2014 Microchip Technology Inc.

DS20005296B-page 1

HV9989

Features

• Three out-of-phase constant-current boost

converters

• Current loop closed, with sub-microsecond PWM-

dimming pulses, supports PWM dimming >20 kHz

• Internal 40V linear regulator

• External clock input

• External individual reference inputs

• Individual PWM dimming inputs

• Programmable slope compensation

• +0.2A/-0.4A gate drivers

• Independent short circuit protection with hiccup

for each channel

• Latching output open-circuit protection

Applications

• LCD panel back-lighting

Description

HV9989 is a three-channel peak current mode PWM

controller designed to drive single switch converters in

a constant-output current mode. It can be used for driv-

ing either RGB LEDs or multiple channels of white

LEDs.

HV9989 features a proprietary PWM-dimming control

algorithm that achieves a dimming pulse of a few hun-

dred nanoseconds from a Continuous-Conduction

Mode (CCM) or Discontinuous-Conduction Mode

(DCM) boost converter, while maintaining the instanta-

neous LED constant current determined by the external

reference voltage input. This feature permits a dimming

frequency outside of the audible range, and can also

yield a wide dimming ratio in excess of 10,000:1 at low

dimming frequency. Each of the three channels fea-

tures individual PWM-dimming and reference voltage

inputs.

The switching frequencies of the three converters are

controlled by an external clock signal, such that the

channels operate at a switching frequency of 1/12th the

external clock frequency, and are positioned 120

°

out-

of-phase to reduce the input current ripple.

HV9989 provides a full protection feature set, including

output-short and open-circuit protection, for each indi-

vidual channel that is independent from the other chan-

nels.

HV9989 is powered by a built-in 40V linear regulator.

Three-Channel CCM/DCM Boost LED Driver

with Sub-Microsecond PWM Dimming

HV9989

DS20005296B-page 2

2014 Microchip Technology Inc.

TO OUR VALUED CUSTOMERS

It is our intention to provide our valued customers with the best documentation possible to ensure successful use of your Microchip

products. To this end, we will continue to improve our publications to better suit your needs. Our publications will be refined and

enhanced as new volumes and updates are introduced.

If you have any questions or comments regarding this publication, please contact the Marketing Communications Department via

E-mail at

docerrors@microchip.com

. We welcome your feedback.

Most Current Data Sheet

To obtain the most up-to-date version of this data sheet, please register at our Worldwide Web site at:

http://www.microchip.com

You can determine the version of a data sheet by examining its literature number found on the bottom outside corner of any page.

The last character of the literature number is the version number, (e.g., DS30000000A is version A of document DS30000000).

Errata

An errata sheet, describing minor operational differences from the data sheet and recommended workarounds, may exist for current

devices. As device/documentation issues become known to us, we will publish an errata sheet. The errata will specify the revision

of silicon and revision of document to which it applies.

To determine if an errata sheet exists for a particular device, please check with one of the following:

• Microchip’s Worldwide Web site;

http://www.microchip.com

• Your local Microchip sales office (see last page)

When contacting a sales office, please specify which device, revision of silicon and data sheet (include literature number) you are

using.

Customer Notification System

Register on our web site at

www.microchip.com

to receive the most current information on all of our products.

