©

2007 Microchip Technology Inc.

DS21291F-page 1

MCP2510

Features

• Implements Full CAN V2.0A and V2.0B at 1 Mb/s:

- 0 - 8 byte message length

- Standard and extended data frames

- Programmable bit rate up to 1 Mb/s

- Support for remote frames

- Two receive buffers with prioritized message

storage

- Six full acceptance filters

- Two full acceptance filter masks

- Three transmit buffers with prioritization and

abort features

- Loop-back mode for self test operation

• Hardware Features:

- High Speed SPI Interface

(5 MHz at 4.5V I temp)

- Supports SPI modes 0,0 and 1,1

- Clock out pin with programmable prescaler

- Interrupt output pin with selectable enables

- ‘Buffer full’ output pins configureable as inter-

rupt pins for each receive buffer or as general

purpose digital outputs

- ‘Request to Send’ input pins configureable as

control pins to request immediate message

transmission for each transmit buffer or as

general purpose digital inputs

- Low Power Sleep mode

• Low power CMOS technology:

- Operates from 3.0V to 5.5V

- 5 mA active current typical

- 10 µA standby current typical at 5.5V

• 18-pin PDIP/SOIC and 20-pin TSSOP packages

• Temperature ranges supported:

Description

The Microchip Technology Inc. MCP2510 is a Full Con-

troller Area Network (CAN) protocol controller imple-

menting CAN specification V2.0 A/B. It supports CAN

1.2, CAN 2.0A, CAN 2.0B Passive, and CAN 2.0B

Active versions of the protocol, and is capable of trans-

mitting and receiving standard and extended mes-

sages. It is also capable of both acceptance filtering

and message management. It includes three transmit

buffers and two receive buffers that reduce the amount

of microcontroller (MCU) management required. The

MCU communication is implemented via an industry

standard Serial Peripheral Interface (SPI) with data

rates up to 5 Mb/s.

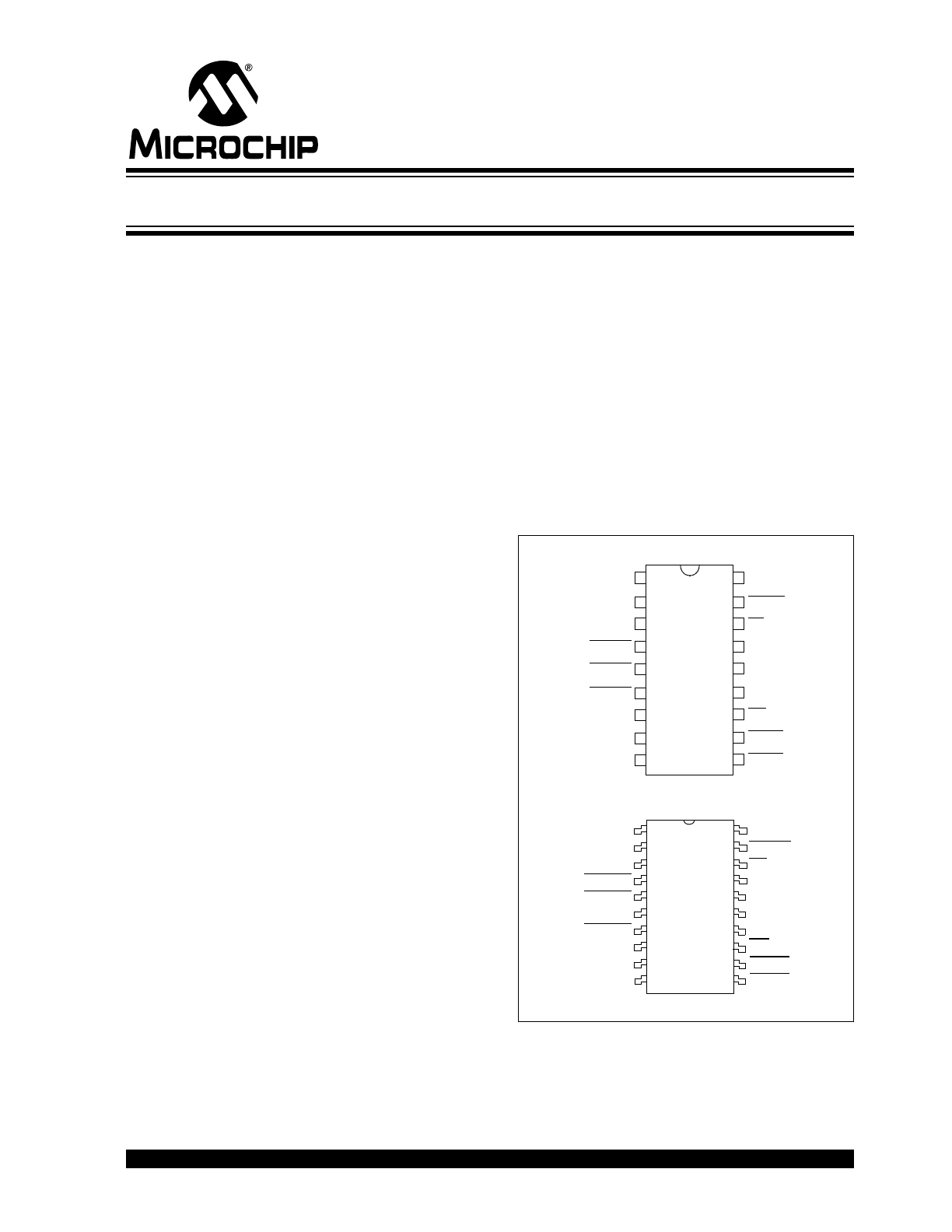

Package Types

- Industrial (I):

-40°C to +85°C

- Extended (E):

