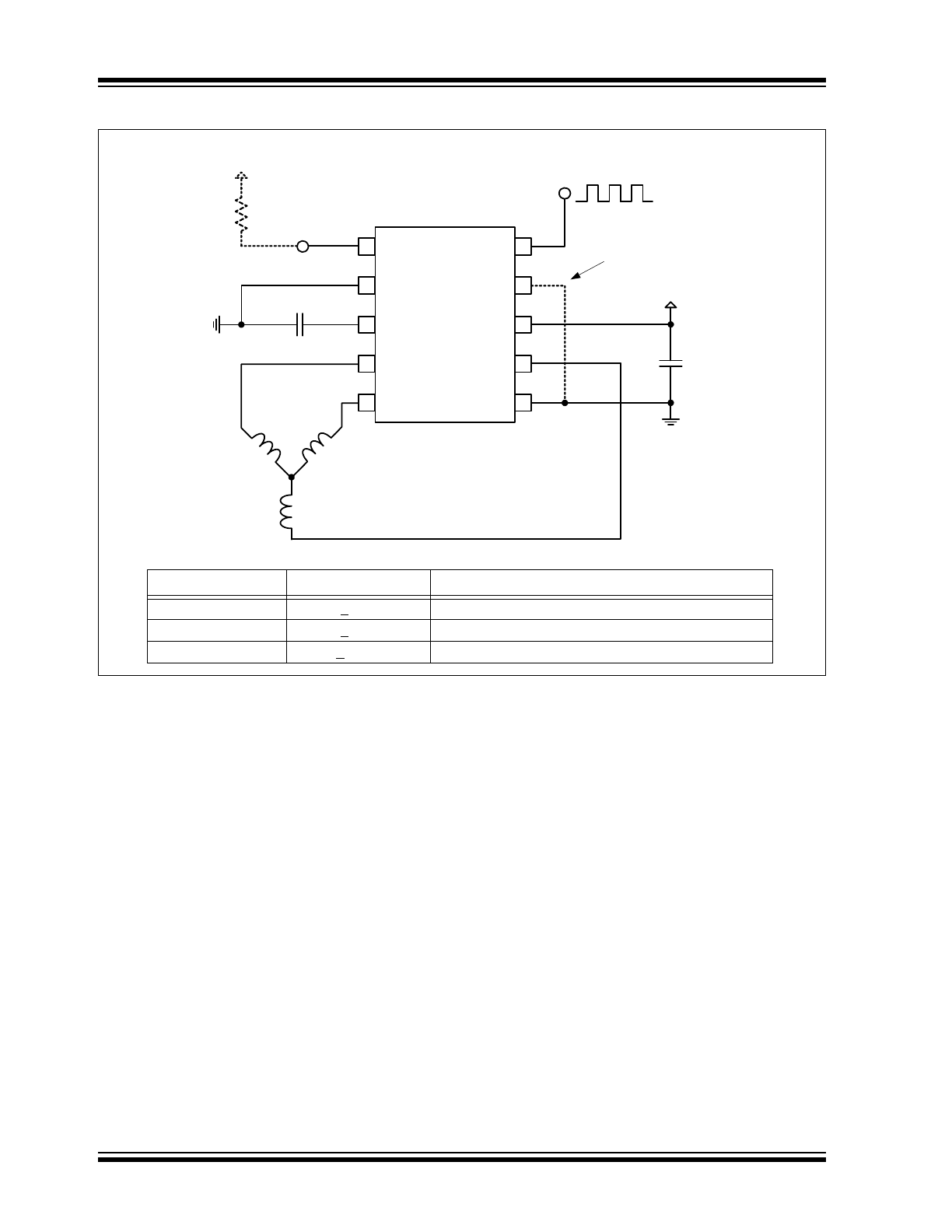

Typical Application – Fan Motor Driver Using the MTD6501D

Recommended External Components for Typical Application

Element

Type/Value

Comment

C1

>1 µF

Connect as close as possible to IC input pins

C2

>1 µF

Connect as close as possible to IC input pins

R1

>10 kΩ

Connect to Vlogic on controller side

OUT1

GND

OUT2

GND

BOOST

PWM

OUT3

1

2

4

5

6

7

9

10

M

T

D6501D

V

DD

VCC

3

8

R

1

V

logic

(controller side)

C

1

C

2

PWM input

(0.02-100 kHz)

FG

Tie to GND

for BOOST

mode

2010-2012 Microchip Technology Inc.

