2014 Microchip Technology Inc.

DS20005013D-page 1

Features

• Single Voltage Read and Write Operations

- 1.65-1.95V

• Serial Interface Architecture

- Mode 0 and Mode 3

- Nibble-wide multiplexed I/O’s with SPI-like serial

command structure

- x1/x2/x4 Serial Peripheral Interface (SPI) Proto-

col

• High Speed Clock Frequency

- 104 MHz max

• Burst Modes

- Continuous linear burst

- 8/16/32/64 Byte linear burst with wrap-around

• Superior Reliability

- Endurance: 100,000 Cycles (min)

- Greater than 100 years Data Retention

• Low Power Consumption:

- Active Read current: 15 mA (typical @ 104 MHz)

- Standby current: 10 μA (typical)

- Deep Power-Down current: 2.5 μA (typical)

• Fast Erase Time

- Sector/Block Erase: 18 ms (typ), 25 ms (max)

- Chip Erase: 35 ms (typ), 50 ms (max)

• Page-Program

- 256 Bytes per page in x1 or x4 mode

• End-of-Write Detection

- Software polling the BUSY bit in status register

• Flexible Erase Capability

- Uniform 4 KByte sectors

- Four 8 KByte top and bottom parameter overlay

blocks

- One 32 KByte top and bottom overlay block

- Uniform 64 KByte overlay blocks

• Write-Suspend

- Suspend Program or Erase operation to access

another block/sector

• Software Reset (RST) mode

• Software Protection

- Individual-Block Write Protection with permanent

lock-down capability

- 64 KByte blocks, two 32 KByte blocks, and

eight 8 KByte parameter blocks

- Read Protection on top and bottom 8 KByte

parameter blocks

• Security ID

- One-Time Programmable (OTP) 2 KByte,

Secure ID

- 64 bit unique, factory pre-programmed identifier

- User-programmable area

• Temperature Range

- Industrial: -40°C to +85°C

• Packages Available

- 8-contact WDFN (6mm x 5mm)

- 8-lead SOIC (150 mil)

- 8-ball Chip Scale Package (Z-Scale™)

• All devices are RoHS compliant

Product Description

The Serial Quad I/O™ (SQI™) family of flash-memory

devices features a six-wire, 4-bit I/O interface that

allows for low-power, high-performance operation in a

low pin-count package. SST26WF016B/016BA also

support full command-set compatibility to traditional

Serial Peripheral Interface (SPI) protocol. System

designs using SQI flash devices occupy less board

space and ultimately lower system costs.

All members of the 26 Series, SQI family are manufac-

tured with SST proprietary, high-performance CMOS

SuperFlash® technology. The split-gate cell design

and thick-oxide tunneling injector attain better reliability

and manufacturability compared with alternate

approaches.

The SST26WF016B/SST26WF016BA significantly

improves performance and reliability, while lowering

power consumption. This device writes (Program or

Erase) with a single power supply of 1.65-1.95V. The

total energy consumed is a function of the applied volt-

age, current, and time of application. Since for any

given voltage range, the SuperFlash technology uses

less current to program and has a shorter erase time,

the total energy consumed during any Erase or Pro-

gram operation is less than alternative flash memory

technologies.

SST26WF016B/016BA is offered in 8-contact WDFN

(6 mm x 5 mm), 8-lead SOIC (150 mil), and 8-ball

XFBGA (Z-Scale™) packages. See

Figure 2-1

for pin

assignments.

Two configurations are available upon order:

SST26WF016B default at power-up has the WP# and

Hold# pins enabled and SST26WF016BA default at

power-up has the WP# and Hold# pins disabled.

SST26WF016B/

SST26WF016BA

1.8V 16 Mbit Serial Quad I/O (SQI) Flash Memory

SST26WF016B/SST26WF016BA

DS20005013D-page 2

2014 Microchip Technology Inc.

TO OUR VALUED CUSTOMERS

It is our intention to provide our valued customers with the best documentation possible to ensure successful use of your Microchip

products. To this end, we will continue to improve our publications to better suit your needs. Our publications will be refined and

enhanced as new volumes and updates are introduced.

If you have any questions or comments regarding this publication, please contact the Marketing Communications Department via E-

mail at

docerrors@microchip.com

. We welcome your feedback.

Most Current Data Sheet

To obtain the most up-to-date version of this data sheet, please register at our Worldwide Web site at:

http://www.microchip.com

You can determine the version of a data sheet by examining its literature number found on the bottom outside corner of any page. The

last character of the literature number is the version number, (e.g., DS30000000A is version A of document DS30000000).

Errata

An errata sheet, describing minor operational differences from the data sheet and recommended workarounds, may exist for current

devices. As device/documentation issues become known to us, we will publish an errata sheet. The errata will specify the revision of

silicon and revision of document to which it applies.

To determine if an errata sheet exists for a particular device, please check with one of the following:

• Microchip’s Worldwide Web site;

http://www.microchip.com

• Your local Microchip sales office (see last page)

When contacting a sales office, please specify which device, revision of silicon and data sheet (include literature number) you are

using.

Customer Notification System

Register on our web site at

www.microchip.com

to receive the most current information on all of our products.

