R&E International

A Subsidiary of Microchip Technology Inc.

RE46C141

CMOS Photoelectric Smoke Detector ASIC with Interconnect

Product Specification

© 2009 Microchip Technology Inc. DS22177B-page 1

General Description

The RE46C141 is low power CMOS photoelectric type

smoke detector IC. With minimal external components

this circuit will provide all the required features for a

photoelectric type smoke detector.

The design incorporates a gain selectable photo

amplifier for use with an infrared emitter/detector pair.

An internal oscillator strobes power to the smoke

detection circuitry for 100us every 8.1 seconds to keep

standby current to a minimum. If smoke is sensed the

detection rate is increased to verify an alarm condition.

A high gain mode is available for push button chamber

testing.

A check for a low battery condition and chamber

integrity is performed every 32 seconds when in

standby. The temporal horn pattern supports the NFPA

72 emergency evacuation signal.

An interconnect pin allows multiple detectors to be

connected such that when one units alarms, all units

will sound.

The RE46C141 is recognized by Underwriters

Laboratories for use in smoke detectors that comply

with specification UL217 and UL268.

Features

• Internal Power On Reset

• Low Quiescent Current Consumption

• Available in 16L PDIP, 16L N SOIC or 16L W SOIC

• ESD Protection on all Pins

• Interconnect up to 40 Detectors

• Temporal Horn Pattern

• Low Battery and Chamber Test

• Compatible with Motorola MC145012

• UL Recognized per File S24036

• Available in Standard Packaging or RoHS

Compliant Pb Free Packaging.

Pin Configuration

16

1

TEST

C1

2

LBSET

C2

15

VSS

DETECT

3

14

STROBE

4

ROSC

13

ABSOLUTE MAXIMUM RATINGS

PARAMETER SYMBOL

VALUE

UNITS

Supply Voltage

V

DD

12.5 V

Input Voltage Range Except FEED, IO

V

in

-.3 to V

dd

+.3 V

FEED Input Voltage Range

V

infd

-10 to +22

V

IO Input Voltage Range

V

io1

-.3 to 17

V

Input Current except FEED

I

in

10

mA

Operating Temperature

T

A

-25 to 75

°C

Storage Temperature

T

STG

-55 to 125

°C

Maximum Junction Temperature

T

J

150

°C

Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are

stress ratings only and operation at these conditions for extended periods may affect device reliability.

This product utilizes CMOS technology with static protection; however proper ESD prevention procedures should be used when

handling this product. Damage can occur when exposed to extremely high static electrical charge.

COSC

5

12

VDD

IRED

IO

HORNB

LE

6

D

11

7

FEED

10

HORNS

8

9

RE46C141

CMOS Photoelectric Smoke Detector ASIC with Interconnect

R&E International

Product Specification

A Subsidiary of Microchip Technology

Inc.

