2017 Microchip Technology Inc.

DS20005588A-page 1

HV9961

Features

• Fast Average Current Control

• Programmable Constant Off-time Switching

• Linear Dimming Input

• PWM Dimming Input

• Output Short-circuit Protection with Skip Mode

• –40°C to +125°C Ambient Operating

Temperature

• Pin-compatible with HV9910B

Applications

• DC/DC or AC/DC LED Driver Applications

• LED Backlight Driver for LCD Displays

• General Purpose Constant-current Source

• LED Signage and Displays

• Architectural and Decorative LED Lighting

• LED Street Lighting

General Description

The

HV9961 is an Average-Current mode

constant-current control LED driver IC operating in a

constant Off-time mode. Unlike the HV9910B, this

control IC does not produce a peak-to-average error.

This greatly improves accuracy as well as the line and

load regulations of the LED current without any need

for loop compensation or high-side current sensing. Its

output LED current accuracy is ±3%.

The IC is equipped with a current limit comparator for

Hiccup mode output short-circuit protection.

The HV9961 can be powered from an 8V–450V supply.

It has a PWM dimming input that accepts an external

control TTL-compatible signal. In addition, the output

current can be programmed by an internal 275 mV

reference or controlled externally through a 0V–1.5V

linear dimming input.

The HV9961 is pin-to-pin compatible with HV9910B,

and it can be used as a drop-in replacement for many

applications to improve LED current accuracy and

regulation.

Package Type

16-lead SOIC

(Top view)

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

8

7

6

5

1

2

3

4

VIN

CS

GND

GATE

RT

LD

VDD

PWMD

VIN

NC

NC

CS

GND

NC

NC

GATE

NC

NC

RT

LD

VDD

NC

NC

PWMD

8-lead SOIC

(Top view)

See

Table 2-1

for pin information.

s

LED Driver with Average-Current Mode Constant-Current Control

HV9961

DS20005588A-page 2

2017 Microchip Technology Inc.

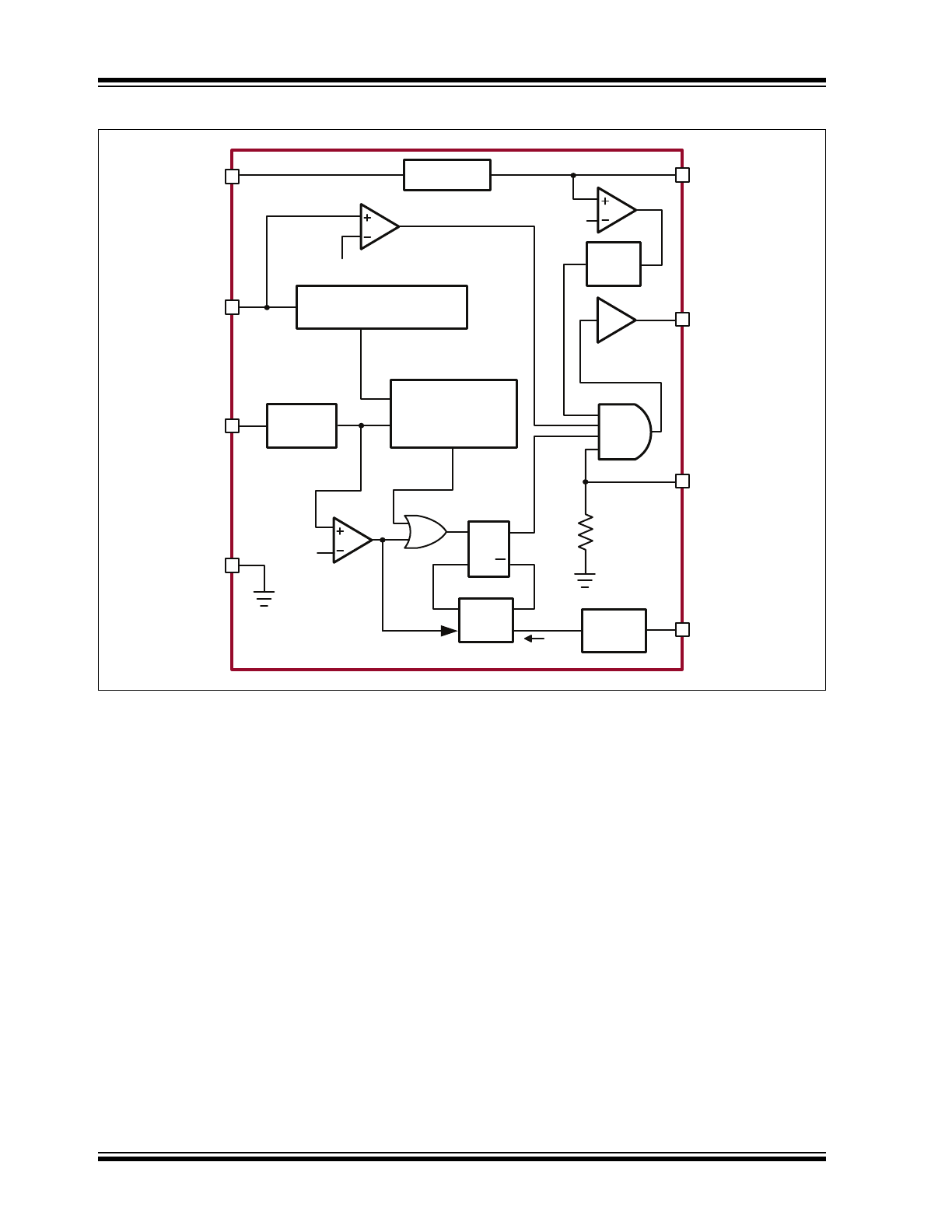

Functional Block Diagram

CS

R

S

Q

Q

T

OFF

Timer

L/E

Blanking

GATE

0.44V

MIN (V

LD

• 0.185, 0.275V)

