2016 Microchip Technology Inc.

DS20005583A-page 1

HV9912

Features

• Switch-mode Controller for Single-switch Drivers:

- Buck

- Boost

- Buck-boost

- SEPIC

• Works with High-side Current Sensors

• Closed-loop Control of Output Current

• High Pulse-Width Modulation (PWM) Dimming

Ratio

• Internal 90V Linear Regulator (can be extended

using external Zener Diodes)

• Internal 2% Voltage Reference (0°C < T

A

< 85°C)

• Constant Frequency or Constant Off-time

Operation

• Programmable Slope Compensation

• Linear and PWM Dimming

• +0.2A/–0.4A Gate Driver

• Hiccup Mode Protection for both Short-circuit and

Open-circuit Conditions

• Output Overvoltage Protection

• Synchronization Capability

• Pin Compatible with HV9911

Applications

• RGB Backlight Applications

• General LED Lighting Applications

• Battery-powered LED Lamps

General Description

HV9912 is an LED driver IC designed to control

single-switch PWM converters (buck, boost,

buck-boost and SEPIC) in a Constant Frequency or

Constant Off-time mode. The controller uses a peak

Current Mode control scheme with programmable

slope compensation and includes an internal

transconductance amplifier to control the output current

in closed loop, enabling high output current accuracy.

In the case of buck and buck-boost converters, the

output current can be sensed using a high-side current

sensor like the HV7800. In the Constant Frequency

mode, multiple HV9912 ICs can be synchronized with

each other or with an external clock, using the SYNC

pin. Programmable MOSFET current limit enables

current limiting during Input Undervoltage and Output

Overload conditions. The IC also includes a 0.2A

source and 0.4A sink gate driver that makes the

HV9912 suitable for high-power applications. An

internal 90V linear regulator powers the IC, eliminating

the need for a separate power supply for the IC. The IC

also provides a FAULT output, which can be used to

disconnect the LEDs in case of a Fault condition using

an external disconnect FET. HV9912 also provides a

TTL-compatible, low-frequency PWM dimming input

that can accept an external control signal with a duty

ratio of 0-100% and a frequency of up to a few kilohertz.

The HV9912 includes hiccup protection from both short

and open circuits, with automatic recovery after the

Fault condition is cleared.

The HV9912 is a pin-compatible replacement for

HV9911. It can be used with existing HV9911 designs,

which have input voltages of less than 90V, by

changing R

OVP1

, R

OVP

, and R

T

.

