2001-2012 Microchip Technology Inc.

DS21365C-page 1

TC120

Features

• Internal Switching Transistor Supports 600mA

Output Current

• External Switching Transistor Control for Output

Currents of 2A+

• 300kHz Oscillator Frequency Supports Small

Inductor Size

• Short Circuit Protection

• Built-In Undervoltage Lockout

• 95% Typical Efficiency

• Automatic Switchover to Current-Saving PFM

Mode at Low Output Loads

• Automatic Output Capacitor Discharge While in

Shutdown

• Programmable Soft-Start

• Power-Saving Shutdown Mode

• Small 8-Pin SOP Package

Applications

• Portable Test Equipment

• Local Logic Supplies

• Portable Audio Systems

• Portable Scanners

• Palmtops

• Electronic Organizers

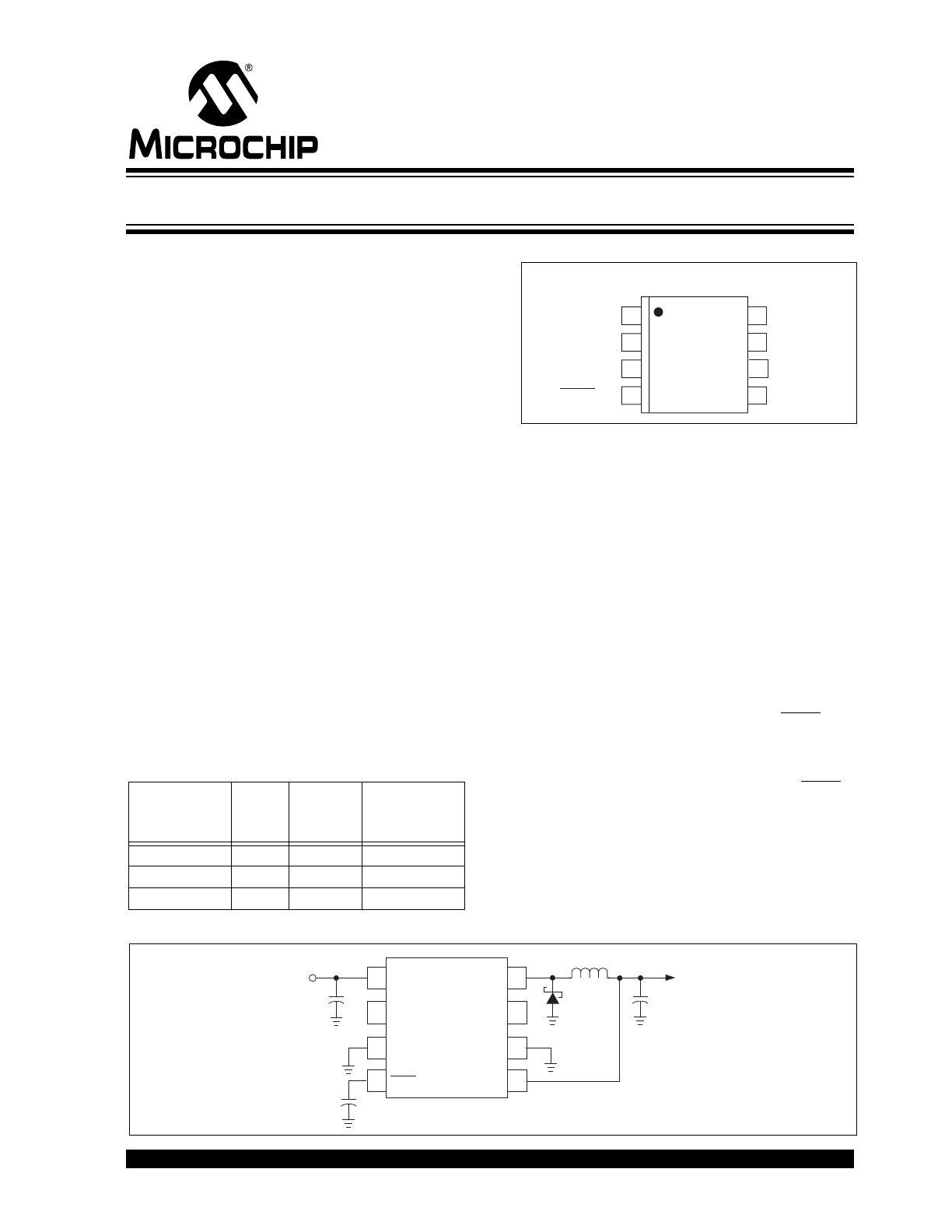

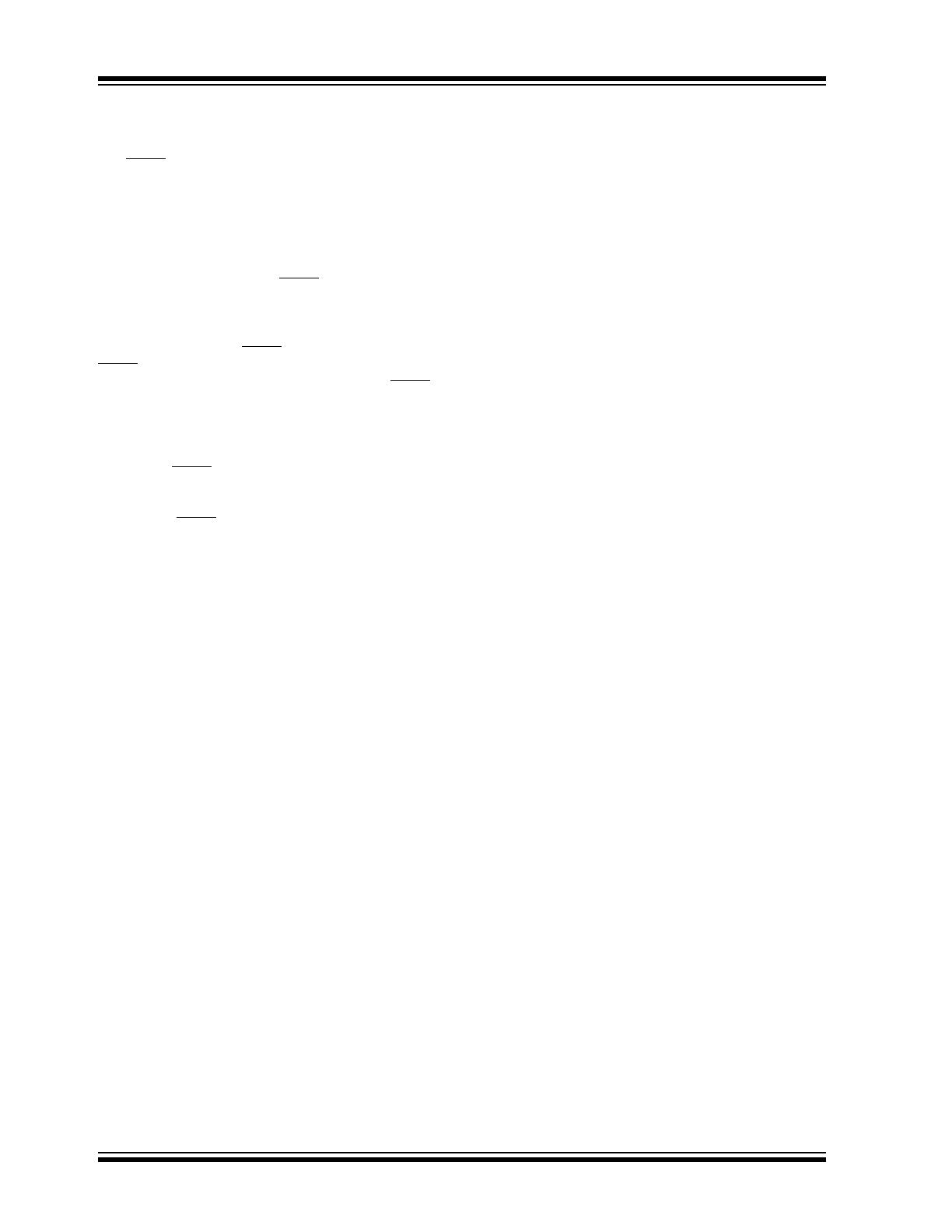

Device Selection Table

Package Type

General Description

TC120 is a 300kHz PFM/PWM step-down (Buck) DC/

DC regulator/controller combination for use in systems

operating from two or more cells, or in line-powered

applications. It uses PWM as the primary modulation

scheme, but automatically converts to PFM at low

output loads for greater efficiency. It requires only an

external inductor, Schottky diode, and two capacitors to

implement a step-down converter having a maximum

output current of 600mA (V

IN

= 5V, V

OUT

= 3.3V). An

external switching transistor (P-channel MOSFET) can

be added to increase output current capability to

support output loads of 2A or more.

The TC120 consumes only 55

A (max) of supply

current (V

OUT

= 3.3V) and can be placed in shutdown

mode by bringing the shutdown input (SHDN) low.

During shutdown, the regulator is disabled, supply

current is reduced to 2.5

A (max), and V

OUT

is

internally pulled to ground, discharging the output

capacitor. Normal operation resumes when SHDN is

brought high. Other features include a built-in under-

