2002-2014 Microchip Technology Inc.

DS20001734C-page 1

TC654/TC655

Features:

• Temperature Proportional Fan Speed for Reduced

Acoustic Noise and Longer Fan Life

• FanSense™ Protects against Fan Failure and

Eliminates the Need for 3-wire Fans

• Overtemperature Detection (TC655)

• Efficient PWM Fan Drive

• Provides RPM Data

• 2-Wire SMBus™-Compatible Interface

• Supports Any Fan Voltage

• Software Controlled Shutdown Mode for "Green"

Systems

• Supports Low-Cost NTC/PTC Thermistors

• Space Saving 10-Pin MSOP Package

• Temperature Range: -40°C to +85ºC

Applications:

• Personal Computers and Servers

• LCD Projectors

• Datacom and Telecom Equipment

• Fan Trays

• File Servers

• Workstations

• General Purpose Fan Speed Control

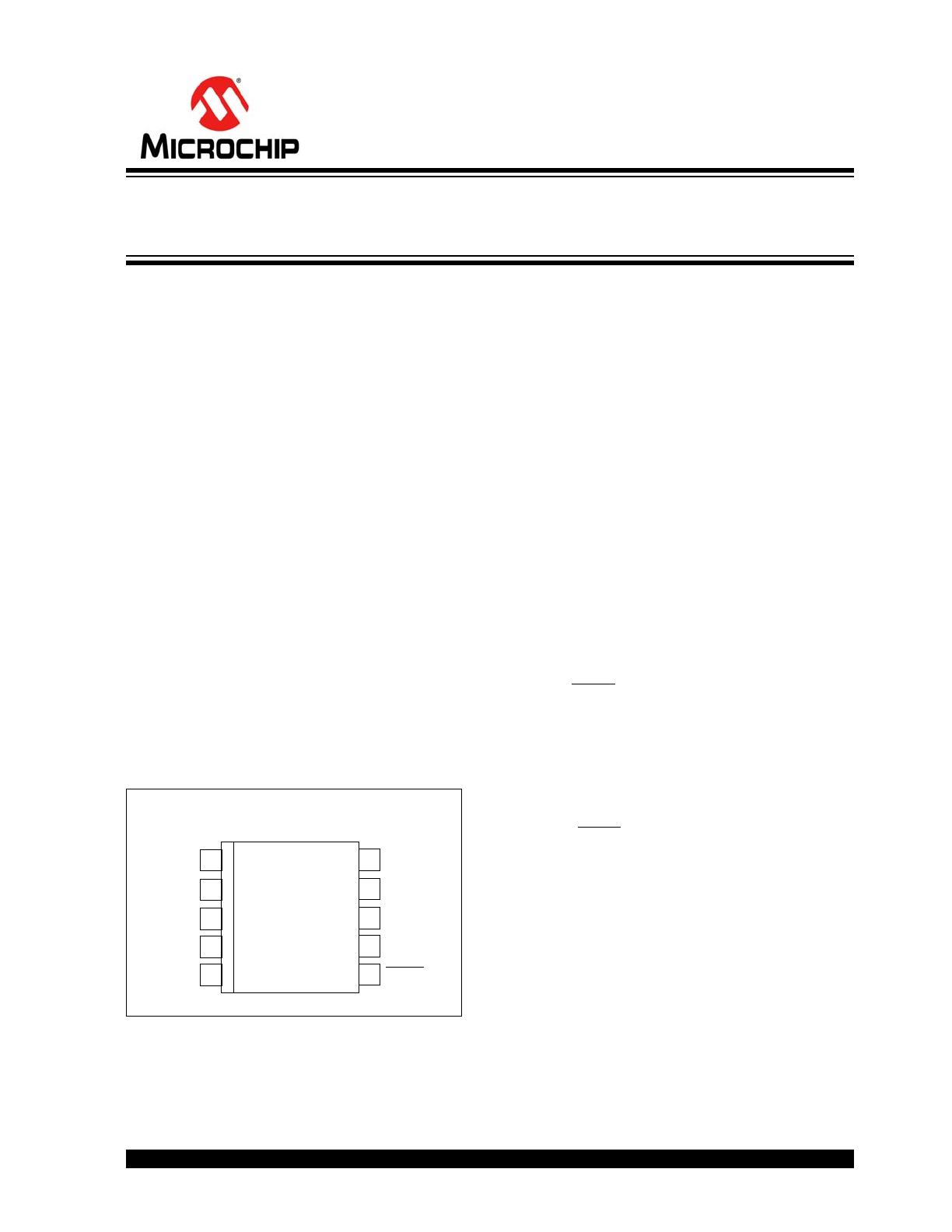

Package Type

Description:

The TC654 and TC655 are PWM mode fan speed con-

trollers with FanSense technology for use with brush-

less DC fans. These devices implement temperature

proportional fan speed control which lowers acoustic

fan noise and increases fan life. The voltage at V

IN

(Pin 1) represents temperature and is typically pro-

vided by an external thermistor or voltage output tem-

perature sensor. The PWM output (V

OUT

) is adjusted

between 30% and 100%, based on the voltage at V

IN

.

The PWM duty cycle can also be programmed via

SMBus to allow fan speed control without the need for

an external thermistor. If V

IN

is not connected, the

TC654/TC655 will start driving the fan at a default duty

cycle of 39.33%. See

Section 4.3 “Fan Start-up”

for

more details.

In normal fan operation, pulse trains are present at

SENSE1 (Pin 8) and SENSE2 (Pin 7). The TC654/

TC655 use these pulses to calculate the fan revolu-

tions per minute (RPM). The fan RPM data is used to

detect a worn out, stalled, open or unconnected fan.

An RPM level below the user-programmable threshold

causes the TC654/TC655 to assert a logic low alert

signal (FAULT). The default threshold value is

500 RPM. Also, if this condition occurs, F1F (bit 0<0>)

or F2F (bit 1<0>) in the Status Register will also be set

to a ‘1’.

An over-temperature condition is indicated when the

voltage at V

IN

exceeds 2.6V (typical). The TC654/

TC655 devices indicate this by setting OTF(bit 5<X>) in

the Status Register to a '1'. The TC655 device also

pulls the FAULT line low during an over-temperature

condition.

The TC654/TC655 devices are available in a 10-Pin

MSOP package and consume 150 µA during opera-

tion. The devices can also enter a low-power Shutdown

mode (5 µA, typ.) by setting the appropriate bit in the

Configuration Register. The operating temperature

range for these devices is -40°C to +85ºC.

10-Pin MSOP

1

2

3

4

5

10

9

8

7

6

V

IN

C

F

SCLK

SDA

GND

V

DD

V

OUT

SENSE1

SENSE2

FAULT

TC654

TC655

Dual SMBus™ PWM Fan Speed Controllers With

Fan Fault Detection

TC654/TC655

DS20001734C-page 2

2002-2014 Microchip Technology Inc.