DS22263B-page 5

MTD6501C/D/G

1.0

ELECTRICAL

CHARACTERISTICS

Absolute Maximum Ratings†

Power Supply Voltage (V

CC_MAX

) .................... -0.7 to +15.3V

Maximum OUT1, 2, 3 Output Voltage (V

OUT_MAX

) .................

................................................................ -0.7 to +15.3V+0.7V

FG Maximum Output Voltage (V

FG_MAX

) ......... -0.7 to +15.3V

Maximum Output Current

(

3

,

4

)

(I

OUT_MAX

)....................800 mA

Maximum Output Current

(

3

,

5

)

(I

OUT_MAX

)....................500 mA

FG Maximum Output Voltage (V

FG_MAX

) ......... -0.7 to +15.3V

FG Maximum Output Current (I

FG_MAX

)

.....................5.0 mA

V

DD

Maximum Voltage (V

DD_MAX

) ..................... -0.7 to +4.0V

PWM Maximum Voltage (V

PWM_MAX

) ................ -0.7 to +4.0V

Allowable Power Dissipation

(

1

,

2

,

4

)

(P

D_MAX

).....................1.0W

Allowable Power Dissipation

(

1

,

2

,

5

)

(P

D_MAX

).....................0.5W

Max Junction Temperature (T

J

)....................................+150°C

† Notice:

Stresses above those listed under “Maximum

Ratings” may cause permanent damage to the device.

This is a stress rating only and functional operation of

the device at those or any other conditions above those

indicated in the operational listings of this specification

is not implied. Exposure to maximum rating conditions

for extended periods may affect device reliability.

Note 1:

Reference PCB, according to JEDEC

standard EIA/JESD 51-9.

2:

Derating applies for ambient temperatures

outside the specified operating range (refer

to

Figure 1-1

).

3:

OUT1, OUT2, OUT3 (Continuous,

100% duty cycle).

4:

MTD6501C and MTD6501G

5:

MTD6501D

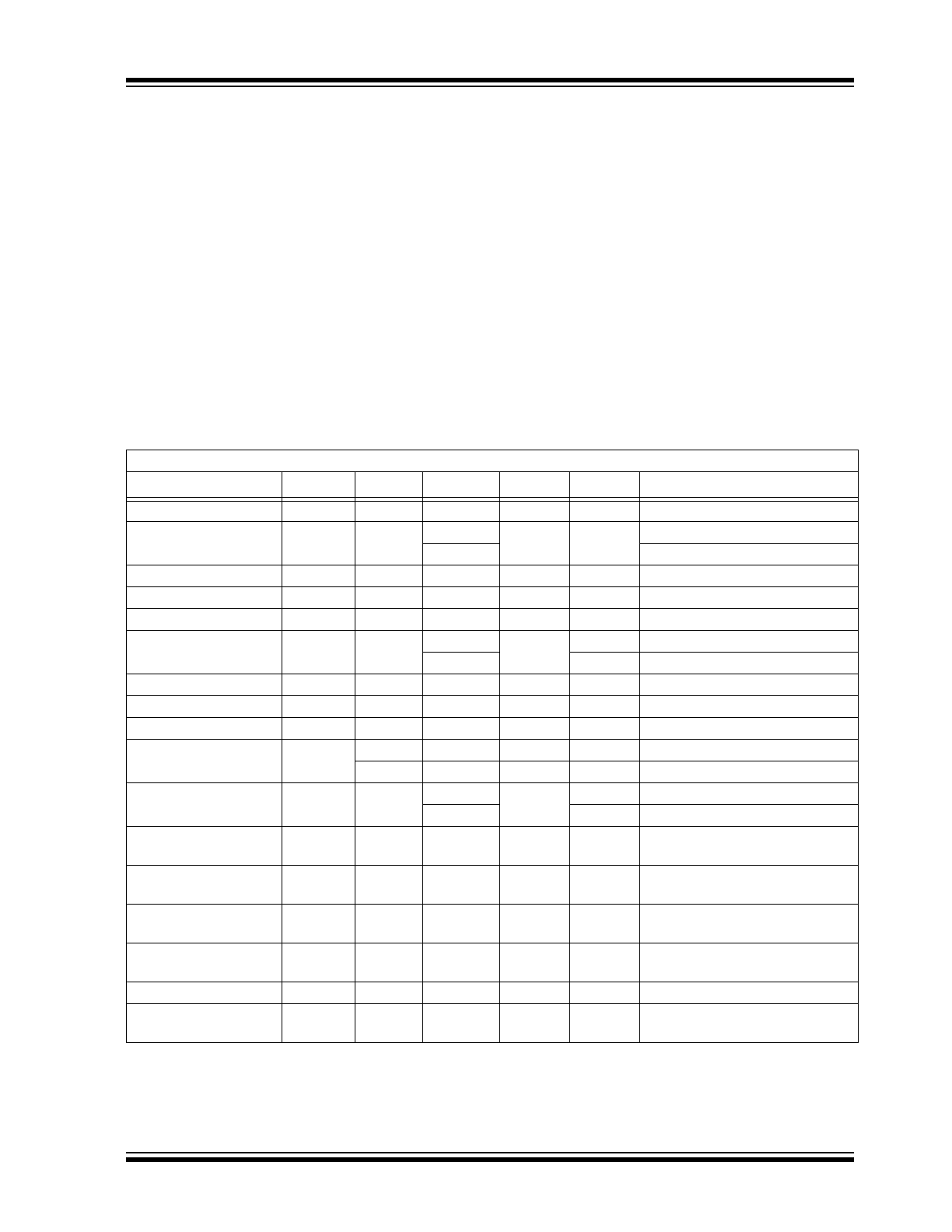

ELECTRICAL CHARACTERISTICS

Electrical Specifications:

Unless otherwise specified, all limits are established for V

CC

= 5.0V, T

A

= +25°C

Parameters

Sym.

Min.

Typ.

Max.

Units

Conditions

Power Supply Voltage

V

CC

2

—

14

V

Power Supply Current

I

VCC

—

10

—

mA

Rotation Mode

5

Lock-Protection Mode

OUTx High Resistance

R

ON(H)

—

0.75

1

Ω

I

OUT

= 0.5A, V

CC

= 3.3V to 14V

OUTx Low Resistance

R

ON(L)

—

0.75

1

Ω

I

OUT

= -0.5A, V

CC

= 3.3V to 14V

OUTx Total Resistance

R

ON(H+L)

—

1.5

2

Ω

I

OUT

= 0.5A, V

CC

= 3.3V to 14V

V

DD

Output Voltage

V

DD

—

3

—

V

V

CC

= 3.3V to 14V

V

CC

– 0.2

V

V

CC

< 3.3V

PWM Input Frequency

f

PWM

0.02

—

100

kHz

—

PWM Input H Level

V

PWM_H

0.8*V

DD

—

3.6

V

—

PWM Input L Level

V

PWM_L

0

—

0.2*V

DD

V

—

PWM Internal Pull-Up

Current

I

PWM_L

17

34

—

µA

PWM = GND, V

CC

= 3.3V to 14V

8

17

—

µA

PWM = GND, V

CC

< 3.3V

PWM Output

Frequency

f

PWM_O

—

20

—

kHz

MTD6501C

and MTD6501D

23

kHz

MTD6501G

FG Output Pin Low

Level Voltage

V

OL_FG

—

—

0.25

V

I

FG

= -1 mA

FG Output Pin Leakage

Current

I

LH_FG

—

—

10

µA

V

FG

= 14V

Lock Protection

Operating Time

T

RUN

—

0.5

—

s

—

Lock Protection Waiting

Time

T

WAIT

4.5

5

5.5

s

—

Thermal Shutdown

T

SD

—

170

—

°C

—

Thermal Shutdown

Hysteresis

T

SD_HYS

—

25

—

°C

—

MTD6501C/D/G

DS22263B-page 6

2010-2012 Microchip Technology Inc.