voltage lockout (UVLO), an externally programmable

soft start time, and output short circuit protection. The

TC120 operates from a maximum input voltage of 10V

and is available in a low-profile 8-Pin SOP package.

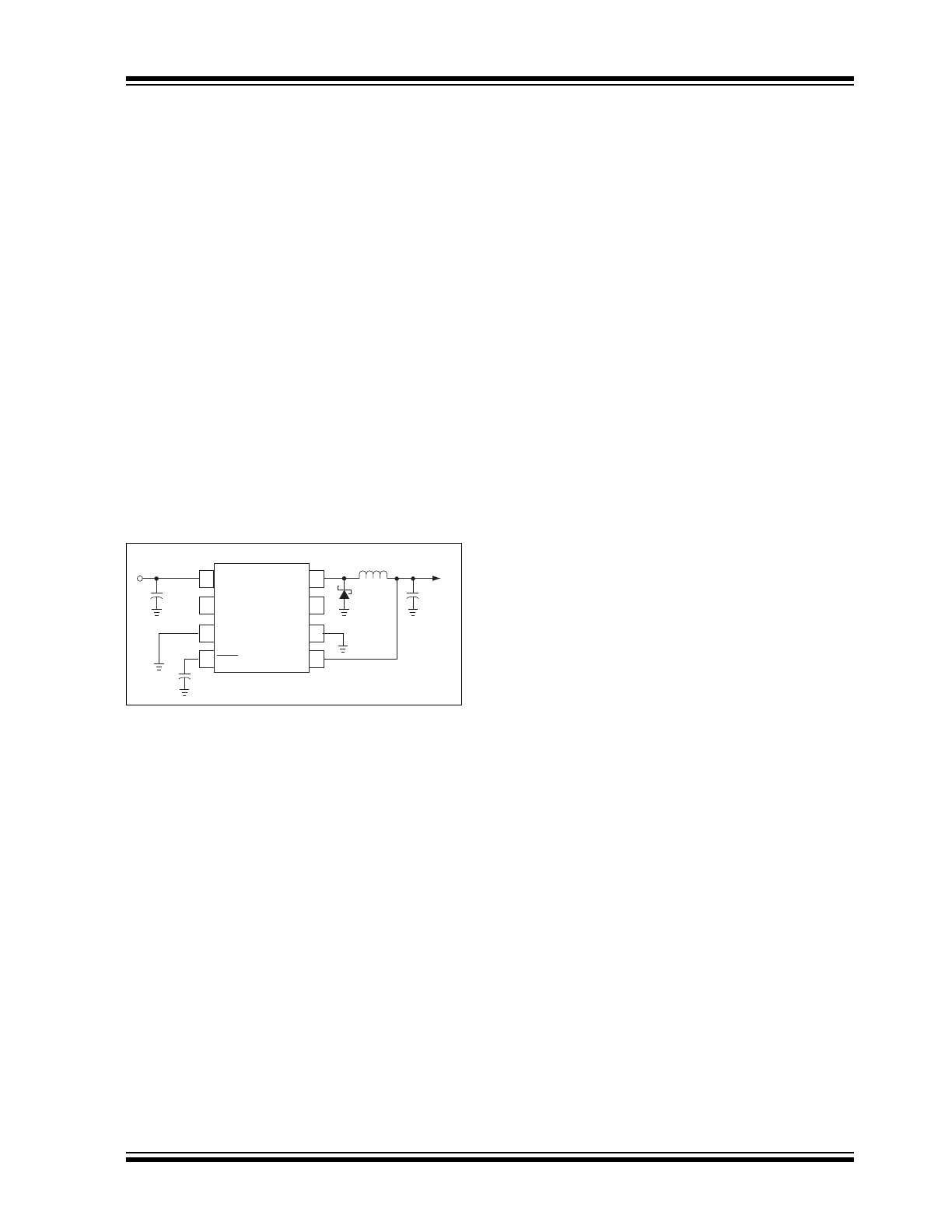

Functional Block Diagram

Part

Number

Output

Voltage

(V)

Package

Operating

Temp.

Range

TC120503EHA

5.0

8-Pin SOP -40°C to +85°C

TC120333EHA

3.3

8-Pin SOP -40°C to +85°C

TC120303EHA

3.0

8-Pin SOP -40°C to +85°C

1

2

3

4

8

7

6

5

TC120

8-Pin SOP

EXTW

CPC

SHDN/SS

V

IN

GND

EXT

SENSE

L

X

TC120XX03

V

IN

EXTW

CPC

SHDN/SS

L

X

EXT

GND

SENSE

C

IN

D1

L1

V

OUT

V

IN

C

OUT

C

SS

4.7nF

PWM/PFM Step-Down Combination Regulator/Controller

TC120

DS21365C-page 2

2001-2012 Microchip Technology Inc.

1.0

ELECTRICAL

CHARACTERISTICS

Absolute Maximum Ratings*

Power Supply Voltage (V

IN

).................... -0.3V to +12V

Voltage on V

OUT

Pin ............................... -0.3V to +12V

Voltage on LX, Boost Pins

................................... (V

IN

– 12V) to (V

IN

+ 0.3V)

Voltage on EXT1, EXT2, SHDN Pins

.......................................... (-0.3V) to (V

IN

+ 0.3V)

L

X

Pin Current .............................................. 700mA pk

EXT1, EXT2 Pin Current ...................................±50mA

Continuous Power Dissipation .........................300mW

Operating Temperature Range............. -40°C to +85°C

Storage Temperature Range ..............-40°C to +150°C

*Stresses above those listed under "Absolute Maximum

Ratings" may cause permanent damage to the device. These

are stress ratings only and functional operation of the device

at these or any other conditions above those indicated in the

operation sections of the specifications is not implied.

Exposure to Absolute Maximum Rating conditions for

extended periods may affect device reliability.

