1996 Microchip Technology Inc.

DS30139I-page 1

This document includes the programming

specifications for the following devices:

1.0

PROGRAMMING THE PIC17CXX

The PIC17CXX is programmed using the TABLWT

instruction. The table pointer points to the internal

EPROM location start. Therefore, a user can program

an EPROM location while executing code (even from

internal EPROM). This programming specification

applies to PIC17CXX devices in all packages.

For the convenience of a programmer developer, a

“program & verify” routine is provided in the on-chip test

program memory space, the program resides in ROM

and not EPROM. Therefore, it is not erasable. The

“program/verify” routine allows the user to load any

address, program a location, verify a location or incre-

ment to the next location. It allows variable program-

ming pulse width.

1.1

Hardware Requirements

Since the PIC17CXX under programming is actually

executing code from “boot ROM,” a clock must be pro-

vided to the part. Furthermore, the PIC17CXX under

programming may have any oscillator configuration

(EC, XT, LF or RC). Therefore, the external clock driver

must be able to overdrive pulldown in RC mode. CMOS

drivers are required since the OSC1 input has a

Schmitt trigger input with levels (typically) of 0.2V

DD

and 0.8V

DD

. See the PIC17C4X data sheet

(DS30412A) for exact specifications.

• PIC17C42

• PIC17C42A

• PIC17CR42

• PIC17C43

• PIC17CR43

• PIC17C44

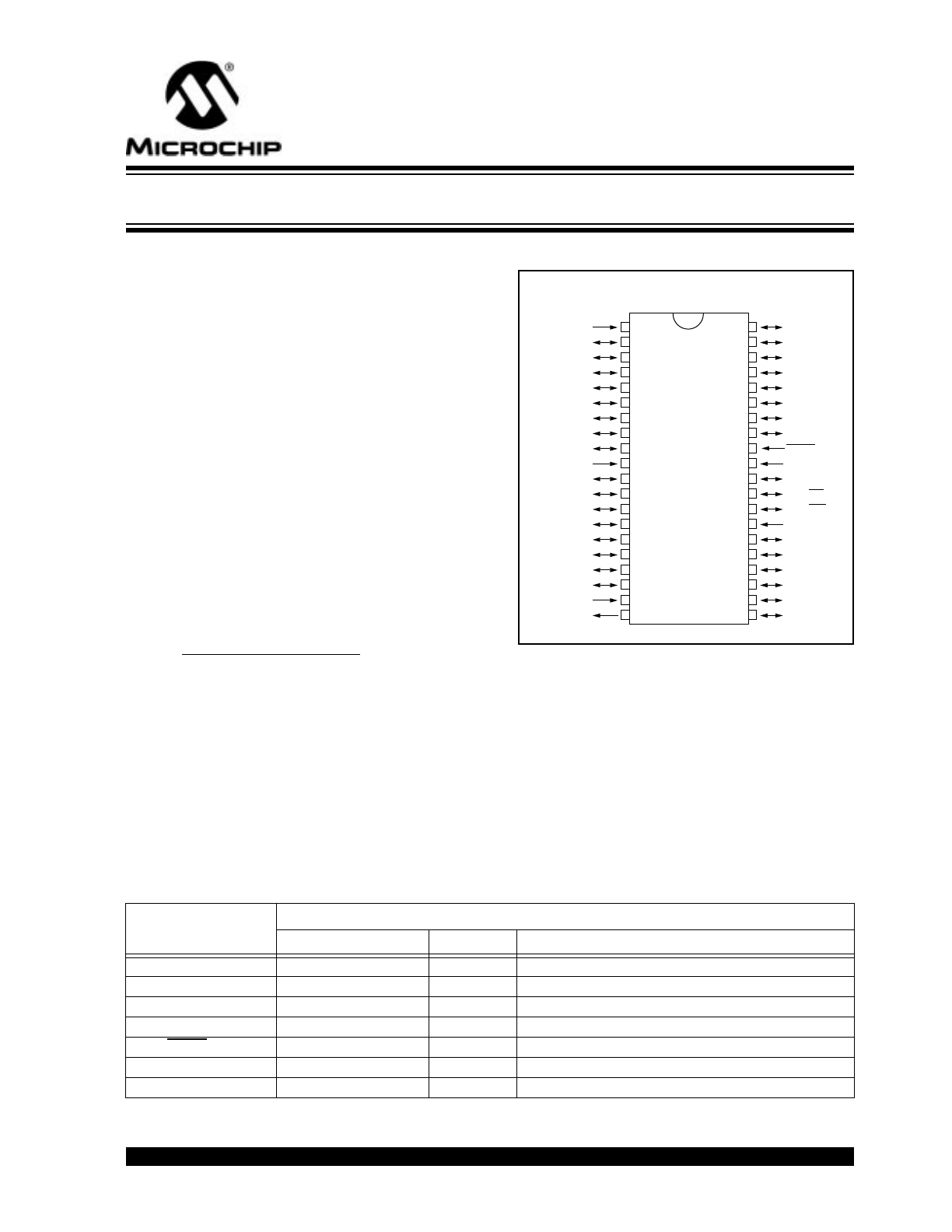

Pin Diagram

The PIC17CXX requires two programmable power

supplies, one for V

DD

(2.5V to 6.0V recommended) and

one for V

PP

(13

±

0.25V). Both supplies should have a

minimum resolution of 0.25V.

The PIC17CXX uses an intelligent algorithm. The algo-

rithm calls for program verification at V

DD

min as well as

V

DD

max. Verification at V

DD

min guarantees good

“erase margin”. Verification at V

DD

max guarantees

good “program margin”. Three times (3X) additional

pulses will increase program margin then beyond V

DD

(max.) and insure safe operation in user system.

RC1/AD1

RD0/AD8

RD1/AD9

RD2/AD10

RD3/AD11

RD4/AD12

RD5/AD13

RD6/AD14

RD7/AD15

MCLR/V

PP

V

SS

RE0/ALE

RE1/OE

RE2/WR

TEST

RA0/INT

RA1/T0CKI

RA2

RA3

RA4/RX/DT

RA5/TX/CK

V

DD

RC0/AD0

RC2/AD2

RC3/AD3

RC4/AD4

RC5/AD5

RC6/AD6

RC7/AD7

V

SS

RB0/CAP1

RB1/CAP2

RB2/PWM1

RB3/PWM2

RB4/TCLK12

RB5/TCLK3

RB6

RB7

OSC1/CLKIN

OSC2/CLKOUT

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

PIC17CXX

40L PDIP, Windowed CERDIP

PIC17CXX

EPROM Memory Programming Specification

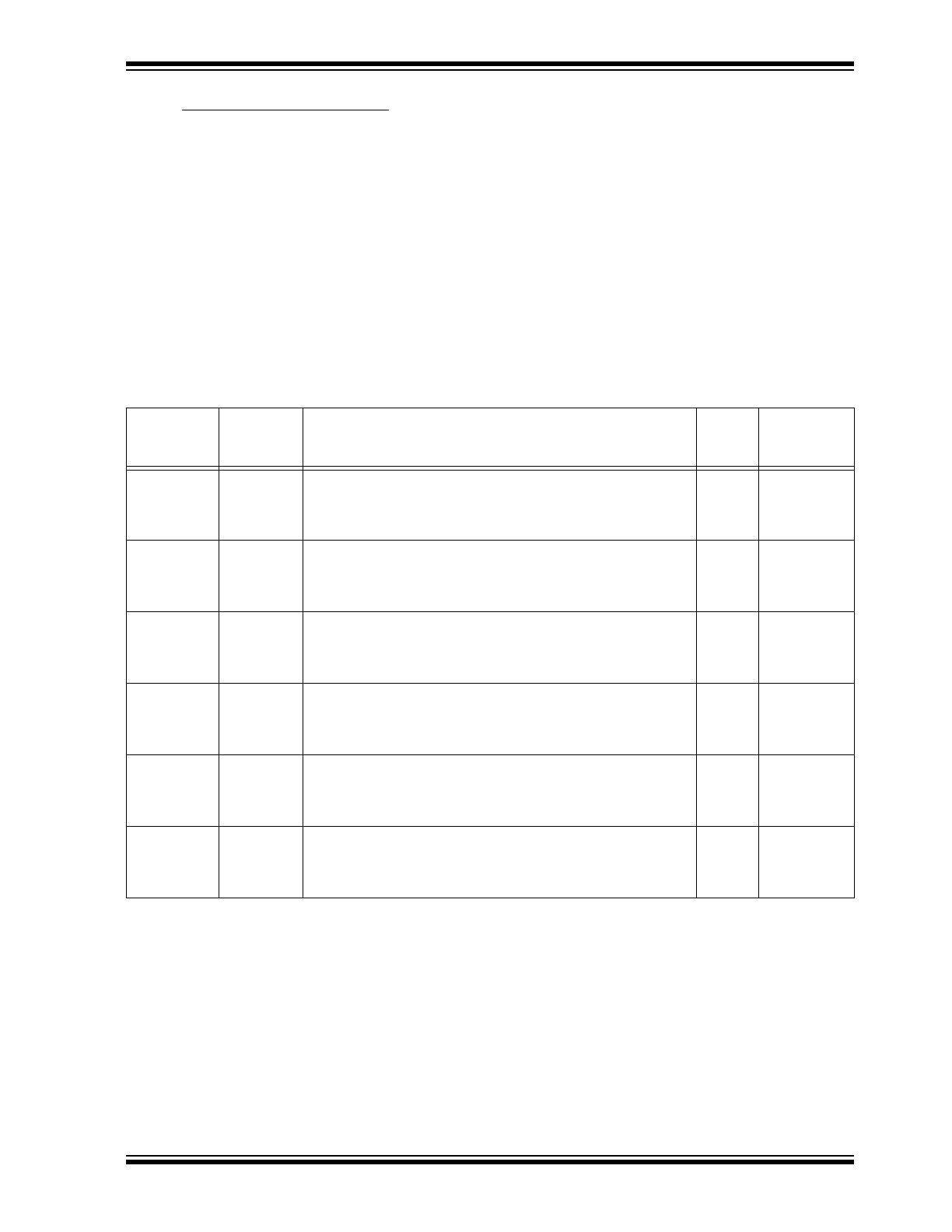

PIN DESCRIPTIONS (DURING PROGRAMMING): PIC17C42/42A/43/44

Pin Name

During Programming

Pin Name

Pin Type

Pin Description

RA <0:4>

RA <0:4>

I

Necessary in programming mode

TEST

TEST

I

Must be set to “high” to enter programming mode

RB <7:0>

PAD <15:8>

I/O

Address & data: high byte

RC <7:0>

PAD <7:0>

I/O

Address & data: low byte

MCLR/V

PP

V

PP

P

Programming Power

V

DD

V

DD

P

Power Supply

V

SS

V

SS

P

Ground

Legend: I = Input, O = Output, P = Power

This document was created with FrameMaker 4 0 4

PIC17CXX

DS30139I-page 2

1996 Microchip Technology Inc.

The actual programming must be done with V

DD

in the

V

DDP

range (4.75 - 5.25V).