2014 Microchip Technology Inc.

DS20005296B-page 3

HV9989

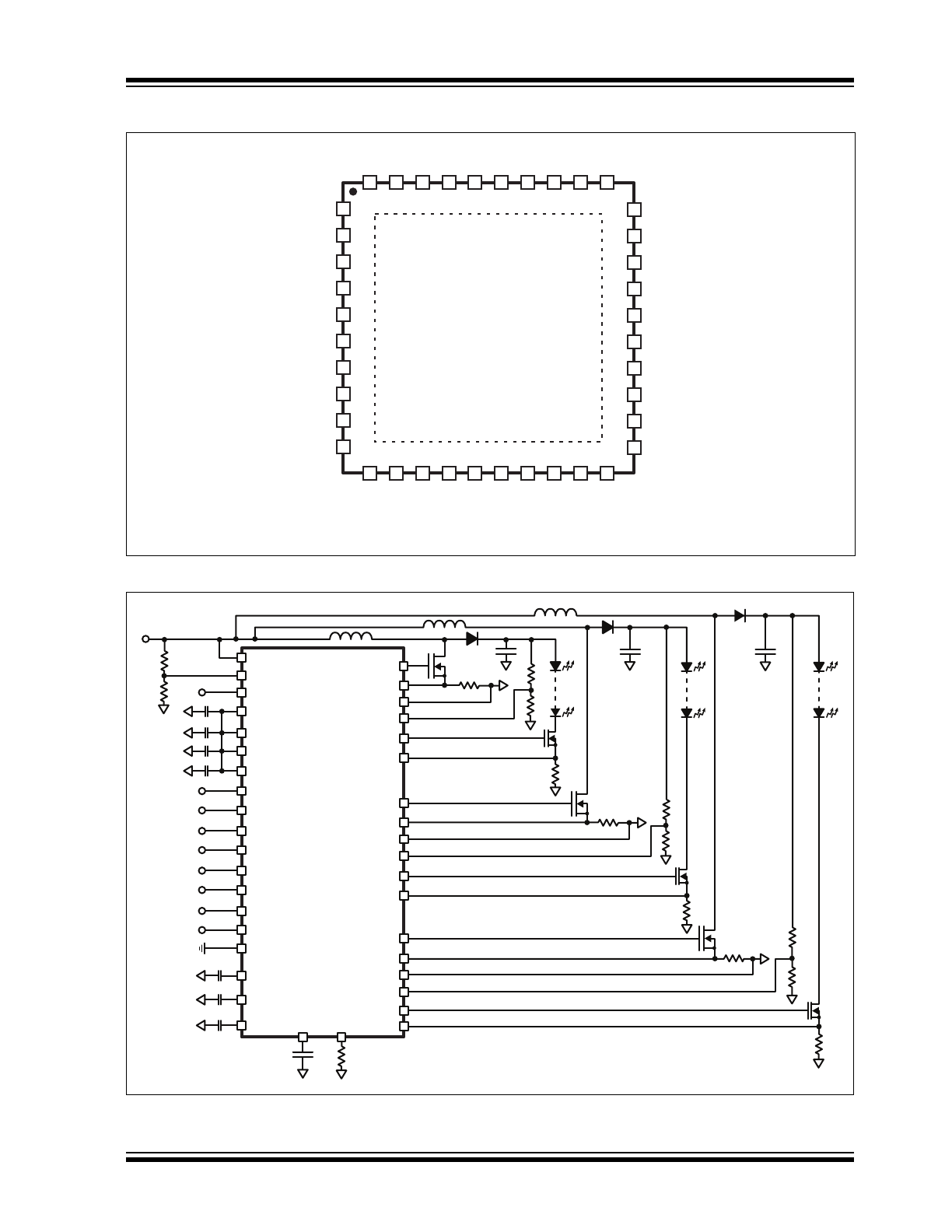

Pin Diagram

Typical Application Circuit

40-Lead QFN

VDD3

FLT3

CS3

COMP3

FDBK3

REF3

OVP3

CLK

FLG

VIN_SNS

GND

1

10

11

20

40

30

21

31

VDD1

FLT1

CS1

COMP1

FDBK1

REF1

OVP1

VIN

VDD

EN

GND

COMP2

REF2

OVP2

SKIP

SC

PWMD1

PWMD2

PWMD3

NC

GATE1

GND1

FDBK2

CS2

FLT2

GATE2

GND2

VDD2

GND3

GATE3

GATE1

CS1

GND1

OVP1

FLT1

FDBK1

GATE2

CS2

GND2

OVP2

FLT2

FDBK2

GATE3

CS3

GND3

OVP3

FLT3

FDBK3

VIN

VIN_SNS

FLG

VDD

VDD1

VDD2

VDD3

PWMD1

PWMD2

PWMD3

REF1

REF2

REF3

EN

CLK

GND

COMP1

COMP2

COMP3

SKIP

SC

HV9989

HV9989

DS20005296B-page 4

2014 Microchip Technology Inc.

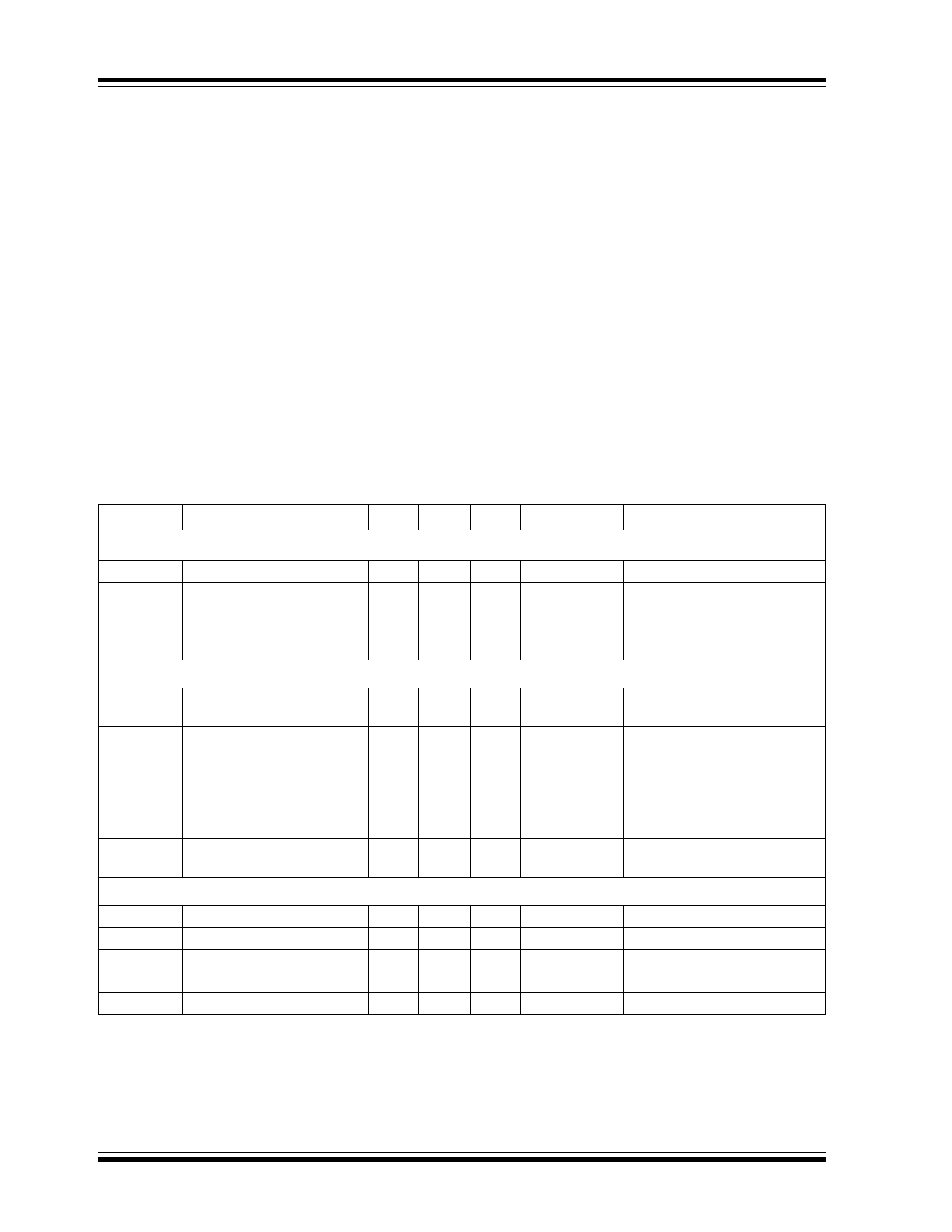

1.0

ELECTRICAL

CHARACTERISTICS

ABSOLUTE MAXIMUM RATINGS †

V

IN

to GND........................................................ -0.5V to +45V

V

DD

to GND, V

DD

1-3 to GND..........................--0.3V to +10V

All other pins to GND .............................-0.3V to (V

DD

+ 0.3V)

Operating temperature ....................................-40°C to +85°C

Storage temperature .....................................-65°C to +150°C

Continuous power dissipation (T

A

= +25°C).............4000 mW

† Notice: Stresses above those listed under “Absolute Maxi-

mum Ratings” may cause permanent damage to the device.

This is a stress rating only and functional operation of the

device at those or any other conditions, above those indi-

cated in the operational listings of this specification, is not

implied. Exposure to maximum rating conditions for extended

periods may affect device reliability.