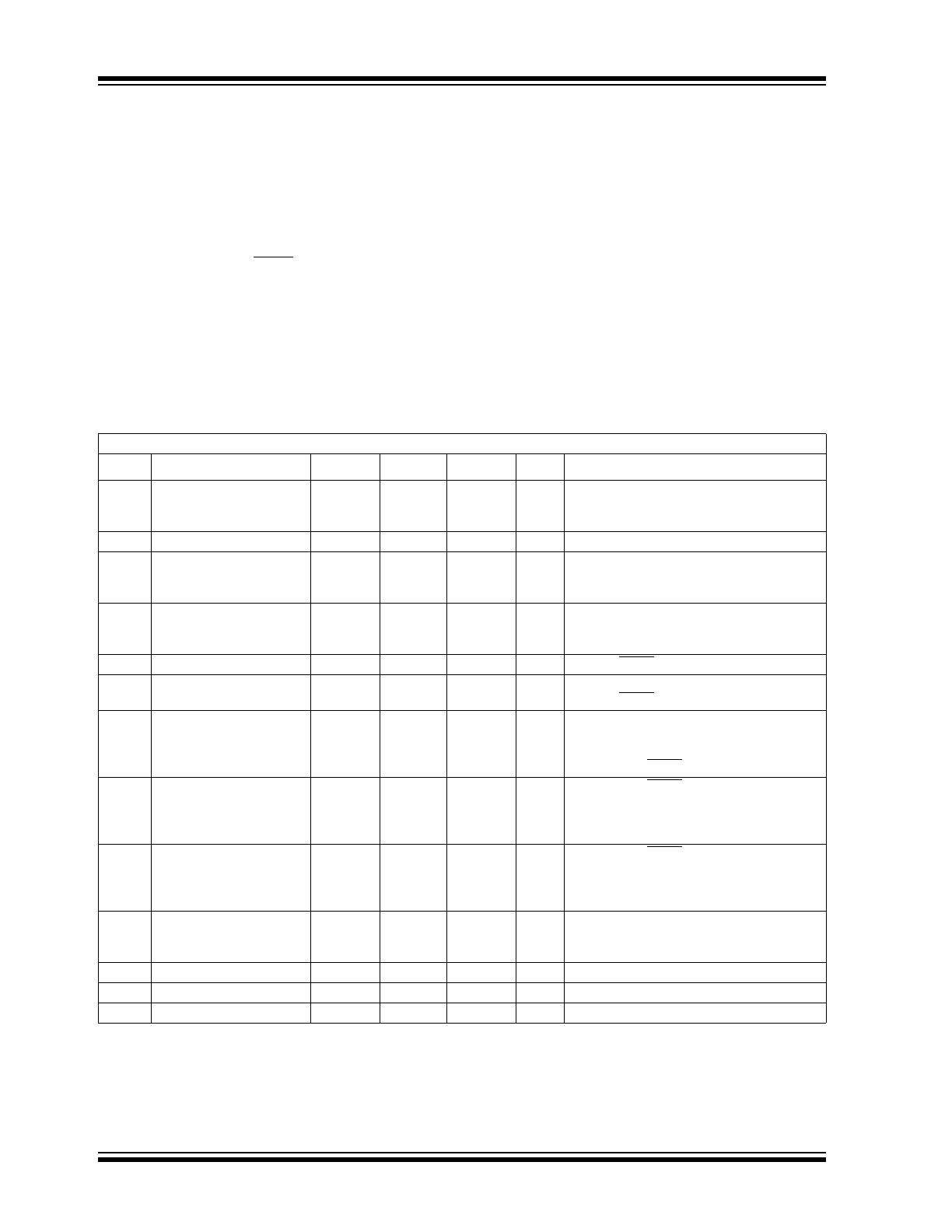

TC120 ELECTRICAL SPECIFICATIONS

Electrical Characteristics: Test circuit of Figure 3-1, T

A

= 25

C, V

IN

= V

R

x 1.2, Note 1 unless otherwise noted.

Symbol

Parameter

Min

Typ

Max

Units

Test Conditions

V

OUT

Output Voltage

V

R

x 0.975 V

R

± 0.5% V

R

x 1.025

V

V

OUT

= 3.0V

V

OUT

= 3.3V

V

OUT

= 5.0V

I

OUT

= 120mA (Note 1)

I

OUT

= 132mA

I

OUT

= 200mA

V

IN

Input Voltage

1.8

—

10.0

V

I

OUT

MAX

Maximum Output Current

500

600

600

—

—

—

—

—

—

mA

V

OUT

= 3.0V

V

OUT

= 3.3V

V

OUT

= 5.0V

I

IN

Supply Current

—

52

55

71

82

86

110

A

V

OUT

= 3.0V

V

OUT

= 3.3V

V

OUT

= 5.0V

V

IN

= V

R

x 1.05, no load

I

SHDN

Shutdown Supply Current

—

1.5

2.5

A

No load, SHDN = 0V, (Note 2)

I

LX

LX Pin Leakage Current

—

—

—

1.5

2

2.5

A

Measured at EXT1 Pin (Note 2)

No load, SHDN = 0V

R

DSON

(

L

X

)

LX Pin ON Resistance

—

—

—

0.69

0.64

0.44

0.94

0.85

0.58

V

OUT

= 3.0V

V

OUT

= 3.3V

V

OUT

= 5.0V

V

OUT

= V

R

x 0.9 (Note 2)

V

LX

= V

IN

– 0.2V, 10

Resistor from L

X

to V

IN

,

SHDN = V

IN

R

EXTH

EXT1, EXT2

On Resistance to V

IN

—

—

—

38

35

24

52

47

32

V

OUT

= 3.0V

V

OUT

= 3.3V

V

OUT

= 5.0V

SHDN = V

IH

; EXT1 and EXT2

connected to 200

load,

V

EXT1

= V

EXT2

= (V

IN

– 0.4V);

V

OUT

= V

IN

(Note 2)

R

EXTL

EXT1, EXT2

On Resistance to GND

—

—

—

31

29

20

41

37

26

V

OUT

= 3.0V

V

OUT

= 3.3V

V

OUT

= 5.0V

SHDN = V

IH

; EXT1 and EXT2

pulled up through a series

resistance of 200

to a voltage

such that VEXT1, 2 = 0.4V

f

OSC

Oscillator Frequency

255

300

345

kHz

Measured at EXT1 Pin,

V

IN

= V

OUT

+ 0.3V,

I

OUT

= 20mA (Note 3)

D

PWM

Maximum PWM Duty Cycle

—

—

100

%

D

PFM

PFM Duty Cycle

15

25

35

%

No load

Efficiency

—

95

—

%

V

IN

> V

R

x 1.2

Note

1:

V

R

is the factory-programmed output voltage setting.

2:

No external components connected, except C

SS.

3:

While operating in PWM Mode.

2001-2012 Microchip Technology Inc.