LD

400µs

PWMD

RT

GND

Current

Mirror

i

Regulator

VIN

VDD

UVLO

POR

0.15/0.20V

Average Current

Control Logic

OUT

Auto-REF

HV9961

CLK

IN

Hiccup

2017 Microchip Technology Inc.

DS20005588A-page 3

HV9961

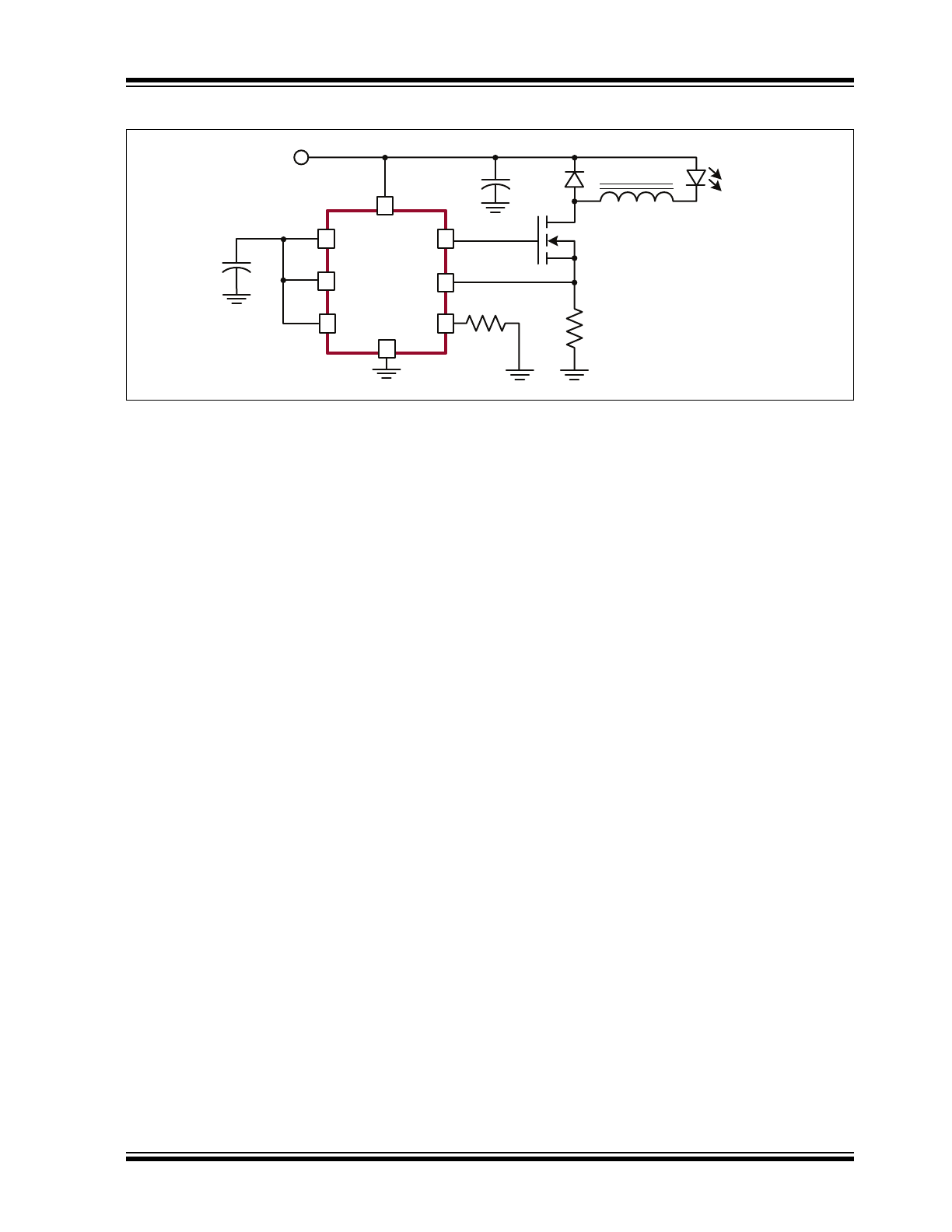

Typical Application Circuit

1

4

2

8

5

6

7

3

HV9961

VIN

GATE

PWMD

LD

VDD

RT

CS

GND

LED

Load

Sets

LED

Current

8V–450V

R

CS

R

T

HV9961

DS20005588A-page 4

2017 Microchip Technology Inc.

1.0

ELECTRICAL CHARACTERISTICS

Absolute Maximum Ratings†

V

IN

to GND ............................................................................................................................................ –0.5V to +470V

V

DD

to GND ............................................................................................................................................................ +12V

CS, LD, PWMD, Gate, RT to GND.................................................................................................... –0.3V to V

DD

+0.3V

Junction Temperature, T

J

.................................................................................................................... –40°C to +150°C

Storage Temperature, T

S

..................................................................................................................... –65°C to +150°C

Continuous Power Dissipation (T

A

= +25°C):

8-lead SOIC ............................................................................................................................................ 650 mW

16-lead SOIC ........................................................................................................................................ 1000 mW

† Notice: Stresses above those listed under “Absolute Maximum Ratings” may cause permanent damage to the

device. This is a stress rating only, and functional operation of the device at those or any other conditions above those

indicated in the operational sections of this specification is not intended. Exposure to maximum rating conditions for

extended periods may affect device reliability.

