2001 Microchip Technology Inc.

DS20072A-page 1

M

MCP2505X

This document includes the programming

specifications for the following devices:

• MCP25050

• MCP25055

1.0

OVERVIEW

This specification describes the requirements to pro-

gram a device. Programming is accomplished through

a serial interface. A serial interface reduces the number

of device pins that must be controlled and eases the

application requirements for the device to be pro-

grammed while in the users system. This capability

increases design flexibility, and is referred to as In-Cir-

cuit Serial Programming™ (ICSP™).

1.1

Hardware Requirements

The MCP2505X requires two programmable power

supplies, one for V

DD

(2.0V to 6.0V recommended) and

one for V

PP

(12V to 14V). Both supplies should have a

minimum resolution of 0.25V.

1.2

Programming Mode

The programming mode for the MCP2505X allows pro-

gramming of user program memory and the configura-

tion word.

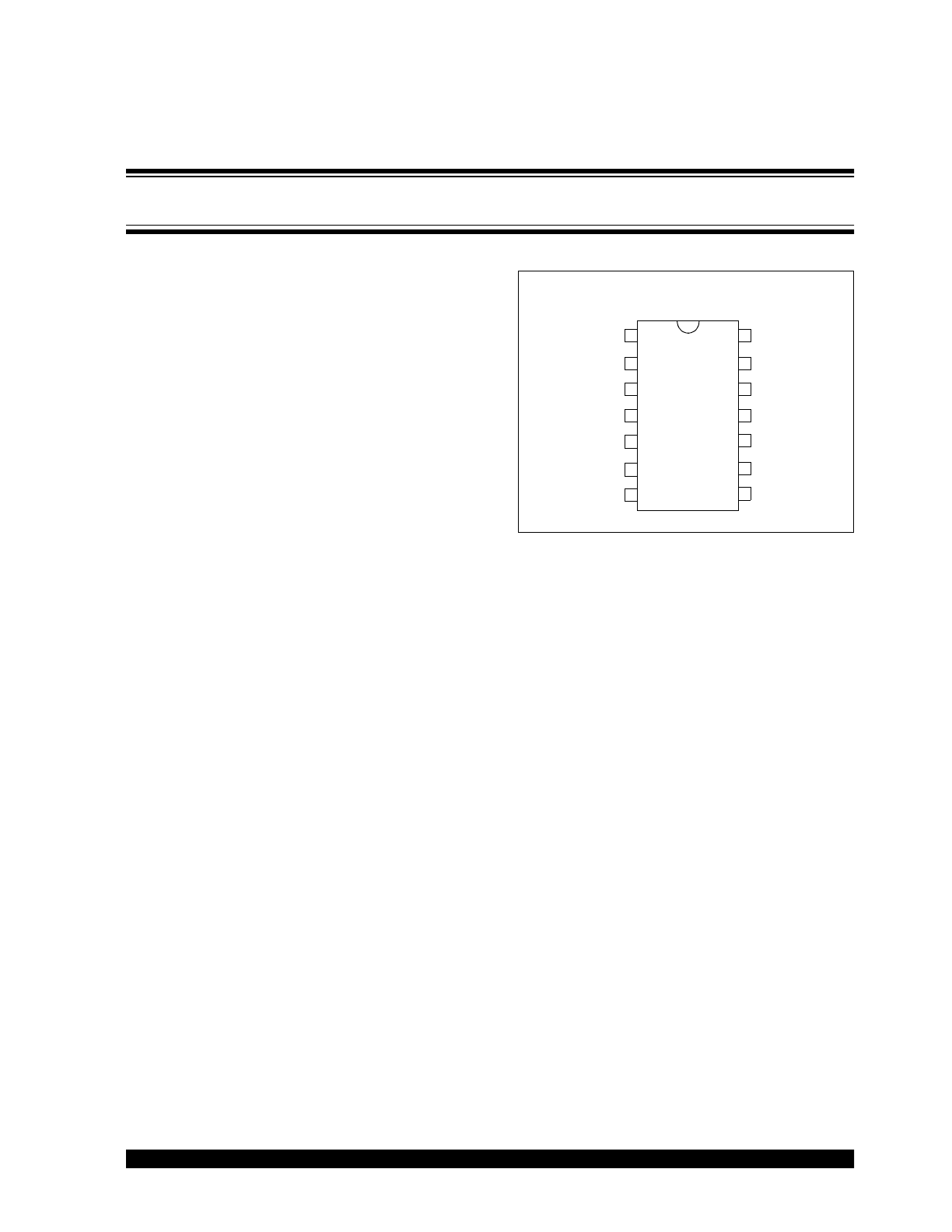

PACKAGE TYPES:

PDIP/SOIC

GP0/AN0

GP1/AN1

V

DD

TXCAN/TXRXCAN

RXCAN/NC

GP5/V

REF

+/CLOCK

1

2

3

4

GP4/V

REF

-/DATA

GP6/CLKOUT

14

13

12

11

10

GP3/AN3/PWM2

OSC1/CLKIN

GP2/AN2/PWM1

5

6

7

8

9

OSC2

V

SS

GP7/RST/V

PP

MCP

25055

MCP

25050

Programming Specifications

MCP2505X

DS20072A-page 2

2001 Microchip Technology Inc.

2.0

MCP2505X MEMORY

The MCP2505X has two memory spaces. The first is

the User EPROM Memory. This memory stores the

default configuration values for the device. The second

memory space is the configuration memory. This con-

tains the values for the device oscillator and reset pin

configurations.

2.1

User EPROM Memory Map

The User EPROM memory space extends from 0x00 to

0x45. Table 2-1 shows this program memory map.

This User EPROM memory is offset within the device

memory map. When programming the device, an offset

to the addresses in Table 2-1 is required.

2.2

Configuration Memory

Configuration memory is accessed with the Load Con-

figuration command. Once in configuration memory,

the only way to access the User EPROM Memory is to

reset the device and re-enter Programming mode, as

described in Section 3.1. Only the lower 3 bits should

be programmed. The remaining 11 bits are reserved

and should be programmed as a ‘1’. Programming

these bits as a ‘1’ will ensure that the factory value is

not modified. When verifying this location, only verify

against the lower 3 bits (the bits that were pro-

grammed).

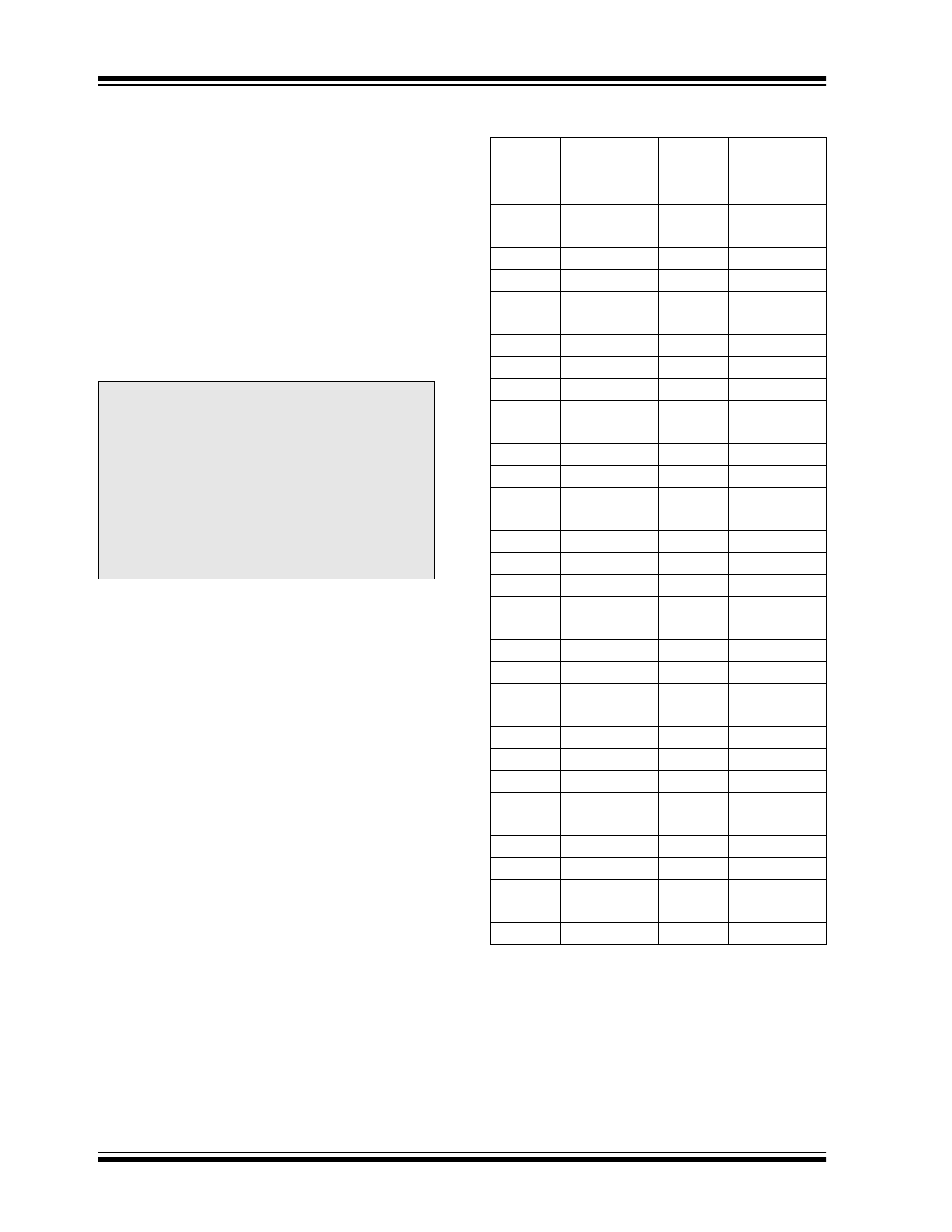

TABLE 2-1:

USER EPROM MEMORY MAP

Note 1: An offset of 0x10 is required to be added

to the addresses shown in the User Pro-

gram Memory Map (Table 2-1) when

programming these locations. There-

fore, there should be 16 Increment

Address commands before program-

ming the contents of the User EPROM

Memory.

2: Do not program outside the specified

user EPROM memory range or

improper operation may occur.

Address

(1)

Location

Name

Address

(1)

Location

Name

00h

IOINTEN

23h

TXID0EID0

01h

IOINTPO

24h

TXID1SIDH

02h

GPLAT

25h

TXID1SIDL

03h

—

(2)

26h

TXID1EID8

04h

OPTREG1

27h

TXID1EID0

05h

T1CON

28h

TXID2SIDH

06h

T2CON

29h

TXID2SIDL

07h

PR1

2Ah

TXID2EID8

08h

PR2

2Bh

TXID2EID0

09h

PWM1DCH

2Ch

ADCMP3H

0Ah

PWM2DCH

2Dh

ADCMP3L

0Bh

CNF1

2Eh

ADCMP2H

0Ch

CNF2

2Fh

ADCMP2L

0Dh

CNF3

30h

ADCMP1H

0Eh

ADCON0

31h

ADCMP1L

0Fh

ADCON1

32h

ADCMP0H

10h

STCON

33h

ADCMP0L

11h

OPTREG2

34h

GPDDR

12h

—

(3)

35h

USER0

13h

—

(3)

36h

USER1

14h

RXMSIDH

37h

USER2

15h

RXMSIDL

38h

USER3

16h

RXMEID8

39h

USER4

17h

RXMEID0

3Ah

USER5

18h

RXF0SIDH

3Bh

USER6

19h

RXF0SIDL

3Ch

USER7

1Ah

RXF0EID8

3Dh

USER8

1Bh

RXF0EID0

3Eh

USER9

1Ch

RXF1SIDH

3Fh

USERA

1Dh

RXF1SIDL

40h

USERB

1Eh

RXF1EID8

41h

USERC

1Fh

RXF1EID0

42h

USERD

20h

TXID0SIDH

43h

USERE

21h

TXID0SIDL

44h

USERF

22h

TXID0EID8

45h

CHKSUM

Note 1: An offset of 0x10 is required.

