TLE6288R

Smart 6 Channel Peak & Hold Switch

Data Sheet, Rev. 2.5, Oct. 2010

Automotive Power

Data Sheet

2

Rev. 2.5, 2010-10-11

TLE6288R

Table of Contents

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2

Pin Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1

Pin Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2

Pin Definitions and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3

Pin Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3

General Product Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1

Absolute Maximum Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2

Thermal Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.1

Gerneral Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.1.1

Output Stage Control: Parallel Control and SPI Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.1.2

Current Regulator: Peak Current Control with Fixed Off-Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2

Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.3

Diagnostic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.3.1

Parallel Diagnostic Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.3.2

Electrical Characteristics: Diagnostic Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5

SPI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1

SPI Signal Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.2

Electrical Characteristics: SPI Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.3

SPI Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.4

SPI Commands, Values and Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.5

SPI Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.6

Bit Assignment and Default Settings for Internal Logic Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.7

SPI Timing Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6

Electrical Characteristics Input / Output Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.1

Power Supply, Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.2

Power Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.3

Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.4

Digital Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7

Application Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.1

Z

thjc

Diagram Junction - Case for Single channel operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.2

Thermal Application Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.3

Overload/Low Inductance Load Detection in Current Regulation Mode . . . . . . . . . . . . . . . . . . . . . . . 29

8

Package Outlines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

9

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table of Contents

Data Sheet

3

Rev. 2.5, 2010-10-11

Type

Package

TLE6288R

PG-DSO-36-54

TLE6288R

Features

•

3 Channel high side with adjustable Peak & Hold current

control

•

3 Channel high/low side configurable

•

Protection

– Overcurrent (current limitation)

– Overtemperature

– Overvoltage (active clamping)

•

Diagnosis

– Overcurrent

– Overtemperature

– Open load (Off-State)

– Short to Ground (Off-state, lowside configuration)

– Short to

V

B

(Off-state, highside configuration)

•

Interface and Control

– 16-Bit Serial Peripheral Interface (2 bit/CH)

– Device programming via SPI

– Separate diagnosis output for each CH (DIAG1

to 6)

– General Fault Flag + Overtemperature Flag

– Direct parallel control of all channels

– General enable signal to control all channels

simultaneously

•

Low Quiescent Current

•

Compatible with 3.3 V and 5 V microcontrollers

•

Electrostatic discharge (ESD) protection of all pins

•

Green Product (RoHS compliant)

•

AEC Qualified

Application

•

Peak & Hold Loads (valves, coils)

•

Solenoids, Relays and Resistive Loads

•

Fast protected Highside Switching

(PWM up to > 10 kHz)

General Description

The TLE6288R is a 6-channel (150 m

Ω) Smart Multichannel Switch in Smart Power Technology. The IC has

embedded protection, diagnosis and configurable functions. Channels 1-3 are highside channels with integrated

charge pump and can be programmed individually to do autonomous peak and hold current regulation with PWM.

Channel 4-6 (also with integrated charge pump) can be configured to work as highside switch or lowside switch.

This IC can be used to drive standard automotive loads in highside or lowside applications with switching

frequencies up to 10 kHz. In addition the TLE6288R can be used to drive autonomously up to 3 inductive

peak & hold (valves, coils) loads with programmable peak and hold current values.

Table 1

Product Summary

Parameter

Symbol

Values

Unit

Logic Supply voltage

V

CC

4.5 … 5.5

V

On resistance

R

DS(ON)1-6

0.15 typ. @ 25 °C

Ω

Lowside clamping voltage

V

cll(max)

+55

V

Highside clamping voltage

V

clh(max)