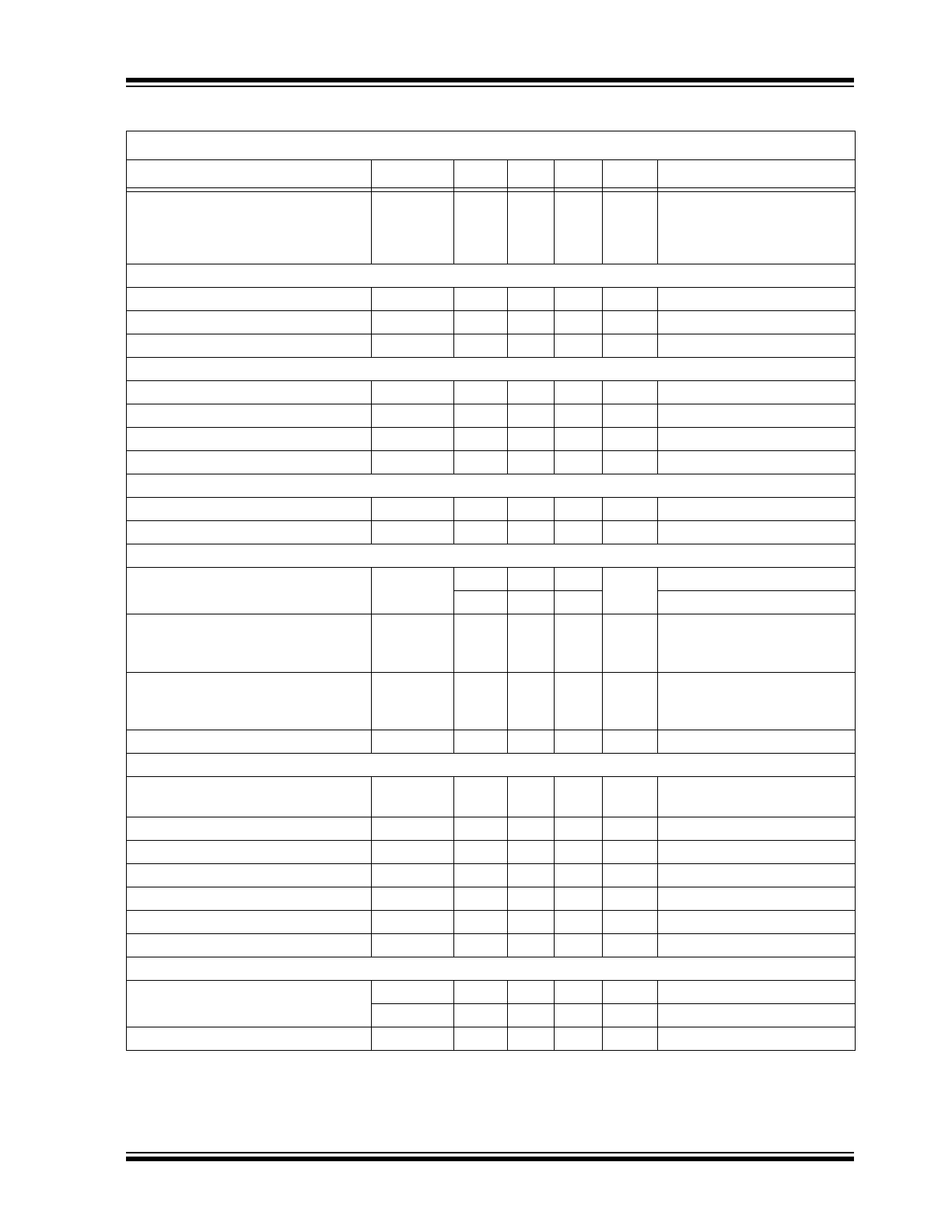

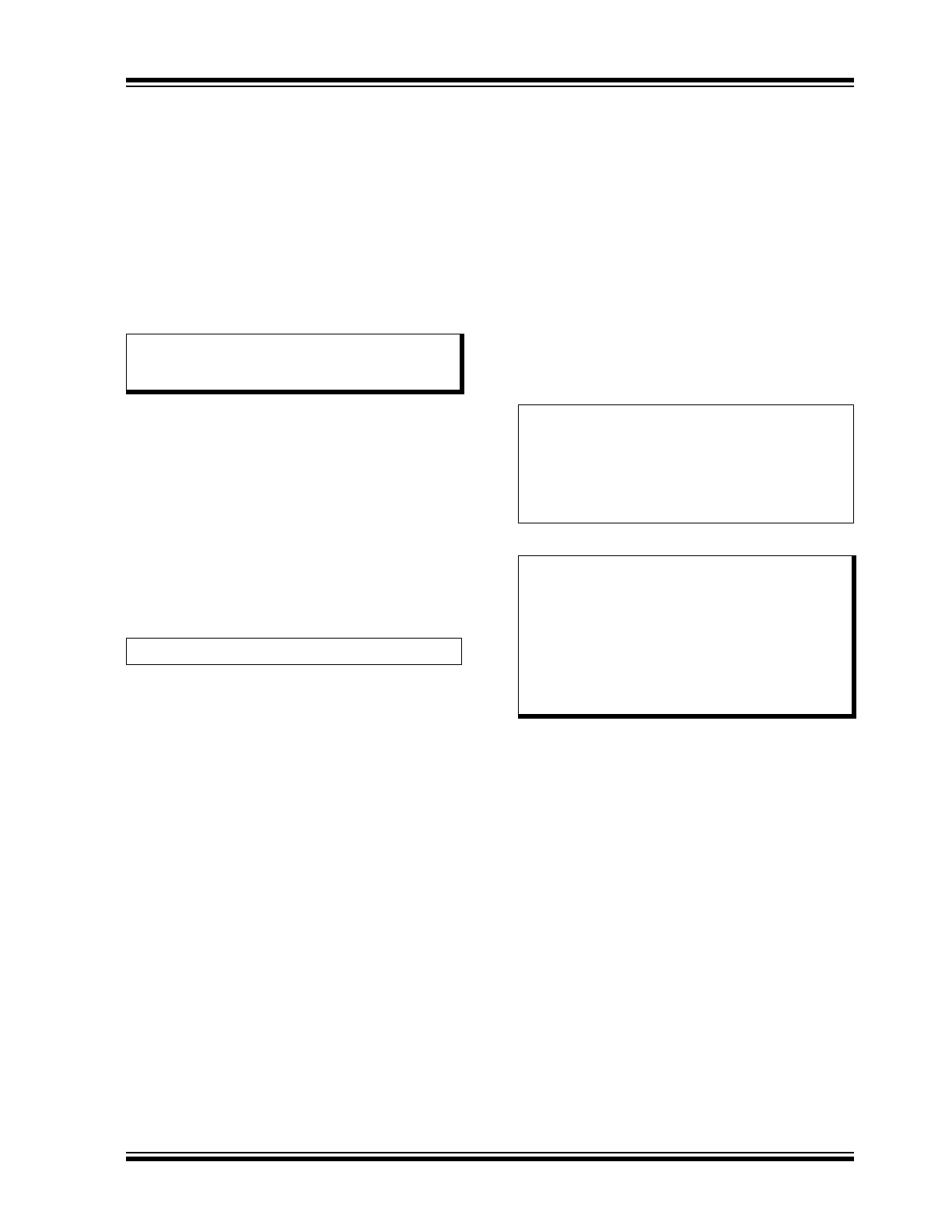

Package Type

VIN

VDD

GATE

GND

CS

SC

RT

SYNC

FDBK

IREF

COMP

PWMD

OVP

FAULT

REF

CLIM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

16-lead SOIC

(Top View)

See

Table 2-1

for pin information.

