© 2009 Microchip Technology Inc.

DS22186C-page 1

MCP2036

Features:

• Complete Inductance Measurement System:

- Low-Impedance Current Driver

- Sensor/Reference Coil Multiplexer

- High-Frequency Detector

• Operating Voltage: 2.7 to 5.5V

• Low-Power Standby Mode

• Gain and Frequency set by external passive

components

Typical Applications:

• Harsh environment inductive keyboards

• Inductive rotational sensor interface

• Inductive displacement sensor interface

• Inductive force sensor interface

Description:

The MCP2036 Inductive Sensor Analog Front End

(AFE) combines all the necessary analog functions for

a complete inductance measurement system.

The device includes:

• High-frequency, current-mode coil driver for

exciting the sensor coil.

• Synchronous detector for converting AC sense

voltages into DC levels.

• Output amplifier/filter to improve resolution and

limit noise.

• Virtual ground reference generator for single

supply operation.

The device is available in 14-pin PDIP, SOIC and

16-pin QFN packages:

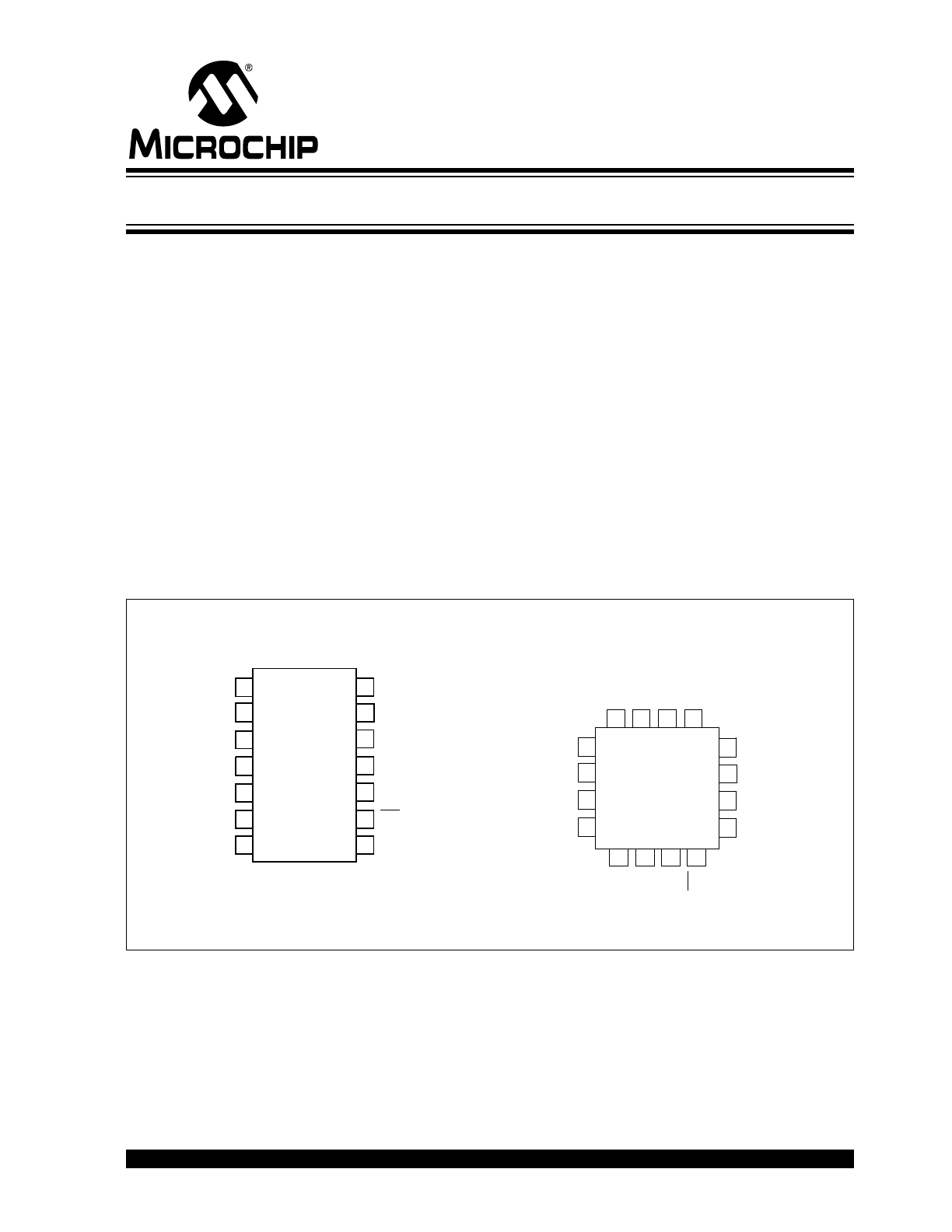

Package Types

1

2

3

6

7

4

5

14

13

8

9

10

11

12

V

REF

LREF

LBTN

V

DD

DRVOUT

DRVIN

CLK

V

DET+

V

DET-

V

DETOUT

V

SS

CS

REFSEL

ISOL

9

10

11

12

6

7

5

8

1

2

3

4

LREF

LBTN

V

DD

DRVOUT

16

15

14

13

DR

VIN

CL

K

REF

SEL

CS

V

DET-

V

DETOUT

V

SS

ISOL

V

DE

T

+

V

RE

F

NC

NC

MCP2036

16-pin QFN

MCP2036

14-pin PDIP, SOIC

Inductive Sensor Analog Front End Device

MCP2036

DS22186C-page 2

© 2009 Microchip Technology Inc.

