2017 Microchip Technology Inc.

DS20005692A-page 1

HV9801A

Features

• Four-level Switch Dimming

• Highly Accurate Current Regulator

• Output Overcurrent or Short-circuit Protection

• IC Overtemperature Protection

Applications

• Switch-dimmable LED Bulbs and Fixtures

General Description

The HV9801A LED driver is ideally suited for

switch-dimmable applications using LED bulbs and

fixtures.

Through switch dimming, the lamp can be adjusted to

four discrete brightness levels by rapid cycling of the

light switch. The brightness levels are traversed in an

up-and-down manner. Brightness resumes at the

highest level when power is removed for more than a

second.

The device can be powered directly from rectified AC

through an internal V

DD

regulator rated at 450V.

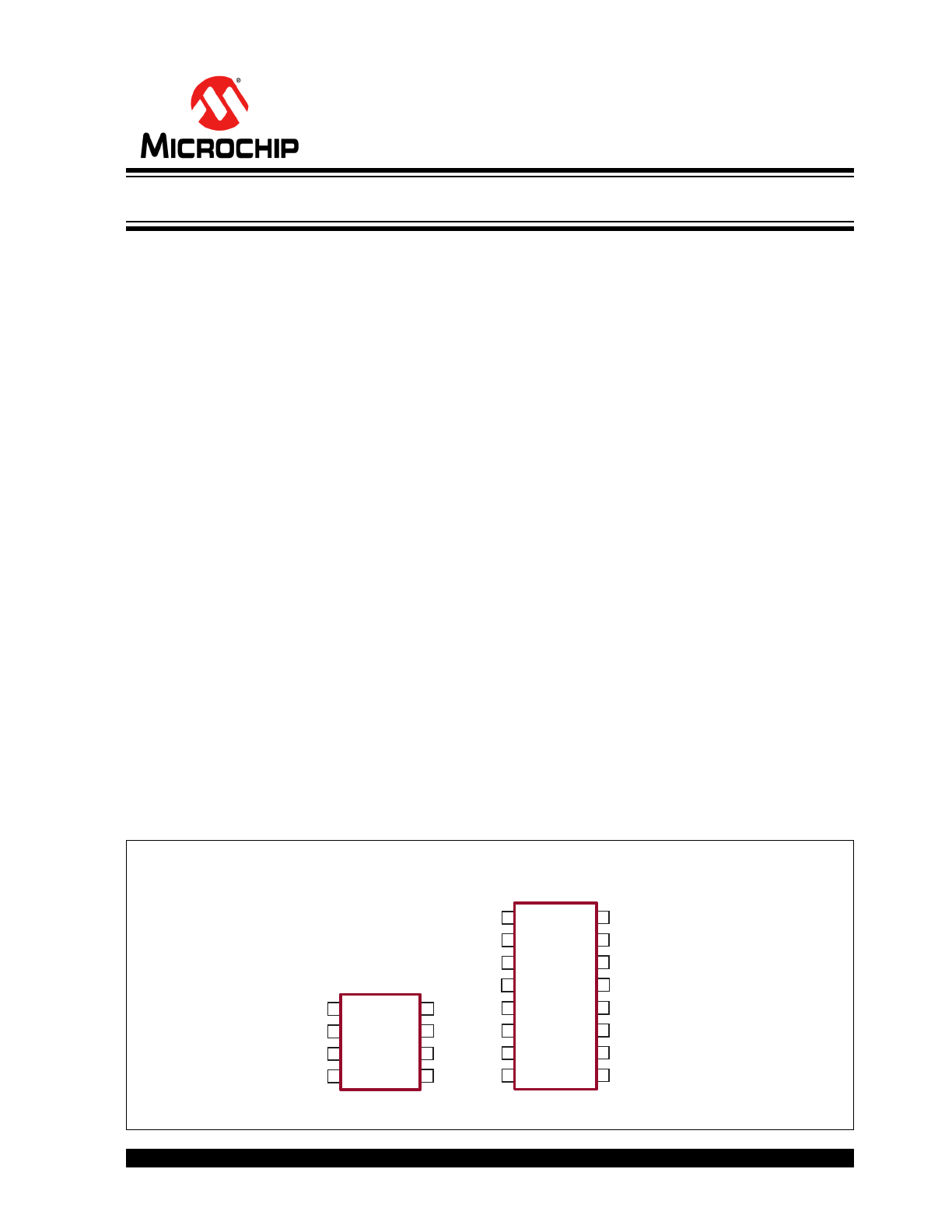

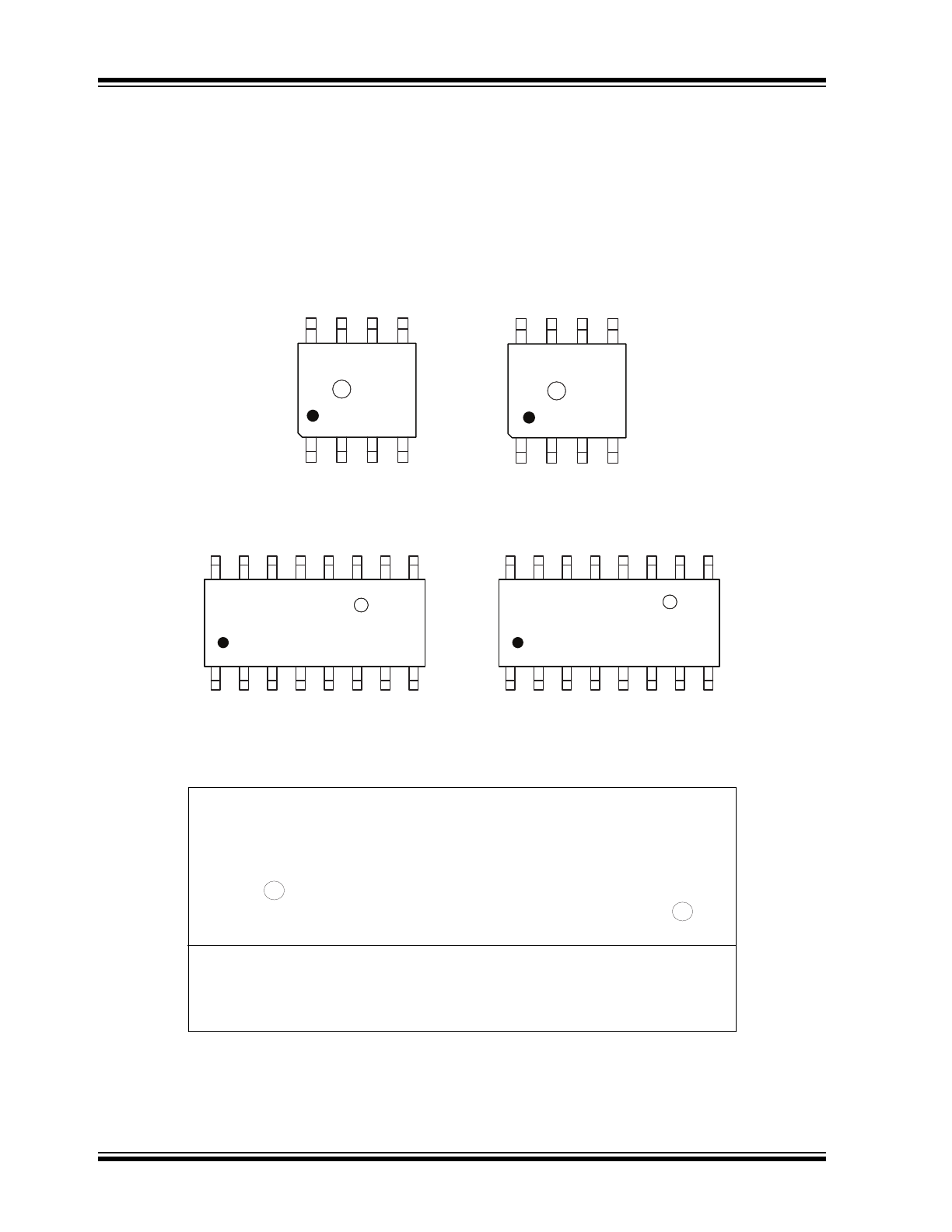

Package Type

See

Table 2-1

for pin information.

8-lead SOIC

(Top view)

16-lead SOIC

(Top view)