1.1

ELECTRICAL SPECIFICATIONS

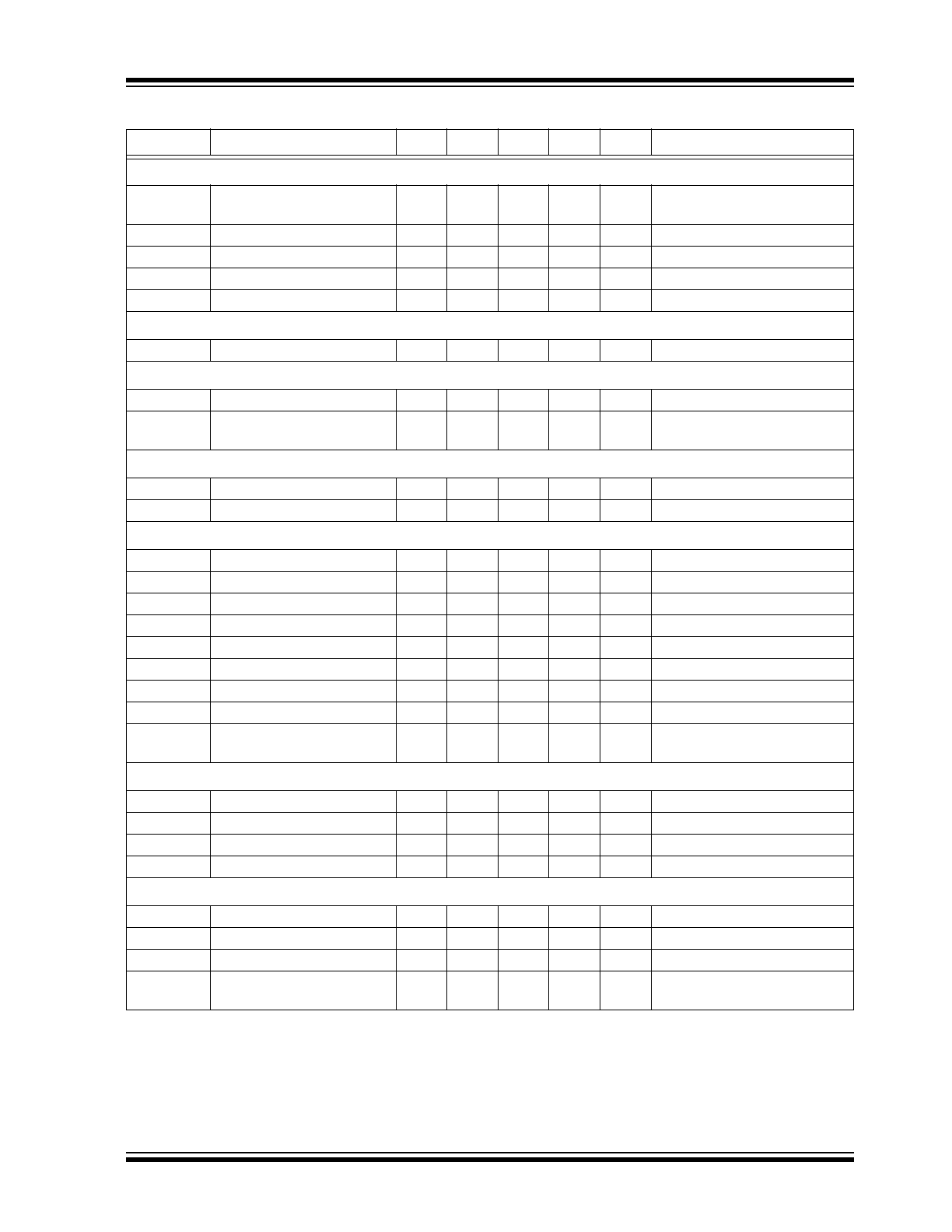

TABLE 1-1:

ELECTRICAL CHARACTERISTICS (SHEET 1 OF 3)

1

Symbol

Parameter

Note

Min

Typ

Max

Units Conditions

Input

VINDC

Input DC supply voltage

1

10

—

40

V

DC input voltage

IINSD

Shut-down mode supply

current

1

—

—

500

μA

EN = 0.8V

IIN

Supply current

—

—

—

4.5

mA

EN ≥ 2.0V; PWMD1 = PWMD2

= PWMD3 = GND

Internal Regulator

VDD

Internally regulated voltage

1

7.0

—

8.1

V

VIN= 11V; EN = GND;

External IDD = 30mA

∆ VDD

Load regulation

—

—

—

80

mV

VIN= 11V; EN = GND;

External IDD(A) = 10mA,

IDD(B) = 30mA

∆ VDD = VDD(A) - VDD(B)

UVLO

VDD under voltage lockout

threshold

—

5.9

—

6.4

V

VDD falling

UVLOHYST

VDD under voltage hystere-

sis

—

-

500

-

mV

VDD rising

PWM Dimming (PWMD1, PWMD2 and PWMD3)

VPWMD(lo) PWMD input low voltage

1

—

—

0.8

V

—

VPWMD(hi) PWMD input high voltage

1

2.0

—

—

V

—

RPWMD

PWMD pull down resistor

—

80

—

160

kΩ

VPWMD = 5.0V

Td

Delay time to PWMD latch

2

50

—

150

ns

—

TDP

DMAX inhibit delay

2

—

400

—

ns

—

Note 1:

Applies over the full operating ambient temperature range of 0°C < T

A

< +85°C.

2:

For design guidance only.

