2017 Microchip Technology Inc.

DS20005715A-page 1

25LC256

Device Selection Table

Features

• Maximum Clock 10 MHz

• Low-Power CMOS Technology:

- Maximum Write current: 5 mA at 5.5V,

10 MHz

- Read current: 6 mA at 5.5V, 10 MHz

- Standby current: 1 µA at 5.5V, 85°C

• 32,768 x 8-bit Organization

• 64-Byte Page

• Self-Timed Erase and Write Cycles (5 ms maxi-

mum)

• Block Write Protection:

- Protect none, 1/4, 1/2 or all of array

• Built-In Write Protection:

- Power-on/off data protection circuitry

- Write enable latch

- Write-protect pin

• Sequential Read

• High Reliability:

- Endurance: 1,000,000 erase/write cycles

- Data retention: >200 years

- ESD protection: >4000V

• Temperature Ranges Supported:

• RoHS Compliant

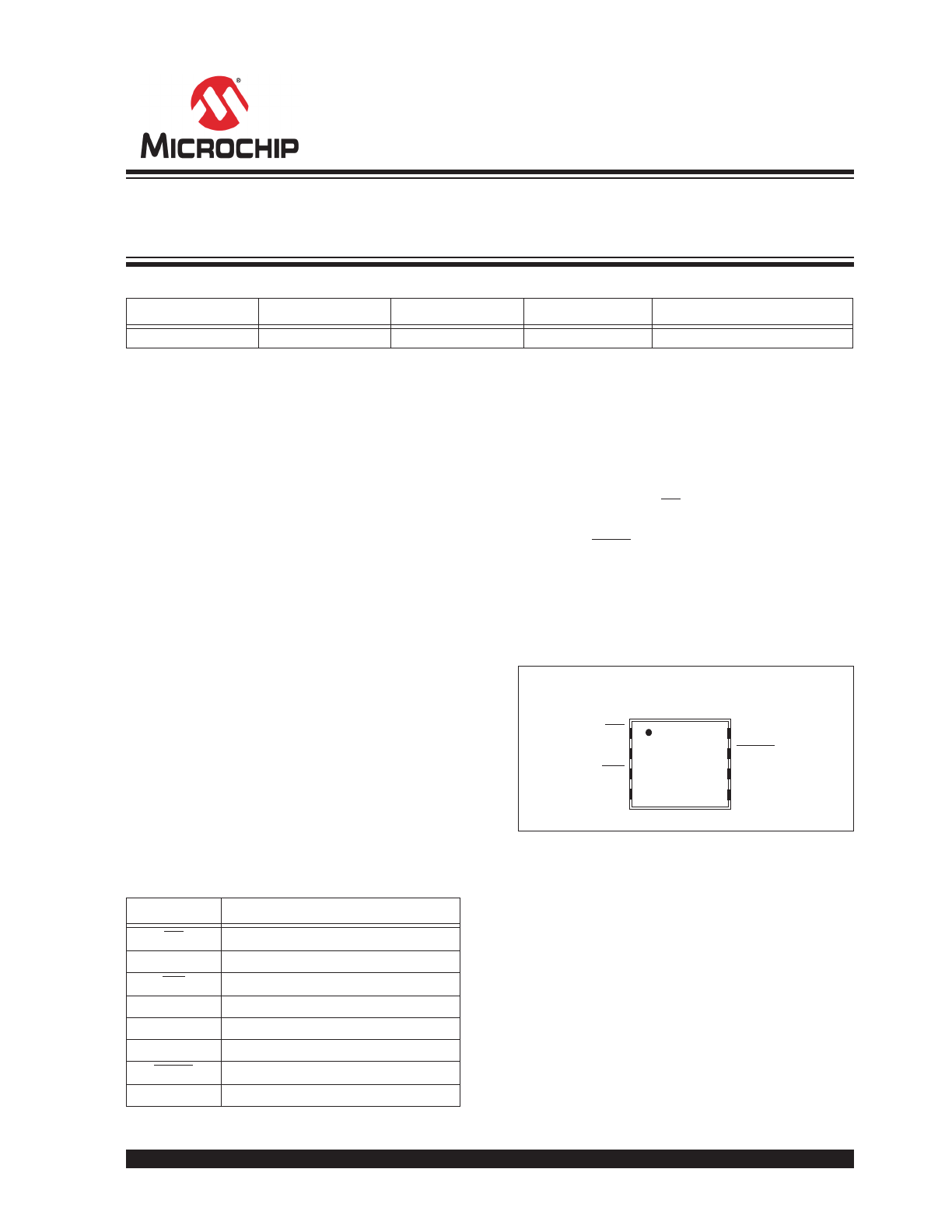

Pin Function Table

Description

The Microchip Technology Inc. 25LC256 is a 256 Kbit

Serial Electrically Erasable PROM. The memory is

accessed via a simple Serial Peripheral Interface (SPI)

compatible serial bus. The bus signals required are a

clock input (SCK) plus separate data in (SI) and data

out (SO) lines. Access to the device is controlled

through a Chip Select (CS) input.

Communication to the device can be paused via the

hold pin (HOLD). While the device is paused,

transitions on its inputs will be ignored, with the

exception of Chip Select, allowing the host to service

higher priority interrupts.

The 25LC256 is available in the 8-lead DFN package.

Package Types (not to scale)

Part Number

V

CC

Range

Page Size

Temp. Ranges

Packages

25LC256

2.5V-5.5V

64 Byte

M

MF

- Extended (M):

-55

C to +125C

Name

Function

CS

Chip Select Input

SO

Serial Data Output

WP

Write-Protect

V

SS

Ground

SI

Serial Data Input

SCK

Serial Clock Input

HOLD

Hold Input

V

CC

Supply Voltage

CS

SO

WP

V

SS

HOLD

SCK

SI

5

6

7

8

4

3

2

1

V

CC

DFN

(MF)

256K SPI Bus Serial EEPROM

Extended (-55

°

C to +125

°

C) Operating Temperatures

25LC256

DS20005715A-page 2

2017 Microchip Technology Inc.

1.0

ELECTRICAL CHARACTERISTICS

Absolute Maximum Ratings

(†)

V

CC

.............................................................................................................................................................................6.5V

All inputs and outputs w.r.t. V

SS

......................................................................................................... -0.6V to V

CC

+1.0V

Storage temperature .................................................................................................................................-65°C to 150°C

Ambient temperature under bias ...............................................................................................................-55°C to 125°C

ESD protection on all pins ..........................................................................................................................................4 kV