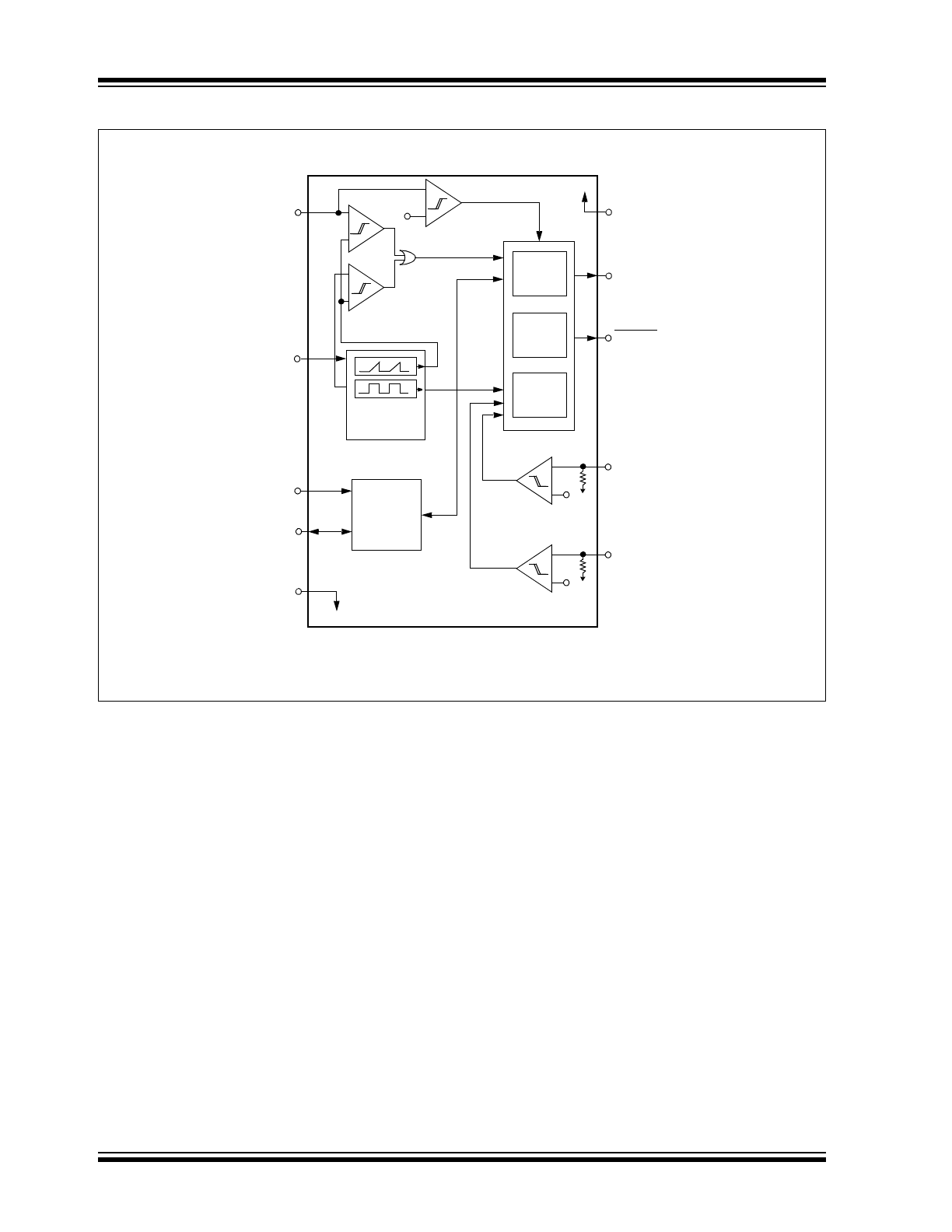

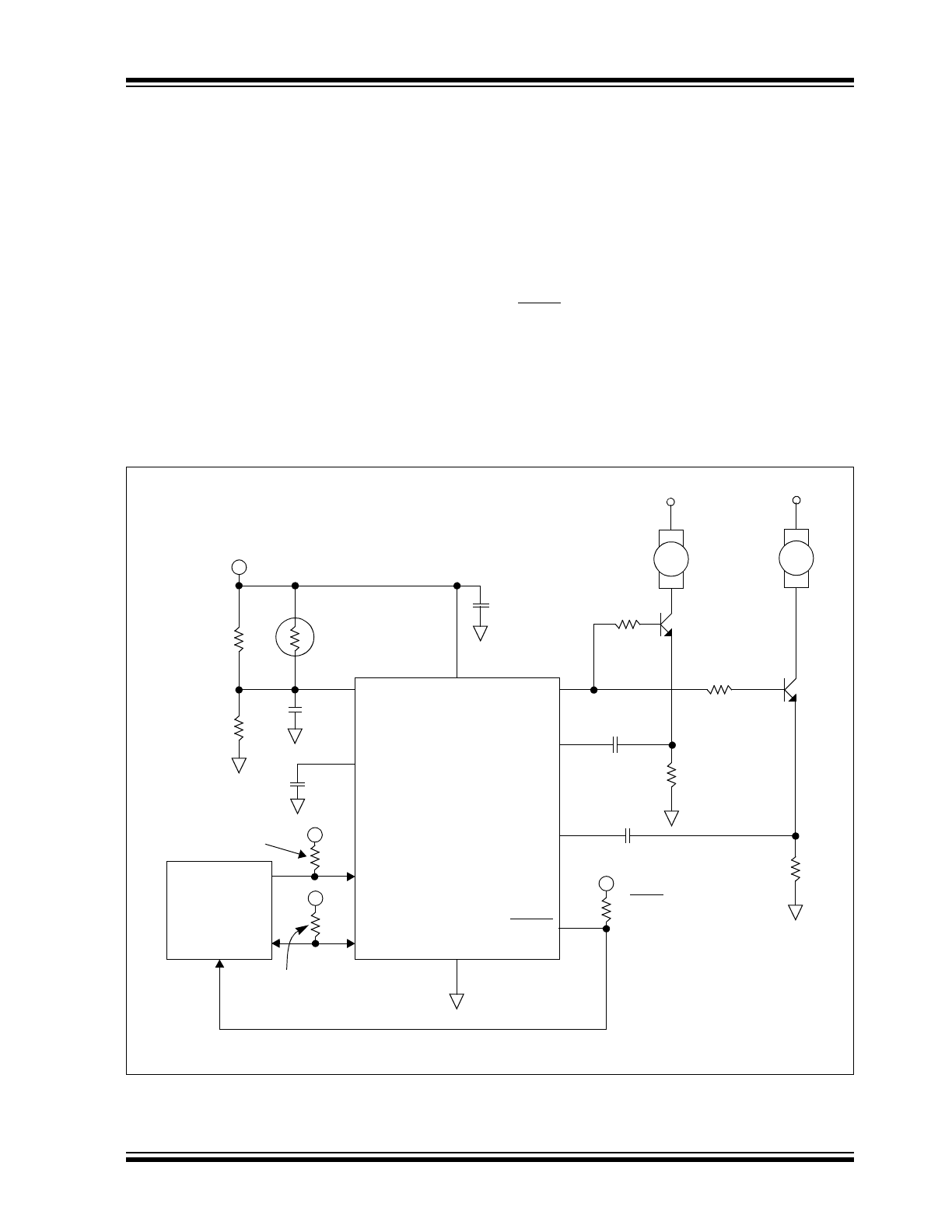

Functional Block Diagram

V

OTF

50 k

OTF

V

MIN

TC654/TC655

SENSE1

FAULT

V

OUT

V

DD

GND

SDA

SCLK

C

F

V

IN

–

+

+

–

Clock

Generator

Serial Port

Interface

Control

Logic

Start-up

Timer

Missing

Pulse

Detect

100 mV (typ.)

–

50 k

SENSE2

100 mV (typ.)

–

–

+

Note: OTF condition applies for the TC655 device only.

Note

2002-2014 Microchip Technology Inc.

DS20001734C-page 3

TC654/TC655

1.0

ELECTRICAL

CHARACTERISTICS

Absolute Maximum Ratings *

V

DD

...................................................................................6.5V

Input Voltages ...................................... -0.3V to (V

DD

+ 0.3V)

Output Voltages .................................... -0.3V to (V

DD

+ 0.3V)

Storage temperature .....................................-65°C to +150°C

Ambient temp. with power applied ................-40°C to +125°C

Maximum Junction Temperature, T

J

............................. 150°C

ESD protection on all pins

4 kV

*Notice: Stresses above those listed under “Maximum rat-

ings” may cause permanent damage to the device. This is a

stress rating only and functional operation of the device at

those or any other conditions above those indicated in the

operational listings of this specification is not implied. Expo-

sure to maximum rating conditions for extended periods may

affect device reliability.