-40°C to +125°C

TXCAN

RXCAN

V

DD

RESET

CS

SO

MC

P

2

51

0

1

2

3

4

18

17

16

15

SI

SCK

INT

RX0BF

14

13

12

11

RX1BF

10

OSC2

OSC1

CLKOUT

TX2RTS

5

6

7

8

V

SS

9

MC

P

2

51

0

TXCAN

RXCAN

TX0RTS

OSC1

CLKOUT

OSC2

CS

V

DD

RESET

SO

SCK

INT

SI

RX0BF

RX1BF

V

SS

TX0RTS

TX1RTS

TX1RTS

TX2RTS

NC

NC

13

12

1

2

3

4

5

6

7

8

9

20

19

18

17

16

15

14

11

10

18 LEAD PDIP/SOIC

20 LEAD TSSOP

Stand-Alone CAN Controller with SPI

™

Interface

MCP2510

DS21291F-page 2

©

2007 Microchip Technology Inc.

Table of Contents

1.0

Device Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.0

Can Message Frames. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.0

Message Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.0

Message Reception . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.0

Bit Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.0

Error Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7.0

Interrupts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8.0

Oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9.0

Modes of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

10.0

Register Map. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

11.0

SPI Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

12.0

Electrical Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

13.0

Packaging Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

On-Line Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Reader Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Product Identification System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Worldwide Sales and Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

TO OUR VALUED CUSTOMERS

It is our intention to provide our valued customers with the best documentation possible to ensure successful use of your Micro-

chip products. To this end, we will continue to improve our publications to better suit your needs. Our publications will be refined

and enhanced as new volumes and updates are introduced.

If you have any questions or comments regarding this publication, please contact the Marketing Communications Department via

E-mail at docerrors@microchip.com or fax the Reader Response Form in the back of this data sheet to (480) 792-4150. We

welcome your feedback.

Most Current Data Sheet

To obtain the most up-to-date version of this data sheet, please register at our Worldwide Web site at:

http://www.microchip.com

You can determine the version of a data sheet by examining its literature number found on the bottom outside corner of any page.

The last character of the literature number is the version number, (e.g., DS30000A is version A of document DS30000).

Errata

An errata sheet, describing minor operational differences from the data sheet and recommended workarounds, may exist for cur-

rent devices. As device/documentation issues become known to us, we will publish an errata sheet. The errata will specify the revi-

sion of silicon and revision of document to which it applies.

To determine if an errata sheet exists for a particular device, please check with one of the following:

• Microchip’s Worldwide Web site; http://www.microchip.com

• Your local Microchip sales office (see last page)

When contacting a sales office, please specify which device, revision of silicon and data sheet (include literature number) you are

using.

Customer Notification System

Register on our web site at www.microchip.com to receive the most current information on all of our products.