2: Reserved, Program this location as

0x3FFF.

3: Unimplemented, Program this location as

0x3FFF.

2001 Microchip Technology Inc.

DS20072A-page 3

MCP2505X

3.0

PROGRAMMING MODE ENTRY

A specific hardware sequence is required to force the

device from the normal operating mode into Program-

ming programming mode. After entering into the Pro-

gramming mode, the 2-wire serial interface can be

used to send the commands to the MCP2505X. These

commands are discussed in Section 4.0.

3.1

Programming Entry Sequence

The Programming mode is entered by raising V

DD

.

Then while holding the CLOCK and DATA pins (GP5

and GP4) low, raising the RST pin from V

IL

IHH

Once in this mode, the User EPROM memory and the

configuration memory can be accessed (read and pro-

grammed). The interface is serial and the CLOCK pin

(GP5) is a Schmitt Trigger input in this mode.

The sequence that forces the device into the Program-

ming mode also puts all other logic into the reset state

(the RST pin was initially at V

IL

). This means that all I/

O are in the reset state (High impedance inputs).

Figure 7-2 shows the waveform for entry into Program-

ming mode.

3.2

Programming Operation

The CLOCK pin (GP5) is used as a clock input pin. The

DATA pin (GP4) is used for entering command bits and

data input/output during serial communication.

To input a command, the CLOCK pin (GP5) is cycled

six times. Each command bit is latched on the falling

edge of the clock with the least significant bit (LSb) of

the command being input first. The data on the DATA

pin (GP4) is required to have a minimum setup and

hold time (see Parameter P3 and Parameter P4) with

respect to the falling edge of the clock. Commands that

have data associated with them (read and load) are

specified to have a minimum delay between the com-

mand and the data (Parameter P6).

After this delay, the clock pin is cycled 16 times with the

first cycle being a start bit and the last cycle being a

stop bit. The data is input/output LSb first. During a

read operation the LSb will be transmitted onto the

DATA pin (GP4) on the rising edge of the second cycle,

and during a load operation the LSb will be latched on

the falling edge of the second cycle.

All commands and data words are transmitted LSb first.

The DATA pin value is latched on the falling edge of the

CLOCK pin. A minimum time between the command

and the data word (or another command) is required.

This separation time is shown in Parameter P6 of the

Electrical Specification.

The commands that are available are listed in Table 4-

1. The waveforms for these commands are shown in

Figure 7-3 through Figure 7-8.

Note 1: Do not power any I/O pins before V

DD

is

applied.

MCP2505X

DS20072A-page 4

2001 Microchip Technology Inc.

4.0

PROGRAMMING COMMANDS

There are six commands that the MCP2505X will exe-

cute when in Programming mode. These commands

are shown in Table 4-1. Three of the commands have

data that are required. The Load commands supply

data to the MCP2505X, and the Read command

retrieve data from the MCP2505X.

When the device enters into Programming mode, the

address pointer is pointing to 0x00. The User Program

Memory has an offset of 0x10. So before starting to

program a desired location in the User Program Mem-

ory Map, the Increment Address command must be

executed 16 times.

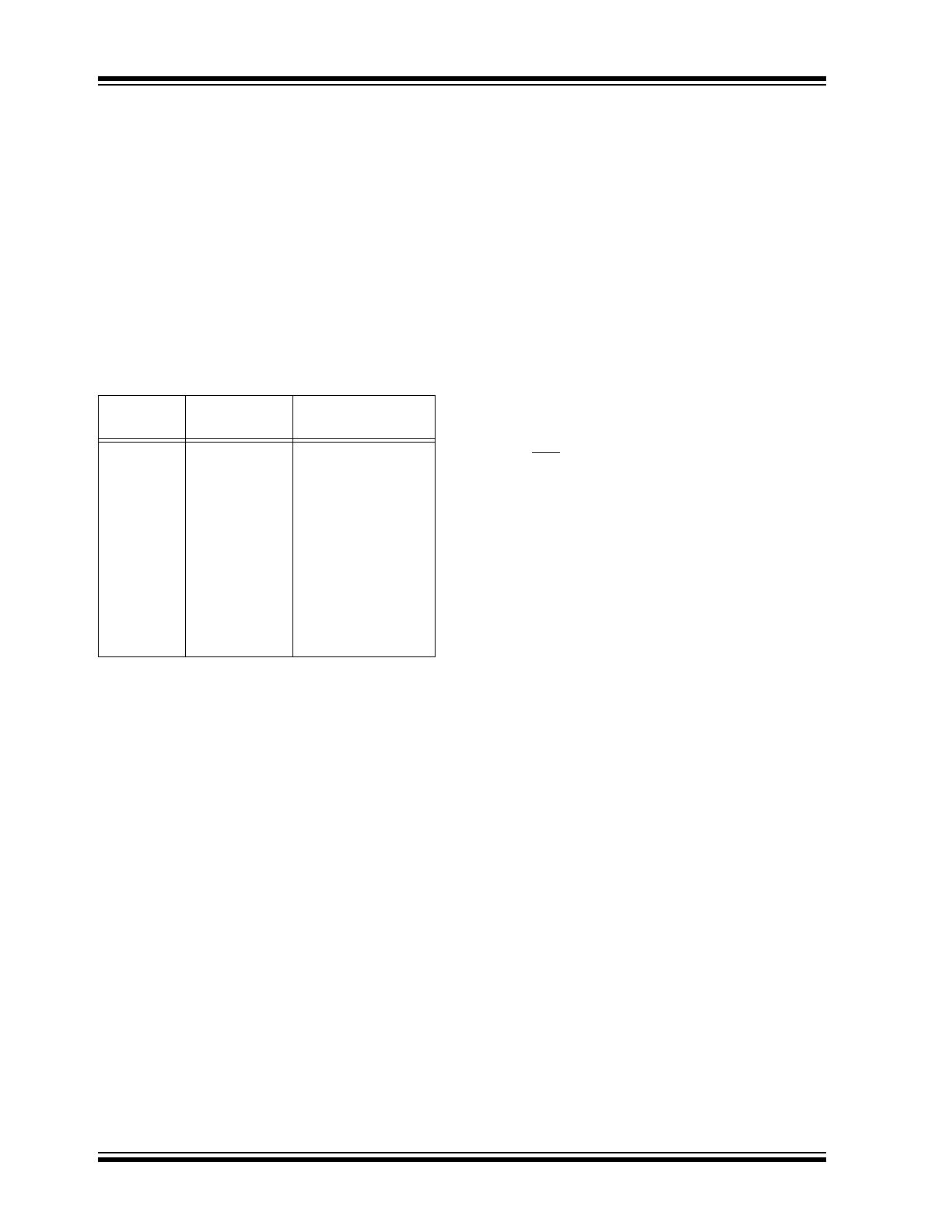

TABLE 4-1:

PROGRAMMING COMMANDS

4.1

Load Configuration

After receiving this command, the address pointer

points to the Configuration memory space. To address

the MCP250XX Configuration word the Increment

command must be given seven times (see Figure 4-2).

Then by applying 16 clock cycles to the CLOCK pin, a

14-bit “data word” will be loaded into the Transfer Latch

(ready to be programmed into the configuration word,

see Register 5-1). Only the lower 3 bits of the “data

word” should be programmed. The remaining 11 bits of

the “data word” are reserved and should be pro-

grammed as a ‘1’. Programming these bits as a ‘1’ will

ensure that the factory value is not modified. When ver-

ifying this location, only verify against the lower 3 bits

(the bits that were programmed).

After the Load Configuration command is supplied, the

only way to have the address pointer return to pointing

at the User Program Memory is to exit the Program-

ming mode. This is accomplished by taking the voltage

on the RST pin to a low level (V

IL

, Parameter PD8) and

the re-entering into Programming mode (see

Section 3.1).

Figure 7-3 shows the waveform for the Load Configu-

ration command and Table 7-3 specifies the timing

parameters that must be meet.

4.2

Load Data

After receiving this command, the chip will load in a

14-bit “data word” into the Transfer latch when 16 clock

cycles are applied to the CLOCK pin.

Figure 7-4 shows the waveform for the Load Data com-

mand and Table 7-4 specifies the timing parameters

that must be meet.

4.3

Read Data

After receiving this command (the first 6 bits), the

device data word at the memory address currently

accessed is loaded into the Transfer latch. Then as the

Data is transmitted, the DATA (GP4) pin is automati-

cally configured into an output on the second rising

clock edge, and reverts back to an input (hi-imped-

ance) after the 16th rising edge.

Figure 7-5 shows the waveform for the Read Data

command and Table 7-5 specifies the timing parame-

ters that must be meet.

This command is useful in the verify sequence of the

programming algorithm. This is used to verify that if the

value that was programmed at this location has been

“well programmed”. That is, that the memory cell was

able to retain the value previously written. A memory

verification should be done at the minimum and maxi-

mum voltage that the device will experience within the

application.

Command

Mapping

(MSb ... LSb)

Data

Load

Configuration

0 0 0 0 0 0 0

, data(14),

0

Load Data

0 0 0 0 1 0 0,1,1,0,1,0,0

,

data(8),

0

Read Data

0 0 0 1 0 0 0

, data(14),

0

Increment

Address

0 0 0 1 1 0

—

Begin

Programming

0 0 1 0 0 0

—

End

Programming

0 0 1 1 1 0

—

2001 Microchip Technology Inc.

DS20072A-page 5

MCP2505X

4.4

Increment Address

The address pointer is incremented when this com-

mand is received.

Figure 7-6 shows the waveform for the Increment

Address command and Table 7-6 specifies the timing

parameters that must be meet.

4.5

Begin Programming

Programming of the appropriate memory (User Pro-

gram Memory or Configuration Memory) will begin after

this command is received and decoded. This program-

ming pulse will continue until an End Programming

command is received. Each programming pulse should

meet a minimum time duration (Parameter P11 in Elec-

trical Specification’s Table 7-7).

Programming should be performed with a series of pro-

gramming pulses (Parameter P11). A programming

pulse is defined as the time between the Begin Pro-

gramming command and the End Programming com-

mand.

Figure 7-7 shows the waveform for the Begin Program-

ming command and Table 7-7 specifies the timing

parameters that must be met.

Example 4-1 shows a typical command sequence that

would be used in the over programming of a device.