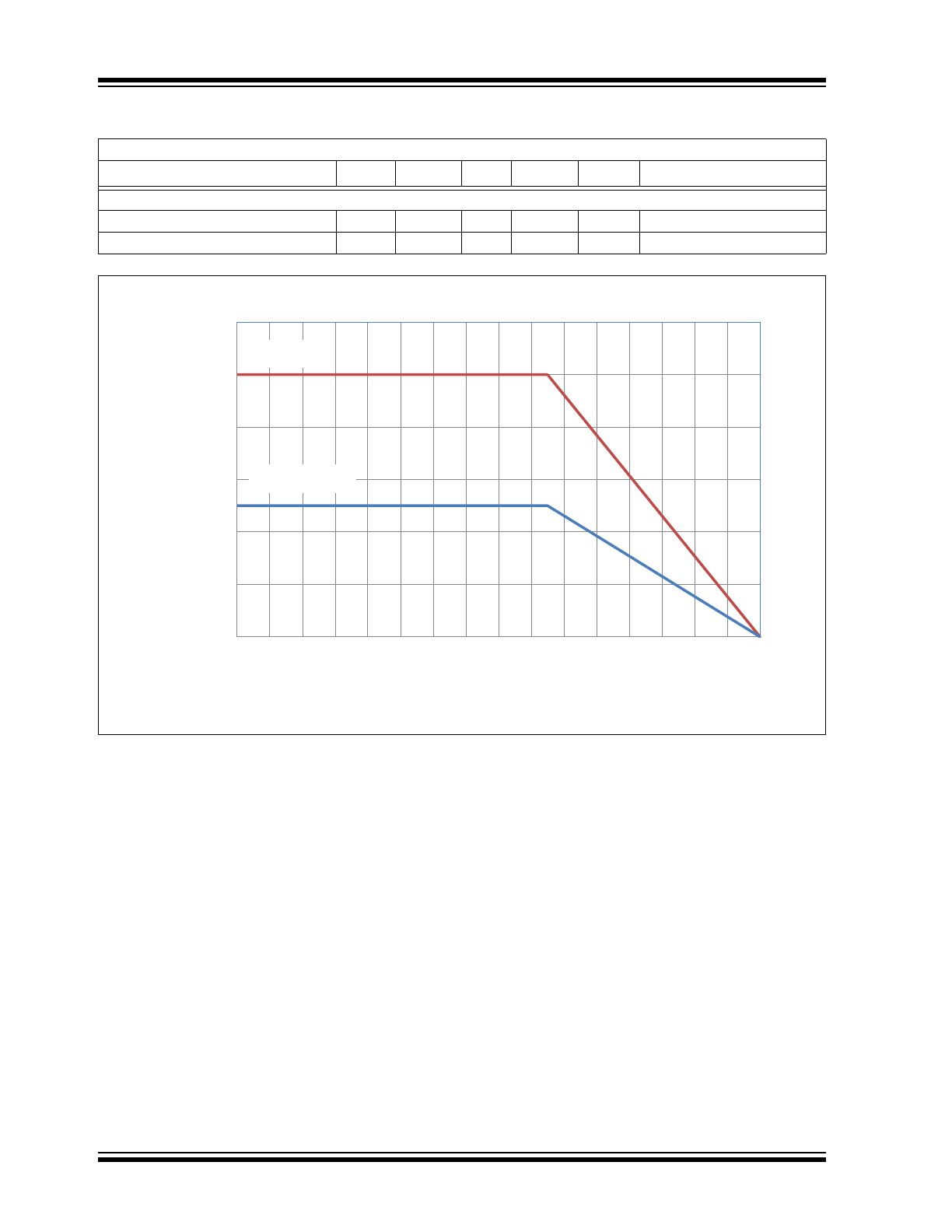

FIGURE 1-1:

Allowable Power Dissipation (P

D_MAX

) as a Function of Ambient Temperature (T

A

).

TEMPERATURE SPECIFICATIONS

Electrical Specifications:

Unless otherwise specified, all limits are established for V

CC

= 5.0V, T

A

= +25°C

Parameters

Sym.

Min.

Typ.

Max.

Units

Conditions

Temperature Ranges

Operating Temperature

T

OPR

-30

—

+95

°C

Storage Temperature Range

T

STG

-55

—

+150

°C

0

0.2

0.4

0.6

0.8

1

1.2

-10

0

10

20

30

40

50

60

70

80

90

100

11

0

120

130

140

150

P

DMA

X

(W)

T

A

(°C)

SOP-8

MSOP-10

2010-2012 Microchip Technology Inc.