© 2009 Microchip Technology Inc. DS22177B-page 2

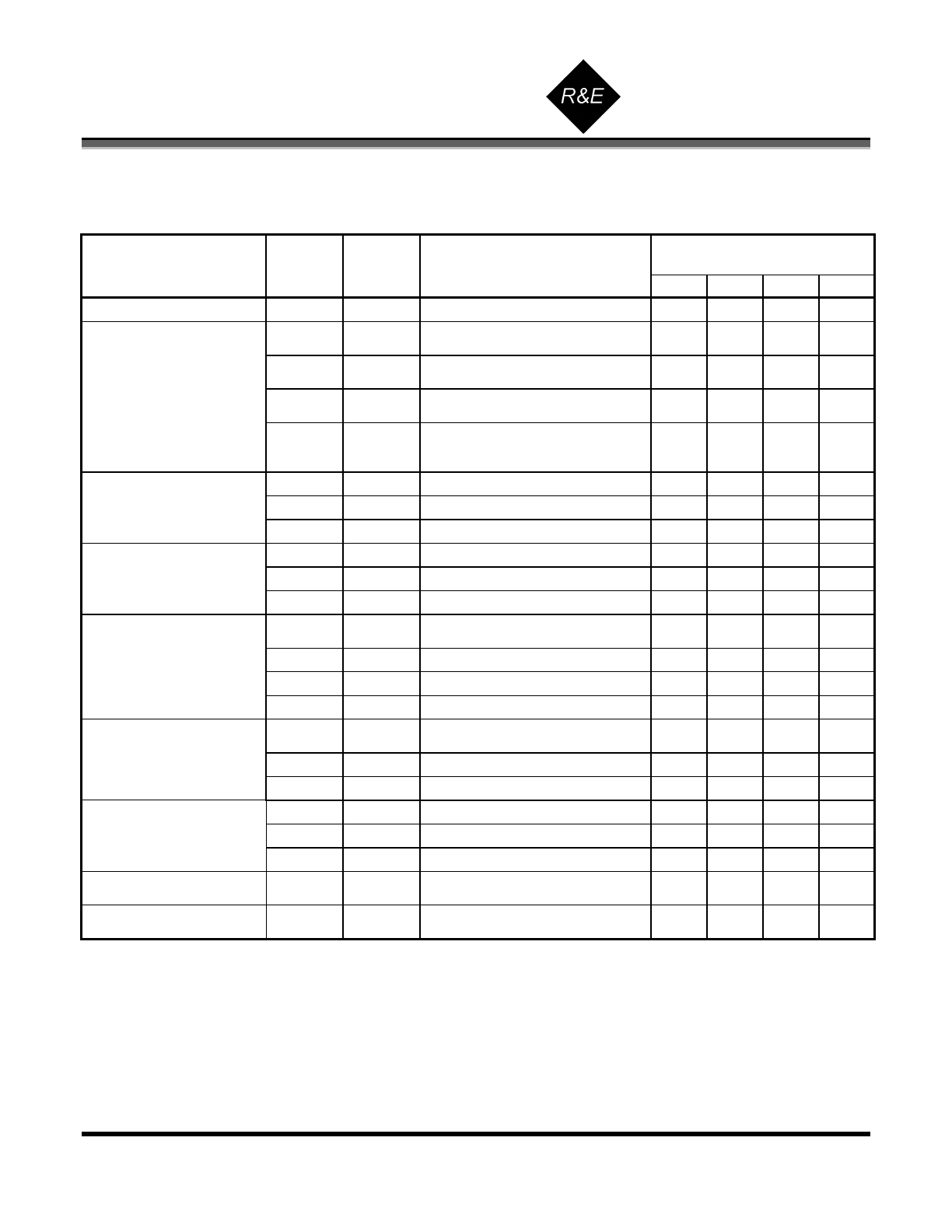

DC Electrical Characteristics at TA = -25° to 75°C, VDD=9V, Typical Application (unless otherwise noted)

Limits

Parameter Symbol

Test

Pin Test

Conditions

Min Typ Max Units

Supply Voltage

V

DD

5 Operating

6 12 V

I

DD1

5

Configured as in Figure 2,

COSC=VSS

4 6

uA

I

DD2

5

Configured as in Figure 2,

VDD=12V, COSC=VSS

5.5 8 uA

I

DD3

5

Configured as in Figure 2,

STROBE on, IRED off, VDD=12V

2

mA

Supply Current

I

DD4

5

Configured as in Figure 2,

STROBE on, IRED on, VDD=12V,

Note 1

3

mA

V

IH1

10 FEED

6.2 4.5 V

V

IH2

7

No Local Alarm, IO as an Input

3.2

V

Input Voltage High

V

IH4

16

TEST

8.5

V

V

IL1

10 FEED

4.5 2.7 V

V

IL2

7

No Local Alarm, IO as an Input

1.5

V

Input Voltage Low

V

IL4

16

TEST

7

V

I

IL1

1,2,3

VDD=12V, COSC=12V, STROBE

active

-100

nA

I

IL2

12,15

VDD=12V,

Vin=VSS

-100

nA

I

IL3

16

VDD=12V,

Vin=VSS

-1

uA

Input Leakage Low

I

LFD

10 FEED=-10V

-50 uA

I

IH1

1,2

VDD=12V, Vin=VDD, STROBE

active

100

nA

I

IH2

3,12,15

VDD=12V,

Vin=VDD

100

nA

Input Leakage High

I

HFD

10 FEED=22V

50 uA

I

PD1

16

Vin=VDD

.25

10

uA

I

PDIO1

7 Vin=VDD

20 80

uA

Input Pull Down Current

I

PDIO2

7

Vin=17V,

VDD=12

140

uA

Output Leakage Current

Low

I

OZL1

11,13

Output Off, Output=VSS

-1

uA

Output Leakage Current

High

I

OZH1

11,13

Output Off, Output=VDD

1

uA

Note 1: Does not include Q3 emitter current.

RE46C141

CMOS Photoelectric Smoke Detector ASIC with Interconnect

R&E International

Product Specification

A Subsidiary of Microchip Technology

Inc.