PIN FUNCTION TABLE

Name

Function

V

IN

Analog Input

C

F

Analog Output

SCLK

Serial Clock Input

SDA

Serial Data In/Out (Open Drain)

GND

Ground

FAULT

Digital (Open Drain) Output

SENSE2

Analog Input

SENSE1

Analog Input

V

OUT

Digital Output

V

DD

Power Supply Input

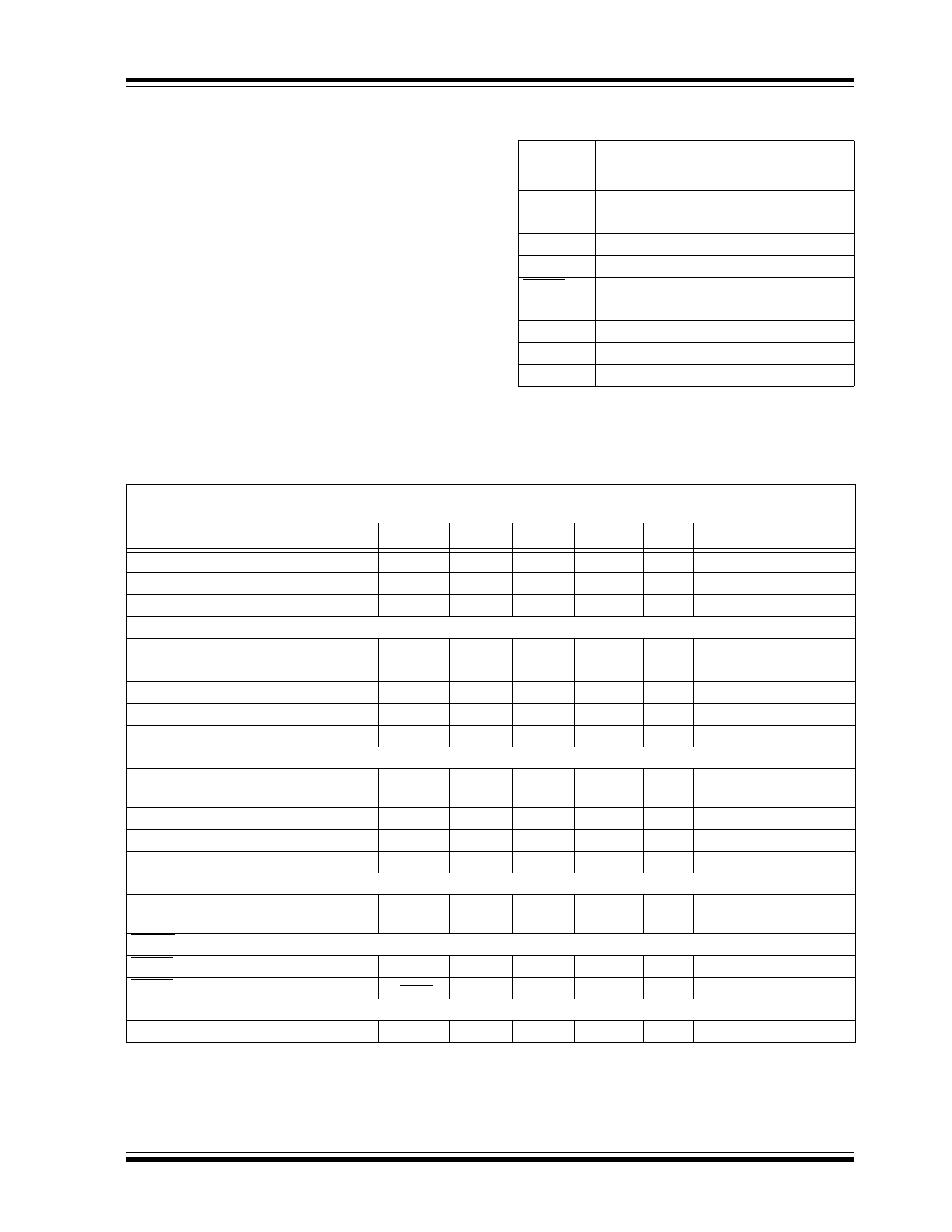

ELECTRICAL SPECIFICATIONS

Electrical Characteristics: Unless otherwise noted, all limits are specified for V

DD

= 3.0V to 5.5V,

-40°C <T

A

< +85°C.

Parameters

Sym.

Min.

Typ.

Max.

Units

Conditions

Supply Voltage

V

DD

3.0

—

5.5

V

Operating Supply Current

I

DD

—

150

300

µA

Pins 7, 8, 9 Open

Shutdown Mode Supply Current

I

DDSHDN

—

5

10

µA

Pins 7, 8, 9 Open

V

OUT

PWM Output

V

OUT

Rise Time

t

R

—

—

50

µsec

I

OH

= 5 mA,

Note 1

V

OUT

Fall Time

t

F

—

—

50

µsec

I

OL

= 1 mA,

Note 1

Sink Current at V

OUT

Output

I

OL

1.0

—

—

mA

V

OL

= 10% of V

DD

Source Current at V

OUT

Output

I

OH

5.0

—

—

mA

V

OH

= 80% of V

DD

PWM Frequency

F

26

30

34

Hz

C

F

= 1 µF

V

IN

Input

V

IN

Input Voltage for 100% PWM

duty-cycle

V

C(MAX)

2.45

2.6

2.75

V

V

C(MAX)

- V

C(MIN)

V

CRANGE

1.25

1.4

1.55

V

V

IN

Input Resistance

—

10M

—

V

DD

= 5.0V

V

IN

Input Leakage Current

I

IN

-1.0

—

+1.0

µA

SENSE Input

SENSE Input Threshold Voltage with

Respect to GND

V

THSENSE

80

100

120

mV

FAULT Output

FAULT Output LOW Voltage

V

OL

—

—

0.3

V

I

OL

= 2.5 mA

FAULT Output Response Time

t

FAULT

—

2.4

—

sec

Fan RPM-to-Digital Output

Fan RPM ERROR

-15

—

+15

%

RPM > 1600

Note 1: Not production tested, ensured by design, tested during characterization.

2: For 5.0V > V

DD

5.5V, the limit for V

IH

= 2.2V.

TC654/TC655

DS20001734C-page 4

2002-2014 Microchip Technology Inc.