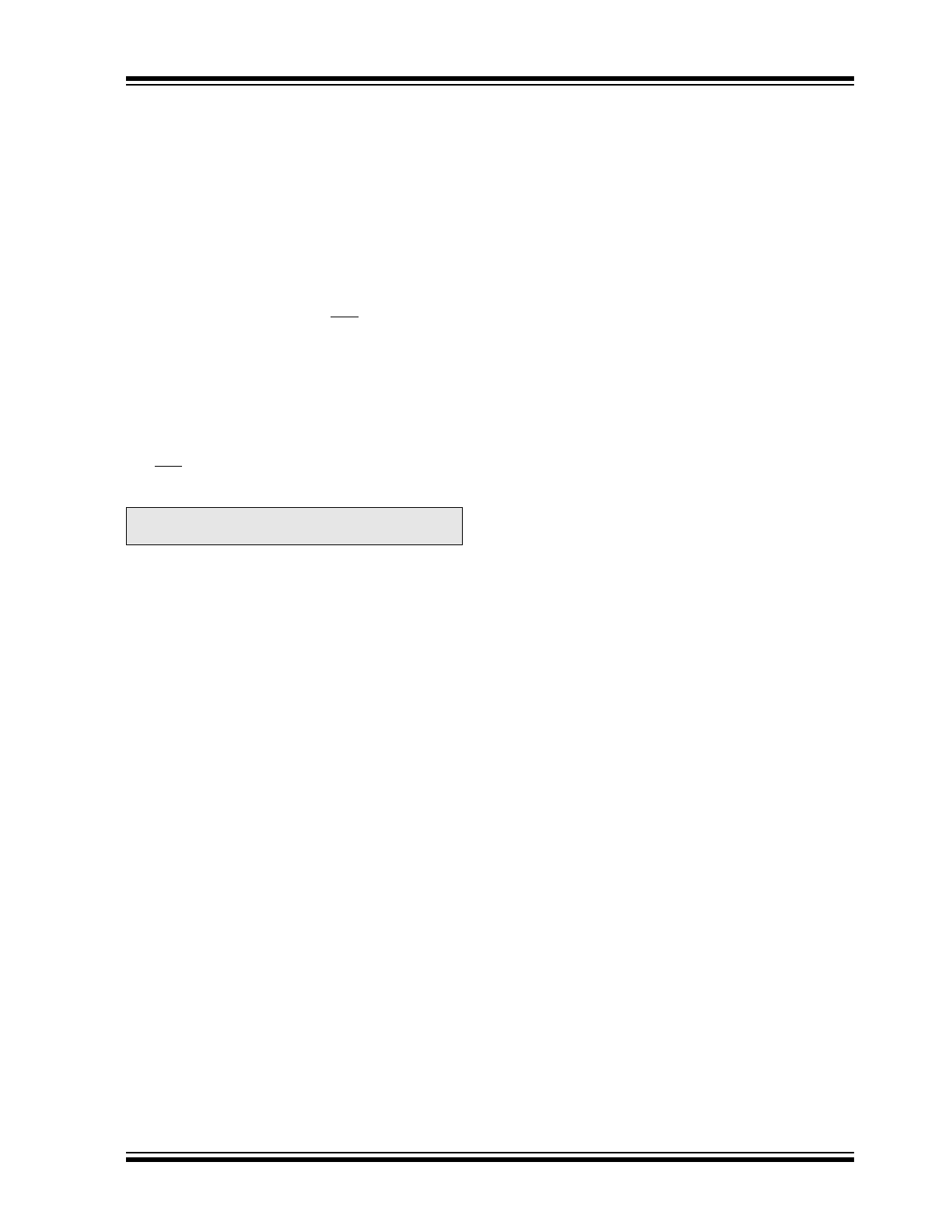

EXAMPLE 4-1:

Command Sequence

4.6

End Programming

After receiving this command, the chip stops program-

ming the memory (configuration program memory or

user program memory) that it was programming at the

time.

Figure 7-8 shows the waveform for the End Program-

ming command and Table 7-8 specifies the timing

parameters that must be met.

4.7

Programming Algorithm Requires

Variable V

DD

The algorithm calls for program verification at V

DD

min

as well as V

DD

max. Verification at V

DD

min guarantees

good “erase margin”. Verification at V

DD

max guaran-

tees good “program margin”.

The actual programming must be done with V

DD

in the

V

DDP

range (Parameter PD1).

V

DDP

=

V

DD

range required during programming.

V

DDV

=

V

DD

range required during verification.

V

DDMIN

=

Minimum operating V

DD

specification for

the device.

V

DDMAX

=

Maximum operating V

DD

specification for

the device.

Programmers must verify the MCP2505X at its speci-

fied V

DDMAX

and V

DDMIN

levels. Since Microchip may

introduce future versions of the MCP2505X with a

broader V

DD

range, it is best that these levels are user

selectable (defaults are ok).

Note:

A load command (load configuration or

load data) must be given before every

Begin Programming command.

Step

Command

Comment

1

Load Command

; Data or Configuration

2

Begin Programming

; Pulse #1

; Wait required delay

3

End Programming

4

Load Command

; Data or Configuration

5

Begin Programming

; Pulse #2

; Wait required delay

6

End Programming

:

: ;

Repeat

Load/Begin/

; End Programming

; sequence as needed

Note:

Any programmer not meeting these

requirements may only be classified as

“prototype” or “development” program-

mer but not a “production” quality pro-

grammer.

MCP2505X

DS20072A-page 6

2001 Microchip Technology Inc.

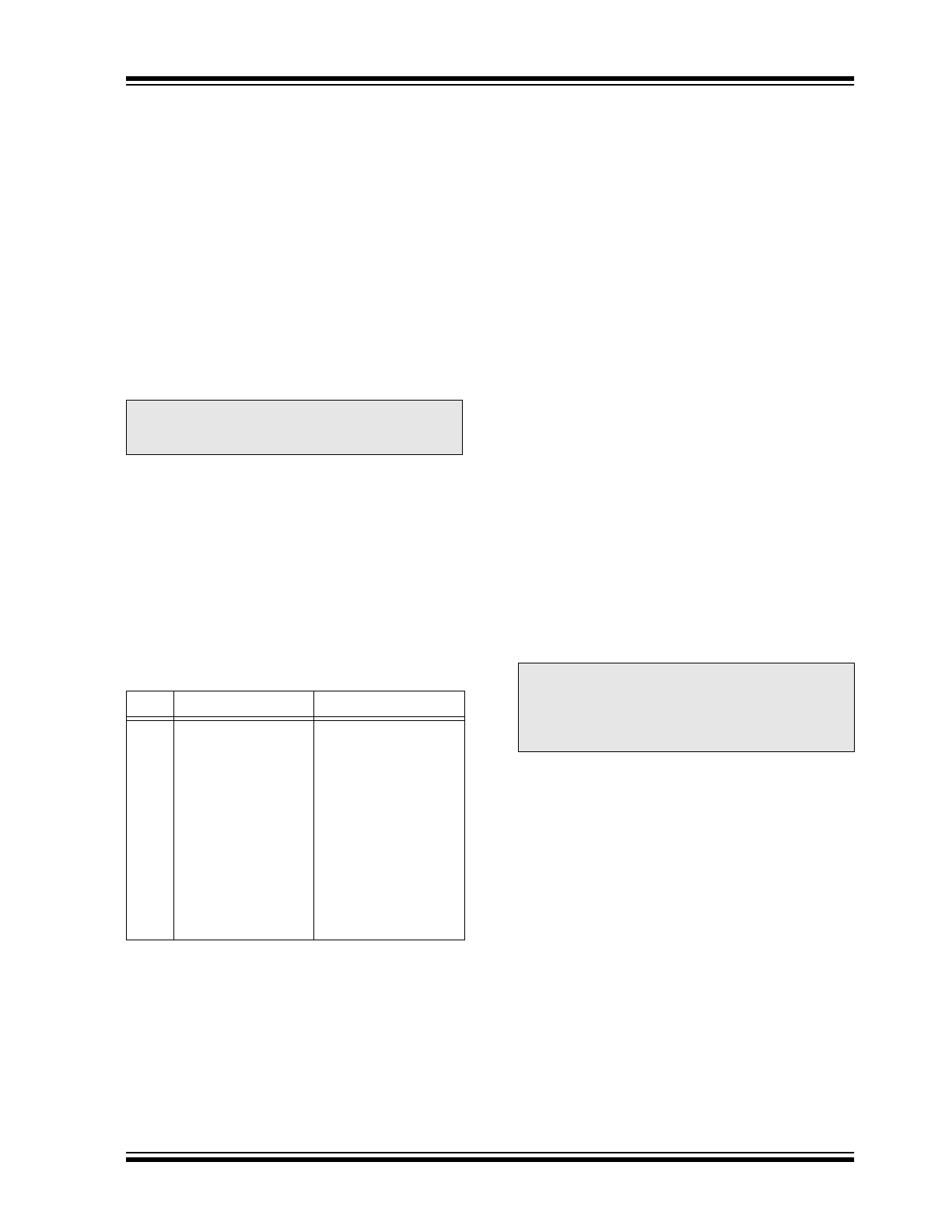

FIGURE 4-1:

PROGRAM FLOW CHART - MCP2505X PROGRAM MEMORY

Start

Set V

DD

= V

DDP

(1)

N = N + 1

Load Data

Command

Increment Address

Command

Report Verify

@ V

DD

MAX

Error

End Programming

Command

Begin Programming

Command

Apply 3N Additional

Program Cycles

Read Data

Command

Program Cycle

N > 25

Data Correct?

Done

No

Yes

Yes

No

No

Yes

Force V

PP

from

Vss to V

IHH

N = 0

All Locations Done?

Verify all Locations

@ V

DD

MIN

.•

V

PP

= V

IHHV

Data Correct?

Yes

Verify all Locations

@ V

DD

MAX

.

V

PP

= V

IHHV

Data Correct?

Yes

Report Programming

Failure

Wait 100

µ

s

Report Verify

@ V

DD

MIN

.

Error

No

No

Note 1:

V

DDP

=

V

DD

range for programming (typically 4.75V - 5.25V).

2:

V

DD

MIN

.

= Minimum

V

DD

for device operation.

V

DD

MAX

.

= Maximum

V

DD

for device operation.

N = # of Program Cycles

Apply 16 Increment

Address Commands

Program Cycle

Return

2001 Microchip Technology Inc.

DS20072A-page 7

MCP2505X

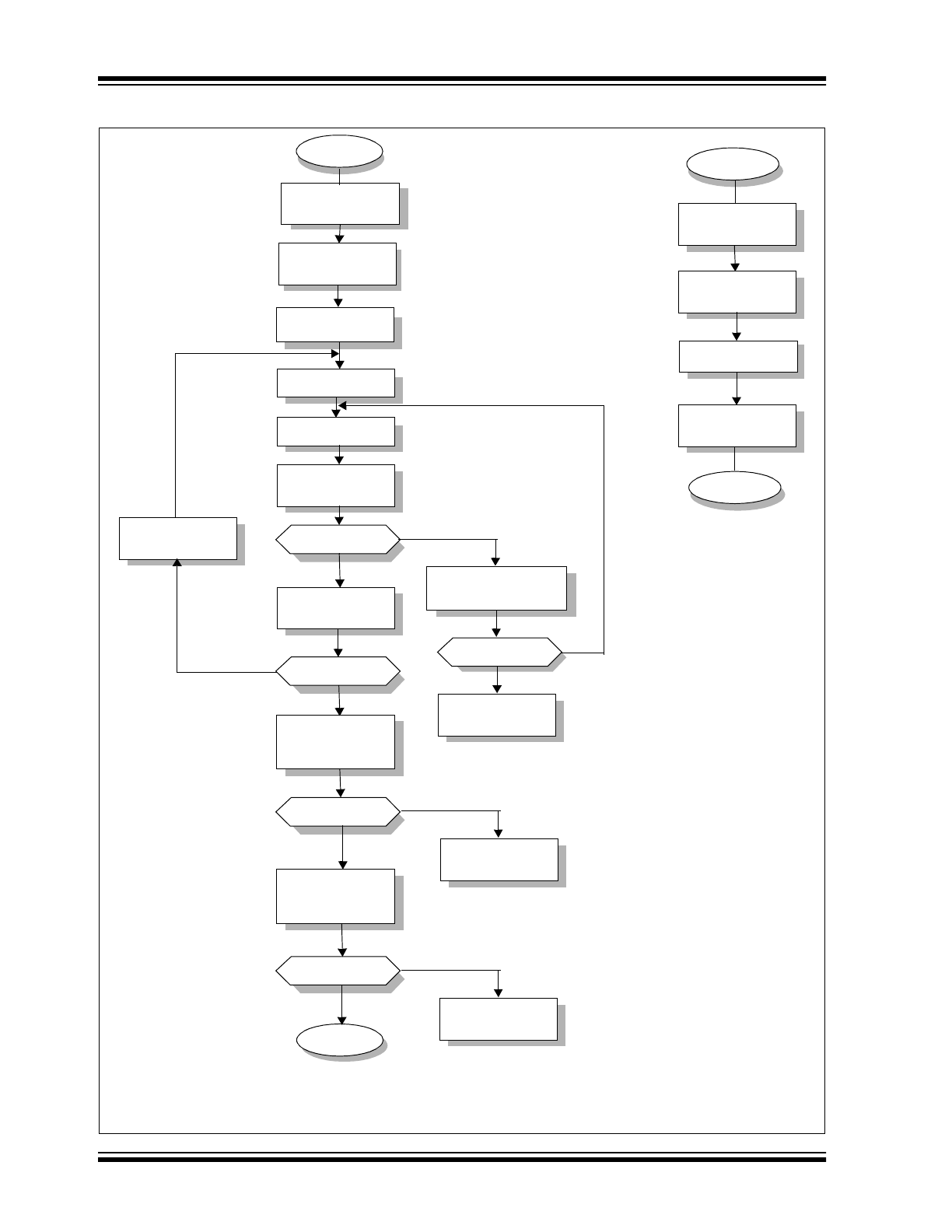

FIGURE 4-2:

PROGRAM FLOW CHART - MCP2505X CONFIGURATION WORD

Start

Load Configuration

Command

Increment Address

Command

Program Cycle

(do 100 times)

Read Data

Command

Report Program

Configuration Error

Data Correct?