-19

V

Peak current range

I

pk

1.2 … 3.6

A

Hold current range

I

hd

0.7 … 2

A

Peak time range

I

p

0 … 3.6

ms

Fixed off time range

I

fo

100 … 400

μs

TLE6288R

Block Diagram

Data Sheet

4

Rev. 2.5, 2010-10-11

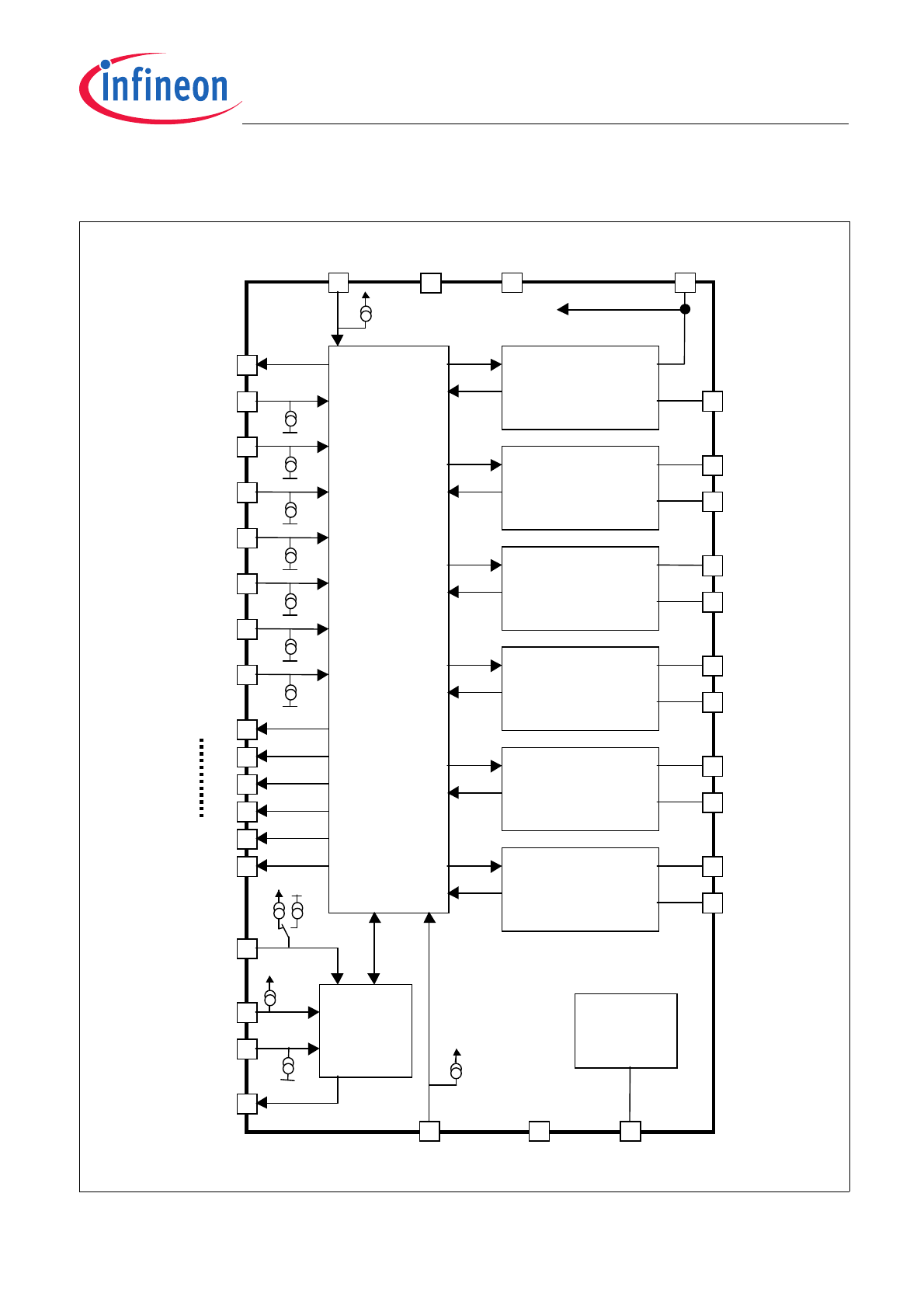

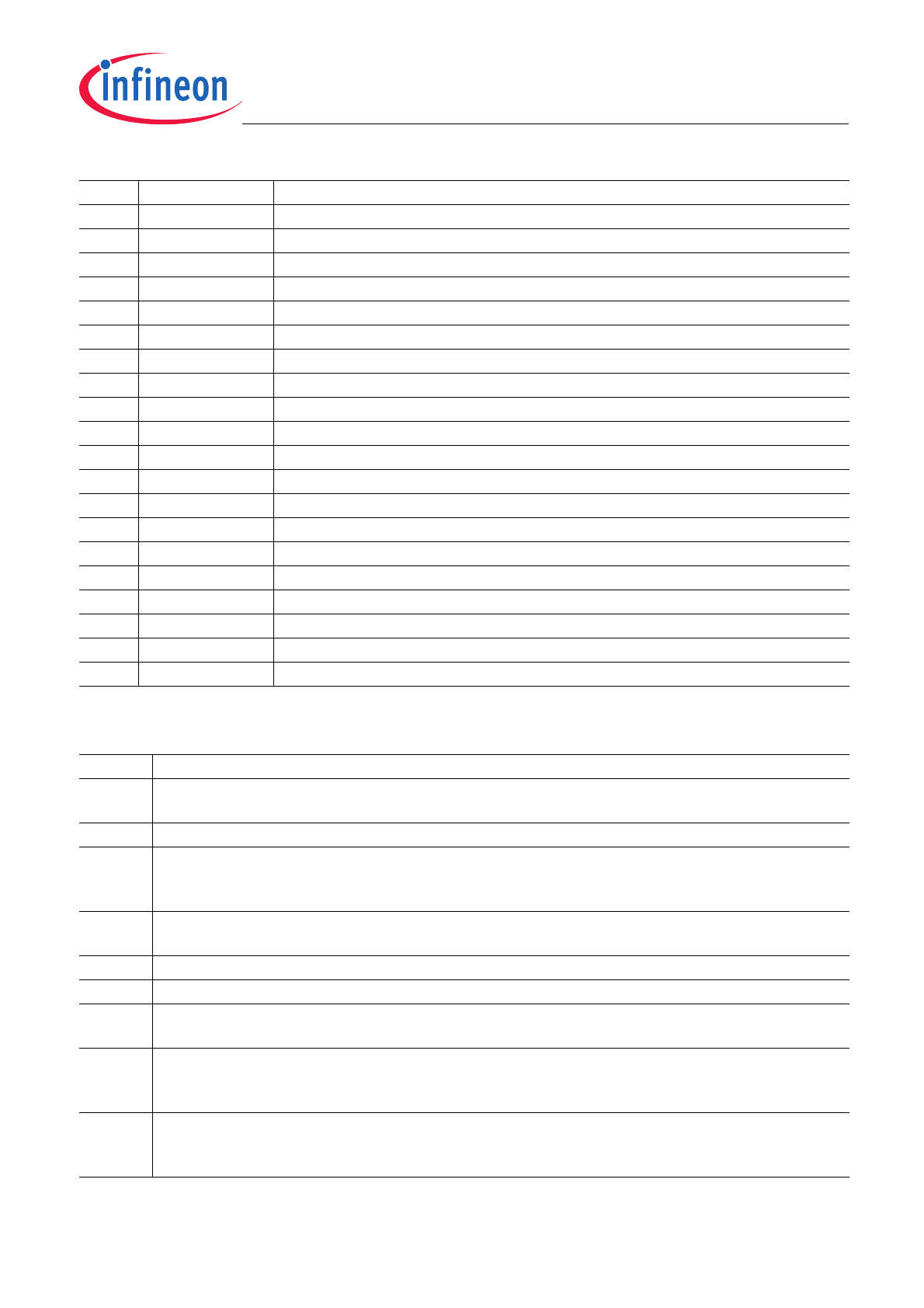

1

Block Diagram

Figure 1

Block Diagram

Charge

pump

VCP

GND

FSIN

Channel 3

Highside 300 mΩ

Peak&Hold

Channel 2

Highside 300 mΩ

Peak&Hold

Channel 1

Highside 300 mΩ

Peak&Hold

Channel 4

Highside/ Lowside

300 mΩ

Channel 5

Highside/ Lowside

300 mΩ

Channel 6

Highside/ Lowside

300 mΩ

VB

VCC

DOUT 3 / VB

SOUT 3

SOUT 2

SOUT 1

DOUT 4

SOUT 4

DOUT 5

SOUT 5

DOUT 6

SOUT 6

SPI

SCLK

CS

SI

SO

Logic

Driver

Diagnosis

IN 1

DIAG 1

IN 2

IN 3

IN 4

IN 5

DIAG 5

IN 6

DIAG 6

Overtemp.

Reset

VDO

CLKProg

Fault

.

.

Vcc

Vcc

.

Vcc

.

.

Vcc

.

.

.

.

.

.

.

