2016 Microchip Technology Inc.

DS20005597A-page 1

AT9933

Features

• Constant Current LED Driver

• Steps Input Voltage Up or Down

• Low Electromagnetic Interference (EMI)

• Variable Frequency Operation

• Internal 75V Linear Regulator

• Input and Output Current Sensing

• Input Current Limit

• Enable and Pulse-width Modulation (PWM)

Dimming

• Ambient Temperature Rating of up to 125°C

Applications

• LED Lighting Applications

General Description

The AT9933 is a variable frequency PWM controller IC,

designed to control an LED lamp driver using a

low-noise boost-buck (Ćuk) topology. It uses

patent-pending Hysteretic Current-mode control to

regulate both the input and the output currents. This

enables superior input surge immunity without the

necessity for complex loop compensation. Input

current control enables current limiting during Startup,

Input Undervoltage and Output Overload conditions.

The AT9933 provides a low-frequency PWM dimming

input that can accept an external control signal with a

duty cycle of 0%–100% and a high dimming ratio.

This AT9933-based LED driver is ideal for LED lamps.

The part is rated for up to 125°C ambient temperatures.

Package Type

REF

CS2

VDD

PWMD

VIN

CS1

GND

GATE

8

7

6

5

1

2

3

4

8-lead SOIC

(Top View)

See

Table 2-1

for pin information.