Data Correct?

Data Correct?

Incremented 7 times?

Done

Yes

No

No

Yes

No

Yes

Yes

No

Read Data Command

Set V

PP

= V

IHHV

Read Data Command

Set V

PP

= V

IHHV

Force V

PP

from

Vss to V

IHH

Set V

DD

= V

DD

max

Load Data

Command

End Programming

Command

Begin Programming

Command

Wait 100

µ

s

Program Cycle

Return

Set V

DD

= V

DD

min

MCP2505X

DS20072A-page 8

2001 Microchip Technology Inc.

5.0

CONFIGURATION WORD

The MCP2505X family members have several configu-

ration bits. These bits can be programmed (reads ’0’) or

left unprogrammed (reads ’1’) to select various device

configurations. Register 5-1 provides an overview of

configuration bits.

Only the lower 3 bits should be programmed. The

remaining 11 bits are reserved and should be pro-

grammed as a ‘1’. Programming these bits as a ‘1’ will

ensure that the factory value is not modified.

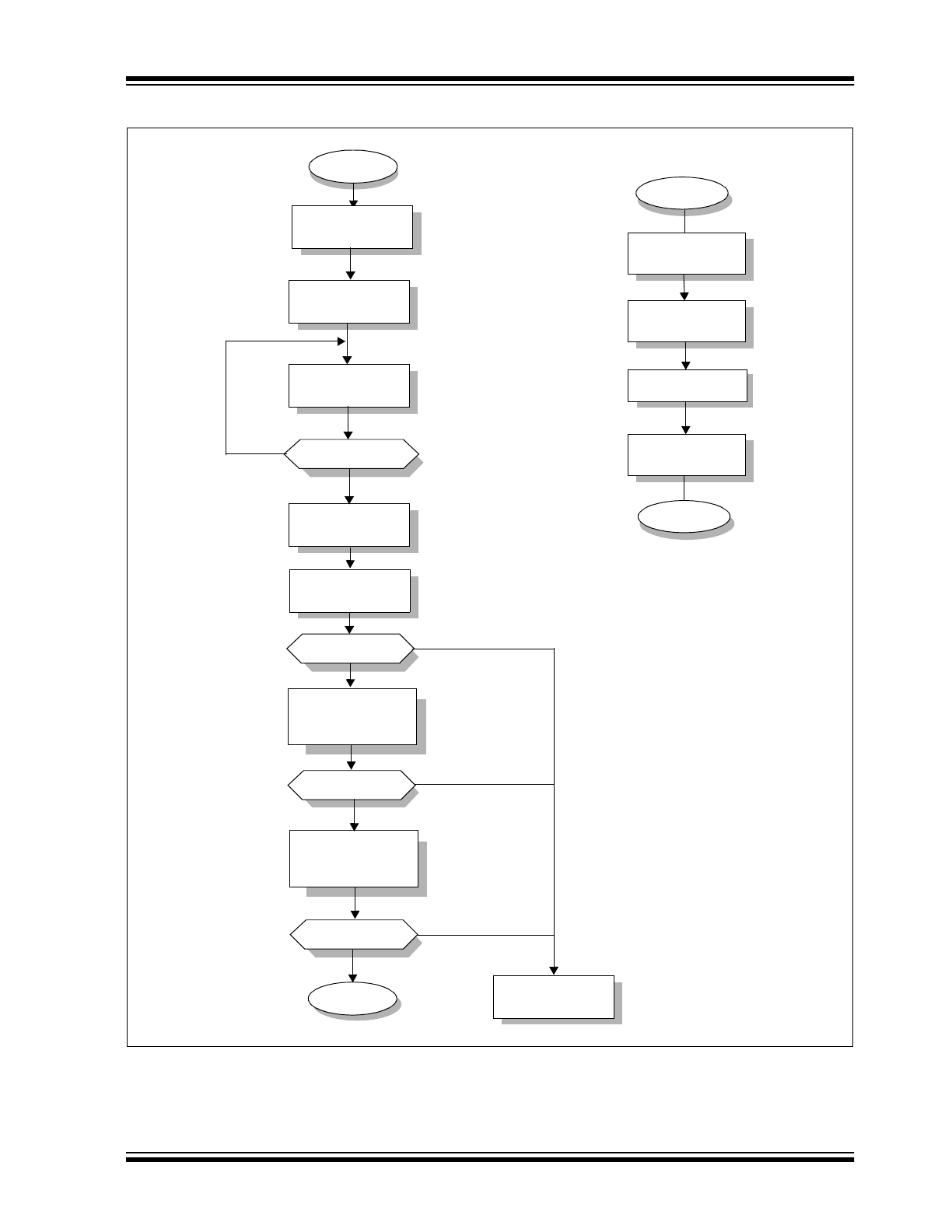

REGISTER 5-1:

CONFIGURATION REGISTER

R-x

R-x

R-x

R-x

R-x

R-x

R-x

R-x

R-x

R-x

R-x

R/P-1

R/P-1

R/P-1

—

—

—

—

—

—

—

—

—

—

—

RSTEN

FOSC1

FOSC0

bit 13

bit 0

bit 13-3 Reserved: Read as ’x’, Program as ‘1’.

bit 2

RSTEN: Reset on GP7 Enable bit

1

= RST function is enabled on the GP7 I/O pin

0

= GP7 is a general purpose I/O pin

bit 1-0

FOSC1:FOSC0: Oscillator Selection bits

11

= RC oscillator

10

= EC (External Clock)

01

= XT oscillator

00

= LP oscillator

Legend:

R = Readable bit

P = Programmable bit

U = Unimplemented bit, read as ‘0’

- n = Value when device is unprogrammed

x = Unknown state

2001 Microchip Technology Inc.

DS20072A-page 9

MCP2505X

6.0

MEMORY VERIFICATION

The User EPROM memory and configuration word is

checksummed. This enhances the validation that the

correct user’s values are programmed into the devices

memory.

6.1 Checksum Calculations

Checksum is calculated by reading the contents of the

MCP2505X User EPROM memory locations and add-

ing the values up. The entire User EPROM memory is

read (00h - 45h). Any carry bits exceeding 16 bits are

ignored. Finally, the configuration word (appropriately

masked) is added to the checksum. Checksum compu-

tation for each member of the MCP2505X devices is

shown in Table 6-1.

The checksum is calculated by summing the following:

• The contents of all User EPROM memory loca-

tions

• The configuration word, appropriately masked

The least significant 16 bits of this sum is the check-

sum.

The Table 6-1 describes how to calculate the check-

sum. When calculating a checksum by reading a

device, the entire User EPROM memory can be read

and summed. The configuration word and ID locations

can always be read.

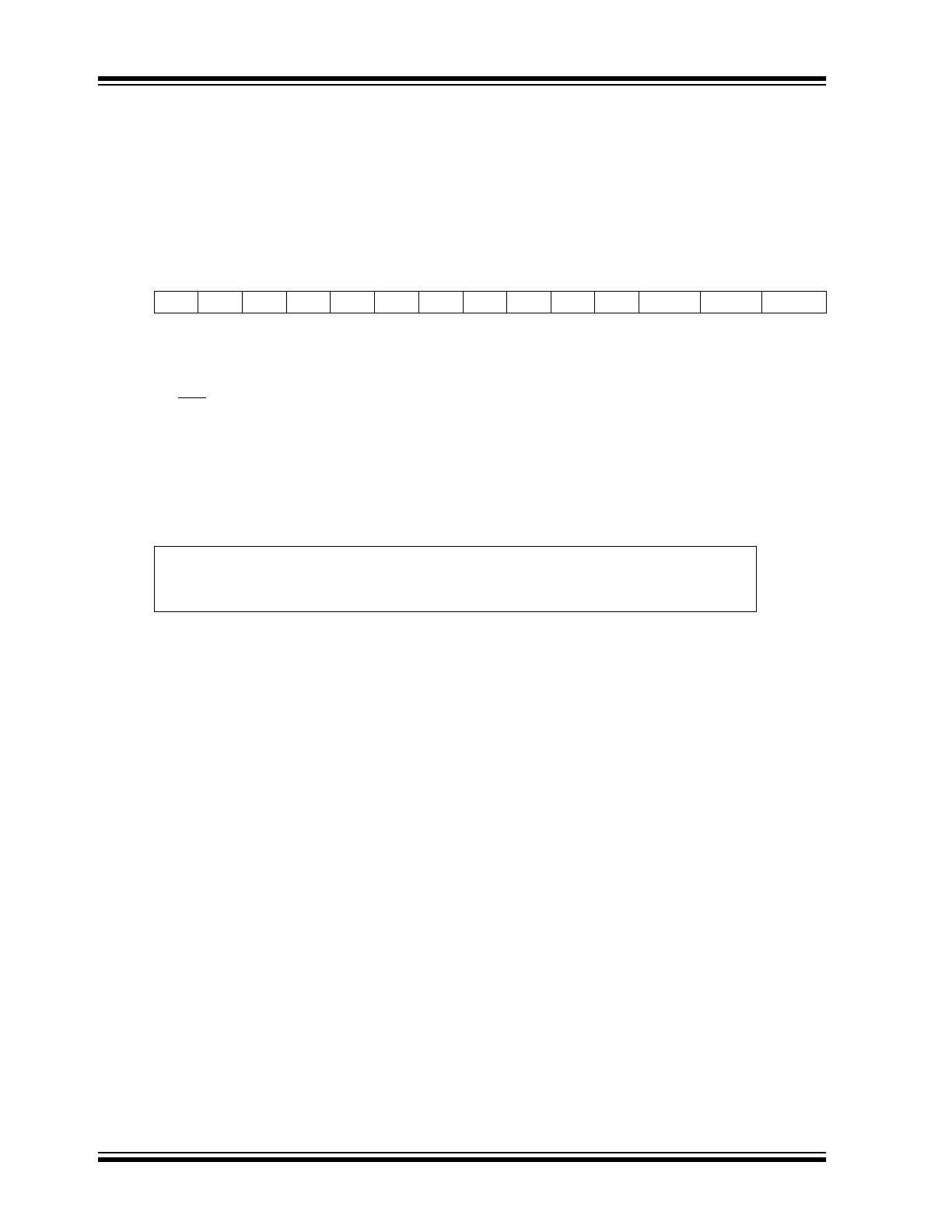

TABLE 6-1:

CHECKSUM COMPUTATION

Device

Checksum

(1)

Value

Unprogrammed

When:

Addr. 0x000 = 0x25E6

Addr. 0x045 = 0x25E6

MCP2505X

(SUM[0x000:0x045] + (CFGW & 0x07) )

0x7FC1

0x4B8F

Legend: SUM[a:b] = [Sum of locations a through b inclusive]

CFGW = Configuration Word

Note 1:

Checksum

=

[Sum of all the individual expressions] MODULO [0xFFFF]

