TLE8242-2

8 Channel Fixed Frequency Constant Current

Control With Current Profile Detection

Data Sheet, Rev. 1.0, Feb 2010

Automotive Power

Data Sheet

2

Rev. 1.0, 2010-02-09

TLE8242-2

Table of Contents

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3.1

Direct PWM Mode Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3.2

Constant Current Mode Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3

Pin Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1

Pin Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2

Pin Definitions and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4

General Product Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.1

Maximum Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2

Functional Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.3

Thermal Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5

Functional Description and Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1

Supply and Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.2

Input / Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.3

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.3.1

On-State Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.3.2

Off-State Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.4

Output Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.5

Current Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.6

Current Feedback Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.7

Direct PWM control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.7.1

Selecting the Frequency of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.7.2

Selecting the Duty Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.8

Current Profile Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.8.1

Zone 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.8.2

Zone 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.8.3

Zone 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.8.4

Current Profile Time out & Detection Interrupted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.9

Serial Peripheral Interface (SPI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.9.1

SPI Signal Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.9.2

SPI Message Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.9.2.1

SPI Message #0 - IC Version / Manufacturer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.9.2.2

SPI Message #1 - Control Method and Fault Mask Configuration . . . . . . . . . . . . . . . . . . . . . . . . 39

5.9.2.3

SPI Message #2 - Diagnostic Configuration (channel 0-3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.9.2.4

SPI Message #3 - Diagnostic Configuration (channel 4-7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.9.2.5

SPI Message #4 - Diagnostic Read (channel 0-3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.9.2.6

SPI Message #5 - Diagnostic Read (channel 4-7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.9.2.7

SPI Message #6 - PWM Offset (channel 0-3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.9.2.8

SPI Message #7 - PWM Offset (channel 4-7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.9.2.9

SPI Message #8 - Main Period Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.9.2.10

SPI Message #9 - Control Variable Set (KP and KI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.9.2.11

SPI Message #10 - Current and Dither Amplitude Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.9.2.12

SPI Message #11 - Dither Period Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Table of Contents

Data Sheet

3

Rev. 1.0, 2010-02-09

TLE8242-2

Table of Contents

5.9.2.13

SPI Message #12 - Max / Min Current Read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.9.2.14

SPI Message #13 - Average Current Read Over Dither Period . . . . . . . . . . . . . . . . . . . . . . . . . 60

5.9.2.15

SPI Message #14 - Autozero Trigger / Read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5.9.2.16

SPI Message #15 - PWM Duty Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

5.9.2.17

SPI Message #16 - Current Profile Detection Setup 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.9.2.18

SPI Message #17 - Current Profile Detection Setup 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

5.9.2.19

SPI Message #18 - Current Profile Detection Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

5.9.2.20

SPI Message #19 - Read Generic Flag Bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

6

Application Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

6.1

Further Application Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

7

Package Outlines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

8

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

PG-LQFP-64

Type

Package

Marking

TLE8242-2

PG-LQFP-64

TLE8242-2L

Data Sheet

4

Rev. 1.0, 2010-02-09

8 Channel Fixed Frequency Constant Current Control

With Current Profile Detection

TLE8242-2

1

Overview

1.1

Features

•

Low side constant current control pre-driver integrated circuit

•

Eight independent channels

•

Output current programmable with 11 bit resolution

– Current range = 0 to 1.2A (typ) with a 0.2

Ω sense resistor

– Resolution = 0.78125 mA/bit (typ) with a 0.2

Ω sense resistor

– +/- 2% full scale error over temperature when autozero is used

•

Programmable PWM frequency via SPI from approximately

10 Hz to 4 kHz (typ)

•

Programmable KP and KI coefficients for the PI controller for each

channel

•

Programmable superimposed dither

– Dither programmed by setting a dither step size and the number of PWM periods in each dither period

– Programmed via the SPI interface

– The dither for each channel can be programmed independently

•

Programmable synchronization of the PWM control signals

– Phase delay time set via the SPI interface

– Synchronization initiated via signal at the PHASE_SYNC input pin

– Channels within one device and between multiple devices can be synchronized

•

Each channel can be configured to for constant current control or for direct PWM control via SPI