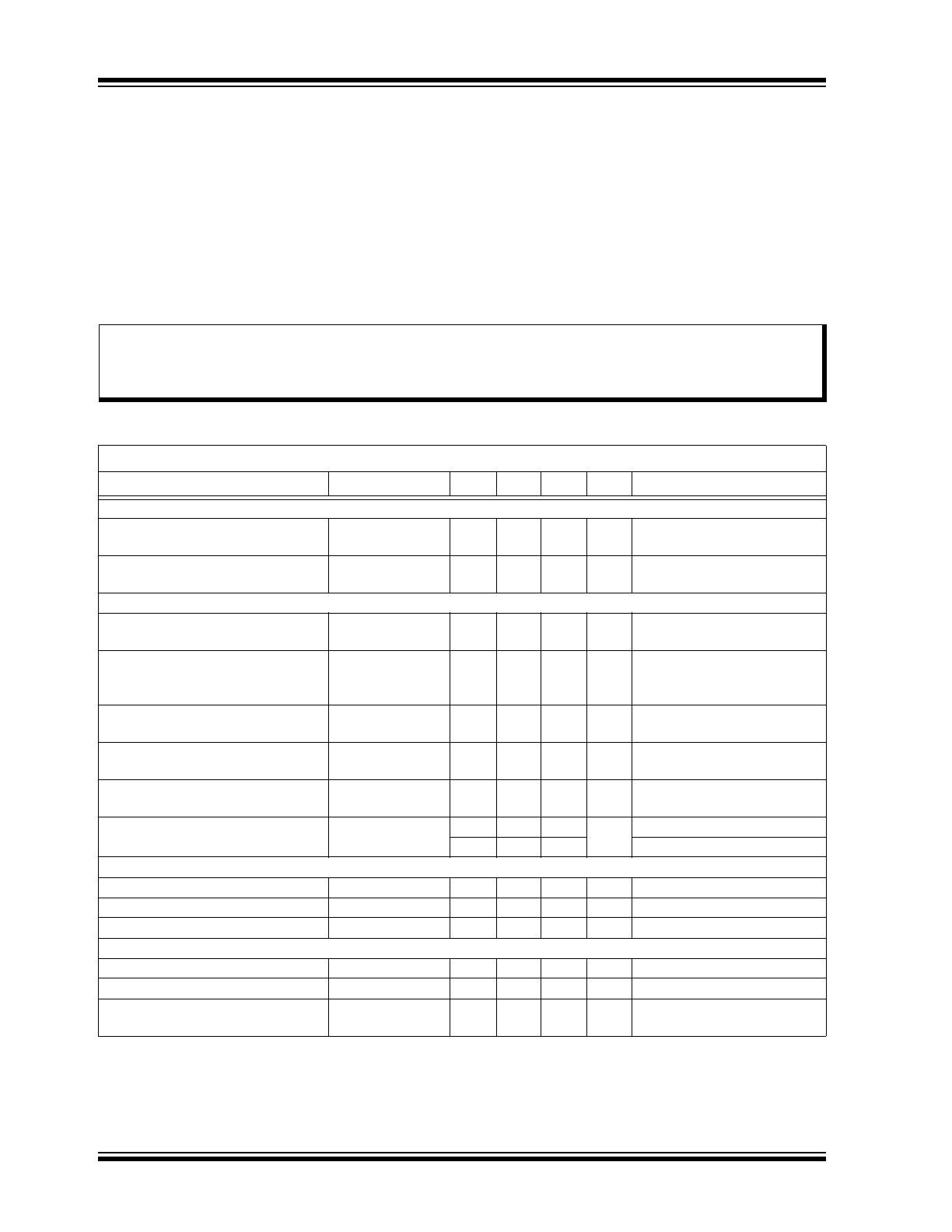

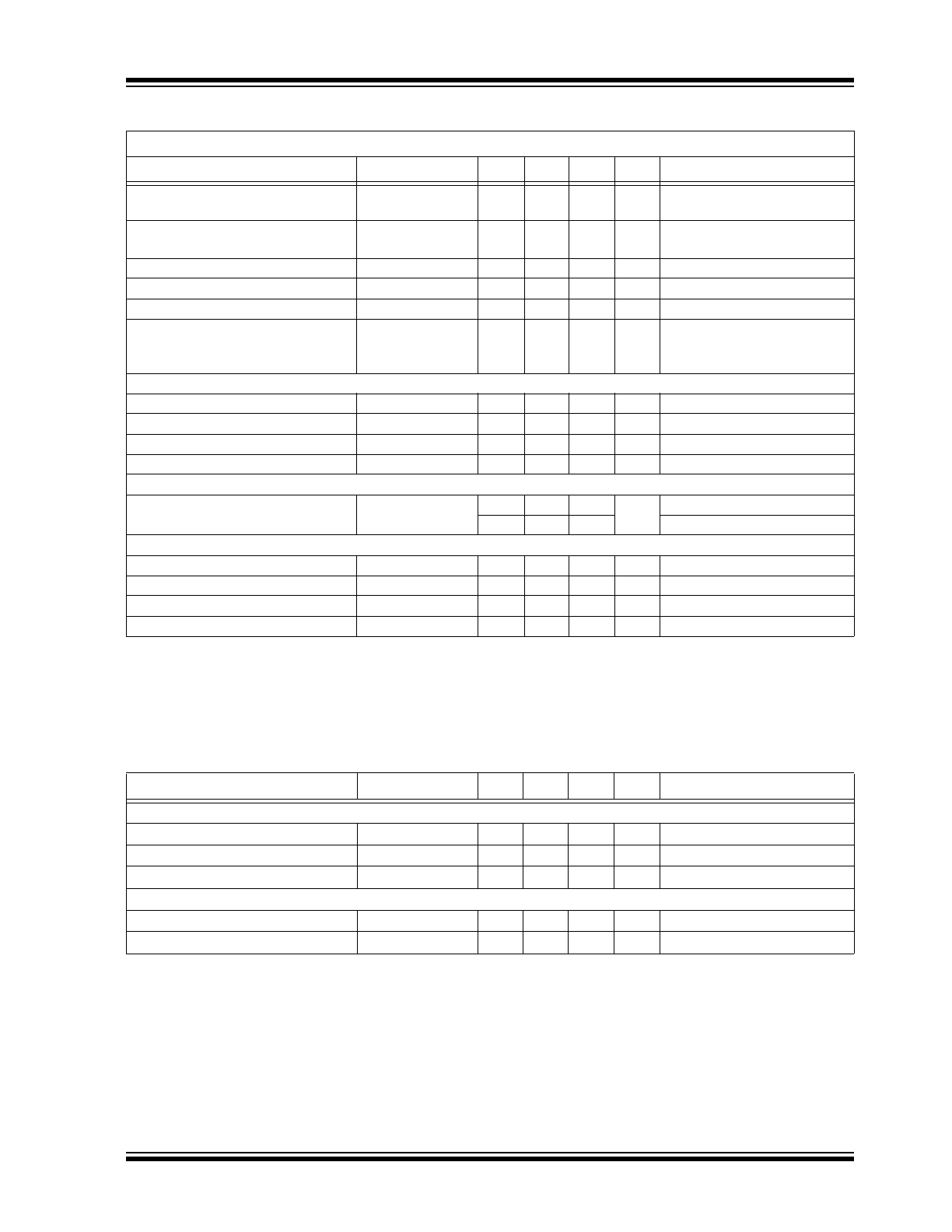

ELECTRICAL CHARACTERISTICS

Electrical Specifications: T

A

= 25°C, V

IN

= 12V, V

LD

= V

DD

, and V

PWMD

= V

DD

unless otherwise specified.

Parameter

Sym.

Min.

Typ.

Max.

Unit

Conditions

INPUT

Input DC Supply Voltage Range

V

INDC

8

—

450

V

DC input voltage

(

Note 1

and

Note 2

)

Shutdown Mode Supply Current

I

INSD

—

0.5

1

mA

Pin PWMD connected to

GND (

Note 2

)

INTERNAL REGULATOR

Internally Regulated Voltage

V

DD

7.25

7.5

7.75

V

V

IN

= 8V, I

DD(EXT)

= 0 mA,

500 pF at gate, R

T

= 226 kΩ

Line Regulation of V

DD

∆V

DD, line

0

—

1

V

V

IN

= 8V–450V,

I

DD(EXT)

= 0 mA,

500 pF at gate, R

T

= 226 kΩ

Load Regulation of V

DD

∆V

DD, load

0

—

100

mV

I

DD(EXT)

= 0 mA–1 mA,

500 pF at gate, R

T

= 226 kΩ

V

DD

Undervoltage Lockout Upper

Threshold

V

UVLO

6.45

6.7

6.95

V

V

IN

rising (

Note 2

)

V

DD

Undervoltage Lockout

Hysteresis

∆V

UVLO

—

500

—

mV

V

IN

falling

Maximum Input Current

(Limited by UVLO)

I

IN, MAX

3.5

—

—

mA

V

IN

= 8V, T

A

= 25°C (

Note 3

)