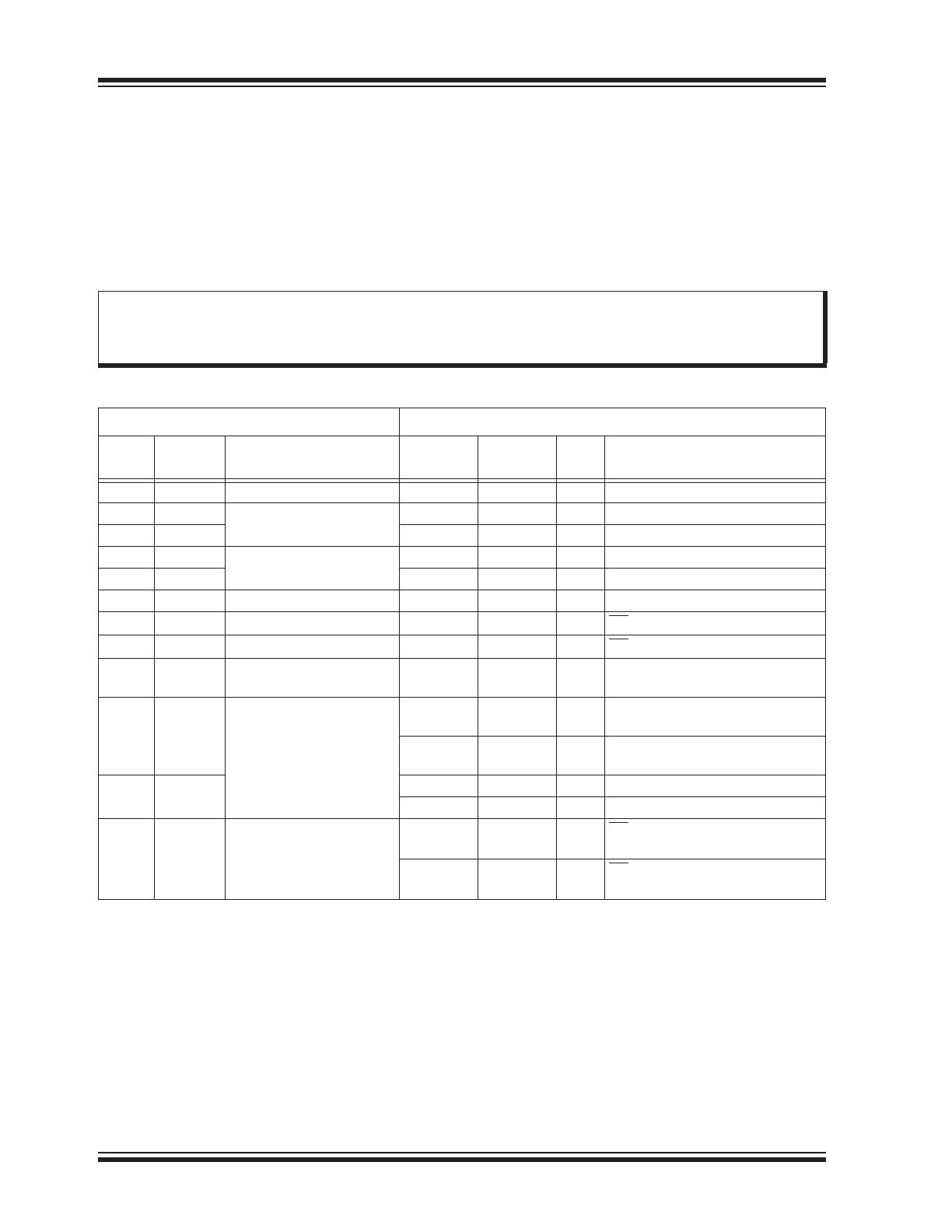

TABLE 1-1:

DC CHARACTERISTICS

† NOTICE: Stresses above those listed under “Absolute Maximum Ratings” may cause permanent damage to the

device. This is a stress rating only and functional operation of the device at those or any other conditions above those

indicated in the operational listings of this specification is not implied. Exposure to maximum rating conditions for an

extended period of time may affect device reliability.

DC CHARACTERISTICS

Extended (M):

T

A

= -55°C to +125°C

V

CC

= 2.5V to 5.5V

Param.

No.

Symbol

Characteristic

Min.

Max.

Units

Test Conditions

D1

V

IH

High-Level Input Voltage

0.7 V

CC

V

CC

+ 1

V

D2

V

IL

Low-Level Input Voltage

-0.3

0.3 V

CC

V

V

CC

≥2.5V

D3

V

IL

-0.3

0.2 V

CC

V

V

CC

< 2.5V

D4

V

OL

Low-Level Output Voltage

—

0.4

V

I

OL

= 2.1 mA, V

CC

= 4.5V

D5

V

OL

—

0.2

V

I

OL

= 1.0 mA, V

CC

= 2.5V

D6

V

OH

High-Level Output Voltage V

CC

– 0.5

—

V

I

OH

= -400 µA

D7

I

LI

Input Leakage Current

—

±1

µA

CS = V

CC

, V

IN

= V

SS

or V

CC

D8

I

LO

Output Leakage Current

—

±1

µA

CS = V

CC

, V

OUT

= V

SS

or V

CC

D9

C

INT

Internal Capacitance

(all inputs and outputs)

—

7

pF

T

A

= 25°C, F

CLK

= 1.0 MHz,

V

CC

= 5.0V (

Note

1

)

D10

I

CCREAD

Operating Current

—

6

mA

V

CC

= 5.5V; F

CLK

= 10.0 MHz;

SO = Open

—

2.5

mA

V

CC

= 2.5V; F

CLK

= 5.0 MHz;

SO = Open

D11

I

CCWRITE

—

5

mA

V

CC

= 5.5V

—

3

mA

V

CC

= 2.5V

D12

I

CCS

Standby Current

—

5

µA

CS = V

CC

= 5.5V, Inputs tied to

V

CC

or V

SS

, 125°C

—

1

µA

CS = V

CC

= 5.5V, Inputs tied to

V

CC

or V

SS

, 85°C

Note 1:

This parameter is periodically sampled and not 100% tested.