1.0

FUNCTIONAL DESCRIPTION

The MCP2036 measures a sensor coil’s impedance by

exciting the coil with a pulsed DC current and

measuring the amplitude of the resulting AC voltage

waveform. The drive current is generated by the

on-chip current amplifier/driver which takes the

high-frequency triangular waveform present on the

DRVIN input, and amplifies it into the pulsed DC current

for exciting the series combination of the sensor coils.

The AC voltages generated across the coils, are then

capacitively coupled into the LBTN and LREF inputs.

An input resistance of 2K between the inputs and the

virtual ground offsets the AC input voltages up to the

signal ground generated by the reference voltage

generator, as shown in

Figure 1-1

.

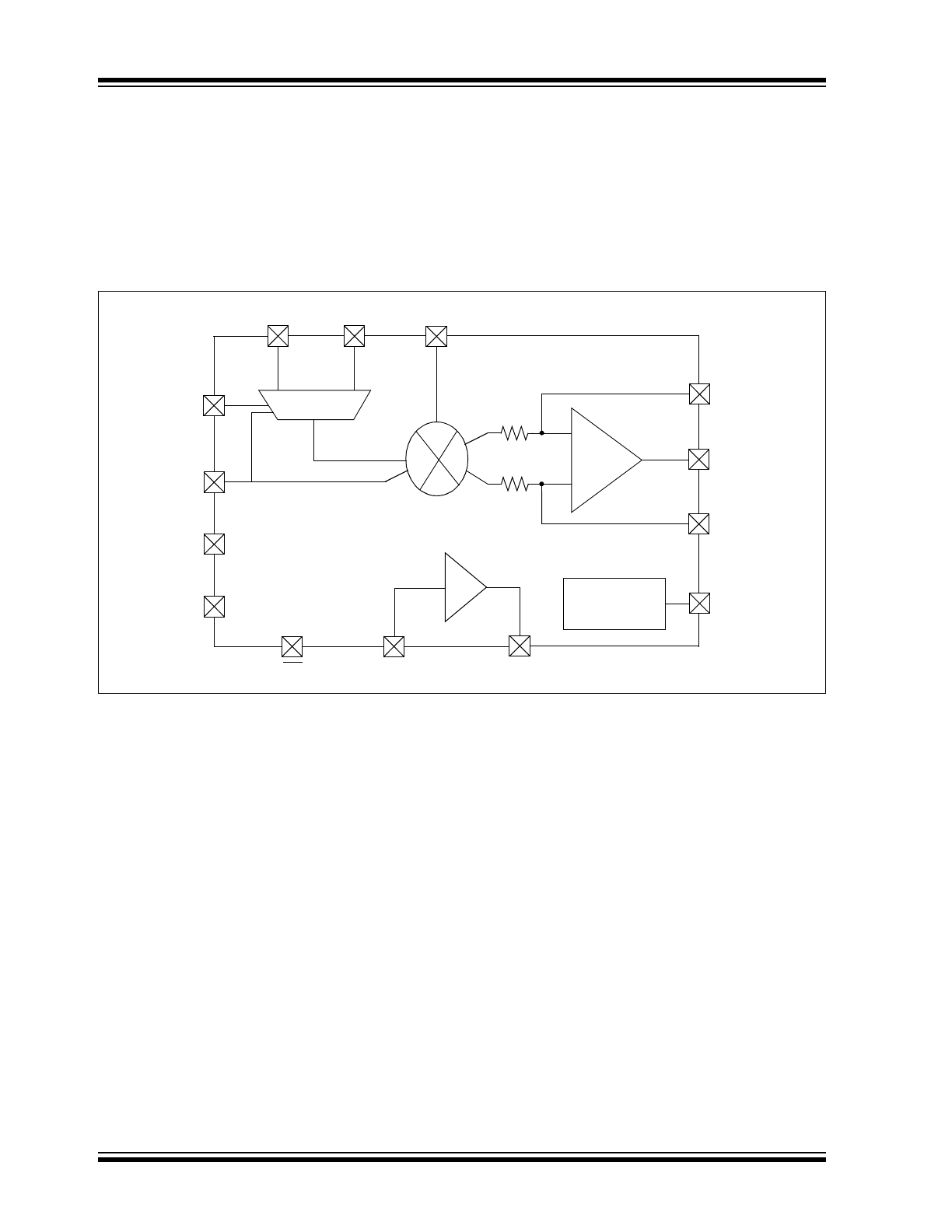

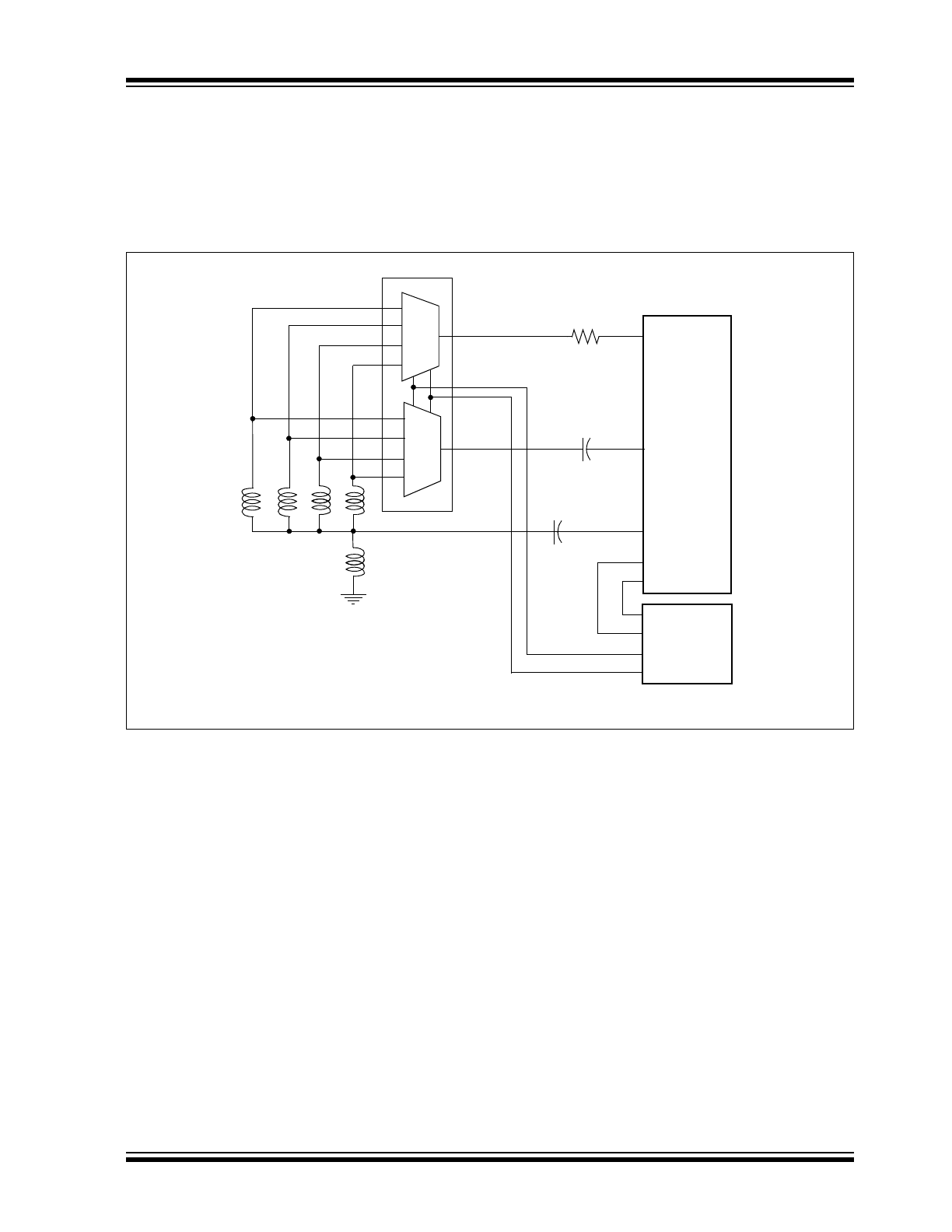

FIGURE 1-1:

MCP2036 Block Diagram

Voltage

Reference

REFSEL

V

DETOUT

DRVIN

CLK

DRVOUT

LBTN

LREF

V

REF

V

DD

V

SS

0

1

Input MUX

CS

Key Inductor Driver

Mixer

V

DET+

V

DET-

+

-

10K

10K

Op. Amp. Block

ISOL

© 2009 Microchip Technology Inc.