Switch-Mode LED Driver IC with High Current Accuracy

and Hiccup Mode Protection

HV9912

DS20005583A-page 2

2016 Microchip Technology Inc.

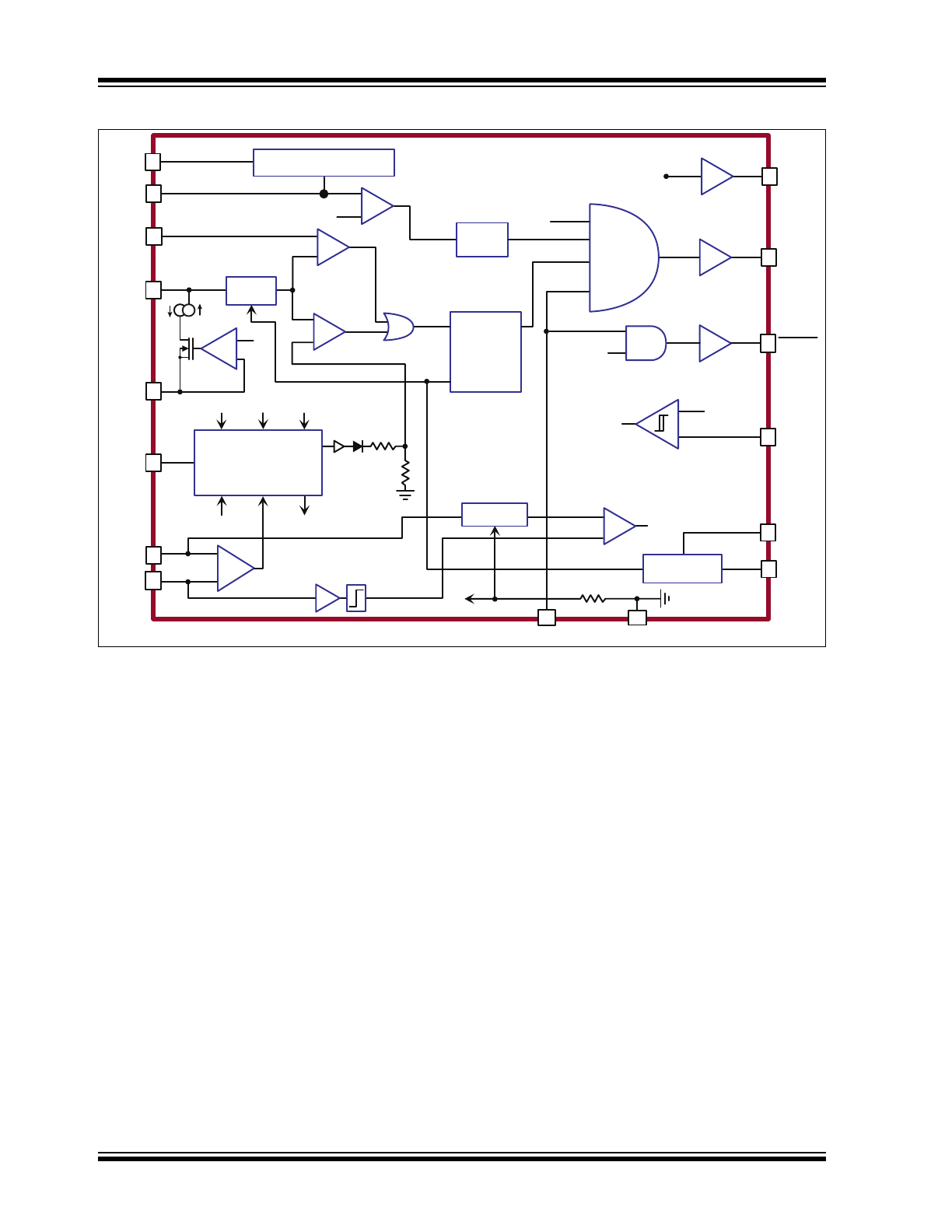

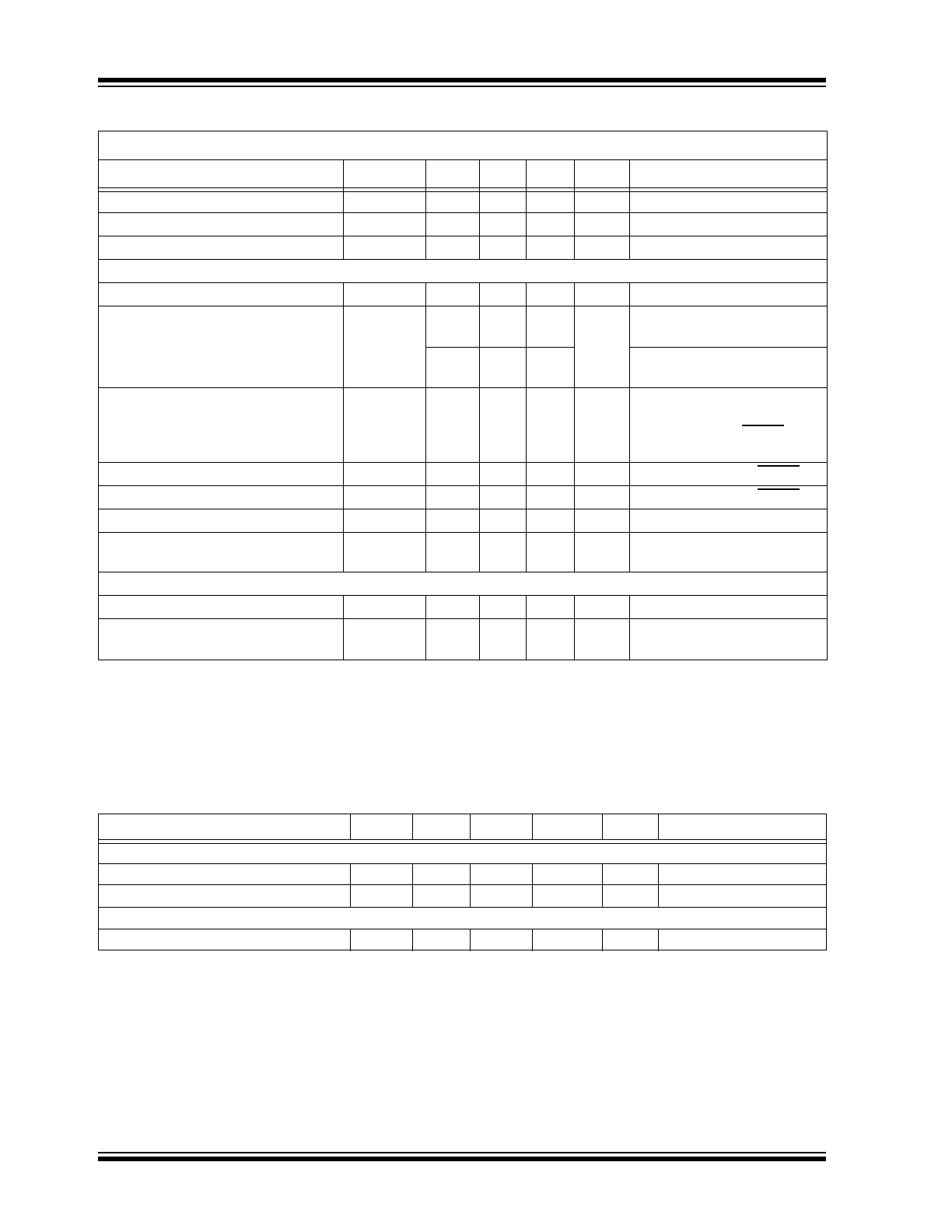

Functional Block Diagram

V

bg

VIN

VDD

REF

GATE

FDBK

IREF

COMP

GND

PWMD

POR

RT

SYNC

S

R

Q

Blanking

CS

SC

ramp

1:2

OVPD

OVP

FAULT

SS

SS

SCD

CLIM

Linear Regulator

One Shot

Hiccup/Dimming

Block

POR

OVD

SCD

PWMD

SS

2

G

M

5V rising

4.5V falling

PWMD

13R

R

5.60/6.10V

T

BLANK

T

BLANK,SC

-

+

+

-

-

+

+

-

+

-

+

-

-

+

2016 Microchip Technology Inc.

DS20005583A-page 3

HV9912

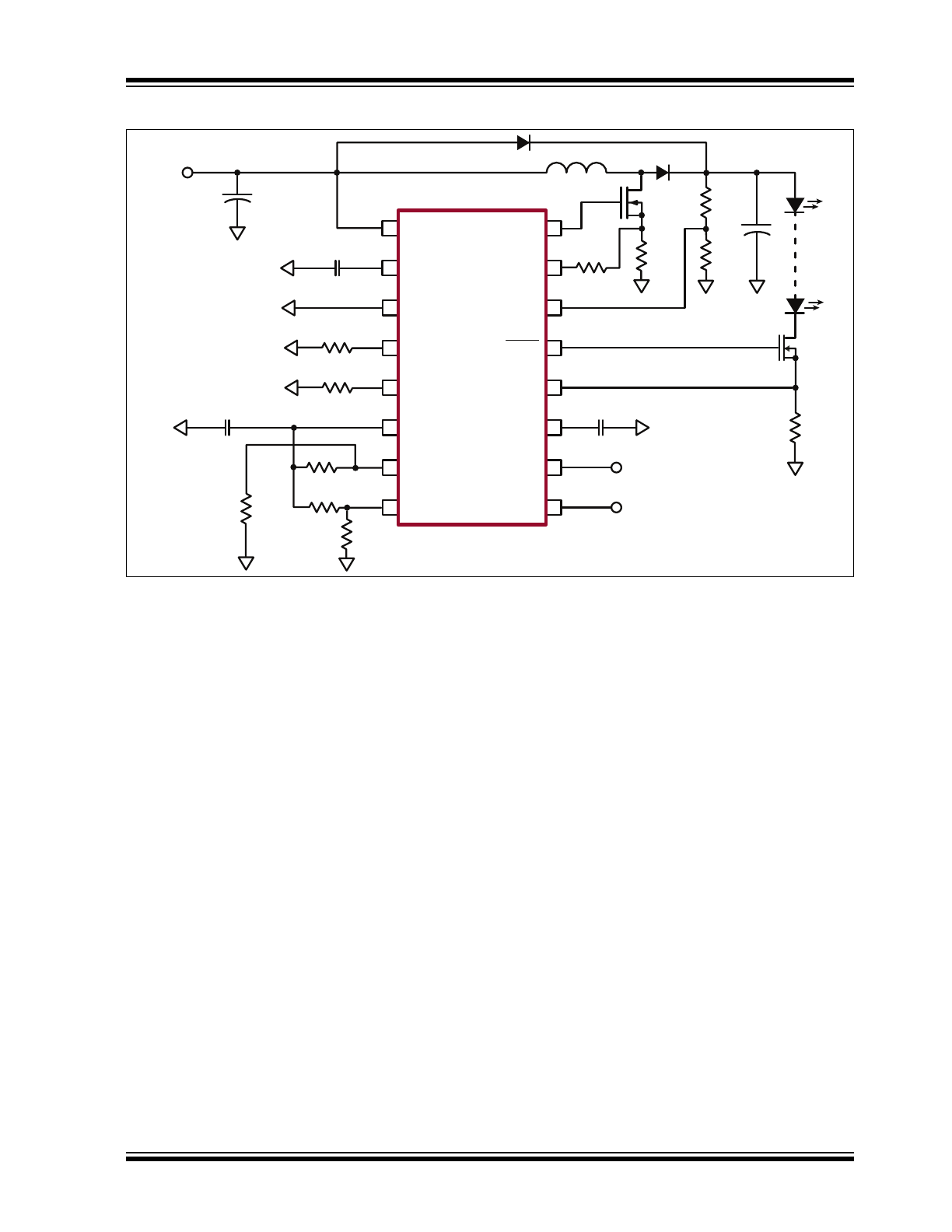

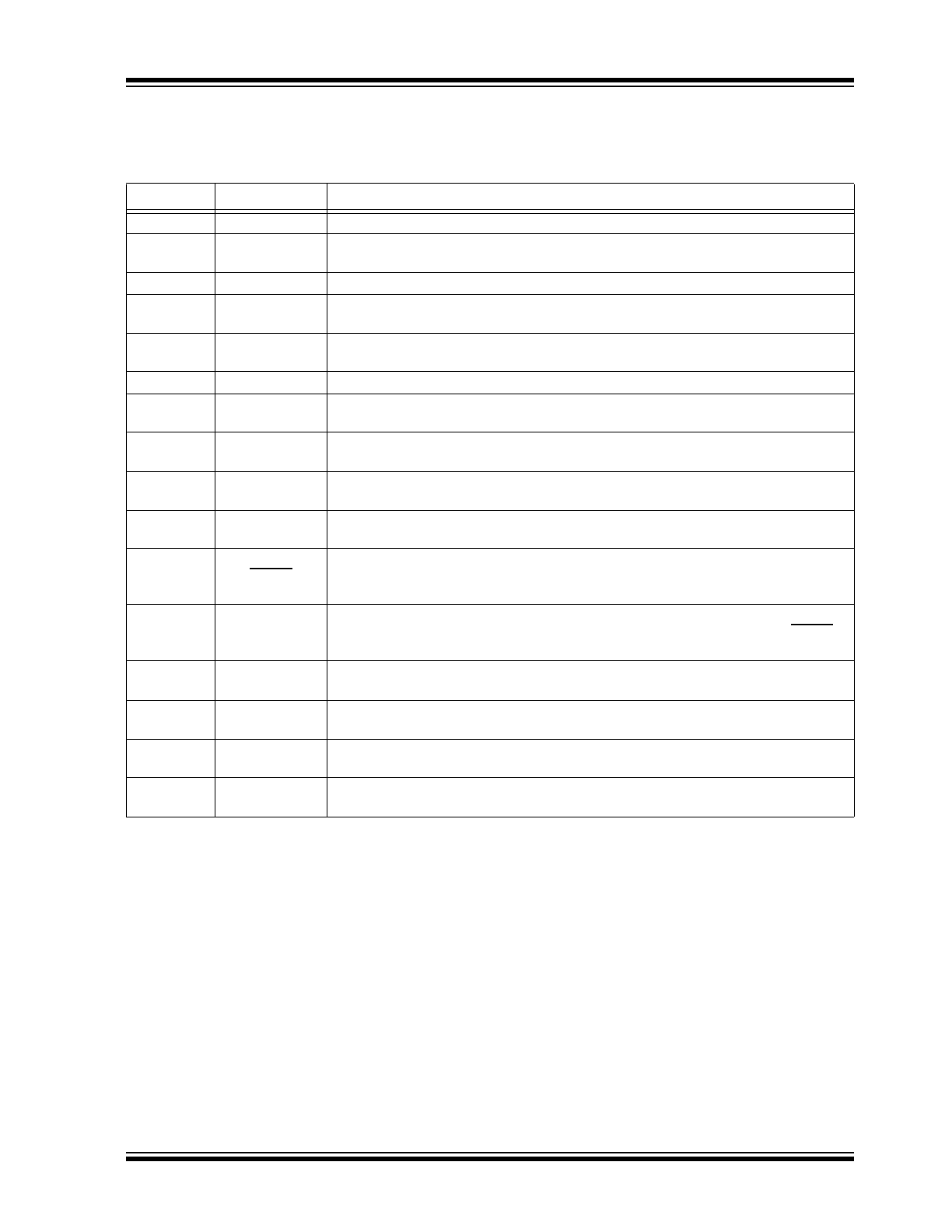

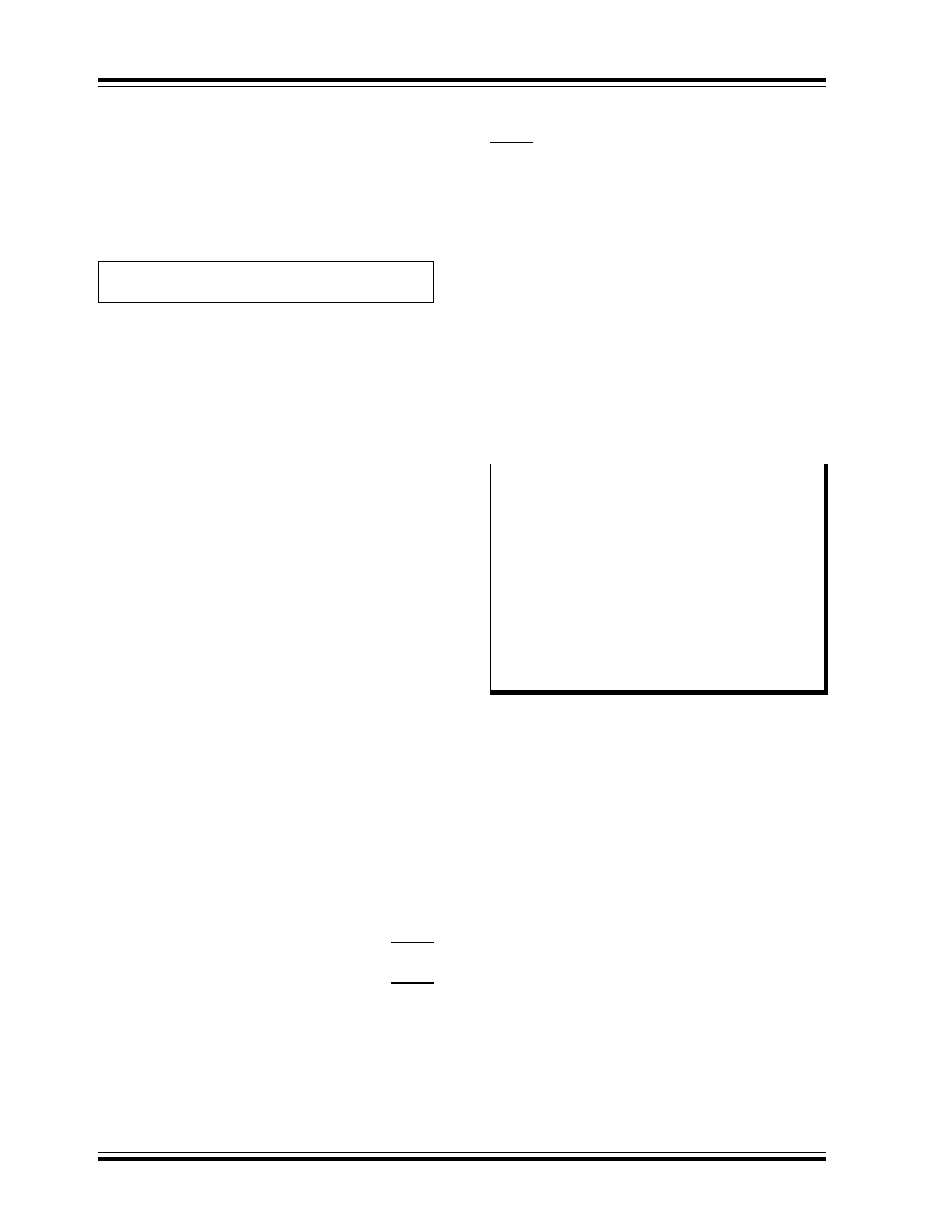

Typical Application Circuit

6

7

10

9

15

8

13

14

16

11

12

5

3

1

2

4

C

IN

C

DD

C

REF

R

R2

R

R1

R

L1

R

L2

R

T

R

SLOPE

R

SC

R

CS

R

OVP1

R

OVP2

C

O

D1

Q1

L1

Q2

C

C

R

S

VIN

VDD

GND

SC

RT

REF

CLIM

IREF

SYNC

PWMD

COMP

FDBK

FAULT

OVP

CS

GATE

HV9912

D2

V

IN

HV9912

DS20005583A-page 4

2016 Microchip Technology Inc.

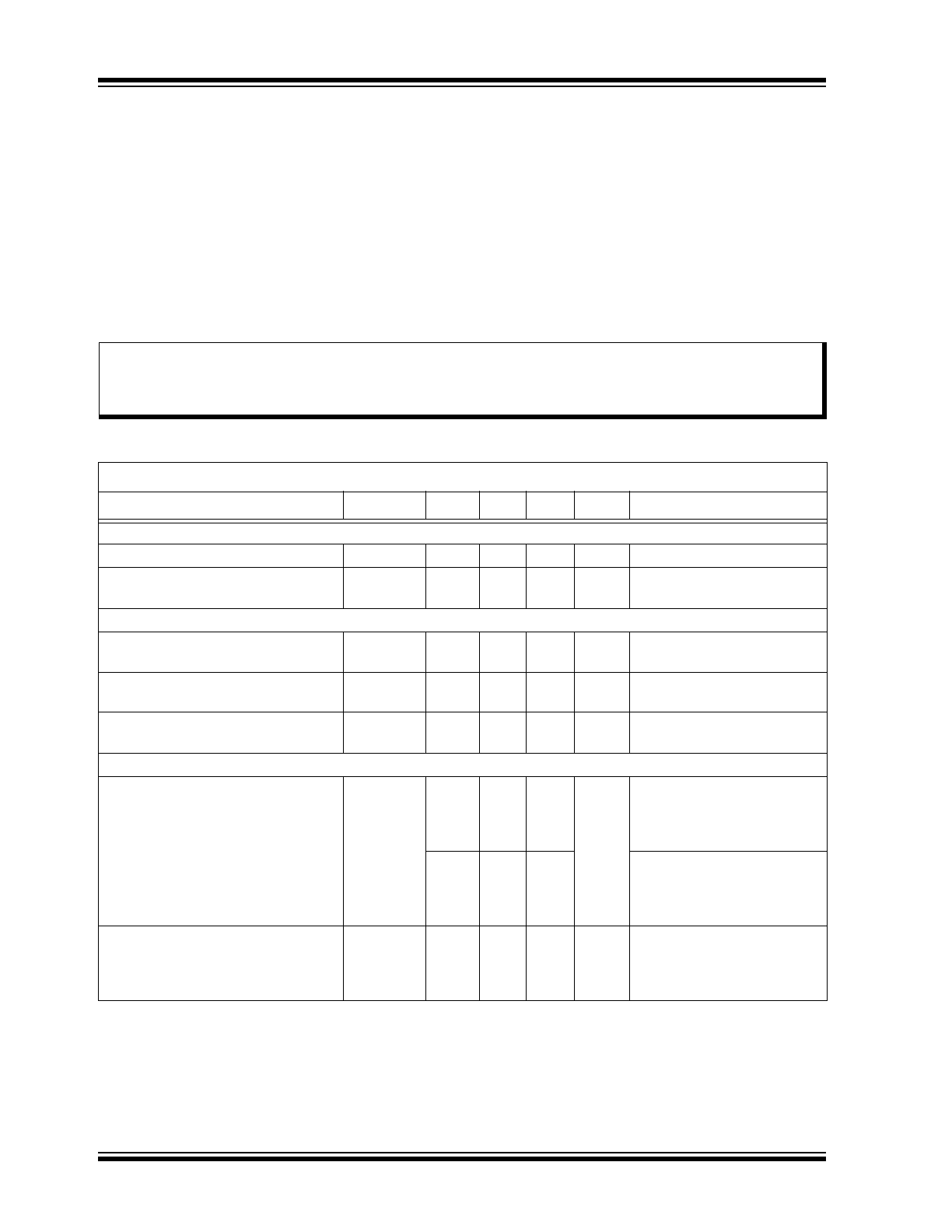

1.0

ELECTRICAL CHARACTERISTICS

Absolute Maximum Ratings †

V

IN

to GND ............................................................................................................................................... –0.5 to +100V

V

DD

to GND............................................................................................................................................–0.3V to +13.5V

CS to GND ........................................................................................................................................ –0.3V to V

DD

+0.3V