2017 Microchip Technology Inc.

DS20005715A-page 3

25LC256

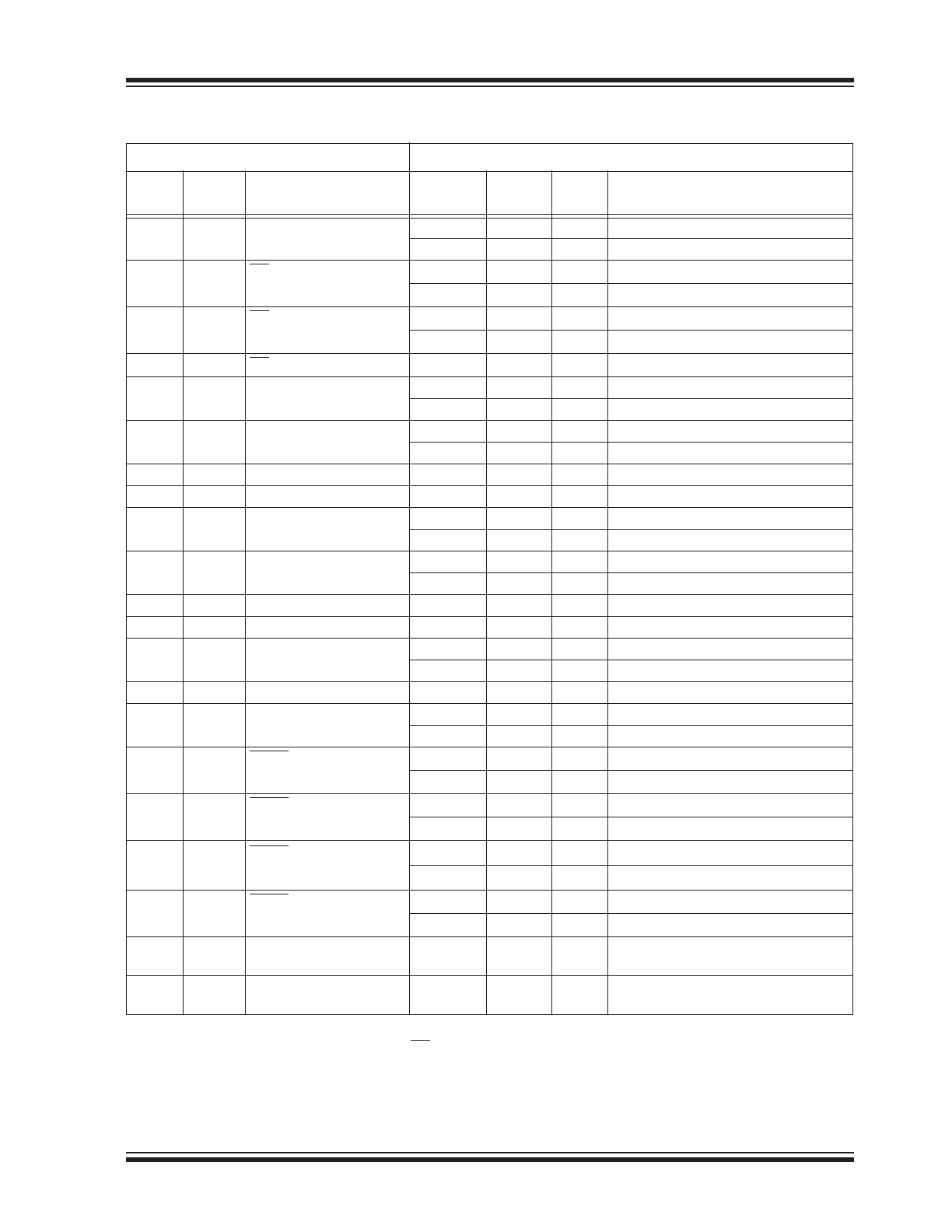

TABLE 1-2:

AC CHARACTERISTICS

AC CHARACTERISTICS

Extended (M):

T

A

= -55°C to +125°C

V

CC

= 2.5V to 5.5V

Param.

No.

Symbol

Characteristic

Min.

Max.

Units

Test Conditions

1

F

CLK

Clock Frequency

—

10

MHz

4.5V ≤

Vcc ≤ 5.5V

—

5

MHz

2.5V ≤

Vcc < 4.5V

2

T

CSS

CS Setup Time

50

—

ns

4.5V ≤

Vcc ≤ 5.5V

100

—

ns

2.5V ≤

Vcc < 4.5V

3

T

CSH

CS Hold Time

100

—

ns

4.5V ≤

Vcc ≤ 5.5V

200

—

ns

2.5V ≤

Vcc < 4.5V

4

T

CSD

CS Disable Time

50

—

ns

5

T

SU

Data Setup Time

10

—

ns

4.5V ≤

Vcc ≤ 5.5V

20

—

ns

2.5V ≤

Vcc < 4.5V

6

T

HD

Data Hold Time

20

—

ns

4.5V ≤

Vcc ≤ 5.5V

40

—

ns

2.5V ≤

Vcc < 4.5V

7

T

R

CLK Rise Time

—

100

ns

Note 1

8

T

F

CLK Fall Time

—

100

ns

Note 1

9

T

HI

Clock High Time

50

—

ns

4.5V ≤

Vcc ≤ 5.5V

100

—

ns

2.5V ≤

Vcc < 4.5V

10

T

LO

Clock Low Time

50

—

ns

4.5V ≤

Vcc ≤ 5.5V

100

—

ns

2.5V ≤

Vcc < 4.5V

11

T

CLD

Clock Delay Time

50

—

ns

12

T

CLE

Clock Enable Time

50

—

ns

13

T

V

Output Valid from Clock

Low

—

50

ns

4.5V ≤

Vcc ≤ 5.5V

—

100

ns

2.5V ≤

Vcc < 4.5V

14

T

HO

Output Hold Time

0

—

ns

Note 1

15

T

DIS

Output Disable Time

—

40

ns

4.5V ≤

Vcc ≤ 5.5V (

Note 1

)

—

80

ns

2.5V ≤

Vcc < 4.5V (

Note 1

)

16

T

HS

HOLD Setup Time

20

—

ns

4.5V ≤

Vcc ≤ 5.5V

40

—

ns

2.5V ≤

Vcc < 4.5V

17

T

HH

HOLD Hold Time

20

—

ns

4.5V ≤

Vcc ≤ 5.5V

40

—

ns

2.5V ≤

Vcc < 4.5V

18

T

HZ

HOLD Low to Output

High Z

30

—

ns

4.5V ≤

Vcc ≤ 5.5V (

Note 1

60

—

ns

2.5V ≤

Vcc < 4.5V (

Note 1

)

19

T

HV

HOLD High to Output

Valid

30

—

ns

4.5V ≤

Vcc ≤ 5.5V

60

—

ns

2.5V ≤

Vcc < 4.5V

20

T

WC

Internal Write Cycle

Time

—

5

ms

Note 2

21

Endurance

1M

—

E/W

Cycles

25°C, V

CC

= 5.5V (

Note 3

)

Note 1: This parameter is periodically sampled and not 100% tested.

2: T

WC

begins on the rising edge of CS after a valid write sequence and ends when the internal write cycle

is complete.

3: This parameter is not tested but ensured by characterization. For endurance estimates in a specific

application, please consult the Total Endurance™ Model which can be obtained from Microchip’s website

at www.microchip.com.

25LC256

DS20005715A-page 4

2017 Microchip Technology Inc.

TABLE 1-3:

AC TEST CONDITIONS

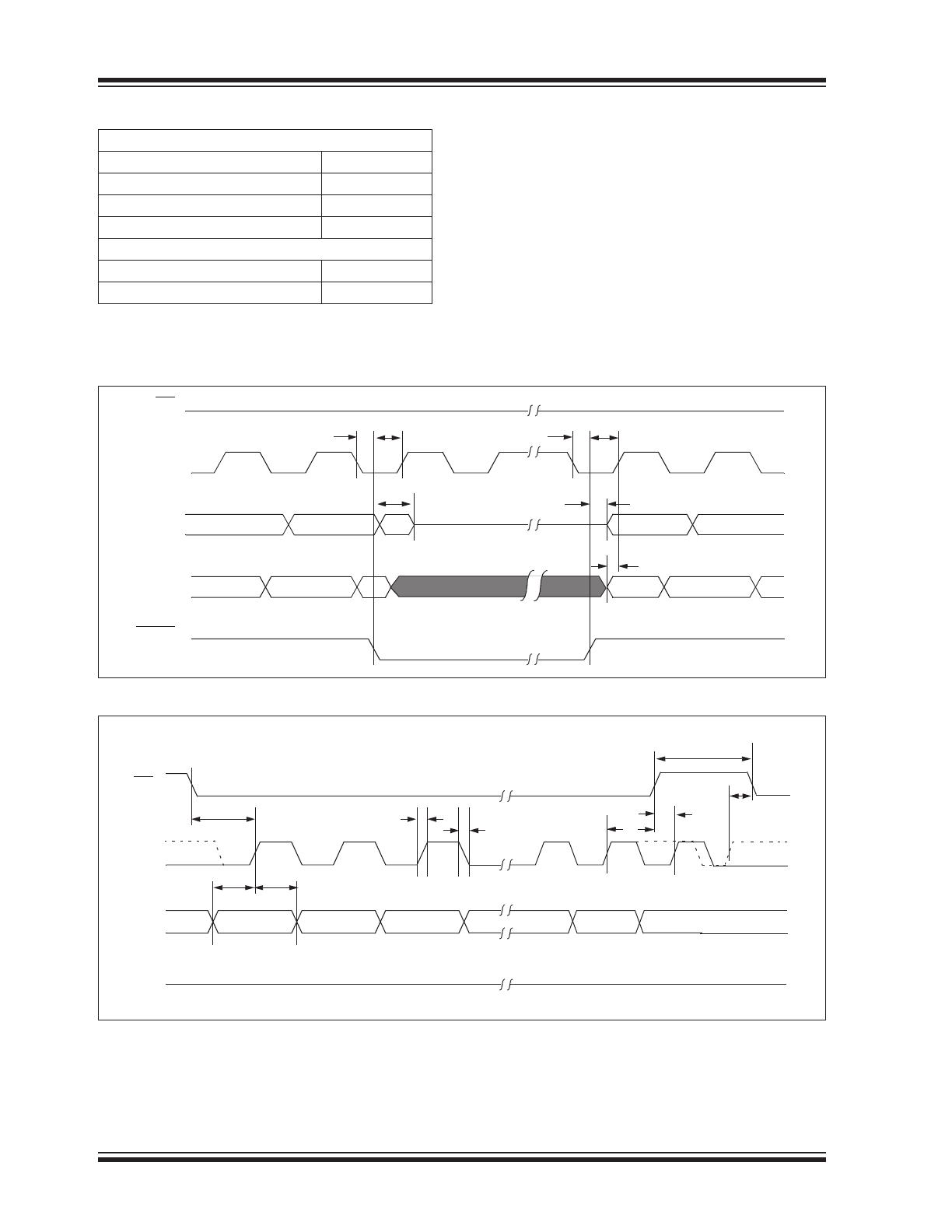

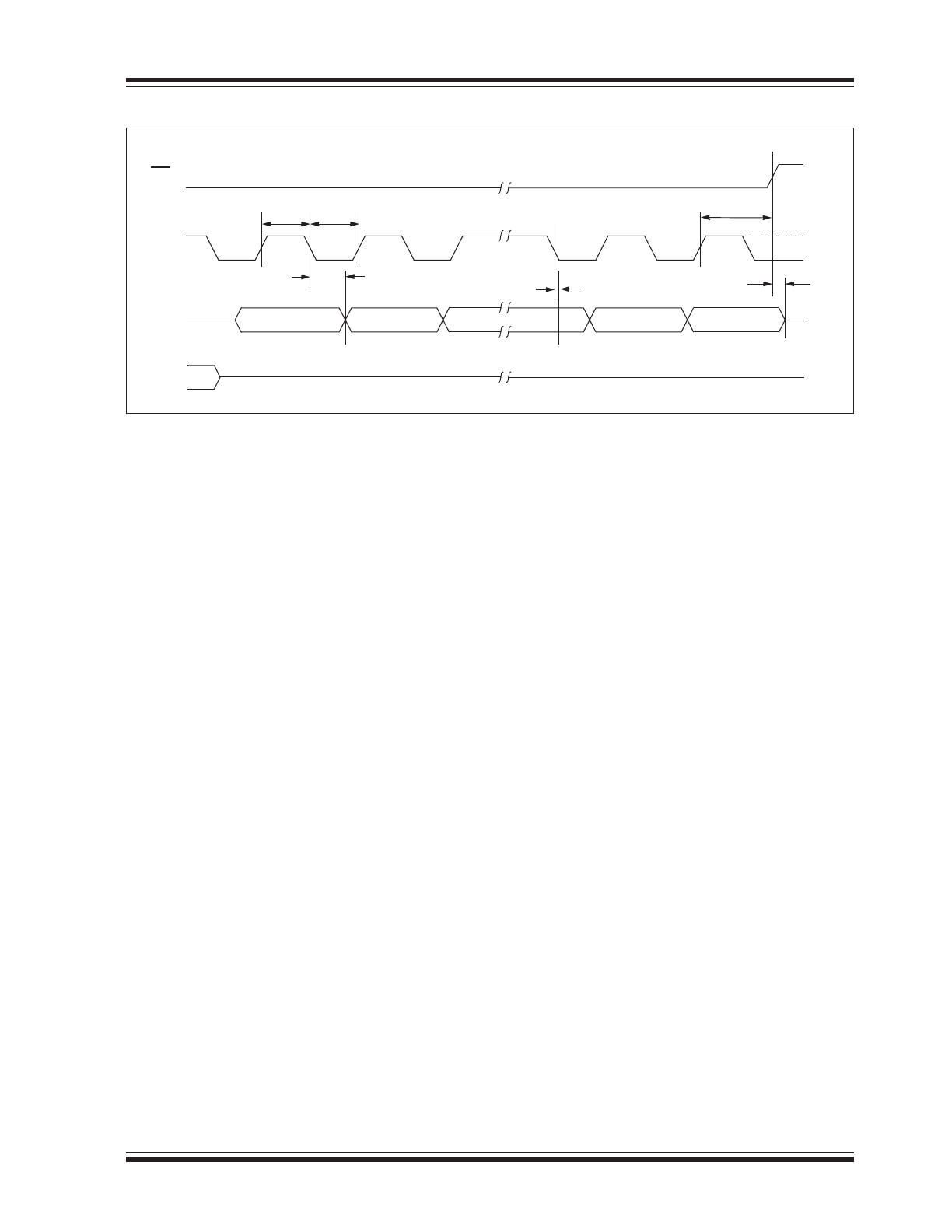

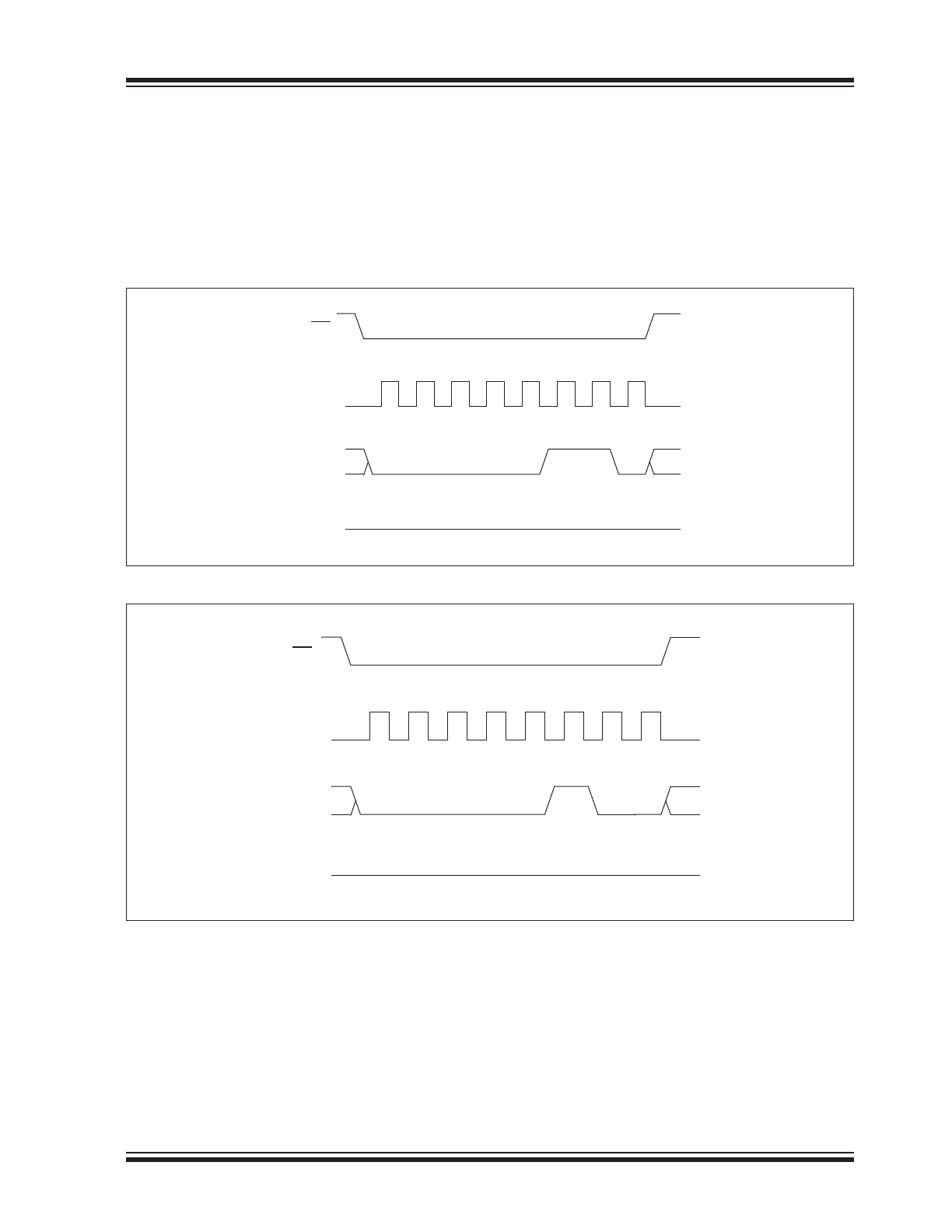

FIGURE 1-1:

HOLD TIMING

FIGURE 1-2:

SERIAL INPUT TIMING

AC Waveform:

V

LO

= 0.2V

—

V

HI

= V

CC

– 0.2V

Note 1

V

HI

= 4.0V

Note 2

C

L

= 50 pF

—

Timing Measurement Reference Level

Input

0.5 V

CC

Output

0.5 V

CC