•

In Direct PWM mode, a current profile detection function is engaged

– Verifies solenoid armature movement

– Profile characteristics programmed via SPI

– Pass / Fail Status can be read via SPI

•

Interface and Control

– 32 Bit SPI (Serial Peripheral Interface) - Slave only

– ENABLE pin to disable all channels or freeze all channels

– Active low RESET_B pin resets internal registers to their default state and disables all channels

– Open drain FAULT pin can be programmed to transition low when various faults are detected

– 5.0V and 3.3V logic compatible I/O

•

Protection

– Over current shutdown - monitored at POSx pin

– Programmable over current threshold

– Programmable over current delay time

– Programmable over current retry time

– Battery pin (BAT) overvoltage shutdown

Data Sheet

5

Rev. 1.0, 2010-02-09

TLE8242-2

Overview

•

Diagnostics

– Over current

– Open load in on state

– Open load in off state

– Short to ground

– Test complete bit - indicates that fault detection test has completed

•

Control loop monitor capabilities

– The average current measurement over the last completed dither cycle for a selected channel can be

accessed via SPI

– The minimum and maximum current measurements over the last completed dither cycle for a selected

channel can be accessed via SPI. This data can be used to measure the achieved dither amplitude

– The duty cycle of each channel can be accessed via SPI

– The auto zero values used to cancel the offsets of the input amplifiers can be accessed via SPI

•

Required External Components:

– N-Channel Logic level (5V) MOSFET transistor with typical Ron

≤ 100 mΩ (e.g. SPD15N06S2L-64)

– Recirculation diode (ultrafast)

– Sense resistor (0.2

Ω for 1.2A average output current range)

•

Green Product (RoHS compliant)

•

AEC Qualified

1.2

Applications

•

Variable Force Solenoids (e.g. automatic transmission solenoids)

•

Other constant current solenoids

– Idle Air Control

– Exhaust Gas Recirculation

– Vapor Management Valve

– Suspension Control

1.3

General Description

The TLE8242G IC is an eight channel low-side constant current control predriver IC. Each channel can be

configured to function either in direct PWM mode or in constant current mode by setting the appropriate CM bit in

SPI message #1.