DS22263B-page 7

MTD6501C/D/G

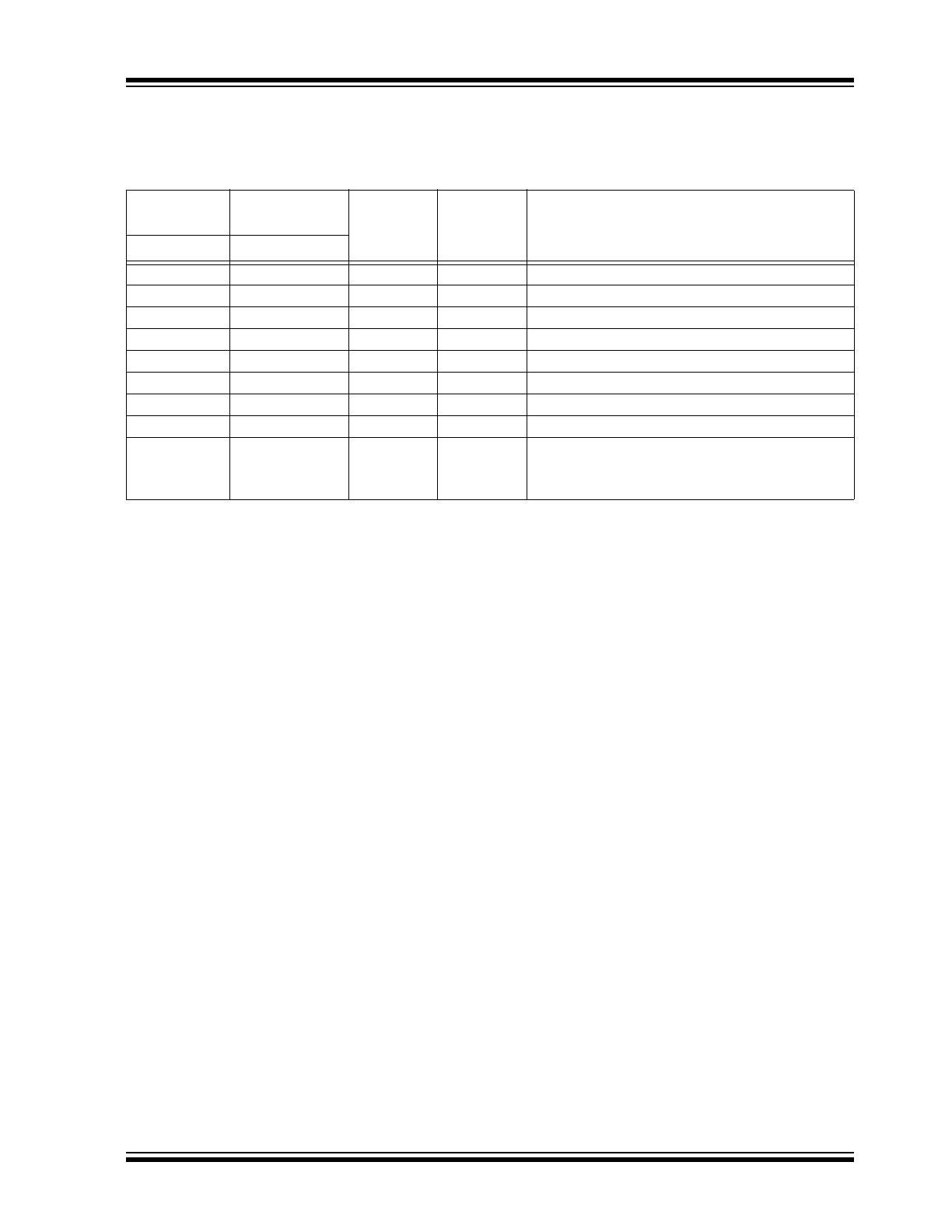

2.0

PIN DESCRIPTIONS

The descriptions of the pins are listed in

Table 2-1

.

TABLE 2-1:

MTD6501C/D/G PIN FUNCTION TABLE

MTD6501C,

MTD6501G

MTD6501D

Type

Symbol

Description

SOP-8

MSOP

1

1

O

FG

Motor speed indication output

2

3

P

V

DD

Internal regulator output (for decoupling only)

3

4

O

OUT1

Single-phase coil output pin

4

5

O

OUT2

Single-phase coil output pin

5

2, 6

P

GND

Negative voltage supply (ground)

6

7

O

OUT3

Single-phase coil output pin

7

8

P

V

CC

Positive voltage supply for motor driver

8

10

I

PWM

PWM input signal for speed control

N/A

9

I

BOOST

Boost mode selection:

• Pin floating for Normal mode

• Pin tied to GND for Boost mode

Legend:

I = Input; O = Output; P = Power

MTD6501C/D/G

DS22263B-page 8

2010-2012 Microchip Technology Inc.