1.5

—

—

V

IN

= 8V, T

A

= 125°C (

Note 3

)

PWM DIMMING

PWMD Input Low Voltage

V

PWMD(LO)

—

—

0.8

V

V

IN

= 8V–450V (

Note 2

)

PWMD Input High Voltage

V

PWMD(HI)

2.2

—

—

V

V

IN

= 8V–450V (

Note 2

)

PWMD Pull-down Resistance

R

PWMD

50

100

150

kΩ

V

PWMD

= 5V

AVERAGE-CURRENT SENSE LOGIC

Current Sense Reference Voltage

V

CST

268

275

286

mV

V

LD

= 1.5V

LD-to-CS Voltage Ratio

A

V(LD)

0.182 0.185 0.188

—

V

LD

= 1.2V

LD-to-CS Voltage Offset

A

V

x V

LD(OFFSET)

0

—

10

mV

Offset = V

CS

– A

V(LD)

x V

LD

,

V

LD

= 1.2V

Note 1: Also limited by package power dissipation limit, whichever is lower

2: Denotes specifications which apply over the full operating ambient temperature range of

–40°C < T

A

< +125°C

3: Specification is obtained by characterization and is not 100% tested.

2017 Microchip Technology Inc.

DS20005588A-page 5

HV9961

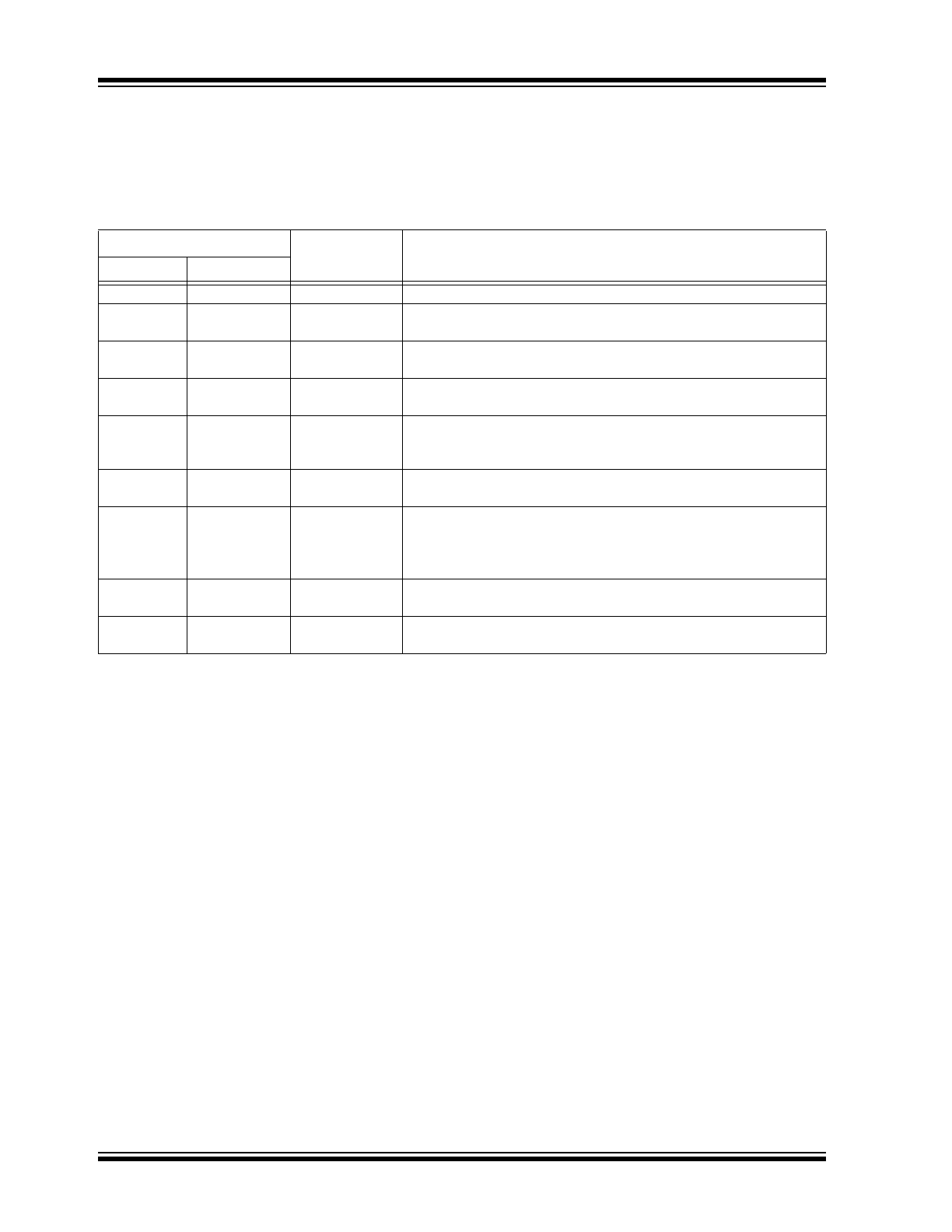

CS Threshold Temperature

Regulation

∆V

CST(TEMP)

—

—

5

mV

(

Note 2

)

LD Input Shutdown Threshold

Voltage

V

LD(OFF)

—

150

—

mV

V

LD

falling

LD Input Enable Threshold Voltage

V

LD(EN)

—

200

—

mV

V

LD

rising

Current Sense Blanking Interval

T

BLANK

150

—

320

ns

(

Note 2

)

Minimum On-time

T

ON(MIN)

—

—

1000

ns

V

CS

= V

CST

+ 30 mV

Maximum Steady-state Duty Cycle

D

MAX

75

—

—

%

Reduction in output LED

current may occur beyond

this duty cycle

SHORT-CIRCUIT PROTECTION

Hiccup Threshold Voltage

V

CSH

410

440

470

mV

Current Limit Delay CS-to-Gate

T

DELAY

—

—

150

ns

V

CS

= V

CSH

+ 30 mV

Short-circuit Hiccup Time

T

HICCUP

350

400

550

μs

Minimum On-time (Short-circuit)

T

ON(MIN),SC

—

—

430

ns

V

CS

= V

DD

T

OFF

TIMER

Off-time

T

OFF

32

40

48

μs

R

T

= 1 MΩ

8

10

12

R

T

= 226 kΩ

GATE DRIVER

Gate Sourcing Current

I

SOURCE

0.165

—

—

A

V

GATE

= 0V, V

DD

= 7.5V

Gate Sinking Current

I

SINK

0.165

—

—

A

V

GATE

= V

DD

, V

DD

= 7.5V

Gate Output Rise Time

t

r

—

30

50

ns

C

GATE

= 500 pF, V

DD

= 7.5V

Gate Output Fall Time

t

f

—

30

50

ns

C

GATE

= 500 pF, V

DD

= 7.5V

TEMPERATURE SPECIFICATIONS

Parameter

Sym.