DS21365C-page 3

TC120

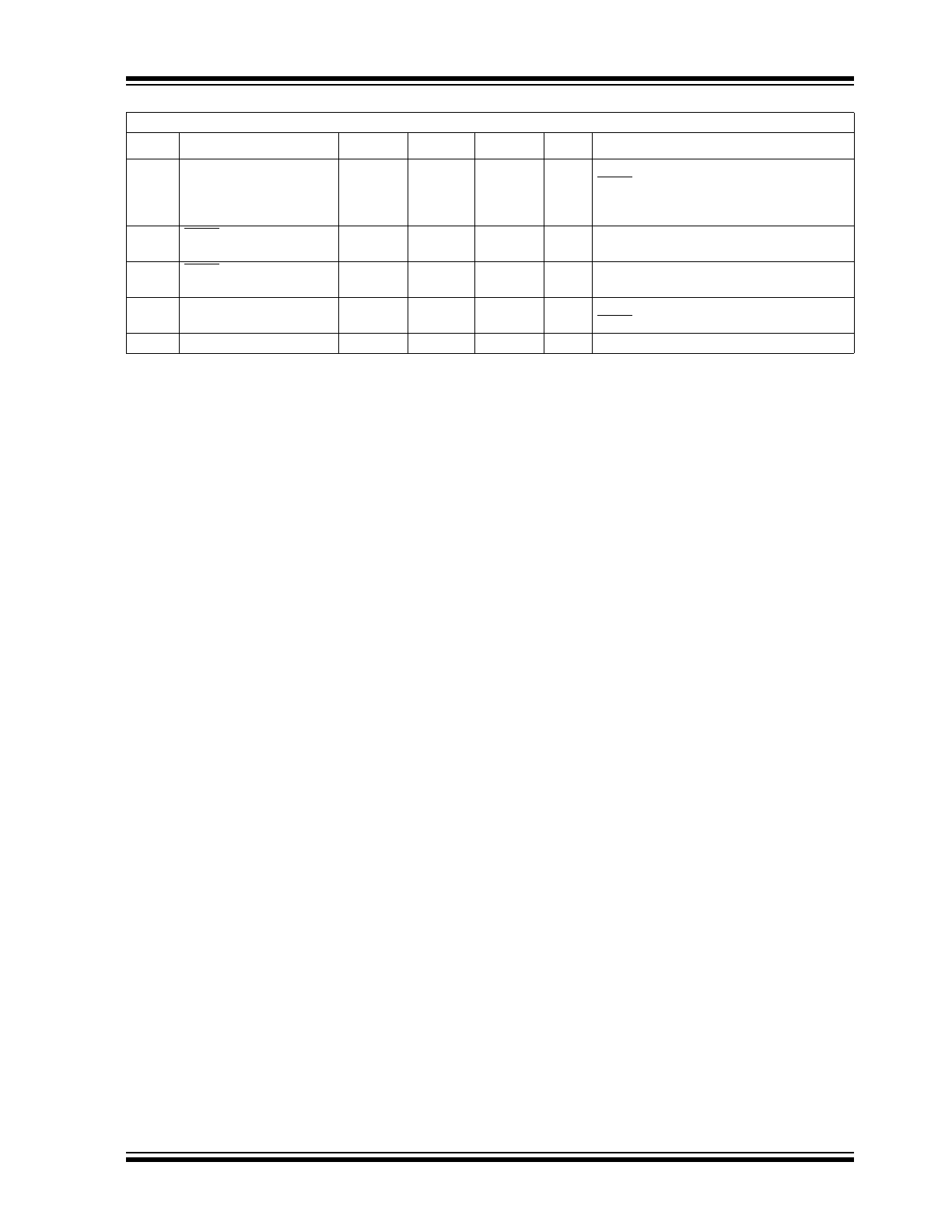

Electrical Characteristics: Test circuit of Figure 3-1, T

A

= 25

C, V

IN

= V

R

x 1.2, Note 1 unless otherwise noted.

Symbol

Parameter

Min

Typ

Max

Units

Test Conditions

V

UVLO

Minimum Operating Voltage

0.9

—

1.8

V

V

OUT

= V

R

x 0.9 (Note 2),

SHDN = V

IN

Measured with internal transistor

in OFF state and V

IN

falling

V

IH

SHDN Input Logic High,

Threshold Voltage

0.65

—

—

V

V

OUT

= 0V, (Note 2)

V

IL

SHDN Input Logic Low,

Threshold Voltage

—

—

0.20

V

V

OUT

= 0V, (Note 2)

t

PRO

Short Circuit Protection

Response Time

3

5

8

msec

Time from V

OUT

= 0V to

SHDN = V

IL

(Note 2)

t

SS

Soft Start Time

6

10

16

msec

Note

1:

V

R

is the factory-programmed output voltage setting.

2:

No external components connected, except C

SS.

3:

While operating in PWM Mode.

TC120

DS21365C-page 4

2001-2012 Microchip Technology Inc.

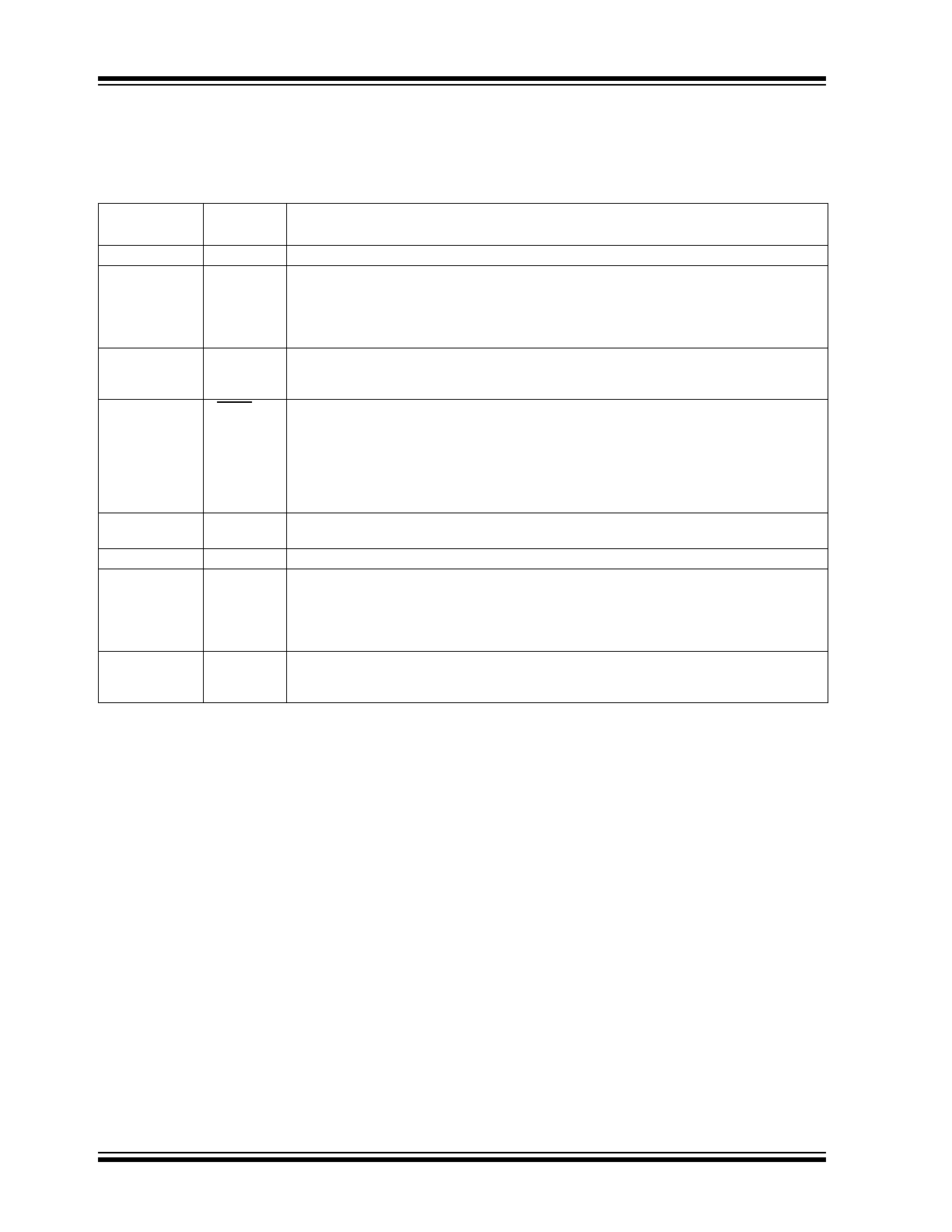

2.0

PIN DESCRIPTIONS

The descriptions of the pins are listed in Table 2-1.