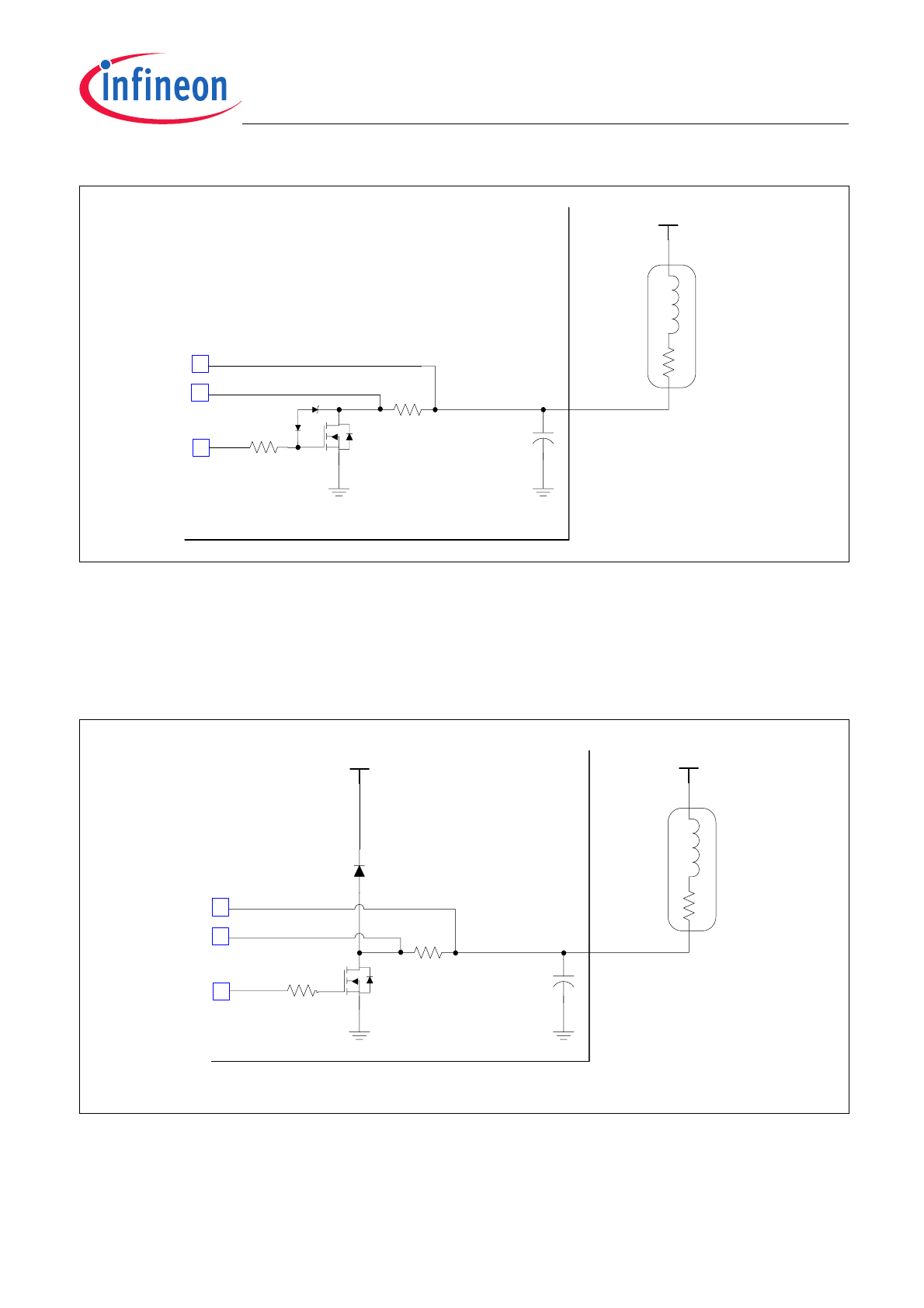

1.3.1

Direct PWM Mode Operation

For Direct PWM operation, the POSx and NEGx pins must be connected to the circuit in either of the configurations

shown in

Figure 1

. If the sense resistor is included, the load current can be monitored by the microcontroller via

a SPI command. The open load in on state fault detection feature is disabled in direct PWM mode.

Note: An external flyback clamp is required in this configuration otherwise the IC may be damaged.

TLE8242-2

Overview

Data Sheet

6

Rev. 1.0, 2010-02-09

Figure 1

External Circuit Diagram for Direct PWM Mode Operation

1.3.2

Constant Current Mode Operation

During constant current operation, the POSx and NEGx pins must be connected to the circuit in the configuration

shown in

Figure 2

.

Note: An external recirculation diode is required in this configuration otherwise the IC may be damaged.