Hysteretic Boost-Buck (Ćuk) LED Driver IC

AT9933

DS20005597A-page 2

2016 Microchip Technology Inc.

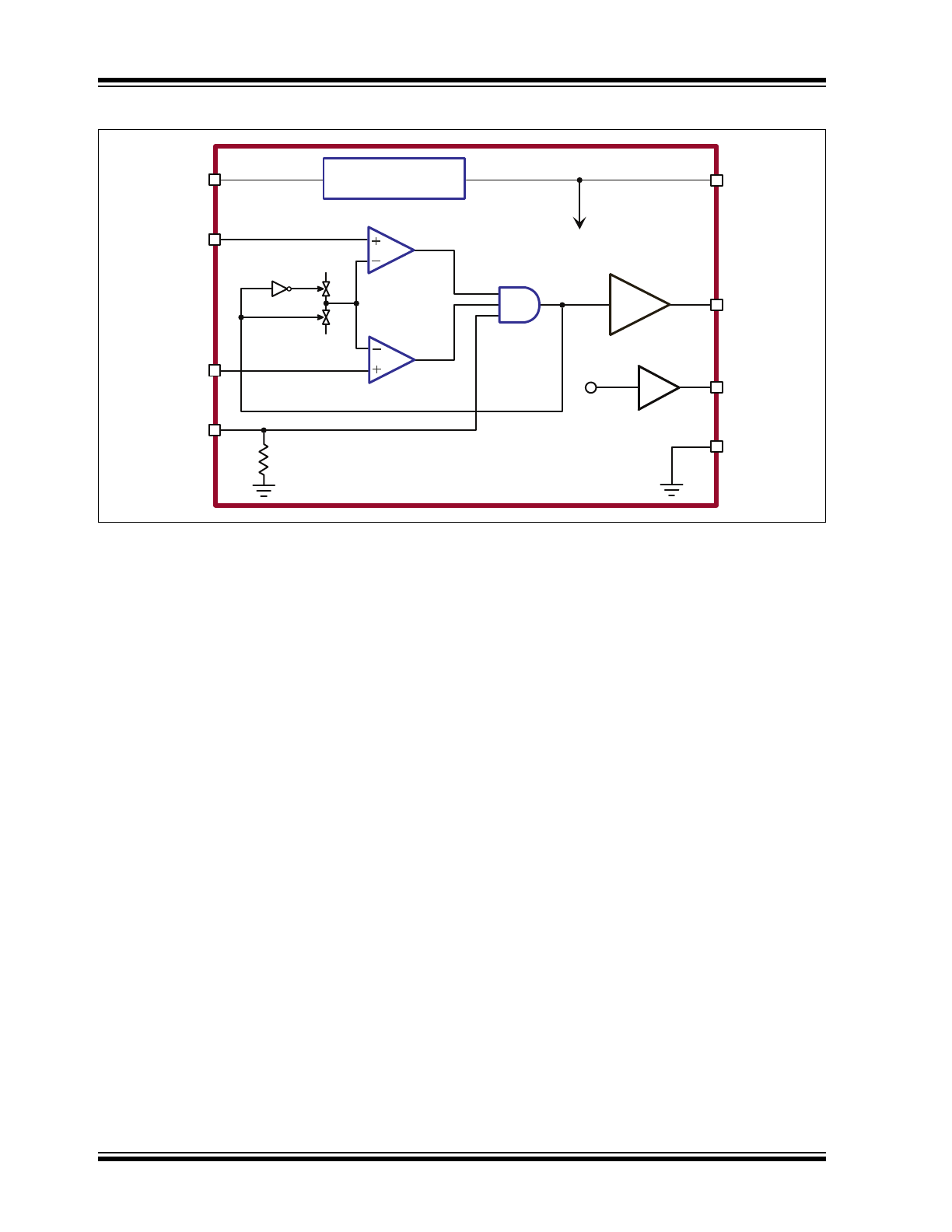

Functional Block Diagram

Regulator

7.5V

VIN

CS1

CS2

PWMD

GATE

VDD

REF

GND

1.25V

AT9933

Input Comparator

Output Comparator

0mV

100mV

2016 Microchip Technology Inc.

DS20005597A-page 3

AT9933

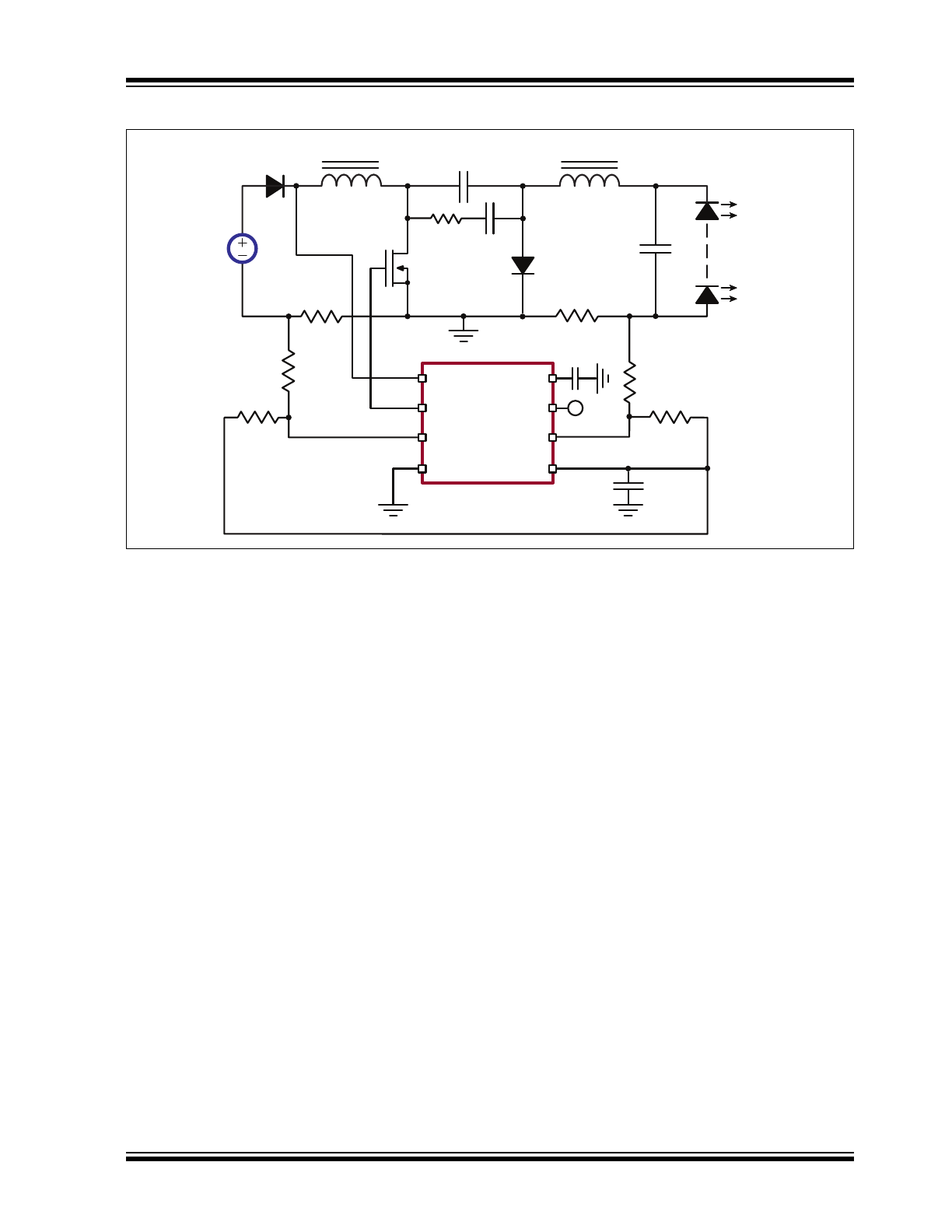

Typical Application

VIN

GATE

CS1

GND

VDD

PWMD

CS2

REF

VDC

L

1

L

2

C

1

Q

1

D

1

R

CS1

R

S2

R

REF2

R

REF1

R

S1

C

2

D

2

(optional)