TEMPERATURE SPECIFICATIONS

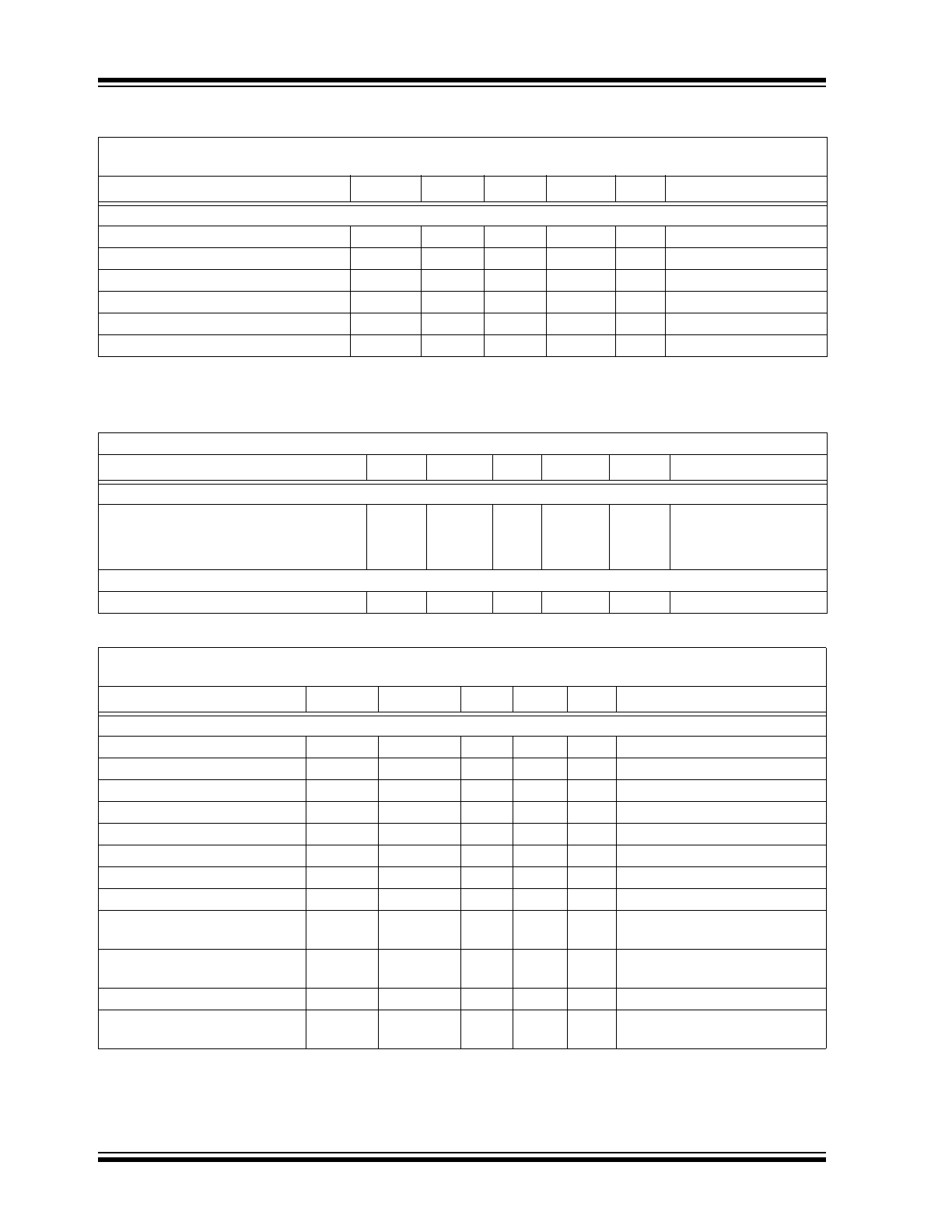

TIMING SPECIFICATIONS

2-Wire Serial Bus Interface

Logic Input High

V

IH

2.1

—

—

V

Note 2

Logic Input Low

V

IL

—

—

0.8

V

Logic Output Low

V

OL

—

—

0.4

V

I

OL

= 3 mA

Input Capacitance SDA, SCLK

C

IN

—

10

15

pF

Note 1

I/O Leakage Current

I

LEAK

-1.0

—

+1.0

µA

SDA Output Low Current

I

OLSDA

6

—

—

mA

V

OL

= 0.6V

Electrical Characteristics: Unless otherwise noted, all parameters apply at V

DD

= 3.0 V to 5.5 V

Parameters

Symbol

Min

Typ

Max

Units

Conditions

Temperature Ranges

Specified Temperature Range

T

A

-40

—

+85

°C

Operating Temperature Range

T

A

-40

—

+125

°C

Storage Temperature Range

T

A

-65

—

+150

°C

Thermal Package Resistances

Thermal Resistance, 10 Pin MSOP

JA

—

113

—

°C/W

Electrical Characteristics: Unless otherwise noted, all limits are specified for V

DD

= 3.0V to 5.5V,

-40°C <T

A

< +85°C

Parameters

Sym

Min

Typ

Max

Units

Conditions

SMBus Interface (See

Figure 1-1

)

Serial Port Frequency

f

SC

0

—

100

kHz

Note 1

Low Clock Period

t

LOW

4.7

—

—

µsec

Note 1

High Clock Period

t

HIGH

4.7

—

—

µsec

Note 1

SCLK and SDA Rise Time

t

R

—

—

1000

nsec

Note 1

SCLK and SDA Fall Time

t

F

—

—

300

nsec

Note 1

Start Condition Setup Time

t

SU(START)

4.7

—

—

µsec

Note 1

SCLK Clock Period Time

t

SC

10

—

—

µsec

Note 1

Start Condition Hold Time

t

H(START)

4.0

—

—

µsec

Note 1

Data in SetupTime to SCLK

High

t

SU-DATA

250

—

—

nsec

Note 1

Data in Hold Time after SCLK

Low

t

H-DATA

300

—

—

nsec

Note 1

Stop Condition Setup Time

t

SU(STOP)

4.0

—

—

µsec

Note 1

Bus Free Time Prior to New

Transition

t

IDLE

4.7

—

µsec

Note 1

and

Note 2

Note 1: Not production tested, ensured by design, tested during characterization.

2: Time the bus must be free before a new transmission can start.

ELECTRICAL SPECIFICATIONS (CONTINUED)

Electrical Characteristics: Unless otherwise noted, all limits are specified for V

DD

= 3.0V to 5.5V,

-40°C <T

A

< +85°C.

Parameters

Sym.

Min.

Typ.

Max.

Units

Conditions

Note 1: Not production tested, ensured by design, tested during characterization.

2: For 5.0V > V

DD

5.5V, the limit for V

IH

= 2.2V.

2002-2014 Microchip Technology Inc.