© 2009 Microchip Technology Inc. DS22177B-page 3

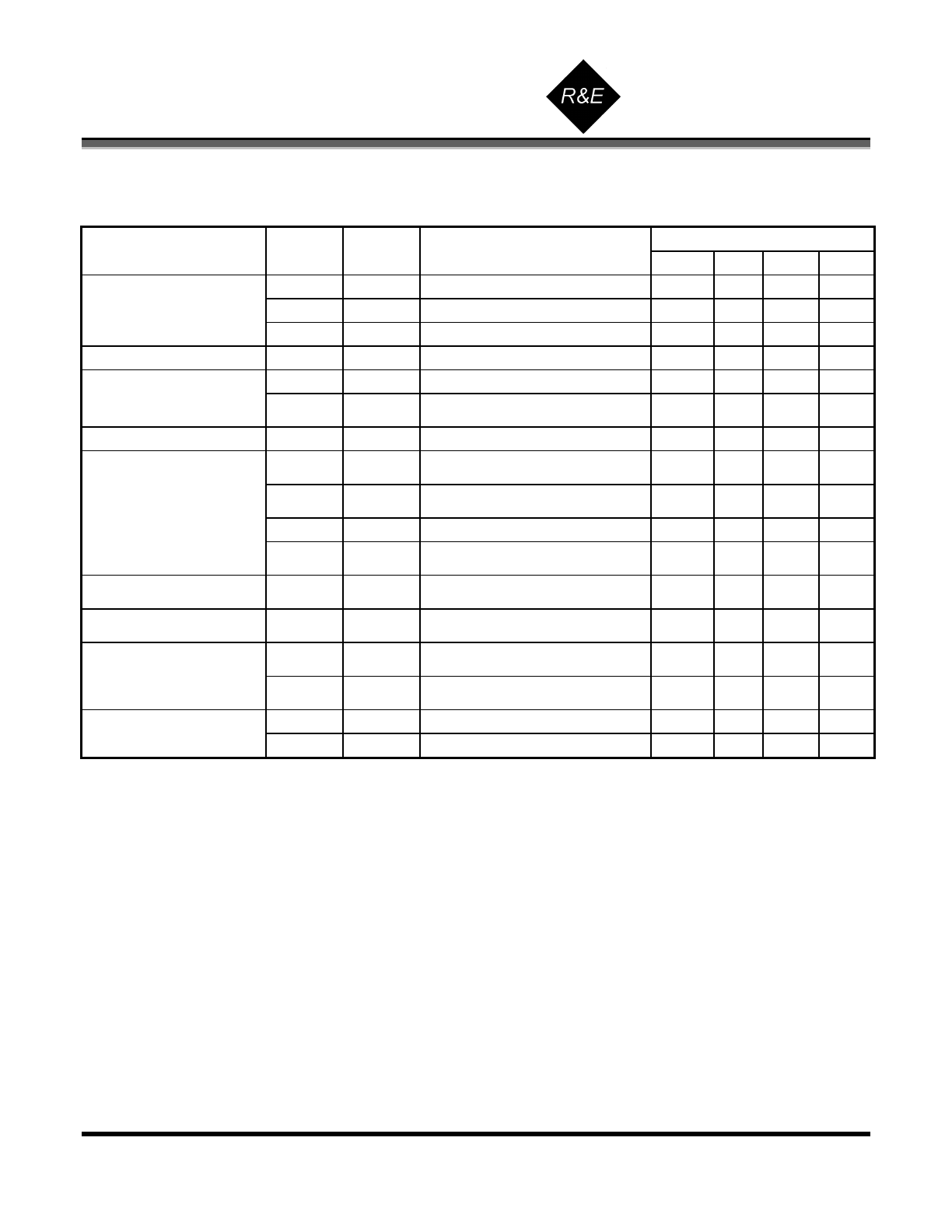

DC Electrical Characteristics (continued) at TA= -25° to 75°, VDD=9V, Typical Application (unless

otherwise noted)

Limits

Parameter Symbol

Test

Pin Test

Conditions Min Typ Max Units

V

OL1

8,9 Iol=16mA,

VDD=6.5V

1 V

V

OL2

13

Iol=5mA,

VDD=6.5V

.5

V

Output Voltage Low

V

OL3

11

Iol=10mA,

VDD=6.5V

.6

V

Output Voltage High

V

Oh1

8,9 Ioh=-16mA,

VDD=6.5V 5.5

V

I

IOH1

7

Alarm, Vio=Vdd-2V or Vio=0V

-4

-16

mA

Output Current

I

IODMP

7

At Conclusion of Local Alarm or

Test, Vio=1V

5 mA

Low Battery Alarm Voltage

V

LB

5

R14=100K,

R15=47K

6.9

7.2

7.5

V

V

STOF

4

STROBE off, VDD=12V,

Iout=-1uA

V

DD

-

.1

V

V

STON

4

STROBE on, VDD=9V

Iout= 100uA to 500uA

V

DD

-

5.3

V

DD

-

5

V

DD

-

4.7

V

V

IREDOF

6

IRED off, VDD=12V, Iout=1uA

.1

V

Output Voltage

V

IREDON

6

IRED on, VDD=9V

Iout=0 to -6mA, Ta=25C

2.25 3.1 3.75 V

Common Mode Voltage

V

CM1

1,2,3

Local smoke, Push to Test or

Chamber Test, Note 1

.5

V

DD

-2 V

Smoke Comparator

Reference

V

ref

- Internal

Reference

V

DD

-

3.85

V

DD

-

3.15

V

TC

ST

4

VDD=6V to 12V, STROBE Output

Voltage

.01 %/ºC

Temperature Coefficient

TC

IRED

6

VDD=6V to 12V, IRED Output

Voltage

.3

%/ºC

ΔV

STON

4,5

Active, VDD=6V to 12V

-50

dB

Line Regulation

ΔV

IREDON

6,5

Active, VDD=6V to 12V

-30

dB

Note 1: Not production tested

Typical values are for design information and are not guaranteed.

Limits over the specified temperature range are not production tested and are based on characterization data.

RE46C141

CMOS Photoelectric Smoke Detector ASIC with Interconnect

R&E International

Product Specification

A Subsidiary of Microchip Technology

Inc.