Min.

Typ.

Max.

Unit

Conditions

TEMPERATURE RANGES

Operating Ambient Temperature

T

A

–40

—

+125

°C

Maximum Junction Temperature

T

J(MAX)

—

—

+150

°C

Storage Temperature

T

S

–65

—

+150

°C

PACKAGE THERMAL RESISTANCE

8-lead SOIC

JA

—

101

—

°C/W

16-lead SOIC

JA

—

83

—

°C/W

ELECTRICAL CHARACTERISTICS (CONTINUED)

Electrical Specifications: T

A

= 25°C, V

IN

= 12V, V

LD

= V

DD

, and V

PWMD

= V

DD

unless otherwise specified.

Parameter

Sym.

Min.

Typ.

Max.

Unit

Conditions

Note 1: Also limited by package power dissipation limit, whichever is lower

2: Denotes specifications which apply over the full operating ambient temperature range of

–40°C < T

A

< +125°C

3: Specification is obtained by characterization and is not 100% tested.

HV9961

DS20005588A-page 6

2017 Microchip Technology Inc.

2.0

PIN DESCRIPTION

The details on the pins of HV9961 are listed on

Table 2-1

. Refer to

Package Types

for the location of

pins.

TABLE 2-1:

PIN FUNCTION TABLE

Pin Number

Pin Name

Description

8-lead SOIC 16-lead SOIC

1

1

VIN

This pin is the input of an 8V–450V linear regulator.

2

4

CS

This pin is the current sense pin used to sense the FET current with

an external sense resistor.

3

5

GND

Ground return for all internal circuitry. This pin must be electrically

connected to the ground of the power train.

4

8

Gate

This pin is the output of gate driver for driving an external N-chan-

nel power MOSFET.

5

9

PWMD

This is the PWM dimming input of the IC. When this pin is pulled to

GND, the gate driver is turned off. When the pin is pulled high, the

gate driver operates normally.

6

12

V

DD

This is the power supply pin for all internal circuits. It must be

bypassed with a low ESR capacitor to GND (at least 0.1 μF).

7

13

LD

This pin is the linear dimming input, and it sets the current sense

threshold as long as the voltage at this pin is less than 1.5V. If volt-

age at LD falls below 150 mV, the gate output is disabled. The gate

signal recovers at 200 mV at LD.

8

14

RT

A resistor connected between this pin and GND programs the gate

off-time.

—

2, 3, 6, 7, 10,

11, 15 and16

NC

No connection

2017 Microchip Technology Inc.

DS20005588A-page 7

HV9961

3.0

APPLICATION INFORMATION

3.1

General Description

Peak current control (as in HV9910B) is the simplest

and the most economical way to regulate a buck

converter's output current. However, it suffers accuracy

and regulation problems that arise from

peak-to-average current error, contributed by the

current ripple in the output inductor and the

propagation delay in the current sense comparator.

The full inductor current signal is unavailable for direct

switch current sensing across the sense resistor at the

ground path in this low-side switch buck converter

when the control switch is at the ground potential

because the switch is turned off. While it is very simple

to detect the peak current in the switch, controlling the

average inductor current is usually implemented by

level translating the sense signal from +V

IN

. Although

this is practical for a relatively low-input voltage, V

IN

,

this type of average-current control may become

excessively complex and expensive in the offline AC or

other high-voltage DC applications.

The HV9961 uses a proprietary control scheme that

allows fast and accurate control of the average current

in the buck inductor by sensing the switch current only.

No compensation of the current control loop is

required. The output LED current’s response to PWMD

input is similar to that of the HV9910B. The effect of

inductor current ripple amplitude on this control

scheme is insignificant. Therefore, the LED current is

independent of the variation in inductance, switching

frequency or output voltage. Constant off-time control

of the buck converter is used for stability and improving

the LED current regulation over a wide range of input

voltages. Unlike HV9910B, the HV9961 does not

support Constant Frequency mode.

3.2

Off Timer

The timing resistor connected between RT and GND

determines the off-time of the gate driver. Wiring this

resistor between RT and Gate as with HV9910B is no

longer supported. Refer to

Equation 3-1

for the

computation of the gate output’s off-time.

EQUATION 3-1:

T

OFF

s

R

T

k

25

------------------- 0.3

+

=

within the range of 30 kΩ ≤ R

T

≤ 1 MΩ

3.3

Average-Current Control

Feedback and Output Short-circuit

Protection

The current through the switching Metal-oxide

Semiconductor Field-effect Transistor (MOSFET)

source is averaged and used to give constant-current

feedback. This current is detected with a sense resistor

at the CS pin. The feedback operates in a fast

Open-loop mode. No compensation is required. Output

current is programmed as seen in

Equation 3-2

.

EQUATION 3-2:

I

LED

0.275V

R

CS

-----------------

=

When the voltage at the LD input V

LD

≥ 1.5V

If the voltage at the LD input is less than 1.5V, the

output current is computed as specified in

Equation 3-3

.

EQUATION 3-3:

I

LED

V

LD

0.185

R

CS

------------------------------

=

When the voltage at the LD input 0.2V ≤ V

LD

< 1.5V

The above equations are only valid for continuous

conduction of the output inductor. It is good design

practice to choose the inductance of the inductor such

that the peak-to-peak inductor current is 30% to 40% of

the average DC full-load current. Hence, the

recommended inductance can be calculated as shown

in

Equation 3-4

.

EQUATION 3-4:

L

O

V

O MAX

T

OFF

0.4 I

O

-----------------------------------------

=

The duty-cycle range of the current control feedback is

limited to D ≤ 0.75. A reduction in the LED current may

occur when the desired LED string voltage V

O

is

greater than 75% of the input voltage V

IN

of the

HV9961 LED driver.

Reducing the targeted output LED string voltage V

O

below V

O(MIN)

= V

IN

x D

MIN

, where D

MIN

= 1 µs/(T

OFF

+1 µs), may also result in the loss of regulation of the

LED current. This condition, however, causes an

increase in the LED current and can potentially trip the

short-circuit protection comparator.