-

VO

+

C

3

R

CS2

D

3

R

D

C

D

AT9933

Circuit

AT9933

DS20005597A-page 4

2016 Microchip Technology Inc.

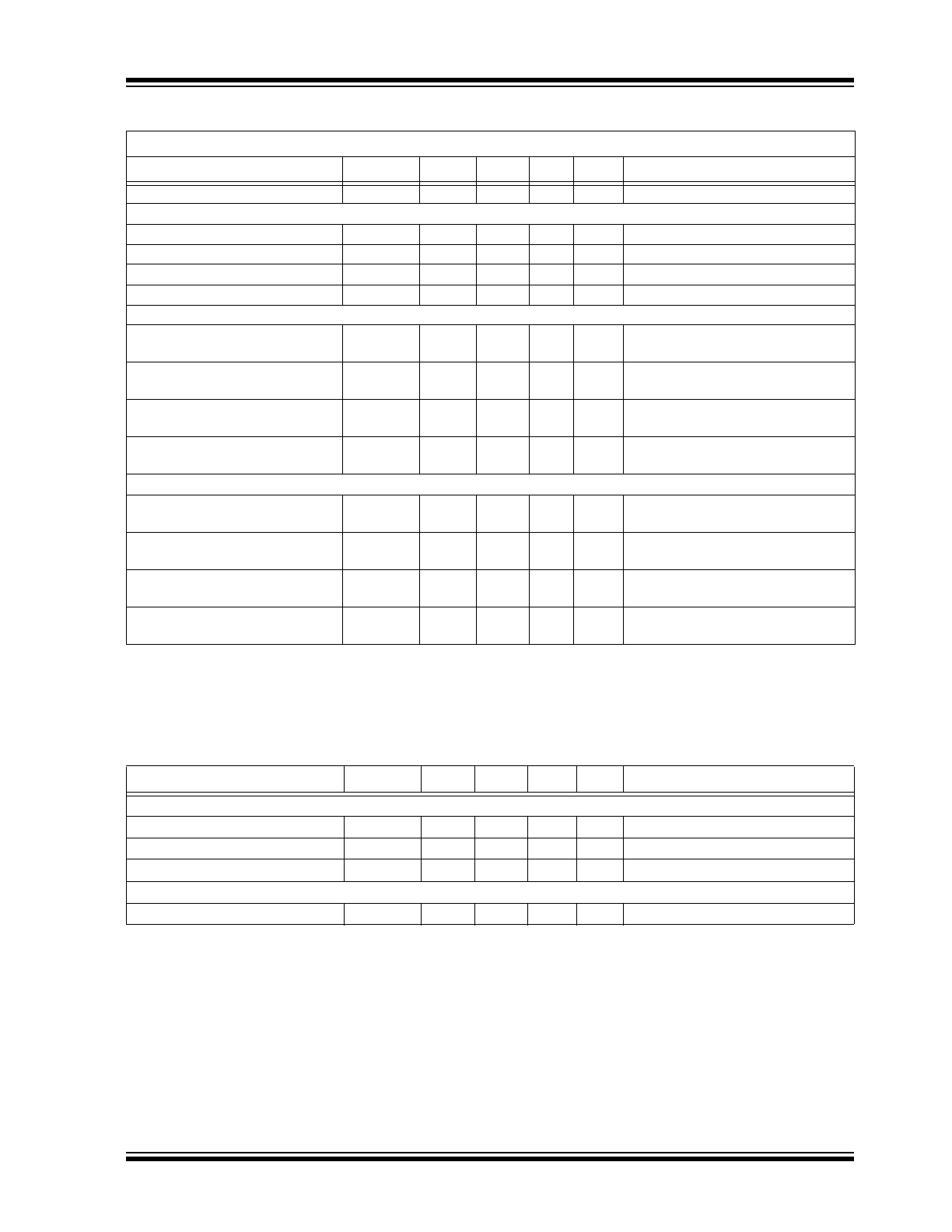

1.0

ELECTRICAL CHARACTERISTICS

Absolute Maximum Ratings†

V

IN

to GND ................................................................................................................................................–0.5V to +75V

CS1, CS2, PWMD and GATE to GND ............................................................................................. –0.3V to V

DD

+0.3V

V

DD(MAX)

................................................................................................................................................................. +12V

Operating Temperature Range............................................................................................................. –40°C to +125°C

Junction Temperature.......................................................................................................................................... +150°C

Storage Temperature Range ............................................................................................................... –65°C to +150°C

Continuous Power Dissipation (T

A

= +25°C):

8-lead SOIC ............................................................................................................................................ 700 mW

† Notice: Stresses above those listed under “Absolute Maximum Ratings” may cause permanent damage to the

device. This is a stress rating only, and functional operation of the device at those or any other conditions above those

indicated in the operational sections of this specification is not intended. Exposure to maximum rating conditions for

extended periods may affect device reliability.

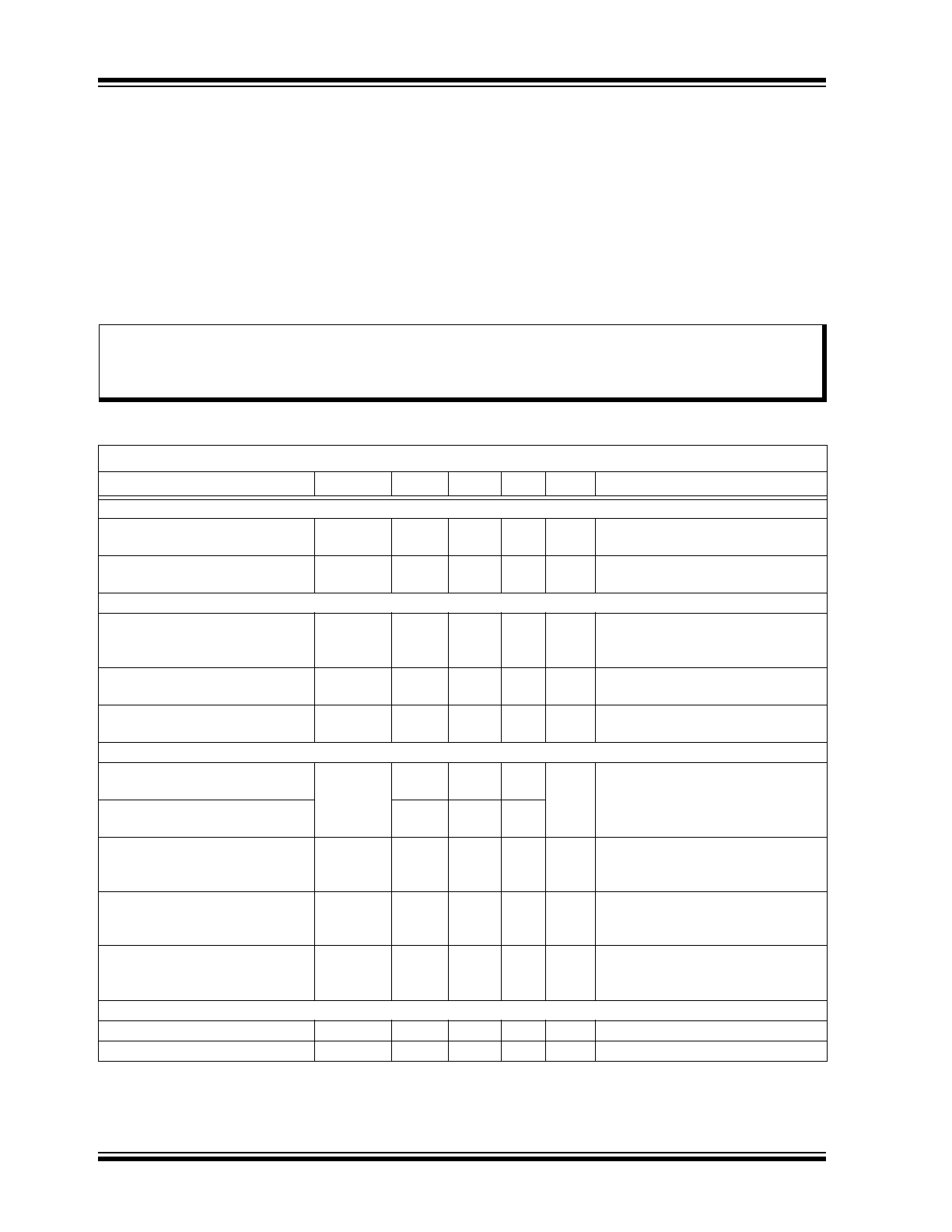

ELECTRICAL CHARACTERISTICS

Electrical Specifications: Specifications are at T

A

= 25°C, V

IN

= Open and V

DD

= 7.5V unless otherwise noted.

Parameter

Sym.

Min.

Typ.

Max.