+ =

Addition

& =

Bitwise

AND

MCP2505X

DS20072A-page 10

2001 Microchip Technology Inc.

7.0

PROGRAM/VERIFY MODE ELECTRICAL CHARACTERISTICS

7.1

DC Characteristics

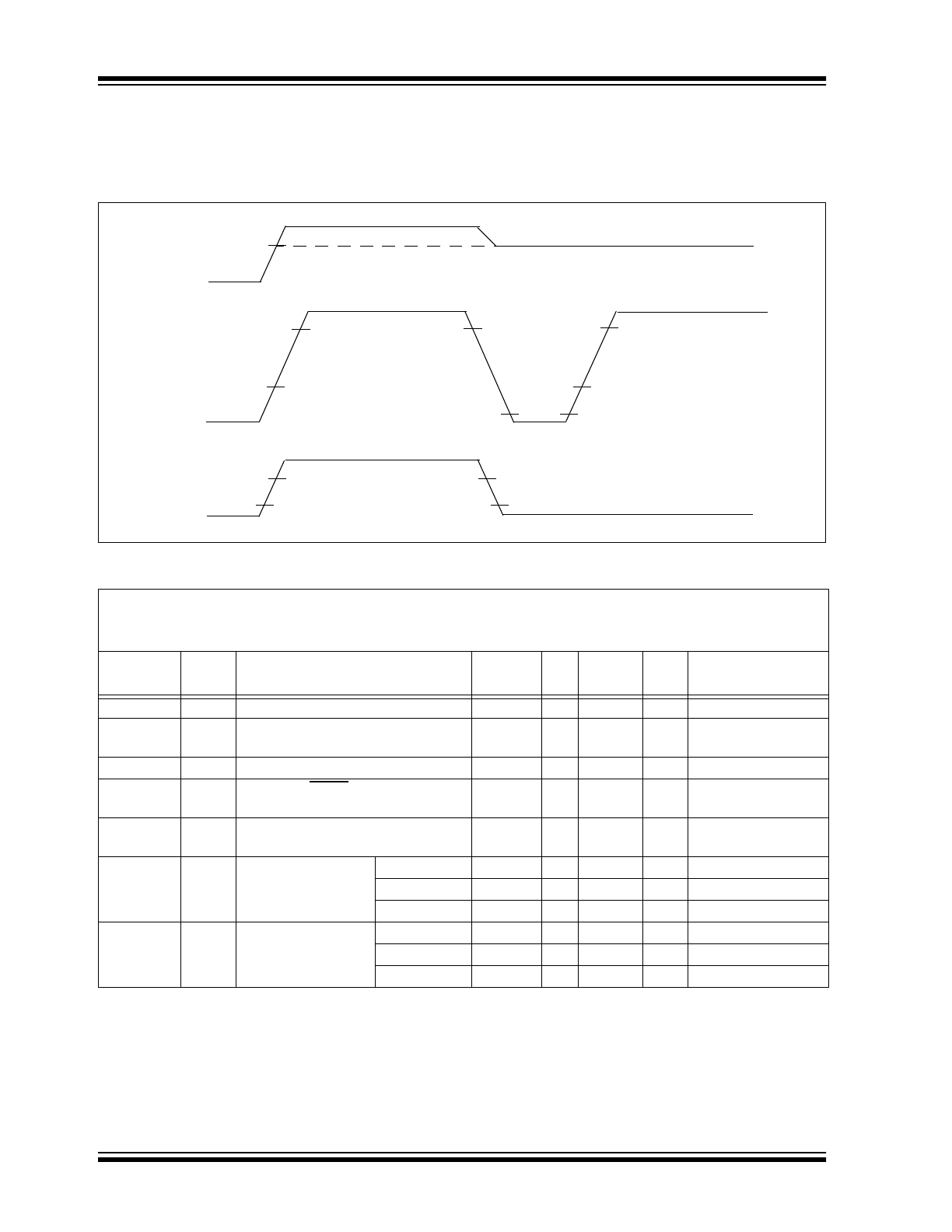

FIGURE 7-1:

PROGRAMMING DC CHARACTERISTICS WAVEFORMS

TABLE 7-1:

DC CHARACTERISTICS FOR PROGRAMMING MODE (PROGRAM/VERIFY)

Standard Operating Conditions:

Operating Temperature: +10

°

C

≤

T

A

≤

+40

°

C, unless otherwise stated, (25

°

C is recommended)

Operating Voltage: 4.5V

≤

V

DD

≤

5.5V, unless otherwise stated.

Parameter

No.

Sym.

Characteristic

Min.

Typ.

Max.

Units Conditions

PD1 V

DDP

Supply voltage during programming

4.75

5.0

5.25

V

—

PD2

I

DDP

Supply current (from V

DD

)

during programming

—

—

20 mA

—

PD3 V

DDV

Supply voltage during verify

V

DD

min

—

V

DD

max

V

PD4

V

IHH

Voltage on MCLR/V

PP

during

programming/verify

12.75

—

13.25

V

—

PD6

I

PP

Programming supply current

(from V

PP

)

—

—

50

mA —

PD8

V

IL

Voltage input low

level

DATA (GP4)

V

SS

—

0.2 V

DD

V

Schmitt Trigger input

CLOCK (GP5)

V

SS

—

0.2 V

DD

V

Schmitt Trigger input

RESET

V

SS

—

0.2 V

DD

V

—

PD9

V

IH

Voltage input high

level

DATA (GP4)

0.8 V

DD

—

V

DD

V

Schmitt Trigger input

CLOCK (GP5)

0.8 V

DD

—

V

DD

V

Schmitt Trigger input

RESET

0.8 V

DD

—

V

DD

V

—

Note 1: Program must be verified at the minimum and maximum V

DD

limits of the device.

V

DD

V

PP

V

IHHMIN

(PD4)

V

DDMIN

V

IH

(PD9)

V

IL

(PD8)

V

IHHMIN

(PD4)

GP4, GP5

V

IH

V

IL

V

IH

(PD9)

2001 Microchip Technology Inc.

DS20072A-page 11

MCP2505X

7.2

Timing (AC) Characteristics

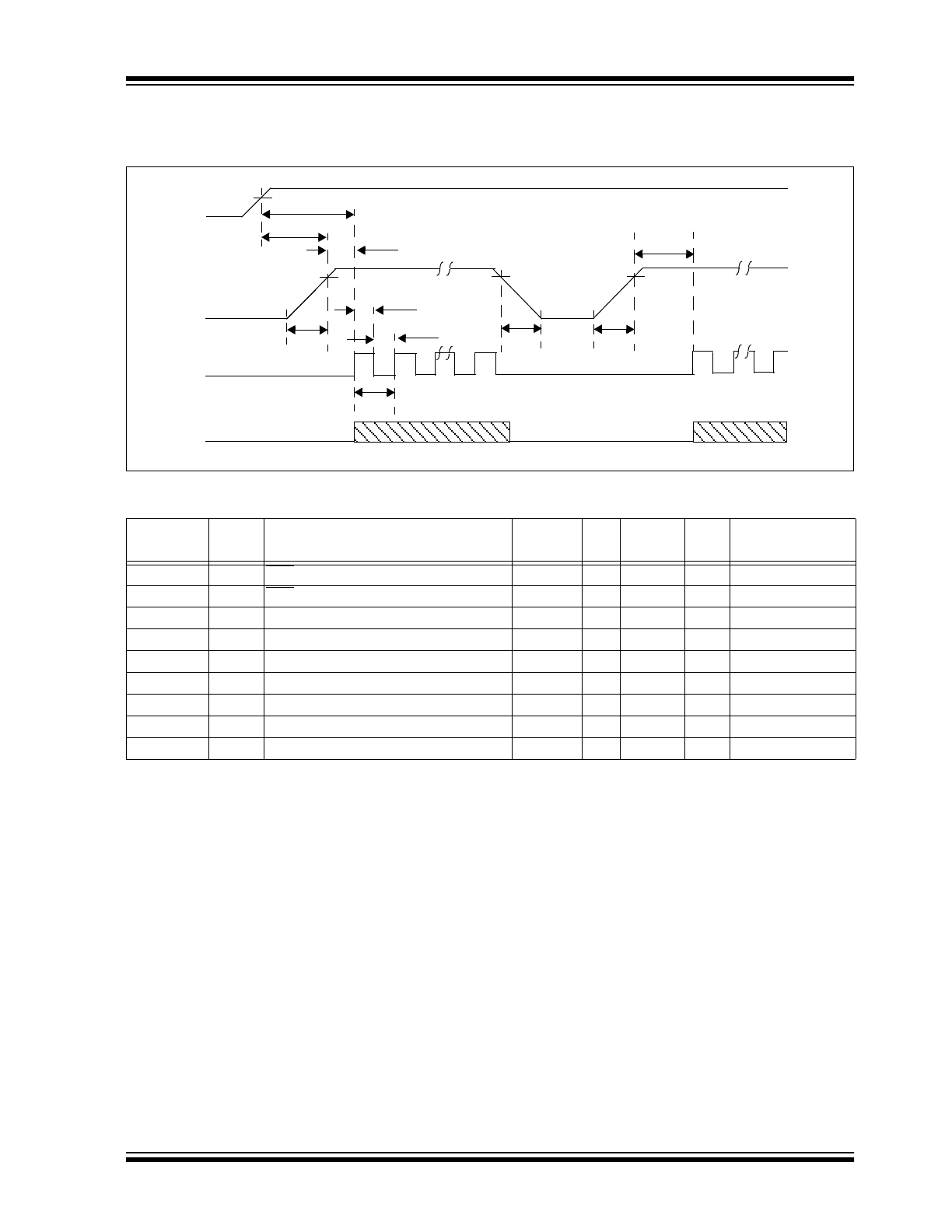

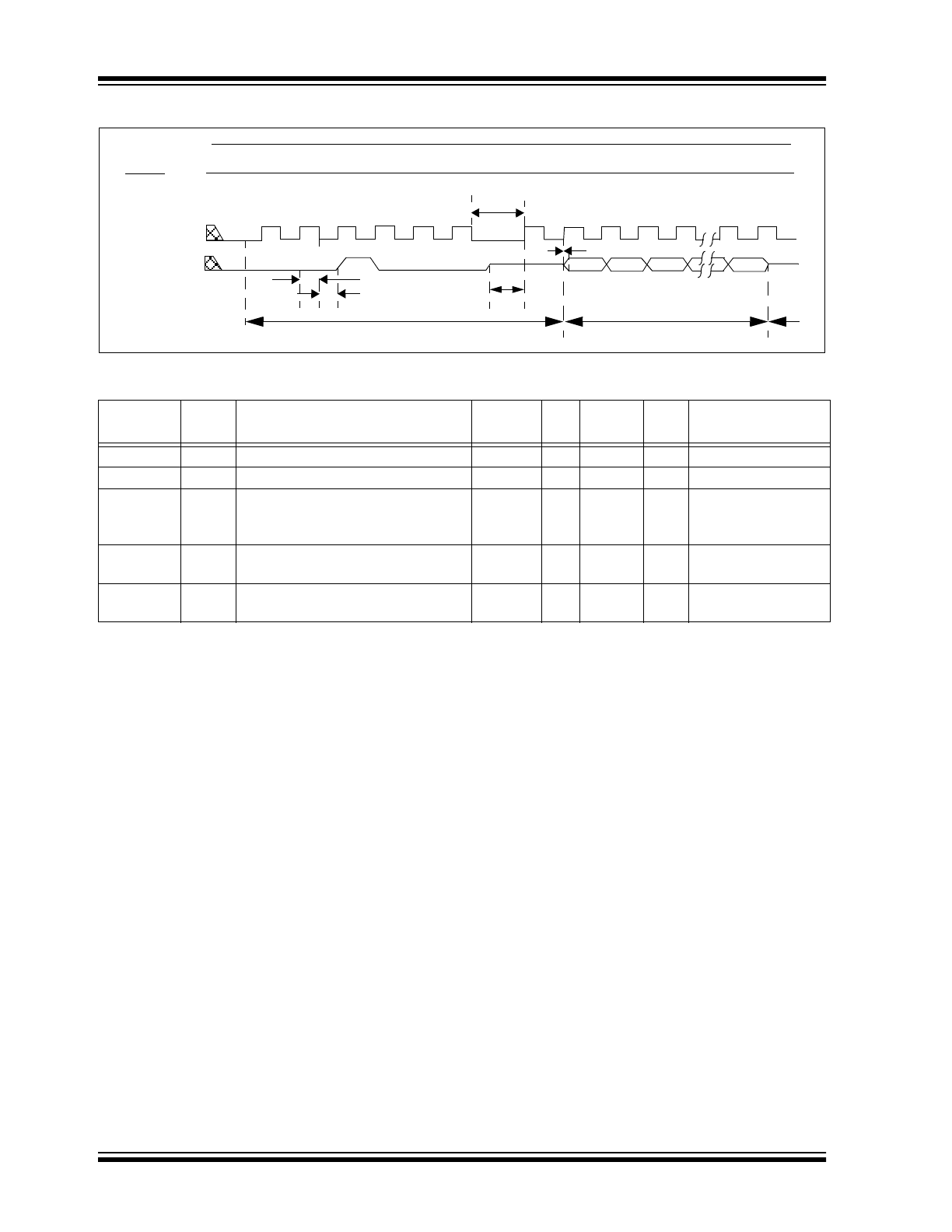

FIGURE 7-2:

PROGRAMMING MODE ENTRY WAVEFORM

TABLE 7-2:

PROGRAMMING MODE ENTRY TIMING

Parameter

No.