©

2007 Microchip Technology Inc.

DS21291F-page 3

MCP2510

1.0

DEVICE FUNCTIONALITY

1.1

Overview

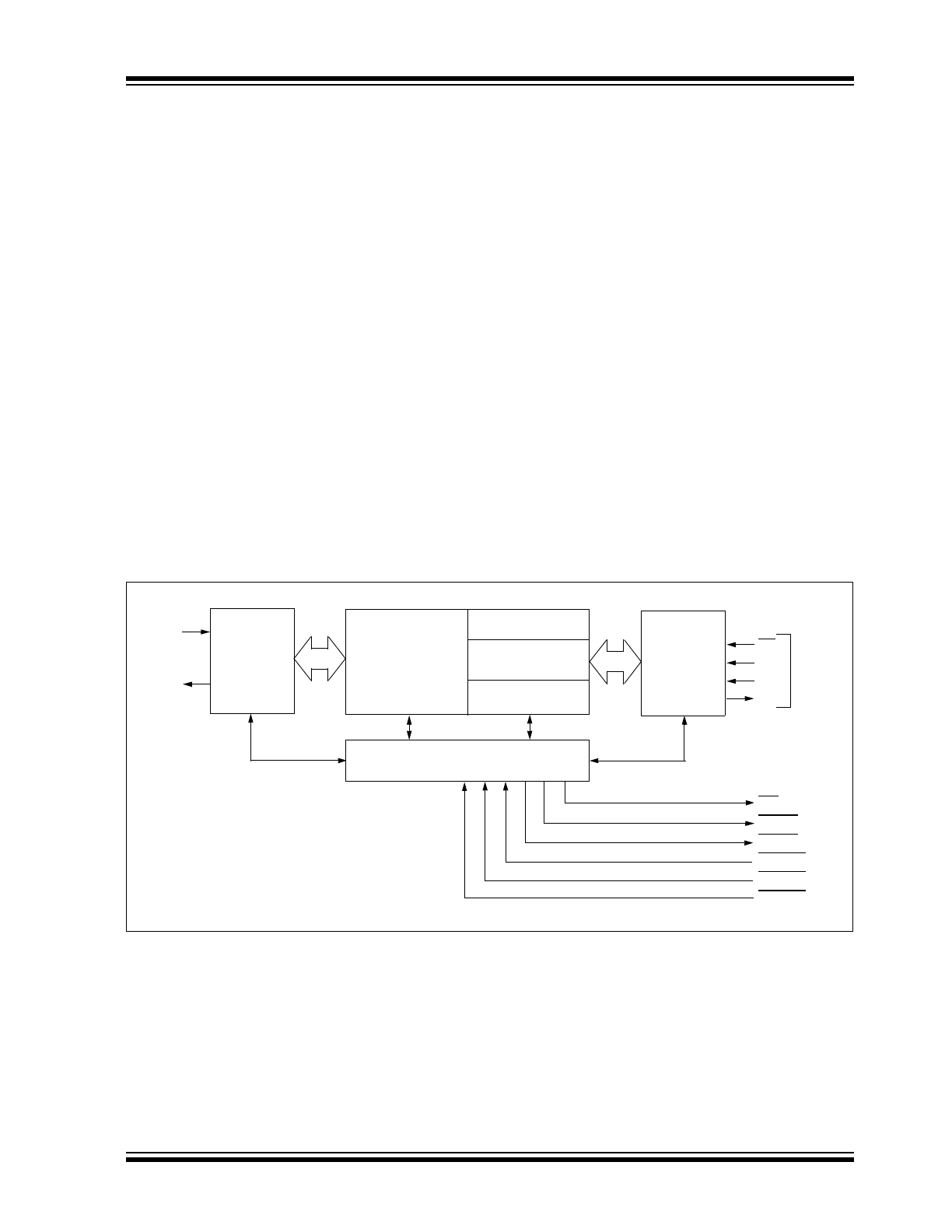

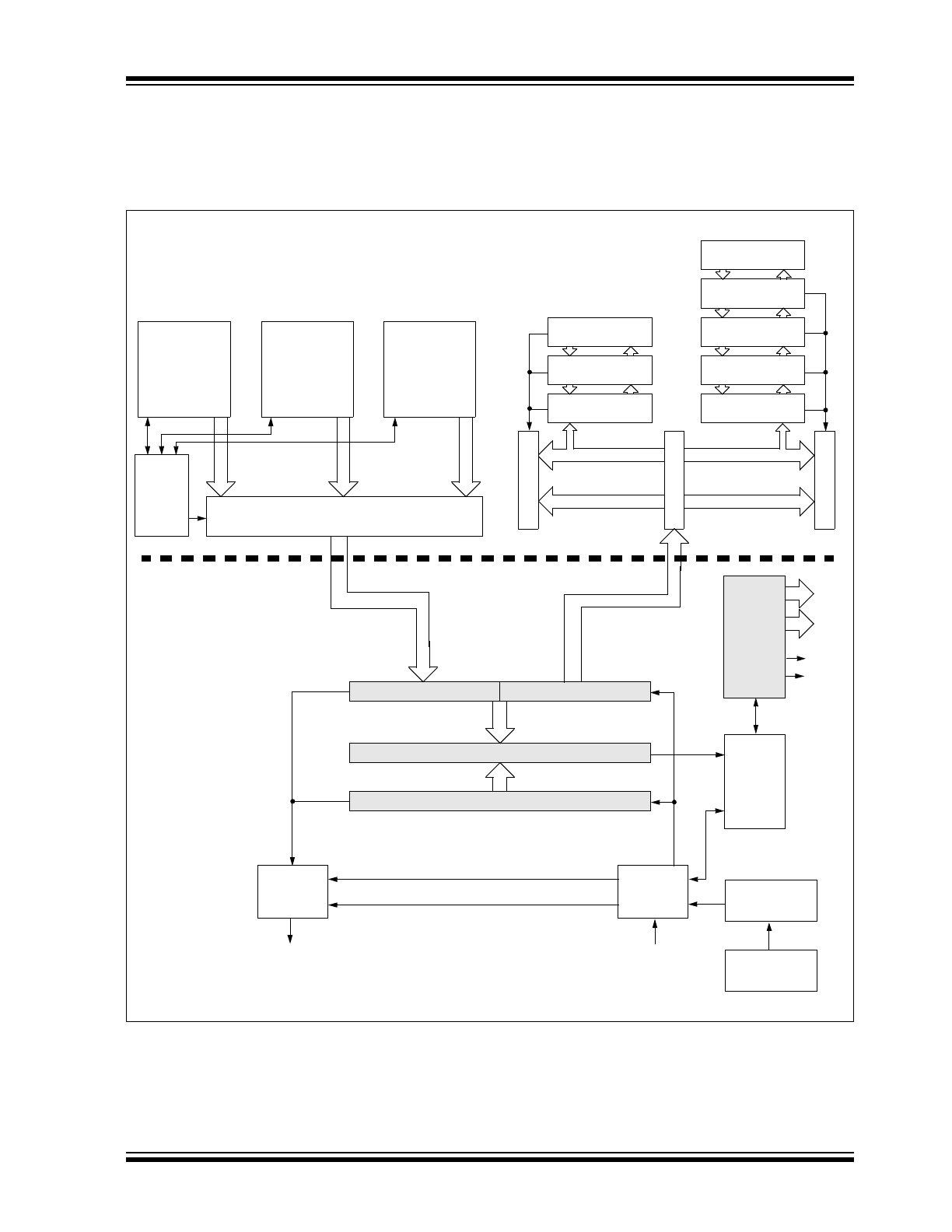

The MCP2510 is a stand-alone CAN controller devel-

oped to simplify applications that require interfacing

with a CAN bus. A simple block diagram of the

MCP2510 is shown in Figure 1-1. The device consists

of three main blocks:

1.

The CAN protocol engine.

2.

The control logic and SRAM registers that are

used to configure the device and its operation.

3.

The SPI protocol block.