Figure 2

External Circuit Diagram for Constant Current Mode Operation

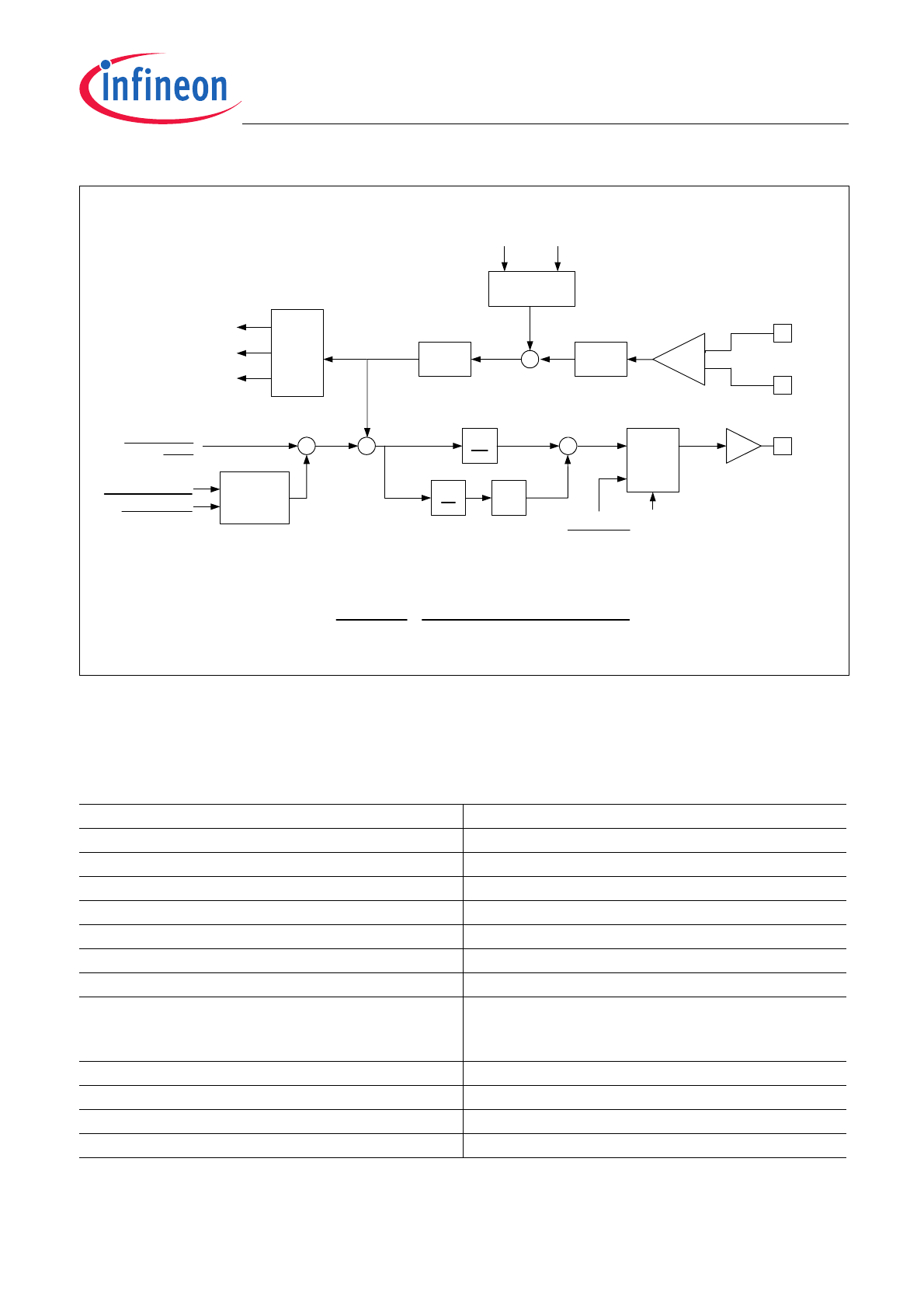

During constant current operation, the PWM control signal driven at the OUTx pin is controlled by the control loop

shown in

Figure 3

. The PWM Frequency is programmed via the SPI message # 8. In this message the main period

10nF

0.2

Ω

P

W

M

or

O

n/O

ff

S

ole

no

id

Vs

POSx

NEGx

OUTx

Electronic

Module

10nF

0.2

Ω

C

ons

ta

nt C

ur

re

nt

So

le

no

id

Vs

Vs

POSx

NEGx

OUTx

Electronic

Module

Data Sheet

7

Rev. 1.0, 2010-02-09

TLE8242-2

Overview

divider, N, can be set to any value between 79 and 2

14

-1 and the divider M can be set to 32, 64, or 128. In direct

PWM mode, the value M can also be set to 512. The equation for calculating the PWM frequency is:

In constant current mode, the value of M is the number of A/D samples within one PWM period. Setting the SAM

bit in SPI Message #8 to a “1” will cause the ADC samples immediately following a change in the state of the OUTx

pin to be discarded. If the SAM bit is set to ‘0’, all M A/D samples are used in the average calculation.

The 11 bit Current Set Point is programmed via the SPI message #10. The equation for calculating the current

setpoint is:

The Proportional coefficient (KP) and the Integral coefficient (KI) of the control loop are programmed in SPI

message #9. The KP and KI values should be set to values that result in the desired transient response of the

control loop. The duty cycle of the OUTx pin can be calculated from the difference equations:

where error is the difference between the commanded average current and measured average current in units of

Amps.

where k indicates the integer number of PWM periods that have elapsed since current regulation was initiated.

N

M

F

F

∗

=

CLK

PWM

[ohm]

R

[mV]

320

2

(11bit)

setpoint

[mA]

Setpoint

Current

SENSE

11

∗

=

( )

(

)

(

)

)

1

(

]

[

1

*

]

[

)

(

)

(

]

[

1

*

]

[

−

+

−

∗

∗

∗

=

+

−

∗

∗

∗

=

k

INT

A

k

error

N

M

0.04

Ohm

Rsense

KI

k

INT

k

INT

A

k

error

N

M

0.04

Ohm

Rsense

KP

k

DutyCycle

TLE8242-2

Overview

Data Sheet

8

Rev. 1.0, 2010-02-09

Figure 3

Control Loop - Simplified Diagram

Table 1 describes the effect on the integrator of the PI controller of several events.