2014 Microchip Technology Inc.

DS20005296B-page 5

HV9989

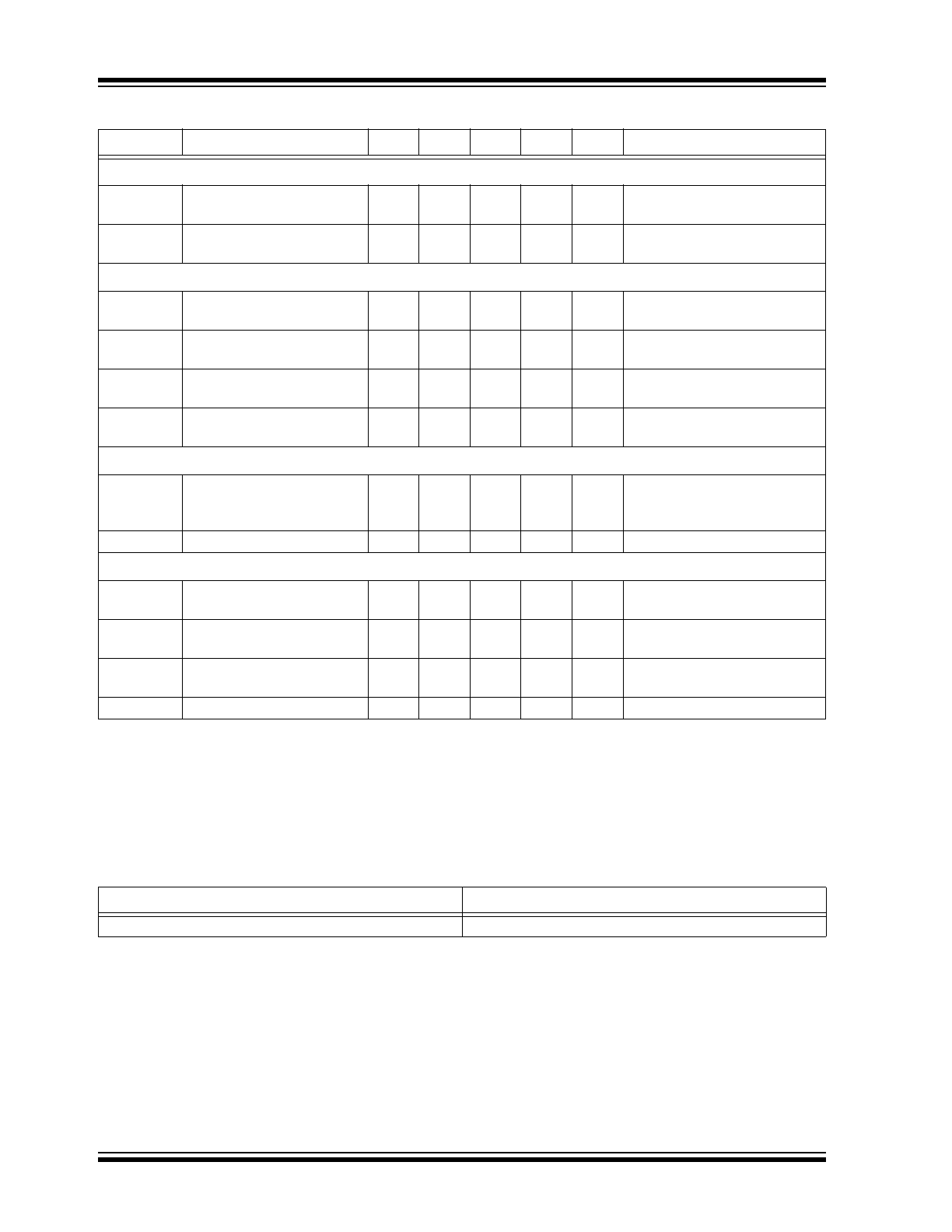

Gate (GATE1, GATE2 and GATE3)

ISOURCE

Gate short circuit current,

sourcing

2

0.2

—

—

A

VGATE = 0V

ISINK

Gate sinking current

2

0.4

—

—

A

VGATE = VDD

TRISE

Gate output rise time

—

—

50

85

ns

CGATE = 1.0nF

TFALL

Gate output fall time

—

—

25

45

ns

CGATE = 1.0nF

DMAX

Maximum duty cycle

2

—

91

—

%

—

Over-voltage Protection (OVP1, OVP2 and OVP3)

VOVP,rising Over-voltage rising trip point

1

4.7

—

5.4

V

OVP rising

Current Sense (CS1, CS2 and CS3)

TBLANK

Leading edge blanking

1

210

—

460

ns

—

TDELAY

Delay to GATE

—

—

—

250

ns

50mV overdrive to the current

sense comparator

Slope Compensation (SC)

CSC(EFF) Effective capacitance

2

0.9

1.0

1.1

nF

—

∆VSC

VDD-to-SC voltage drop

1

1.25

—

3.25

V

RSC = 120kΩ

Internal Transconductance Opamp (Gm1, Gm2 and Gm3)

GB

Gain bandwidth product

2

—

1.0

—

MHz

75pF capacitance at COMP pin

AV

Open loop DC gain

—

65

—

—

dB

Output open

KCOMP

COMP-to-CS divider ratio

2

—

1/12

—

—

—

VCM

Input common-mode range

2

-0.3

—

3.0

V

—

VO

Output voltage range

2

0.7

—

6.75

V

—

Gm

Transconductance

—

500

—

700

μA/V

—

VOFFSET Input offset voltage

—

-5.0

—

5.0

mV

—

IBIAS

Input bias current

2

—

0.5

1.0

nA

—

TR

Recovery delay

2

—

120

—

ns

FDBK = 0V, REF = 0.5V,

PWMD rising

Oscillator (CLOCK)

fOSC1

Oscillator frequency

—

—

500

—

kHz

FCLOCK = 6.0MHz

KSW

Oscillator divider ratio

2

—

12

—

-

—

Phi1

GATE1-GATE2 phase delay

2

—

120

—

°

—

Phi1

GATE1-GATE3 phase delay

2

—

240

—

°

—

Oscillator (CLOCK)

TOFF

CLOCK low time

2

50

—

—

ns

—

TON

CLOCK high time

2

50

—

—

ns

—

VCLOCK,HI CLOCK input high

1

2.0

—

—

V

—

VCLOCK,L

O

CLOCK input low

1

—

—

0.8

V

—

TABLE 1-1:

ELECTRICAL CHARACTERISTICS (CONTINUED) (SHEET 2 OF 3)

1

Symbol

Parameter

Note

Min

Typ

Max

Units Conditions

Note 1:

Applies over the full operating ambient temperature range of 0°C < T

A

< +85°C.

2:

For design guidance only.

HV9989

DS20005296B-page 6

2014 Microchip Technology Inc.

Disconnect Driver (FLT1, FLT2 and FLT3)

TRISE,FAU

LT

Fault output rise time

—

—

—

300

ns

330 pF capacitor at FLTx pin

TFALL,FAU

LT

Fault output fall time

—

—

—

200

ns

330 pF capacitor at FLTx pin

Short Circuit Protection (all three channels)

TBLANK,S

C

Blanking time

1

400

—

800

ns

—

GSC

Gain for short circuit

comparator

—

1.9

2.0

2.1

—

—

Vomin

Minimum current limit

threshold

2

0.15

—

—

V

REF = GND

TOFF

Propagation time for short

circuit detection

—

—

—

250

ns

FDBK = 2 • REF + 0.1V

HICCUP timer

IHC,SOUR

CE

Current source at SKIP pin

used for hiccup mode pro-

tection

—

—

10

—

μA

—

∆VCAP

SKIP voltage swing

2

—

4.0

—

V

—

Low output detection (OVP1, OVP2, OVP3, VIN_SNS, FLG)

VOVP_OS_

F

OVP offset voltage

1

-25

—

25

mV

OVP falling

VOVP_OS_

R

OVP offset voltage

—

40

—

70

mV

OVP rising

VFLG(LOW

)

FLG low voltage

—

0

—

0.4

V

I(FLG) = 1.0mA

VIN_CM

Input common-mode range

2

-0.3

—

5.0

V

—

1

TABLE 1-1:

ELECTRICAL CHARACTERISTICS (CONTINUED) (SHEET 3 OF 3)

1

Symbol

Parameter

Note

Min

Typ

Max

Units Conditions

Note 1:

Applies over the full operating ambient temperature range of 0°C < T

A

< +85°C.