Symbol Characteristic

Min.

Typ.

Max.

Units Conditions

P1

T

R

RST/V

PP

rise time (V

SS

to V

IHH

) 0.15

—

1.0

µ

s

—

P2

T

F

RST Fall time

0.5

—

1.0

µ

s

—

P8

T

HLD

0 Hold time after V

DD

valid to V

PP

= V

IHH

0

—

—

ns

—

P8A

T

PPDP

Hold time after V

PP

= V

IHH

to CLOCK

↑

2

—

—

µ

s

—

P8B

T

HLD

0 Hold time after V

DD

valid to CLOCK

↑

2

—

—

µ

s

—

P9

T

CLOCK

CLOCK pin Period (in Time)

250

—

—

ns

—

P9A

F

CLOCK

CLOCK pin Period (in Frequency)

—

—

4

MHz —

P10A

T

CLK

H CLOCK pin High time

100

—

—

ns

—

P10B

T

CLK

L CLOCK pin Low time

100

—

—

ns

—

Note 1: Program must be verified at the minimum and maximum V

DD

limits of the device.

V

DD

V

PP

V

IHH

V

IH

P1

P8B

CLOCK

P2

P1

P9

P8A

DATA

(GP4)

(GP5)

P8

P10B

P10A

P8A

MCP2505X

DS20072A-page 12

2001 Microchip Technology Inc.

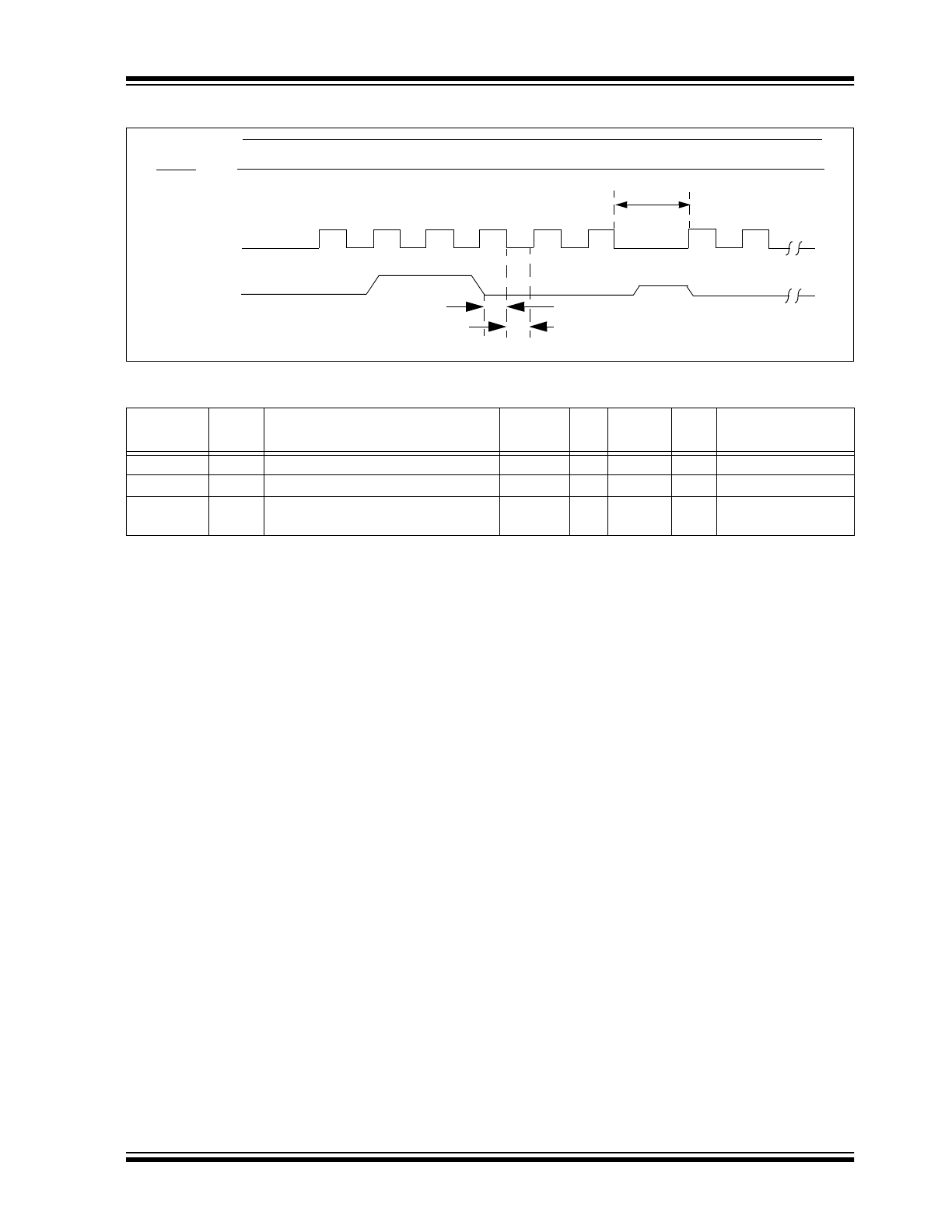

FIGURE 7-3:

LOAD CONFIGURATION COMMAND WAVEFORM

TABLE 7-3:

LOAD CONFIGURATION COMMAND TIMING

Parameter

No.

Symbol Characteristic

Min.

Typ.

Max.

Units Conditions

P3

T

SET

1 Data in setup time before clock

↓

100

—

—

ns

—

P4

T

HLD

1 Data in hold time after clock

↓

100

—

—

ns

—

P6

T

DLY

2 Delay between clock

↓

to clock

↑

of next

command or data

1.0

—

—

µ

s

—

Note 1: Program must be verified at the minimum and maximum V

DD

limits of the device.

P3

P4

0

0

0

P6

0

15

5

4

3

2

1

6

5

0

4

3

0

0

2

1

0

bit 1 bit 2

1

1

CLOCK

DATA

MCLR/V

PP

= V

IHH

V

DD

= V

DDMIN

16

bit 0

2001 Microchip Technology Inc.

DS20072A-page 13

MCP2505X

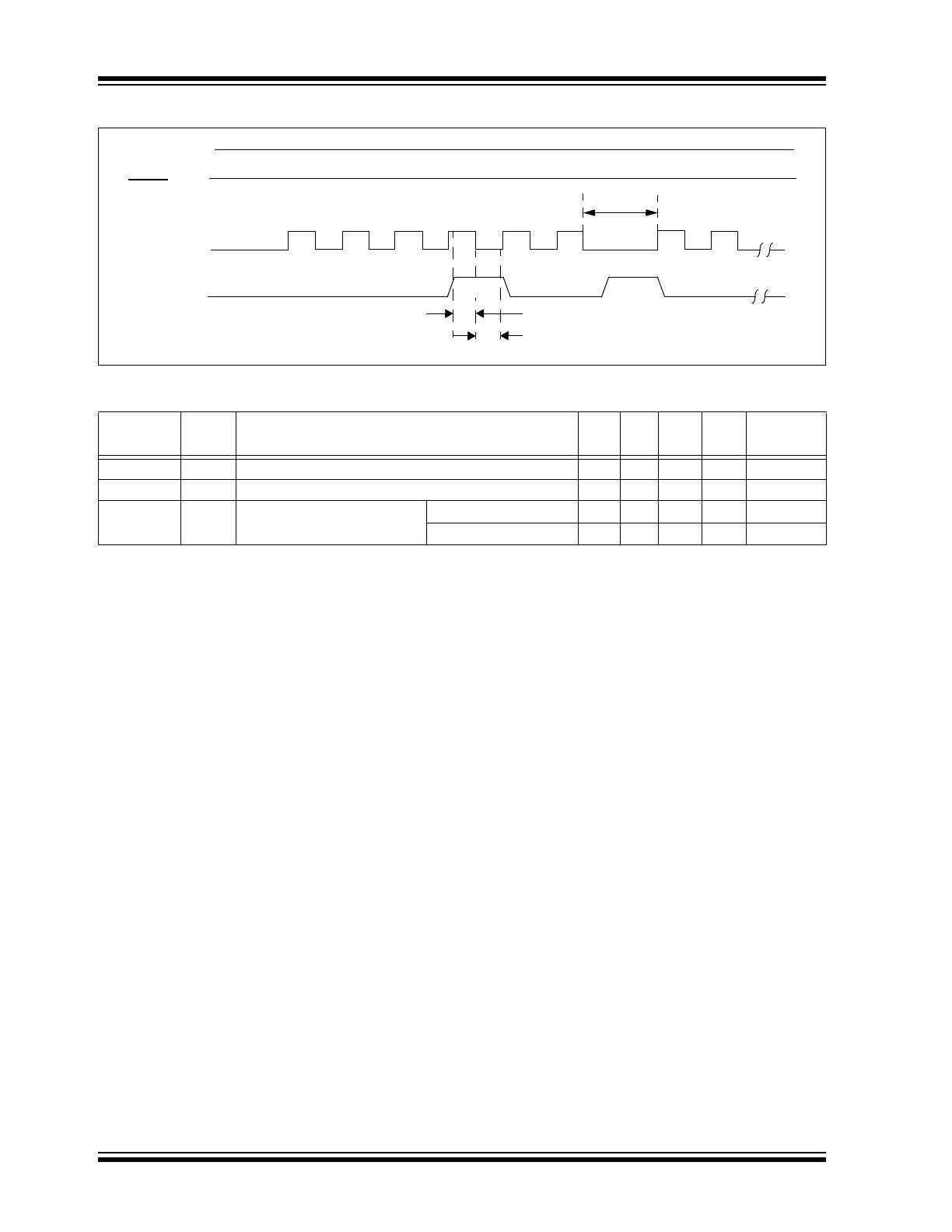

FIGURE 7-4:

LOAD DATA COMMAND WAVEFORM

TABLE 7-4:

LOAD DATA COMMAND TIMING

Parameter

No.

Symbol Characteristic

Min.

Typ.

Max.

Units Conditions

P3

T

SET

1 Data in setup time before clock

↓

100

—

—

ns

—

P4

T

HLD

1 Data in hold time after clock

↓

100

—

—

ns

—

P6

T

DLY

2 Delay between clock

↓

to clock

↑

of

next command or data

1.0

—

—

µ

s

—

Note 1: Program must be verified at the minimum and maximum V

DD

limits of the device.

0

0

0

P6

0

15

5

4

3

2

1

6

5

0

4

3

0

1

2

1

0

CLOCK

DATA

MCLR/V

PP

= V

IHH

V

DD

= V

DDMIN

P3

P4

P3

P4

16

MCP2505X

DS20072A-page 14

2001 Microchip Technology Inc.

FIGURE 7-5:

READ DATA COMMAND WAVEFORM

TABLE 7-5:

READ DATA COMMAND TIMING

Parameter

No.

Symbol Characteristic

Min.

Typ.