© 2009 Microchip Technology Inc. DS22177B-page 4

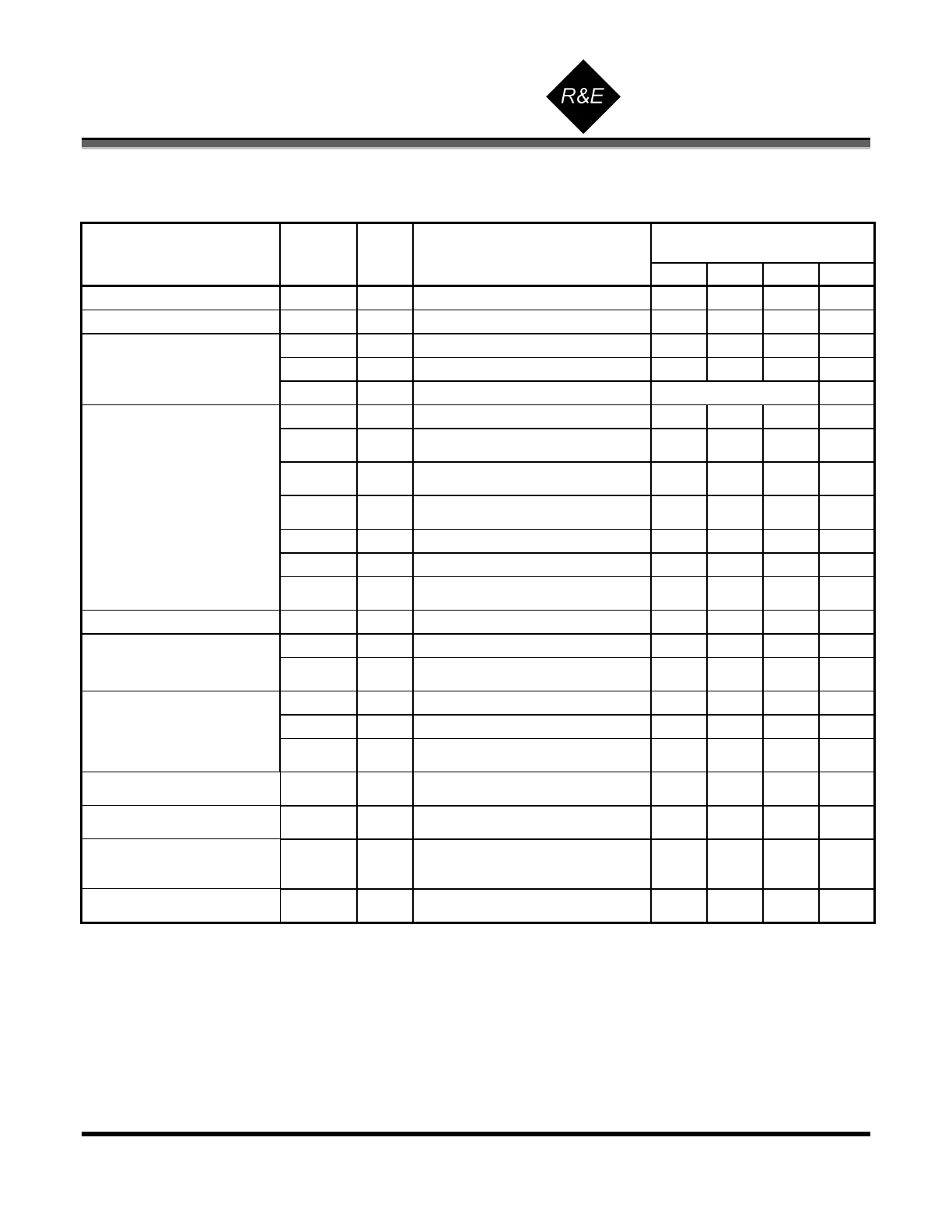

AC Electrical Characteristics at TA =-25° to 75°, VDD=9V, VSS=0V, Component Values from Figure 2 ;

R9=100KΩ, R12=10MΩ, C5= 1.5nF(unless otherwise noted)

Limits

Parameter Symbol

Test

Pin Test

Conditions Min Typ Max Units

Oscillator Period

T

POSC

12

No Alarm Condition,

Note 2

7.1 7.9 8.6 mS

LED and STROBE On Time

T

ON1

11,4 Operating

7.1 7.9 8.6 mS

T

PLED1

11

Standby, No Alarm

28.8

32.4

35.2

S

T

PLED2

11

Local Alarm Condition

.45

.5

.55

S

LED Period

T

PLED4

11

Remote Alarm Only

LED IS NOT ON

S

T

PER1

4,6

Standby, No Alarm

7.3

8.1

8.8

S

T

PER1A

4,6

Standby, After 1 Valid Smoke

Sample

1.8 2 2.2 S

T

PER1B

4,6

Standby, After 2 Consecutive Valid

Smoke Samples

.9 1 1.1 S

T

PER2

4,6

In Local Alarm – (3 Consecutive

Valid Smoke Samples)

.9 1 1.1 S

T

PER3

4,6

In Remote Alarm

7.3

8.1

8.8

S

T

PER4

4,6

Pushbutton

Test

250 mS

STROBE and IRED Pulse

Period

T

PER5

4,6

Chamber Test or Low Battery

Test, no Alarms

28.8 35.2 S

IRED On Time

T

ON2

6 Operating,

Note 2

94

104

115

uS

T

HON1

8,9

Operating, Alarm Condition, Note 1

450

500

550

mS

Horn On Time

T

HON2

8,9

Low Battery or Failed Chamber

Test , No Alarm

7.1 7.9 8.6 mS

T

HOF1

8,9

Operating, Alarm Condition, Note 1

450

500

550

mS

T

HOF2

8,9

Operating, Alarm Condition, Note 1

1.35

1.5

1.65

S

Horn Off Time

T

HOF3

8,9

Low Battery or Failed Chamber

Test, No Alarm

28.8 32.4 35.2 S

IO Charge Dump Duration

T

IODMP

7

At Conclusion of Local Alarm or

Test

.68 1.1 S

IO Delay

T

IODLY1

7

From Start of Local Alarm to IO

Active

0 S

IO Filter

T

IOFILT

7

IO pulse width guaranteed to be

filtered. IO as Input, No Local

Alarm

450

mS

Remote Alarm Delay

T

IODLY2

7

No Local Alarm, From IO Active

Horn Active

.9

1.65

S

Note 1 - See timing diagram for Horn Temporal Pattern

Note 2 - T

POSC

and T

ON2

are 100%

production tested. All other timing is guaranteed by functional testing.