2:

For design guidance only.

TABLE 1-2:

THERMAL RESISTANCE

Package

θja

40-Lead QFN

24°C/W

2014 Microchip Technology Inc.

DS20005296B-page 7

HV9989

2.0

PIN DESCRIPTION

The descriptions of the pins are listed in

Table 2-1

.

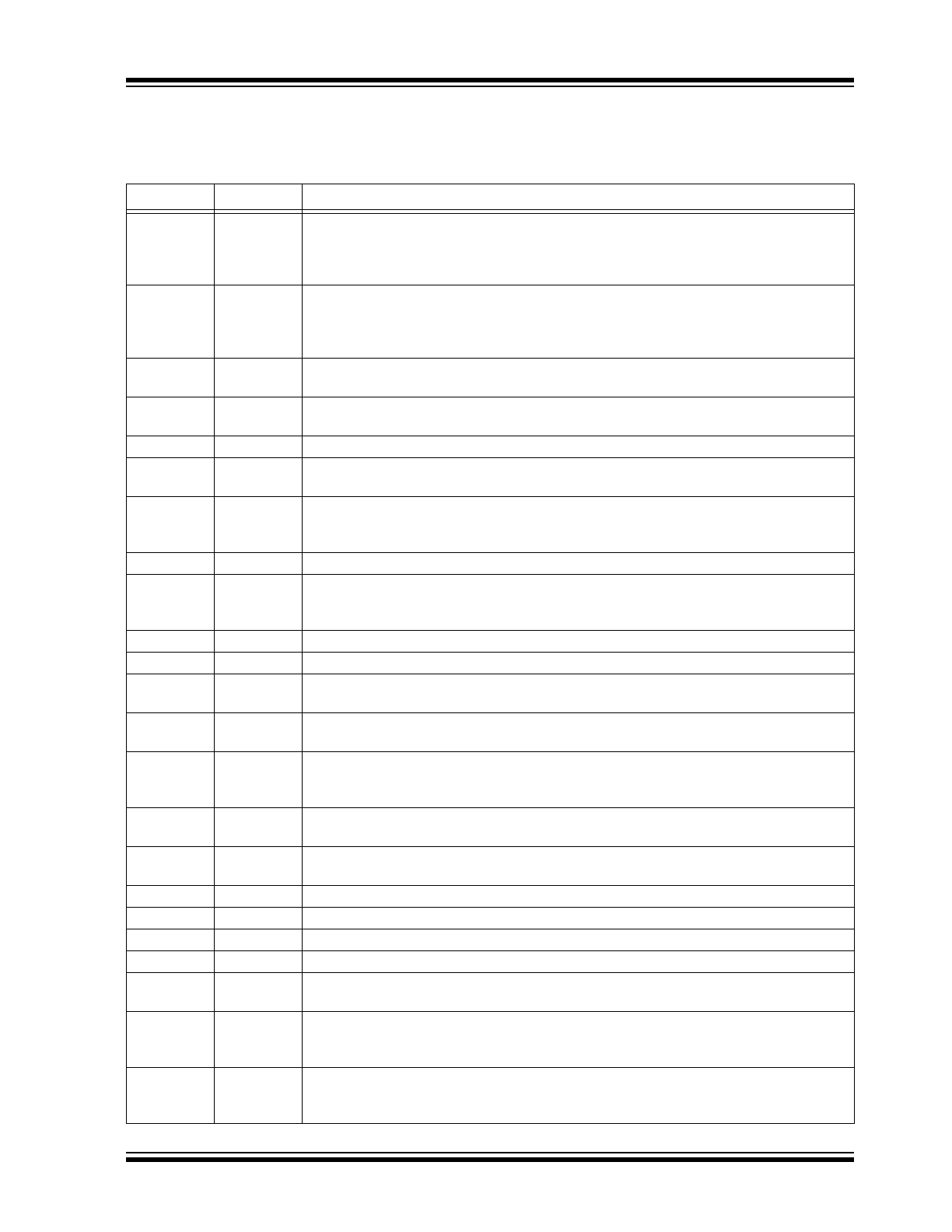

TABLE 2-1:

PIN DESCRIPTION (SHEET 1 OF 2)

Pin #

Name

Description

1

VDD1

Power supply pin for channel 1. It can either be connected to the VDD pin or supplied

with an external power supply. It must be bypassed with a low ESR capacitor to their

respective GND1 (at least 0.1 μF). All VDD pins (VDD, VDD1-3) must be connected

together externally.

2

FLT1

Drives external disconnect switches. The disconnect switches are used to protect the

LEDs in case of fault conditions, and also help to provide excellent PWM dimming

response by disconnecting and reconnecting the LEDs from the output capacitor during

PWM dimming.

3

CS1

Senses the source current of the external power FET used with channel 1. It includes a

built-in 210 ns (min) blanking timer.

4

COMP1

Stable closed loop control can be accomplished by connecting a compensation network

between the COMP pin and its GND.

5

FDBK1

Provides output current feedback for channel 1 by using a current sense resistor.

6

REF1

The voltage at this pin sets the output current level for channel 1. Recommended voltage

range for this pin is 0V-1.25V.

7

OVP1

Provides the over voltage protection for the converter. When the voltage at this pin

exceeds 5V, channel 1 of the HV9989 is turned off. The fault is reset by re-enabling the

IC using the EN pin.

8

VIN

Input of the internal 40V linear regulator.

9

VDD

Output of the linear regulator. It maintains a regulated 7.75V as long as the voltage of the VIN

pin is between 10 and 40V. It must be bypassed with a low ESR capacitor to GND (at least 0.1

μF). This pin can be used as a power supply for the three channels.

10

EN

When the pin is pulled below 0.8V, the IC goes into a standby mode and draws minimal current.

11

GND

Ground connection for the common circuitry in the HV9989.

12

COMP2

Stable closed loop control can be accomplished by connecting a compensation network

between the COMP pin and its GND.