Note 1: For V

CC

≤ 4.0V

2: For V

CC

> 4.0V

CS

SCK

SO

SI

HOLD

17

16

16

17

19

18

Don’t Care

5

High-Impedance

n + 2

n + 1

n

n - 1

n

n + 2

n + 1

n

n

n - 1

CS

SCK

SI

SO

6

5

8

7

11

3

LSB in

MSB in

High-Impedance

12

Mode 1,1

Mode 0,0

2

4

2017 Microchip Technology Inc.

DS20005715A-page 5

25LC256

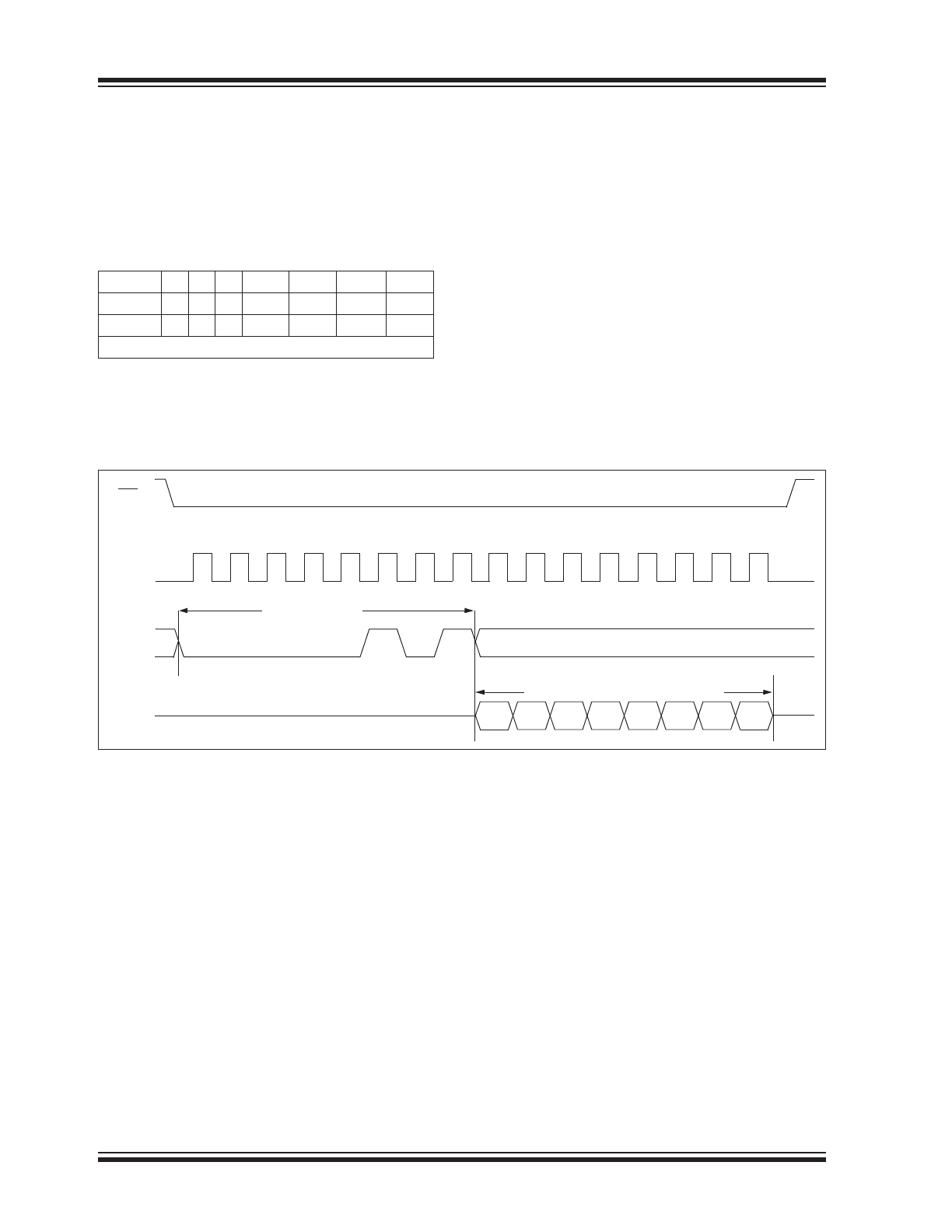

FIGURE 1-3:

SERIAL OUTPUT TIMING

CS

SCK

SO

10

9

13

MSB out

ISB out

3

15

Don’t Care

SI

Mode 1,1

Mode 0,0

14

25LC256

DS20005715A-page 6

2017 Microchip Technology Inc.

2.0

FUNCTIONAL DESCRIPTION

2.1

Principles of Operation

The 25LC256 is a 32,768-byte Serial EEPROM

designed to interface directly with the Serial Peripheral

Interface (SPI) port of many of today’s popular

microcontroller families, including Microchip’s PIC

®

microcontrollers. It may also interface with microcon-

trollers that do not have a built-in SPI port by using

discrete I/O lines programmed properly in firmware to

match the SPI protocol.

The 25LC256 contains an 8-bit instruction register. The

device is accessed via the SI pin, with data being

clocked in on the rising edge of SCK. The CS pin must

be low and the HOLD pin must be high for the entire

operation.

Table 2-1

contains a list of the possible instruction

bytes and format for device operation. All instructions,

addresses, and data are transferred MSB first, LSB

last.

Data (SI) is sampled on the first rising edge of SCK

after CS goes low. If the clock line is shared with other

peripheral devices on the SPI bus, the user can assert

the HOLD input and place the 25LC256 in ‘HOLD’

mode. After releasing the HOLD pin, operation will

resume from the point when the HOLD was asserted.

2.2

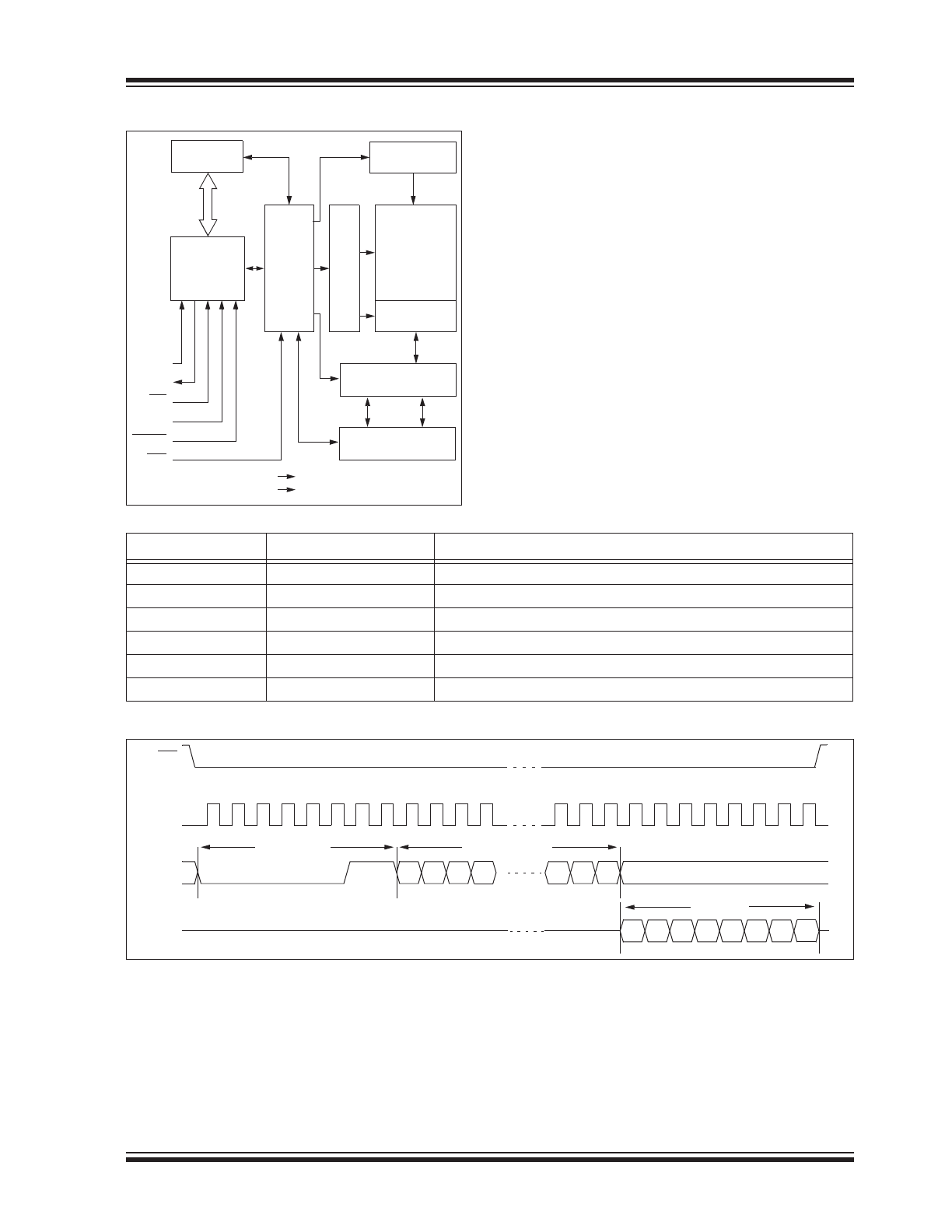

Read Sequence

The device is selected by pulling CS low. The 8-bit

READ instruction is transmitted to the 25LC256

followed by the 16-bit address, with the first MSB of the

address being a “don’t care” bit. After the correct READ

instruction and address are sent, the data stored in the

memory at the selected address is shifted out on the

SO pin. The data stored in the memory at the next

address can be read sequentially by continuing to

provide clock pulses. The internal Address Pointer is

automatically incremented to the next higher address

after each byte of data is shifted out. When the highest

address is reached (7FFFh), the address counter rolls

over to address 0000h allowing the read cycle to be

continued indefinitely. The read operation is terminated

by raising the CS pin (

Figure 2-1

).