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

8

7

6

5

1

2

3

4

VIN

CS

GND

GATE

RT

DNC

VDD

DNC

VIN

DNC

DNC

CS

GND

DNC

DNC

GATE

DNC

DNC

RT

DNC

VDD

DNC

DNC

DNC

s

Switch-Dimmable LED Driver

VIN

VDD

CS

RT

GATE

HV9801A

250mV

440mV

VDD Regulator

Current Mirror from VDD Rail

Leading

Edge

Blanking

S Q

R Q

OR

Average

Current

Regulator

OFF

Time

Generator

OTP

AND

UVLO

GND

Hiccup

HV9801A

DS20005692A-page 2

2017 Microchip Technology Inc.

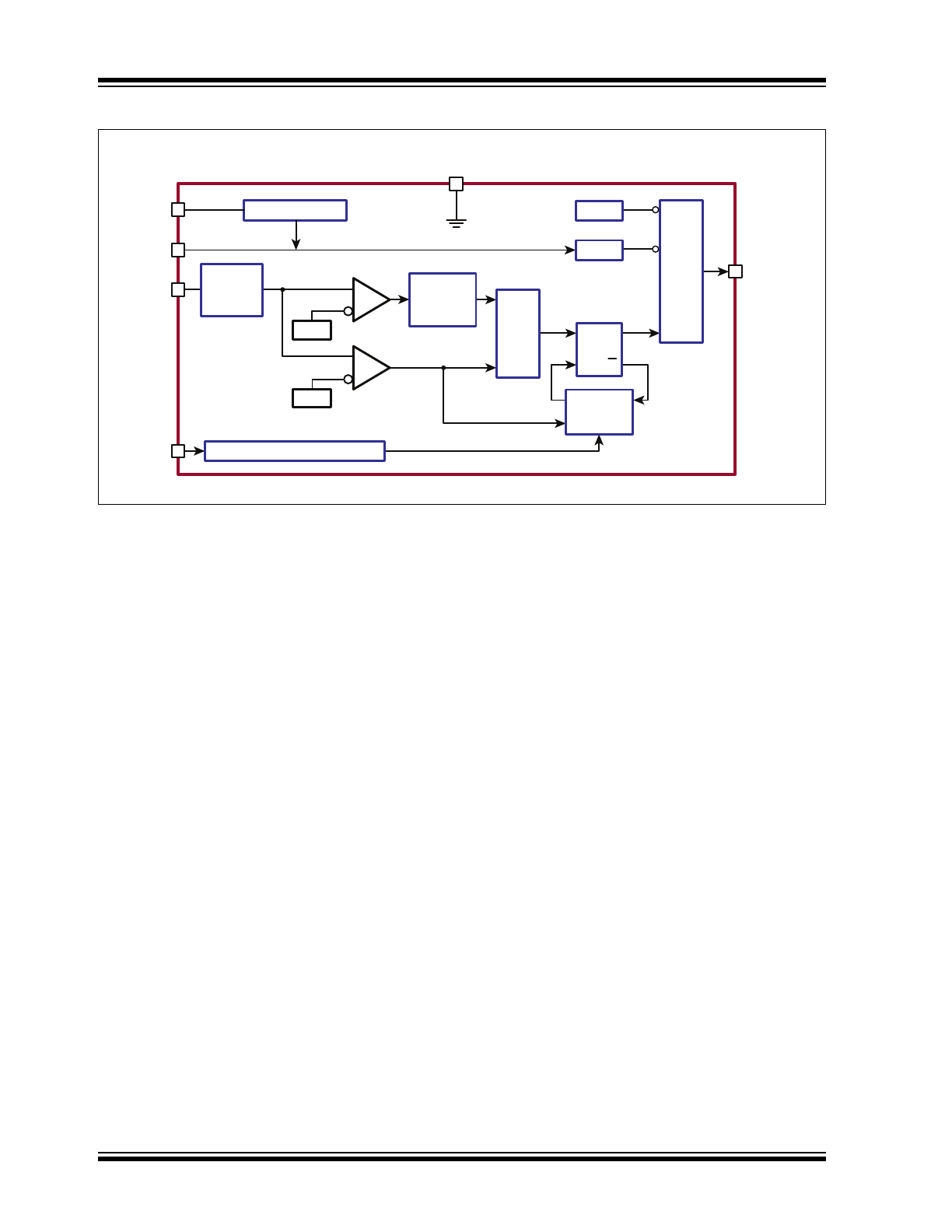

Functional Block Diagram

2017 Microchip Technology Inc.

DS20005692A-page 3

HV9801A

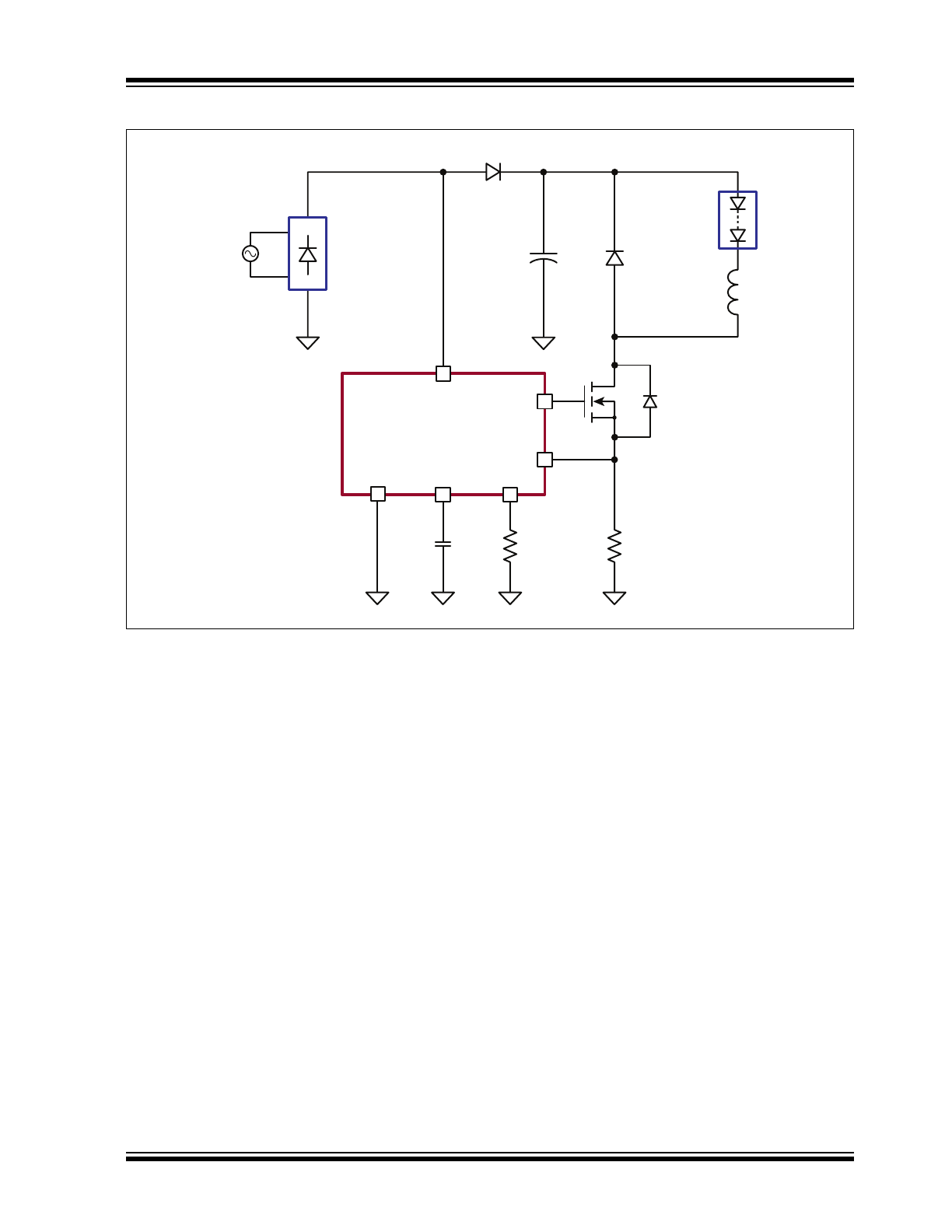

Typical Application Circuit

VIN

GATE

CS

GND VDD RT

HV9801A

C

DD

R

T

R

CS

L

AC

VIN

BUS

HV9801A

DS20005692A-page 4

2017 Microchip Technology Inc.

1.0

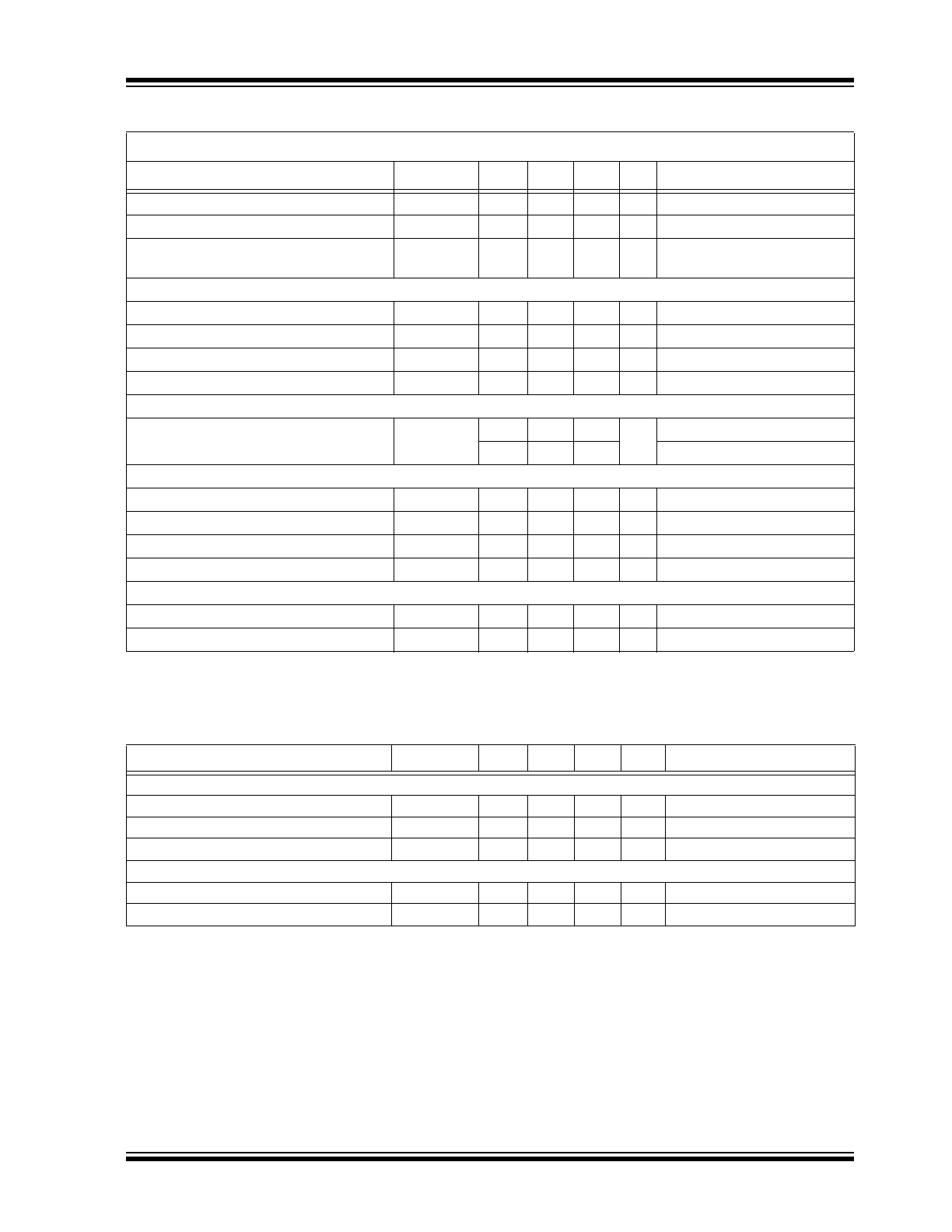

ELECTRICAL CHARACTERISTICS

Absolute Maximum Ratings†

V

IN

.......................................................................................................................................................................... 470V

V

DD

........................................................................................................................................................................... 12V

V

CS

, V

GATE

....................................................................................................................................–0.3V to (V

DD

+0.3V)

Junction Temperature Range, T

J

......................................................................................................... –40°C to +150°C

Storage Temperature Range, T

S

......................................................................................................... –65°C to +150°C

Power Dissipation (T

A

= 25 °C):

8-lead SOIC

............................................................................................................................................ 650 mW

16-lead SOIC

........................................................................................................................................ 1000 mW

† Notice: Stresses above those listed under “Absolute Maximum Ratings” may cause permanent damage to the

device. This is a stress rating only, and functional operation of the device at those or any other conditions above those

indicated in the operational sections of this specification is not intended. Exposure to maximum rating conditions for

extended periods may affect device reliability.