Table 1

Control Loop Integrator Control

Condition

Action to Integrator

Reset Active

Cleared

V5D undervoltage

Cleared

V5Ax undervoltage

Cleared

ENABLE pin low (SPI message #10 bit EN = 0)

Cleared

ENABLE pin low (SPI message #10 bit EN = 1)

Remains Operational

VBAT overvoltage

Held at current value

Short to BAT

Cleared

Phase_Sync Transition

Remains Operational

Integrator value for first PWM cycle = value from end of

last complete PWM cycle.

Average Current set to 0

Cleared

Control Mode set to Direct PWM

Cleared

Main Period Set (N, M) Changed

Remains Operational

KP, KI settings Changed

Remains Operational

A/D

Average

Autozero

Value

“ON”

-

CURRENT SET

POINT

DITHER STEP SIZE

Dither

Generation

+

+

+

KP

Σ

KI

PWM

Block

+

+

DITHER STEPS

OUTx

POSx

NEGx

Amp

+

-

Auto Zero

Autozero

Value

“OFF”

DUTY

CYCLE

AVG

CURRENT READ

Italics = CAN BE MONITORED VIA SPI

Underlined = CAN BE PROGRAMMED VIA SPI

Current

Readout

MIN

CURRENT READ

MAX

CURRENT READ

CL K

DIRECT PWM

Data Sheet

9

Rev. 1.0, 2010-02-09

TLE8242-2

Overview

Auto Zero

The TLE8242 includes an autozero feature for each channel. When the setpoint of a channel is set to 0 mA and

the autozero is triggered by an SPI command, the offset of the amplifiers and analog to digital converters are

measured. The time required for the autozero sequence is calculated according to the formula:

The measured offsets can be read via SPI message #14. these offsets will be subtracted from the A/D converter

output as shown in

Figure 3

when the current set point is greater than 0.

Dither

A triangular dither waveform can be superimposed on the current set point by setting the amplitude and frequency

parameters of the dither waveform via SPI messages #10 and #11. See the SPI message section for details.

The first programmed value is the step size of the dither waveform which is the number of bits added or subtracted

from the setpoint per PWM period. One LSb of the dither step size is 1/4

th

the magnitude of the nominal setpoint

current value. The second programmed value is the number of steps in one quarter of the dither waveform.

When dither is enabled, a new average current set point will not be activated until the current dither cycle has

completed. The dither cycle is completed on the positive zero crossing of the dither waveform. A new dither

amplitude setting or a new dither frequency setting will also not be activated until the current dither cycle has

completed. See

Figure 4

.