PWMD to GND.................................................................................................................................. –0.3V to V

DD

+0.3V

GATE to GND.................................................................................................................................... –0.3V to V

DD

+0.3V

All Other Pins to GND ....................................................................................................................... –0.3V to V

DD

+0.3V

Continuous Power Dissipation (T

A

= +25°C)..................................................................................................... 1200 mW

Operating Junction Temperature Range .............................................................................................. –40°C to +125°C

Storage Temperature Range ................................................................................................................ –65°C to +150°C

† Notice: Stresses above those listed under “Absolute Maximum Ratings” may cause permanent damage to the

device. This is a stress rating only, and functional operation of the device at those or any other conditions above those

indicated in the operational sections of this specification is not intended. Exposure to maximum rating conditions for

extended periods may affect device reliability.

ELECTRICAL CHARACTERISTICS

Electrical Specifications: T

A

= 25°C and V

IN

= 12V unless otherwise specified.

Parameters

Sym.

Min.

Typ.

Max.

Units

Conditions

INPUT

Input DC Supply Voltage Range

V

INDC

Note 1

—

90

V

DC input voltage (

Note 2

)

Shutdown Mode Supply Current

I

INSD

—

—

1.5

mA

PWMD connected to GND

(

Note 2

)

INTERNAL REGULATOR

Internally Regulated Voltage

V

DD

7.25

7.75

8.25

V

V

IN

= 9V–90V; PWMD con-

nected to GND (

Note 2

)

V

DD

Undervoltage Lockout

Threshold

UVLO

RISE

6.5

—

7

V

V