2014 Microchip Technology Inc.

DS20005013D-page 3

SST26WF016B/SST26WF016BA

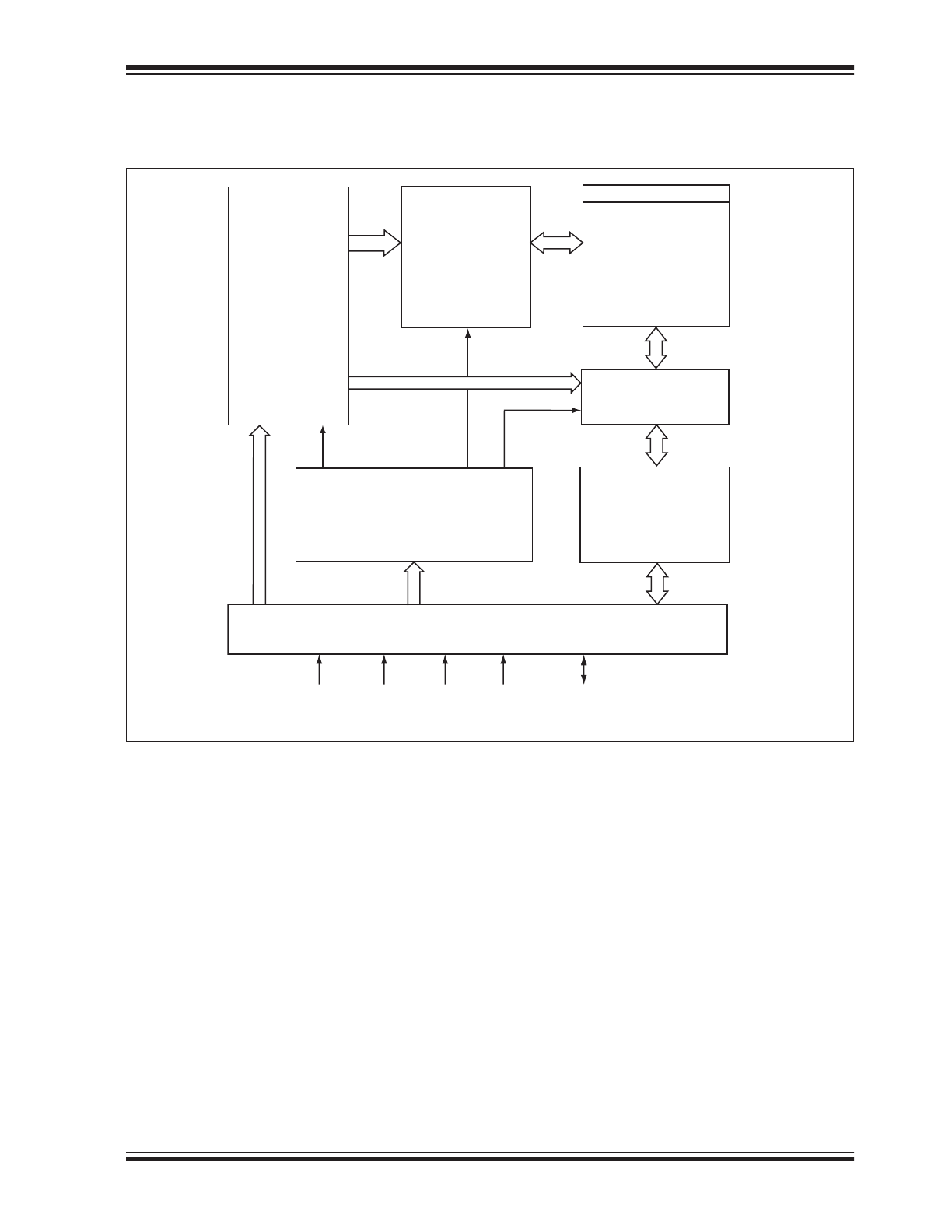

1.0

BLOCK DIAGRAM

FIGURE 1-1:

FUNCTIONAL BLOCK DIAGRAM

1432 B1.0

Page Buffer,

I/O Buffers

and

Data Latches

SuperFlash

Memory

X - Decoder

Control Logic

Address

Buffers

and

Latches

HOLD#

Y - Decoder

CE#

SIO [3:0]

Serial Interface

OTP

WP#

SCK

SST26WF016B/SST26WF016BA

DS20005013D-page 4

2014 Microchip Technology Inc.

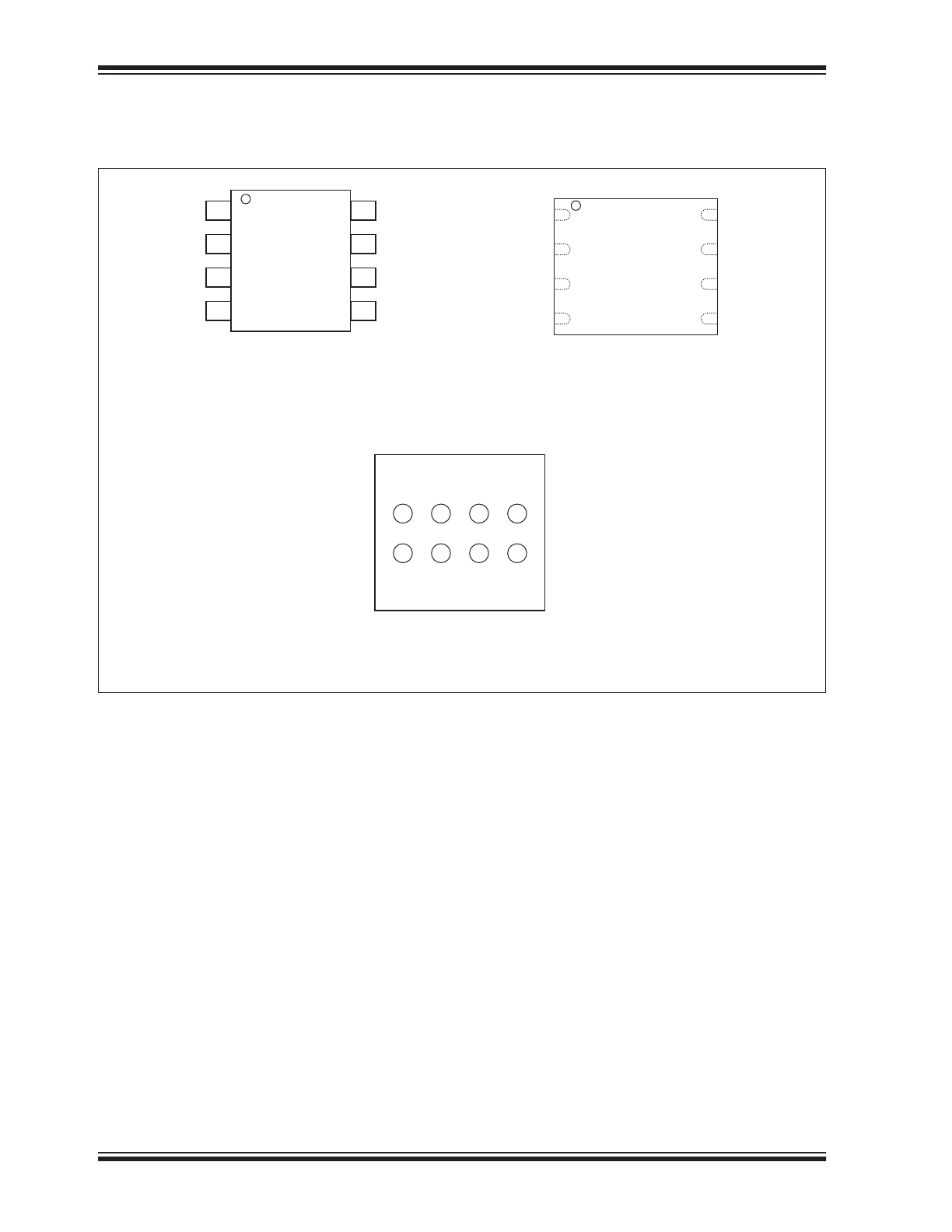

2.0

PIN DESCRIPTION

FIGURE 2-1:

PIN DESCRIPTION FOR 8-LEAD SOIC, 8-CONTACT WDFN, AND 8-BALL XFBGA

1

2

3

4

8

7

6

5

CE#

SO/SIO1

WP#/SIO2

VSS

VDD

HOLD/SIO3

SCK

SI/SIO0

Top View

1432 08-soic S2A P1.0

1

2

3

4

8

7

6

5

CE#

SO/SIO1

WP#/SIO2

VSS

Top View

VDD

HOLD/SIO3

SCK

SI/SIO0

1432 08-wson QA P1.0

8-Lead SOIC

8-Contact WDFN

8-Ball XFBGA

Top View

8-xfbga P1.0

CE#

V

DD

SO/SIO1

HOLD/

SIO3

WP#/

SIO2

SCK

V

SS

SI/SIO0

A

B

C

D

2

1

(Balls Facing Down)

2014 Microchip Technology Inc.

DS20005013D-page 5

SST26WF016B/SST26WF016BA

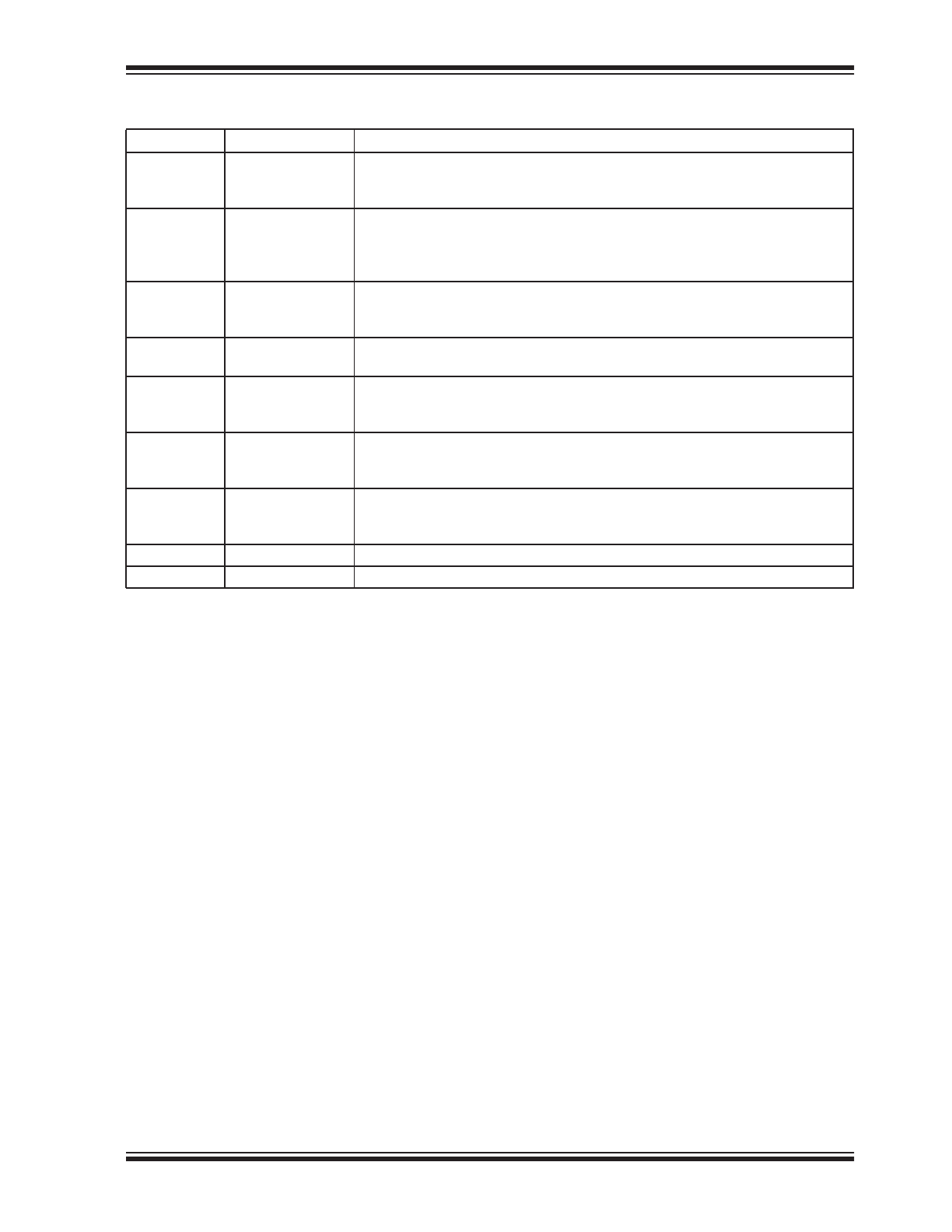

TABLE 2-1:

PIN DESCRIPTION

Symbol

Pin Name

Functions

SCK

Serial Clock

To provide the timing of the serial interface.

Commands, addresses, or input data are latched on the rising edge of the clock

input, while output data is shifted out on the falling edge of the clock input.

SIO[3:0]

Serial Data

Input/Output

To transfer commands, addresses, or data serially into the device or data out of

the device. Inputs are latched on the rising edge of the serial clock. Data is

shifted out on the falling edge of the serial clock. The Enable Quad I/O (EQIO)

command instruction configures these pins for Quad I/O mode.

SI

Serial Data Input

for SPI mode

To transfer commands, addresses or data serially into the device. Inputs are

latched on the rising edge of the serial clock. SI is the default state after a

power on reset.

SO

Serial Data Output

for SPI mode

To transfer data serially out of the device. Data is shifted out on the falling edge

of the serial clock. SO is the default state after a power on reset.

CE#

Chip Enable

The device is enabled by a high to low transition on CE#. CE# must remain low

for the duration of any command sequence; or in the case of Write operations,

for the command/data input sequence.

WP#

Write Protect

The WP# pin is used in conjunction with the WPEN and IOC bits in the configu-

ration register to prohibit Write operations to the Block-Protection register. This

pin only works in SPI, single-bit and dual-bit Read mode.

HOLD#

Hold

Temporarily stops serial communication with the SPI Flash memory while the

device is selected. This pin only works in SPI, single-bit and dual-bit Read

mode. This pin must be tied high when not in use.

V

DD

Power Supply

To provide power supply voltage.