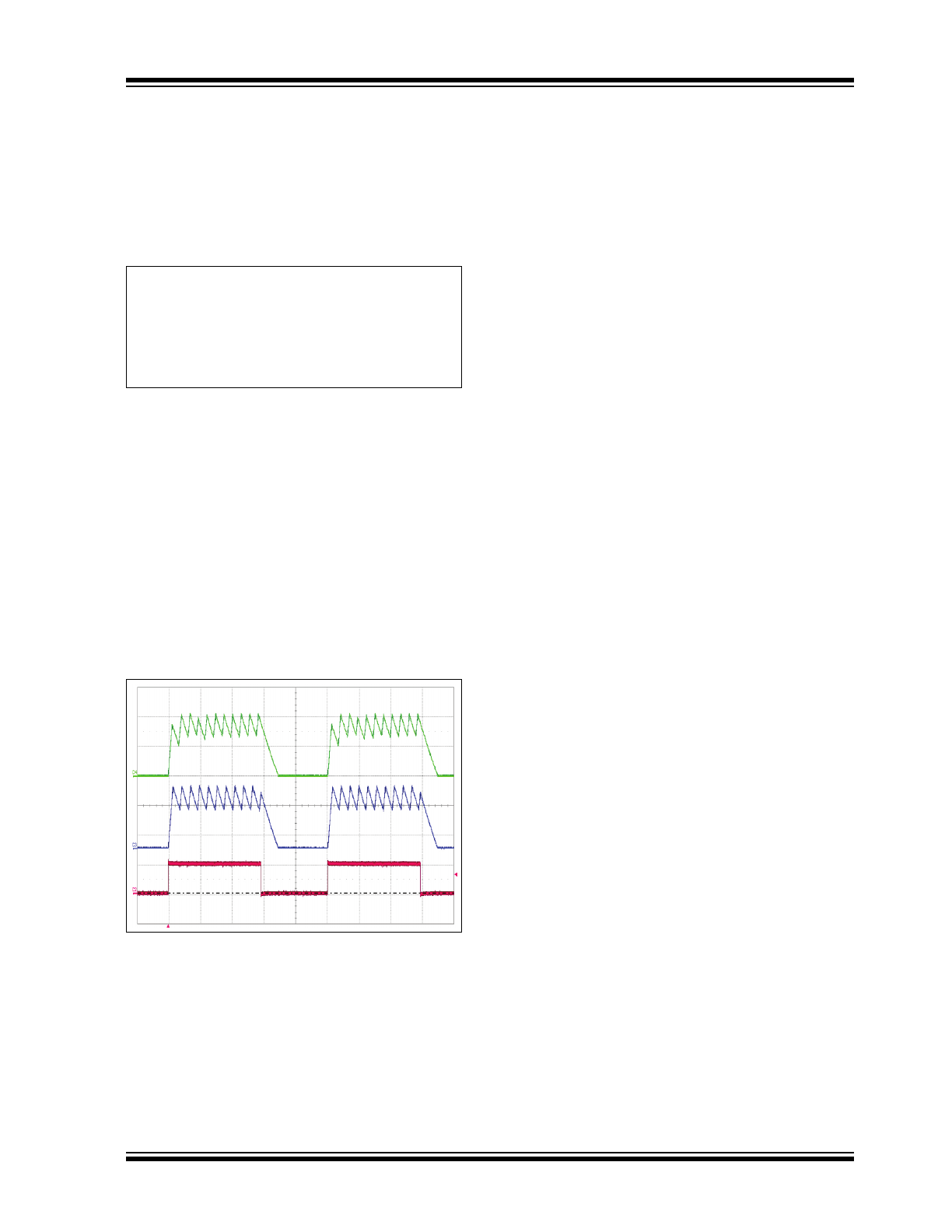

The typical output characteristic of the HV9961 LED

driver is shown in

Figure 3-1

. The corresponding

HV9910B characteristic is given for the comparison.

HV9961

DS20005588A-page 8

2017 Microchip Technology Inc.

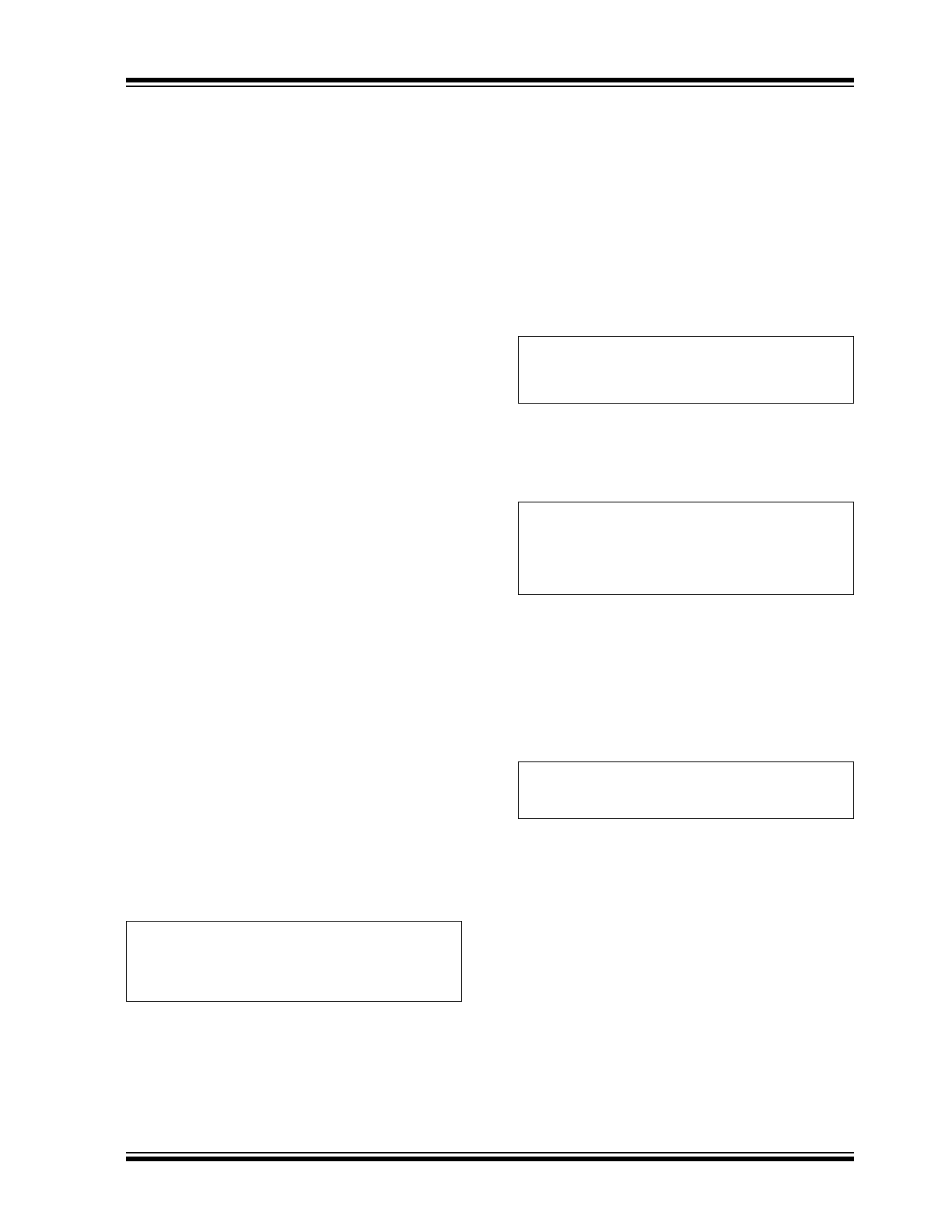

FIGURE 3-1:

Typical Output

Characteristic of an HV9961 LED Driver.