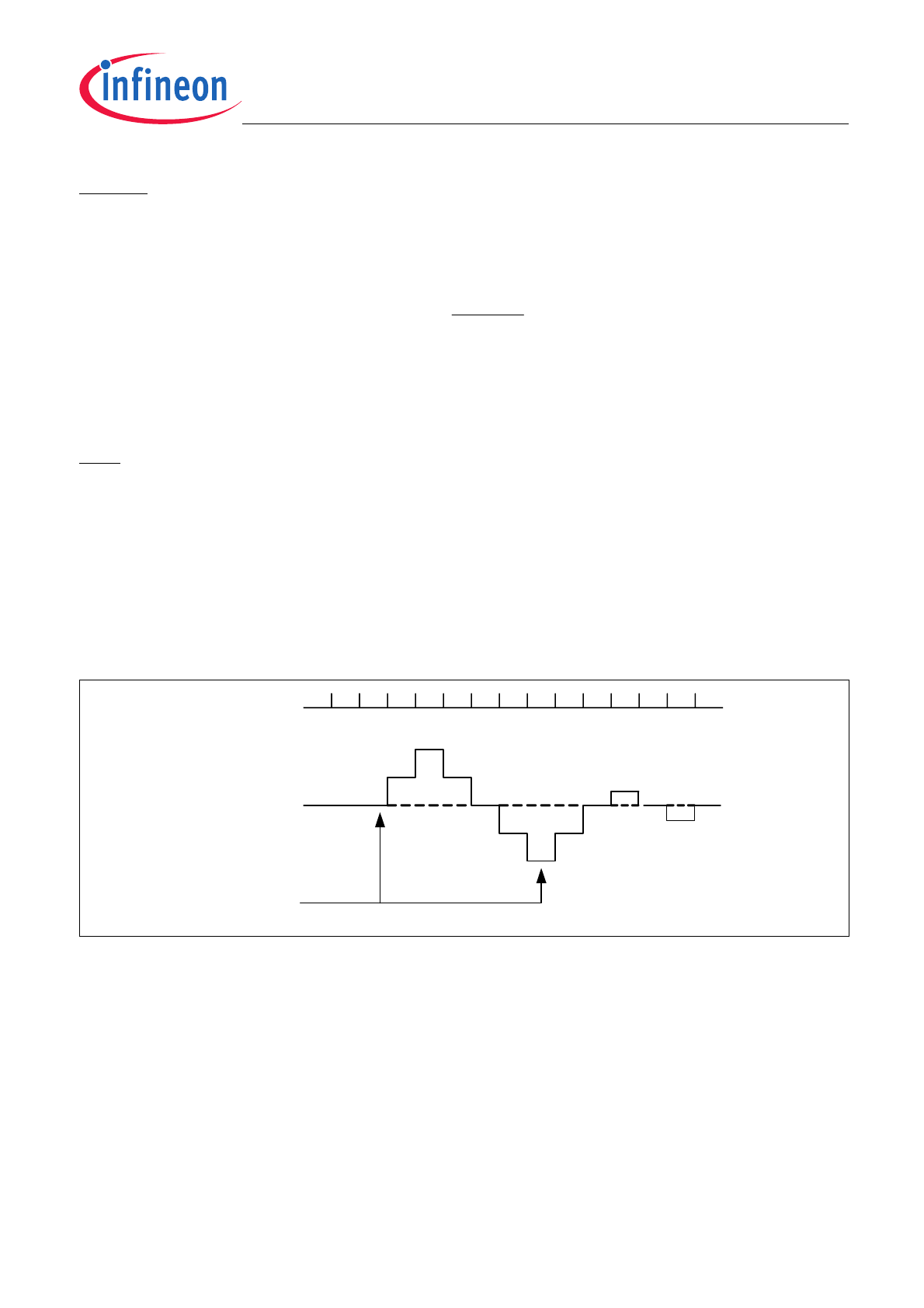

Figure 4

New Dither Values Programmed and the Resulting Waveform Timing

Note: The actual measured dither waveform is attenuated and phase shifted according to the frequency response

of the control loop.