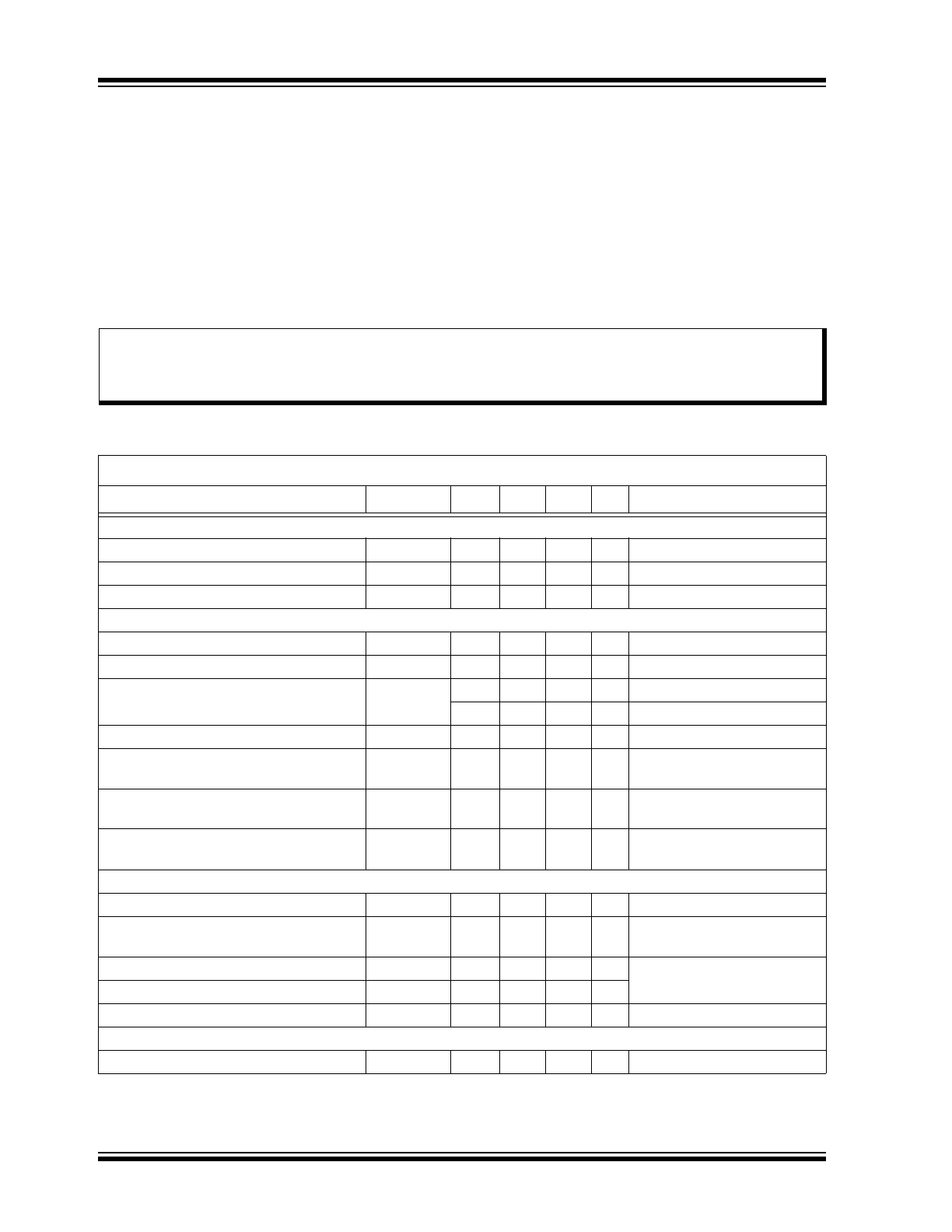

ELECTRICAL CHARACTERISTICS

Electrical Specifications: Specifications are at T

A

= 25°C, V

IN

= 15V unless otherwise noted.

Parameter

Sym.

Min.

Typ.

Max. Unit

Conditions

INPUT

Input Voltage

V

IN

15

—

450

V

Note 2

Input Current

I

IN

—

1

2

mA

Supply Current, OTP Shutdown

I

IN, OT

—

—

500

μA

Note 1

V

DD

REGULATOR

Undervoltage Lockout Threshold

V

UVLO

6.45

6.7

7.1

V

V

IN

rising (

Note 2

)

Undervoltage Lockout Hysteresis

∆V

UVLO

—

500

—

mV V

IN

falling

Maximum Input Current, Limited by UVLO

I

UVLO

3.5

—

—

mA T

A

= 25°C (

Note 1

)

1.5

—

—

mA T

A

= 125°C (

Note 1

)

Output Voltage

V

DD

7.25

7.5

7.75

V

C

GATE

= 500 pF, R

T

= 226 kΩ

Line Regulation

∆V

DD, LINE

—

—

1

V

V

IN

= 15V to 450V,

C

GATE

= 500 pF, R

T

= 226 kΩ

V

DD

Voltage Margin

∆V

DD(UV)

500

—

—

mV

∆V

DD(UV)

= V

DD

–V

UVLO, FALL

(

Note 2

)

Load Regulation

∆V

DD, LOAD

—

—

100

mV

I

VDD

= 0 mA to 1 mA,

C

GATE

= 500 pF, R

T

= 226 kΩ

SWITCH DIMMING

Supply Current after Power Loss

I

VDDX

—

—

700

μA

Note 2

Undervoltage Lockout during V

IN

Power Loss

V

UVLO, DIM

—

3.5

—

V

V

IN

falling

Power Loss, Qualification Time

T

PL1

—

60

—

ms V

IN

falling below V

UVLO

(

Note 1

)

Power Loss, Time to Reset

T

PL2

—

1

—

s

PWM Dimming Frequency

F

PWM

—

1.2

—

kHz

LED CURRENT REGULATOR

Current Sense Threshold

V

CST

236

250

256

mV

Note 2

Note 1: Determined by characterization; not production tested

2: Specifications apply over the full operating ambient temperature range of –40°C < T

A

< +125°C.