Typical values are for design information and are not guaranteed.

Limits over the specified temperature range are not production tested and are based on characterization data.

RE46C141

CMOS Photoelectric Smoke Detector ASIC with Interconnect

R&E International

Product Specification

A Subsidiary of Microchip Technology

Inc.

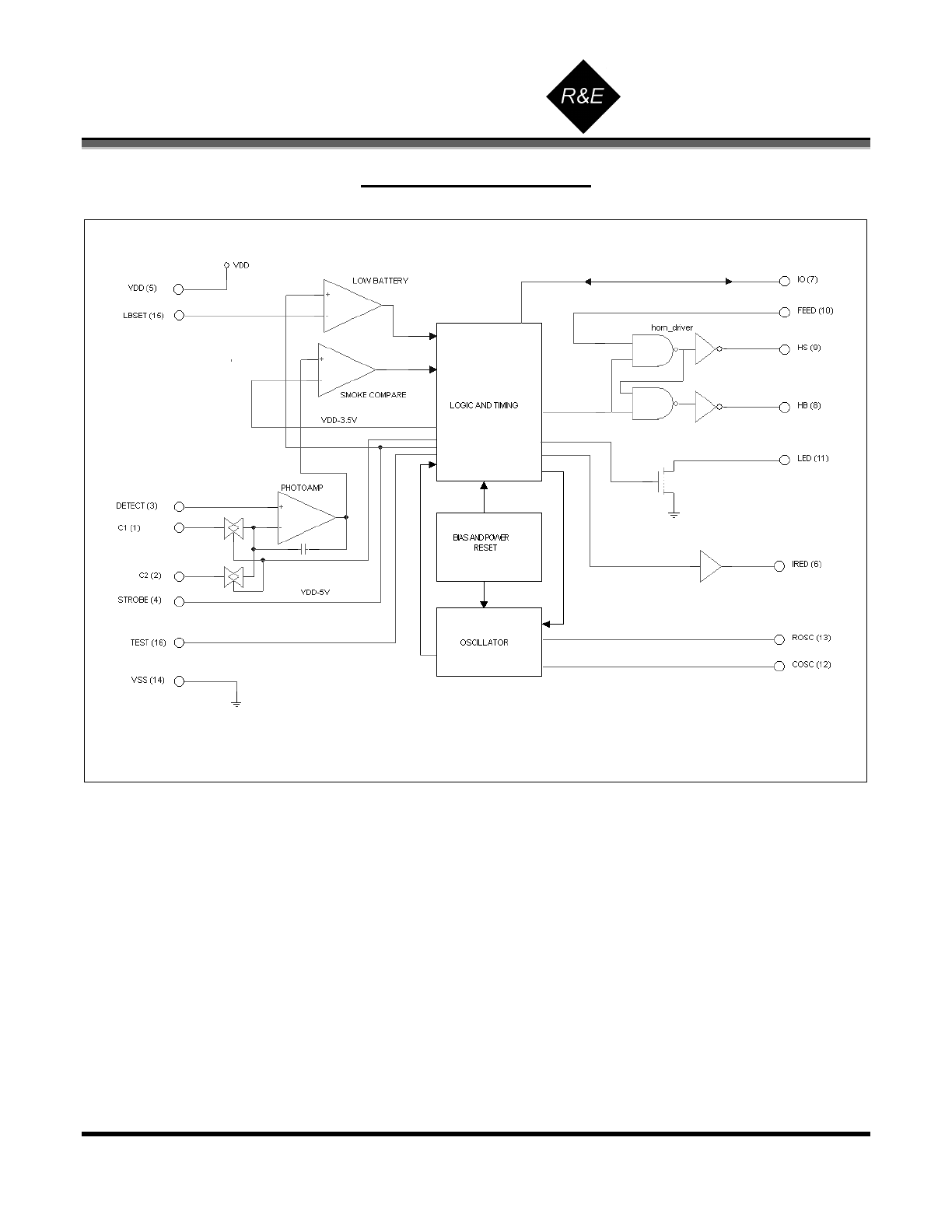

Functional Block Diagram

Figure 1

© 2009 Microchip Technology Inc. DS22177B-page 5

RE46C141

CMOS Photoelectric Smoke Detector ASIC with Interconnect

R&E International

Product Specification

A Subsidiary of Microchip Technology

Inc.

© 2009 Microchip Technology Inc. DS22177B-page 6

PIN DESCRIPTIONS

PIN#

PIN NAME

DESCRIPTION

1

C1

The capacitor connected to this pin sets the photo amplifier gain (high) for the

push-to-test and chamber sensitivity test. The size of this capacitor will depend

on the chamber background reflections. A=1+ (C1/10) where C1 is in pF. The

gain should be <10000.

2

C2

The capacitor connected to this pin sets the photo amplifier gain (normal) during

standby. The value of this capacitor will depend on the smoke sensitivity

required. A=1+ (C2/10) where C2 is in pF.