CLK

AZ

F

N

M

4

T

∗

∗

=

PWM_START

Dither

Dither

Parameter

Change

TLE8242-2

Block Diagram

Data Sheet

10

Rev. 1.0, 2010-02-09

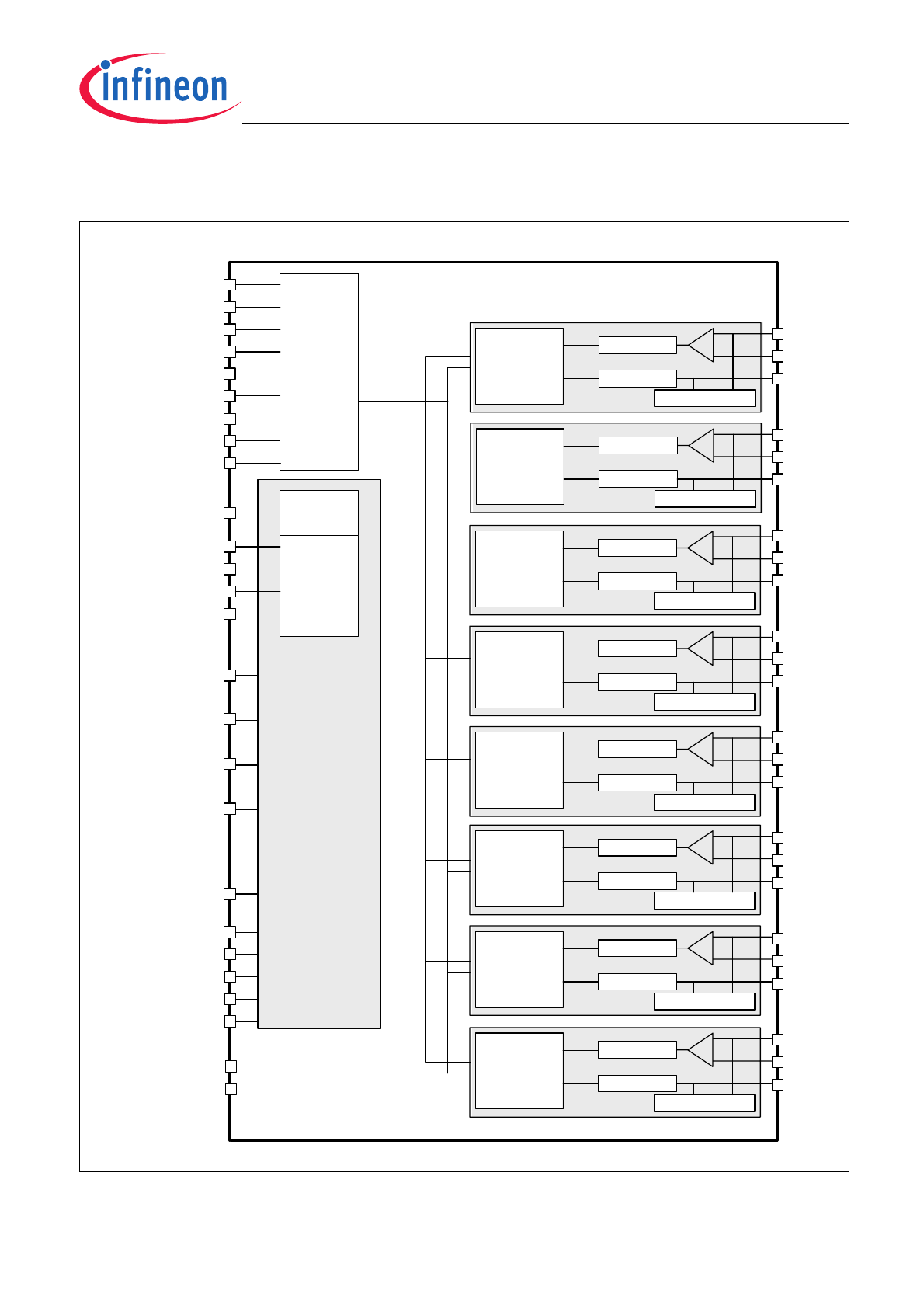

2

Block Diagram

Figure 5

Block Diagram

POS0

OUT0

NEG0

SCK

SI

SO

CS_B

FAULT

RESET_B

PHASE_SYNC

V5D

GND_D

GNDA1

CLK

ENABLE

V_SIGNAL

TEST

Power

POS1

OUT1

NEG1

POS2

OUT2

NEG2

POS3

OUT3

NEG3

POS4

OUT4

NEG4

POS5

OUT5

NEG5

POS6

OUT6

NEG6

POS7

OUT7

NEG7

Logic

SPI

Interface

SO

Supply

BAT

A/D Converter

PWM

Diagnostics

Current Control,

Dither,

PWM,

Autozero,

Channel Logic,

Current Profile

A/D Converter

PWM

Diagnostics

Current Control,

Dither,

PWM,

Autozero,

Channel Logic,

Current Profile

A/D Converter

PWM

Diagnostics

Current Control,

Dither,

PWM,

Autozero,

Channel Logic,

Current Profile

A/D Converter

PWM

Diagnostics

Current Control,

Dither,

PWM,

Autozero,

Channel Logic,

Current Profile

A/D Converter

PWM

Diagnostics

Current Control,

Dither,

PWM,

Autozero,

Channel Logic,

Current Profile

A/D Converter

PWM

Diagnostics

Current Control,

Dither,

PWM,

Autozero,

Channel Logic,

Current Profile

A/D Converter

PWM

Diagnostics

Current Control,

Dither,

PWM,

Autozero,

Channel Logic,

Current Profile

A/D Converter

PWM

Diagnostics

Current Control,

Dither,

PWM,

Autozero,

Channel Logic,

Current Profile

V5A1

V5A2

V5A3

GNDA2

GNDA3

SCI3

SCO2

SCO3

AMUX

GNDSA

GNDSD