Max.

Units Conditions

P3

T

SET

1 Data in setup time before clock

↓

100

—

—

ns

—

P4

T

HLD

1 Data in hold time after clock

↓

100

—

—

ns

—

P5

T

DLY

1 Data input not driven to next clock

input (delay required between com-

mand/data or command/command)

0.9

—

—

µ

s

—

P6

T

DLY

2 Delay between clock

↓

to clock

↑

of

next command or data

1.0

—

—

µ

s

—

P7

T

DLY

3 Clock

↑

to data out valid

(during read data)

—

—

200

ns

—

Note 1: Program must be verified at the minimum and maximum V

DD

limits of the device.

0

0

P5

P6

15

5

4

3

2

1

6

5

0

4

3

0

1

2

1

CLOCK

DATA

0

DATA line is input to device

DATA line is output

P7

MCLR/V

PP

= V

IHH

V

DD

= V

DDMIN

from device

16

P4

P3

2001 Microchip Technology Inc.

DS20072A-page 15

MCP2505X

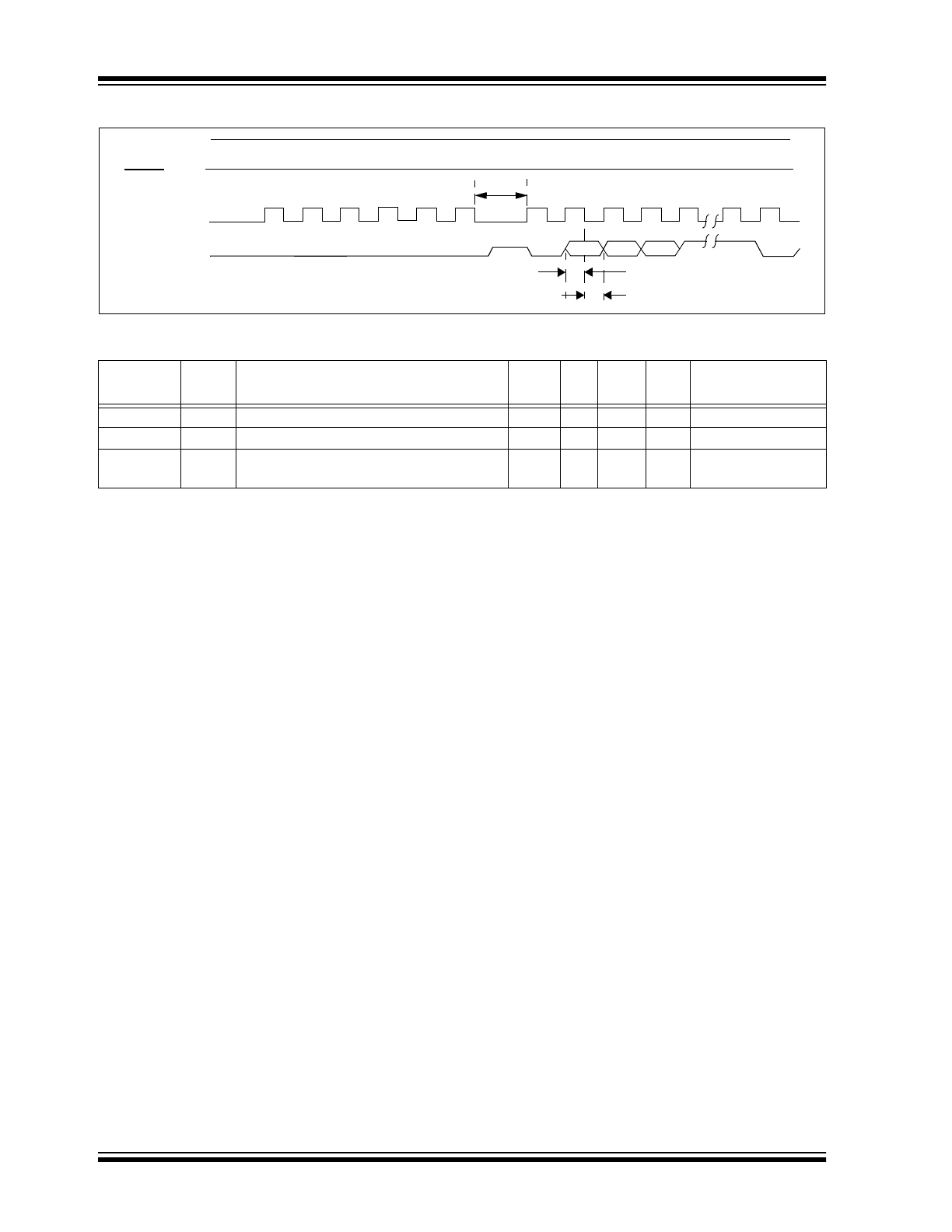

FIGURE 7-6:

INCREMENT ADDRESS COMMAND WAVEFORM

TABLE 7-6:

INCREMENT ADDRESS TIMING

Parameter

No.

Symbol Characteristic

Min.

Typ.

Max.

Units Conditions

P3

T

SET

1 Data in setup time before clock

↓

100

—

—

ns

—

P4

T

HLD

1 Data in hold time after clock

↓

100

—

—

ns

—

P6

T

DLY

2 Delay between clock

↓

to clock

↑

of

next command or data

1.0

—

—

µ

s

—

Note 1: Program must be verified at the minimum and maximum V

DD

limits of the device.

0

0

0

0

0

0

1

1

1

2

3

4

5

6

1

2

P3

P4

P6

Next Command

CLOCK

DATA

MCLR/V

PP

= V

IHH

V

DD

= V

DDMIN

MCP2505X

DS20072A-page 16

2001 Microchip Technology Inc.

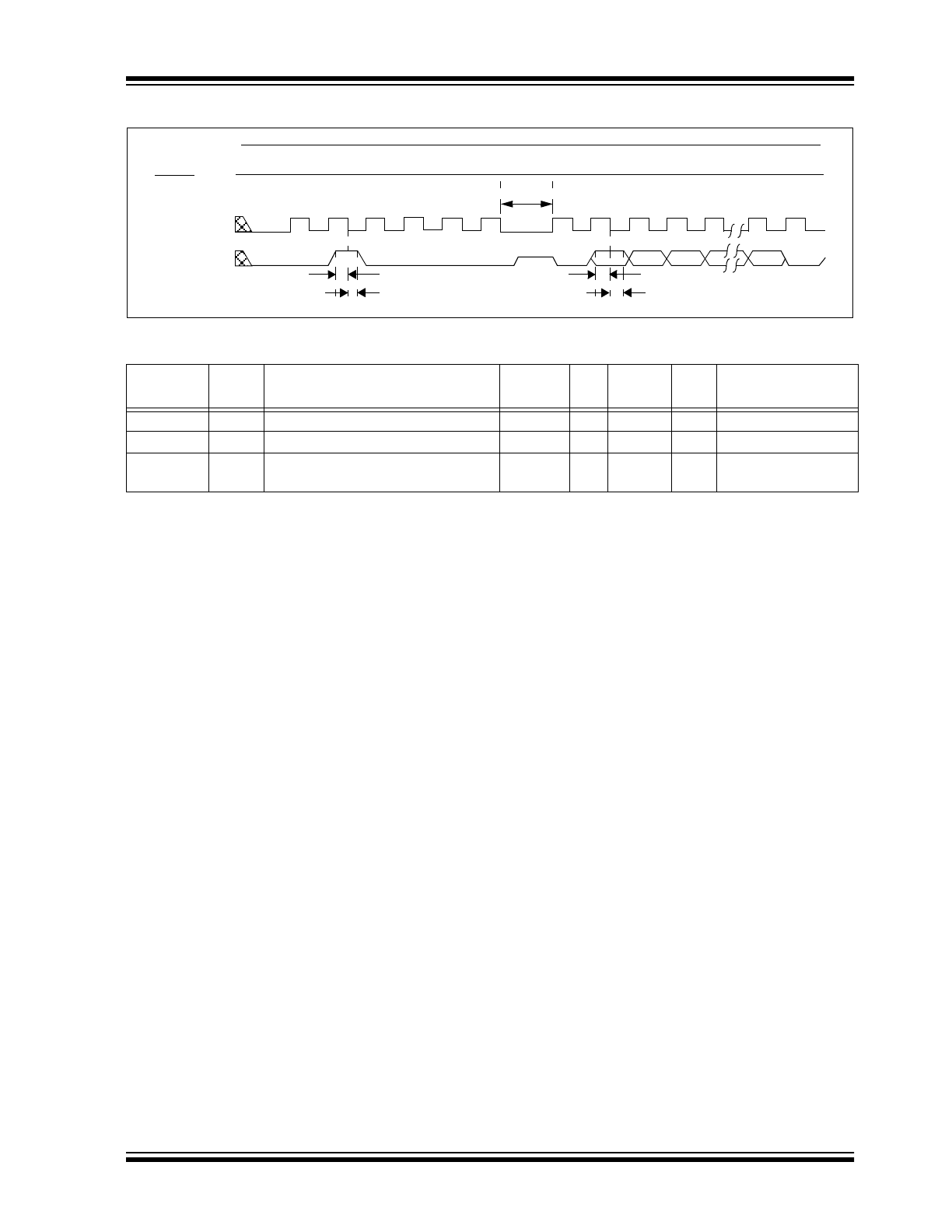

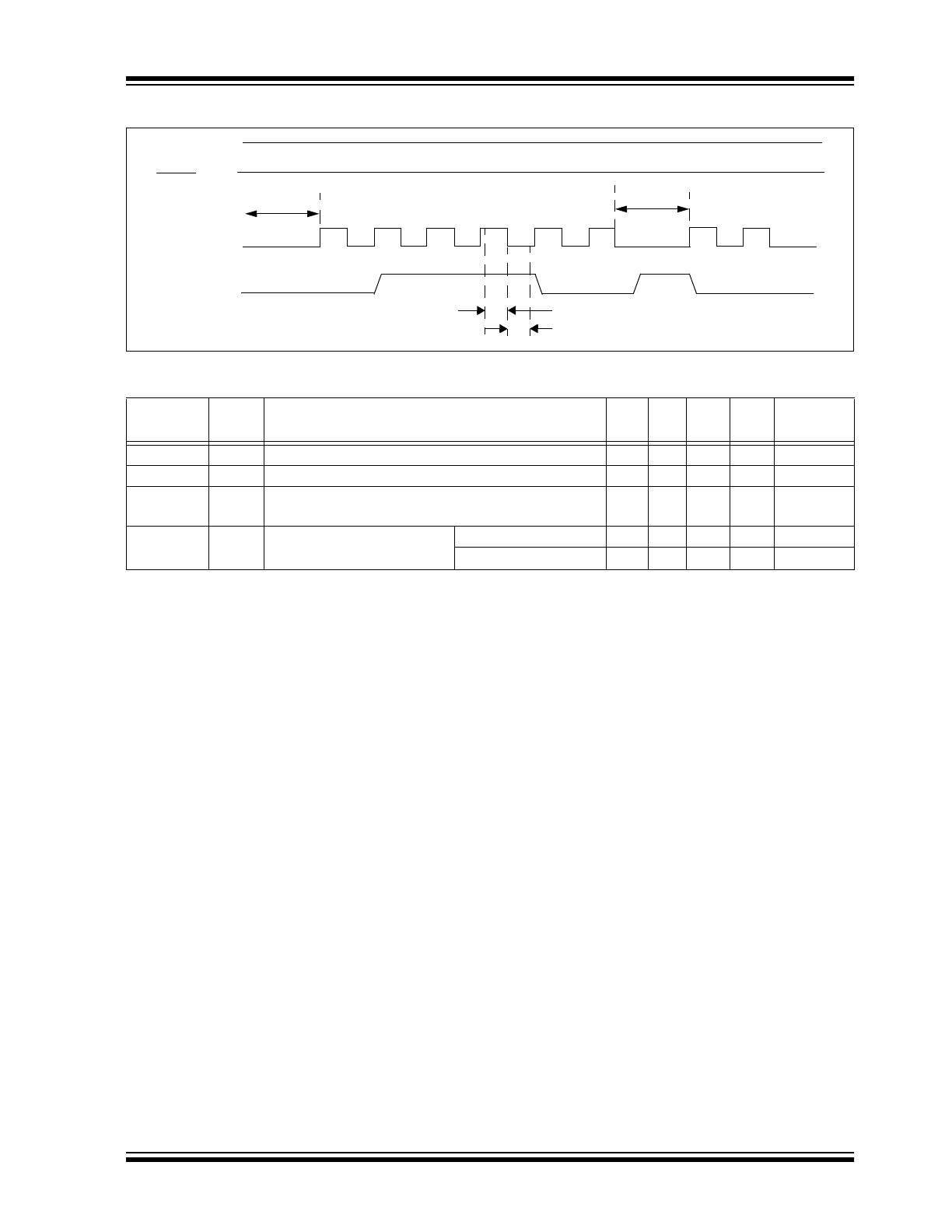

FIGURE 7-7:

BEGIN PROGRAMMING COMMAND WAVEFORM

TABLE 7-7:

BEGIN PROGRAMMING COMMAND TIMING

Parameter

No.