DS20001734C-page 5

TC654/TC655

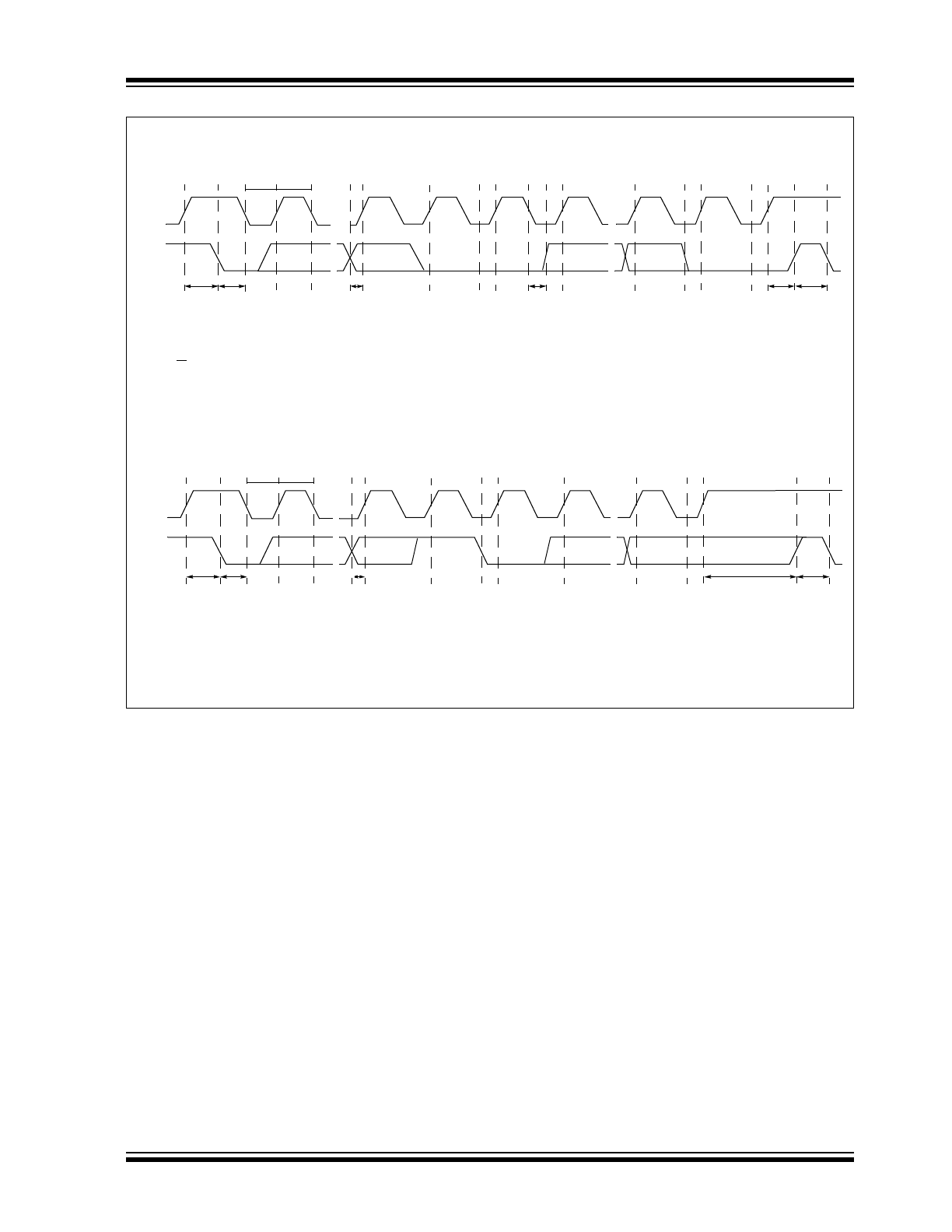

FIGURE 1-1:

Bus Timing Data.

t

SU(START)

t

H(START)

t

SU-DATA

t

SU(STOP)

t

IDLE

A = Start Condition

B = MSB of Address Clocked into Slave

C = LSB of Address Clocked into Slave

D = R/W Bit Clocked into Slave

E = Slave Pulls SDA Line Low

A

B

C

D

E

F

G

H

I

J

K

L

M

F = Acknowledge Bit Clocked into Master

G = MSB of Data Clocked into Slave

H = LSB of Data Clocked into Slave

I = Slave Pulls SDA Line Low

J = Acknowledge Clocked into Master

K = Acknowledge Clock Pulse

L = Stop Condition, Data Executed by Slave

M = New Start Condition

t

LOW

t

HIGH

SCLK

SDA

t

H-DATA

SMBus Write Timing Diagram

t

SU(START)

t

H(START)

t

SU-DATA

t

SU(STOP)

t

IDLE

A = Start Condition

B = MSB of Address Clocked into Slave

C = LSB of Address Clocked into Slave

D = R/W Bit Clocked into Slave

A

B

C

D

E F

G

H

I

J

K

E = Slave Pulls SDA Line Low

F = Acknowledge Bit Clocked into Master

G = MSB of Data Clocked into Master

H = LSB of Data Clocked into Master

t

LOW

t

HIGH

I = Acknowledge Clock Pulse

J = Stop Condition

K = New Start Condition

SCLK

SDA

SMBus Read Timing Diagram

E

TC654/TC655

DS20001734C-page 6

2002-2014 Microchip Technology Inc.

2.0

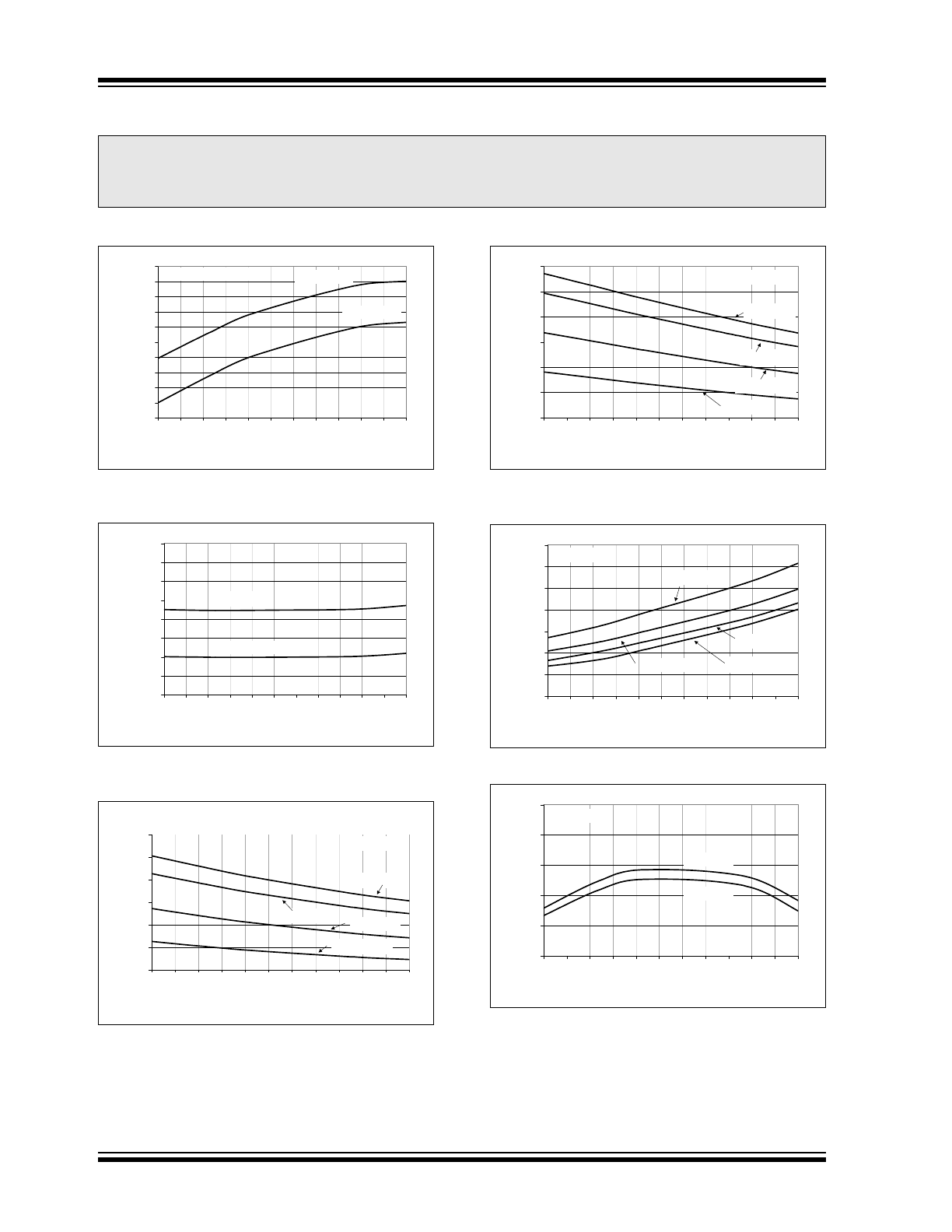

TYPICAL PERFORMANCE CURVES

FIGURE 2-1:

I

DD

vs. Temperature.

FIGURE 2-2:

I

DD

Shutdown vs.

Temperature.

FIGURE 2-3:

PWM, Source Current vs.

Temperature.

FIGURE 2-4:

PWM, Sink Current vs.

Temperature.

FIGURE 2-5:

Fault V

OL

vs. Temperature.

FIGURE 2-6:

PWM Frequency vs.

Temperature.

Note:

The graphs and tables provided following this note are a statistical summary based on a limited number of

samples and are provided for informational purposes only. The performance characteristics listed herein

are not tested or guaranteed. In some graphs or tables, the data presented may be outside the specified

operating range (e.g., outside specified power supply range) and therefore outside the warranted range.