V

SS

Ground

SST26WF016B/SST26WF016BA

DS20005013D-page 6

2014 Microchip Technology Inc.

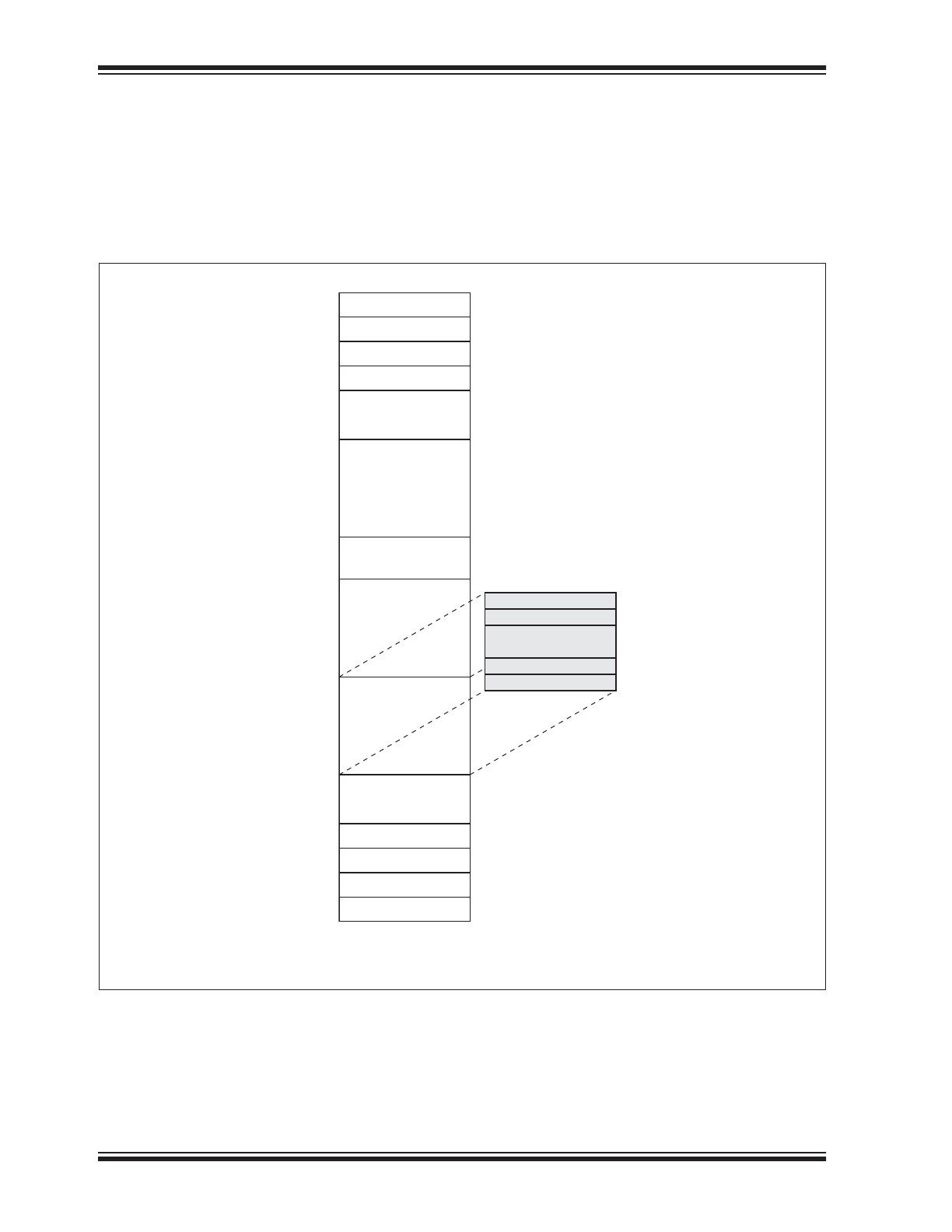

3.0

MEMORY ORGANIZATION

The SST26WF016B/016BA SQI memory array is orga-

nized in uniform, 4 KByte erasable sectors with the fol-

lowing erasable blocks: eight 8 KByte parameter, two

32 KByte overlay, and thirty 64 KByte overlay blocks.

See

Figure 3-1

.

FIGURE 3-1:

MEMORY MAP

1432 F41.0

Top of Memory Block

8 KByte

8 KByte

8 KByte

8 KByte

32 KByte

64 KByte

64 KByte

64 KByte

32 KByte

8 KByte

8 KByte

8 KByte

8 KByte

Bottom of Memory Block

4 KByte

4 KByte

4 KByte

4 KByte

. . .

2 Sectors for 8 KByte blocks

8 Sectors for 32 KByte blocks

16 Sectors for 64 KByte blocks

. . .