NOTES:

2010-2012 Microchip Technology Inc.

DS22263B-page 9

MTD6501C/D/G

3.0

FUNCTIONAL DESCRIPTION

The MTD6501C/D/G devices generate a full-wave sig-

nal to drive a 3-phase sensorless BLDC motor. High

efficiency and low-power consumption are achieved

due to DMOS transistors and synchronous rectification

drive type. The current carrying order of the output is as

follows: OUT1

OUT2 OUT3.

3.1

Speed Control

The rotational speed of the motor can be controlled

either through the PWM digital input signal or by acting

directly on the power supply (V

CC

). When the PWM

signal is “High” (or left open) the motor rotates at full

speed. When the PWM signal is “Low”, the motor is

stopped (and the IC outputs are set to high-

impedance). By changing the PWM duty cycle, the

speed can be adjusted. Notice that the PWM frequency

has no special meaning for the motor speed and is

asynchronous with the activation of the output

transistors. Thus, the user has maximum freedom to

choose the PWM system frequency within a wide range

(from 20 Hz to 100 kHz), while the output transistor

activation always occurs at a fixed rate, which is

outside of the range of audible frequencies. The

MTD6501C and MTD6501D typical output frequency is

20 kHz. The MTD6501G output frequency is 23 kHz.

3.2

Frequency Generator Function

The Frequency Generator output is a “Hall-sensor

equivalent” digital output, giving information to an

external controller about the speed and phase of the

motor. The FG pin is an open drain output, connecting

to a logical voltage level through an external pull-up

resistor. When a lock (or out-of-sync) situation is

detected by the driver, this output is set to high-imped-

ance until the motor is restarted. Leave the pin open

when not used. The FG signal can be used to compute

the motor speed in rotations per minute (RPM). Typi-

cally, for a four pole BLDC fan, the speed in RPMs is 30

FG frequency (Hz).

3.3

Lockup Protection and Automatic

Restart

If the motor is stopped (blocked) or if it loses

synchronization with the driver, a lock-up protection

circuit detects this situation and disables the driver (by

setting its outputs to high-impedance) in order to

prevent the motor coil from burnout. After a “waiting

time” (T

WAIT

), the lock-up protection is released and

normal operation resumes for a given time (T

RUN

). In

case the motor is still blocked, a new period of waiting

time is started. T

WAIT

and T

RUN

timings are fixed

internally, so that no external capacitor is needed.

3.4

Overcurrent Protection and Short

Circuit Detection

The motor peak current is limited by the driver to a fixed

value (defined internally), thus limiting the maximum

power dissipation in the coils. The detection of a short-

circuit situation immediately sets the driver outputs to

high-impedance, in order to avoid permanent damage

to the IC.