3

DETECT

Positive input to the photo amplifier. This input is normally connected to the

cathode of an external photo diode operated at zero bias.

4

STROBE

Regulated output voltage of VDD-5 which is active during a test for smoke. This

output is the negative side of the photo amplifier circuitry.

5

VDD

Connect to the positive supply voltage

6

IRED

Provides a regulated pulsed output voltage pre-driver for the infrared emitter.

This output usually drives the base of an NPN transistor.

7

IO

This bidirectional pin provides the capability to interconnect many detectors in a

single system. This pin has an internal pull-down device.

8

HB

This pin is connected to the metal electrode of a piezoelectric transducer.

9

HS

HS is a complementary output to HB and connects to the ceramic electrode of

the piezoelectric transducer.

10

FEED

Usually connected to the feedback electrode through a current limiting resistor. If

not used this pin must be connected to VDD or VSS.

11

LED

Open drain NMOS output used to drive a visible LED.

12

COSC

A capacitor connected to this pin with parallel resistor sets the internal clock low

time which is approximately the clock period.

13

ROSC

A resistor between this pin and pin 12 (COSC) sets the internal clock high time.

This also sets the IRED pulse width (100-200uS).

14

VSS

Connect to the negative supply voltage.

15

LBSET

This input is connected to a VDD reference voltage to set the low battery

warning voltage.

16

TEST

This input is used to invoke two test modes. This input has an internal pull-down.

RE46C141

CMOS Photoelectric Smoke Detector ASIC with Interconnect

R&E International

Product Specification

A Subsidiary of Microchip Technology

Inc.

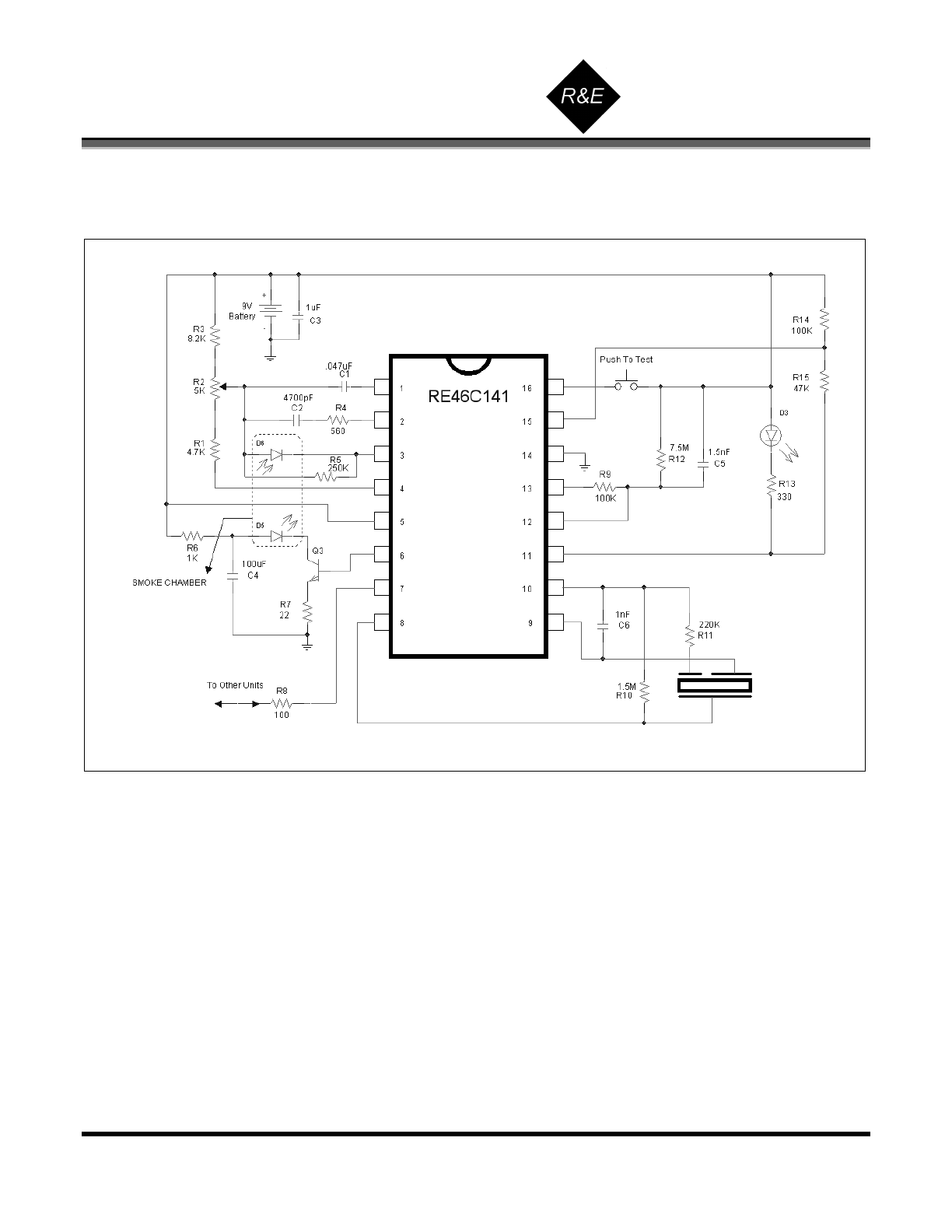

Typical Application

Figure 2

Notes:

1.