2014 Microchip Technology Inc.

DS20005013D-page 7

SST26WF016B/SST26WF016BA

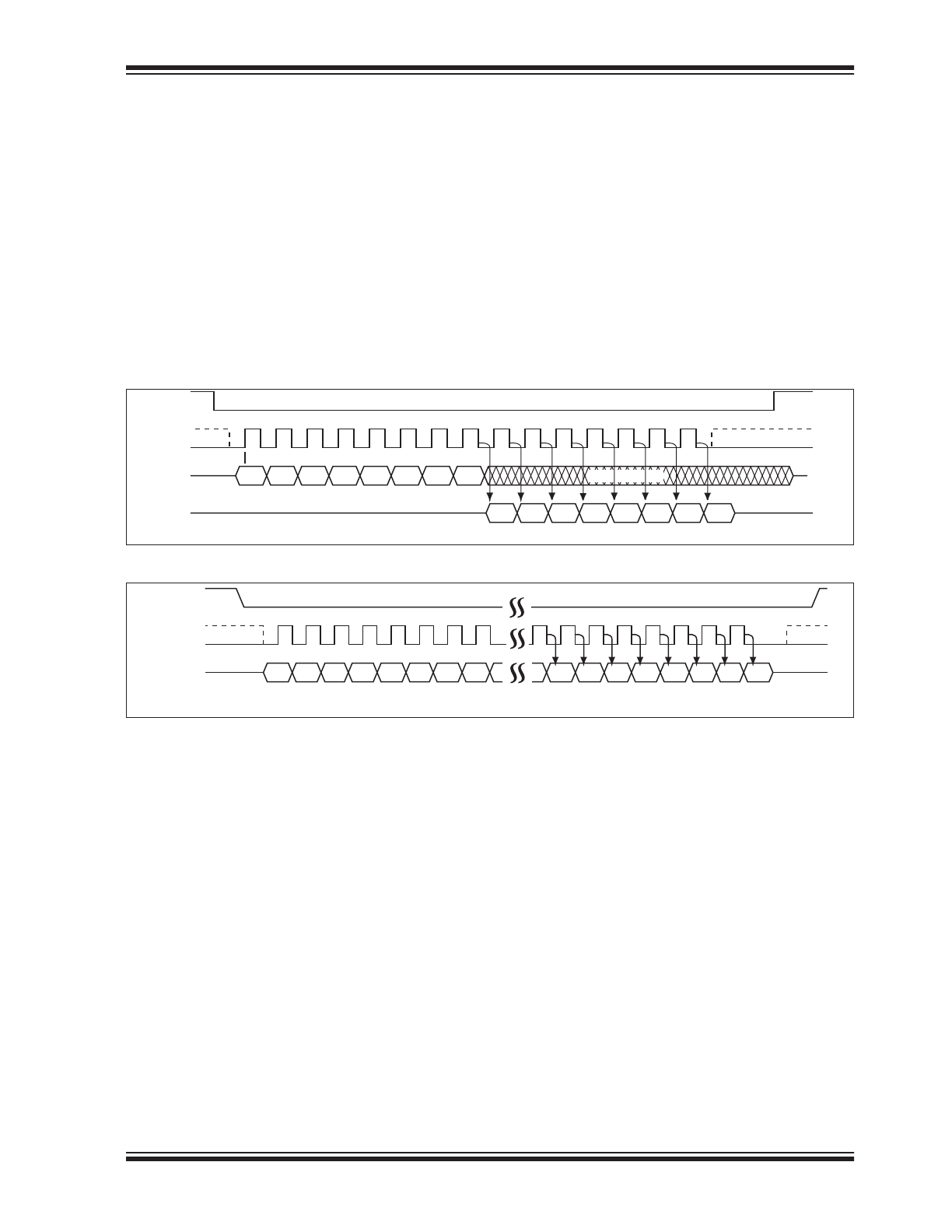

4.0

DEVICE OPERATION

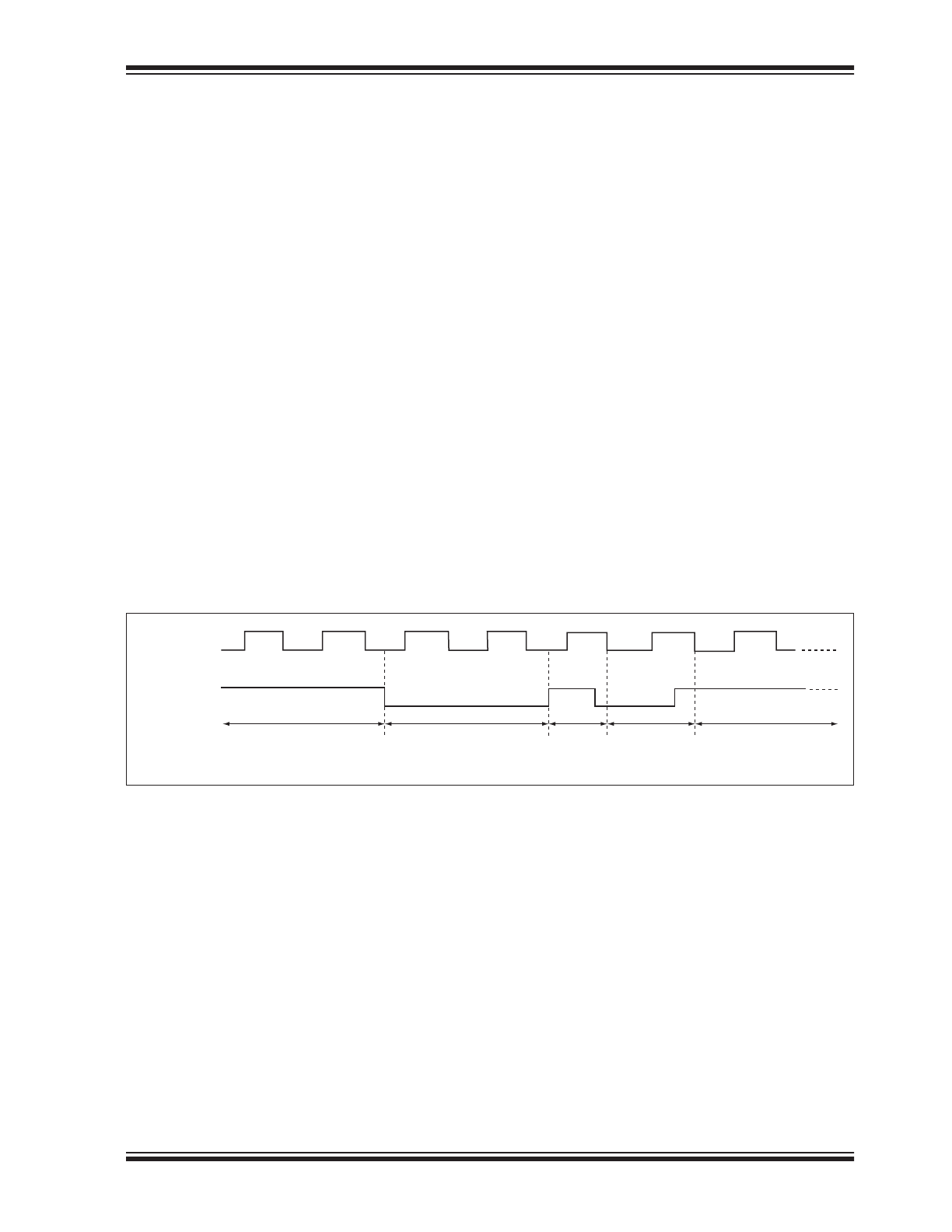

The SST26WF016B/016BA support both Serial

Peripheral Interface (SPI) bus protocol and a 4-bit mul-

tiplexed SQI bus protocol. To provide backward com-

patibility to traditional SPI Serial Flash devices, the

device’s initial state after a power-on reset is SPI mode

which supports multi-I/O (x1/x2/x4) Read/Write com-

mands. A command instruction configures the device

to SQI mode. The dataflow in the SQI mode is similar

to the SPI mode, except it uses four multiplexed I/O sig-

nals for command, address, and data sequence.

SQI Flash Memory supports both Mode 0 (0,0) and

Mode 3 (1,1) bus operations. The difference between

the two modes is the state of the SCK signal when the

bus master is in stand-by mode and no data is being

transferred. The SCK signal is low for Mode 0 and SCK

signal is high for Mode 3. For both modes, the Serial

Data I/O (SIO[3:0]) is sampled at the rising edge of the

SCK clock signal for input, and driven after the falling

edge of the SCK clock signal for output. The traditional

SPI protocol uses separate input (SI) and output (SO)

data signals as shown in

Figure 4-1

. The SQI protocol

uses four multiplexed signals, SIO[3:0], for both data in

and data out, as shown in

Figure 4-2

. This means the

SQI protocol quadruples the traditional bus transfer

speed at the same clock frequency, without the need

for more pins on the package.