V

DDP

=V

DD

range required during programming.

V

DD

min.=minimum operating V

DD

spec for the part.

V

DD

max.=maximum operating V

CC

spec for the part.

Programmers must verify the PIC17CXX at its speci-

fied V

DD

max and V

DD

min levels. Since Microchip may

introduce future versions of the PIC17CXX with a

broader V

DD

range, it is best that these levels are user

selectable (defaults are ok).

2.0

PROGRAM MODE ENTRY

To execute the programming routine, the user must

hold TEST pin high, RA2, RA3 must be low and RA4

must be high (after power-up) while keeping MCLR low

and then raise MCLR pin from V

IL

to V

DD

or V

PP

. This

will force FFE0h in the program counter and execution

will begin at that location (the beginning of the boot

code) following reset. Execution is forced to Internal

mode by overriding the fuse configuration. The code

protect bit is not overwritten. The program immediately

polls PORT RB<7:0> to determine a branch address.

Presenting E1h on PORT RB will cause the program to

jump to and execute the “program/verify” routine.

Note:

Any programmer not meeting these

requirements may only be classified as

"prototype" or "development" programmer

but not a "production" quality programmer.

All unused pins during programming are in high imped-

ance state.

PORTB (RB) has internal weak pull-ups which are

active during the programming mode. When TEST pin

is high, Power-up timer (PWRT) and Oscillator Start-up

Timers (OST) are disabled.

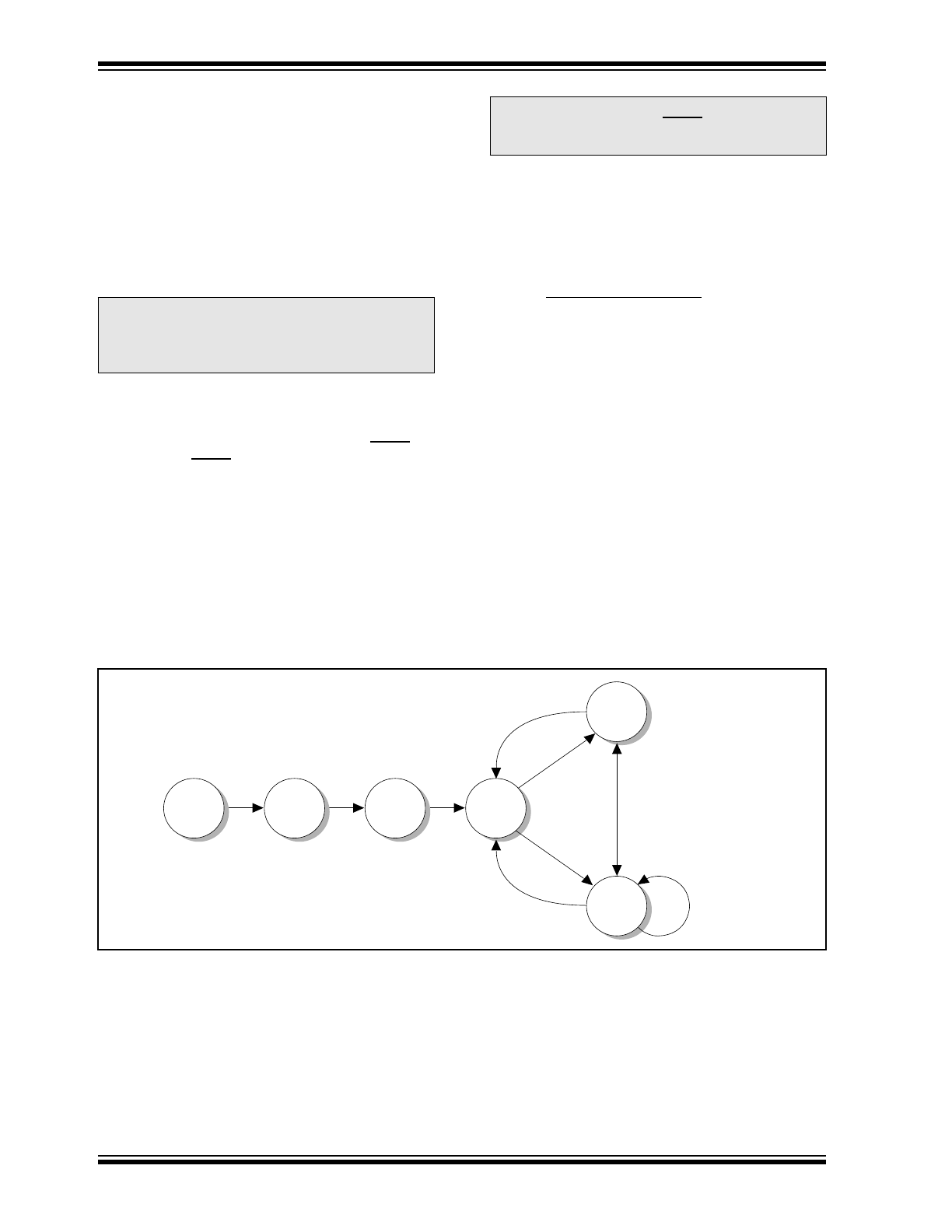

2.1

Program/Verify Mode

The program/verify mode is intended for full-feature

programmers. This mode offers the following capabili-

ties:

a)

Load any arbitrary 16-bit address to start pro-

gram and/or verify at that location.

b)

Increment address to program/verify the next

location.

c)

Allows arbitrary length programming pulse width.

d)

Following a “verify” allows option to program the

same location or increment and verify the next

location.

e)

Following a “program” allows options to program

the same location again, verify the same loca-

tion or to increment and verify the next location.

Note:

The OSC must not have 72 osc clocks

while the device MCLR is between V

IL

and

V

IHH

.