TABLE 2-1:

PIN FUNCTION TABLE

Pin No.

(8-Pin SOP)

Symbol

Description

1

V

IN

Unregulated supply input.

2

EXTW

Extended external switching transistor drive output. This output follows the timing on the EXT

output with an additional 100nsec blanking time on both the leading and trailing edges. That is,

this output transitions from high-to-low 100 nsec prior to the same transition on EXT; and

transitions low-to-high 100nsec after the same transition on EXT; resulting in a longer external

switch ON time. (See Section 3.9 External Switching Transistor Selection).

3

CPC

Charge pump capacitor input. An inverting charge pump is formed by attaching a capacitor and

diode to this input. (See Section 3.5 Improving High Load Efficiency In Regulator Operating

Mode).

4

SHDN/SS

Shutdown and soft-start control input. A soft start capacitor of 100pF (min) must be connected to

this input. The soft start capacitor is charged by an internal

A current source that gently ramps

the TC120 into service. Shutdown control is best implemented with an external open collector (or

open drain) switch. The TC120 enters shutdown when this input is low. During shutdown, the

regulator is disabled, and supply current is reduced to less than 2.5

A. Normal operation is

restored when this input is open-circuited, and allowed to float high. (See Section 3.6 Low Power

Shutdown Mode/Soft Start Input).

5

SENSE

Voltage sense input. This input must be connected to the output voltage node at the physical

location that requires the tightest voltage regulation.

6

GND

Ground terminal.

7

EXT

External switching transistor drive output. This output connects directly to the gate of an external

P-channel MOSFET for applications requiring output currents greater than 600mA. The timing of

this output exactly matches that of the gate drive for the internal P-channel transistor. This output

can drive a maximum capacitance of 1000pF. (See Section 3.9 External Switching Transistor

Selection).

8

Lx

Inductor terminal. This pin is connected to the drain of the internal P-channel switching transistor.

If the TC120 is operated as a regulator (i.e., using the internal switch); the inductor must be

connected between this pin and the SENSE pin.

2001-2012 Microchip Technology Inc.

DS21365C-page 5

TC120

3.0

DETAILED DESCRIPTION

The TC120 can be operated as an integrated step-

down regulator (using the internal switching transistor);

or as a step-down regulator controller (using an

external switching transistor). When operating as an

integrated regulator, the only required external compo-

nents are a Schottky diode, inductor and an output

capacitor. Operating in this configuration, the TC120 is

capable of supporting output load currents to a

maximum of 600mA with operating efficiencies above

85%. Efficiencies at high loads can be further improved

by using the on-board charge pump circuit to pull the

gate of the internal switching transistor below ground

for the lowest possible ON resistance. (For more infor-

mation, see Section 3.5 Improving High Load

Efficiency in Regulator Operating Mode).

Higher output currents are achieved by operating the

TC120 with an external P-channel switching transistor

(controller mode). In this operating configuration, the

maximum output current is determined primarily by the

ON resistance of the P-channel switch and the series

resistance of the inductor.

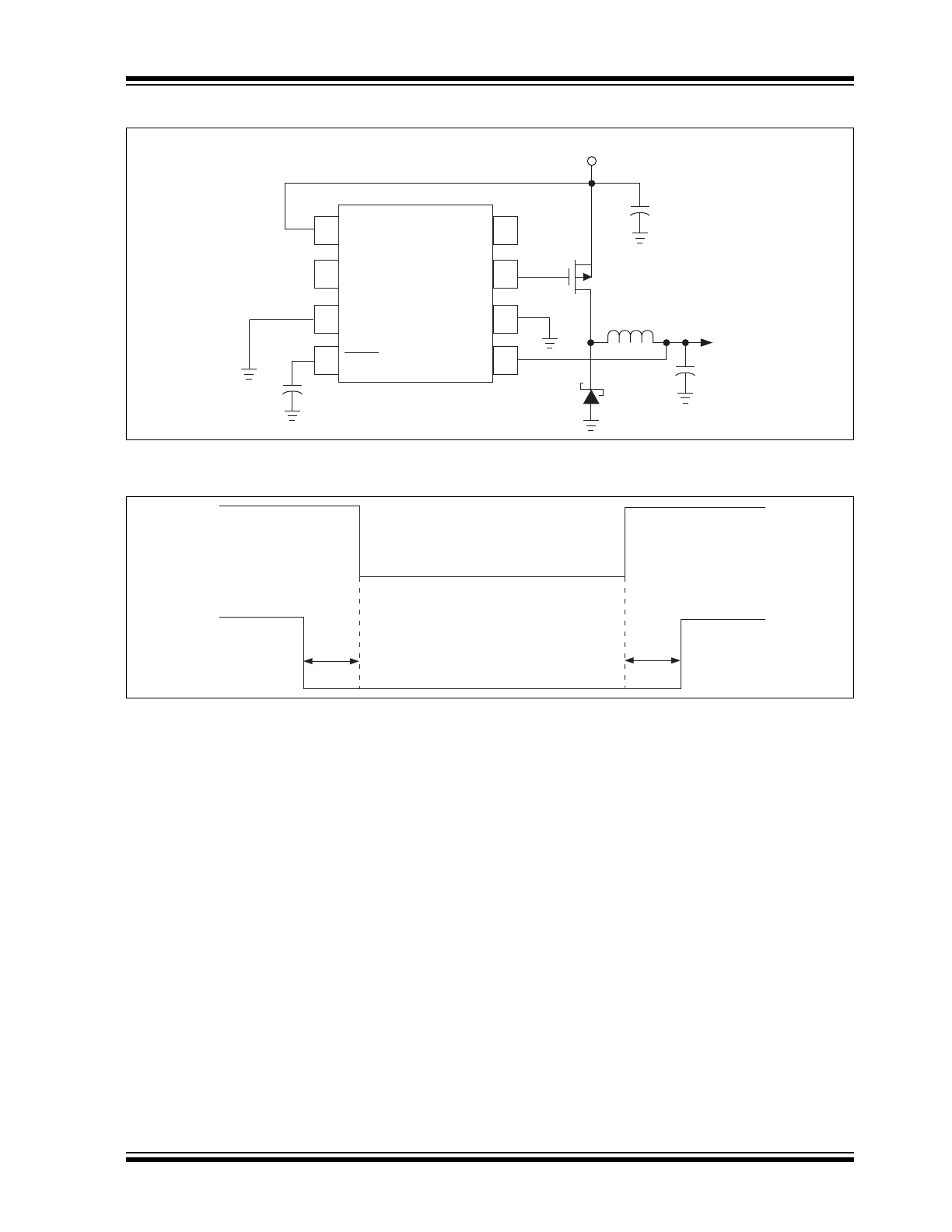

FIGURE 3-1:

TEST CIRCUIT

3.1

Inductor Selection

Selecting the proper inductor value is a trade-off

between physical size and power conversion require-

ments. Lower value inductors cost less, but result in

higher ripple current and core losses. They are also

more prone to saturate since the coil current ramps

faster and could overshoot the desired peak value. This

not only reduces efficiency, but could also cause the

current rating of the external components to be

exceeded. Larger inductor values reduce both ripple

current and core losses, but are larger in physical size

and tend to increase the start-up time slightly. A 22

H

inductor is the best overall compromise and is recom-

mended for use with the TC120. For highest efficiency,

use inductors with a low DC resistance (less than

20m

). To minimize radiated noise, consider using a

toroid, pot core or shielded-bobbin inductor.