DD

rising

V

DD

Undervoltage Lockout

Hysteresis

UVLO

HYST

—

500

—

mV

V

DD

falling

REFERENCE

REF Pin Voltage

V

REF

1.225

1.25

1.285

V

REF bypassed with a 0.1 µF

capacitor to GND; I

REF

= 0;

PWMD = GND;

0°C < T

A

< +85°C

1.225

1.25

1.29

REF bypassed with a 0.1 µF

capacitor to GND; I

REF

= 0;

PWMD = GND;

–40°C < T

A

< 125°C

Line Regulation of Reference Voltage

V

REFLINE

0

—

20

mV

REF bypassed with a 0.1 µF

capacitor to GND; I

REF

= 0;

V

DD

= 7.25V–12V;

PWMD = GND

Note 1: See

Section 3.3 “Minimum Input Voltage at VIN Pin”

for the minimum input voltage.

2: The specifications which apply over the full operating temperature range at

–40°C < T

A

< +85°C are guaranteed by design and characterization.

3: For design guidance only

2016 Microchip Technology Inc.

DS20005583A-page 5

HV9912

Load Regulation of Reference

Voltage

V

REFLOAD

0

—

10

mV

REF bypassed with a 0.1 µF

capacitor to GND;

I

REF

= 0 µA–500 µA;

PWMD = GND

PWM DIMMING

PWMD Input Low Voltage

V

PWMD(LO)

—

—

0.8

V

Note 2

PWMD Input High Voltage

V

PWMD(HI)

2

—

—

V

Note 2

PWMD Pull-down Resistance

R

PWMD

50

100

150

kΩ

V

PWMD

= 5V

GATE

GATE Short-circuit Current

I

SOURCE

0.2

—

—

A

V

GATE

= 0V

GATE Sinking Current

I

SINK

0.4

—

—

A

V

GATE

= V

DD

GATE Output Rise Time

T

RISE

—

50

85

ns

C

GATE

= 1 nF

GATE Output Fall Time

T

FALL

—

25

45

ns

C

GATE

= 1 nF

OVERVOLTAGE PROTECTION

Overvoltage Rising Trip Point

V

OVP,RISING

4.75

5

5.25

V

OVP rising

Overvoltage Hysteresis

V

OVP,HYST

—

0.5

—

V

OVP falling

CURRENT SENSE

Leading Edge Blanking

T

BLANK

100

—

280

ns

0°C < T

A

< +85°C

100

—

330

–40°C < T

A

< +125°C

Delay to Output of C

OMP

Comparator

T

DELAY1

—

—

200

ns

COMP = V

DD

; C

LIM

= REF;