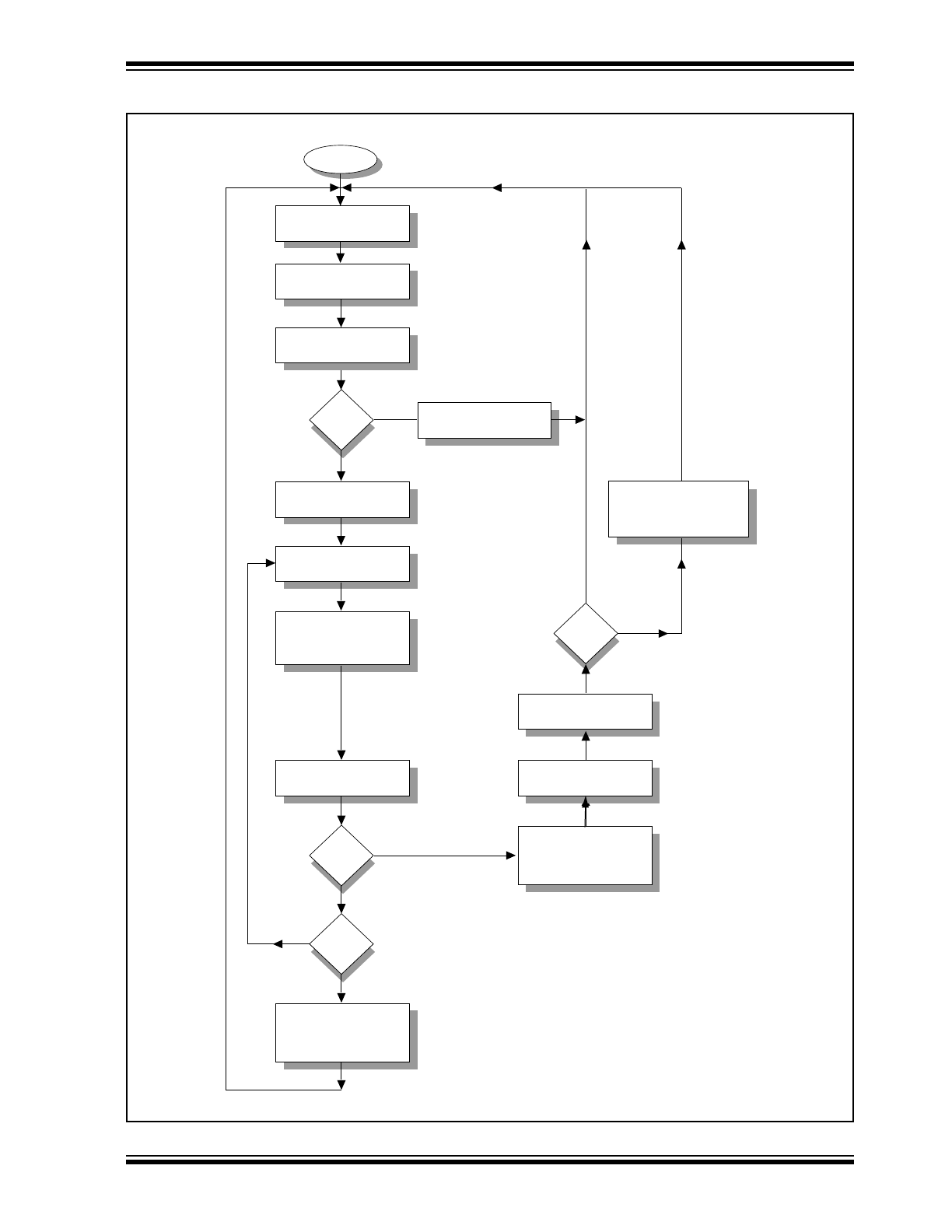

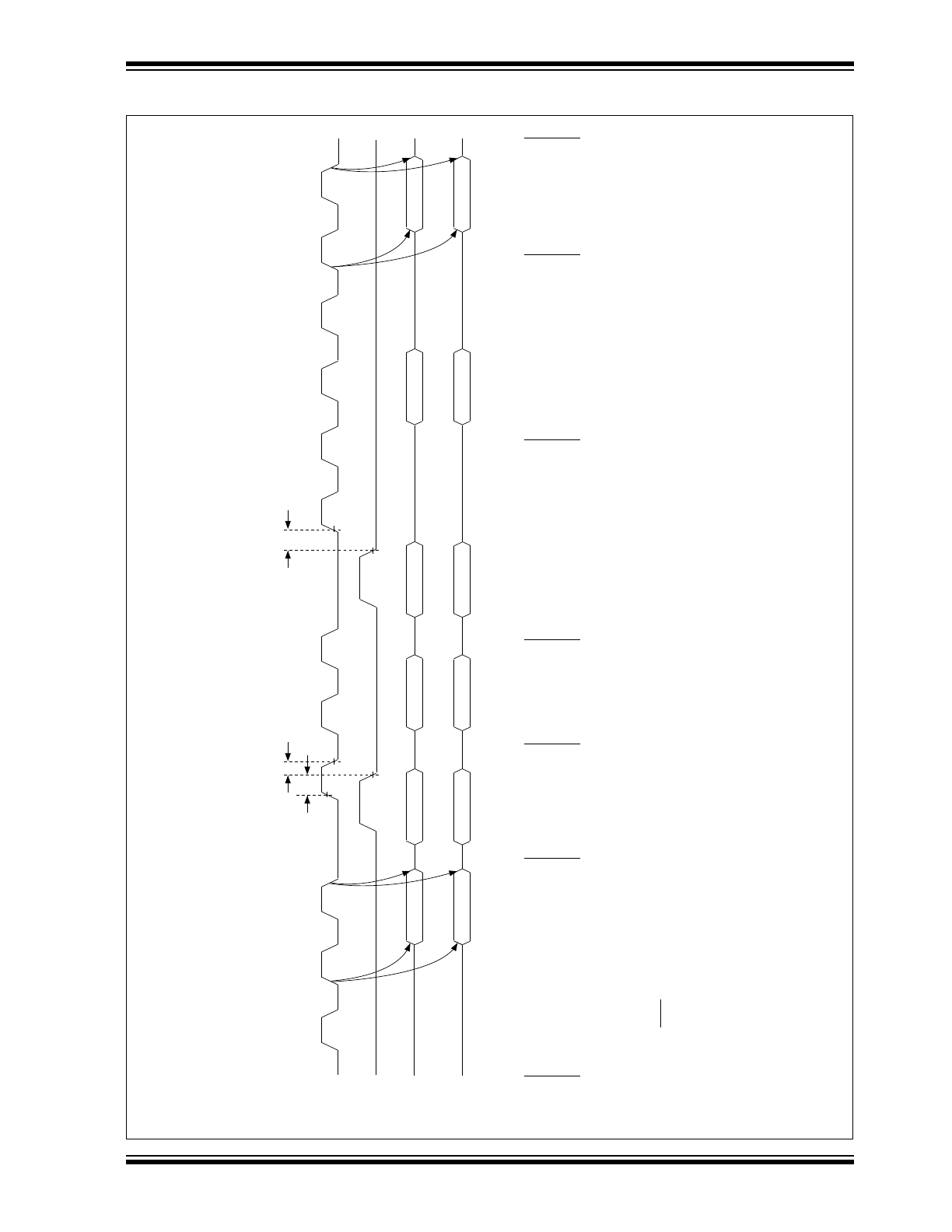

FIGURE 2-1:

PROGRAMMING/VERIFY STATE DIAGRAM

Increment

Address

Program

Verify

Pulse RA1

(Raise RA1

after RA0

↓

)

Pulse RA0

(RA0 pulse

width is

programming time)

Pulse

RA1

Pulse

RA1

RA0

↑

Raise RA1

before RA0

↓

Load

Address

Jump to

Program

Routine

Reset

Pulse

RA1

1996 Microchip Technology Inc.

DS30139I-page 3

EPROM Memory Programming Specification

2.1.1

LOADING NEW ADDRESS

The program allows new address to be loaded right out

of reset. A 16-bit address is presented on ports RB

(high byte) and RC (low byte) and the RA1 is pulsed

(0

→

1, then 1

→

0). The address is latched on the ris-

ing edge of RA1. See timing diagrams for details. After

loading an address, the program automatically goes

into a “verify cycle”. To load a new address at any time,

the PIC17C4X must be reset and the programming

mode re-entered.

2.1.2

VERIFY (OR READ) MODE

“Verify mode” can be entered from “Load address”

mode, “program mode” or “verify mode”. In verify mode

pulsing RA1 will turn on PORTS RB and RC output

drivers and output the 16-bit value from the current

location. Pulsing RA1 again will increment location

count and be ready for the next verify cycle. Pulsing

RA0 will begin a program cycle.

2.1.3

PROGRAM CYCLE

“Program cycle” is entered from “verify cycle” or pro-

gram cycle” itself. After a verify, pulsing RA0 will begin

a program cycle. 16-bit data must be presented on

PORTS RB (high byte) and RC (low byte) before RA0

is raised.

The data is sampled 3 T

CY

cycles after the rising edge

of RA0. Programming continues for the duration of RA0

pulse.

At the end of programming the user can choose one of

three different routes. If RA1 is kept low and RA0 is

pulsed again, the same location will be programmed

again. This is useful for applying over programming

pulses. If RA1 is raised before RA0 falling edge, then a

verify cycle is started without address increment. Rais-

ing RA1 after RA0 goes low will increment address and

begin verify cycle on the next address.

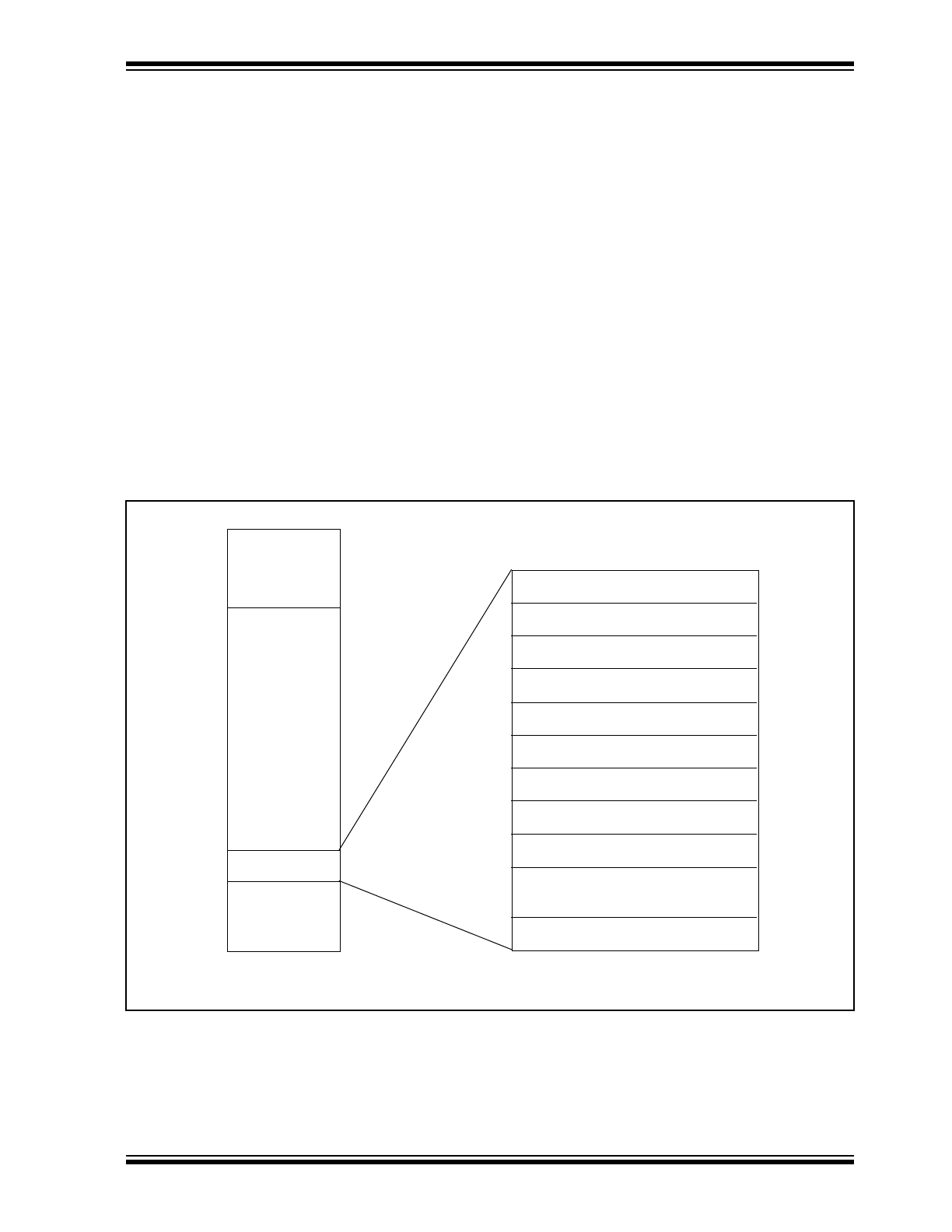

FIGURE 2-2:

PIC17C4X PROGRAM MEMORY MAP

On chip

Program

EPROM

Configuration

Word

FOSC0

FOSC1

WDTPS0

WDTPS1

PM0

PM1

PM2*

Reserved

Reserved

Reserved

FE00

FE01

FE02

FE03

FE04

FE05

FE06

FE07

FE08

FE09

FE0F

Reserved

0000

07FF

FE00

FE0F

FFFF

*This location does not exist for PIC17C42

PIC17CXX

DS30139I-page 4

1996 Microchip Technology Inc.

3.0

PROGRAMMING SPECIFICATIONS

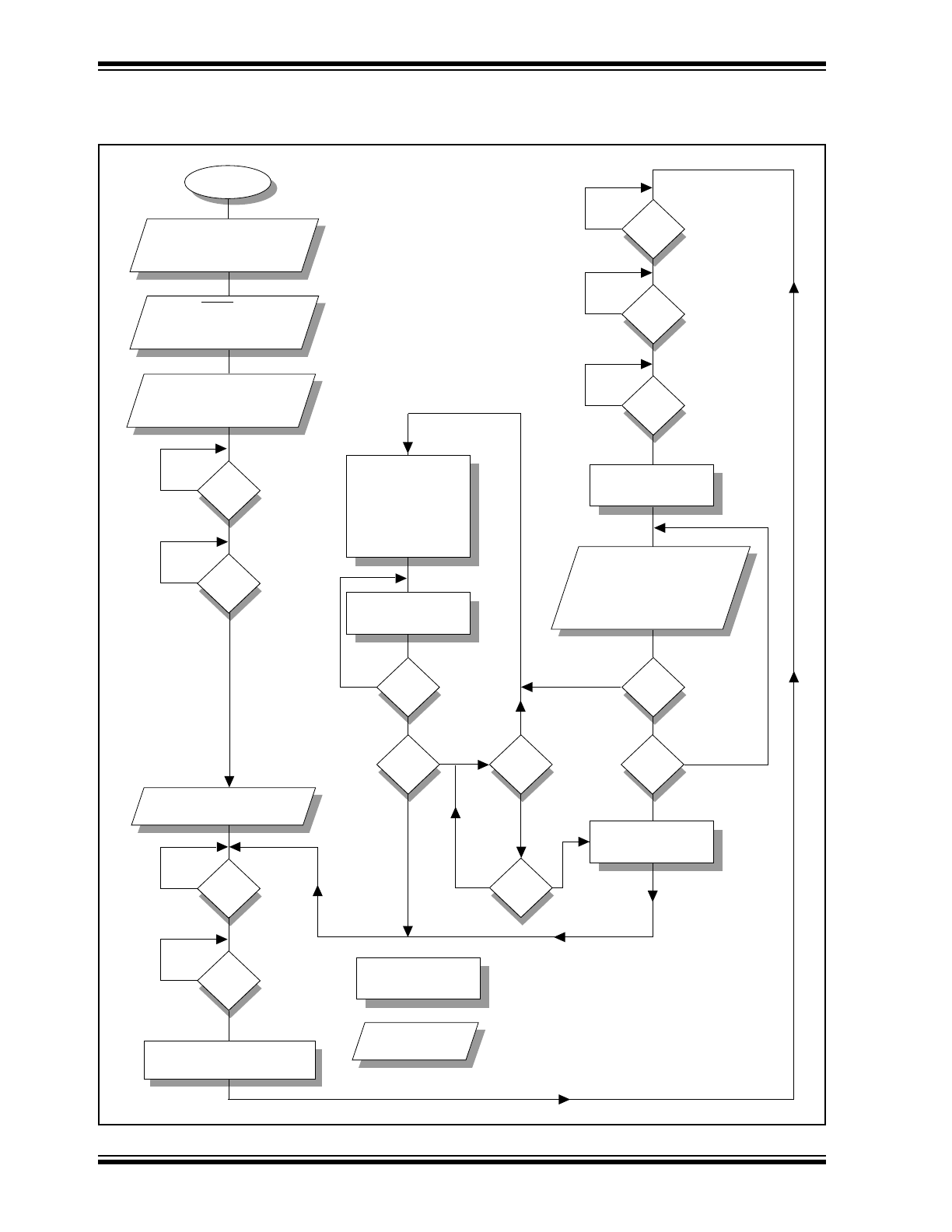

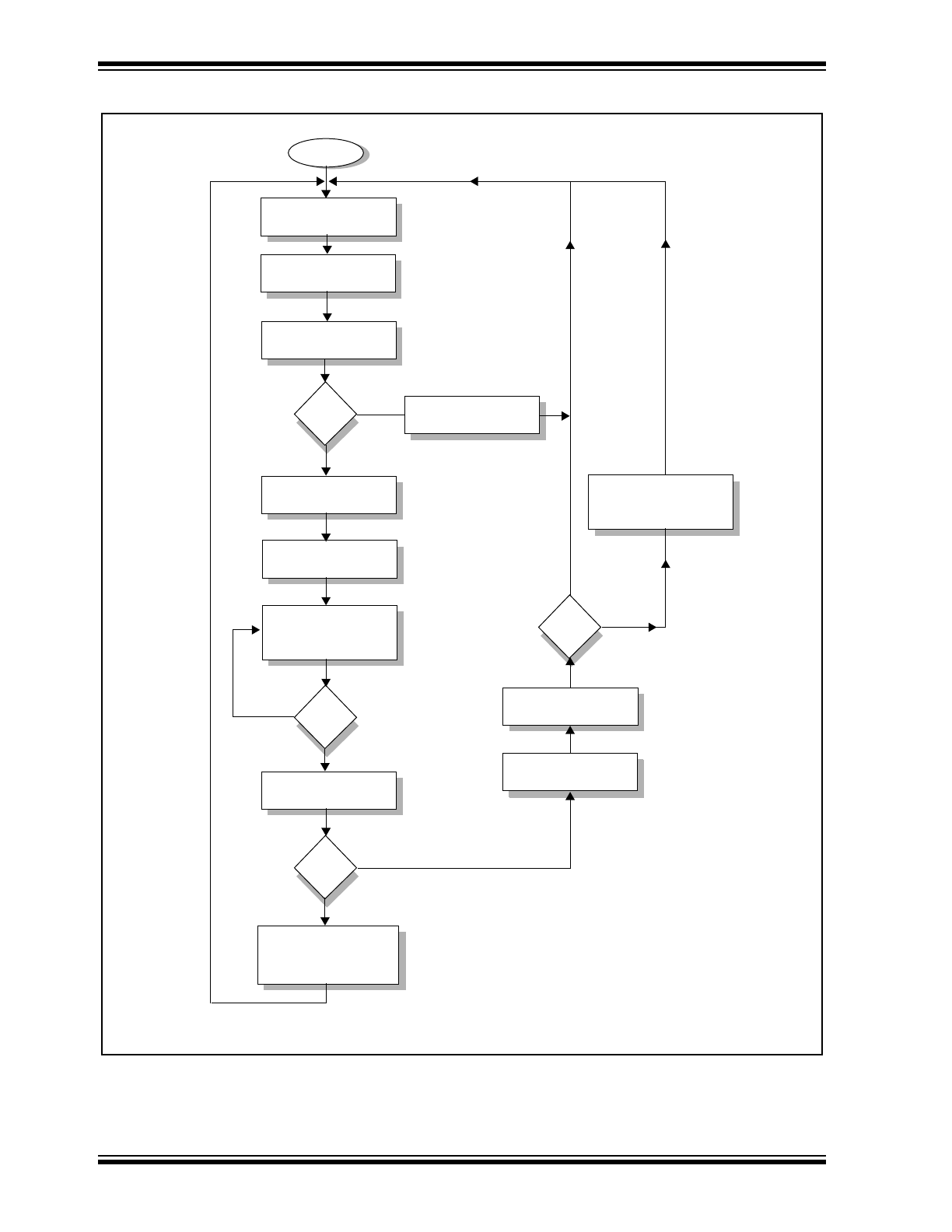

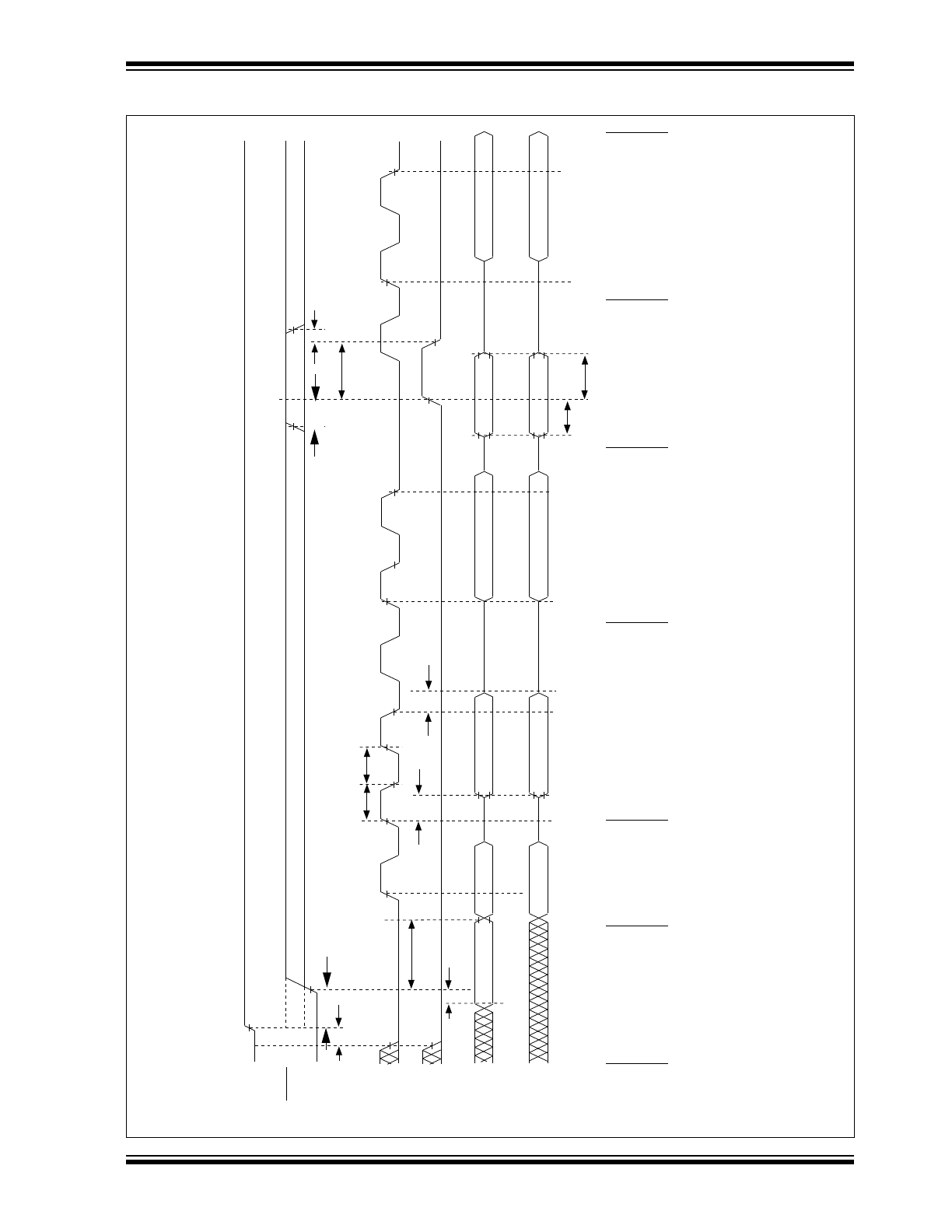

FIGURE 3-1:

PROGRAMMING ROUTINE FLOWCHART

If programming is desired,

force port B = MSB of data

force port C = LSB of data

(hold 10Tcyc after

RA0 is raised)

Present address on ports

RB, RC hold Tcy

after RA1 changes to 1

Reset

RA2 = 0

RA3 = 0

RA4 = 1

MCLR = 1

B port = 0xE1

(hold for 10 Tcy)

RA1

= 0

No

RA1

= 1

Yes

Stop driving address

on port

RA1

= 0

No

RA1

= 1

No

Yes

Yes

B port = MSB of Data

C port = LSB of Data

Read MSB of data

from port-B.

Read LSB of data

from port-C.