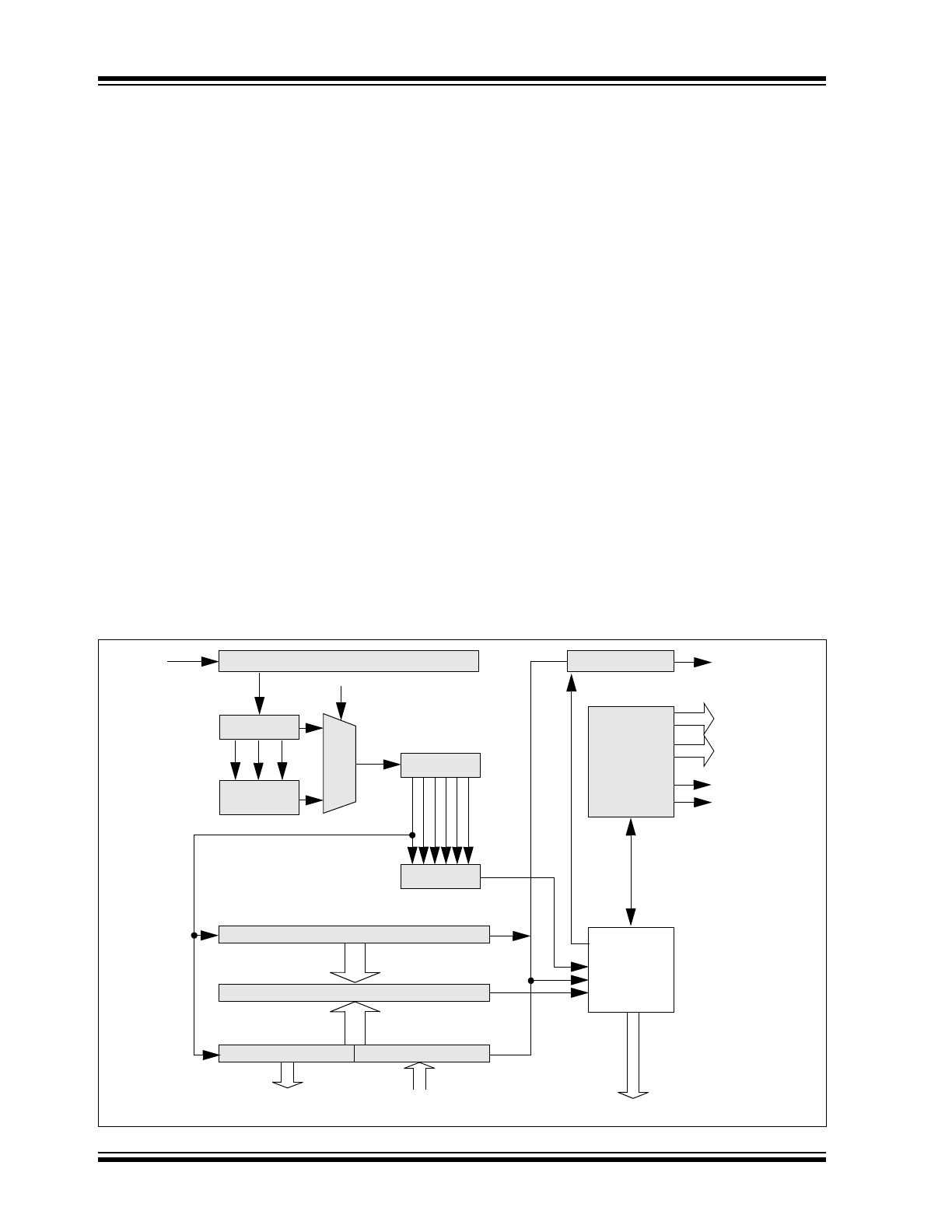

A typical system implementation using the device is

shown in Figure 1-2.

The CAN protocol engine handles all functions for

receiving and transmitting messages on the bus. Mes-

sages are transmitted by first loading the appropriate

message buffer and control registers. Transmission is

initiated by using control register bits, via the SPI inter-

face, or by using the transmit enable pins. Status and

errors can be checked by reading the appropriate reg-

isters. Any message detected on the CAN bus is

checked for errors and then matched against the user

defined filters to see if it should be moved into one of

the two receive buffers.

The MCU interfaces to the device via the SPI interface.

Writing to and reading from all registers is done using

standard SPI read and write commands.

Interrupt pins are provided to allow greater system flex-

ibility. There is one multi-purpose interrupt pin as well

as specific interrupt pins for each of the receive regis-

ters that can be used to indicate when a valid message

has been received and loaded into one of the receive

buffers. Use of the specific interrupt pins is optional,

and the general purpose interrupt pin as well as status

registers (accessed via the SPI interface) can also be

used to determine when a valid message has been

received.

There are also three pins available to initiate immediate

transmission of a message that has been loaded into

one of the three transmit registers. Use of these pins is

optional and initiating message transmission can also

be done by utilizing control registers accessed via the

SPI interface.

Table 1-1 gives a complete list of all of the pins on the

MCP2510.

FIGURE 1-1:

BLOCK DIAGRAM

3 TX

Buffers

2 RX Buffers

Message Assembly

6 Acceptance

Filters

SPI

Interface

Logic

SPI

Bus

INT

Buffer

CS

SCK

SI

SO

CAN

Protocol

Engine

RXCAN

TXCAN

Control Logic

RX0BF

RX1BF

TX0RTS

TX1RTS

TX2RTS

MCP2510

DS21291F-page 4

©

2007 Microchip Technology Inc.

FIGURE 1-2:

TYPICAL SYSTEM IMPLEMENTATION

TABLE 1-1:

PIN DESCRIPTIONS

Name

DIP/

SOIC

Pin #

TSSOP

Pin #

I/O/P

Type

Description

TXCAN

1

1

O

Transmit output pin to CAN bus

RXCAN

2

2

I

Receive input pin from CAN bus

CLKOUT

3

3

O

Clock output pin with programmable prescaler

TX0RTS

4

4

I

Transmit buffer TXB0 request to send or general purpose digital input. 100 k

Ω

internal pullup to V

DD

TX1RTS

5

5

I

Transmit buffer TXB1 request to send or general purpose digital input. 100 k

Ω

internal pullup to V

DD

TX2RTS

6

7

I

Transmit buffer TXB2 request to send or general purpose digital input. 100 k

Ω

internal pullup to V

DD

OSC2

7

8

O

Oscillator output

OSC1

8

9

I

Oscillator input

V

SS

9

10

P

Ground reference for logic and I/O pins

RX1BF

10

11

O

Receive buffer RXB1 interrupt pin or general purpose digital output

RX0BF

11

12

O

Receive buffer RXB0 interrupt pin or general purpose digital output

INT

12

13

O

Interrupt output pin

SCK

13

14

I

Clock input pin for SPI interface

SI

14

16

I

Data input pin for SPI interface

SO

15

17

O

Data output pin for SPI interface

CS

16

18

I

Chip select input pin for SPI interface

RESET

17

19

I

Active low device reset input

V

DD

18

20

P

Positive supply for logic and I/O pins

NC

—

6,15

—

No internal connection

Note:

Type Identification: I=Input; O=Output; P=Power

MCP2510

SPI

MCP2510

MCP2510

MCP2510

INTERFACE

CAN

BUS

MCP2510

Main

System

Controller

CAN

Transceiver

CAN

Transceiver

CAN

Transceiver

CAN

Transceiver

CAN

Transceiver

Node

Controller

Node

Controller

Node

Controller

Node

Controller

©

2007 Microchip Technology Inc.

DS21291F-page 5

MCP2510

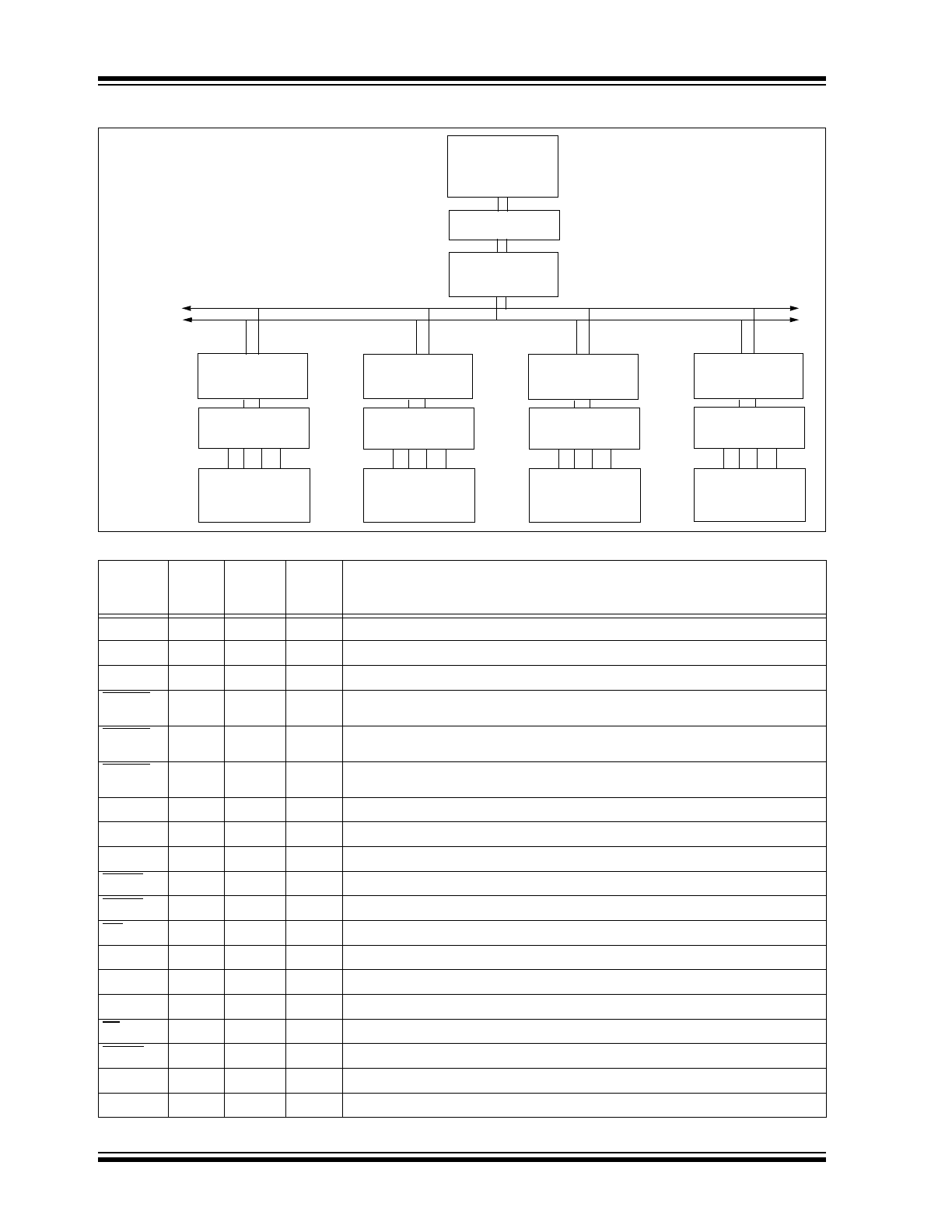

1.2

Transmit/Receive Buffers

The MCP2510 has three transmit and two receive buffers, two acceptance masks (one for each receive buffer), and a

total of six acceptance filters. Figure 1-3 is a block diagram of these buffers and their connection to the protocol engine.

FIGURE 1-3:

CAN BUFFERS AND PROTOCOL ENGINE BLOCK DIAGRAM

Acceptance Filter

RXF2

R

X

B

1

Identifier

Data Field

Data Field

Identifier

Acceptance Mask

RXM1

Acceptance Filter

RXF3

Acceptance Filter

RXF4

Acceptance Filter

RXF5

M

A

B

Acceptance Filter

RXF0

Acceptance Filter

RXF1

R

X

B

0

TX

R

E

Q

TXB2

ABT

F

ML

O

A

TX

ERR

ME

SS

AGE

Message

Queue

Control

Transmit Byte Sequencer

TX

R

E

Q

TXB0

ABT

F

ML

O

A

TX

ERR

ME

SS

AGE

CRC<14:0>

Comparator

Receive<7:0>

Transmit<7:0>

Receive

Error

Transmit

Error

Protocol

REC

TEC

ErrPas

BusOff

Finite

State

Machine

Counter

Counter

Shift<14:0>

{Transmit<5:0>, Receive<8:0>}

Transmit

Logic

Bit

Timing

Logic

TX

RX

Configuration

Registers

Clock

Generator

PROTOCOL

ENGINE

BUFFERS

TX

R

E

Q

TXB1

ABT

F

ML

O

A

TX

ERR

ME

SS

AGE

Acceptance Mask

RXM0

A

c

c

e

p

t

A

c

c

e

p

t

MCP2510

DS21291F-page 6

©

2007 Microchip Technology Inc.

1.3

CAN Protocol Engine

The CAN protocol engine combines several functional

blocks, shown in Figure 1-4. These blocks and their

functions are described below.

1.4

Protocol Finite State Machine

The heart of the engine is the Finite State Machine

(FSM). This state machine sequences through mes-

sages on a bit by bit basis, changing states as the fields

of the various frame types are transmitted or received.

The FSM is a sequencer controlling the sequential data

stream between the TX/RX Shift Register, the CRC

Register, and the bus line. The FSM also controls the

Error Management Logic (EML) and the parallel data

stream between the TX/RX Shift Registers and the

buffers. The FSM insures that the processes of recep-

tion, arbitration, transmission, and error signaling are

performed according to the CAN protocol. The auto-

matic retransmission of messages on the bus line is

also handled by the FSM.