V

IN

= 170VDC

HV9961

HV9910B

0 10 20 30 40 50 60

0.60

0.55

0.50

0.45

0.40

0.35

0.30

0.25

LED Current (A)

Output Voltage (V)

Output Characteristics

The short-circuit protection comparator trips when the

voltage at CS exceeds 0.44V. When this occurs, the

short-circuit gate off-time T

HICCUP

= 400 µs is

generated to prevent the staircasing of the inductor

current and, potentially, its saturation due to insufficient

output voltage. The typical short-circuit inductor current

is shown in the waveform of

Figure 3-2

.

400µs

0.44V/R

CS

FIGURE 3-2:

Short-circuit Inductor

Current.

A leading-edge blanking delay is provided at CS to

prevent false triggering of the current feedback and the

short-circuit protection.

3.4

Linear Dimming

When the voltage at LD falls below 1.5V, the internal

275 mV reference to the constant-current feedback

becomes overridden by V

LD

x 0.185. As long as the

current in the inductor remains continuous, the LED

current is given by

Equation 3-3

. However, when V

LD

falls below 150 mV, the gate output becomes disabled.

The gate signal recovers when V

LD

exceeds 200 mV. It

is required in some applications to use the same

brightness control signal input to shut off the lamp. The

typical linear dimming response is shown in

Figure 3-3

.

FIGURE 3-3:

0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6

0.40

0.35

0.30

0.25

0.20

0.15

0.10

0.05

0

LED Current (A)

LD (V)

LD Response Characteristics

Typical Linear Dimming

Response of an HV9961 LED Driver.

The linear dimming input could also be used for

“mixed-mode” dimming to expand the dimming ratio. In

such case, a pulse-width modulated signal with an

amplitude below 1.5V should be applied to LD.

3.5

Input Voltage Regulator

The HV9961 can be powered directly from an

8 V

DC

–450 V

DC

supply through its V

IN

input. When this

voltage is applied at the V

IN

pin, the HV9961 maintains

a constant 7.5V level at V

DD

. This voltage can be used

to power the IC and external circuitry connected to V

DD

within the rated maximum current or within the thermal

ratings of the package, whichever limit is lower. The

V

DD

pin must be bypassed by a low ESR capacitor to

provide a low-impedance path for the high-frequency

current of the gate output. The HV9961 can also be

powered through the V

DD

pin directly with a voltage

greater than the internally regulated 7.5V, but less than

12V.

Despite the instantaneous voltage rating of 450V,

continuous voltage at V

IN

is limited by the power

dissipation in the package. For example, when HV9961

draws I

IN

= 2.5 mA from the V

IN

input, and the 8-pin

SOIC package is used, the maximum continuous

voltage at V

IN

is limited to the value shown in

Equation 3-5

.

EQUATION 3-5:

V

IN MAX

T

J MAX

T

A

–

R

JA

I

IN

--------------------------------

=

396V

=

Where:

Ambient temperature: T

A

= 25°C

Maximum working junction temperature: T

J(MAX)

= 125°C

Junction-to-ambient thermal resistance:

R

θ,JA

= 101°C/W

2017 Microchip Technology Inc.

DS20005588A-page 9

HV9961

In such cases, when it is needed to operate the

HV9961 from a higher voltage, a resistor or a Zener

diode can be added in series with the V

IN

input to divert

some of the power loss from the HV9961. In the above

example, using a 100V Zener diode will allow the circuit

to work up to 490V. The input current drawn from the

V

IN

pin is represented by

Equation 3-6

.

EQUATION 3-6:

I

IN

1mA Q

G

f

S

+

Where:

f

S

= Switching frequency

Q

G

= Gate charge of the external FET (obtained from

the manufacturer’s data sheet)

3.6

Gate Output

The gate output of the HV9961 is used to drive an

external MOSFET. It is recommended that the gate

charge Q

G

of the external MOSFET be less than 25 nC

for switching frequencies ≤100 kHz and less than

15 nC for switching frequencies >100 kHz.