C3 should be located as close as possible to the device power pins.

2.

C3 is typical for an alkaline battery. This capacitance should be increased to 4.7uF or greater for a carbon battery.

3.

R10, R11 and C6 are typical values and may be adjusted to maximize sound pressure.

© 2009 Microchip Technology Inc. DS22177B-page 7

RE46C141

CMOS Photoelectric Smoke Detector ASIC with Interconnect

R&E International

Product Specification

A Subsidiary of Microchip Technology

Inc.

© 2009 Microchip Technology Inc. DS22177B-page 8

CIRCUIT DESCRIPTION AND APPLICATION NOTES

Note: All timing references are nominal. See electrical characteristics for limits.

Standby Internal Timing – With the external components specified in the typical application figure for ROSC and

COSC the internal oscillator has a nominal period of 7.9mS. Normally the analog circuitry is powered down to

minimize standby current (typically 4uA at 9V). Once every 8.1 seconds the detection circuitry (normal gain) is

powered up for 7.9mS. Prior to completion of the 7.9mS period the IRED pulse is active for 100uS. At the

conclusion of this 7.9mS period the photo amplifier is compared to an internal reference to determine the

chamber status and latched. If a smoke condition is present the period to the next detection decreases and

additional checks are made. Three consecutive smoke detections will cause the device to go into alarm and the

horn circuit and interconnect will be active.

Once every 32 seconds the status of the battery voltage is checked. This status is checked and latched at the

conclusion of the LED pulse. In addition, once every 32 seconds the chamber is activated and using the high gain

mode (capacitor C1) a check of the chamber is made by amplifying background reflections. If either the low

battery or the photo chamber test fails the horn will chirp for 7.9mS every 32 seconds.

The oscillator period is determined by the values of R9, R12 and C5 (see typical application FIG 2). The oscillator

period T=T

R

+ T

F

where T

R

=.6931 * R12 * C5 and T

F

=.6931 * R9 * C5

Smoke Detection Circuitry – A comparator compares the photo amp output to an internal reference voltage. If the

required number of consecutive smoke conditions is met the device will go into local alarm and the horn will be

active. In local alarm the C2 gain is internally increased by ~10% to provide alarm hysteresis.

Push to Test Operation – If the TEST input pin is activated (Vih) then, after one internal clock cycle, the smoke

detection rate increases to once every 250mS. In this mode the high gain capacitor C1 is selected and

background reflections are used to simulate a smoke condition. After the required consecutive detections the

device will go into a local alarm condition. When the TEST input is deactivated (Vil) and after one clock cycle the

normal gain capacitor C1 is selected. The detection rate continues at once every 250mS until 3 consecutive no

smoke conditions are detected. At this point the device returns to standby timing.

LED Operation – In standby the LED is pulsed on for 7.9mS every 32 Seconds. In a local alarm condition or the

push to test alarm the LED pulse frequency is increased to once every 0.5 seconds. In the case of a remote alarm

the LED not active.

Interconnect Operation – The bidirectional IO pin allows for interconnection of multiple detectors. In a local alarm

condition this pin is driven high immediately through a constant current source. Shorting this output to ground will

not cause excessive current. The IO is ignored as an input during a local alarm.

The IO pin also has an NMOS discharge device that is active for 1 second after the conclusion of any type of local

alarm. This device helps to quickly discharge any capacitance associated with the interconnect line.

If a remote active high signal is detected the device goes into remote alarm and the horn will be active. Internal

protection circuitry allows for the signaling unit to have a higher supply voltage than the signaled unit without

excessive current draw.

The interconnect input has a 500mS nominal digital filter. This allows for interconnection to other types of alarms

(carbon monoxide for example) that may have a pulsed interconnect signal.

RE46C141

CMOS Photoelectric Smoke Detector ASIC with Interconnect

R&E International

Product Specification

A Subsidiary of Microchip Technology

Inc.

© 2009 Microchip Technology Inc. DS22177B-page 9

Low Battery and Chamber Test – In standby an internal reference is compared to the voltage divided VDD supply.

Low battery status is latched at the conclusion of the LED pulse. The horn will chirp for 7.9ms every 32 seconds

until the low battery condition no longer exists. In standby a chamber test is also performed every 32 seconds by

switching to the high gain capacitor C1 and sensing the photo chamber background reflections. Two consecutive

chamber tests failures will also cause the horn to chirp for 7.9mS every 32 seconds. The low battery chirp occurs

next to the LED pulse and the failed chamber test chirp 16.2 seconds later. The low battery and chamber tests

are not performed in a local or remote alarm condition. The low battery alarm threshold is approximately equal to

((5*R15)/R14)+5 where R15 and R16 are in the same units.

Diagnostic Mode – In addition to the normal function of the TEST input a special diagnostic mode is available for

calibration and test of the smoke detector. Taking the TEST pin below VSS and sourcing ~300uA out of the pin

for 1 clock cycle will enable the diagnostic mode. In the diagnostic mode some of the pin functions are redefined.

Refer to the table below for redefined pin functions in the diagnostic mode. In addition in this mode STROBE is

always enabled and the IRED is pulsed at the clock rate of 10.5mS nominal.