Unit

Conditions

INPUT

Input DC Supply Voltage Range

V

INDC

Note 3

—

75

V

DC input voltage

(

Note 1

and

Note 2

)

Shutdown Mode Supply Current

I

INSD

—

0.5

1

mA

PWMD connected to GND,

V

IN

= 12V (

Note 2

)

INTERNAL REGULATOR

Internally Regulated Voltage

V

DD

7

7.5

9

V

V

IN

= 8V–75V, I

DD(EXT)

= 0,

500 pF capacitor at GATE,

PWMD = GND (

Note 1

)

V

DD

Undervoltage Lockout

Threshold

UVLO

6.35

6.7

7.05

V

V

DD

rising (

Note 1

)

V

DD

Undervoltage Lock-out

Hysteresis

∆UVLO

—

500

—

mV

REFERENCE

REF Pin Voltage

0°C < T

A

< +85°C

V

REF

1.212

1.25

1.288

V

REF bypassed with a 0.1 µF

capacitor to GND, I

REF

= 0,

PWMD = 5V

REF Pin Voltage

–40°C < T

A

< +125°C

1.187

1.25

1.312

Line Regulation of Reference

Voltage

V

REFLINE

0

—

20

mV

REF bypassed with a 0.1 µF capac-

itor to GND, I

REF

= 0,

V

DD

= 7V–9V, PWMD = 5V

Reference Output Current Range

I

REF

–0.01

—

500

µA

REF bypassed with a 0.1 µF capac-

itor to GND, I

REF

= 0, V

DD

= 7V–9V,

PWMD = 5V

Load Regulation of Reference

Voltage

V

REFLOAD

0

—

10

mV

REF bypassed with a 0.1 µF capac-

itor to GND, I

REF

= 0 µA–500 µA,

PWMD = 5V

PWM DIMMING

PWMD Input Low Voltage

V

PWMD(LO)

—

—

0.8

V

V

DD

= 7V–9V (

Note 1

)

PWMD Input High Voltage

V

PWMD(HI)

2

—

—

V

V

DD

= 7V–9V (

Note 1

)

Note 1:

Specifications apply over the full operating ambient temperature range of –40ºC < T

A

< +125ºC.

2: Also limited by package power dissipation limit, whichever is lower

3: Depends on the current drawn by the part. See

Section 4.0 “Application Information”

2016 Microchip Technology Inc.

DS20005597A-page 5

AT9933

PWMD Pull-down Resistance

R

PWMD

50

100

150

kΩ

V

PWMD

= 5V

GATE DRIVER

GATE Short Circuit Current

I

SOURCE

0.165

—

—

A

V

GATE

= 0V

GATE Sinking Current

I

SINK

0.165

—

—

A

V

GATE

= V

DD

GATE Output Rise Time

T

RISE

—

30

50

ns

C

GATE

= 500 pF

GATE Output Fall Time

T

FALL

—

30

50

ns

C

GATE

= 500 pF

INPUT CURRENT SENSE COMPARATOR

Voltage required to turn on GATE V

TURNON1

85

100

115

mV

C

S2

= 200 mV, C

S1

increasing,

GATE goes LOW to HIGH (

Note 1

)

Voltage required to turn off GATE

V

TURN-

OFF1

–15

0

15

mV

C

S2

= 200 mV, C

S1

decreasing,

GATE goes HIGH to LOW (

Note 1

)

Delay to Output (Turn-on)

T

D1,ON

—

150

250

ns

C

S2

= 200 mV,

C

S1

= 50 mV to +200 mV step

Delay to Output (Turn-off)

T

D1,OFF

—

150

250

ns

C

S2

= 200 mV,

C

S1

= 50 mV to –100 mV step

OUTPUT CURRENT SENSE COMPARATOR

Voltage required to turn on GATE V

TURNON2

85

100

115

mV

C

S1

= 200 mV, C

S2

increasing,

GATE goes LOW to HIGH (

Note 1

)

Voltage required to turn off GATE

V

TURN-

OFF2

–15

0

15

mV

C

S1

= 200 mV, C

S2

decreasing,

GATE goes HIGH to LOW (

Note 1

)

Delay to Output (Turn-on)

T

D2,ON

—

150

250

ns

C

S1

= 200 mV,

C

S2

= 50 mV to +200 mV step

Delay to Output (Turn-off)

T

D2,OFF

—

150

250

ns

C

S1

= 200 mV,

C

S2

= 50 mV to –100 mV step

TEMPERATURE SPECIFICATIONS

Parameter

Sym.

Min.

Typ.

Max.

Unit

Conditions

TEMPERATURE RANGE

Operating Temperature

T

A

–40

—

+125

°C

Junction Temperature

T

J

—

—

+150

°C

Storage Temperature

T

S

–65

—

+150

°C

PACKAGE THERMAL RESISTANCE

8-lead SOIC

JA

—

+101

—

°C/W

Note 1

Note 1: Mounted on a FR-4 board, 25 mm x 25 mm x 1.57 mm

ELECTRICAL CHARACTERISTICS (CONTINUED)

Electrical Specifications: Specifications are at T

A

= 25°C, V

IN

= Open and V

DD

= 7.5V unless otherwise noted.

Parameter

Sym.

Min.

Typ.

Max.

Unit

Conditions

Note 1:

Specifications apply over the full operating ambient temperature range of –40ºC < T

A

< +125ºC.