FIGURE 4-1:

SPI PROTOCOL (TRADITIONAL 25 SERIES SPI DEVICE)

FIGURE 4-2:

SQI SERIAL QUAD I/O PROTOCOL

4.1

Device Protection

The SST26WF016B/016BA offers a flexible memory

protection scheme that allows the protection state of

each individual block to be controlled separately. In addi-

tion, the Write-Protection Lock-Down register prevents

any change of the lock status during device operation.

To avoid inadvertent writes during power-up, the device

is write-protected by default after a power-on reset cycle.

A Global Block-Protection Unlock command offers a sin-

gle command cycle that unlocks the entire memory array

for faster manufacturing throughput.

For extra protection, there is an additional non-volatile

register that can permanently write-protect the Block-

Protection register bits for each individual block. Each

of the corresponding lock-down bits are one time pro-

grammable (OTP)—once written, they cannot be

erased. Data that had been previously programmed

into these blocks cannot be altered by programming or

erase and is not reversible

4.1.1

INDIVIDUAL BLOCK PROTECTION

The SST26WF016B/016BA has a Block-Protection

register which provides a software mechanism to write-

lock the individual memory blocks and write-lock, and/

or read-lock, the individual parameter blocks. The

Block-Protection register is 48 bits wide: two bits each

for the eight 8 KByte parameter blocks (write-lock and

read-lock), and one bit each for the remaining 32 KByte

and 64 KByte overlay blocks (write-lock). See

Table 5-

6

for address range protected per register bit.

Each bit in the Block-Protection register (BPR) can be

written to a ‘1’ (protected) or ‘0’ (unprotected). For the

parameter blocks, the most significant bit is for read-lock,

and the least significant bit is for write-lock. Read-locking

the parameter blocks provides additional security for sen-

sitive data after retrieval (e.g., after initial boot). If a block

is read-locked all reads to the block return data 00H.

The Write Block-Protection Register command is a

two-cycle command which requires that Write-Enable

(WREN) is executed prior to the Write Block-Protection

1432 F03.0

MODE 3

SCK

SI

SO

CE#

MODE 3

DON T CARE

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

MODE 0

MODE 0

HIGH IMPEDANCE

MSB

MSB

1432 F04.0

MODE 3

CLK

SIO(3:0)

CE#

MODE 3

C1

C0

A5

A4

A3

A2

A1

A0

H0

L0

H1

L1

H2

L2

H3

L3

MODE 0

MODE 0

MSB

SST26WF016B/SST26WF016BA

DS20005013D-page 8

2014 Microchip Technology Inc.

Register command. The Global Block-Protection

Unlock command clears all write protection bits in the

Block-Protection register.

4.1.2

WRITE-PROTECTION LOCK-

DOWN (VOLATILE)

To prevent changes to the Block-Protection register,

use the Lock-Down Block-Protection Register (LBPR)

command to enable Write-Protection Lock-Down.

Once Write-Protection Lock-Down is enabled, the

Block-Protection register can not be changed. To avoid

inadvertent lock down, the WREN command must be

executed prior to the LBPR command.

To reset Write-Protection Lock-Down, performing a

power cycle on the device is required. The Write-Protec-

tion Lock-Down status may be read from the Status reg-

ister.

4.1.3

WRITE-LOCK LOCK-DOWN (NON-

VOLATILE)

The non-Volatile Write-Lock Lock-Down register is an

alternate register that permanently prevents changes

to the block-protect bits. The non-Volatile Write-Lock

Lock-Down register (nVWLDR) is 40 bits wide per

device: one bit each for the eight 8-KByte parameter

blocks, and one bit each for the remaining 32 KByte

and 64 KByte overlay blocks. See

Table 5-6

for

address range protected per register bit.

Writing ‘1’ to any or all of the nVWLDR bits disables the

change mechanism for the corresponding Write-Lock

bit in the BPR, and permanently sets this bit to a ‘1’

(protected) state. After this change, both bits will be set

to ‘1’, regardless of the data entered in subsequent

writes to either the nVWLDR or the BPR. Subsequent

writes to the nVWLDR can only alter available locations

that have not been previously written to a ‘1’. This

method provides write-protection for the corresponding

memory-array block by protecting it from future pro-

gram or erase operations.

Writing a ‘0’ in any location in the nVWLDR has no effect

on either the nVWLDR or the corresponding Write-Lock

bit in the BPR.

Note that if the Block-Protection register had been pre-

viously locked down, see “ Write-Protection Lock-

Down (Volatile)”, the device must be power cycled

before using the nVWLDR. If the Block-Protection reg-

ister is locked down and the Write nVWLDR command

is accessed, the command will be ignored.

4.2

Hardware Write Protection

The hardware Write Protection pin (WP#) is used in con-

junction with the WPEN and IOC bits in the configuration

register to prohibit write operations to the Block-Protec-

tion and Configuration registers. The WP# pin function

only works in SPI single-bit and dual-bit read mode when

the IOC bit in the configuration register is set to ‘0’.

The WP# pin function is disabled when the WPEN bit

in the configuration register is ‘0’. This allows installa-

tion of the SST26WF016B/016BA in a system with a

grounded WP# pin while still enabling Write to the

Block-Protection register. The Lock-Down function of

the Block-Protection Register supersedes the WP# pin,

see

Table 4-1

for Write Protection Lock-Down states.

The factory default setting at power-up of the WPEN bit

is ‘0’, disabling the Write Protect function of the WP#

after power-up. WPEN is a non-volatile bit; once the bit

is set to ‘1’, the Write Protect function of the WP# pin

continues to be enabled after power-up. The WP# pin

only protects the Block-Protection Register and Config-

uration Register from changes. Therefore, if the WP#

pin is set to low before or after a Program or Erase

command, or while an internal Write is in progress, it

will have no effect on the Write command.

The IOC bit takes priority over the WPEN bit in the con-

figuration register. When the IOC bit is ‘1’, the function

of the WP# pin is disabled and the WPEN bit serves no

function. When the IOC bit is ‘0’ and WPEN is ‘1’, set-

ting the WP# pin active low prohibits Write operations

to the Block Protection Register.