Enable RA0 to end

prog cycle

RA0 = 0

No

RA1

= 0

Yes

Yes

No

RA0= 1

RA1

= 1

No

No

Yes

RA0= 1

RA1

= 1

Yes

Yes

No

No

Yes

RA1

= 0

No

Yes

RA1

= 1

No

Yes

RA1

= 0

No

Yes

- B port is forced by the part

B port = xxx

- B port is tri-state, should be forced by user

Min RA1 high or low = 10 Tcy

Yes

No

B port = xxx

Increment

Address

Program 16 bit

data

B & C ports not

driven by part

1996 Microchip Technology Inc.

DS30139I-page 5

EPROM Memory Programming Specification

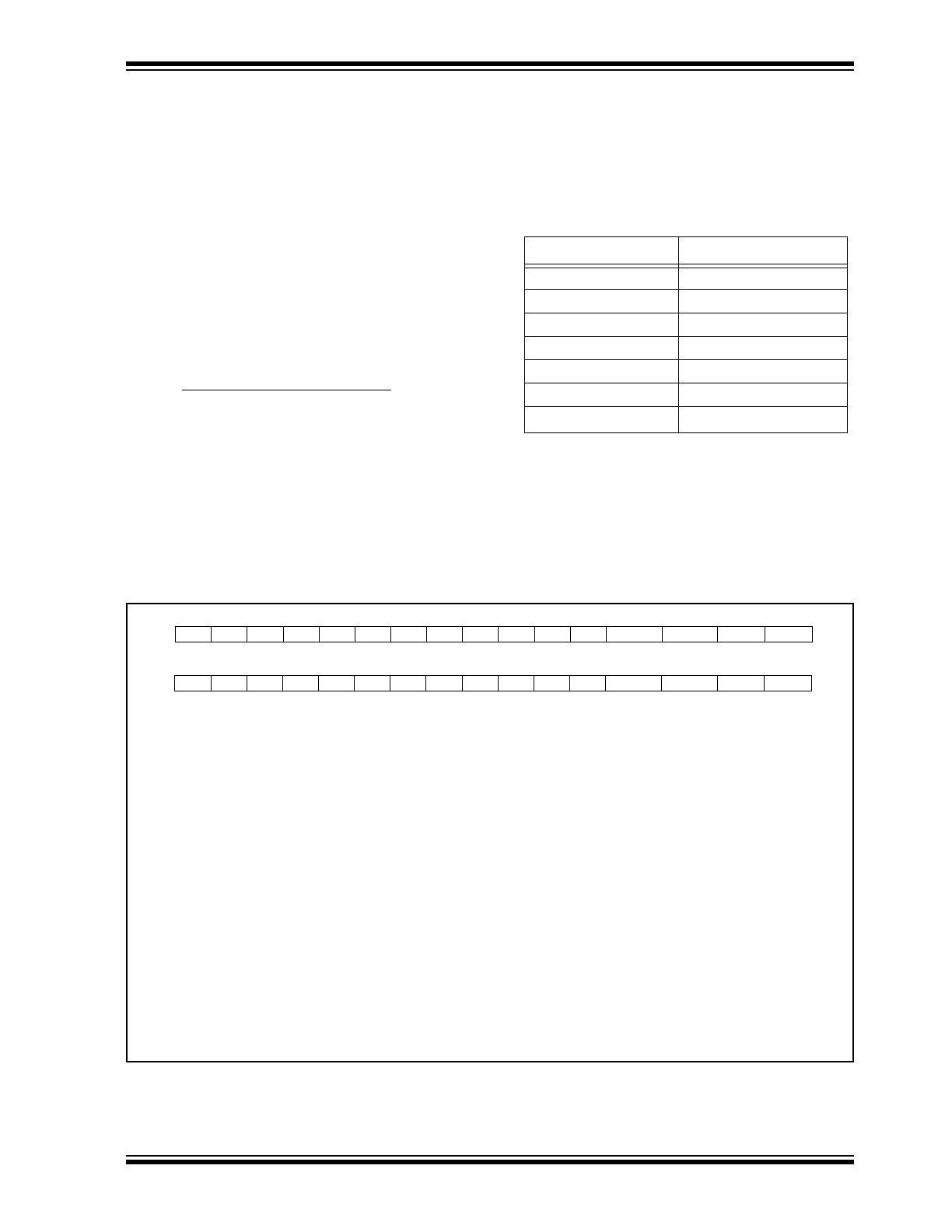

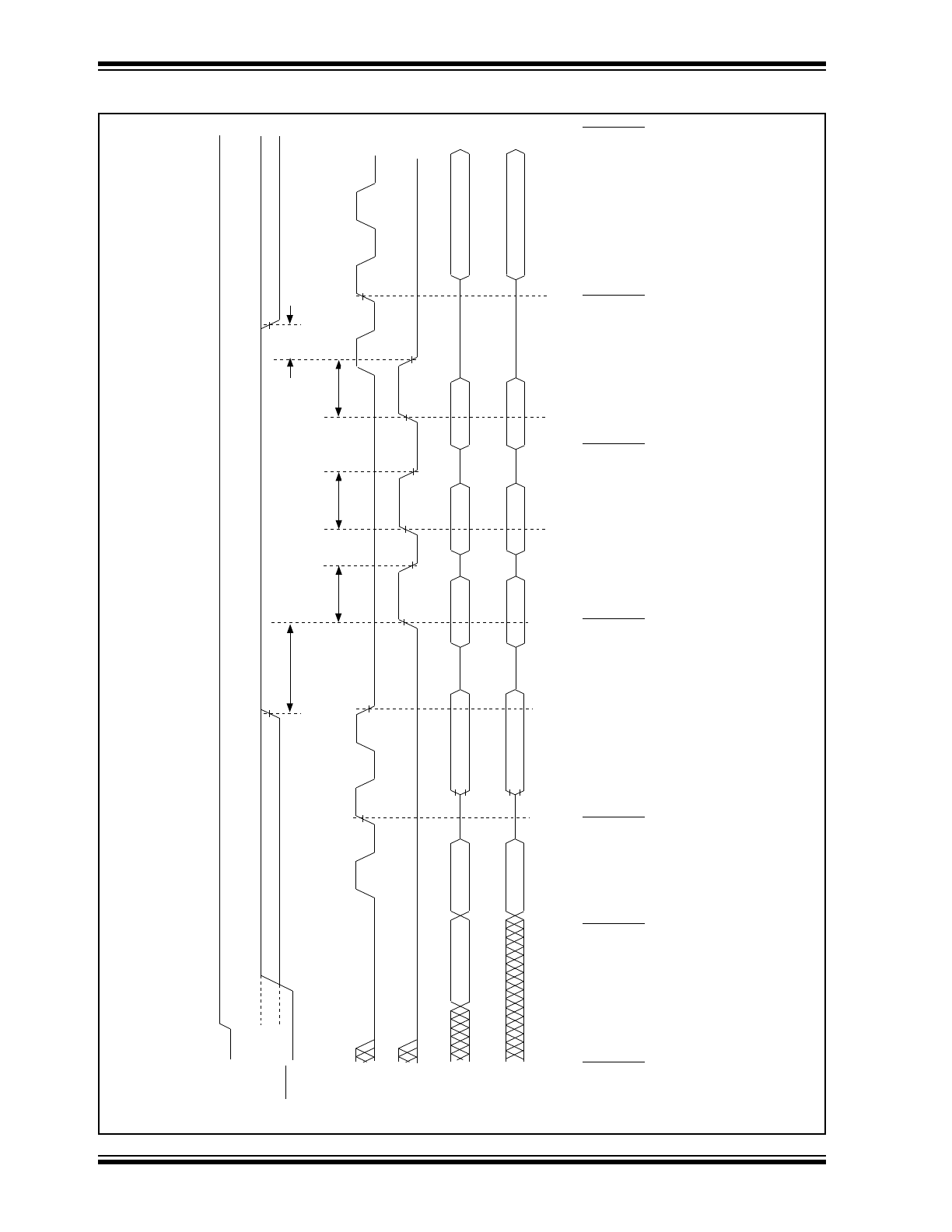

FIGURE 3-2:

RECOMMENDED PROGRAMMING ALGORITHM FOR USER EPROM

Start

Pass

Blank

check?

Yes

Yes

No

No

Pass?

Pulse-

count

>25

No

Apply (3 x Pulse-count)

more 100 µs programming

pulses for margin

(Over programming)

Load new address

Pulse-count = 0

Pass?

No

Yes

Verify blank

Issue "Blank check fail"

error message

Load new data

Set V

DD

= V

DDP

Verify location for

correct data

Program using 100µs

pulse increment

pulse-count

Location fails

programming, issue error

message "Unable to

program location"

Set V

DD

= V

DD

min

Verify location

Programming error:

Issue error message

"Fail verify @ V

DD

min/max"

Set V

DD

= V

DD

min

Set V

DD

= V

DD

max.

Verify location(s)

Set V

DD

= V

DD

max

Set V

DD

= V

DD

min

Set V

DD

= V

DD

min

“Fail verify @ V

DD

min/max”

PIC17CXX

DS30139I-page 6

1996 Microchip Technology Inc.

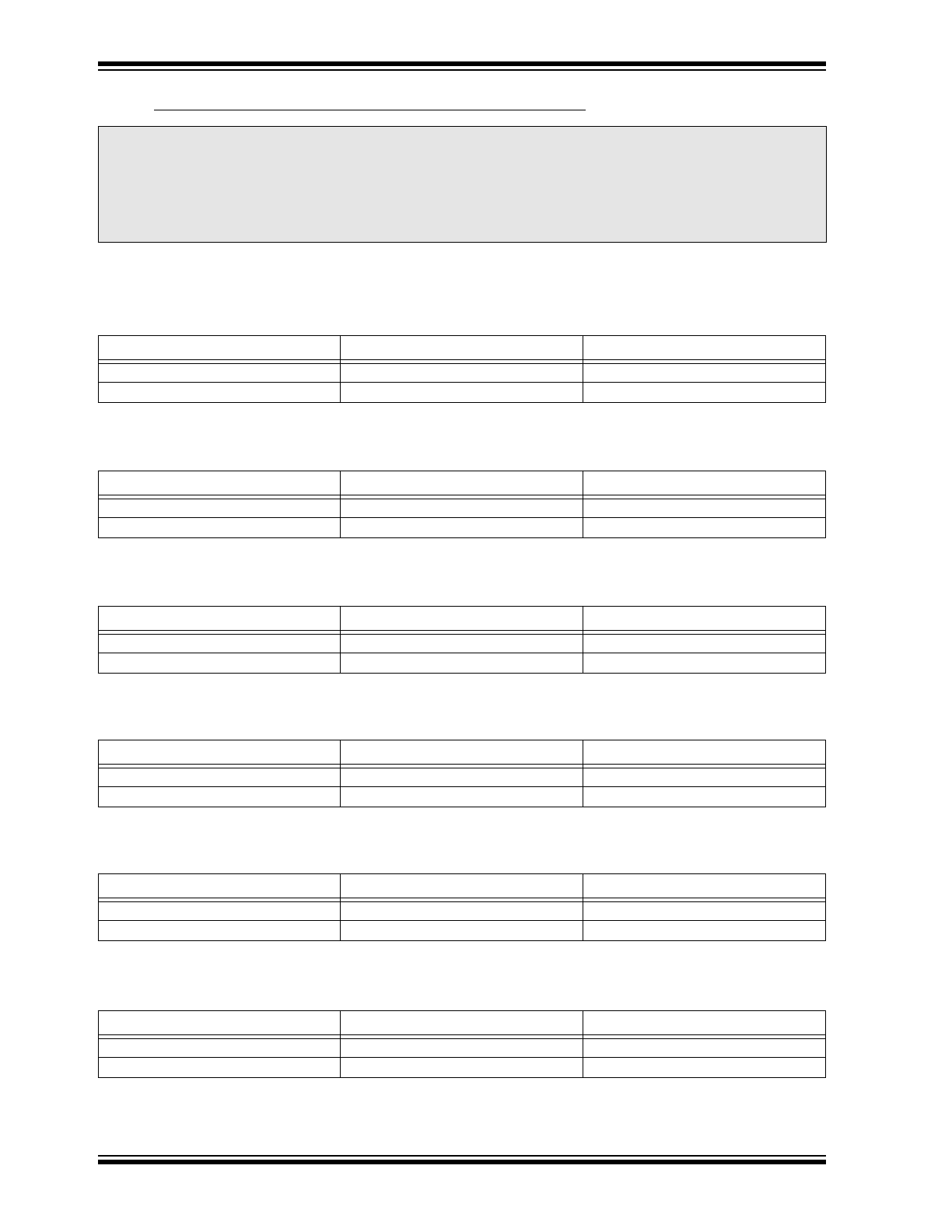

FIGURE 3-3:

RECOMMENDED PROGRAMMING ALGORITHM FOR CONFIGURATION WORDS

Load new address

Pulse-count = 0

Set V

DD

= V

DD

min

Verify blank

Issue “blank check fail”

Load new data

Set V

DD

= V

DDP

Set V

DD

= V

DD

max

Set V

DD

= V

DD

min

Verify location for

Program using 100

µ

s

Location fails

Programming error:

No

Yes

No

No

Yes

Yes

Start

Pass

Blank

check?

pulse increment

pulse-count

Pass?