2017 Microchip Technology Inc.

DS20005692A-page 5

HV9801A

Leading Edge Blanking Time

T

LEB

110

—

260

ns

Note 2

Minimum On-time

T

ONX

—

—

760

ns

V

CS

= V

CST

+ 30 mV

Maximum Duty Cycle Maintaining

Regulation

D

MAX

80

—

—

%

LED current falls beyond this

duty cycle

SHORT-CIRCUIT PROTECTION

Hiccup Threshold

V

CSH

—

440

—

mV

V

CS

High to Gate Low Delay

T

DLY

—

—

180

ns

V

CS

= V

CSH

+ 30 mV

Hiccup Time

T

SCH

—

750

—

μs

Minimum On-time

T

ONXSC

—

—

430

ns

V

CS

= V

DD

T

OFF

TIMER

Off-time

T

OFF

32

40

48

μs

R

T

= 1 MΩ

8

10

12

R

T

= 226 kΩ

GATE DRIVER

Sourcing Current

I

SRC

165

—

—

mA V

GATE

= 0V

Sinking Current

I

SINK

165

—

—

mA V

GATE

= V

DD

Rise Time

t

r

—

30

50

ns

C

GATE

= 500 pF

Fall Time

t

f

—

30

50

ns

C

GATE

= 500 pF

OVERTEMPERATURE PROTECTION

Trip Temperature

T

TRIP

—

140

—

°C

Note 1

Hysteresis

∆T

TRIP

—

20

—

°C

Note 1

TEMPERATURE SPECIFICATIONS

Parameter

Sym.

Min.

Typ.

Max.

Unit

Conditions

TEMPERATURE RANGE

Operating Ambient Temperature

T

A

–40

—

+125

°C

Maximum Junction Temperature

T

J

–40

—

+150

°C

Storage Temperature

T

S

–65

—

+150

°C

PACKAGE THERMAL RESISTANCE

8-lead SOIC

JA

—

101

—

°C/W

16-lead SOIC

JA

—

83

—

°C/W

ELECTRICAL CHARACTERISTICS (CONTINUED)

Electrical Specifications: Specifications are at T

A

= 25°C, V

IN

= 15V unless otherwise noted.

Parameter

Sym.

Min.

Typ.

Max. Unit

Conditions

Note 1: Determined by characterization; not production tested

2: Specifications apply over the full operating ambient temperature range of –40°C < T

A

< +125°C.

HV9801A

DS20005692A-page 6

2017 Microchip Technology Inc.

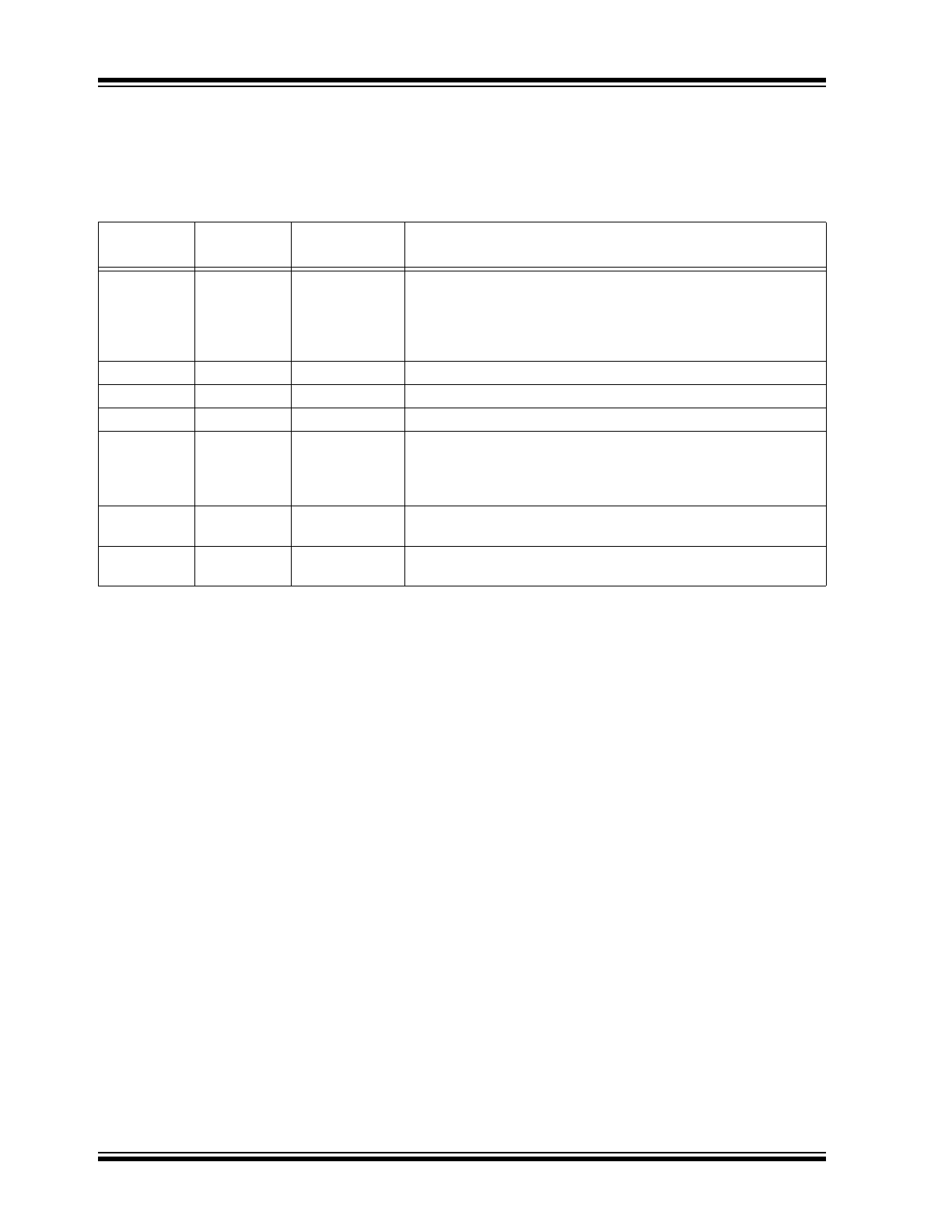

2.0

PIN DESCRIPTION

The details on the pins of HV9801A are listed on

Table 2-1

. See location of pins in

Package Types

.

TABLE 2-1:

PIN FUNCTION TABLE

Pin Name

8-lead SOIC

Pin Number

16-lead SOIC

Pin Number

Description

VIN

1

1

Connect to bridge rectifier output. Supplies power to the V

DD

regulator. Detects light switch power-off event through loss of

bridge rectifier output voltage. Do not connect excessive capaci-

tance before or after the bridge to allow V

IN

to drop rapidly after

loss of power.

CS

2

4

Current sense input

GND

3

5

Ground

GATE

4

8

Gate driver output

VDD

6

12

V

DD

regulator output. Connect a high-frequency bypass and a

hold-up capacitor at V

DD

. Bypass capacitor to be 100 nF minimum.

See

Section 3.0 “Application Information”

for hold-up capaci-

tance.

RT

8

14

Off-time programming input. Connect programming resistor to

GND.

DNC

5, 7

2, 3, 6, 7, 9, 10,

11, 13, 15, 16

Stands for “Do Not Connect.”

2017 Microchip Technology Inc.

DS20005692A-page 7

HV9801A

3.0

APPLICATION INFORMATION

3.1

Current Control

3.1.1

CONTINUOUS CONDUCTION

MODE (CCM)

The HV9801A is designed to control a buck converter

operating in CCM.

Continuous Conduction Mode operation is

characterized by converter operation with non-zero

inductor current throughout the switching cycle. Such

operation can be achieved by proper selection of the

inductance.