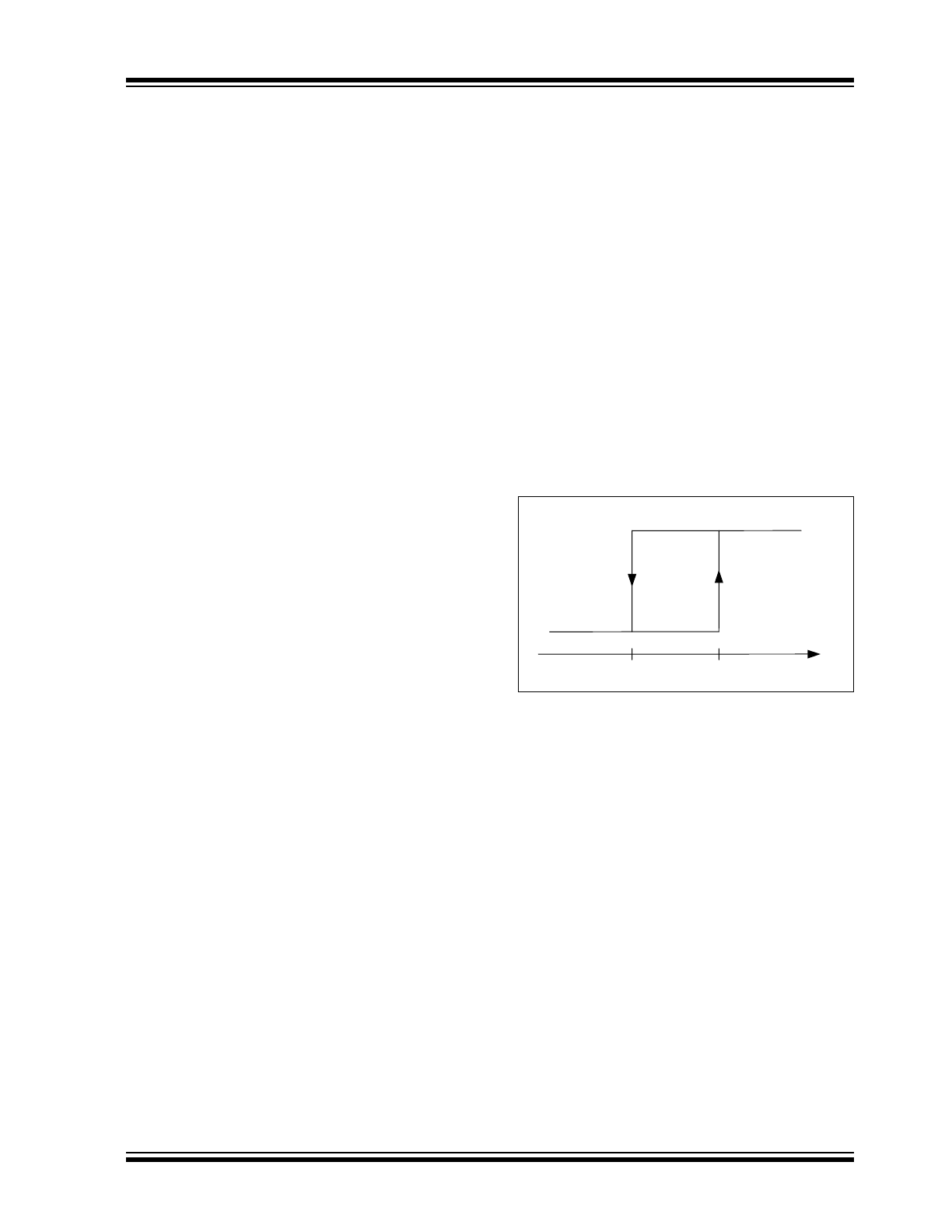

3.5

Thermal Shutdown

The MTD6501C/D/G have a thermal protection

function which detects when the die temperature

exceeds T

SD

= +170°C. When this temperature is

reached, the circuit enters Thermal Shutdown mode

and the outputs OUT1, OUT2 and OUT3 are disabled

(high-impedance), avoiding IC destruction and allowing

the circuit to cool down. Once the junction temperature

(T

SD

) has dropped below +145°C, the normal operation

resumes (thermal detection circuit has +25°C

hysteresis function).

FIGURE 3-1:

Thermal Protection

Hysteresis.

3.6

Internal Voltage Regulator

V

DD

voltage is generated internally and is used to

supply internal logical blocks. The V

DD

pin is used to

connect an external decoupling capacitor (1 µF or

higher). Notice that this pin is for IC internal use and is

not designed to supply DC current to external blocks.

T

SD

+145°C

Thermal Shutdown

+170°C

Normal operation

MTD6501C/D/G

DS22263B-page 10

2010-2012 Microchip Technology Inc.

3.7

Boost Mode (MTD6501D)

The Boost mode is an optional BEMF pre-amplification

by a factor of three. The intention of Boost mode is to

compensate for motors with a low coupling coefficient

(= BEMF coefficient), thus allowing it to cover an even

wider range of motor characteristics. Notice that Boost

mode impacts the mechanical performance of the

motor altogether. In Boost mode, the speed of the

motor will adjust faster to variations of the control (V

CC

or PWM) and/or of the load, including at start-up.

However, when the BEMF is amplified too much, the

mechanical performance (in terms of vibration and

acoustic noise) may start degrading. Thus, Boost mode

may be inappropriate for motors that already have a

good coupling coefficient. The optimum choice

between normal mode and Boost mode depends both

on the application requirements and on the motor

characteristics.

Refer to

Table 3-1

for usage of Boost pin 9; leaving this

pin floating results in the normal mode of operation,

while tying this pin to GND activates Boost mode

(active low feature, internal pull-up).

TABLE 3-1:

POSSIBLE MODES OF

OPERATION BASED ON THE

BOOST PIN CONNECTION

BOOST Pin

Mode of Operation

Floating

Normal

Tied to GND

Boost