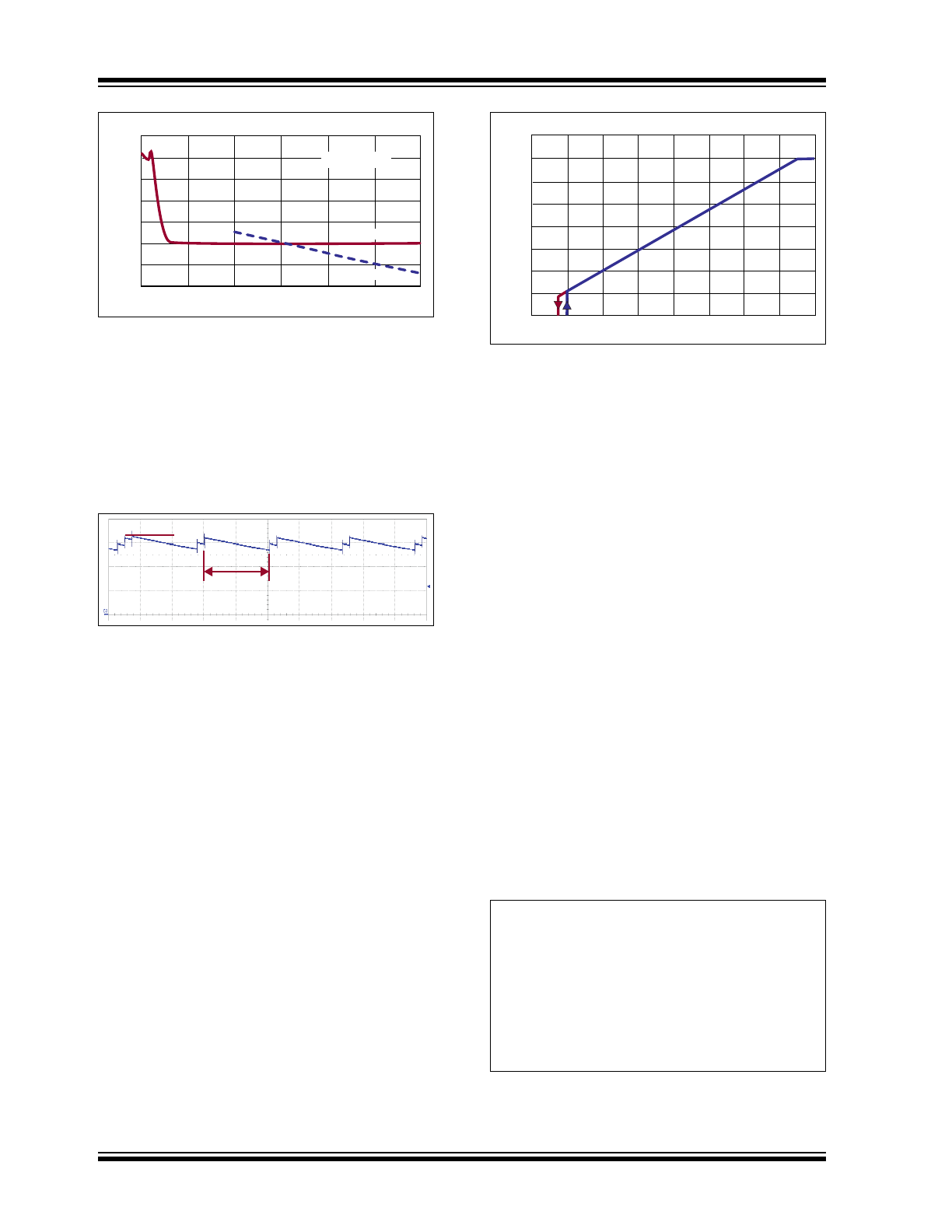

3.7

PWM Dimming

Due to the fast open-loop response of the

average-current control loop of the HV9961, its PWM

dimming performance nearly matches that of the

HV9910B. The inductor current waveform comparison

is shown in

Figure 3-4

.

CH4 = Inductor Current

CH3 = Inductor Current

of HV9910B

for comparison

CH2 = V

PWMD

FIGURE 3-4:

Typical PWM Dimming

Response of an HV9961 LED Driver.

The rising and falling edges are limited by the current

slew rate in the inductor. The first switching cycle is

terminated upon reaching the 275 mV or V

LD

x 0.185

level at CS. The circuit is further reaching its

steady-state within 3–4 switching cycles regardless of

the switching frequency.

HV9961

DS20005588A-page 10

2017 Microchip Technology Inc.

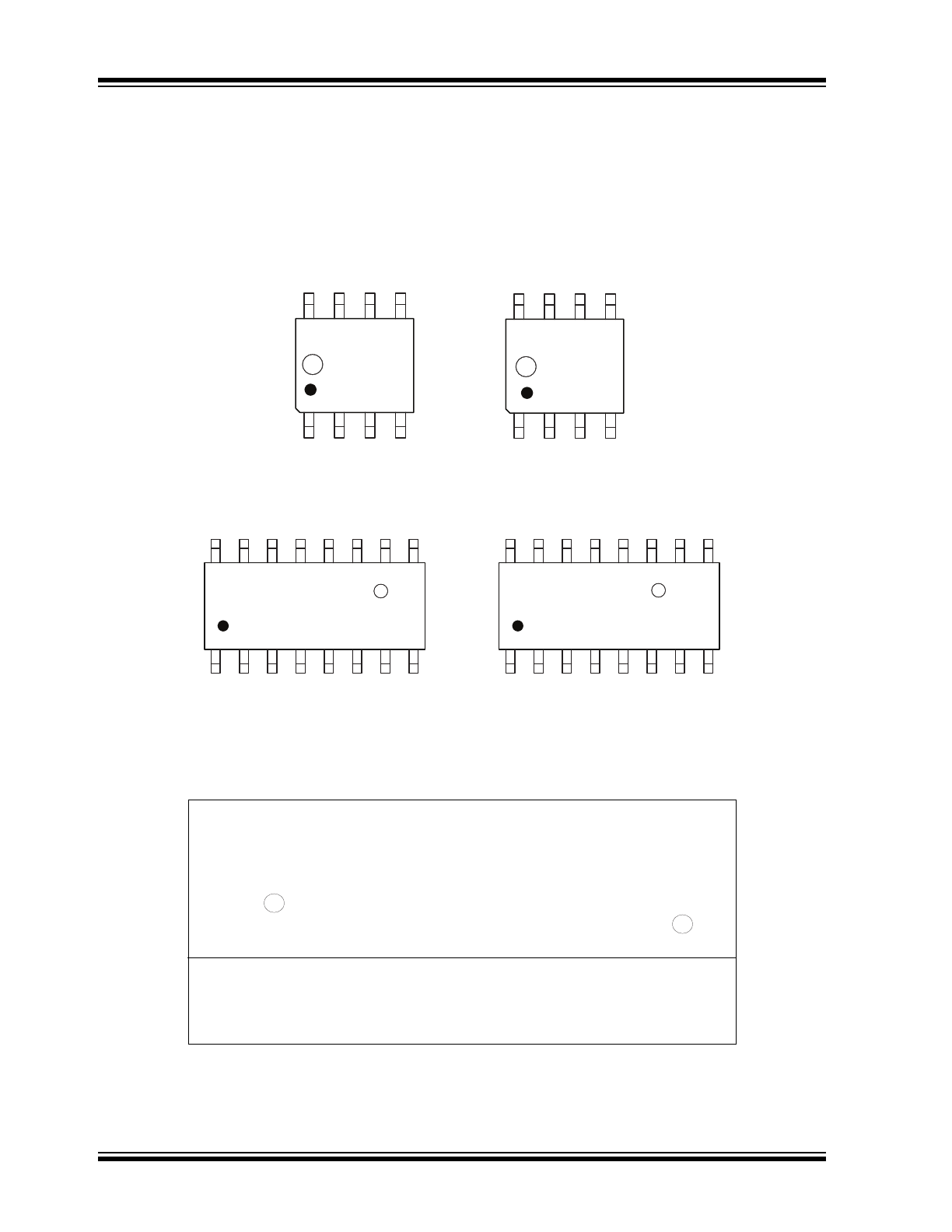

4.0

PACKAGING INFORMATION

4.1

Package Marking Information

Legend: XX...X

Product Code or Customer-specific information

Y

Year code (last digit of calendar year)

YY

Year code (last 2 digits of calendar year)

WW

Week code (week of January 1 is week ‘01’)

NNN

Alphanumeric traceability code

Pb-free JEDEC

®

designator for Matte Tin (Sn)

*

This package is Pb-free. The Pb-free JEDEC designator ( )

can be found on the outer packaging for this package.

Note:

In the event the full Microchip part number cannot be marked on one line, it will

be carried over to the next line, thus limiting the number of available

characters for product code or customer-specific information. Package may or

not include the corporate logo.

3

e

3

e

8-lead SOIC

Example

NNN

XXXXXXXX

YYWW

e3

888

HV9961LG

1725

e3

16-lead SOIC

XXXXXXXXX

YYWWNNN

Example

HV9961NG

1714789

e3

e3