1.5

Cyclic Redundancy Check

The Cyclic Redundancy Check Register generates the

Cyclic Redundancy Check (CRC) code which is trans-

mitted after either the Control Field (for messages with

0 data bytes) or the Data Field, and is used to check the

CRC field of incoming messages.

1.6

Error Management Logic

The Error Management Logic is responsible for the

fault confinement of the CAN device. Its two counters,

the Receive Error Counter (REC) and the Transmit

Error Counter (TEC), are incremented and decre-

mented by commands from the Bit Stream Processor.

According to the values of the error counters, the CAN

controller is set into the states error-active, error-pas-

sive or bus-off.

1.7

Bit Timing Logic

The Bit Timing Logic (BTL) monitors the bus line input

and handles the bus related bit timing according to the

CAN protocol. The BTL synchronizes on a recessive to

dominant bus transition at Start of Frame (hard syn-

chronization) and on any further recessive to dominant

bus line transition if the CAN controller itself does not

transmit a dominant bit (resynchronization). The BTL

also provides programmable time segments to com-

pensate for the propagation delay time, phase shifts,

and to define the position of the Sample Point within the

bit time. The programming of the BTL depends upon

the baud rate and external physical delay times.

FIGURE 1-4:

CAN PROTOCOL ENGINE BLOCK DIAGRAM

Bit Timing Logic

CRC<14:0>

Comparator

Receive<7:0>

Transmit<7:0>

Sample<2:0>

Majority

Decision

StuffReg<5:0>

Comparator

Transmit Logic

Receive

Error Counter

Transmit

Error Counter

Protocol

FSM

RX

SAM

BusMon

Rec/Trm Addr.

RecData<7:0>

TrmData<7:0>

Shift<14:0>

(Transmit<5:0>, Receive<7:0>)

TX

REC

TEC

ErrPas

BusOff

Interface to Standard Buffer

©

2007 Microchip Technology Inc.

DS21291F-page 7

MCP2510

2.0

CAN MESSAGE FRAMES

The MCP2510 supports Standard Data Frames,

Extended Data Frames, and Remote Frames (Stan-

dard and Extended) as defined in the CAN 2.0B speci-

fication.

2.1

Standard Data Frame

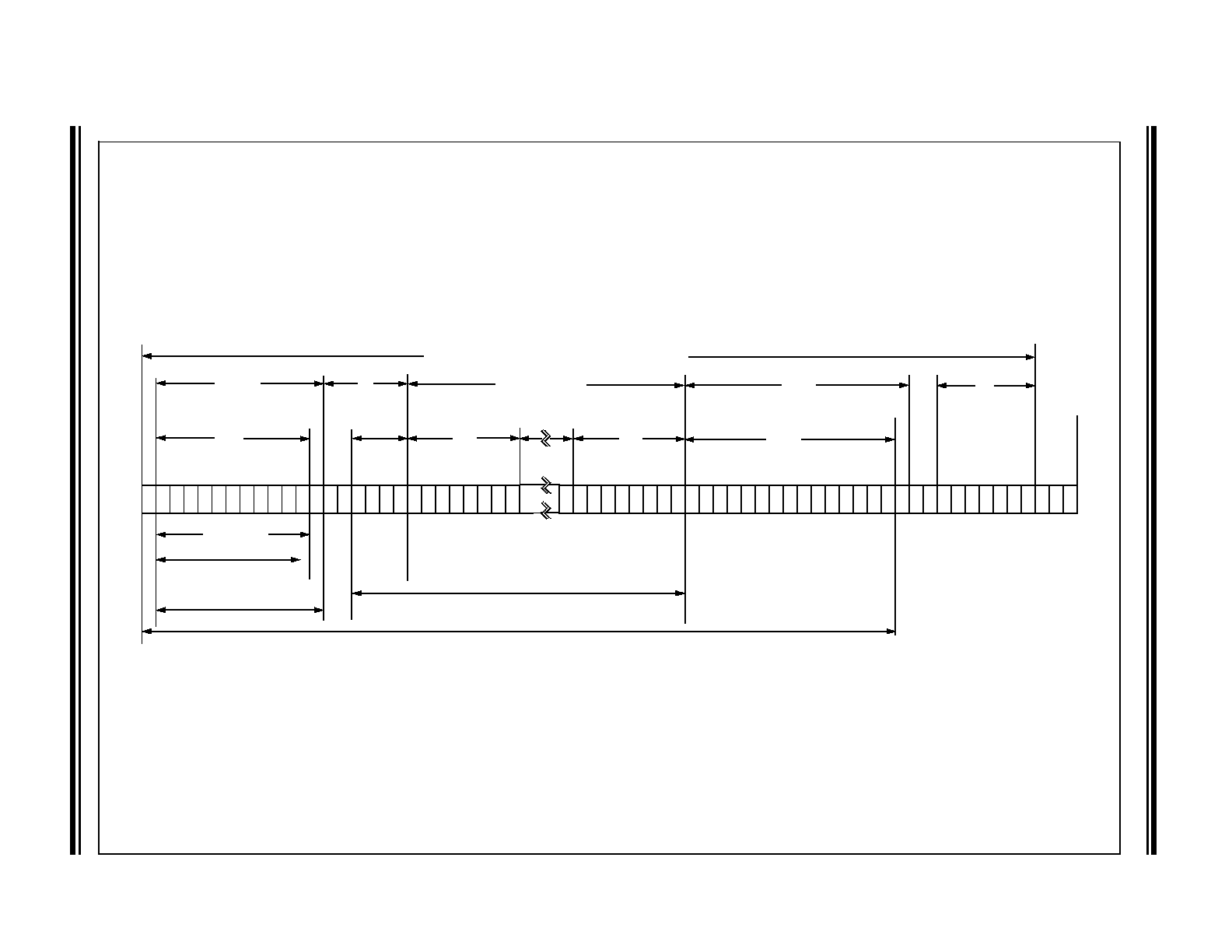

The CAN Standard Data Frame is shown in Figure 2-1.

In common with all other frames, the frame begins with

a Start Of Frame (SOF) bit, which is of the dominant

state, which allows hard synchronization of all nodes.