130

135

140

145

150

155

160

165

170

175

180

-40

-25

-10

5

20

35

50

65

80

95

110 125

Temperature (°C)

I

DD

(µA

)

V

DD

= 5.5 V

V

DD

= 3.0 V

Pins 7,8, and 9 Open

1.000

2.000

3.000

4.000

5.000

6.000

7.000

8.000

9.000

-40

-25

-10

5

20

35

50

65

80

95

110 125

Temperature (ºC)

S

hutdow

n I

DD

(µA

)

V

DD

= 3.0 V

V

DD

= 5.5 V

5

10

15

20

25

30

35

-40

-25

-10

5

20

35

50

65

80

95

110

125

Temperature (°C)

S

our

ce C

u

rr

e

nt (m

A

)

V

DD

= 5.5 V

V

DD

= 5.0 V

V

DD

= 4.0 V

V

DD

= 3.0 V

V

OH

= 0.8V

DD

2

4

6

8

10

12

14

-40

-25

-10

5

20

35

50

65

80

95

110 125

Temperature (°C)

S

ink C

u

rr

e

nt (m

A

)

V

DD

= 5.5 V

V

DD

= 5.0 V

V

DD

= 4.0 V

V

DD

= 3.0 V

V

OL

= 0.1 V

DD

15

20

25

30

35

40

45

50

-40

-25

-10

5

20

35

50

65

80

95

110 125

Temperature (ºC)

Faul

t V

OL

(m

V

)

I

OL

= 2.5 mA

V

DD

= 5.5 V

V

DD

= 5.0 V

V

DD

= 4.0 V

V

DD

= 3.0 V

27

28

29

30

31

32

-40

-25

-10

5

20

35

50

65

80

95

110 125

Temperature (ºC)

P

W

M Fr

equency (H

z

)

V

DD

= 5.5 V

V

DD

= 3.0 V

C

F

= 1.0 µF

2002-2014 Microchip Technology Inc.

DS20001734C-page 7

TC654/TC655

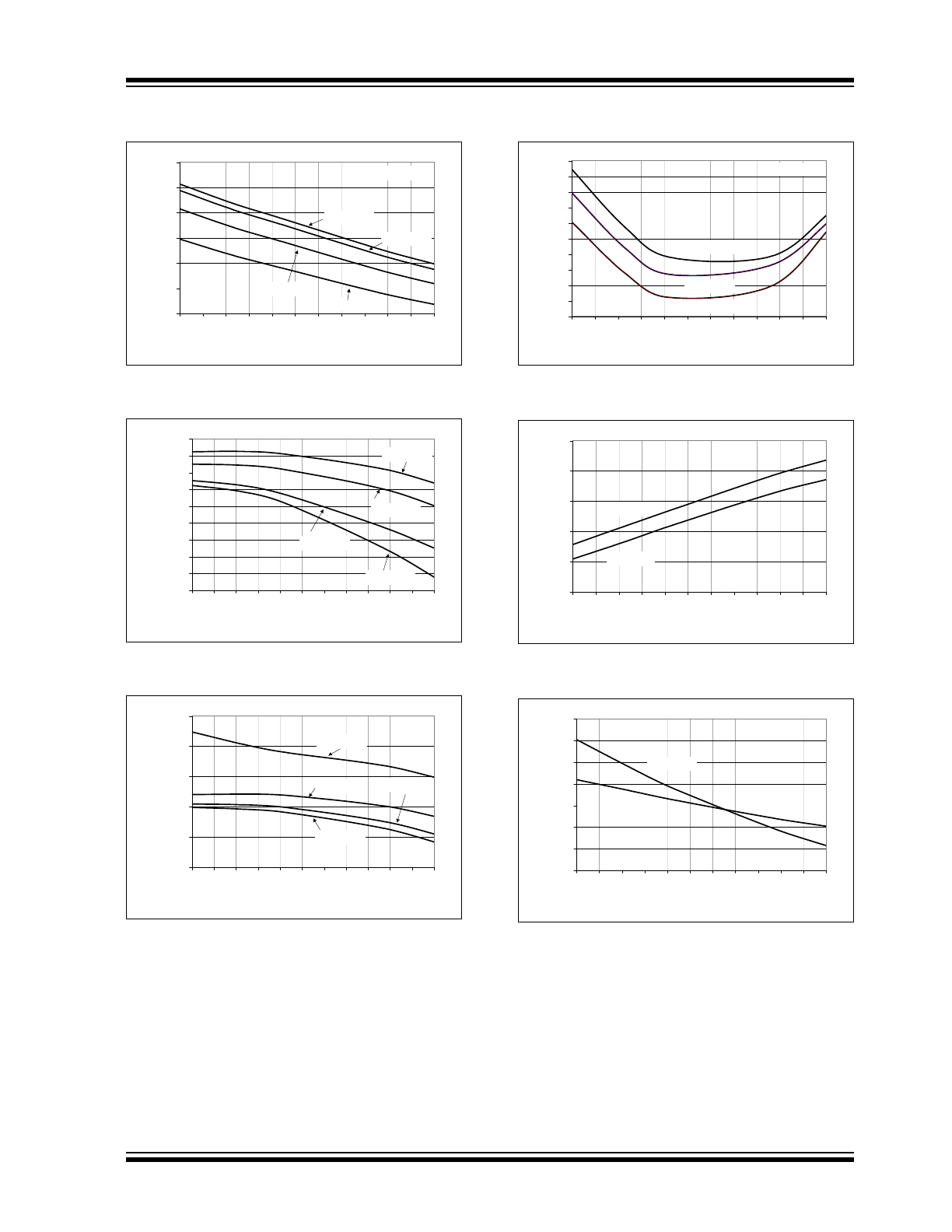

FIGURE 2-7:

SDA I

OL

vs. Temperature.

FIGURE 2-8:

V

CMAX

vs. Temperature.

FIGURE 2-9:

V

CMIN

vs. Temperature.

FIGURE 2-10:

RPM %error vs.

Temperature.

FIGURE 2-11:

Sense Threshold

(V

THSENSE

) Hysteresis vs. Temperature.

FIGURE 2-12:

SDA, SCLK Hysteresis vs.

Temperature.

20

25

30

35

40

45

50

-40

-25

-10

5

20

35

50

65

80

95

110 125

Temperature (ºC)

SDA I

OL

(m

A

)

V

OL

= 0.4 V

V

DD

= 5.5 V

V

DD

= 5.0 V

V

DD

= 4.0 V

V

DD

= 3.0 V

2.575

2.580

2.585

2.590

2.595

2.600

2.605

2.610

2.615

2.620

-40

-25

-10

5

20

35

50

65

80

95

110 125

Temperature (ºC)

V

CM

a

x

(V

)

V

DD

= 3.0 V

V

DD

= 4.0 V

V

DD

= 5.0 V

V

DD

= 5.5 V

1.180

1.185

1.190

1.195

1.200

1.205

-40

-25

-10

5

20

35

50

65

80

95

110 125

Temperature (ºC)

V

CM

IN

(V

)

V

DD

= 3.0 V

V

DD

= 5.0 V

V

DD

= 5.5 V

V

DD

= 4.0 V

0

1

2

3

4

5

6

7

8

9

10

-40

-25

-10

5

20

35

50

65

80

95

110 125

Temperature (ºC)

R

P

M

Erro

r (

%

)

V

DD

= 3.0 V

V

DD

= 5.5 V

V

DD

= 5.0 V

C

F

= 1.0 µF

20

25

30

35

40

45

-40

-25

-10

5

20

35

50

65

80

95

110 125

Temperature (ºC)

V

THSENSE

H

yster

esis (m

V

)

V

DD

= 3.0V

V

DD

= 5.5V

80

90

100

110

120

130

140

150

-40

-25

-10

5

20

35

50

65

80

95

110 125

Temperature (ºC)

S

D

A

&

S

C

LK

H

yster

esis (m

V

)

V

DD

= 3.0 V

V

DD

= 5.0 V

TC654/TC655

DS20001734C-page 8

2002-2014 Microchip Technology Inc.