3.2

Input Bypass Capacitor

Using an input bypass capacitor reduces peak current

transients drawn from the input supply, and reduces the

switching noise generated by the regulator. The source

impedance of the input supply determines the size of

the capacitor that should be used.

3.3

Output Capacitor

The effective series resistance of the output capacitor

directly affects the amplitude of the output voltage

ripple. (The product of the peak inductor current and

the ESR determines output ripple amplitude.) There-

fore, a capacitor with the lowest possible ESR should

be selected. Smaller capacitors are acceptable for light

loads or in applications where ripple is not a concern. A

47

F Tantalum capacitor is recommended for most

applications. The Sprague 595D series of tantalum

capacitors are amongst the smallest of all low ESR

surface mount capacitors available. Table 3-1 lists

suggested components and suppliers.

3.4

Catch Diode

The high operating frequency of the TC120 requires a

high-speed diode. Schottky diodes such as the MA737

or 1N5817 through 1N5823 (and the equivalent surface

mount versions) are recommended. Select a diode

whose average current rating is greater than the peak

inductor current; and whose voltage rating is higher

than V

IN

MAX

.

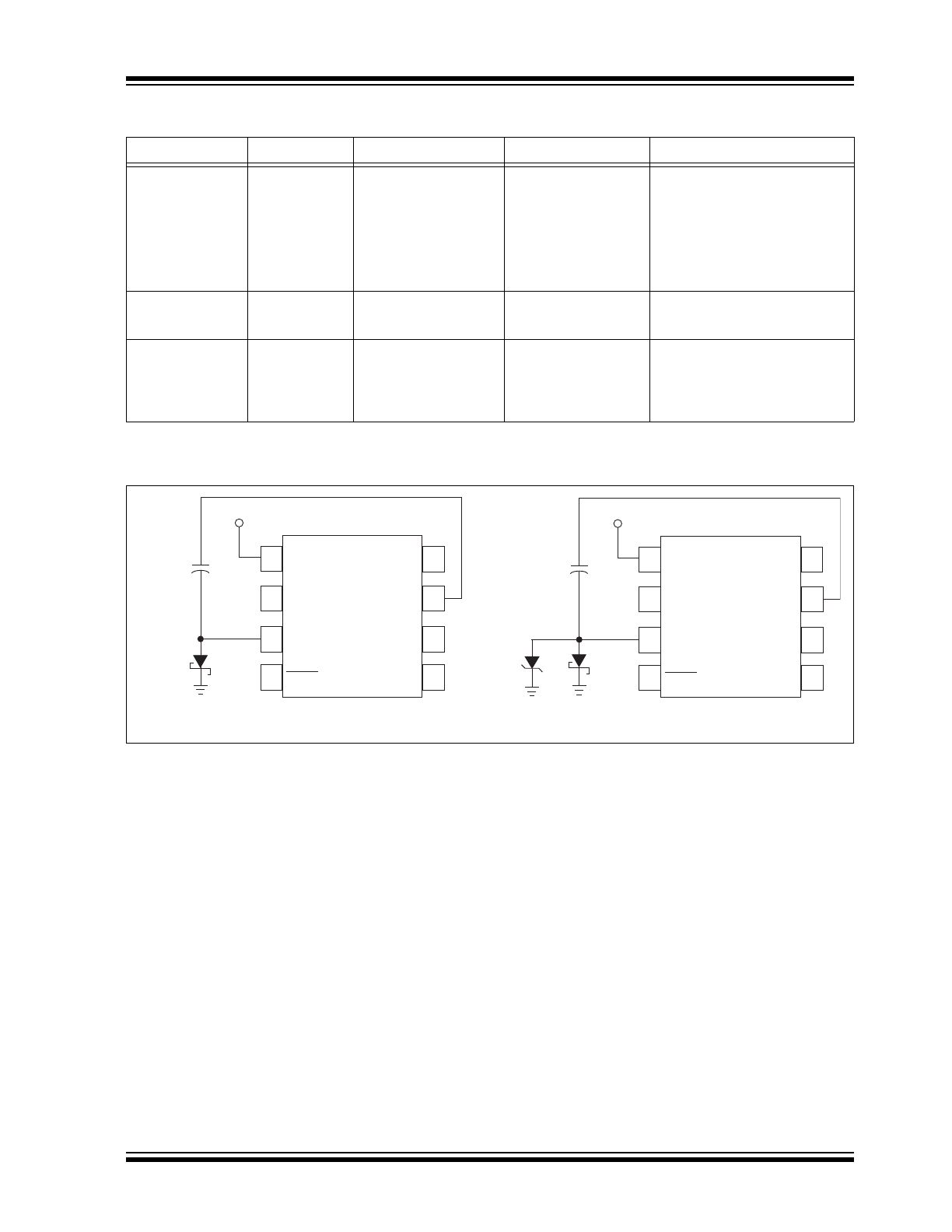

3.5

Improving High Load Efficiency in

Regulator Operating Mode

If the TC120 is operated at high output loads most (or

all) of the time, efficiency can be improved with the

addition of two components. Ordinarily, the voltage

swing on the gate of the internal P-channel transistor is

from ground to V

IN

. By adding a capacitor and diode as

shown in Figure 3-2, an inverting charge pump is

formed, enabling the internal gate voltage to swing

from a negative voltage to +V

IN

. This increased drive

lowers the R

DS

ON

of the internal transistor, improving

efficiency at high output currents. Care must be taken

to ensure the voltage measured between V

IN

and CPC

does not exceed an absolute value of 10V. While this is

not a problem at values of V

IN

at (or below) 5V, higher

V

IN

values will require the addition of a clamping

mechanism (such as a Zener diode) to limit the voltage

as described. While this technique improves efficiency

at high output loads, it is at the expense of low load

efficiency because energy is expended charging and

discharging the charge pump capacitor. This technique

is therefore not recommended for applications that

operate the TC120 at low output currents for extended

time periods. If unused, CPC must be grounded.

TC120XX03

V

IN

EXTW

CPC

SHDN/SS

L

X

EXT

GND

SENSE

47

μF/10V

Tantalum

C

SS

4.7nF

IN5817

L1

22

μH

V

OUT

V

IN

C

OUT

47

μF/10V

Tantalum

+

–

+

–

TC120

DS21365C-page 6

2001-2012 Microchip Technology Inc.