2: Also limited by package power dissipation limit, whichever is lower

3: Depends on the current drawn by the part. See

Section 4.0 “Application Information”

AT9933

DS20005597A-page 6

2016 Microchip Technology Inc.

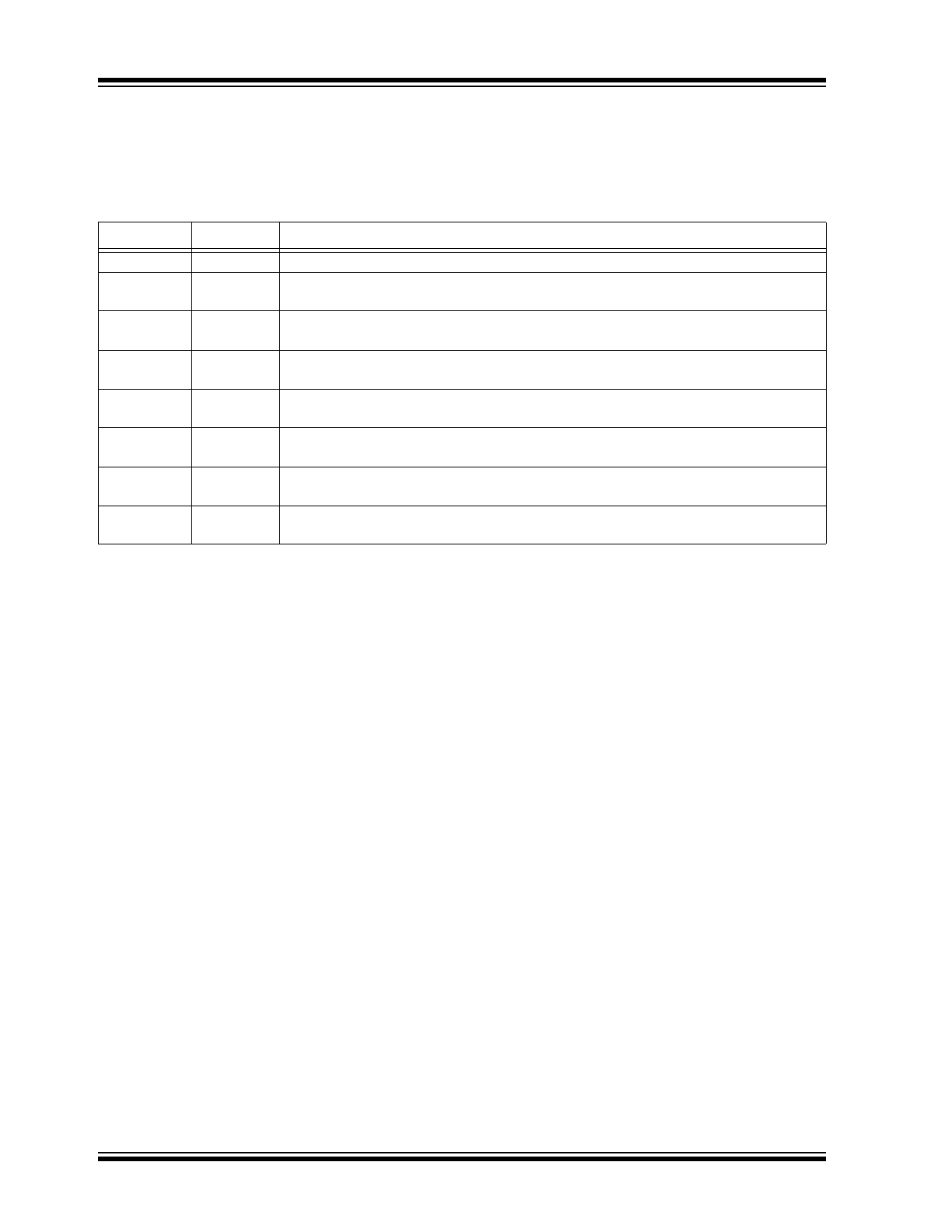

2.0

PIN DESCRIPTION

The details on the pins of AT9933 are listed on

Table 2-1

. Refer to

Package Type

for the location of

the pins.

TABLE 2-1:

PIN FUNCTION TABLE

Pin Number

Pin Name

Description

1

VIN

This pin is the input of an 8V–75V voltage regulator.

2

CS1

This pin is used to sense the input and output currents of the boost-buck converter. It is

a non-inverting input of the internal comparator.

3

GND

This is the ground return for all the internal circuitry. This pin must be electrically

connected to the ground of the power train.

4

GATE

This pin is the output gate driver for an external N-channel power Metal-oxide

Semiconductor Field-effect Transistor (MOSFET).

5

PWMD

When this pin is left open or pulled to GND, the gate driver is disabled. Pulling the pin to

a voltage greater than 2V will enable the gate driver output.

6

VDD

This is a power supply pin for all internal circuits. It must be bypassed to GND with a

low-ESR capacitor greater than 0.1 µF.

7

CS2

This pin is used to sense the input and output currents of the boost-buck converter. It is

a non-inverting input of the internal comparator.

8

REF

This pin provides accurate reference voltage. It must be bypassed with a

0.01 µF–0.1 µF capacitor to GND.

2016 Microchip Technology Inc.

DS20005597A-page 7

AT9933

3.0

DETAILED DESCRIPTION

3.1

Power Topology

The AT9933 is optimized to drive a Continuous

Conduction Mode (CCM) boost-buck DC/DC converter

topology commonly referred to as Ćuk converter.

(Refer to

Typical Application Circuit

.) This power

converter topology offers numerous advantages useful

for driving high-brightness light-emitting diodes (HB

LED). These advantages include step-up or step-down

voltage conversion ratio and low input and output

current ripple. The output load is decoupled from the

input voltage with a capacitor, making the driver

inherently failure-safe for the output load.

The AT9933 offers a simple and effective control

technique for a boost-buck LED driver. It uses two

Hysteretic mode controllers—one for the input and one

for the output. The outputs of these two hysteretic

comparators are ANDED and used to drive the external

FET. This control scheme gives accurate current

control and constant output current in the presence of

input voltage transients without the need for

complicated loop design.

3.2

Input Voltage Regulator

The AT9933 can be powered directly from its V

IN

pin

that can withstand a maximum voltage of up to 75V.

When a voltage is applied to the V

IN

pin, the AT9933

seeks to regulate a constant 7.5V (typical) at the V

DD

pin. The regulator also has a built-in undervoltage

lockout which shuts off the IC when the voltage at the

V

DD

pin falls below the UVLO threshold.

The V

DD

pin must be bypassed by a low-ESR capacitor

(≥0.1 μF) to provide a low-impedance path for the high

frequency current of the output gate driver.

The input current drawn from the V

IN

pin is the sum of

the 1 mA current drawn by the internal circuit and the

current drawn by the gate driver, which in turn depends

on the switching frequency and the gate charge of the

external FET. Refer to

Equation 3-1

.