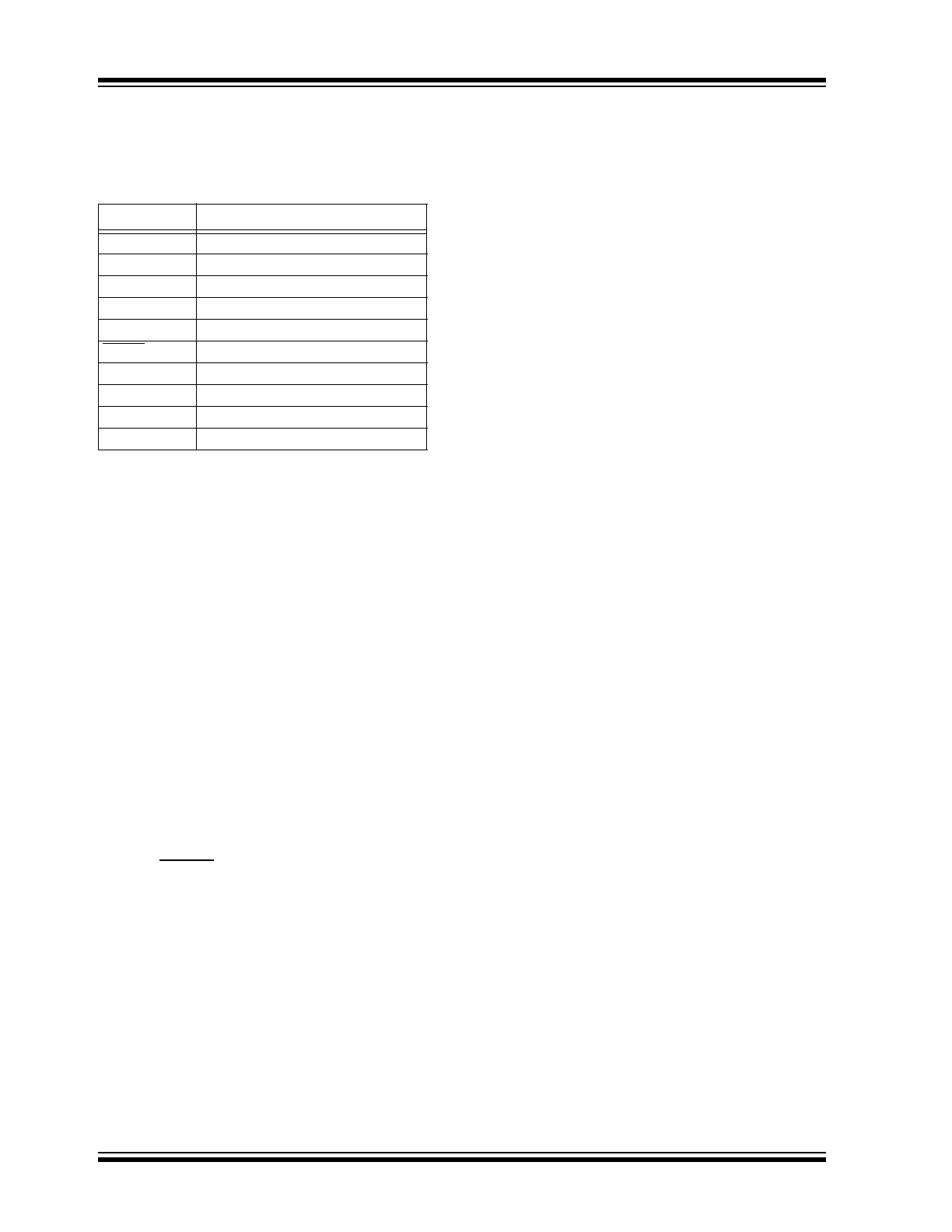

3.0

PIN FUNCTIONS

The descriptions of the pins are listed in

Table 3-1

.

TABLE 3-1:

PIN FUNCTION TABLE

3.1

Analog Input (V

IN

)

A voltage range of 1.62V to 2.6V (typical) on this pin

drives an active duty-cycle of 30% to 100% on the

V

OUT

pin.

3.2

Analog Output (C

F

)

Positive terminal for the PWM ramp generator timing

capacitor. The recommended C

F

is 1 µF for 30 Hz

PWM operation.

3.3

SMBus Serial Clock Input (SCLK)

Clocks data into and out of the TC654/TC655. See

Section 5.0 “Serial Communication”

for more infor-

mation on the serial interface.

3.4

Serial Data (Bi-directional) (SDA)

Serial data is transferred on the SMBus in both direc-

tions using this pin. See

Section 5.0 “Serial Commu-

nication”

for more information on the serial interface.

3.5

Digital (Open Drain) Output

(FAULT)

When the fan’s RPM falls below the user-set RPM

threshold (or OTF occurs with TC655), a logic low sig-

nal is asserted.

3.6

Analog Input (SENSE2)

Fan current pulses are detected at this pin. These

pulses are counted and used in the calculation of the

Fan 2 RPM.

3.7

Analog Input (SENSE1)

Fan current pulses are detected at this pin. These

pulses are counted and used in the calculation of the

Fan 1 RPM.

3.8

Digital Output (V

OUT

)

This active high complimentary output drives the base

of an external transistor or the gate of a MOSFET.

3.9

Power Supply Input (V

DD

)

The V

DD

pin with respect to GND provides power to the

device. This bias supply voltage may be independent of

the fan power supply.

Name

Function

V

IN

Analog Input

C

F

Analog Output

SCLK

Serial Clock Input

SDA

Serial Data In/Out (Open Drain)

GND

Ground

FAULT

Digital (Open Drain) Output

SENSE2

Analog Input

SENSE1

Analog Input

V

OUT

Digital Output

V

DD

Power Supply Input

2002-2014 Microchip Technology Inc.

DS20001734C-page 9

TC654/TC655

4.0

DEVICE OPERATION

The TC654 and TC655 devices allow you to control,

monitor and communicate (via SMBus) fan speed for 2-

wire and 3-wire DC brushless fans. By pulse-width

modulating (PWM) the voltage across the fan, the

TC654/TC655 controls fan speed according to the sys-

tem temperature.The goal of temperature proportional

fan speed control is to reduce fan power consumption,

increase fan life and reduce system acoustic noise.

With the TC654 and TC655 devices, fan speed can be

controlled by the analog input V

IN

or the SMBus inter-

face, allowing for high system flexibility.

The TC654 and TC655 also measure and monitor fan

revolutions per minute (RPM). A fan’s speed (RPM) is

a measure of its health. As a fan’s bearings wear out,

the fan slows down and eventually stops (locked rotor).

By monitoring the fan’s RPM level, the TC654/TC655

devices can detect open, shorted, unconnected and

locked rotor fan conditions. The fan speed threshold

can be set to provide a predictive fan failure feature.

This feature can be used to give a system warning and,

in many cases, help to avoid a system thermal shut-

down condition. The fan RPM data and threshold reg-

isters are available over the SMBus interface which

allows for complete system control.

The TC654/TC655 devices are identical in every

aspect except for how they indicate an over-tempera-

ture condition. When V

IN

voltage exceeds 2.6V (typi-

cal), both devices will set OTF (bit 5<X>) in the Status

Register to a '1'. The TC655 will additionally pull the

FAULT output low during an over-temperature condi-

tion.

FIGURE 4-1:

Typical Application Circuit.

1

2

3

4

5

6

7

8

9

10

V

IN

C

F

SCLK

SDA

GND

FAULT

SENSE2

SENSE1

V

OUT

V

DD

+5V

FAN

FAN

R

ISO1

R

ISO2

R

SENSE2

R

SENSE1

C

SENSE2

C

SENSE1

1

2

NTC Thermistor

R

1

R

2

C

1

0.01 µF

C

2

1 µF

100 k

@ 25°C

PIC

®

Microcontroller

+12V

+5V

+5V

+5V

+5V

34.8 k

14.7 k

C

F

1.0 µF

R

SCLK

20 k

R

SDA

20 k

715

0.1 µF

0.1 µF

715

R

FAULT

20 k

Note: Refer to

Table 7-1

for R

SENSE1

and R

SENSE2

values.