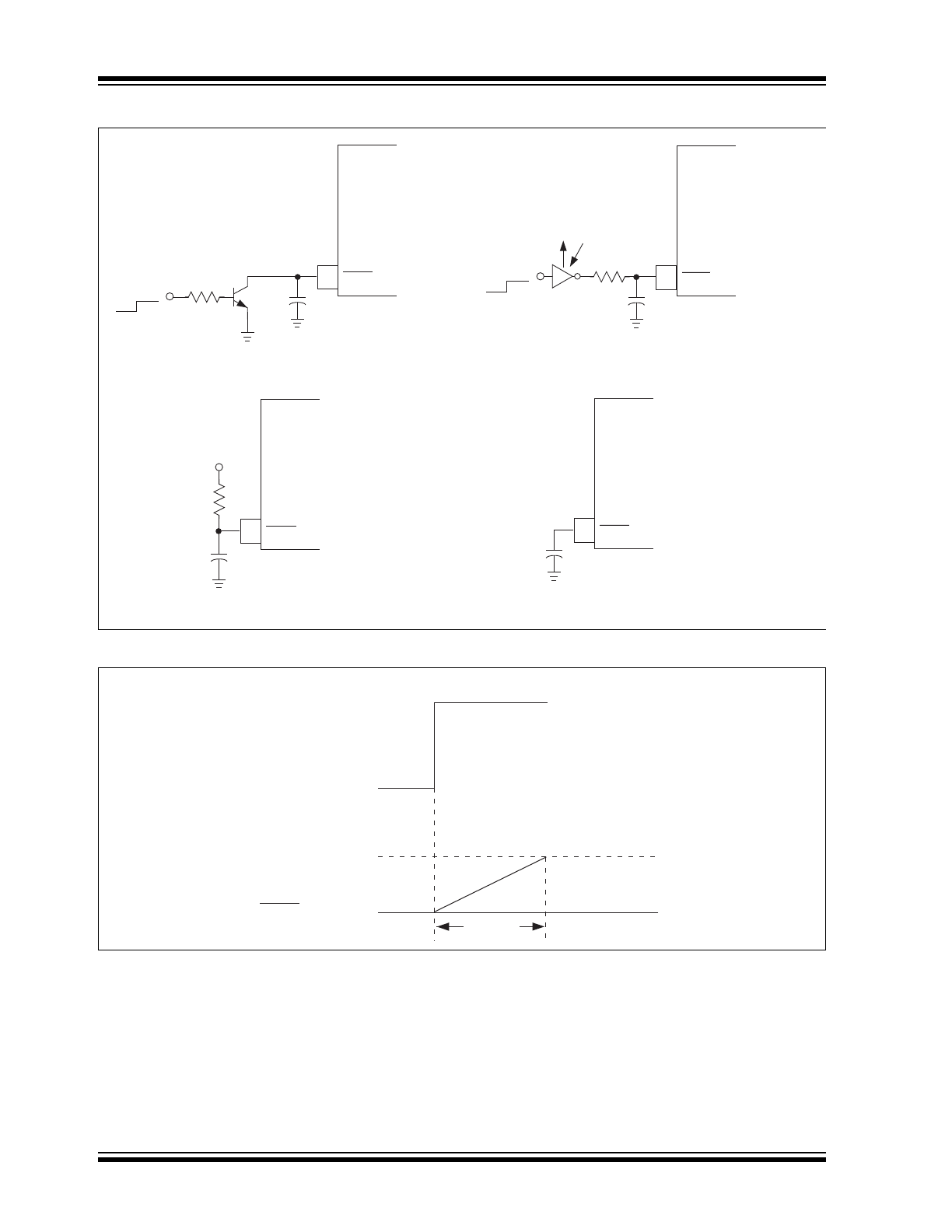

3.6

Low Power Shutdown Mode/Soft

Start Input

The SHDN/SS input acts as both the shutdown control

and the node for the external soft start capacitor, which

is charged by an internal 1

A current source. A value

of 4700pF (100pF minimum) is recommended for the

soft start capacitor. Failure to do this may cause large

overshoot voltages and/or large inrush currents result-

ing in possible instability. The TC120 enters a low

power shutdown mode when SHDN/SS is brought low.

While in shutdown, the oscillator is disabled and the

output discharge switch is turned on, discharging the

output capacitor. Figure 3-3 shows the recommended

interface circuits to the SHDN/SS input. As shown, the

SHDN/SS input should be controlled using an open

collector (or open drain) device, such that the SHDN/

SS input is grounded for shutdown mode, and open-

circuited for normal operation (Figure 3-3a). If a CMOS

device is used to control shutdown (Figure 3-3b), the

value of R1 and C

SS

should be chosen such that the

voltage on SHDN/SS rises from ground to 0.65V in

1.5msec (Figure 3-4). If shutdown is not used, C

SS

must still be connected as shown in Figure 3-3c and

Figure 3-3d. SHDN/SS may be pulled up with a resistor

(Figure 3-3c) as long as the values of R

SS

and C

SS

provide the approximate charging characteristic on

power up shown in Figure 3-4. C

SS

only may also be

connected as shown in Figure 3-3d with C

SS

chosen at

4700pF (minimum 100pF).

3.7

Undervoltage Lockout (UVLO)

The TC120 is disabled whenever V

IN

is below the

undervoltage lockout threshold. This threshold is equal

to the guaranteed minimum operating voltage for the

TC120 (i.e., 2.2V). When UVLO is active, the TC120 is

completely disabled.

3.8

Short Circuit Protection

Upon detection of an output short circuit condition, the

TC120 reduces the PWM duty cycle to a minimum

value using its internal protection timer. The sequence

of events is as follows: when an output voltage

decrease to near zero is detected (as the result of an

overload), the internal (5msec) protection timer is

started. If the output voltage has not recovered to

nominal value prior to the expiration of the protection

timer, the TC120 is momentarily shut down by

dedicated, internal circuitry. Immediately following this

action, the soft start sequence is engaged in an attempt

to re-start the TC120. If the output short circuit is

removed, normal operation is automatically restored. If

the short circuit is still present, the timed self-shutdown

sequence described above is repeated.

3.9

External Switching Transistor

Selection

EXT is a complimentary output with a maximum ON

resistances of 32

to V

DD

when high and 26

to

ground when low, at V

OUT

= 5V. It is designed to

directly drive a P-channel MOSFET (Figure 3-5). The

P-channel MOSFET selection is determined mainly by

the on-resistance, gate-source threshold and gate

charge requirements. Also, the drain-to-source and

gate-to-source breakdown voltage ratings must be

greater than V

IN

MAX

. The total gate charge specification

should be less than 100nC for best efficiency. The

MOSFET must be capable of handling the required

peak inductor current, and should have a very low on-

resistance at that current. For example, a Si9430

MOSFET has a drain-to-source rating of -20V, and a

typical on-resistance r

DS

ON

of 0.07

at 2A, with V

GS

=

-4.5V. (EXTW (Figure 3-6) may be gated with external

circuitry to add blanking, or as an auxiliary timing

signal.) Table 3-1 lists suggested components and

suppliers.

3.10

Board Layout Guidelines

As with all inductive switching regulators, the TC120

generates fast switching waveforms, which radiate

noise. Interconnecting lead lengths should be

minimized to keep stray capacitance, trace resistance

and radiated noise as low as possible. In addition, the

GND pin, input bypass capacitor and output filter

capacitor ground leads should be connected to a single

point. The input capacitor should be placed as close to

power and ground pins of the TC120 as possible. The

length of the EXT trace must also be kept as short as

possible.

2001-2012 Microchip Technology Inc.