3.1.2

LED CURRENT

The HV9801A regulates the LED current with an

accuracy far superior to that of competing Peak Current

mode controllers.

Average LED current is set by the current sense

resistor R

CS

and the current regulator reference

voltage. See

Equation 3-1

and

Equation 3-2

.

EQUATION 3-1:

V

I R

=

EQUATION 3-2:

250mV

I

LED

R

CS

=

For example, a 2Ω resistor corresponds to a 125 mA

(average) LED current.

3.1.3

CURRENT CONTROL

PERFORMANCE

The control method of the HV9801A virtually eliminates

the regulation errors associated with Peak Current

mode controllers, such as errors caused by inductor

tolerance, propagation delay of the current sense

comparator, tolerance in the oscillator frequency or

off-timer and changes in line and load voltage.

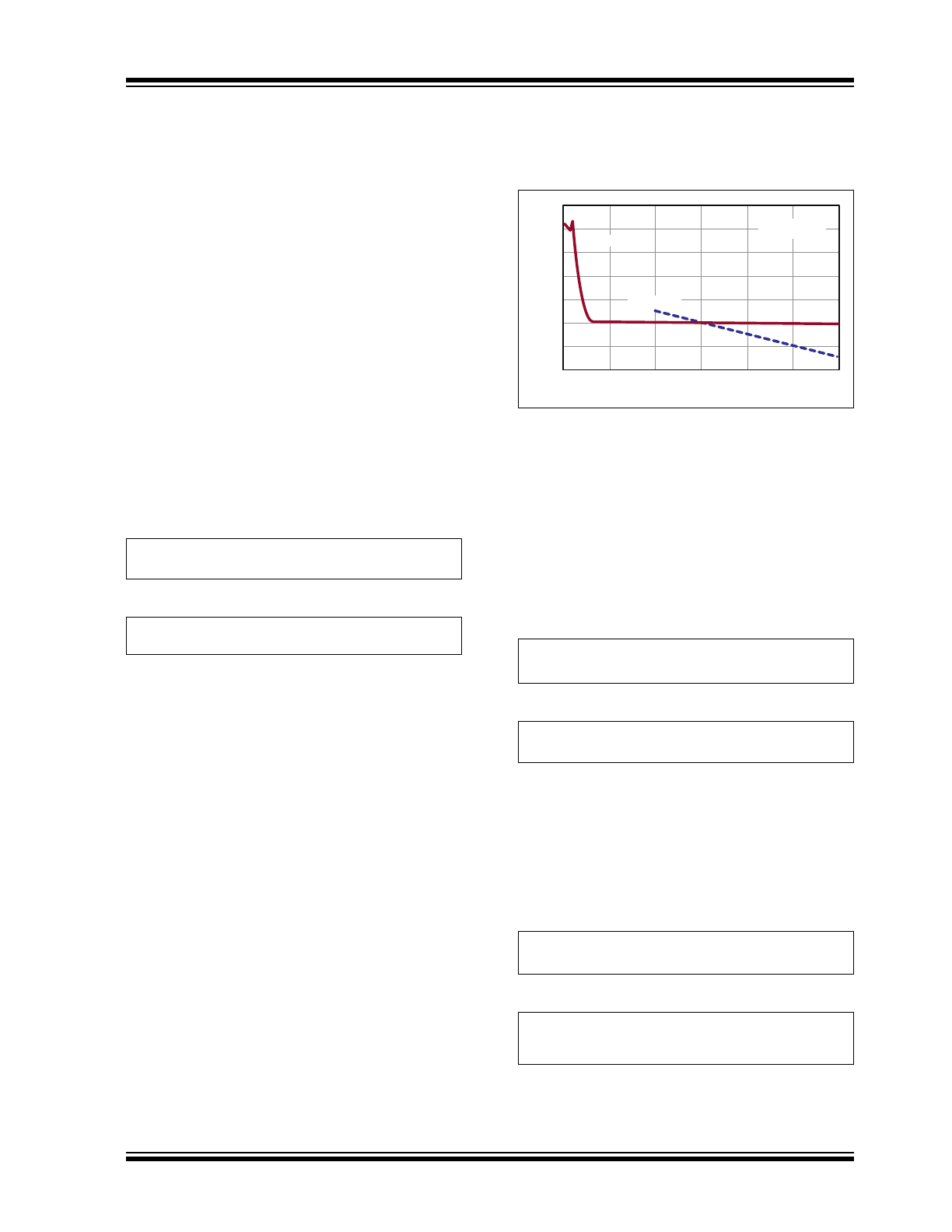

Figure 3-1

compares the load regulation of the

HV9801A and that of a device with peak current

control. The graph clearly shows the difference in load

regulation between the HV9801A and the HV9910B,

which is a peak current regulator.

0.60

0.55

0.50

0.45

0.40

0.35

0.30

0.25

0 10 20 30 40 50 60

HV9910B

HV9801A

V

IN

= 170VDC

Output Voltage, V

LED Current,

A

FIGURE 3-1:

Output Characteristics of the

HV9801A LED Driver.

3.2

Duty Cycle, Off-time, On-time and

Inductor

3.2.1

DUTY CYCLE

The duty cycle (D) is related to the load voltage (V

LED

)

and input voltage (V

BUS

) by the simple relation shown

in

Equation 3-3

and

Equation 3-4

.

EQUATION 3-3:

V

OUT

D V

IN

=

EQUATION 3-4:

V

LED

D V

BUS

=

3.2.2

OFF-TIME

The HV9801A operates with constant off-time control,

which avoids subharmonic oscillation.

Switching period and switching frequency are related to

on-time and off-time as shown in

Equation 3-5

and

Equation 3-6

.

EQUATION 3-5:

T

SW

T

ON

T

OFF

+

=

EQUATION 3-6:

F

SW

1

T

SW

----------

=

HV9801A

DS20005692A-page 8

2017 Microchip Technology Inc.

On-time is related to off-time and duty cycle. See

Equation 3-7

.

EQUATION 3-7:

D

T

ON

T

ON

T

OFF

+

-----------------------------------

=

T

ON

D 1 D

–

T

OFF

=

With a given T

OFF

, the HV9801A dynamically adjusts

T

ON

to regulate the LED current. Specifically, T

ON

adapts to the duty cycle associated with the given V

BUS

and V

LED

.

3.2.3

OFF-TIME PROGRAMMING

Off-time is programmed by the R

T

resistor as illustrated

in

Equation 3-8

.

EQUATION 3-8:

T

OFF

A R

T

B

+

=

Where: A = 40 ps / Ω and B = 300 ns

For instance, a 200 kΩ resistor corresponds to 8.3 μs

off-time.

An acceptable range for R

T

is 30 kΩ to 1 MΩ,

corresponding to an off-time range between 1.5 µs and

40.3 µs.

3.2.4

INDUCTOR

Because the converter should operate in CCM, the

inductor current should not fall to zero within a

switching cycle and the inductor current ripple should

be sized accordingly.