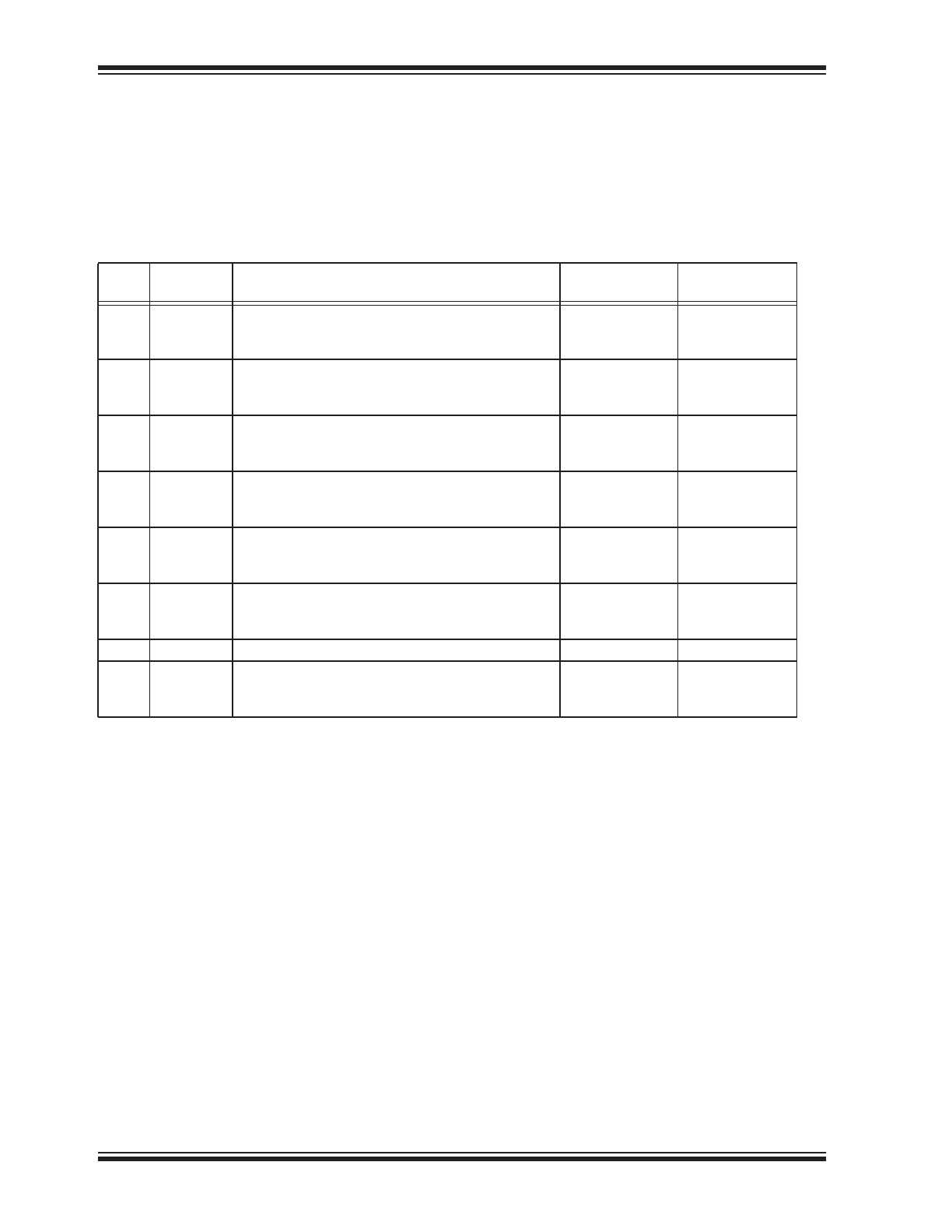

TABLE 4-1:

WRITE PROTECTION LOCK-DOWN STATES

WP#

IOC

WPEN

WPLD

Execute WBPR Instruction

Configuration Register

L

0

1

1

Not Allowed

Protected

L

0

0

1

Not Allowed

Writable

L

0

1

0

Not Allowed

Protected

L

0

1

1. Default at power-up Register settings for SST26WF016B

0

2

2. Factory default setting is ‘0’. This is a non-volatile bit; default at power-up is the value set prior to power-down.

0

Allowed

Writable

H

0

X

1

Not Allowed

Writable

H

0

X

0

Allowed

Writable

X

1

X

1

Not Allowed

Writable

X

1

3

3. Default at power-up Register settings for SST26WF016BA

0

2

0

Allowed

Writable

2014 Microchip Technology Inc.

DS20005013D-page 9

SST26WF016B/SST26WF016BA

4.3

Security ID

SST26WF016B/016BA offers a 2 KByte Security ID

(Sec ID) feature. The Security ID space is divided into

two parts – one factory-programmed, 64-bit segment

and one user-programmable segment. The factory-

programmed segment is programmed during manufac-

turing with a unique number and cannot be changed.

The user-programmable segment is left unpro-

grammed for the customer to program as desired.

Use the Program Security ID (PSID) command to pro-

gram the Security ID using the address shown in

Table

5-5

. The Security ID can be locked using the Lockout

Security ID (LSID) command. This prevents any future

write operations to the Security ID.

The factory-programmed portion of the Security ID

can’t be programmed by the user; neither the factory-

programmed nor user-programmable areas can be

erased.

4.4

Hold Operation

The HOLD# pin pauses active serial sequences with-

out resetting the clocking sequence. This pin is active

after every power up and only operates during SPI

single-bit and dual-bit modes. Two factory configura-

tions are available: SST26WF016B ships with the IOC

bit set to ‘0’ and the HOLD# pin function enabled;

SST26WF016BA ships with the IOC bit set to ‘1’ and

the HOLD# pin function disabled. The HOLD# pin is

always disabled in SQI mode and only works in SPI sin-

gle-bit and dual-bit read mode.

To activate the Hold mode, CE# must be in active low

state. The Hold mode begins when the SCK active low

state coincides with the falling edge of the HOLD# sig-

nal. The Hold mode ends when the HOLD# signal’s ris-

ing edge coincides with the SCK active low state.

If the falling edge of the HOLD# signal does not coin-

cide with the SCK active low state, then the device

enters Hold mode when the SCK next reaches the

active low state. Similarly, if the rising edge of the

HOLD# signal does not coincide with the SCK active

low state, then the device exits Hold mode when the

SCK next reaches the active low state. See

Figure 4-3

.

Once the device enters Hold mode, SO will be in high

impedance state while SI and SCK can be V

IL

or V

IH

.

If CE# is driven active high during a Hold condition, it

resets the internal logic of the device. As long as

HOLD# signal is low, the memory remains in the Hold

condition. To resume communication with the device,

HOLD# must be driven active high, and CE# must be

driven active low.

FIGURE 4-3:

HOLD CONDITION WAVEFORM.