13

REF2

The voltage at this pin sets the output current level for channel 2. Recommended voltage

range for this pin is 0-1.25V.

14

OVP2

Provides the over voltage protection for the converter. When the voltage at this pin

exceeds 5V, channel 2 of the HV9989 is turned off. The fault is reset by re-enabling the

IC using the EN pin.

15

SKIP

Programs the hiccup timer for short circuit fault on any of the three channels. A capacitor

to GND programs the hiccup time.

16

SC

Sets the current to program slope compensation voltage ramp at the three CS inputs.

Connect a resistor to GND.

17

PWMD1

Used to PWM dim channel 1.

18

PWMD2

Used to PWM dim channel 2.

19

PWMD3

Used to PWM dim channel 3.

20

NC

No connection.

21

VIN_SNS

When voltage at this pin exceeds any of the voltages at OVP 1-3, the high-impedance

state is issued at the FLG output.

22

FLG

Open-drain logic output reporting a high-impedance state in the case of any of the OVP

1-3 voltages falling below the VIN_SNS voltage. A hysteresis is added at VIN_SNS to

avoid oscillation.

23

CLK

Clock input for the HV9989. The input to the CLK pin should be a TTL compatible square

wave signal. The three channels will switch at 1/12th the switching frequency of the sig-

nal applied at the CLK pin.

HV9989

DS20005296B-page 8

2014 Microchip Technology Inc.

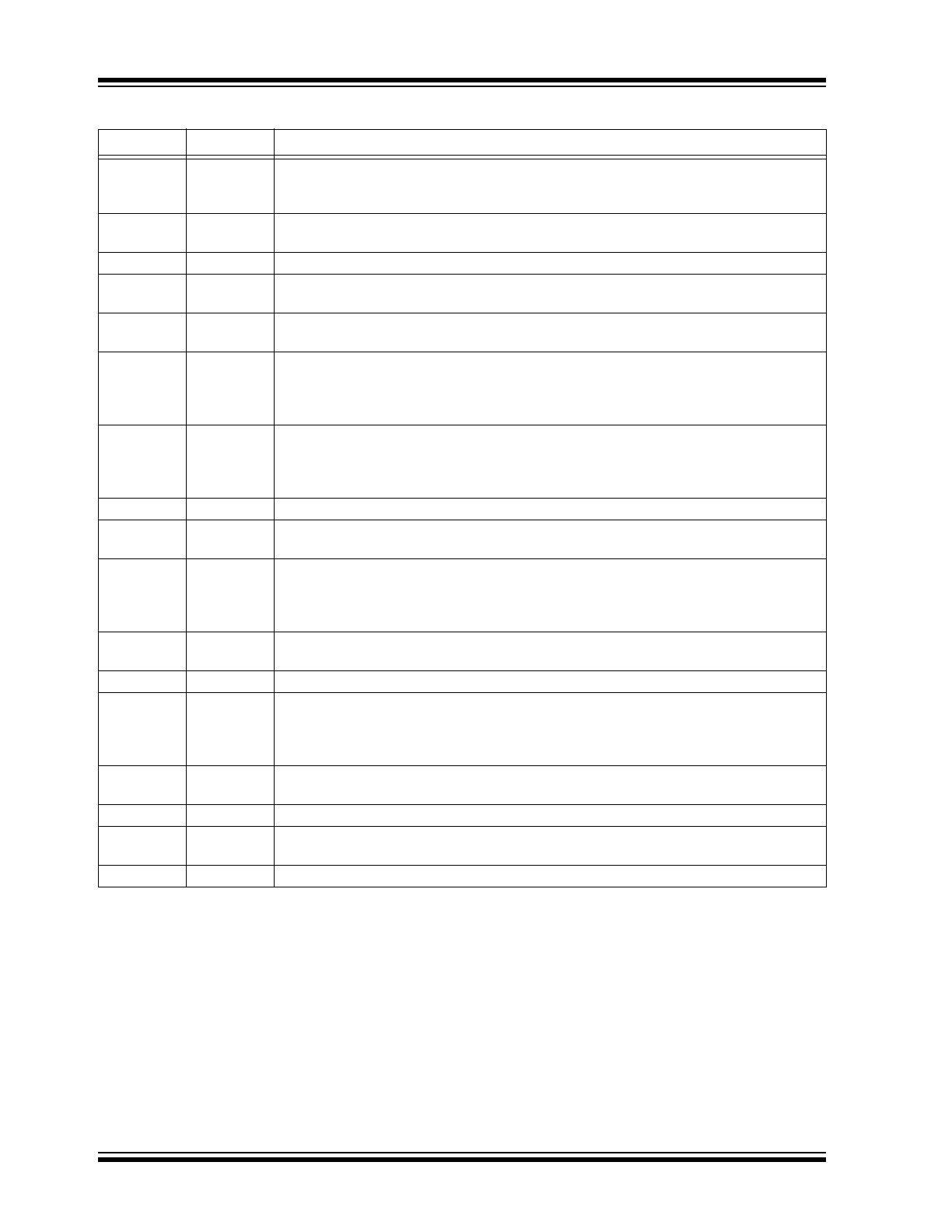

24

OVP3

Provides the over voltage protection for the converter. When the voltage at this pin

exceeds 5V, channel 3 of the HV9989 is turned off. The fault is reset by re-enabling the

IC using the EN pin.

25

REF3

The voltage at this pin sets the output current level for channel 3. Recommended voltage

range for this pin is 0V-1.25V.

26

FDBK3

Provides output current feedback for channel 3 by using a current sense resistor.

27

COMP3

Stable closed loop control can be accomplished by connecting a compensation network

between the COMP pin and its GND.

28

CS3

Used to sense the source current of the external power FET used with channel 3. It

includes a built-in 210 ns (min) blanking timer.

29

FLT3

Used to drive external disconnect switches. The disconnect switches are used to protect

the LEDs in case of fault conditions and also help to provide excellent PWM dimming

response by disconnecting and reconnecting the LEDs from the output capacitor during

PWM dimming.

30

VDD3

Power supply pin for channel 3. It can either be connected to the VDD pin or supplied

with an external power supply. It must be bypassed with a low ESR capacitor to their

respective GND3 (at least 0.1 μF). All VDD pins (VDD, VDD1-3) must be connected

together externally.

31

GATE3

Output gate driver for the external N-channel power MOSFET.

32

GND3

Ground return for channel 3. It is recommended that all the GNDs of the IC be connected

together in a STAR connection at the input GND terminal to ensure best performance.