C

SENSE

= 0 mV to 600 mV

(step up)

Delay to Output of C

LIMIT

Comparator

T

DELAY2

—

—

200

ns

COMP = V

DD

; C

LIM

= 300 mV;

C

SENSE

= 0 mV to 400 mV

(step up)

Comparator Offset Voltage

V

OFFSET

–10

—

10

mV

INTERNAL TRANSCONDUCTANCE OPAMP

Gain Bandwidth Product

GBW

—

1

—

MHz

75 pF capacitance at OP pin

(

Note 3

)

Open-loop DC Gain

A

V

60

—

—

dB

Output open

Input Common Mode Range

V

CM

–0.3

—

3

V

Note 3

Output Voltage Range

V

O

0.7

—

6.75

V

Note 3

Transconductance

g

M

450

550

650

µA/V

Input Offset Voltage

V

OFFSET

–5

—

5

mV

Input Bias Current

I

BIAS

—

0.5

1

nA

Note 3

OSCILLATOR

Oscillator Frequency

f

OSC1

99

106

118

kHz

R

T

= 500 kΩ (

Note 2

)

f

OSC2

510

580

650

kHz

R

T

= 96 kΩ (

Note 2

)

Maximum Duty Cycle

D

MAX

87

—

93

%

ELECTRICAL CHARACTERISTICS (CONTINUED)

Electrical Specifications: T

A

= 25°C and V

IN

= 12V unless otherwise specified.

Parameters

Sym.

Min.

Typ.

Max.

Units

Conditions

Note 1: See

Section 3.3 “Minimum Input Voltage at VIN Pin”

for the minimum input voltage.

2: The specifications which apply over the full operating temperature range at

–40°C < T

A

< +85°C are guaranteed by design and characterization.

3: For design guidance only

HV9912

DS20005583A-page 6

2016 Microchip Technology Inc.

SYNC Input High

V

SYNCH

2

—

—

V

SYNC Input Low

V

SYNCL

—

—

0.8

V

SYNC Output Current

I

OUTSYNC

—

18

—

µA

OUTPUT SHORT-CIRCUIT

Gain for Short-circuit Comparator

G

SC

1.9

2

2.1

V

Minimum Output Voltage of the Gain

Stage

V

OMIN

0.125

—

0.25

V

0°C < T

A

< +85°C;

I

REF

= GND

0.125

—

0.26

–40°C < T

A

< +125°C;

I

REF

= GND

Propagation Time for Short-circuit

Detection

T

OFF

—

—

250

ns

PWMD = V

DD

; I

REF

= 400 mA;

FDBK step from

0 mV to 900 mV; FAULT goes

from high to low

Fault Output Rise Time

T

RISE,FAULT

—

—

300

ns

330 pF capacitor at FAULT pin

Fault Output Fall Time

T

FALL,FAULT

—

—

300

ns

330 pF capacitor at FAULT pin

Blanking Time

T

BLANK,SC

480

—

900

ns

Current Source at COMP Pin used for

Hiccup Mode Protection

I

HICCUP

—

5

—

µA

SLOPE COMPENSATION

Current Sourced Out of SC Pin

I

SLOPE

0

—

100

µA

Note 2

Internal Current Mirror Ratio

G

SLOPE

1.8

2

2.26

I

SLOPE

= 50 µA;

R

SC

= 1 kΩ

TEMPERATURE SPECIFICATIONS

Parameters

Sym.

Min.

Typ.

Max.

Units

Conditions

TEMPERATURE RANGES

Operating Junction Temperature

T

J

–40

—

+125

°C

Storage Temperature

Ts

–65

—

+150

°C

PACKAGE THERMAL RESISTANCE

16-lead SOIC

JA

—

83

—

°C/W

ELECTRICAL CHARACTERISTICS (CONTINUED)

Electrical Specifications: T

A

= 25°C and V

IN

= 12V unless otherwise specified.

Parameters

Sym.

Min.

Typ.

Max.

Units

Conditions

Note 1: See

Section 3.3 “Minimum Input Voltage at VIN Pin”

for the minimum input voltage.

2: The specifications which apply over the full operating temperature range at

–40°C < T

A

< +85°C are guaranteed by design and characterization.

3: For design guidance only

2016 Microchip Technology Inc.

DS20005583A-page 7

HV9912

2.0

PIN DESCRIPTION

Table 2-1

shows the pin description details of HV9912.

TABLE 2-1:

PIN DESCRIPTION TABLE

Pin Number

Name

Description

1

VIN

This pin is the input of a 90V high-voltage regulator.

2

VDD

This is a power supply pin for all internal circuits. It must be bypassed with a

low-ESR capacitor to GND (at least 0.1 µF).

3

GATE

This pin is the output gate driver for an external N-channel power MOSFET.

4

GND

This is the ground return for all the low-power analog internal circuitry. This pin must

be connected to the return path from the input.

5

CS

This pin is used to sense the source current of the external power FET. It includes a

built-in 100 ns (minimum) blanking time.

6

SC

This pin is used to set the slope compensation.

7

RT

This pin sets the frequency of the power circuit. A resistor between RT and GND will

program the circuit in Constant Frequency mode.

8

SYNC

This I/O pin may be connected to the SYNC pin of other HV9912 circuits and will

cause the oscillators to lock to the highest frequency oscillator.

9

CLIM

This pin provides a programmable input current limit for the converter. The current

limit can be set using a resistor divider from the REF pin.

10

REF

This pin provides 2% accurate reference voltage. It must be bypassed with a

0.01 μF–0.1 μF capacitor to GND.

11

FAULT

This pin is pulled to ground when there is an Output Short-circuit condition or Output

Overvoltage condition. This pin can be used to drive an external MOSFET (in the

case of boost converters) to disconnect the load from the source.

12

OVP

This pin provides the overvoltage protection for the converter. When the voltage at

this pin exceeds 5V, the GATE output of the HV9912 is turned off, and the FAULT

goes low. The IC will turn on when the voltage at the pin goes below 4.5V.

13

PWMD

When this pin is pulled to GND (or left open), switching of the HV9912 is disabled.

When an external TTL high level is applied to it, switching will resume.

14

COMP

Stable Closed-loop control can be accomplished by connecting a compensation net-

work between COMP and GND. This capacitor also controls the hiccup time.

15

IREF

The voltage at this pin sets the output current level. The current reference can be set

using a resistor divider from the REF pin.

16

FDBK

This pin provides output current feedback to the HV9912 by using a current sense

resistor.

HV9912

DS20005583A-page 8

2016 Microchip Technology Inc.

3.0

DETAILED DESCRIPTION

3.1

Power Topology

The HV9912 is a Switch-mode converter LED driver

designed to control a Continuous Conduction mode

buck or boost in a Constant Frequency or Constant

Off-time mode. The IC includes an internal linear

regulator, which operates from input voltages up to

90V, eliminating the need for an external power supply

for the IC. The IC includes features typically required in

LED drivers, such as open LED protection, output

short-circuit protection, linear and PWM dimming,

programmable input current limiting and accurate

control of the LED current. A high-current gate drive

output enables the controller to be used in high-power

converters.