2.3

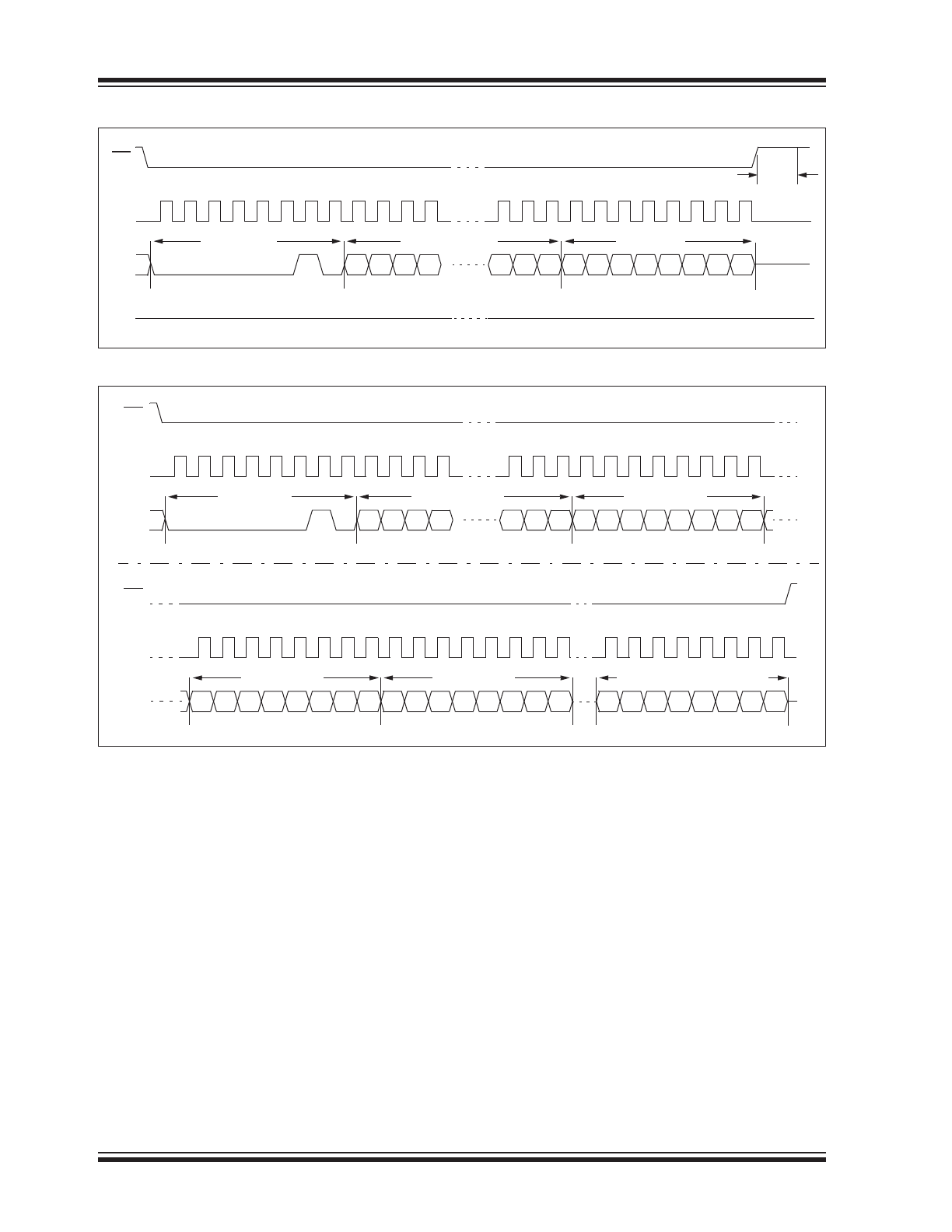

Write Sequence

Prior to any attempt to write data to the 25LC256, the

write enable latch must be set by issuing the WREN

instruction (

Figure 2-4

). This is done by setting CS low

and then clocking out the proper instruction into the

25LC256. After all eight bits of the instruction are

transmitted, the CS must be brought high to set the

write enable latch. If the write operation is initiated

immediately after the WREN instruction without CS

being brought high, the data will not be written to the

array because the write enable latch will not have been

properly set.

Once the write enable latch is set, the user may

proceed by setting the CS low, issuing a WRITE

instruction, followed by the 16-bit address, with the first

MSB of the address being a “don’t care” bit, and then

the data to be written. Up to 64 bytes of data can be

sent to the device before a write cycle is necessary.

The only restriction is that all of the bytes must reside

in the same page.

For the data to be actually written to the array, the CS

must be brought high after the Least Significant bit (D0)

of the n

th

data byte has been clocked in. If CS is

brought high at any other time, the write operation will

not be completed. Refer to

Figure 2-2

and

Figure 2-3

for more detailed illustrations on the byte write

sequence and the page write sequence, respectively.

While the write is in progress, the STATUS register may

be read to check the status of the WPEN, WIP, WEL,

BP1 and BP0 bits (

Figure 2-6

). A read attempt of a

memory array location will not be possible during a

write cycle. When the write cycle is completed, the

write enable latch is reset.

Note:

Page write operations are limited to

writing bytes within a single physical page,

regardless of the number of bytes

actually being written. Physical page

boundaries start at addresses that are

integer multiples of the page buffer size

(or ‘page size’) and, end at addresses that

are integer multiples of page size – 1. If a

Page Write command attempts to write

across a physical page boundary, the

result is that the data wraps around to the

beginning of the current page (overwriting

data previously stored there), instead of

being written to the next page as might be

expected. It is therefore necessary for the

application software to prevent page write

operations that would attempt to cross a

page boundary.