33

VDD2

Power supply pin for channel 2. It can either be connected to the VDD pin or supplied

with an external power supply. It must be bypassed with a low ESR capacitor to their

respective GND2 (at least 0.1 μF). All VDD pins (VDD, VDD1-3) must be connected

together externally.

34

GND2

Ground return for channel 2. It is recommended that all the GNDs of the IC be connected

together in a STAR connection at the input GND terminal to ensure best performance.

35

GATE2

Output gate driver for the external N-channel power MOSFET.

36

FLT2

Used to drive external disconnect switches. The disconnect switches are used to protect

the LEDs in case of fault conditions and also help to provide excellent PWM dimming

response by disconnecting and reconnecting the LEDs from the output capacitor during

PWM dimming.

37

CS2

Used to sense the source current of the external power FET used with channel 2. It

includes a built-in 210 ns (min) blanking timer.

38

FDBK2

Provides output current feedback for channel 2 by using a current sense resistor.

39

GND1

Ground return for channel 1. It is recommended that all the GNDs of the IC be connected

together in a STAR connection at the input GND terminal to ensure best performance.

40

GATE1

Output gate driver for the external N-channel power MOSFET.

TABLE 2-1:

PIN DESCRIPTION (CONTINUED) (SHEET 2 OF 2)

Pin #

Name

Description

2014 Microchip Technology Inc.

DS20005296B-page 9

HV9989

3.0

FUNCTIONAL DESCRIPTION

3.1

Power Topology

HV9989 is a three-channel, switch-mode converter,

LED driver designed to control a continuous conduction

mode boost or SEPIC device in a constant frequency

mode. The IC includes an internal linear regulator,

which operates from 10 to 40V input voltages. This

device can also be powered directly using the VDD

pins and bypassing the internal linear regulator.

HV9989 includes features typically required in LED

drivers such as open LED protection, output short cir-

cuit protection, linear and PWM dimming, programma-

ble input current limiting and accurate control of the

LED current. A high current gate drive output enables

the controller to be used in high power converters.

HV9989 is ideally suited for back-light applications

using either RGB or multi-channel white LED

configurations.

3.2

Power Supply to the IC (VIN, VDD,

VDD1-3)

The HV9989 can be powered directly from its VIN pin

that takes a voltage up to 40V. When a voltage is

applied at the VIN pin, the HV9989 tries to maintain a

constant 7.75V (typ) at the VDD pin. The regulator also

has a built in under-voltage lockout which shuts off the

IC if the voltage at the VDD pin falls below the UVLO

threshold. By connecting this VDD pin to the individual

VDD pins of the three channels, the internal regulator

can be used to power all three channels in the IC.

In case the internal regulator is not utilized, an external

power supply (7-9V) can be used to power the IC. In

this case, the power supply is directly connected to the

VDD pins and the VIN pin is left unconnected.

All four VDD pins must be bypassed by a low ESR

capacitor (≥0.1 µF) to provide a low impedance path for

the high frequency current of the output gate driver.

These capacitors must be referenced to the individual

grounds for proper noise rejection. Also, in all cases,

the four VDD pins must be connected together

externally.

The input current drawn from the external power supply

(or VIN pin) is a sum of the 4 mA current drawn by the

all the internal circuitry (for all three channels) and the

current drawn by the gate drivers (which in turn

depends on the switching frequency and the gate

charge of the external FET).

In the preceding equation, f

S

is the switching frequency

of the converters and Q

G1-3

are the gate charges of the

external FETs (which can be obtained from the FET

data sheets).

The EN pin is a TTL-compatible input used to disable

the IC. Pulling the EN pin to GND will shut down the IC

and reduce the quiescent current drawn by the IC to be

lower than 500 μA. If the enable function is not

required, the EN pin can be connected to VDD.

3.3

Clock Input (CLK)

The switching frequency of the converters are set by

using a TTL-compatible square wave input at the CLK

pin. The switching frequencies of the three converters

will be 1/12th the frequency of the external clock.

3.4

Current Sense (CS1-3)

The current sense input is used to sense the source

current of the switching FET. The CS input of the

HV9989 includes a built-in 100 ns (minimum) blanking

time to prevent spurious turn off due to the initial current

spike when the FET turns on.

The IC includes an internal resistor divider network,

which steps down the voltage at the COMP pins by a

factor of 12 (including the internal diode drop). This

stepped-down voltage is given to one of the

comparators as the current reference.

It is recommended that the sense resistor R

CS

be cho-

sen so as to provide about 250 mV current sense signal.

3.5

Slope Compensation

For continuous conduction mode converters operating in

the Constant Frequency mode, slope compensation

becomes necessary to ensure stability of the peak cur-

rent mode controller, if the operating duty cycle is greater

than 0.5. Choosing a slope compensation which is one

half of the down slope of the inductor current ensures

that the converter will be stable for all duty cycles.

Slope compensation in the HV9989 can be pro-

grammed by a single resistor at SC input common for

all three channels. Assuming a down slope of DS (A/

ms) for the inductor current, the SC resistor can be

computed as:

where R

CS

is the current sense resistor at the CS

X

inputs.

I

IN

4mA

Q

G1

Q

G2

Q

G3

+

+

+

f

s

=

R

SC

2

V

DD

V

SC

–

DS 10

6

R

CS

C

SC EFF

--------------------------------------------------------------

11

V

DS R

CS

C

SC EFF

-----------------------------------------------

=

HV9989

DS20005296B-page 10

2014 Microchip Technology Inc.

3.6

Control of the LED Current

The LED currents in the HV9989 are controlled in a

closed-loop manner. The current references which set

the three LED currents are provided at the REF pins

(REF1-3). This reference voltage is compared to the

FDBK voltages (FDBK1-3) which sense the LED cur-

rents in the three channels using current sense resis-

tors. The HV9989 includes three 1MHz

transconductance amplifiers with tri-state outputs,

which are used to close the feedback loops and provide

accurate current control. The compensation networks

are connected at the COMP pins (COMP1-3).

The outputs of the op amps are buffered and connected

to the current sense comparators using 12:1 dividers.

The buffer helps to prevent the integrator capacitor from

discharging during the PWM dimming state.

The outputs of the op amps are controlled by the signal

applied to the PWMD pins (PWMD1-3). When PWMD

is high, the output of the op amp is connected to the

COMP pin. When PWMD is low, the output is left open.

This enables the integrating capacitor to hold the

charge when the PWMD signal has turned off the gate

drive. When the IC is enabled, the voltage on the inte-

grating capacitor will force the converter into steady

state almost instantaneously.