The SOF is followed by the arbitration field, consisting

of 12 bits; the 11-bit ldentifier and the Remote Trans-

mission Request (RTR) bit. The RTR bit is used to dis-

tinguish a data frame (RTR bit dominant) from a remote

frame (RTR bit recessive).

Following the arbitration field is the control field, con-

sisting of six bits. The first bit of this field is the Identifier

Extension (IDE) bit which must be dominant to specify

a standard frame. The following bit, Reserved Bit Zero

(RB0), is reserved and is defined to be a dominant bit

by the can protocol. the remaining four bits of the con-

trol field are the Data Length Code (DLC) which speci-

fies the number of bytes of data contained in the

message.

After the control field is the data field, which contains

any data bytes that are being sent, and is of the length

defined by the DLC above (0-8 bytes).

The Cyclic Redundancy Check (CRC) Field follows the

data field and is used to detect transmission errors. The

CRC Field consists of a 15-bit CRC sequence, followed

by the recessive CRC Delimiter bit.

The final field is the two-bit acknowledge field. During

the ACK Slot bit, the transmitting node sends out a

recessive bit. Any node that has received an error free

frame acknowledges the correct reception of the frame

by sending back a dominant bit (regardless of whether

the node is configured to accept that specific message

or not). The recessive acknowledge delimiter com-

pletes the acknowledge field and may not be overwrit-

ten by a dominant bit.

2.2

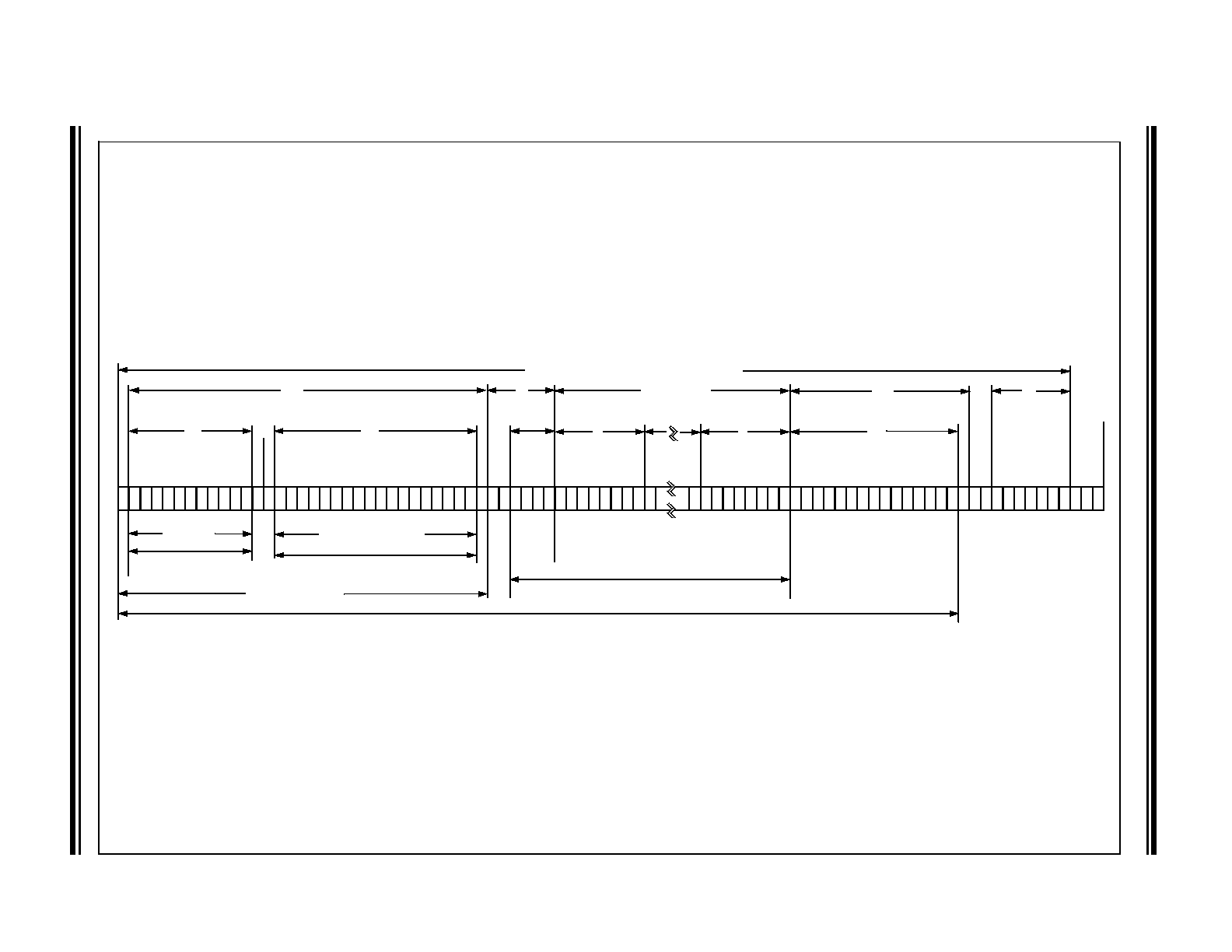

Extended Data Frame

In the Extended CAN Data Frame, the SOF bit is fol-

lowed by the arbitration field which consists of 32 bits,

as shown in Figure 2-2. The first 11 bits are the most

significant bits (Base-lD) of the 29-bit identifier. These

11 bits are followed by the Substitute Remote Request

(SRR) bit which is defined to be recessive. The SRR bit

is followed by the lDE bit which is recessive to denote

an extended CAN frame.

It should be noted that if arbitration remains unresolved

after transmission of the first 11 bits of the identifier, and

one of the nodes involved in the arbitration is sending

a standard CAN frame (11-bit identifier), then the stan-

dard CAN frame will win arbitration due to the assertion

of a dominant lDE bit. Also, the SRR bit in an extended

CAN frame must be recessive to allow the assertion of

a dominant RTR bit by a node that is sending a stan-

dard CAN remote frame.

The SRR and lDE bits are followed by the remaining 18

bits of the identifier (Extended lD) and the remote trans-

mission request bit.