DS22186C-page 3

MCP2036

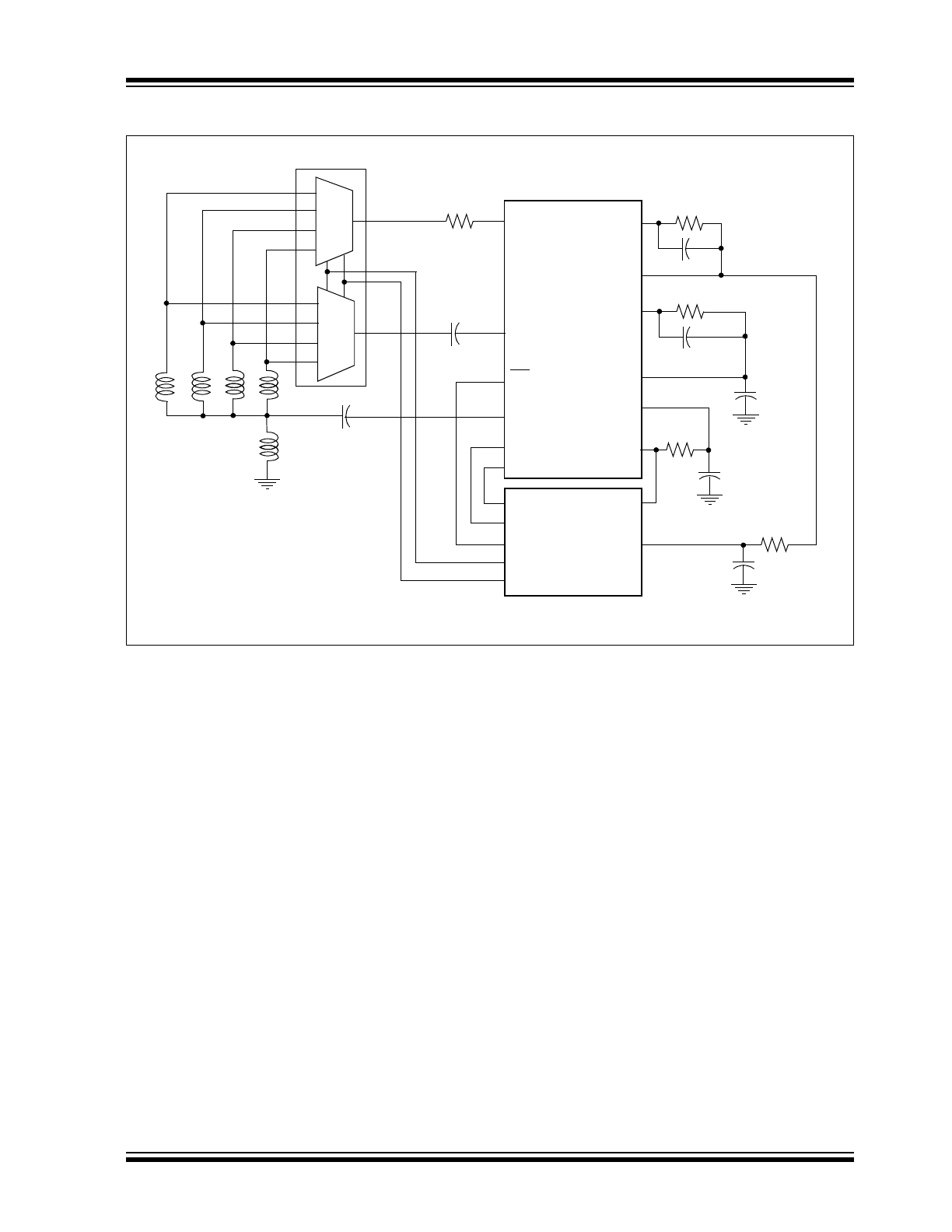

FIGURE 1-2:

MCP2036 Typical Application

The coil voltages are then multiplexed into the

Synchronous Detector section by the LBTN/LREF

multiplexer. This allows the microcontroller to select

which signal is sampled by the detector. The detector

converts the coil voltages into a DC level using a

frequency mixer, amplifier, and filter.

The mixer is composed of two switches driven by the

clock present on the CLK signal input. The switches

toggle the amplifier/filter between an inverting and

non-inverting topology, at a rate equal to the clock input

frequency. This inverts and amplifies the negative side

of the signal, while amplifying the positive side. The

result is a pulsed DC signal with a peak voltage,

proportional to the amplitude of the AC coil voltage.

The gain of the detector is set by two pairs of resistors;

one pair are the internal fixed series resistors between

the frequency mixer and the amplifier. The second

resistor pair are the two external gain set resistors

(R

GAIN

). The two capacitors (C

FILTER

) in parallel with

the external gain setting resistors form a low pass filter

which converts the pulsed DC output signal into a

smooth DC voltage which is proportional to the AC

sensor voltage input. The output of the system is

present on the V

DETOUT

pin, which drives the

microcontroller’s ADC input for conversion into a digital

value.

The virtual ground reference for the detector/amplifier

is generated by a second internal op amp which

produces a virtual ground equal to ½ the supply

voltage. The virtual ground is available externally at the

V

REF

output and used internally throughout the

detector circuit, allowing single supply operation. A

small external capacitance is required to stabilize this

output and limit noise.

The ISOL input is used to isolate the detector from

potential noise sources during the measurement of the

virtual ground reference during a button measurement.

MCP2036

LREF

LBTN

LREF

DRVOUT

10

Ω

10nF

REFSEL

10nF

I/O

I/O

I/O

0

1

2

3

0

1

3

2

CD4052

Key Coils

PIC

®

Microcontroller

CS

I/O

V

DET-

V

DETOUT

V

DET+

V

REF

CLK

DRVIN

PWM

ADC

C

FILTER

C

FILTER

R

GAIN

R

GAIN

C

RGND

R

IN

C

IN

R

ADC

C

ADC

ISOL

I/O

MCP2036

DS22186C-page 4

© 2009 Microchip Technology Inc.

1.1

Coil Driver

The coil driver produces the excitation current for the

sensor coils.

The coil driver input is derived from the digital clock

supplied to the CLK input. The digital signal is first

filtered through a low-pass filter, composed of R

IN

and

C

IN

, and passed to the DRVIN input. The driver will

create a triangular current in phase and proportional

with the input voltage. Because the digital drive into the

R

IN

-C

IN

filter has a 50% duty cycle, the voltage on the

DRVIN input will be centered at V

DD

/2. The relationship

between voltage, current, inductance and frequency is

shown in

Equation 1-1

.

EQUATION 1-1:

1.2

Synchronous Detector and Output

Amplifier

The Synchronous Detector has two inputs, LREF and

LBTN, selectable by REFSEL. This routes either signal

into the frequency mixer of the detector. The frequency

mixer then converts the AC waveform into a pulsed DC

signal which is amplified and filtered.

The gain of the amplifier is user-settable, using an

external resistor, R

GAIN

(see

Equation 1-2

).

EQUATION 1-2:

An ADC plus firmware algorithm then digitizes the

detector output voltage and uses the resulting data to

detect a key press event.

1.3

Virtual Ground Voltage Reference

Circuit

To create both an inverting and non-inverting amplifier

topology, a pseudo split supply design is required. To

generate the dual supplies required, a rail splitter is

included, which generates the virtual ground by creat-

ing a voltage output at V

DD

/2. The output is used by the

external passive network of the Detector/Amplifier sec-

tion as a reference on the non-inverting input. A bypass

capacitor of 0.1 uF is required to ensure the stability of

the output. For reference accuracy, no more than 3 mA

should be supplied to, or drawn from the reference

output pin.

ΔV

OUT

ΔI

DRV

L

COIL

•

2

F

DRV

•

•

(

)

=

V

OUT

Pulsed Output Voltage

=

ΔI

DR V

AC Drive Current Amplitude

=

F

DRV

AC Drive Current Frequency

=

L

COIL

Inductance of the Sensor Coil

=

Note:

These equations assume a 50% duty cycle.

Note:

The output amplifier/filter uses a

differential connection, so its output is

centered to V

REF

(V

DD

/2). The amplitude

of the detected signal should be calculated

as the difference between voltages at the

output of the detector and the reference

voltage.