A common choice for peak-to-peak inductor current

ripple (PPR) is 30% to 40% of nominal LED current.

Inductance can be calculated from the current drop

during off-time as shown in

Equation 3-9

and

Equation 3-10

.

EQUATION 3-9:

L

I

V

T

=

EQUATION 3-10:

L PPR I

LED

V

LED

T

OFF

=

For example, 30% PPR on 350 mA average current

equates to 105 mA ripple, which together with 5 µs

off-time and 30V LED string voltage corresponds to

1.43 mH inductance.

A design with 30V LED voltage and 150V bus voltage

corresponds to a 20% duty cycle, while a 120V bus

voltage coincides with a 25% duty cycle. A 20% duty

cycle corresponds to 1.25 µs on-time, and a 25% duty

cycle corresponds to 1.67 µs on-time. Hence, the

switching frequency is 160 kHz at 150V bus voltage

and 150 kHz at 120V bus voltage.

3.2.5

MAXIMUM DUTY CYCLE

Duty cycle should be limited to the specified maximum

of 80%. Accordingly, the targeted LED string voltage

and the bus voltage are limited to the same ratio.

Operation at a larger desired duty cycle than the

maximum duty cycle results in an LED current lower

than programmed.

3.2.6

MINIMUM DUTY CYCLE

Duty cycle is limited on the low side by the minimum

on-time specification (760 ns). Operation at a smaller

desired on-time than the minimum causes the LED

current to exceed the programmed value.

LED string voltage cannot be made arbitrarily low.

Minimum LED string voltage can be determined with

Equation 3-11

.

EQUATION 3-11:

D

MIN

T

ONX

T

OFF

T

ONX

+

--------------------------------------

=

V

LED

D

MIN

V

BUS

=

For instance, with 5 µs off-time, the duty cycle should

be kept above 13%. Such a duty cycle corresponds to

an LED string voltage of 19.5V at 150V bus voltage.

A design that needs a lower LED string voltage

requires a longer off-time.

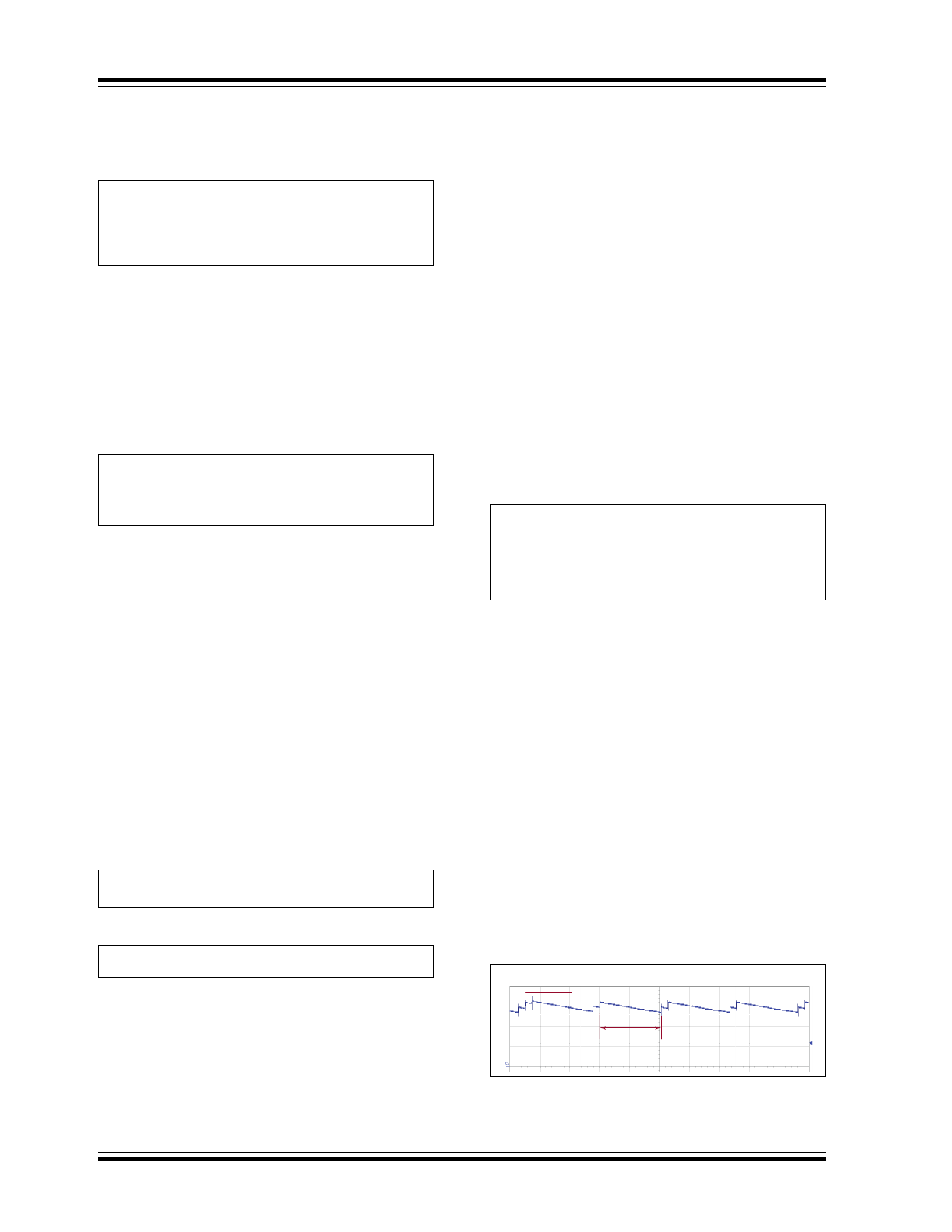

3.2.7

SHORT-CIRCUIT PROTECTION

An increase in the LED current sense signal above

440 mV (176% of nominal) trips the short-circuit

comparator, thereby causing the converter to switch to

Hiccup mode. In Hiccup mode, off-time is lengthened to

about 750 µs to allow the inductor current to drop to a

safe level.

Without the extended off-time, the inductor current

increases with every switching cycle, causing an

overcurrent damage to the converter.