GND

GND

DOUT 2

DOUT 1

Data Sheet

5

Rev. 2.5, 2010-10-11

TLE6288R

Pin Configuration

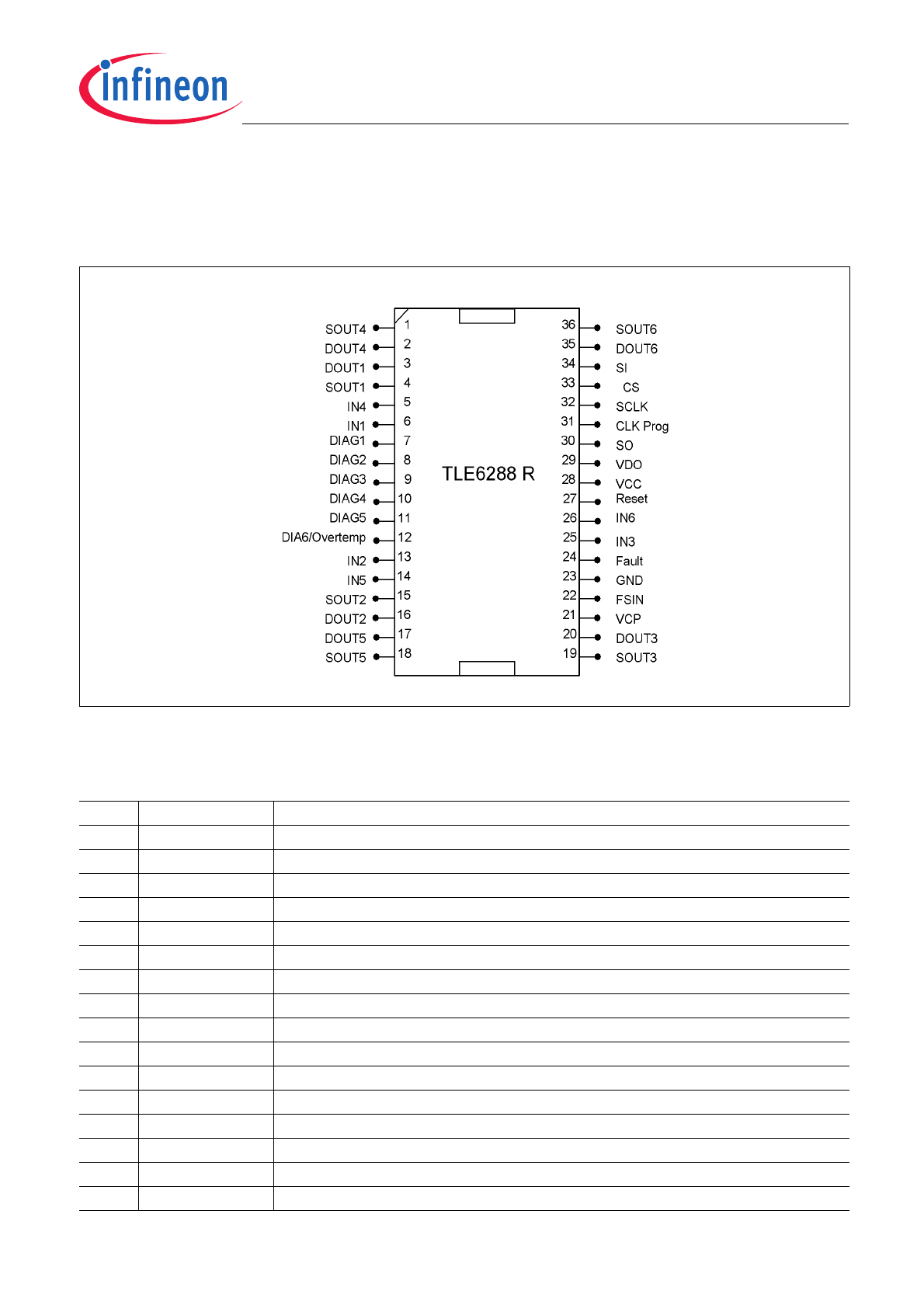

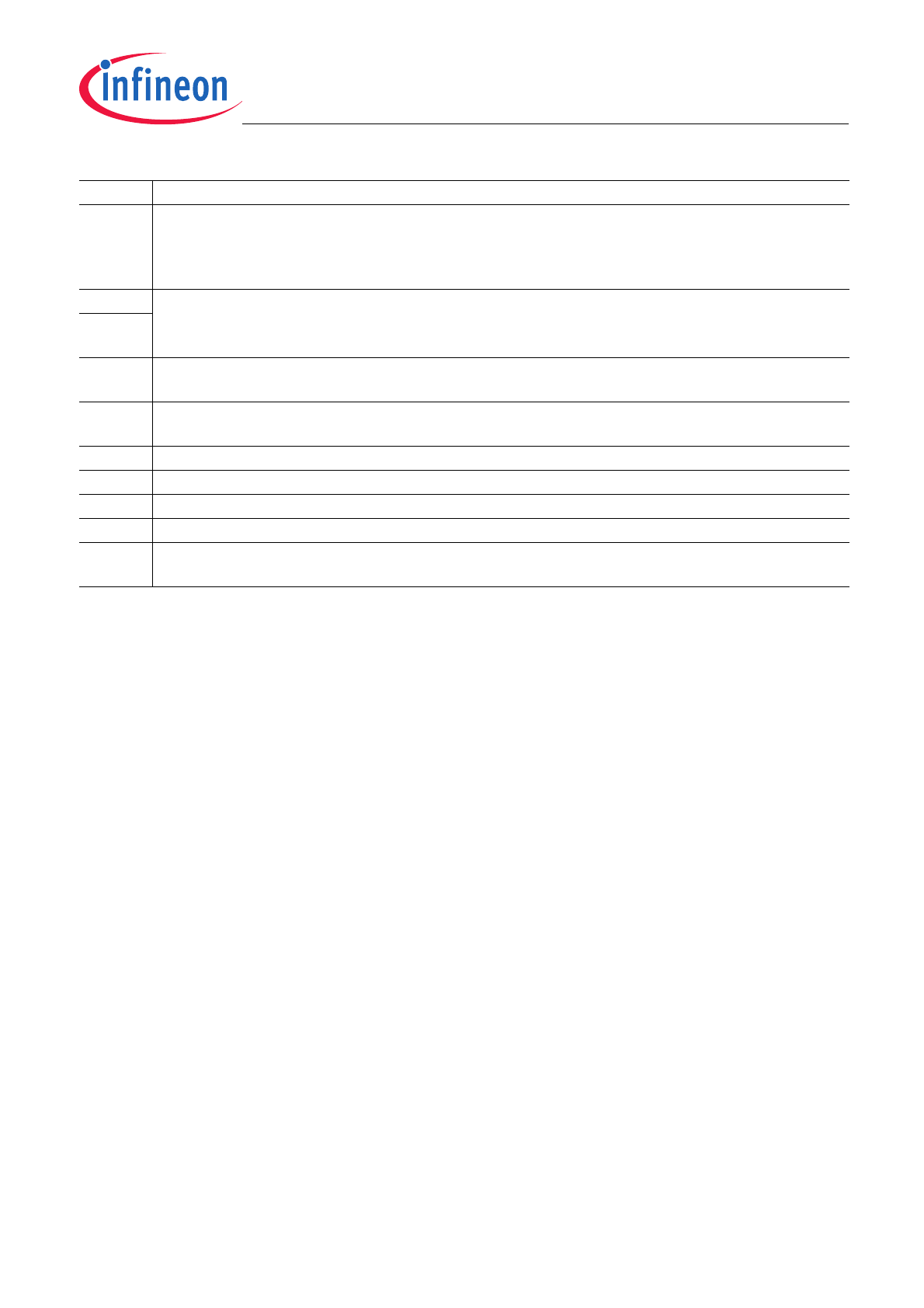

2

Pin Configuration

2.1

Pin Assignment

Figure 2

Pin Configuration PG-DSO-36-54

2.2

Pin Definitions and Functions

Pin

Symbol

Function

1

SOUT4

Source Output CH 4 (high/low side)

2

DOUT4

Drain Output CH 4 (high/low side)

3

DOUT1

Drain Output CH 1 (high side)

4

SOUT1

Source Output CH 1 (high side)

5

IN4

Control Input Channel 4

6

IN1

Control Input Channel 1

7

DIAG1

Diagnostic Output CH 1

8

DIAG2

Diagnostic Output CH 2

9

DIAG3

Diagnostic Output CH 3

10

DIAG4

Diagnostic Output CH 4

11

DIAG5

Diagnostic Output CH 5

12

DIAG6/Overtemp Diagnostic Output CH 6 / Overtemp

13

IN2

Control Input Channel 2

14

IN5

Control Input Channel 5

15

SOUT2

Source Output CH 2 (high side)