The HV9912 is an enhanced version of the HV9911

with hysteretic overvoltage protection and Hiccup

mode short-circuit protection. The IC includes a

blanking network controlled by the PWMD input to

prevent the short-circuit protection from triggering

prematurely during PWM dimming due to the parasitic

capacitance of the LED string. It also allows the I

REF

pin to be pulled all the way down to GND without

triggering the short-circuit protection. It is a

pin-compatible replacement for the HV9911.

3.2

Linear Regulator

The HV9912 can be powered directly from its V

IN

pin

that withstands a voltage of up to 90V. When a voltage

is applied to the V

IN

pin, the HV9912 tries to maintain a

constant 7.75V (typical) at the V

DD

pin. The regulator

also has a built-in undervoltage lockout which shuts off

the IC if the voltage at the V

DD

pin falls below the UVLO

threshold.

The V

DD

pin must be bypassed by a low-ESR capacitor

(≥0.1 µF) to provide a low-impedance path for the

high-frequency current of the output gate driver.

The input current drawn from the V

IN

pin is the sum of

the 1.5 mA current drawn by the internal circuit and the

current drawn by the gate driver, which in turn depends

on the switching frequency and the gate charge of the

external FET. See

Equation 3-1

.

EQUATION 3-1:

I

IN

1.5mA

Q

G

f

S

+

=

In the above equation, f

S

is the switching frequency,

and Q

G

is the external FET’s gate charge, which can be

obtained from the data sheet of the FET.

3.3

Minimum Input Voltage at V

IN

Pin

The minimum input voltage at which the converter will

start and stop depends on the minimum voltage drop

required for the linear regulator. The internal linear

regulator will control the voltage at the V

DD

pin when

V

IN

is between 9V and 90V. However, when V

IN

is less

than 9V, the converter will still function as long as V

DD

is greater than the undervoltage lockout. Thus, the

converter might be able to start at input voltages lower

than 9V. The start/stop voltages at the V

IN

pin can be

determined using the minimum voltage drop across the

linear regulator as a function of the current drawn. This

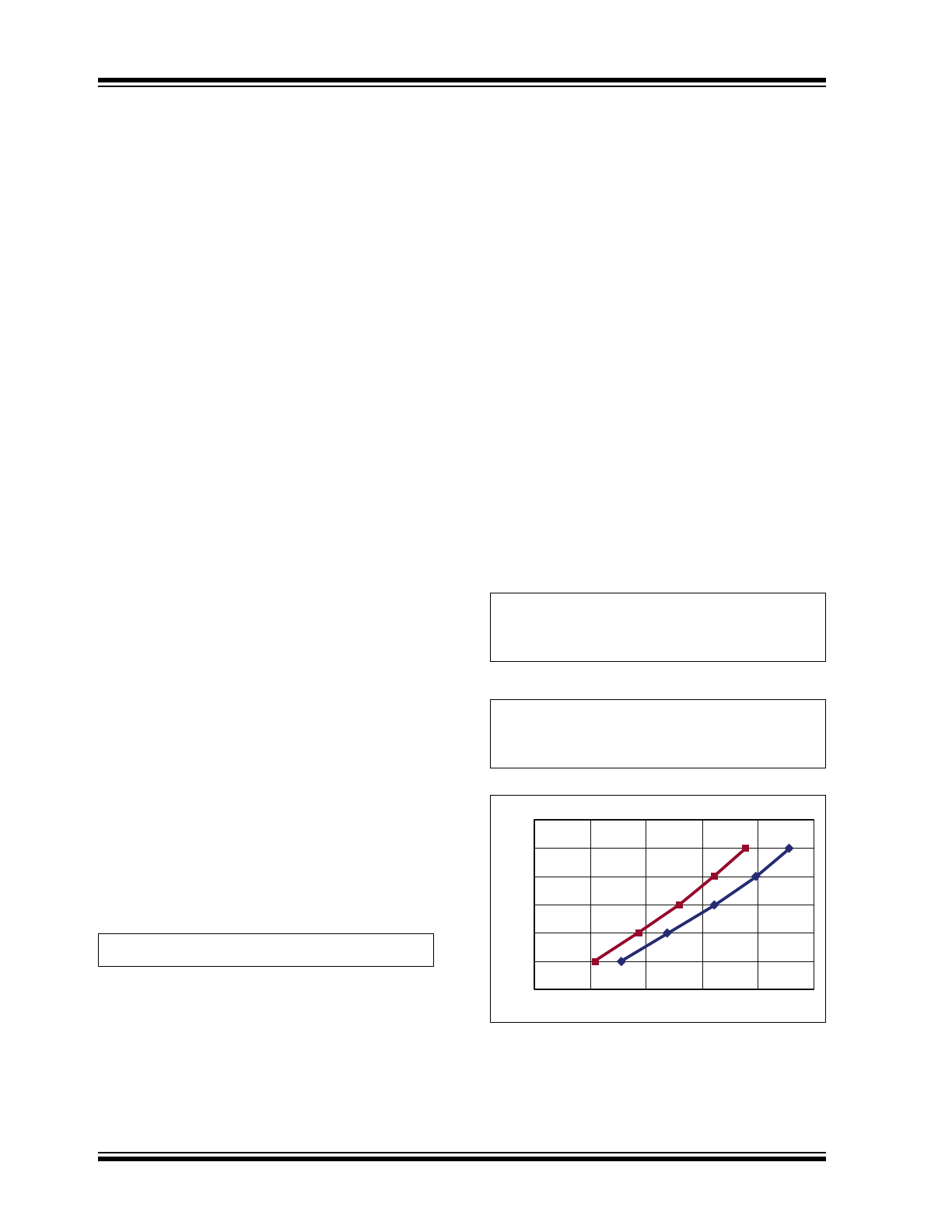

data is shown in

Figure 3-1

for ambient temperatures of

25°C and 85°C.

Assume an ambient temperature of 85°C. Provided

that the IC is driving a 15 nC gate charge FET at

200 kHz, the total input current is estimated to be

4.5 mA when

Equation 3-1

is used. At this input

current, the minimum voltage drop from

Figure 3-1

would be around V

DROP

= 1.25V. However, before the

IC starts switching, the current drawn would have been

1.5 mA. At this current level, the voltage drop would be

approximately V

DROP1

= 0.3V. Thus, the start/stop V

IN

voltages could be computed as demonstrated in

Equation 3-2

and

Equation 3-3

below:

EQUATION 3-2:

V

IN START

UVLO

MAX

V

DROP1

+

=

7V 0.3V

+

=

7.3V

=

EQUATION 3-3:

V

IN STOP

UVLO

MAX

UVLO

–

V

DROP

+

=

7V 0.5V

–

1.25V

+

=

7.75V

=

Minimum Voltage Drop vs. I

IN

0

0.5

1

1.5

2

2.5

3

0 2 4 6 8 10

I

IN

(mA)

M

in

im

u

m V

o

lt

a

g

e D

ro

p (

V

)

T

A

= 25

O

C

T

A

= 85

O

C

FIGURE 3-1:

Headroom vs. Input Current.

In this case, the gate driver draws too much current and

V

INSTART

is less than V

INSTOP

. When this happens, the

IC will oscillate between ON and OFF if the input

2016 Microchip Technology Inc.

DS20005583A-page 9

HV9912

voltage is between the start and stop voltages.

Therefore, it is recommended that the input voltage be

kept higher than V

INSTOP

.

3.4

Reference

HV9912 includes a 2% accurate 1.25V reference,

which can be used as the reference for the output

current as well as to set the switch current limit. The

reference is buffered so that it can deliver a maximum

of 500 µA external current to drive the external circuitry.

The reference should be bypassed with at least a 10 nF

low-ESR capacitor.

Note:

To avoid abnormal Startup conditions, the

bypass capacitor at the REF pin should

not exceed 0.1 µF.