Gain

R

GAIN

10kOhm

⁄

∼

© 2009 Microchip Technology Inc.

DS22186C-page 5

MCP2036

2.0

PIN DESCRIPTION

Descriptions of the pins are listed in

Table 2-1

.

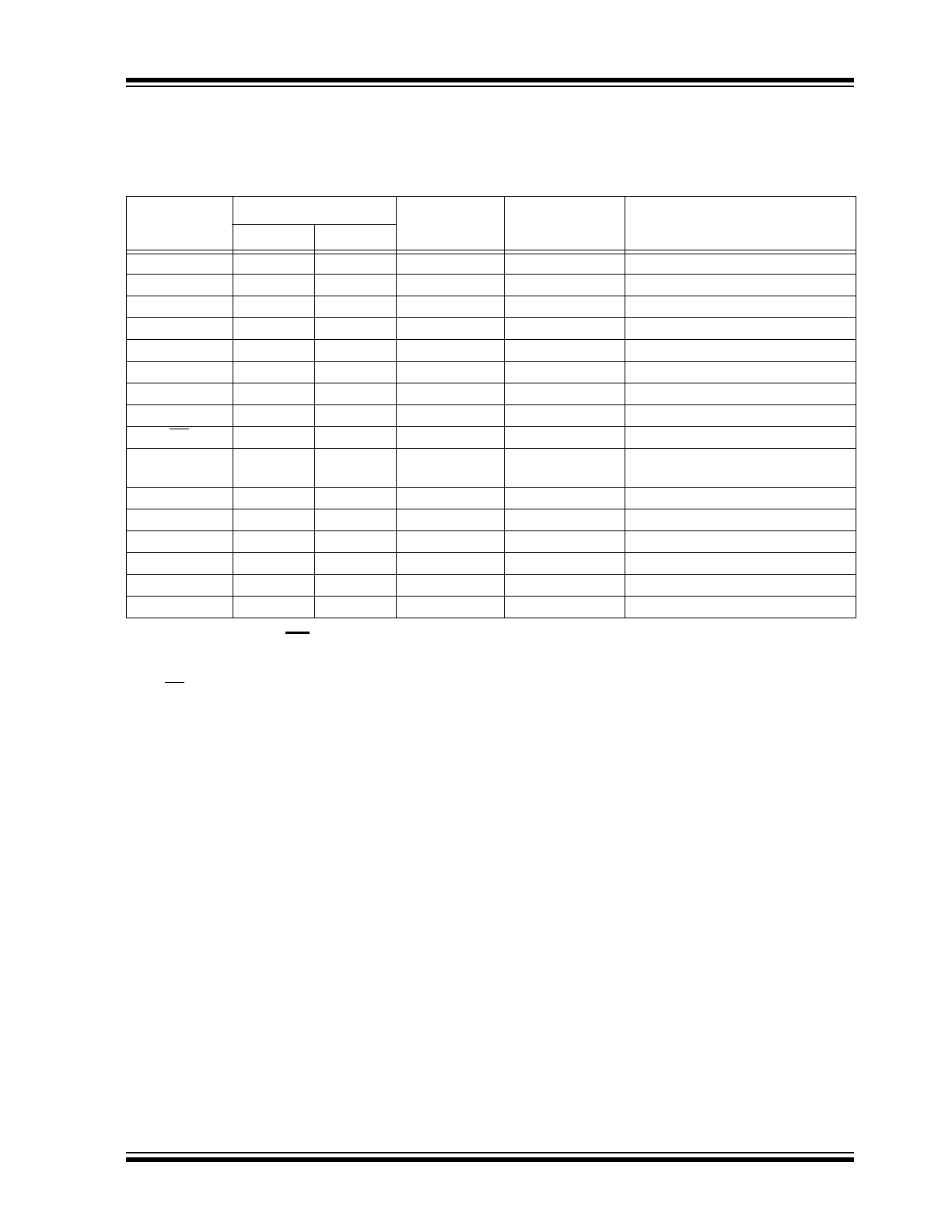

TABLE 2-1:

PIN FUNCTION TABLE

2.1

Chip Select (CS)

The circuit is fully enabled when a logic-low is applied

to the CS input. The circuit enters in Low-Power mode

when a logic-high is applied to this input. During

Low-Power mode, the detector output voltage falls to

V

REF

and the supply current is reduced to 0.5 μA (typ.).

This pin has an internal pull-up resistor to ensure

proper selection of the circuit.

2.2

Voltage Reference (

V

REF

)

V

REF

is a mid-scale reference output. It can source and

sink small currents and has low output impedance. A

load capacitor between 100 nF and 1 μF needs to be

located close to this pin.

2.3

Power Supply (V

DD

, V

SS

)

The V

DD

pin is the power supply pin for the analog and

digital circuitry within the MCP2036. This pin requires

an appropriate bypass capacitor of 100 nF. The voltage

on this pin should be maintained in the 2.7V-5.5V range

for specified operation.

The V

SS

pin is the ground pin and the current return

path for both analog and digital circuitry of the

MCP2036. If an analog ground plane is available, it is

recommended that this device be tied to the analog

ground plane of the PCB.

2.4

Inductor Inputs (LREF, LBTN)

These pins are inputs for the external coils (reference

and sensor). The inputs should be AC coupled to the

coils by a 10 nF ceramic capacitor.

2.5

Input Selection (REFSEL)

Digital input that is used to select between coil inputs

(reference and sensor).