DS21365C-page 7

TC120

TABLE 3-1:

SUGGESTED COMPONENTS AND SUPPLIERS

FIGURE 3-2:

TC120 WITH ADDED COMPONENTS FOR IMPROVED EFFICIENCY AT

HIGH OUTPUT CURRENTS

Type

Inductors

Capacitors

Diodes

Transistors

Surface Mount

Sumida

CD54 Series

CDRH Series

Coilcraft

DO Series

AVX

TPS Series

Sprague

595D Series

ON Semiconductor

MBRS340T3

Nihon

NSQ Series

Matsushita

MA737

Silconix

Little Foot MOSFET Series

Zetex FZT749

PNP Bipolar Transistor

Toshiba 2SA1213 PNP

Transistor

Miniature

Through-Hole

Sumida

RCH Series

Sanyo

OS-CON Series

IRC

OAR Series

Standard

Through-Hole

Coilcraft

PCH Series

Nichicon

PL Series

United Chemi-Conv

LXF Series

ON Semiconductor

TMOS Power MOSFETs

TC120XX03

V

IN

EXTW

CPC

SHDN/SS

L

X

EXT

GND

SENSE

D

1

IN5817

a) For V

IN

≤ 5V

C

P

2200 pF

Ceramic

TC120XX03

V

IN

EXTW

CPC

SHDN/SS

L

X

EXT

GND

SENSE

D

1

IN5817

b) For V

IN

> 5V

C

P

2200 pF

Ceramic

10V

Zener

Diode

V

IN

≤ 5V

V

IN

> 5V

TC120

DS21365C-page 8

2001-2012 Microchip Technology Inc.

FIGURE 3-3:

SHUTDOWN CONTROL CIRCUITS

FIGURE 3-4:

SOFT START TIMING

SHDN/SS

TC120XX03

C

SS

SHDN/SS

TC120XX03

C

SS

SHDN/SS

TC120XX03

C

SS

4.7nF

SHDN/SS

TC120XX03

R

SS

V

IN

SHDN

ON OFF

47K

2N2222

C

SS

4.7nF

R

1

V

IN

CMOS

Gate

a) Using an Open Collector Device

b) Using a Complementary Output Device

c) Shutdown Not Used – with Pull-Up

d) Shutdown Not Used – No Pull-Up

SHDN

ON OFF

OFF

ON

0.65V

0V

1.5msec

SHDN/SS

Shutdown

Signal

X

2001-2012 Microchip Technology Inc.

DS21365C-page 9

TC120

FIGURE 3-5:

USING EXTERNAL TRANSISTOR SWITCH

FIGURE 3-6:

EXTERNAL (EXT) AND EXTENDED EXTERNAL (EXTW) SWITCHING

TRANSISTOR DRIVE OUTPUT

TC120XX03

V

IN

EXTW

CPC

L

X

EXT

GND

SENSE

SHDN/SS

C

SS

4.7 nF

IN5817

L1

22

μH

V

OUT

V

IN

C

IN

47

μF

Tantalum

C

OUT

47

μF

Tantalum

EXT

EXTW

100nsec

100nsec

TC120

DS21365C-page 10

2001-2012 Microchip Technology Inc.

4.0

PACKAGING INFORMATION

4.1

Package Marking Information

Package marking data not available at this time.

4.2

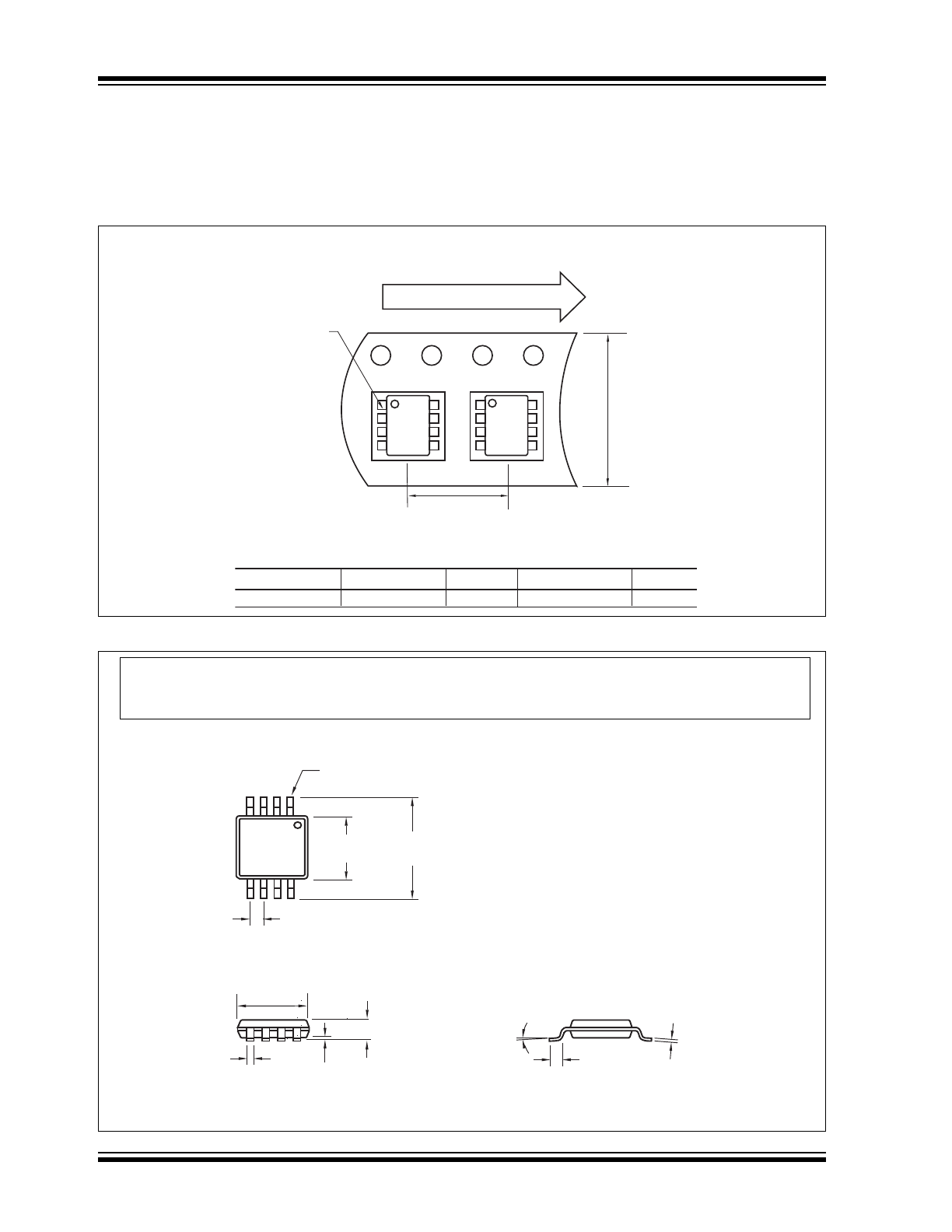

Taping Form

4.3

Package Dimensions

Component Taping Orientation for 8-Pin SOP Devices

Package

Carrier Width (W)

Pitch (P)

Part Per Full Reel

Reel Size

8-Pin SOP

12 mm

8 mm

1000

7 in

Carrier Tape, Number of Components Per Reel and Reel Size

PIN 1

User Direction of Feed

Standard Reel Component Orientation

for TR Suffix Device

W

P

8-Pin SOP

.181 (4.60)

.165 (4.20)

.217 (5.50)

.193 (4.90)

.069 (1.75)

.055 (1.40)

.008 (0.20)

.000 (0.00)

.020 (0.50)

.012 (0.30)

.256 (6.50)

.232 (5.90)

PIN 1

.010 (0.25)

.004 (0.10)

.018 (0.45)

.014 (0.35)

8

° MAX.

.051 (1.30)

.049 (1.24)

Dimensions: inches (mm)

Note:

For the most current package drawings, please see the Microchip Packaging Specification located

at http://www.microchip.com/packaging