Pin Name Pin Number

Description

IO

7

Disabled as an output. A high on this pin directs the photo amplifier output to pin C1

(1) or C2 (2), determined by the level on LBSET (15). Amplification occurs during

the IRED active time.

LBSET

15

If IO is high then this pin controls the gain capacitor that is used. If LBSET is low

then normal gain is selected and the photo amp output appears on C1 (1). If LBSET

is high then high gain is selected and the photo amp output is on C2 (2).

FEED

10

If LBSET (15) is low then taking this input high will enable hysteresis, which is a

nominal 10% gain increase in normal gain mode.

COSC

12

If desired this pin can be driven by an external clock.

HORNB

8

This pin becomes the smoke integrator output. A high level indicates that an alarm

condition has been detected.

LED

11

The LED pin is used as a low battery indicator. For VDD above the low battery

threshold the open drain NMOS is off. If VDD falls below the threshold the NMOS

turns on.

RE46C141

CMOS Photoelectric Smoke Detector ASIC with Interconnect

R&E International

Product Specification

A Subsidiary of Microchip Technology

Inc.

Timing Diagrams

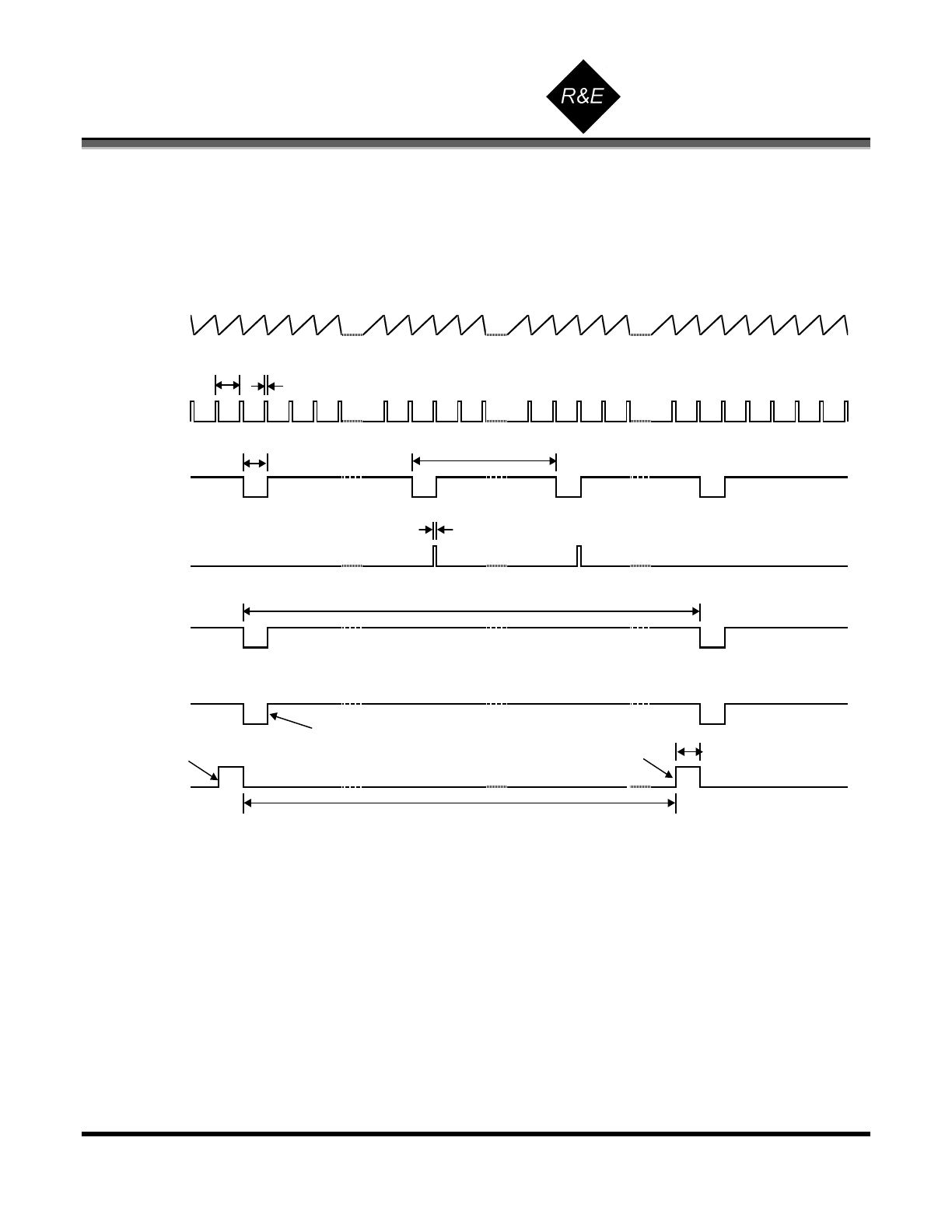

Standby Timing, No Alarm (not to scale)

Oscillator

T

POSC

T

PWOSC

Internal Clock

T

ON1

T

PER1

STROBE

T

ON2

IRED

T

PLED1

LED

Low Supply or Chamber Test Failure

LED

Low BatteryTest

T

HON3

Low BatteryWarning Chirp

Low Battery Warning Chirp

Horn

T

HOF3

Chamber Test and Warning is Offset from Low Battery Test and Warning by 21.5 Seconds

© 2009 Microchip Technology Inc. DS22177B-page 10