2.6

Detector Isolate (ISOL)

Digital input that is used to isolate the detector circuit

while measuring the system virtual ground. Pulling the

input high disables the detector input multiplexers,

isolating the op amp circuitry from the coils inputs.

Pulling the input low reconnects the inputs for

measuring both reference and button coil inputs.

2.7

Clock (CLK)

The external clock input is used for synchronous

detection of the AC waveforms on the coils. The clock

signal is also used to generate a triangular waveform

applied to coil driver input.

Pad Name

Pin Number

I/O

Type

Description

14 Pins

16 Pins

V

REF

1

16

OUT

AN

Voltage Reference

LREF

2

1

IN

AN

Reference Inductor Input

LBTN

3

2

IN

AN

Active Inductor Input

V

DD

4

3

PWR

AN

Power Supply

DRVOUT

5

4

OUT

AN

Current Driver Output for Inductors

DRVIN

6

5

IN

AN

Current Driver Input

CLK

7

6

IN

CMOS

Clock Signal

REFSEL

8

7

IN

CMOS

Detector Select Input

CS

9

8

IN

CMOS

Chip Select, Active low

ISOL

10

9

IN

CMOS

Detector Isolation Control Input,

high = isolate

V

SS

11

10

PWR

AN

Power Supply Return

V

DETOUT

12

11

OUT

AN

Detector Output Voltage

V

DET-

13

12

IN

AN

Negative Input for Output Detector

V

DET+

14

13

IN

AN

Positive Input for Output Detector

NC

14

—

—

No connect

NC

15

—

—

No connect

MCP2036

DS22186C-page 6

© 2009 Microchip Technology Inc.

2.8

Inductor Driver Input (DRVIN)

The analog input to the coil driver. The triangular

waveform applied to this input should be in phase with

the clock signal for best performance.

2.9

Inductor Driver Output (DRVOUT)

Driver output used to excite the sensor coils. It is a

current-mode output designed to drive small inductive

loads.

2.10

Detector Output Voltage (V

DETOUT

)

The amplifier/filter output from the detector. This is a

low-impedance analog output pin (V

OUT

) for driving the

microcontroller ADC. The detector output is rail-to-rail.

2.11

Inputs for Output Detector (V

DET+

,

V

DET-

)

The non-inverting and inverting inputs for the

amplifier/filter op amp. The two inputs are connected to

the output of the mixer circuit through two internal

10K

Ω resistors.

© 2009 Microchip Technology Inc.

DS22186C-page 7

MCP2036

3.0

APPLICATIONS

The MCP2036 is an Analog Front End device that uses

the electromagnetic interaction between a conductive

target and a sensing coil to detect the pressure applied

by the user on the surface of a touch panel. The device

incorporates all analog blocks for a simple inductor

impedance measurement circuit.