Active

Hold

Active

Hold

Active

1432 F46.0

SCK

HOLD#

SST26WF016B/SST26WF016BA

DS20005013D-page 10

2014 Microchip Technology Inc.

4.5

Status Register

The Status register is a read-only register that provides

the following status information: whether the flash

memory array is available for any Read or Write oper-

ation, if the device is write-enabled, whether an erase

or program operation is suspended, and if the Block-

Protection register and/or Security ID are locked down.

During an internal Erase or Program operation, the Sta-

tus register may be read to determine the completion of

an operation in progress.

Table 4-2

describes the func-

tion of each bit in the Status register.

4.5.1

WRITE-ENABLE LATCH (WEL)

The Write-Enable Latch (WEL) bit indicates the status

of the internal memory’s Write-Enable Latch. If the

WEL bit is set to ‘1’, the device is write enabled. If the

bit is set to ‘0’ (reset), the device is not write enabled

and does not accept any memory Program or Erase,

Protection Register Write, or Lock-Down commands.

The Write-Enable Latch bit is automatically reset under

the following conditions:

• Power-up

• Reset

• Write-Disable (WRDI) instruction

• Page-Program instruction completion

• Sector-Erase instruction completion

• Block-Erase instruction completion

• Chip-Erase instruction completion

• Write-Block-Protection register instruction

• Lock-Down Block-Protection register instruction

• Program Security ID instruction completion

• Lockout Security ID instruction completion

• Write-Suspend instruction

• SPI Quad Page Program

• Write Status Register

4.5.2

WRITE SUSPEND ERASE STATUS

(WSE)

The Write Suspend-Erase status (WSE) indicates

when an Erase operation has been suspended. The

WSE bit is ‘1’ after the host issues a suspend command

during an Erase operation. Once the suspended Erase

resumes, the WSE bit is reset to ‘0’.

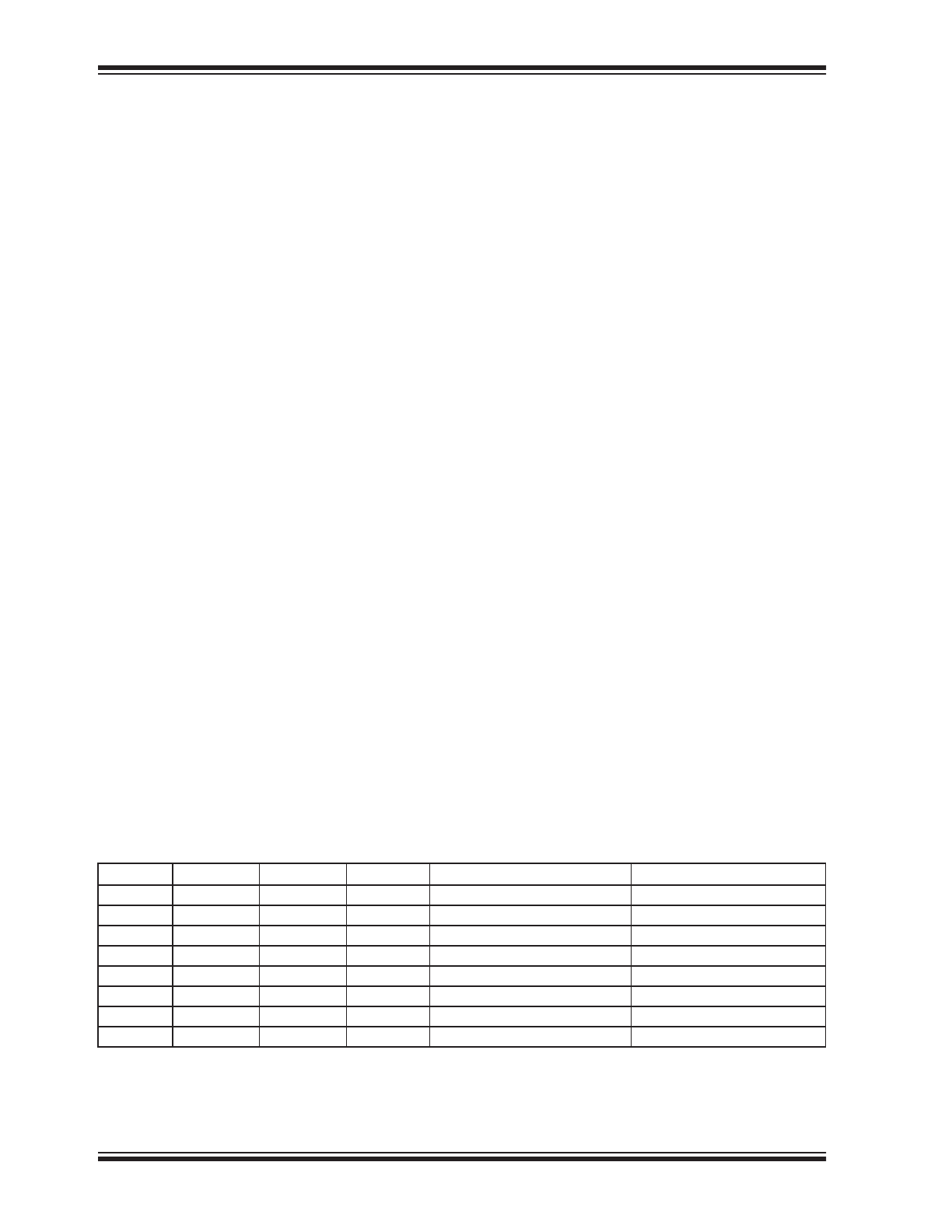

TABLE 4-2:

STATUS REGISTER

Bit

Name

Function

Default at

Power-up

Read/Write (R/

W)

0

BUSY

Write operation status

1 = Internal Write operation is in progress

0 = No internal Write operation is in progress

0

R

1

WEL

Write-Enable Latch status

1 = Device is write-enabled

0 = Device is not write-enabled

0

R

2

WSE

Write Suspend-Erase status

1 = Erase suspended

0 = Erase is not suspended

0

R

3

WSP

Write Suspend-Program status

1 = Program suspended

0 = Program is not suspended

0

R

4

WPLD

Write Protection Lock-Down status

1 = Write Protection Lock-Down enabled

0 = Write Protection Lock-Down disabled

0

R

5

SEC

1

1. The Security ID status will always be ‘1’ at power-up after a successful execution of the Lockout Security ID instruction,

otherwise default at power-up is ‘0’.

Security ID status

1 = Security ID space locked

0 = Security ID space not locked

0

1

R

6

RES

Reserved for future use

0

R

7

BUSY

Write operation status

1 = Internal Write operation is in progress

0 = No internal Write operation is in progress

0

R