To enable standard and extended frames to be sent

across a shared network, it is necessary to split the 29-

bit extended message identifier into 11-bit (most signif-

icant) and 18-bit (least significant) sections. This split

ensures that the lDE bit can remain at the same bit

position in both standard and extended frames.

Following the arbitration field is the six-bit control field.

the first two bits of this field are reserved and must be

dominant. the remaining four bits of the control field are

the Data Length Code (DLC) which specifies the num-

ber of data bytes contained in the message.

The remaining portion of the frame (data field, CRC

field, acknowledge field, end of frame and lntermission)

is constructed in the same way as for a standard data

frame (see Section 2.1).

2.3

Remote Frame

Normally, data transmission is performed on an auton-

omous basis by the data source node (e.g. a sensor

sending out a data frame). It is possible, however, for a

destination node to request data from the source. To

accomplish this, the destination node sends a remote

frame with an identifier that matches the identifier of the

required data frame. The appropriate data source node

will then send a data frame in response to the remote

frame request.

There are two differences between a remote frame

(shown in Figure 2-3) and a data frame. First, the RTR

bit is at the recessive state, and second, there is no

data field. In the event of a data frame and a remote

frame with the same identifier being transmitted at the

same time, the data frame wins arbitration due to the

dominant RTR bit following the identifier. In this way,

the node that transmitted the remote frame receives

the desired data immediately.

2.4

Error Frame

An Error Frame is generated by any node that detects

a bus error. An error frame, shown in Figure 2-4, con-

sists of two fields, an error flag field followed by an error

delimiter field. There are two types of error flag fields.

Which type of error flag field is sent depends upon the

error status of the node that detects and generates the

error flag field.

If an error-active node detects a bus error then the

node interrupts transmission of the current message by

generating an active error flag. The active error flag is

composed of six consecutive dominant bits. This bit

MCP2510

DS21291F-page 8

©

2007 Microchip Technology Inc.

sequence actively violates the bit stuffing rule. All other

stations recognize the resulting bit stuffing error and in

turn generate error frames themselves, called error

echo flags. The error flag field, therefore, consists of

between six and twelve consecutive dominant bits

(generated by one or more nodes). The error delimiter

field completes the error frame. After completion of the

error frame, bus activity returns to normal and the inter-

rupted node attempts to resend the aborted message.

If an error-passive node detects a bus error then the

node transmits an error-passive flag followed by the

error delimiter field. The error-passive flag consists of

six consecutive recessive bits, and the error frame for

an error-passive node consists of 14 recessive bits.

From this, it follows that unless the bus error is

detected by the node that is actually transmitting, the

transmission of an error frame by an error-passive

node will not affect any other node on the network. If

the transmitting node generates an error-passive flag

then this will cause other nodes to generate error

frames due to the resulting bit stuffing violation. After

transmission of an error frame, an error-passive node

must wait for six consecutive recessive bits on the bus

before attempting to rejoin bus communications.

The error delimiter consists of eight recessive bits and

allows the bus nodes to restart bus communications

cleanly after an error has occurred.

2.5

Overload Frame

An Overload Frame, shown in Figure 2-5, has the

same format as an active error frame. An overload

frame, however can only be generated during an lnter-

frame space. In this way an overload frame can be dif-

ferentiated from an error frame (an error frame is sent

during the transmission of a message). The overload

frame consists of two fields, an overload flag followed

by an overload delimiter. The overload flag consists of

six dominant bits followed by overload flags generated

by other nodes (and, as for an active error flag, giving

a maximum of twelve dominant bits). The overload

delimiter consists of eight recessive bits. An overload

frame can be generated by a node as a result of two

conditions. First, the node detects a dominant bit during

the interframe space which is an illegal condition. Sec-

ond, due to internal conditions the node is not yet able

to start reception of the next message. A node may

generate a maximum of two sequential overload

frames to delay the start of the next message.

2.6

Interframe Space

The lnterframe Space separates a preceeding frame

(of any type) from a subsequent data or remote frame.

The interframe space is composed of at least three

recessive bits called the Intermission. This is provided

to allow nodes time for internal processing before the

start of the next message frame. After the intermission,

the bus line remains in the recessive state (bus idle)

until the next transmission starts.

©

2007

Micr

ochip T

e

ch

nol

ogy

I

n

c.

DS

21291F

-page 9

MCP2

510

FIGURE 2-1:

STANDARD DATA FRAME

0

S

ta

rt

of

F

rame

Data Frame (number of bits = 44 + 8N)

12

Arbitration Field

ID 1

0

11

ID3

ID0

Identifier

Message

Filtering

Stored in Buffers

RTR

ID

E

RB

0

DLC

3

DL

C0

6

4

Control

Field

Data

Length

Code

Reserv

ed B

it

8N (0

≤

N

≤

8)

Data Field

8

8

Stored in Transmit/Receive Buffers

Bit Stuffing

16

CRC Field

15

CRC

7

End of

Frame

C

RC De

l

A

ck Sl

ot Bi

t

AC

K

D

e

l

IFS

0 0 0

1

1 1 1 1 1 1 1 1 1 1 1

©

2007

Micr

ochip T

e

ch

nol

ogy

I

n

c.

DS

21291F

-page 10

MCP2

510

FIGURE 2-2:

EXTENDED DATA FRAME

0

1 1

0 0 0

1

S

tar

t of

F

rame

Arbitration Field

32

11

ID1

0

ID3

ID

0

ID

E

Identifier

Message

Filtering

Stored in Buffers

SR

R

EI

D

1

7

EI

D

0

RTR RB

1

RB

0

DLC3

18

DLC0

6

Control

Field

4

Res

e

rved bit

s

Data

Length

Code

Stored in Transmit/Receive Buffers

8

8

Data Frame (number of bits = 64 + 8N)

8N (0

≤

N

≤

8)

Data Field

1 1 1 1 1 1 1 1

16

CRC Field

15

CRC

CRC

Del

Ac

k S

lot

Bi

t

AC

K

D

e

l

End of

Frame

7

Bit Stuffing

IFS

Extended Identifier

1 1 1