Symbol Characteristic

Min. Typ. Max. Units Conditions

P3

T

SET

1 Data in setup time before clock

↓

100

—

—

ns

—

P4

T

HLD

1 Data in hold time after clock

↓

100

—

—

ns

—

P11

Programming Pulse Width

User Memory

90

100

110

µ

s

—

Configuration Memory

90

100

110

µ

s

—

Note 1: Program must be verified at the minimum and maximum V

DD

limits of the device.

0

1

0

0

0

0

0

0

1

2

3

4

5

6

1

2

P11

End Programming

CLOCK

DATA

MCLR/V

PP

= V

IHH

V

DD

= V

DDMIN

Command

P3

P4

2001 Microchip Technology Inc.

DS20072A-page 17

MCP2505X

FIGURE 7-8:

END PROGRAMMING COMMAND WAVEFORM

TABLE 7-8:

END PROGRAMMING COMMAND TIMING

Parameter

No.

Symbol Characteristic

Min. Typ. Max. Units Conditions

P3

T

SET

1 Data in setup time before clock

↓

100

—

—

ns

—

P4

T

HLD

1 Data in hold time after clock

↓

100

—

—

ns

—

P6

T

DLY

2 Delay between clock

↓

to clock

↑

of next command or

data

1.0

—

—

µ

s

—

P11

Programming Pulse Width

(1)

User

Memory

90

100

110

µ

s

—

Configuration Memory

90

100

110

µ

s

—

Note 1: Only required if the previous command was the Begin Programming Command.

2: Program must be verified at the minimum and maximum V

DD

limits of the device.

0

1

0

0

0

0

1

1

1

2

3

4

5

6

1

2

P6

Next Command

CLOCK

DATA

MCLR/V

PP

= V

IHH

V

DD

= V

DDMIN

P11

P3

P4

MCP2505X

DS20072A-page 18

2001 Microchip Technology Inc.

NOTES:

2001 Microchip Technology Inc.

DS20072A-page 19

MCP2505X

“All rights reserved. Copyright © 2001, Microchip

Technology Incorporated, USA. Information contained

in this publication regarding device applications and the

like is intended through suggestion only and may be

superseded by updates. No representation or warranty

is given and no liability is assumed by Microchip

Technology Incorporated with respect to the accuracy

or use of such information, or infringement of patents or

other intellectual property rights arising from such use

or otherwise. Use of Microchip’s products as critical

components in life support systems is not authorized

except with express written approval by Microchip. No

licenses are conveyed, implicitly or otherwise, under

any intellectual property rights. The Microchip logo and

name are registered trademarks of Microchip

Technology Inc. in the U.S.A. and other countries. All

rights reserved. All other trademarks mentioned herein

are the property of their respective companies. No

licenses are conveyed, implicitly or otherwise, under

any intellectual property rights.”

Trademarks

The Microchip name, logo, PIC, PICmicro,

PICMASTER, PICSTART, PRO MATE, K

EE

L

OQ

,

SEEVAL, MPLAB and The Embedded Control

Solutions Company are registered trademarks of

Microchip Technology Incorporated in the U.S.A. and

other countries.

Total Endurance, ICSP, In-Circuit Serial Programming,

FilterLab, MXDEV, microID, FlexROM, fuzzyLAB,

MPASM, MPLINK, MPLIB, PICDEM, ICEPIC,

Migratable Memory, FanSense, ECONOMONITOR,

SelectMode and microPort are trademarks of

Microchip Technology Incorporated in the U.S.A.

Serialized Quick Term Programming (SQTP) is a

service mark of Microchip Technology Incorporated in

the U.S.A.

All other trademarks mentioned herein are property of

their respective companies.

© 2001, Microchip Technology Incorporated, Printed in

the U.S.A., All Rights Reserved.

Microchip received QS-9000 quality system

certification for its worldwide headquarters,

design and wafer fabrication facilities in

Chandler and Tempe, Arizona in July 1999. The

Company’s quality system processes and

procedures are QS-9000 compliant for its

PICmicro

®

8-bit MCUs, K

EE

L

OQ

®

code hopping

devices, Serial EEPROMs and microperipheral

products. In addition, Microchip’s quality

system for the design and manufacture of

development systems is ISO 9001 certified.

Information contained in this publication regarding device applications and the like is intended through suggestion only and may be superseded by

updates. It is your responsibility to ensure that your application meets with your specifications. No representation or warranty is given and no liability is

assumed by Microchip Technology Incorporated with respect to the accuracy or use of such information, or infringement of patents or other intellectual

property rights arising from such use or otherwise. Use of Microchip’s products as critical components in life support systems is not authorized except with

express written approval by Microchip. No licenses are conveyed, implicitly or otherwise, except as maybe explicitly expressed herein, under any intellec-

tual property rights. The Microchip logo and name are registered trademarks of Microchip Technology Inc. in the U.S.A. and other countries. All rights

reserved. All other trademarks mentioned herein are the property of their respective companies.

DS20072A-page 20

2001 Microchip Technology Inc.

All rights reserved. © 2001 Microchip Technology Incorporated. Printed in the USA. 3/01

Printed on recycled paper.

M

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200 Fax: 480-792-7277

Technical Support: 480-792-7627

Web Address: http://www.microchip.com

Rocky Mountain

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7966 Fax: 480-792-7456

Atlanta

500 Sugar Mill Road, Suite 200B

Atlanta, GA 30350

Tel: 770-640-0034 Fax: 770-640-0307

Austin

Analog Product Sales

8303 MoPac Expressway North

Suite A-201

Austin, TX 78759

Tel: 512-345-2030 Fax: 512-345-6085

Boston

2 Lan Drive, Suite 120

Westford, MA 01886

Tel: 978-692-3848 Fax: 978-692-3821

Boston

Analog Product Sales

Unit A-8-1 Millbrook Tarry Condominium

97 Lowell Road

Concord, MA 01742

Tel: 978-371-6400 Fax: 978-371-0050

Chicago

333 Pierce Road, Suite 180

Itasca, IL 60143

Tel: 630-285-0071 Fax: 630-285-0075

Dallas

4570 Westgrove Drive, Suite 160

Addison, TX 75001

Tel: 972-818-7423 Fax: 972-818-2924

Dayton

Two Prestige Place, Suite 130

Miamisburg, OH 45342

Tel: 937-291-1654 Fax: 937-291-9175

Detroit

Tri-Atria Office Building

32255 Northwestern Highway, Suite 190

Farmington Hills, MI 48334

Tel: 248-538-2250 Fax: 248-538-2260

Los Angeles

18201 Von Karman, Suite 1090

Irvine, CA 92612

Tel: 949-263-1888 Fax: 949-263-1338

Mountain View

Analog Product Sales

1300 Terra Bella Avenue

Mountain View, CA 94043-1836

Tel: 650-968-9241 Fax: 650-967-1590

New York

150 Motor Parkway, Suite 202

Hauppauge, NY 11788

Tel: 631-273-5305 Fax: 631-273-5335

San Jose

Microchip Technology Inc.

2107 North First Street, Suite 590

San Jose, CA 95131

Tel: 408-436-7950 Fax: 408-436-7955

Toronto

6285 Northam Drive, Suite 108

Mississauga, Ontario L4V 1X5, Canada

Tel: 905-673-0699 Fax: 905-673-6509

ASIA/PACIFIC

Australia

Microchip Technology Australia Pty Ltd

Suite 22, 41 Rawson Street

Epping 2121, NSW

Australia

Tel: 61-2-9868-6733 Fax: 61-2-9868-6755

China - Beijing

Microchip Technology Beijing Office

Unit 915

New China Hong Kong Manhattan Bldg.

No. 6 Chaoyangmen Beidajie

Beijing, 100027, No. China

Tel: 86-10-85282100 Fax: 86-10-85282104

China - Shanghai

Microchip Technology Shanghai Office

Room 701, Bldg. B

Far East International Plaza

No. 317 Xian Xia Road

Shanghai, 200051

Tel: 86-21-6275-5700 Fax: 86-21-6275-5060

Hong Kong

Microchip Asia Pacific

RM 2101, Tower 2, Metroplaza

223 Hing Fong Road

Kwai Fong, N.T., Hong Kong

Tel: 852-2401-1200 Fax: 852-2401-3431

India

Microchip Technology Inc.

India Liaison Office

Divyasree Chambers

1 Floor, Wing A (A3/A4)

No. 11, O’Shaugnessey Road

Bangalore, 560 025, India

Tel: 91-80-2290061 Fax: 91-80-2290062

Japan

Microchip Technology Intl. Inc.

Benex S-1 6F

3-18-20, Shinyokohama

Kohoku-Ku, Yokohama-shi

Kanagawa, 222-0033, Japan

Tel: 81-45-471- 6166 Fax: 81-45-471-6122

ASIA/PACIFIC

(continued)

Korea

Microchip Technology Korea

168-1, Youngbo Bldg. 3 Floor

Samsung-Dong, Kangnam-Ku

Seoul, Korea

Tel: 82-2-554-7200 Fax: 82-2-558-5934

Singapore

Microchip Technology Singapore Pte Ltd.

200 Middle Road

#07-02 Prime Centre

Singapore, 188980

Tel: 65-334-8870 Fax: 65-334-8850

Taiwan

Microchip Technology Taiwan

11F-3, No. 207

Tung Hua North Road

Taipei, 105, Taiwan

Tel: 886-2-2717-7175 Fax: 886-2-2545-0139

EUROPE

Denmark

Microchip Technology Denmark ApS

Regus Business Centre

Lautrup hoj 1-3

Ballerup DK-2750 Denmark

Tel: 45 4420 9895 Fax: 45 4420 9910

France

Arizona Microchip Technology SARL

Parc d’Activite du Moulin de Massy

43 Rue du Saule Trapu

Batiment A - ler Etage

91300 Massy, France

Tel: 33-1-69-53-63-20 Fax: 33-1-69-30-90-79

Germany

Arizona Microchip Technology GmbH

Gustav-Heinemann Ring 125

D-81739 Munich, Germany

Tel: 49-89-627-144 0 Fax: 49-89-627-144-44

Germany

Analog Product Sales

Lochhamer Strasse 13

D-82152 Martinsried, Germany

Tel: 49-89-895650-0 Fax: 49-89-895650-22

Italy

Arizona Microchip Technology SRL

Centro Direzionale Colleoni

Palazzo Taurus 1 V. Le Colleoni 1

20041 Agrate Brianza

Milan, Italy

Tel: 39-039-65791-1 Fax: 39-039-6899883

United Kingdom

Arizona Microchip Technology Ltd.

505 Eskdale Road

Winnersh Triangle

Wokingham

Berkshire, England RG41 5TU

Tel: 44 118 921 5869 Fax: 44-118 921-5820

01/30/01

W

ORLDWIDE

S

ALES

AND

S

ERVICE