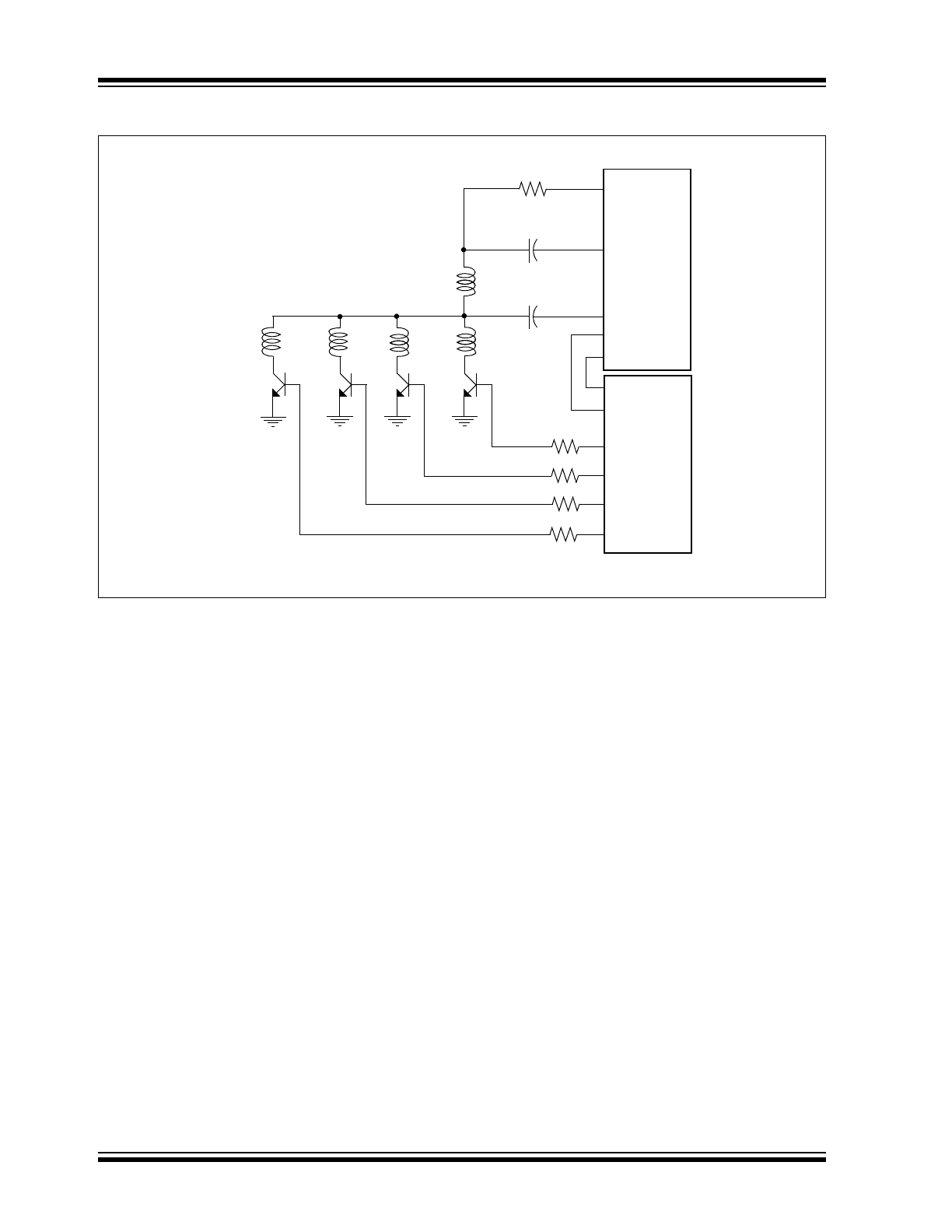

For an inductive touch system, two methods are used

for switching the driver and measurement circuitry

between the different sensor coils: analog multiplexers

and GPIO grounding (see

Figure 3-1

and

Figure 3-2

).

The MCP2036 is designed to work with both

configurations:

FIGURE 3-1:

Using Analog-Multiplexer for Key Selection (Example)

MCP2036

LREF

LBTN

LREF

DRVOUT

10

Ω

10nF

REFSEL

10nF

I/O

I/O

I/O

0

1

2

3

0

1

3

2

CD4052

Key Coils

PIC

®

Microcontroller

ISOL