3.7

Linear Dimming

Linear dimming can be accomplished in the HV9989 by

varying the voltages at the REF pins. Note that since

the HV9989 is a peak current mode controller, it has a

minimum on-time for the GATE outputs. This minimum

on-time will prevent the converters from completely

turning off even when the REF pins are pulled to GND.

Thus, linear dimming cannot accomplish true zero LED

current. To get zero LED current, PWM dimming has to

be used. Note that different signals can be connected

to the three REF pins if desired, and they need not be

connected together.

Due to the offset voltage of the short circuit comparator,

as well as the non-linearity of the X2 gain stage, pulling

the REF pin very close to GND would cause the inter-

nal short circuit comparator to trigger and shut down

the IC. To overcome this, the output of the gain stage is

limited to 125mV (minimum), allowing the REF pin to

be pulled all the way to 0V without triggering the short

circuit comparator.

3.8

PWM Dimming

PWM dimming in HV9989 can be accomplished using

a TTL-compatible square wave source at the PWMD1-

3 pins.

HV9989 has an enhanced PWM dimming capability,

which allows PWM dimming to widths less than one

switching cycle with no drop in the LED current.

The enhanced PWM dimming performance of the

HV9989 can be best explained by considering typical

boost converter circuits without this functionality. When

the PWM dimming pulse becomes very small (less than

one switching cycle for a DCM design or less than a few

switching cycles for a CCM design), the boost con-

verter is turned off before the input current can reach its

steady state value. This causes the input power to

drop, which is manifested in the output as a drop in the

LED current (

Figure 3-1

and

Figure 3-2

for a CCM

design).

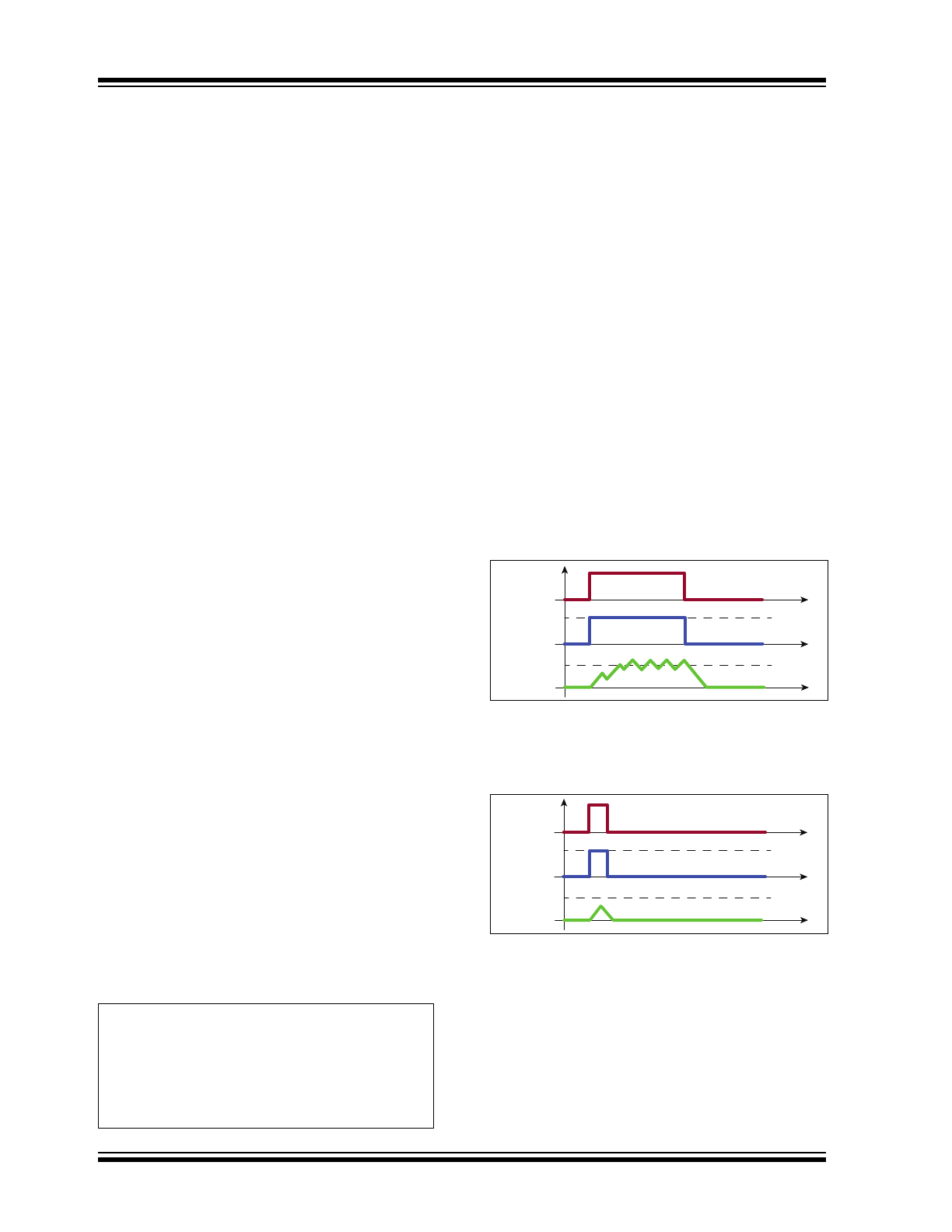

FIGURE 3-1:

PWM DIMMING WITH

DIMMING ON-TIME FAR

GREATER THAN ONE

SWITCHING TIME PERIOD

FIGURE 3-2:

PWM DIMMING WITH

DIMMING ON-TIME

EQUAL TO ONE

SWITCHING TIME PERIOD

In the above figures, I

O

(SS) and I

L

(SS) refer to the

steady state values (PWMD = 100%) for the output cur-

rent and inductor current respectively. As can be seen,

the inductor current does not rise enough to trip the CS

comparator. This causes the closed loop amplifier to

lose control of the LED current and COMP rails to VDD.

Note:

This control IC is a peak current mode control-

ler; therefore, pulling the REF pin to zero will

not cause the LED current to go to zero. The

converter will still be operating at its minimum

on-time causing a very small current to flow

through the LEDs. To get zero LED current,

the PWMD input has to be pulled to GND.

PWMD

I

LED

I

INDUCTOR

I

O

(SS)

I

O

(SS)

PWMD

I

LED

I

INDUCTOR

I

O

(SS)

I

L

(SS)