2017 Microchip Technology Inc.

DS20005715A-page 7

25LC256

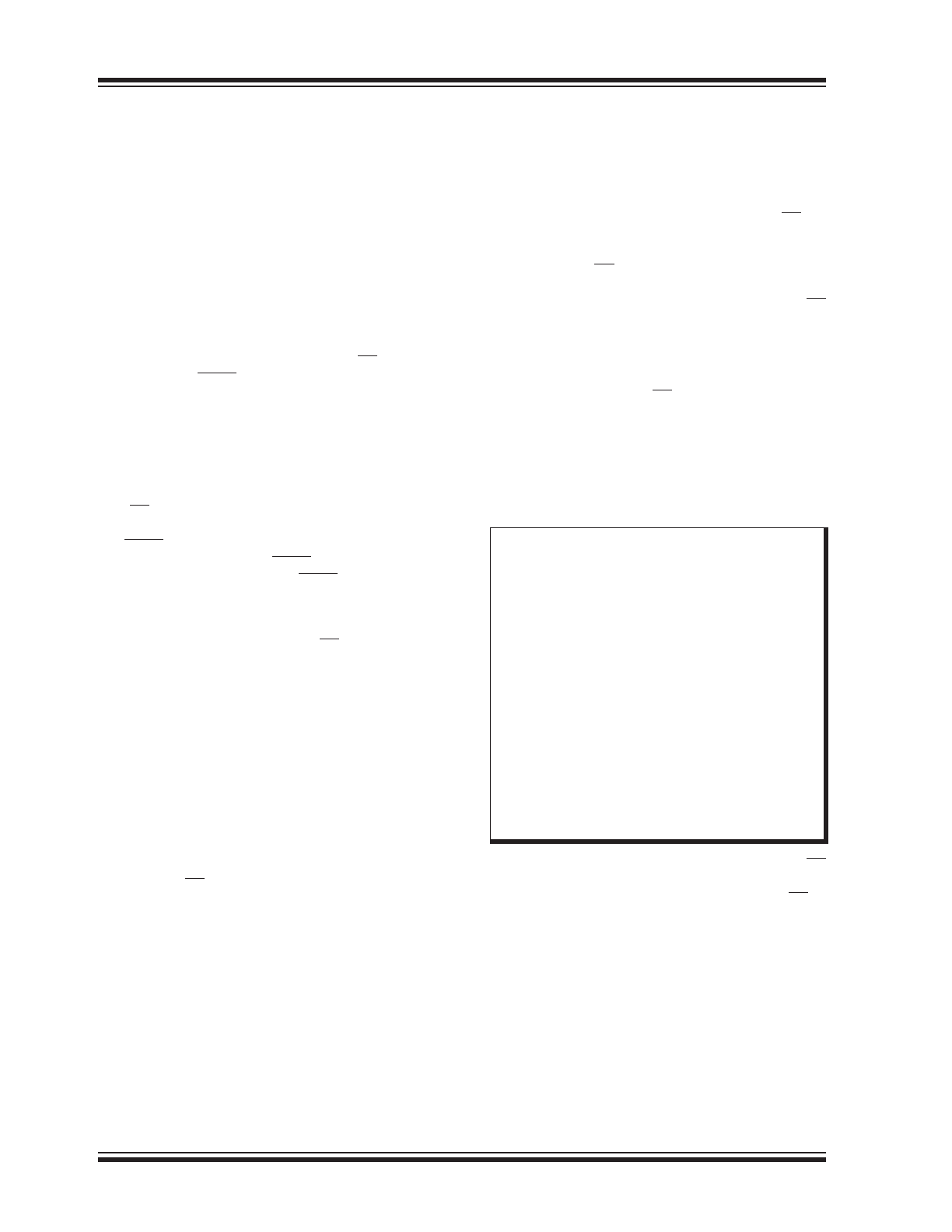

BLOCK DIAGRAM

FIGURE 2-1:

READ SEQUENCE

SI

SO

SCK

CS

HOLD

WP

STATUS

Register

I/O Control

Memory

Control

Logic

X

Dec

HV Generator

EEPROM

Array

Page Latches

Y Decoder

Sense Amp.

R/W Control

Logic

V

CC

V

SS

TABLE 2-1:

INSTRUCTION SET

Instruction Name

Instruction Format

Description

READ

0000 0011

Read data from memory array beginning at selected address

WRITE

0000 0010

Write data to memory array beginning at selected address

WRDI

0000 0100

Reset the write enable latch (disable write operations)

WREN

0000 0110

Set the write enable latch (enable write operations)

RDSR

0000 0101

Read STATUS register

WRSR

0000 0001

Write STATUS register

SO

SI

SCK

CS

0

2

3

4

5

6

7

8

9 10 11

21 22 23 24 25 26 27 28 29 30 31

1

0

1

0

0

0

0

0

1

15 14 13 12

2

1

0

7

6

5

4

3

2

1

0

Instruction

16-bit Address

Data Out

High-Impedance

25LC256

DS20005715A-page 8

2017 Microchip Technology Inc.

FIGURE 2-2:

BYTE WRITE SEQUENCE

FIGURE 2-3:

PAGE WRITE SEQUENCE

SO

SI

CS

9 10 11

21 22 23 24 25 26 27 28 29 30 31

0

0

0

0

0

0

0

1

15 14 13 12

2

1

0 7

6

5

4

3

2

1

0

Instruction

16-bit Address

Data Byte

High-Impedance

SCK

0

2

3

4

5

6

7

1

8

Twc

SI

CS

9 10 11

21 22 23 24 25 26 27 28 29 30 31

0

0

0

0

0

0

0

1

15 14 13 12

2

1

0

7

6

5

4

3

2

1

0

Instruction

16-bit Address

Data Byte 1

SCK

0

2

3

4

5

6

7

1

8

SI

CS

41 42 43

46 47

7

6

5

4

3

2

1

0

Data Byte n (64 max)

SCK

32

34 35 36 37 38 39

33

40

7

6

5

4

3

2

1

0

Data Byte 3

7

6

5

4

3

2

1

0

Data Byte 2

44 45

2017 Microchip Technology Inc.

DS20005715A-page 9

25LC256

2.4

Write Enable (WREN) and Write

Disable (WRDI)

The 25LC256 contains a write enable latch. See

Table 2-1

for the Write-Protect Functionality Matrix.

This latch must be set before any write operation will be

completed internally. The WREN instruction will set the

latch, and the WRDI will reset the latch.

The following is a list of conditions under which the

write enable latch will be reset:

• Power-up

• WRDI instruction successfully executed

• WRSR instruction successfully executed

• WRITE instruction successfully executed

FIGURE 2-4:

WRITE ENABLE SEQUENCE (WREN)

FIGURE 2-5:

WRITE DISABLE SEQUENCE (WRDI)

SCK

0

2

3

4

5

6

7

1

SI

High-Impedance

SO

CS

0

1

0

0

0

0

0

1

SCK

0

2

3

4

5

6

7

1

SI

High-Impedance

SO

CS

0

1

0

0

0

0

0

10

25LC256

DS20005715A-page 10

2017 Microchip Technology Inc.

2.5

Read Status Register Instruction

(RDSR)

The Read Status Register instruction (RDSR) provides

access to the STATUS register. The STATUS register

may be read at any time, even during a write cycle. The

STATUS register is formatted as follows:

TABLE 2-2:

STATUS REGISTER

The Write-In-Process (WIP) bit indicates whether the

25LC256 is busy with a write operation. When set to a

‘

1

’, a write is in progress, when set to a ‘

0

’, no write is

in progress. This bit is read-only.

The Write Enable Latch (WEL) bit indicates the status

of the write enable latch and is read-only. When set to

a ‘

1

’, the latch allows writes to the array, when set to a

‘

0

’, the latch prohibits writes to the array. The state of

this bit can always be updated via the WREN or WRDI

commands, regardless of the state of write protection

on the STATUS register. These commands are shown

in

Figure 2-4

and

Figure 2-5

.

The Block Protection (BP0 and BP1) bits indicate

which blocks are currently write-protected. These bits

are set by the user issuing the WRSR instruction. These

bits are nonvolatile, and are shown in

Table 2-3

.

See

Figure 2-6

for the RDSR timing sequence.

FIGURE 2-6:

READ STATUS REGISTER TIMING SEQUENCE (RDSR)

7

6

5

4

3

2

1

0

W/R

-

-

-

W/R

W/R

R

R

WPEN

x

x

x

BP1

BP0

WEL

WIP

W/R = writable/readable. R = read-only.

SO

SI

CS

9

10

11

12

13

14

15

1

1

0

0

0

0

0

0

7

6

5

4

2

1

0

Instruction

Data from STATUS Register

High-Impedance

SCK

0

2

3

4

5

6

7

1

8

3