I/O

MCP2036

DS22186C-page 8

© 2009 Microchip Technology Inc.

FIGURE 3-2:

Using NPN transistors for Key Selection (Example)

LREF

MCP2036

LBTN

LREF

DRVOUT

REFSEL

I/O

I/O

10

Ω

10nF

I/O

I/O

10nF

4K7

4K7

PIC

®

Microcontroller

I/O

4K7

4K7

Key Coils

ISOL

I/O

© 2009 Microchip Technology Inc.

DS22186C-page 9

MCP2036

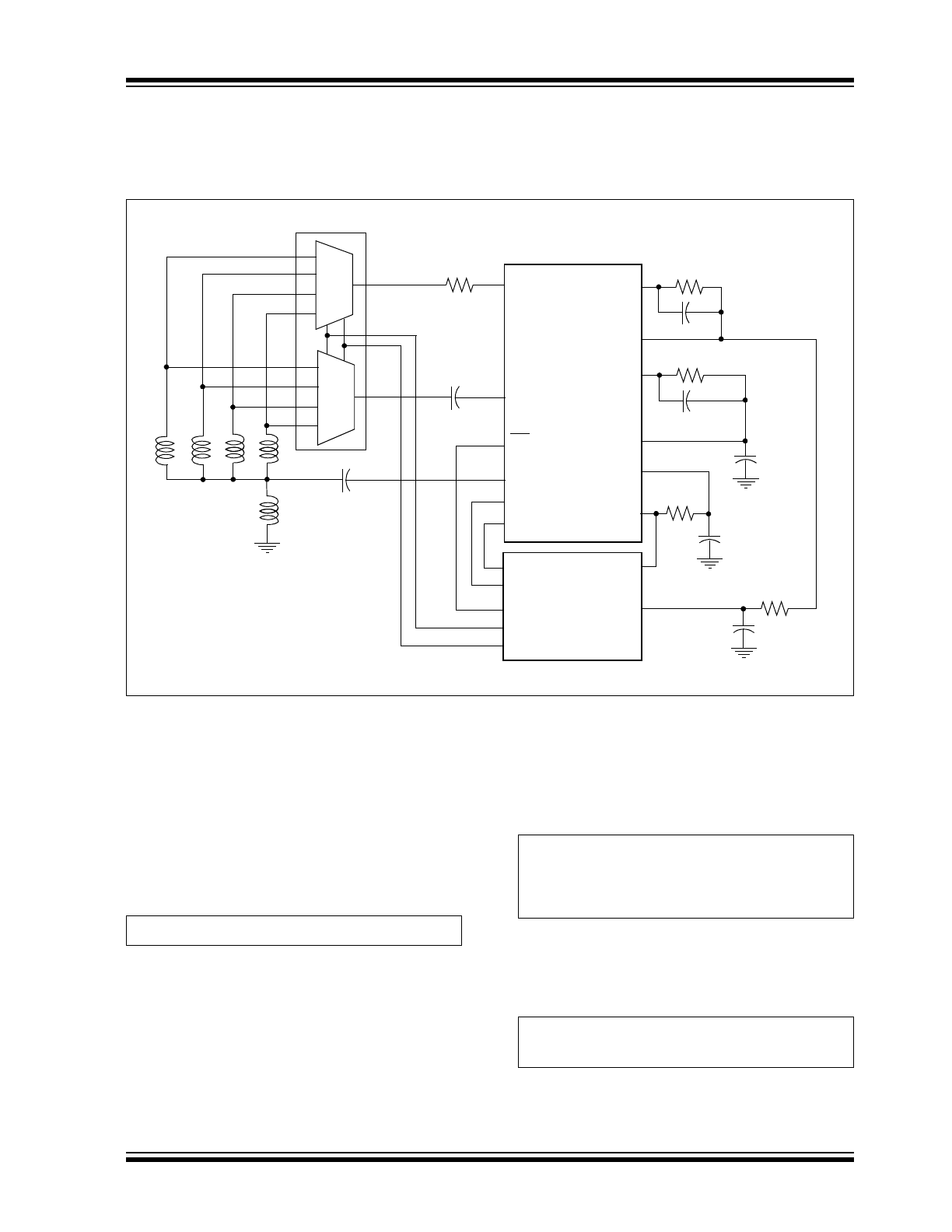

3.1

Application example

Figure 3-3

shows an example for a 4-key Inductive

Touch keyboard with key controlled by the IO pins of

the PIC

®

MCU.