3.5

Oscillator

Connecting the resistor between R

T

and GND will

program the time period.

In both cases, resistor R

T

sets the current, which

charges an internal oscillator capacitor. The capacitor

voltage ramps up linearly. When the voltage increases

beyond the internal set voltage, a comparator triggers

the set input of the internal SR flip-flop. This starts the

next switching cycle. The time period of the oscillator

can be computed as shown in

Equation 3-4

.

EQUATION 3-4:

T

S

R

T

18pF

3.6

Synchronization

The SYNC pin is an input/output (I/O) port to a

fault-tolerant peer-to-peer and/or master clock

synchronization circuit. For synchronization, the SYNC

pins of multiple HV9912-based converters can be

connected together and may also be connected to the

open drain output of a master clock. When connected

in this manner, the oscillators will lock to the device with

the highest operating frequency. When synchronizing

multiple ICs, it is recommended that the same timing

resistor (corresponding to the switching frequency) be

used in all the HV9912 circuits.

On rare occasions, given the length of the connecting

lines for the SYNC pins, a resistor between SYNC and

GND may be required to damp any ringing due to

parasitic capacitances. It is recommended that the

resistor chosen be greater than 300 kΩ.

When synchronized in this manner, a permanent High

or Low condition on the SYNC pin will result in a loss of

synchronization, but the HV9912-based converters will

continue to operate at their individually set operating

frequencies. Since loss of synchronization will not

result in total system failure, the SYNC pin is

considered fault tolerant.

3.7

Slope Compensation

For Continuous Conduction mode converters operating

in the Constant Frequency mode, slope compensation

becomes necessary to ensure stability of the Peak

Current mode controller if the operating duty cycle is

greater than 50%. Choosing a slope compensation

which is one half of the down slope of the inductor

current ensures that the converter will be stable for all

duty cycles.

Slope compensation can be programmed by two

resistors R

SLOPE

and R

SC

. Assuming a down slope of

DS (A/µs) for the inductor current, the slope

compensation resistors can be computed as illustrated

in

Equation 3-5

.

EQUATION 3-5:

R

SC

R

SLOPE

DS 10

6

T

S

R

CS

10

--------------------------------------------------------------------------

=

Where R

CS

is the current sense resistor which

senses the switching FET current

Note:

The maximum current that can be sourced

out of the SC pin is 100 µA. This limits the

minimum value of the R

SLOPE

resistor to

25 kΩ. If the equation for slope

compensation produces a R

SLOPE

less

than this value, then R

SC

would have to be

reduced accordingly. It is recommended

that R

SLOPE

be chosen within the range of

25 kΩ to 50 kΩ.

3.8

Current Sense

The current sense input of the HV9912 includes a

built-in 100 ns (minimum) blanking time to prevent

spurious turn-off due to the initial current spike when

the FET turns on.

The HV9912 includes two high-speed comparators—

one is used during normal operation and the other is

used to limit the maximum input current during Input

Undervoltage or Overload conditions.

The IC includes an internal resistor divider network,

which steps down the voltage at the COMP pin by a

factor of 15. This stepped-down voltage is given to one

of the comparators as the current reference. The

reference to the other comparator, which acts to limit

the maximum inductor current, is given externally.

It is recommended that the sense resistor R

CS

be

chosen so as to provide about 250 mV current sense

signal.

HV9912

DS20005583A-page 10

2016 Microchip Technology Inc.

3.9

Current Limit

Current limit has to be set by a resistor divider from the

1.25V reference available on the IC. Assuming a

maximum operating inductor current I

pk

(including

ripple current), the maximum voltage at the C

LIM

pin

can be set as shown in

Equation 3-6

.

EQUATION 3-6:

V

CLIM

1.2 I

PK

R

CS

5 R

CS

R

SLOPE

+

0.9

Note that this equation assumes a current limit at 120%

of the maximum input current. Also, if V

CLIM

is greater

than 450 mV, the saturation of the internal opamp will

determine the limit on the input current rather than the

C

LIM

pin. In such a case, the sense resistor R

CS

should

be reduced until V

CLIM

reduces below 550 mV.

It is recommended that no capacitor be connected

between C

LIM

and GND.

3.10

Internal 1 MHz Transconductance

Amplifier

HV9912 includes a built-in 1 MHz transconductance

amplifier with tri-state output, which can be used to

close the feedback loop. The output current sense

signal is connected to the FDBK pin and the current

reference is connected to the I

REF

pin.

The output of the opamp is controlled by the signal

applied to the PWMD pin. When PWMD is high, the

output of the opamp is connected to the COMP pin.

When PWMD is low, the output is left open. This

enables the integrating capacitor to hold the charge

when the PWMD signal has turned off the gate drive.

When the IC is enabled, the voltage on the integrating

capacitor will force the converter into Steady state

almost instantaneously.

The output of the opamp is buffered and connected to

the current sense comparator using a 15:1 divider. The

buffer helps to prevent the integrator capacitor from

discharging during the PWM Dimming state.

3.11

PWM Dimming

PWM dimming can be achieved by driving the PWMD

pin with a TTL-compatible square wave source. The

PWM signal is connected internally to three different

nodes—the transconductance amplifier, the FAULT

output and the GATE output.

When the PWMD signal is high, the GATE and FAULT

pins are enabled and the transconductance opamp’s

output is connected to the external compensation

network. Thus, the internal amplifier controls the output

current. When the PWMD signal goes low, the output of

the transconductance amplifier is disconnected from

the compensation network. Therefore the integrating

capacitor maintains the voltage across it. The GATE is

disabled, so the converter stops switching and the

FAULT pin goes low, turning off the disconnect switch.

The output capacitor of the converter determines the

converter’s PWM dimming response because the

capacitor has to get charged and discharged whenever

the PWMD signal goes high or low. In the case of a

buck converter, since the inductor current is

continuous, a very small capacitor is used across the

LEDs. This minimizes the effect of the capacitor on the

converter’s PWM dimming response. However, in the

case of a boost converter, the output current is

discontinuous, and a very large output capacitor is

required to reduce the ripple in the LED current. Thus,

this capacitor will have a significant impact on the PWM

dimming response. By turning off the disconnect switch

when PWMD goes low, the output capacitor is

prevented from being discharged. This dramatically

improves the boost converter’s PWM dimming

response.

Note:

In case of Continuous Conduction mode

boost converters, disconnecting the

capacitor might cause a sudden spike in

the capacitor voltage as the energy in the

inductor is dumped into the capacitor. This

increase in the capacitor voltage might

cause the OVP comparator to trip if the

OVP point is set too close to the maximum

operating voltage. Thus, either the capac-

itor has to be larger to absorb this energy

without increasing the capacitor voltage

significantly or the OVP set point has to be

increased.

3.12

False Triggering of the

Short-Circuit Comparator During

PWM Dimming

During PWM dimming, the parasitic capacitance of the

LED string causes a spike in the output current when

the disconnect FET is turned on. With the HV9911, this

parasitic spike in the output current makes the IC

falsely detect an Overcurrent condition and shut down.

To prevent this false shutdown, an R-C filter is used at

the FDBK pin to filter this spike.

To prevent false triggering in the HV9912, there is a

built-in 500 ns blanking network for the short-circuit

comparator, which eliminates the need for the external

R-C low-pass filter. This blanking network is activated

when the PWMD input goes high. Thus, the

short-circuit comparator will not see the spike in the

LED current during the PWM Dimming turn-on

transition. Once the blanking timer is completed, the

short-circuit comparator will start monitoring the output

current. Thus, the total delay time for detecting a

short-circuit will depend on the condition of the PWMD

input.