Issue error message

“Fail verify @ V

DD

min/max”

Verify location(s)

Pass?

No

Yes

Pulse

count

<100

programming, issue error

message “Unable to

program location”

correct data

error message

Set V

DD

= V

DD

min

Set V

DD

= V

DD

min

Verify location

1996 Microchip Technology Inc.

DS30139I-page 7

EPROM Memory Programming Specification

4.0

CONFIGURATION WORD

Configuration bits are mapped into program memory.

Each bit is assigned one memory location. In erased

condition a bit will read as '1'. To program a bit, the user

needs to write to the memory address. The data is

immaterial; the very act of writing will program the bit.

The configuration word locations are shown in

Table 4-3.

The programmer should not program the

reserved locations to avoid unpredictable results

and to be compatible with future variations of the

PIC17C4X

.

It is also mandatory that configuration

locations are programmed in the strict order start-

ing from the first location (0xFE00) and ending with

the last (0xFE0F). Unpredictable results may occur

if the sequence is violated.

4.1

Reading Configuration Word

The PIC17CXX has seven configuration locations (see

Table 4-1). These locations can be programmed (read

as '0') or left unprogrammed (read as '1') to select var-

ious device configurations. Any write to a configuration

location, regardless of the data, will program that con-

figuration bit. Reading any configuration location

between 0xFE00 and 0xFE07 will place the low byte of

the configuration word (see Table 4-2) into PAD<7:0>

(PORTC). PAD<15:8> (PORTB) will be set to 0xFF.

Reading a configuration location between 0xFE08 and

0xFE0F will place the high byte of the configuration

word into PAD<7:0> (PORTC). PAD<15:8> (PORTB)

will be set to 0xFF.

TABLE 4-1:

CONFIGURATION BIT

PROGRAMMING LOCATIONS

†

This location does not exist on the PIC17C42.

Bit

Address

FOSC0

0xFE00

FOSC1

0xFE01

WDTPS0

0xFE02

WDTPS1

0xFE03

PM0

0xFE04

PM1

0xFE06

PM2

†

0xFE0F

TABLE 4-2:

READ MAPPING OF CONFIGURATION BITS

—=Unused

PM<2:0>, Processor Mode Select bits

111 = Microprocessor mode

110 = Microcontroller mode

101 = Extended Microcontroller mode

000 = Code protected microcontroller mode

WDTPS<1:0>, WDT Prescaler Select bits.

11 = WDT enabled, postscaler = 0

10 = WDT enabled, postscaler = 256

01 = WDT enabled, postscaler = 64

00 = WDT disabled, 16-bit overflow timer

FOSC<1:0>, Oscillator Select bits

11

= EC oscillator

10 = XT oscillator

01 = RC oscillator

00 = LF oscillator

*

This bit does not exist on PIC17C42.

WDTPS1

FOSC1 FOSC0

WDTPS0

PM0

PM1

—

—

PM2*

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

—

—

—

8

9

10

11

12

13

14

15

0

1

2

3

4

5

6

7

—

—

—

8

9

10

11

12

13

14

15

0

1

2

3

4

5

6

7

—

PIC17CXX

DS30139I-page 8

1996 Microchip Technology Inc.

4.2

Embedding Configuration Word Information in the Hex File

TABLE 4-3:

CONFIGURATION WORD

PIC17C42

To code protect:

• Protect all memory

XXXXXXXXX0X0XXXX

PIC17C42A

To code protect:

• Protect all memory

0XXXXXXXX0X0XXXX

PIC17CR42

To code protect:

• Protect all memory

0XXXXXXX0X0XXXX

PIC17C43

To code protect:

• Protect all memory

0XXXXXXX0X0XXXX

PIC17CR43

To code protect:

• Protect all memory

0XXXXXXX0X0XXXX

PIC17C44

To code protect:

• Protect all memory

0XXXXXXX0X0XXXX

Legend: X = Don’t care

*Write to on-chip EPROM memory is disabled. The only way these locations can be programmed is if a TABLWT

instruction is issued from an “on-chip” program memory space to program an on-chip memory location.

To allow portability of code, a PIC17C4X programmer is required to read the configuration word locations from the hex

file when loading the hex file. If configuration word information was not present in the hex file then a simple warning

message may be issued. Similarly, while saving a hex file, all configuration word information must be included. An

option to not include the configuration word information may be provided. When embedding configuration word infor-

mation in the hex file, it should be to address FE00h.

Microchip Technology Inc. feels strongly that this feature is important for the benefit of the end customer.

Program Memory Segment

R/W in Protected Mode

R/W in Unprotected Mode

Configuration Word (0xFE00)

Read Scrambled, Write Enabled

Read Unscrambled, Write Enabled

All memory

Read Scrambled, Write Disabled*

Read Unscrambled, Write Enabled

Program Memory Segment

R/W in Protected Mode

R/W in Unprotected Mode

Configuration Word (0xFE00)

Read Scrambled, Write Enabled

Read Unscrambled, Write Enabled

All memory

Read Scrambled, Write Disabled*

Read Unscrambled, Write Enabled

Program Memory Segment

R/W in Protected Mode

R/W in Unprotected Mode

Configuration Word (0xFE00)

Read Scrambled, Write Enabled

Read Unscrambled, Write Enabled

All memory

Read Scrambled, Write Disabled*

Read Unscrambled, Write Enabled

Program Memory Segment

R/W in Protected Mode

R/W in Unprotected Mode

Configuration Word (0xFE00)

Read Scrambled, Write Enabled

Read Unscrambled, Write Enabled

All memory

Read Scrambled, Write Disabled*

Read Unscrambled, Write Enabled

Program Memory Segment

R/W in Protected Mode

R/W in Unprotected Mode

Configuration Word (0xFE00)

Read Scrambled, Write Enabled

Read Unscrambled, Write Enabled

All memory

Read Scrambled, Write Disabled*

Read Unscrambled, Write Enabled

Program Memory Segment

R/W in Protected Mode

R/W in Unprotected Mode

Configuration Word (0xFE00)

Read Scrambled, Write Enabled

Read Unscrambled, Write Enabled

All memory

Read Scrambled, Write Disabled*

Read Unscrambled, Write Enabled

1996 Microchip Technology Inc.

DS30139I-page 9

EPROM Memory Programming Specification

4.3

CHECKSUM COMPUTATION

The checksum is calculated by summing the following:

• The contents of all program memory locations

• The configuration word, appropriately masked

• Masked ID locations (when applicable)

The least significant 16 bits of this sum is the check-

sum.

The following table describes how to calculate the

checksum for each device. Note that the checksum cal-

culation differs depending on the code protect setting.

Since the program memory locations read out differ-

ently depending on the code protect setting, the table

describes how to manipulate the actual program mem-

ory values to simulate the values that would be read

from a protected device. When calculating a checksum

by reading a device, the entire program memory can

simply be read and summed. The configuration word

and ID locations can always be read.

Note that some older devices have an additional value

added in the checksum. This is to maintain compatibil-

ity with older device programmer checksums.

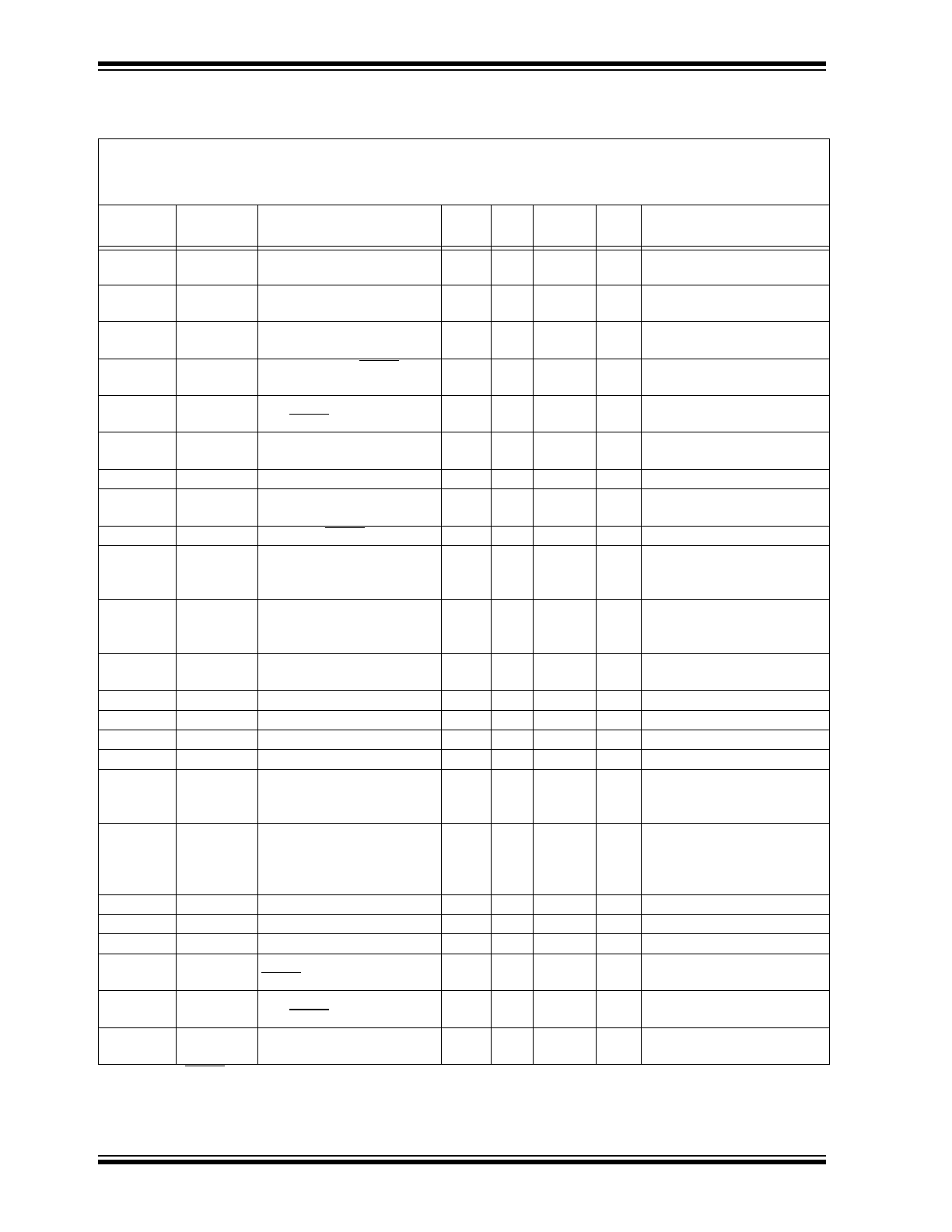

TABLE 4-4:

CHECKSUM COMPUTATION

Device

Code

Protect

Checksum*

Blank

Value

0xC0DE at 0

and max

address

PIC17C42

MP mode

MC mode

EMC mode

PMC mode

SUM[0x000:0x7FF] + CFGW & 0x005F + 0xFFA0

SUM[0x000:0x7FF] + CFGW & 0x005F + 0xFFA0

SUM[0x000:0x7FF] + CFGW & 0x005F + 0xFFA0

SUM_XNOR8[0x000:0x7FF] + CFGW & 0x005F + 0xFFA0

0xF7FF

0xF7EF

0xF7BF

0xF7AF

0x79BD

0x79AD

0x797D

0xBB73

PIC17C42A

MP mode

MC mode

EMC mode

PMC mode

SUM[0x000:0x7FF] + CFGW & 0x015F

SUM[0x000:0x7FF] + CFGW & 0x015F

SUM[0x000:0x7FF] + CFGW & 0x015F

SUM_XNOR8[0x000:0x7FF] + CFGW & 0x015F

0xF95F

0xF94F

0xF91F

0xF80F

0x7B1D

0x7B0D

0x7ADD

0xBBD3

PIC17CR42

MP mode

MC mode

EMC mode

PMC mode

SUM[0x000:0x7FF] + CFGW & 0x015F

SUM[0x000:0x7FF] + CFGW & 0x015F

SUM[0x000:0x7FF] + CFGW & 0x015F

SUM_XNOR8[0x000:0x7FF] + CFGW & 0x015F

0xF95F

0xF94F

0xF91F

0xF80F

0x7B1D

0x7B0D

0x7ADD

0xBBD3

PIC17C43

MP mode

MC mode

EMC mode

PMC mode

SUM[0x000:0xFFF] + CFGW & 0x015F

SUM[0x000:0xFFF] + CFGW & 0x015F

SUM[0x000:0xFFF] + CFGW & 0x015F

SUM_XNOR8[0x000:0xFFF] + CFGW & 0x015F

0xF15F

0xF14F

0xF11F

0xF00F

0x731D

0x730D

0x72DD

0xB3D3

PIC17CR43

MP mode

MC mode

EMC mode

PMC mode

SUM[0x000:0xFFF] + CFGW & 0x015F

SUM[0x000:0xFFF] + CFGW & 0x015F

SUM[0x000:0xFFF] + CFGW & 0x015F

SUM_XNOR8[0x000:0xFFF] + CFGW & 0x015F

0xF15F

0xF14F

0xF11F

0xF00F

0x731D

0x730D

0x72DD

0xB3D3

PIC17C44

MP mode

MC mode

EMC mode

PMC mode

SUM[0x000:0x1FFF] + CFGW & 0x015F

SUM[0x000:0x1FFF] + CFGW & 0x015F

SUM[0x000:0x1FFF] + CFGW & 0x015F

SUM_XNOR8[0x000:0x1FFF] + CFGW & 0x015F

0xE15F

0xE14F

0xE11F

0xE00F

0x631D

0x630D

0x62DD

0xA3D3

Legend: CFGW = Configuration Word

SUM[a:b] = [Sum of locations a to b inclusive]

SUM_XNOR8(a:b) = [Sum of 8-bit wide XNOR copied into upper and lower byte, of locations a to b inclusive]

*Checksum = [Sum of all the individual expressions] MODULO [0xFFFF]

+ = Addition

& = Bitwise AND

PIC17CXX

DS30139I-page 10

1996 Microchip Technology Inc.

5.0

AC/DC CHARACTERISTICS

TIMING REQUIREMENTS FOR PROGRAM/VERIFY TEST MODE

Standard Operating Conditions

Operating Temperature:

+10

°

C

≤

T

A

≤

+70

°

C, unless otherwise stated, (25

°

C is recommended)

Operating Voltage:

4.5V

≤

V

DD

≤

5.25V, unless otherwise stated.

Parameter

No.

Sym.

Characteristic

Min.

Typ.

Max.

Units

Conditions/Comments

PD1

V

DDP

Supply voltage during pro-

gramming

4.75

5.0

5.25

V

PD2

I

DDP

Supply current during pro-

gramming

50

mA

Freq = 10MHz, V

DD

= 5.5V

Note 3

PD3

V

DDV

Supply voltage during verify

V

DD

min.

V

DD

max.

V

Note 2

PD4

V

PP

Voltage on V

PP

/MCLR pin

during programming

12.75

13.25

V

Note 1

PD6

I

PP

Programming current on

V

PP

/MCLR pin

25

50

mA

Note 3

P1

F

OSCP

Osc/clockin frequency dur-

ing programming

4

10

MHz

P2

T

CY

Instruction cycle

1

0.4

µ

s

T

CY

= 4/F

OSCP

P3

TirV2tsH

RA0, RA1, RA2, RA3, RA4

setup before TEST

↑

1

µ

s

P4

TtsH2mcH TEST

↑

to MCLR

↑

1

µ

s

P5

TbcV2irH

RC<7:0>, RB<7:0> valid to

RA1 or RA0

↑

:Address/Data

input setup time

0

µ

s

P6

TirH2bcl

RA1 or RA0

↑

to RB<7:0>,

RC<7:0> invalid ; Address

data hold time;

10 T

CY

µ

s

P7

T0ckiL2rbc

Z

RT

↓

to RB<7:0>, RC<7:0>

high impedance

8 T

CY

P8

T0ckiH2bcV RA1

↑

to data out valid

10 T

CY

P9

Tprog

Programming pulse width

10

100

1000

µ

s

P10

TirH2irL

RA0, RA1 high pulse width

10 T

CY

µ

s

P11

TirL2irH

RA0, RA1 low pulse width

10 T

CY

µ

s

P12

T0ckiV2inL RA1

↑

before INT

↓

(to go

from prog cycle to verify w/o

increment)

0

µ

s

P13

TinL2rtl

RA1 valid after RA0 (to

select increment or no incre-

ment going from program to

verify cycle

10 T

CY

µ

s

P14

Tvpps

V

PP

setup time before RA0

↑

100

µ

s

Note 1

P15

Tvpph

V

PP

hold time after INT

↓

0

µ

s

Note 1

P16

TvdV2tsH V

DD

stable to TEST

↑

10 ms

P17

TrbV2mcH RB input (E1h) valid to V

PP

/

MCLR

↑

0

µ

s

P18

TmcH2rbI RB input (E1h) hold after

V

PP

/MCLR

↑

10 T

CY

ns

P19

TvpL2vdL V

DD

power down after V

PP

power down

10

ms

Note 1: V

PP

/MCLR pin must only be equal to or greater than V

DD

at times other than programming.

Note 2: Program must be verified at the minimum and maximum V

DD

limits for the part.

Note 3: These parameters are for design guidance only and are not tested nor characterized.

1996 Microchip Technology Inc.

DS30139I-page 11

EPROM Memory Programming Specification

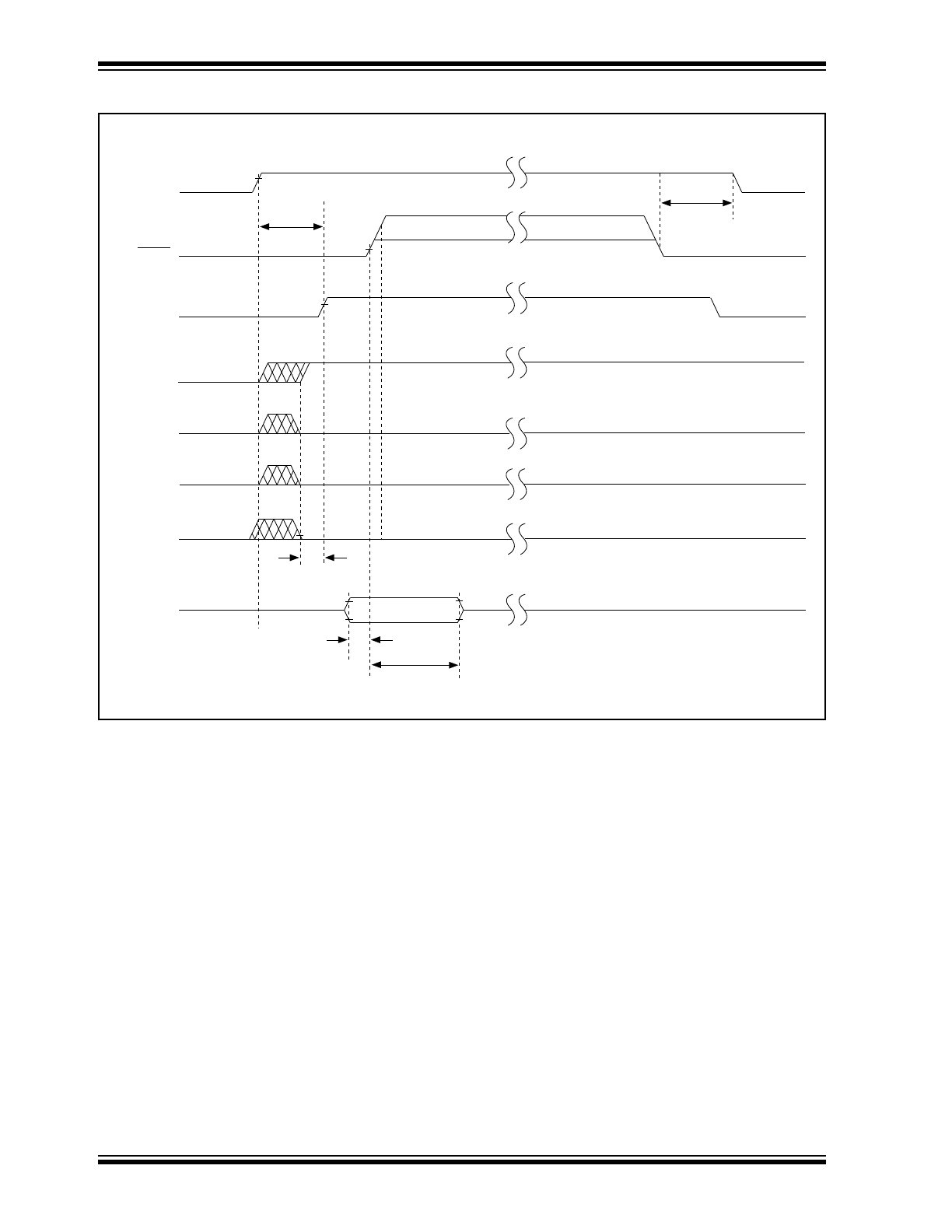

FIGURE 5-1:

PROGRAMMING AND VERIFY TIMINGS I

Test

13V

V

PP

/MCLR

5V

tirV2tsH

ttsH2mcH

RA1

RA0

E1H

RB<7:0>

Jump Address

Input

ADDR_HI

DATA_HI OUT

DATA_HI OUT

RC<7:0>

ADDR_LO

DATA_LO OUT

DATA_LO OUT

DATA_LO_IN

DATA_LO OUT

tmcH2rbL

tirH2lrL

tirL2lrH

tra1H2bcV

tra1L2bcZ

DATA_HI OUT

INC

ADDR

DATA_HI_IN

Programming

Mode entry

Load address X

Verify location X

Increment address to X + 1

by pulsing RA1

Verify location X + 1

Program location X + 1

Do not increment PC

by raising RA1 before

RA0

↓

Verify location X + 1

tbcV2irH

tirH2bc

I

tvpps

tvppH

tprog

trbV2mcH

Note:

RA2 = 0

RA3 = 0

RA4 = 1

P15

P14

P9

P1

1

P10

P8

P7

P3

P4

P17

P18

P5

P6

PIC17CXX

DS30139I-page 12

1996 Microchip Technology Inc.

FIGURE 5-2:

PROGRAMMING AND VERIFY TIMINGS II

Test

13V

V

PP

/MCLR

5V

RA1

RA0

E1H

RB<7:0>

Jump Address

Input

ADDR_HI

DATA_HI OUT

RC<7:0>

ADDR_LO

DATA_LO OUT

DATA_LO_IN

DATA_LO_IN

Programming

mode entry

Load address X

Verify location X

Program location X

Program location X

Move to verify cycle

Prevent increment of

PC by raising RA1

before RA0

↓

Verify location X

tvpps

tvppH

tprog

tprog

DATA_HI_IN

tprog

DATA_HI_IN

DATA_HI_IN

DATA_HI OUT

DATA_LO OUT

DATA_LO_IN

Note:

RA2 = 0

RA3 = 0

RA4 = 1

P15

P9

P9

P9

P14

1996 Microchip Technology Inc.

DS30139I-page 13

EPROM Memory Programming Specification

FIGURE 5-3:

PROGRAMMING AND VERIFY TIMINGS III

RA1

RA0

RB<7:0>

RC<7:0>

Verify location X

Verify location X

Verify location X +1

Pulse RA1 to increment

address to X +2

INC PC

tinL2ra1l

tra1V2inL

tinL2ra1l

INC PC

INC PC

DATA_HI OUT

DATA_HI IN

DATA_HI OUT

DATA_HI IN

DATA_HI OUT

DATA_HI OUT

DATA_LO OUT

DATA_LO IN

DATA_LO OUT

DATA_LO IN

DATA_LO OUT

DATA_LO OUT

Verify location X +2

Program location X

Do not increment PC

Raise RA1 before

RA0

↓

to do this

Program location X

Raise RA1 after RA0

↓

to increment to location X +1

Note:

Device in PGM mode

Test = +5

V

PP

/MCLR = V

PP

RA2 = 0

RA3 = 0

RA4 = 1

P13

P13

P12

PIC17CXX

DS30139I-page 14

1996 Microchip Technology Inc.

FIGURE 5-4:

POWER-UP/DOWN SEQUENCE FOR PROGRAMMING

V

DD

V

PP

/MCLR

TEST

tvpL2vcL

tvcV2tsH

RA0

tirV2tsH

E1H

RB<7:0>

trbV2mcH

tmcH2rbI

RA2

RA3

RA4

P16

P19

P3

P17

P18

1996 Microchip Technology Inc.

DS30139I-page 15

EPROM Memory Programming Specification

NOTES:

Information contained in this publication regarding device applications and the like is intended for suggestion only and may be superseded by updates. No representation or warranty is given and no liability is assumed

by Microchip Technology Incorporated with respect to the accuracy or use of such information, or infringement of patents or other intellectual property rights arising from such use or otherwise. Use of Microchip’s products

as critical components in life support systems is not authorized except with express written approval by Microchip. No licenses are conveyed, implicitly or otherwise, under any intellectual property rights. The Microchip

logo and name are registered trademarks of Microchip Technology Inc. in the U.S.A. and other countries. All rights reserved. All other trademarks mentioned herein are the property of their respective companies.

1999 Microchip Technology Inc.

All rights reserved. © 1999 Microchip Technology Incorporated. Printed in the USA. 11/99

Printed on recycled paper.

AMERICAS

Corporate Office

Microchip Technology Inc.

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-786-7200 Fax: 480-786-7277

Technical Support: 480-786-7627

Web Address: http://www.microchip.com

Atlanta

Microchip Technology Inc.

500 Sugar Mill Road, Suite 200B

Atlanta, GA 30350

Tel: 770-640-0034 Fax: 770-640-0307

Boston

Microchip Technology Inc.

5 Mount Royal Avenue

Marlborough, MA 01752

Tel: 508-480-9990 Fax: 508-480-8575

Chicago

Microchip Technology Inc.

333 Pierce Road, Suite 180

Itasca, IL 60143

Tel: 630-285-0071 Fax: 630-285-0075

Dallas

Microchip Technology Inc.

4570 Westgrove Drive, Suite 160

Addison, TX 75248

Tel: 972-818-7423 Fax: 972-818-2924

Dayton

Microchip Technology Inc.

Two Prestige Place, Suite 150

Miamisburg, OH 45342

Tel: 937-291-1654 Fax: 937-291-9175

Detroit

Microchip Technology Inc.

Tri-Atria Office Building

32255 Northwestern Highway, Suite 190

Farmington Hills, MI 48334

Tel: 248-538-2250 Fax: 248-538-2260

Los Angeles

Microchip Technology Inc.

18201 Von Karman, Suite 1090

Irvine, CA 92612

Tel: 949-263-1888 Fax: 949-263-1338

New York

Microchip Technology Inc.

150 Motor Parkway, Suite 202

Hauppauge, NY 11788

Tel: 631-273-5305 Fax: 631-273-5335

San Jose

Microchip Technology Inc.

2107 North First Street, Suite 590

San Jose, CA 95131

Tel: 408-436-7950 Fax: 408-436-7955

AMERICAS

(continued)

Toronto

Microchip Technology Inc.

5925 Airport Road, Suite 200

Mississauga, Ontario L4V 1W1, Canada

Tel: 905-405-6279 Fax: 905-405-6253

ASIA/PACIFIC

Hong Kong

Microchip Asia Pacific

Unit 2101, Tower 2

Metroplaza

223 Hing Fong Road

Kwai Fong, N.T., Hong Kong

Tel: 852-2-401-1200 Fax: 852-2-401-3431

Beijing

Microchip Technology, Beijing

Unit 915, 6 Chaoyangmen Bei Dajie

Dong Erhuan Road, Dongcheng District

New China Hong Kong Manhattan Building

Beijing 100027 PRC

Tel: 86-10-85282100 Fax: 86-10-85282104

India

Microchip Technology Inc.

India Liaison Office

No. 6, Legacy, Convent Road

Bangalore 560 025, India

Tel: 91-80-229-0061 Fax: 91-80-229-0062

Japan

Microchip Technology Intl. Inc.

Benex S-1 6F

3-18-20, Shinyokohama

Kohoku-Ku, Yokohama-shi

Kanagawa 222-0033 Japan

Tel: 81-45-471- 6166 Fax: 81-45-471-6122

Korea

Microchip Technology Korea

168-1, Youngbo Bldg. 3 Floor

Samsung-Dong, Kangnam-Ku

Seoul, Korea

Tel: 82-2-554-7200 Fax: 82-2-558-5934

Shanghai

Microchip Technology

RM 406 Shanghai Golden Bridge Bldg.

2077 Yan’an Road West, Hong Qiao District

Shanghai, PRC 200335

Tel: 86-21-6275-5700 Fax: 86 21-6275-5060

ASIA/PACIFIC

(continued)

Singapore

Microchip Technology Singapore Pte Ltd.

200 Middle Road

#07-02 Prime Centre

Singapore 188980

Tel: 65-334-8870 Fax: 65-334-8850

Taiwan, R.O.C

Microchip Technology Taiwan

10F-1C 207

Tung Hua North Road

Taipei, Taiwan, ROC

Tel: 886-2-2717-7175 Fax: 886-2-2545-0139

EUROPE

United Kingdom

Arizona Microchip Technology Ltd.

505 Eskdale Road

Winnersh Triangle

Wokingham

Berkshire, England RG41 5TU

Tel: 44 118 921 5858 Fax: 44-118 921-5835

Denmark

Microchip Technology Denmark ApS

Regus Business Centre

Lautrup hoj 1-3

Ballerup DK-2750 Denmark

Tel: 45 4420 9895 Fax: 45 4420 9910

France

Arizona Microchip Technology SARL

Parc d’Activite du Moulin de Massy

43 Rue du Saule Trapu

Batiment A - ler Etage

91300 Massy, France

Tel: 33-1-69-53-63-20 Fax: 33-1-69-30-90-79

Germany

Arizona Microchip Technology GmbH

Gustav-Heinemann-Ring 125

D-81739 München, Germany

Tel: 49-89-627-144 0 Fax: 49-89-627-144-44

Italy

Arizona Microchip Technology SRL

Centro Direzionale Colleoni

Palazzo Taurus 1 V. Le Colleoni 1

20041 Agrate Brianza

Milan, Italy

Tel: 39-039-65791-1 Fax: 39-039-6899883

11/15/99

W

ORLDWIDE

S

ALES

AND

S

ERVICE

Microchip received QS-9000 quality system

certification for its worldwide headquarters,

design and wafer fabrication facilities in

Chandler and Tempe, Arizona in July 1999. The

Company’s quality system processes and

procedures are QS-9000 compliant for its

PICmicro

®

8-bit MCUs, K

EE

L

OQ

®

code hopping

devices, Serial EEPROMs and microperipheral

products. In addition, Microchip’s quality

system for the design and manufacture of

development systems is ISO 9001 certified.