FIGURE 3-3:

MCP2036 Typical Application

The PIC

®

microcontroller is used to generate a square

wave signal and to do all the necessary operations for

proper detection of the key press event.

Then, R

IN

-C

IN

filter converts the square wave output of

the PWM into a quasi-triangular waveform.

To calculate the amplitude of the triangular signal, the

standard charging time equation for an RC network will

be used, as shown in

Equation 3-1

:

EQUATION 3-1:

For the first half of the square wave, the capacitor C

IN

is charged through R

IN

, for the second half, it is

discharged through R

IN

, and assuming that clock

signal has a 50% duty cycle factor, we can consider:

EQUATION 3-2:

When the PWM signal switches from low-to-high or

from high-to-low, the step voltage applied to the

capacitor C

IN

will be:

EQUATION 3-3:

MCP2036

LREF

LBTN

LREF

DRVOUT

10

Ω

10nF

REFSEL

10nF

I/O

I/O

I/O

0

1

2

3

0

1

3

2

CD4052

Key Coils

PIC

®

Microcontroller

CS

I/O

V

DET-

V

DETOUT

V

DET+

V

REF

CLK

DRVIN

PWM

ADC

C

FILTER

C

FILTER

R

GAIN

R

GAIN

C

RGND

R

IN

C

IN

R

ADC

C

ADC

ISOL

I/O

V t

( ) V

step

1

t RC

⁄

–

(

)

exp

–

[

]

•

=

V

start

V

DD

2

⁄ -ΔV

=

V

stop

V

DD

2

⁄ +ΔV

=

V

step

V

DD

2

⁄

ΔV

+

(

)

=

MCP2036

DS22186C-page 10

© 2009 Microchip Technology Inc.

Substituting in the equation for an RC network:

EQUATION 3-4:

The peak-to-peak amplitude of the resulting triangular

waveform, at the coil driver input, is shown in

Equation 3-5

:

EQUATION 3-5:

From the previous equation, the designer should

choose values for V

PKPK

and R

IN

. Using the equation

above, the value of C

IN

will be:

EQUATION 3-6:

The amplitude of the pulsed current applied to key

inductors will be:

EQUATION 3-7:

This current produces a pulsed voltage to key inductors

ends. The amplitude of this voltage will be:

EQUATION 3-8:

The total voltage across both the reference and sensor

coils would be double (two series inductors). For a

specific power supply voltage, half of this power supply,

relative to the voltage reference, is available for output

amplifier/detector. Assuming a 30% margin, the

desired gain for the detector should be about:

EQUATION 3-9:

The gain of the amplifier is user-settable, using an

external resistor, R

GAIN.

The value of that resistor will

be determined using the following equation:

EQUATION 3-10:

With a 10-bit ADC, using oversampling and averaging

techniques, the effective resolution is close to 11 bits.

As shown in AN1239, “Inductive Touch Sensor

Design

”, the typical shift in sensor impedance is typi-

cally 3-4%, so the actual number of counts per press is

typically between 20 and 40 counts. In this way, the

microcontroller firmware could easily detect press

event.

Note:

V

PKPK

should not exceed specified value

(600mV) for best performance.

Note:

Assuming a power supply of 5V and

V

PKPK

=500mV, for R

IN

=3.9K

Ω, C

IN

should

have about 320pF. A 330pF capacitor will

be used.

ΔV

V

DD

2

-----------

1

t

–

R

IN

C

IN

------------------

⎝

⎠

⎛

⎞

exp

–

1

t

–

R

IN

C

IN

------------------

⎝

⎠

⎛

⎞

exp

+

-------------------------------------------

•

=

2

ΔV

V

DD

2

⁄

ΔV

+

(

)

1

t RC

⁄

–

(

)

exp

–

[

]

•

=

V

PK PK

2

ΔV

=

V

PKPK

V

DD

1

t

–

R

IN

C

IN

------------------

⎝

⎠

⎛

⎞

exp

–

1

t

–

R

IN

C

IN

------------------

⎝

⎠

⎛

⎞

exp

+

-------------------------------------------

•

=

C

IN

t

R

IN

ln

V

DD

V

PKPK

–

V

DD

V

PKPK

+

----------------------------------------

⎝

⎠

⎜

⎟

⎛

⎞

•

-------------------------------------------------------------------

1

2

F

R

IN

V

DD

V

PKPK

–

V

DD

V

PKPK

+

----------------------------------------

⎝

⎠

⎜

⎟

⎛

⎞

ln

•

•

•

-------------------------------------------------------------------------------------

=

=

ΔI V

PK PK

G

DRV

•

=

G

DRV

- Gain of Coil Driver

Note:

For a PWM frequency of 2 MHz and

inductor value of 2.7µH, the amplitude of

pulsed voltage will be:

Note:

For a power supply of 5V and

ΔU = 10mV,

the resulted gain is 81. To obtain this gain,

R

GAIN

= 820kOhm should be used.

ΔU L ΔI

Δt

------

•

L

V

PK PK

G

DRV

•

•

2F

•

=

=

F

- PWM Frequency

L

- Inductance of Key Inductor

ΔU 10.8mV

=

Gain

70%

V

DD

2

-----------

⎝

⎠

⎛

⎞

•

2

ΔU

•

---------------------------------

=

Gain

R

GAIN

/10kOhm

∼