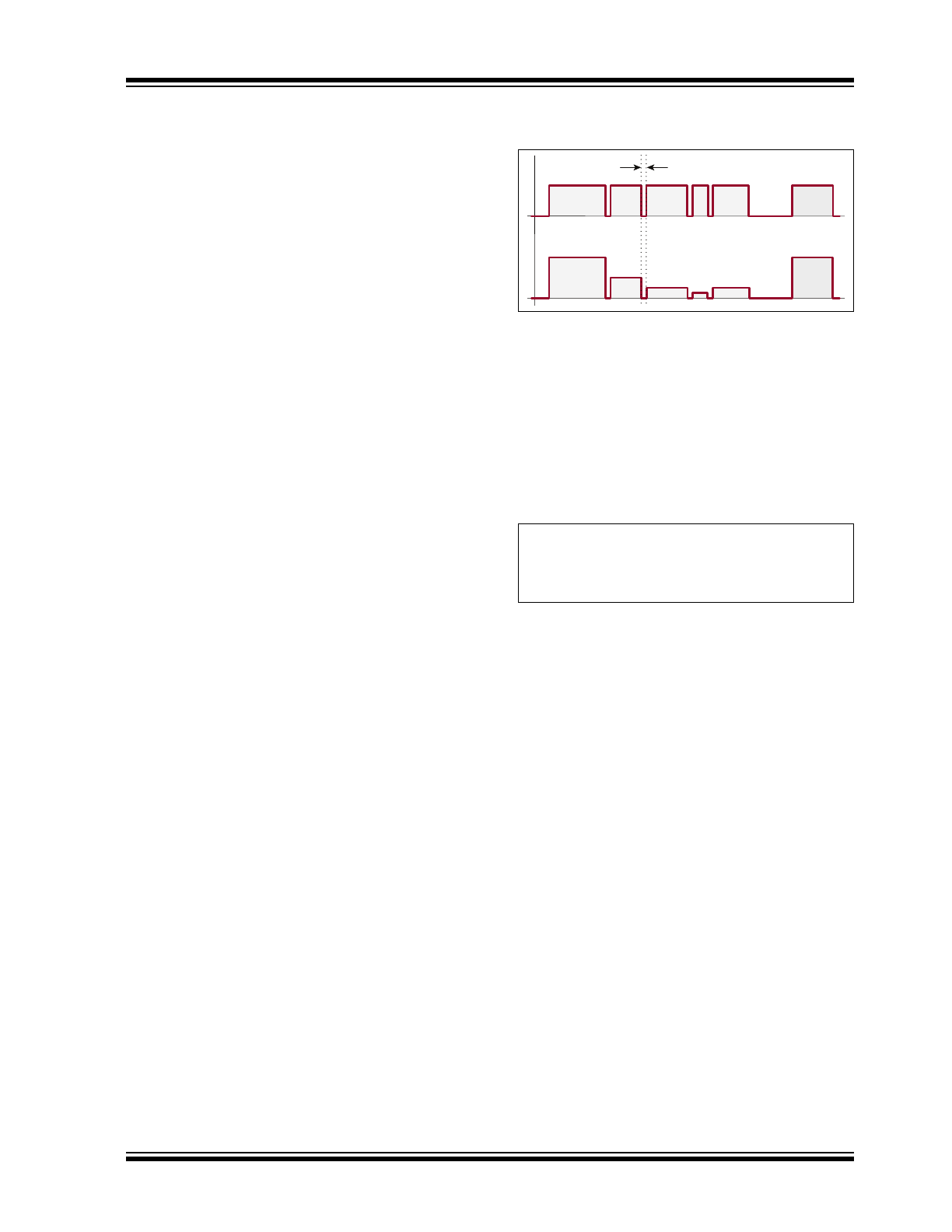

The off-time extension can be observed in

Figure 3-2

below.

~750µs

440mV/R

CS

S

FIGURE 3-2:

Short-circuit Inductor

Current.

2017 Microchip Technology Inc.

DS20005692A-page 9

HV9801A

3.2.8

LEADING EDGE BLANKING

The MOSFET drain current and the current sense

signal exhibit a spike at the start of a switching cycle,

which arises from the MOSFET gate charging current

and the current required for discharging the MOSFET

drain node. These two currents typically exceed the

inductor by quite a margin.

The current sense signal is blanked at the start of the

switching cycle in order to avoid a premature trigger of

the current sense and the short-circuit protection

comparators.

3.2.9

V

DD

REGULATOR

The V

DD

regulator generates a source of regulated

voltage for operation of internal and external circuits

from the power applied at the V

IN

pin. Alternatively, the

V

DD

voltage can be supplied from a source directly

connected to the V

DD

pin.

3.3

Switch Dimming

3.3.1

GENERAL

Lamp brightness can be adjusted to one of four

discrete levels by rapidly cycling power with the light

switch. The brightness levels are traversed in an

up-and-down manner, the four levels being 100%,

50%, 25% and 12.5%. Brightness resumes at the

highest level when power is removed for more than a

second.

Reduction of LED current is accomplished through

PWM dimming with a PWM dimming frequency of

about 1 kHz. The PWM frequency is generated by an

internal oscillator, and the PWM duty cycle is controlled

by digital logic.

Turning the light switch off and on within one second

adjusts LED current to the next level in each dimming

step. The direction of dimming depends on the existing

position in the dimming sequence. The illustration in

Figure 3-3

shows more details. The sequence starts at

100% and adjusts to the next lower level by the first

dimming step and then adjusts to the next lower level

by the next dimming step. Upon reaching the lowest or

highest level, the direction of the sequence reverses.

Therefore, the actual overall dimming sequence is

100%, 50%, 25%, 12.5%, 25%, 50%, 100%, and the

sequence repeats as the dimming steps continue.

When power is removed for more than one second, the

dimming sequence is terminated and the brightness is

reset to 100% upon turn-on of the light switch.

OFF/ON cycle time 1second (max.)

100%

50%

25% 12.5% 25%

100%

Brightness

AC Line Power

ON

FIGURE 3-3:

LED Brightness and AC

Line Power.

3.3.2

V

DD

CAPACITOR

The V

DD

voltage should be maintained for at least one

second and above the 3.5V level after loss of V

IN

power

to allow certain timing circuits to function.

The minimum V

DD

capacitance required can be

calculated with

Equation 3-12

.

EQUATION 3-12:

C

V

I

T

=

C

DD

7.5V 3.5V

–

I

VDDX

1s

=

With 700 µA of I

VDDX

the bypass capacitance should be

175 µF.

3.3.3

DETECTION OF POWER CYCLING

The presence of AC line power is detected at the V

IN

pin. To this end, loss of AC power should result in a

rapidly falling voltage at the output of the bridge

rectifier.

The V

IN

voltage drops due to the current draw from the

V

DD

regulator. In order to facilitate a quick drop in

voltage, a diode should be added to isolate the bus

capacitor from the V

IN

pin as shown in the

Typical

Application Circuit

.

HV9801A

DS20005692A-page 10

2017 Microchip Technology Inc.

4.0

PACKAGING INFORMATION

4.1

Package Marking Information

Legend: XX...X

Product Code or Customer-specific information

Y

Year code (last digit of calendar year)

YY

Year code (last 2 digits of calendar year)

WW

Week code (week of January 1 is week ‘01’)

NNN

Alphanumeric traceability code

Pb-free JEDEC

®

designator for Matte Tin (Sn)

*

This package is Pb-free. The Pb-free JEDEC designator ( )

can be found on the outer packaging for this package.

Note:

In the event the full Microchip part number cannot be marked on one line, it will

be carried over to the next line, thus limiting the number of available

characters for product code or customer-specific information. Package may or

not include the corporate logo.

3

e

3

e

8-lead SOIC

Example

NNN

XXXXXXXX

YYWW

e3

991

HV9801A

1727

LG

XX

e3

16-lead SOIC

XXXXXXXX

YYWWNNN

e3

Example

HV9801ANG

1711541

e3