EQUATION 3-1:

I

IN

1mA Q

G

f

S

+

=

In the above equation, f

S

is the switching frequency,

and Q

G

is the gate charge of the external FET which

can be obtained from the data sheet of the FET.

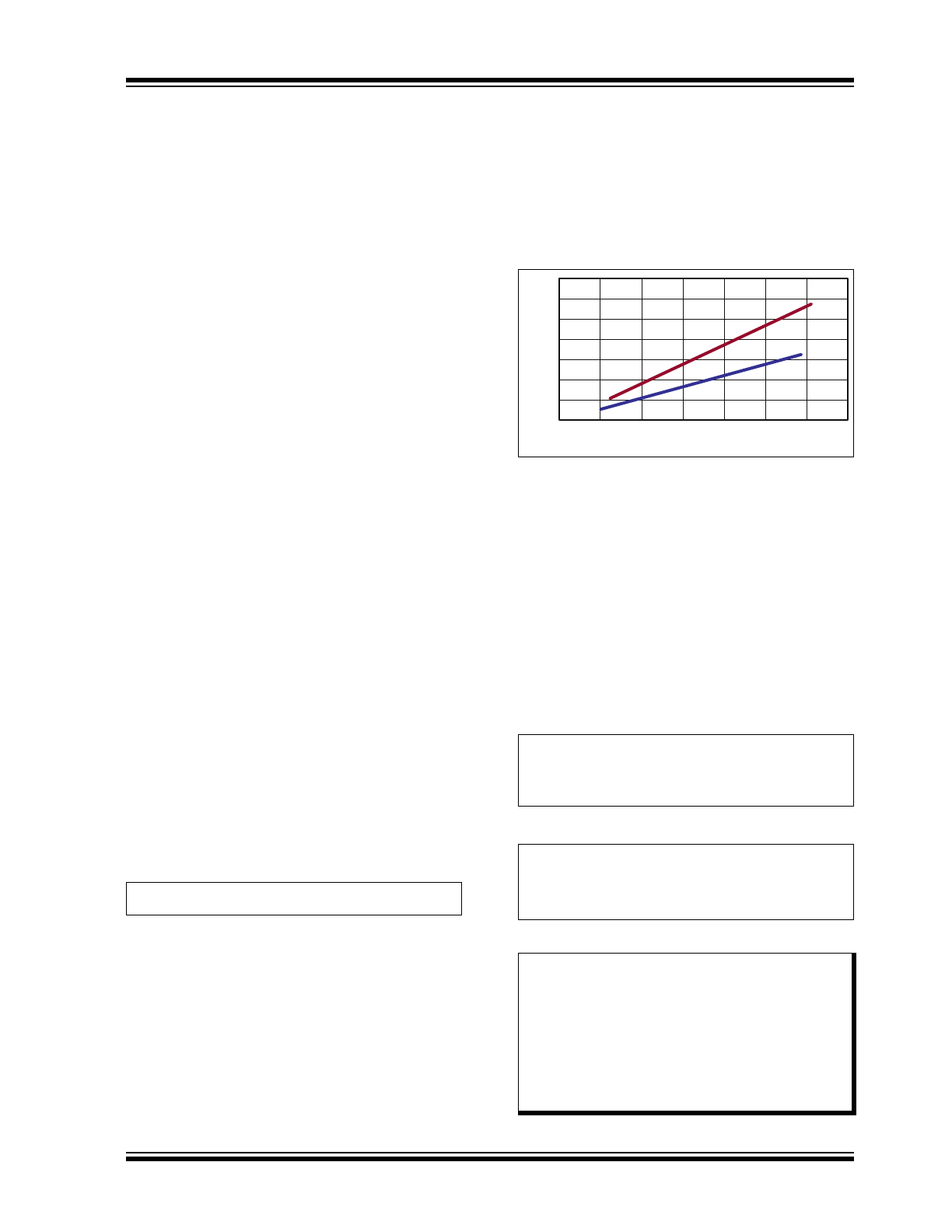

3.3

Minimum Input Voltage at V

IN

Pin

The minimum input voltage at which the converter will

start and stop depends on the minimum voltage drop

required for the linear regulator. The internal linear

regulator will control the voltage at the V

DD

pin when

V

IN

is between 8V and 75V. However, when the V

IN

is

less than 8V, the converter will still function as long as

the V

DD

is greater than the undervoltage lockout. Thus,

under certain conditions, the converter will be able to

start at V

IN

voltages of less than 8V. The start/stop

voltages at the V

IN

pin can be determined using the

maximum voltage drop across the linear regulator as a

function of the current drawn. The data for ambient

temperatures 25ºC and 125ºC are shown in

Figure 3-1

below:

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0

0 1 2 3 4 5 6 7

I

IN

(mA)

Voltage Drop

(V

)

125

O

C

25

O

C

FIGURE 3-1:

Maximum Voltage Drop vs.

Input Current.

Assume an ambient temperature of 125°C. Provided

that the IC is driving a 15 nC gate charge FET at

300 kHz, the total input current is estimated to be

5.5 mA (using

Equation 3-1

). At this input current, the

maximum voltage drop from

Figure 3-1

can be

approximately estimated to be V

DROP

= 2.7V. However,

before the IC starts switching, the current drawn will be

1 mA. At this current level, the voltage drop is

approximately V

DROP1

= 0.5V. Thus, the start/stop V

IN

voltages can be computed as shown in

Equation 3-2

and

Equation 3-3

:

EQUATION 3-2:

V

IN START

–

UVLO

MAX

V

DROP1

+

=

6.95V 0.5V

+

=

7.45V

=

EQUATION 3-3:

V

IN STOP

–

UVLO

MAX

UVLO V

DROP

+

–

=

6.95V 0.5V

–

2.7V

+

=

9.15V

=

Note:

Since the gate driver draws too much cur-

rent in this situation, V

IN-START

is less than

V

IN-STOP

. The control IC will oscillate

between on and off if the input voltage is

between the start and stop voltages. In

these circumstances, it is recommended

that the input voltage be kept higher than

V

IN-STOP

. The IC will operate normally if

the input voltage is kept higher than 9.2V.