TC654/TC655

TC654/TC655

DS20001734C-page 10

2002-2014 Microchip Technology Inc.

4.1

Fan Speed Control Methods

The speed of a DC brushless fan is proportional to the

voltage across it. For example, if a fan’s rating is

5000 RPM at 12V, it’s speed would be 2500 RPM at 6V.

This, of course, will not be exact, but should be close.

There are two main methods for fan speed control. The

first is pulse width modulation (PWM) and the second

is linear. Using either method the total system power

requirement to run the fan is equal. The difference

between the two methods is where the power is

consumed.

The following example compares the two methods for

a 12V, 120 mA fan running at 50% speed. With 6V

applied across the fan, the fan draws an average cur-

rent of 68 mA. Using a linear control method, there are

6V across the fan and 6V across the drive element.

With 6V and 68 mA, the drive element is dissipating

410 mW of power. Using the PWM approach, the fan is

modulated at a 50% duty cycle, with most of the 12V

being dropped across the fan. With 50% duty cycle, the

fan draws an RMS current of 110 mA and an average

current of 72 mA. Using a MOSFET with a 1

RDS

(on)

(a fairly typical value for this low current) the power dis-

sipation in the drive element would be: 12 mW (Irms

2

*

RDS

(on)

). Using a standard 2N2222A NPN transistor

(assuming a Vce-sat of 0.8V), the power dissipation

would be 58 mW (Iavg* Vce-sat).

The PWM approach to fan speed control causes much

less power dissipation in the drive element. This allows

smaller devices to be used and will not require any spe-

cial heatsinking to get rid of the power being dissipated

in the package.

The other advantage to the PWM approach is that the

voltage being applied to the fan is always near 12V.

This eliminates any concern about not supplying a high

enough voltage to run the internal fan components,

which is very relevant in linear fan speed control.

4.2

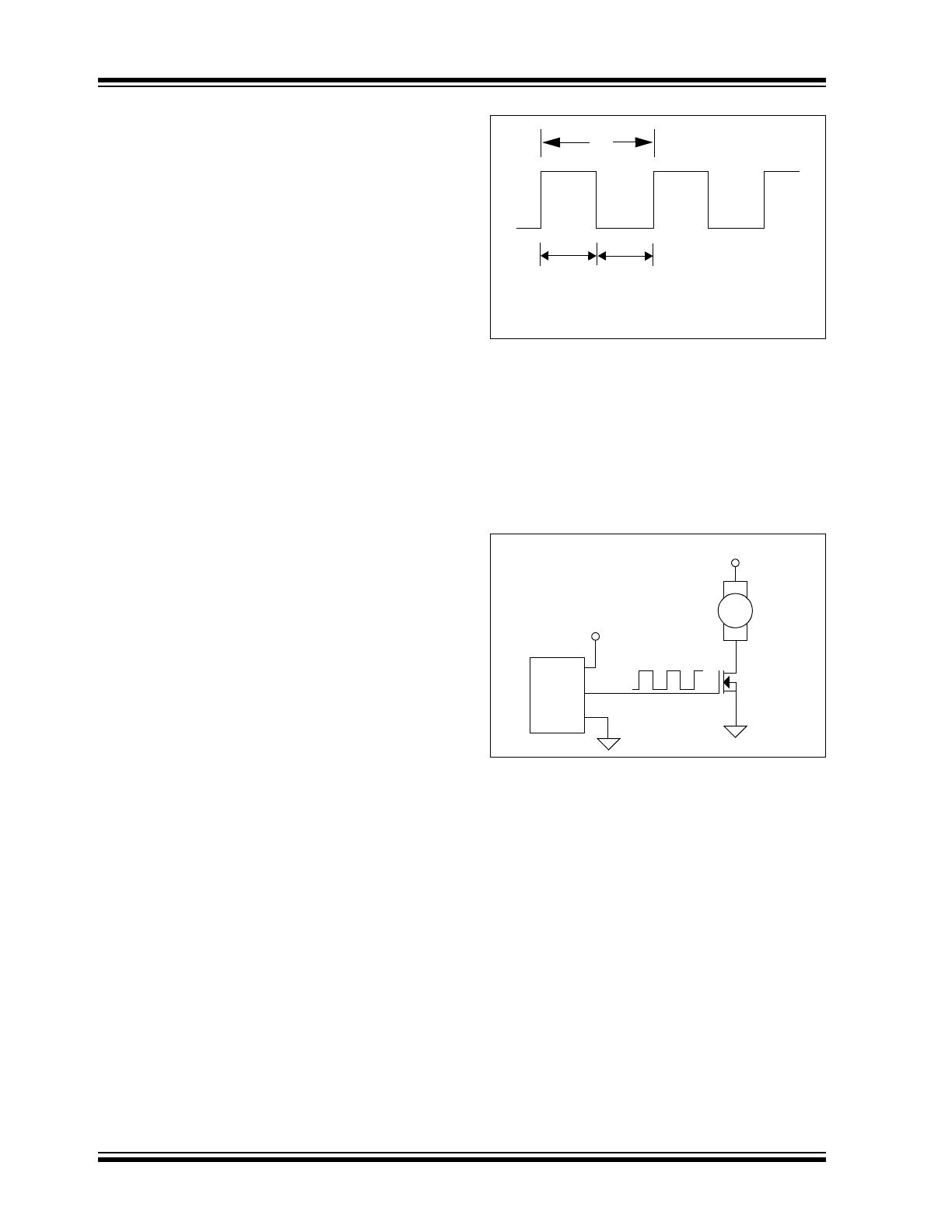

PWM Fan Speed Control

The TC654 and TC655 devices implement PWM fan

speed control by varying the duty cycle of a fixed fre-

quency pulse train. The duty cycle of a waveform is the

on time divided by the total period of the pulse. For

example, given a 100 Hz waveform (10 msec.) with an

on time of 5.0 msec, the duty cycle of this waveform is

50% (5.0 msec/10.0 msec). An example of this is

illustrated in

Figure 4-2

.

FIGURE 4-2:

Duty Cycle Of A PWM

Waveform.

The TC654 and TC655 generate a pulse train with a

typical frequency of 30 Hz (C

F

= 1 µF). The duty cycle

can be varied from 30% to 100%. The pulse train gen-

erated by the TC654/TC655 devices drives the gate of

an external N-channel MOSFET or the base of an NPN

transistor (

Figure 4-3

). See

Section 7.5 “Output Drive

Device Selection”

for more information on output

drive device selection.

FIGURE 4-3:

PWM Fan Drive.

By modulating the voltage applied to the gate of the

MOSFET Qdrive, the voltage applied to the fan is also

modulated. When the V

OUT

pulse is high, the gate of

the MOSFET is turned on, pulling the voltage at the

drain of Qdrive to 0V. This places the full 12V across

the fan for the Ton period of the pulse. When the duty

cycle of the drive pulse is 100% (full on, Ton = T), the

fan will run at full speed. As the duty cycle is decreased

(pulse on time “Ton” is lowered), the fan will slow down

proportionally. With the TC654 and TC655 devices, the

duty cycle can be controlled through the analog input

pin (V

IN

) or through the SMBus interface by using the

Duty-Cycle Register. See

Section 4.5 “Duty Cycle

Control (V

IN

and Duty-Cycle Register)”

for more

details on duty cycle control.

T

Ton

Toff

T = Period

T = 1/F

F = Frequency

D = Duty Cycle

D = Ton / T

TC654/

TC655

FAN

12V

Qdrive

V

DD

GND

V

OUT

G

D

S