AT9933

DS20005597A-page 8

2016 Microchip Technology Inc.

In case of input transients that reduce the input voltage

below 8V (e.g. Cold Crank condition in an automotive

system), the V

IN

pin of the AT9933 can be connected to

the MOSFET drain through a switching diode using a

small (1 nF) capacitor between V

IN

and GND as long as

the drain voltage does not exceed 75V. Since the drain

of the FET is at a voltage equal to the sum of the input

and output voltages, the IC will still be operational when

the input goes below 8V. Therefore, a larger capacitor

is needed at the V

DD

pin to supply power to the IC when

the MOSFET is switched on.

In this case, V

DD UVLO

cannot be relied upon to turn off

the IC at low input voltages when input current levels

can get too large. In such cases, the input current limit

must be chosen to ensure that the input current is set

to a safe level.

3.4

Reference

An internally trimmed voltage reference of 1.25V is

provided at the REF pin. The reference can supply a

maximum output current of 500 µA to drive external

resistor dividers.

This reference can be used to set the current

thresholds of the two comparators as shown in the

Typical Application Circuit

section.

3.5

Current Comparators

The AT9933 features two identical comparators with a

built-in 100 mV hysteresis. When the GATE is low, the

inverting terminal is connected to 100 mV, but when the

GATE is high, it is connected to GND. One comparator

is used for the input current control and the other for the

output current control.

The input side hysteretic controller is in operation

during Start-up, Overload and Input Undervoltage

conditions. This ensures that the input current never

exceeds the designed value. During normal operation,

the input current is less than the programmed current.

Therefore, the output of the input side comparator will

be high. The output of the AND gate will then be

dictated by the output current controller.

The output side hysteretic comparator controls the

external MOSFET during Steady state operation of the

circuit. This comparator turns the MOSFET on and off

based on the LED current.

3.6

PWM Dimming

PWM Dimming can be achieved by applying a

TTL-compatible square wave signal to the PWM pin.

When the PWMD pin is pulled high, the gate driver is

enabled and the circuit operates normally. When the

PWMD pin is left open or connected to GND, the gate

driver is disabled and the external MOSFET turns off.

The signal at the PWMD pin inhibits the driver only and

the IC need not go through the entire start-up cycle

each time, ensuring a quick response time for the

output current. The recommended PWM dimming

frequency range is from 100 Hz to a few kilohertz.

The flying capacitor in the Ćuk converter (C1) is initially

charged to the input voltage VDC (through diodes D

1

and D

2

). When the circuit is turned on and reaches

Steady state, the voltage across C1 will be VDC+VO. In

the absence of diode D

2

, when the circuit is turned off,

capacitor C

1

will discharge through the LEDs and the

input voltage source VDC. Thus, during PWM dimming,

if capacitor C

1

has to be charged and discharged each

cycle, the transient response of the circuit will be

limited. By adding diode D

2

, the voltage across

capacitor C

1

is held at VDC+VO even when the circuit

is turned off, enabling the circuit to return quickly to its

Steady state (and bypassing the start-up stage) upon

being enabled.

2016 Microchip Technology Inc.

DS20005597A-page 9

AT9933

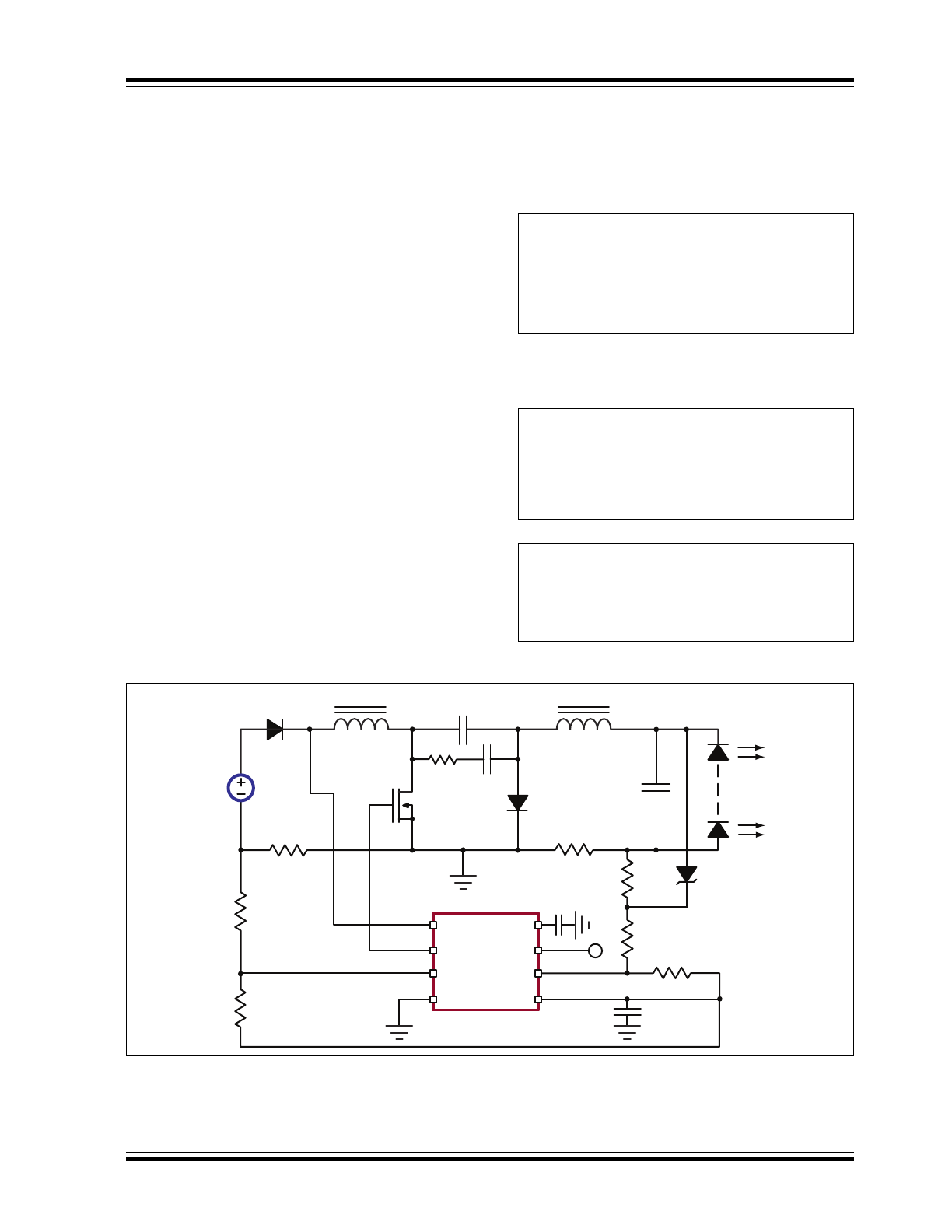

4.0

APPLICATION INFORMATION

4.1

Overvoltage Protection

Overvoltage protection can be added by splitting the

output side resistor R

S2

into two components and

adding a Zener diode D

3

. (Refer to

Figure 4-1

below.)

When there is an Open LED condition, the diode D

3

will

clamp the output voltage and the Zener diode current

will be regulated by the sum of R

S2A

and R

CS2

.

4.2

Damping Circuit

The Ćuk converter is inherently unstable when the

output current is being controlled. An uncontrolled input

current will lead to an undamped oscillation between L

1

and C

1

, causing excessively high voltages across

capacitor C

1

. To prevent these oscillations, a damping

circuit consisting of R

D

and C

D

is applied across the

capacitor C

1

. This damping circuit will stabilize the

circuit and help in the proper operation of the converter.

4.3

Design and Operation of the

Boost-buck Converter

For details on the design for a boost-buck converter

using the AT9933 and the calculation of the damping

components, refer to Application Notes AN-H51 and

AN-H58.

4.4

Design Example

The choice of the resistor dividers to set the input and

output current levels is illustrated by means of the

design example given below.

The parameters of the power circuit are:

V

IN MIN

9.01V

=

V

IN MAX

16V

=

V

O

28V

=

I

O

0.35A

=

f

S MIN

300kHz

=

Using these parameters, the values of the power stage

inductors and capacitor can be computed. (See figures

below.) Refer to Application Note AN-H51 for more

details.

L

1

82

H

=

L

2

150

H

=

C

1

0.22

F

=

The input and output currents for this design are:

I

IN MAX

1.6A

=

I

IN

0.21A

=

I

O

350mA

=

I

O

87.5mA

=

VIN

GATE

CS1

GND

VDD

PWMD

CS2

REF

VDC

L

1

L

2

C

1

Q

1

D1

R

CS1

R

S2A

R

REF2

R

REF1

R

S1

C

2

D

2

(optional)

-

VO

+

C

3

R

CS2

C

O

R

D

C

D

AT9933

R

S2B

D

3

FIGURE 4-1:

Design Example Circuit.

AT9933

DS20005597A-page 10

2016 Microchip Technology Inc.

4.5

Current Limits

The current sense resistor R

CS2

, combined with the

other resistors R

S2

and R

REF2

, determines the output

current limits.

The resistors can be chosen using

Equation 4-1

and

Equation 4-2

.

EQUATION 4-1:

I R

CS

1.2V

R

S

R

REF

-------------

0.05V

–

=

Where I is the current (either I

O

or I

IN

) and ∆I is the

peak-to-peak ripple in the current (either

∆I

O

or

∆I

IN

).

EQUATION 4-2:

I R

CS

0.1V

R

S

R

REF

-------------

0.1V

+

=

Where I is the current (either I

O

or I

IN

) and ∆I is the

peak-to-peak ripple in the current (either

∆I

O

or

∆I

IN

).

For the input side, the current level used in the

equations should be larger than the maximum input

current, so that it does not interfere with the normal

operation of the circuit. The peak input current can be

computed as shown in

Equation 4-3

.

EQUATION 4-3:

I

IN PK

I

IN MAX

I

IN

2

----------

+

=

1.706A

=

Assuming a 30% peak-to-peak ripple when the

converter is in Input Current Limit mode, the minimum

value of the input current is calculated as seen in

Equation 4-4

.

EQUATION 4-4:

I

LIM MIN

0.85 I

IN LIM

=

Setting

I

LIM MIN

1.05 I

IN PK

=

The current level to limit the converter can then be

computed. See equation

Equation 4-5

.

EQUATION 4-5:

I

IN LIM

1.05

0.85

----------

I

IN PK

=

2.1A

=

Using I

O

= 350 mA and ∆I

O

= 87.5 mA in

Equation 4-1

and

Equation 4-2

, R

CS2

= 1.78Ω and

R

S2

/R

REF2

= 0.5625.

Before the design of the output side is complete,

overvoltage protection has to be included in the design.

For this application, choose a 33V Zener diode. This is

the voltage at which the output will clamp in case of an

Open LED condition. For a 350 mW diode, the

maximum current rating at 33V works out to about

10 mA. Using a 2.5 mA current level during Open LED

conditions, and assuming the same R

S2

/R

REF2

ratio,

the Zener current limiting resistor can be determined as

illustrated in

Equation 4-6

.

EQUATION 4-6:

R

CS

R

S2A

+

120

=

Choose the following values for the resistors:

R

CS2

= 1.65Ω, 1/4W, 1%

R

REF2

= 10 kΩ, 1/8W, 1%

R

S2A

= 100Ω, 1/8W, 1%

R

S2B

= 5.23 kΩ, 1/8W, 1%

The current sense resistor needs to be at least a 1/4W,

1% resistor.

Similarly, using I

IN

= 2.1A and ∆I

IN

= 0.3 x I

IN

= 0.63 in

Equation 4-1

and

Equation 4-2

, the following values

can be determined:

R

S1

R

REF1

---------------

0.442

=

P

RCS1

I

2

IN LIM

R

CS1

=

Choose the following values for the resistors:

R

CS1

= parallel combination of three 0.68Ω, 1/2W, 5%

resistors

R

REF1

= 10kΩ, 1/8W, 1%

R

S1

= 4.42kΩ, 1/8W, 1%

R

CS1

0.228

=

1W

=