16

DOUT2

Drain Output CH 2 (high side)

TLE6288R

Pin Configuration

Data Sheet

6

Rev. 2.5, 2010-10-11

2.3

Pin Description

17

DOUT5

Drain Output CH 5 (high/low side)

18

SOUT5

Source Output CH 5 (high/low side)

19

SOUT3

Source Output CH 3 (high side)

20

DOUT3

Drain Output CH 3 (high side)

21

VCP

Charge Pump capacitor pin

22

FSIN

All Channels Enable/Disable

23

GND

Logic Ground

24

Fault

General Fault Flag

25

IN3

Control Input Channel 3

26

IN6

Control Input Channel 6

27

Reset

Reset pin (+ Standby Mode)

28

V

CC

Logic Supply Voltage (5 V)

29

V

DO

Supply pin for digital outputs

30

SO

SPI Serial Data Output

31

CLKProg

Program pin of SPI Clock

32

SCLK

SPI Serial Clock

33

CS

SPI Chip Select

34

SI

SPI Serial Data Input

35

DOUT6

Drain Output CH 6 (high/low side)

36

SOUT6

Source Output CH 6 (high/low side)

Symbol

Description

DOUT1-3 Drain of the 3 highside channels. These pins must always be connected to the same power (battery)

supply line (

V

B

).

SOUT1-3 Source of the 3 highside channels. Outputs of the highside channels where the load is connected.

DOUT4-6 Drain pins of the 3 configurable channels. In highside configuration they must be connected to the

same voltage as DOUT1-3. In lowside configuration they are the output pins and connected to the

load.

SOUT4-6 Source of the 3 configurable channels. In highside configuration they are the outputs and connected

to the load. In lowside configuration they must be connected with GND.

IN1-6

Parallel input pins for the 6 power outputs. These pins have an internal pull-down structure.

GND

Logic ground pin, the heat slug has to be connected to this potential.

FSIN

Disable pin. If the FSIN pin is in a logic low state, it switches all outputs OFF. The pin has an internal

pull-up structure.

Reset

Reset pin. When the reset is low all channels are off, the internal biasing is deactivated, all internal

registers are cleared and the supply-current consumption is reduced (standby mode). The pin has an

internal pull-up structure.

Fault

General Fault pin. There is a general fault pin (open drain) which shows a high to low transition as

soon as an error is latched into the diagnosis register. When the diagnosis register is cleared this flag

is also reset (high ohmic). This fault indication can be used to generate a

μC interrupt.

Pin

Symbol

Function

Data Sheet

7

Rev. 2.5, 2010-10-11

TLE6288R

Pin Configuration

For more details about the SPI see

Chapter 5

.

CLKProg Programming pin for the SPI Clock signal. This pin can be used to configure the clock signal input of

the SPI. In low state the SPI will read data at the rising clock edge and write data at the falling clock

edge. In high state the SPI will read data at the falling clock edge and write data at the rising clock

edge. The pin has an internal pull-down structure.

DIAG1-5

Parallel diagnostic pins (push-pull) change state according to the input signal of the corresponding

channel. For further details refer to

Chapter 4.3.1

DIAG6/

Overtemp

VCP

Pin to connect the external capacitor of the integrated charge pump. Connect a ceramic capacitor with

47 nF between this pin and DOUT3 (

V

B

).

V

DO

Supply pin of the push-pull digital output drivers. This pin can be used to vary the high-state output

voltage of the SO pin and the DIAG1-6 pins.

V

CC

Logic supply pin. This pin is used to supply the integrated circuitry.

CS

Chip Select of the SPI (active low)

SO

Signal Output of the Serial Peripheral Interface

SI

Signal Input of the Serial Peripheral Interface. The pin has an internal pull-down structure.

SCLK

Clock Input of the Serial Peripheral Interface. The pin has an internal pull-up structure

(if CLKProg = L) or an pull-down structure (if CLKProg = H).

Symbol

Description

TLE6288R

General Product Characteristics

Data Sheet

8

Rev. 2.5, 2010-10-11

3

General Product Characteristics

3.1

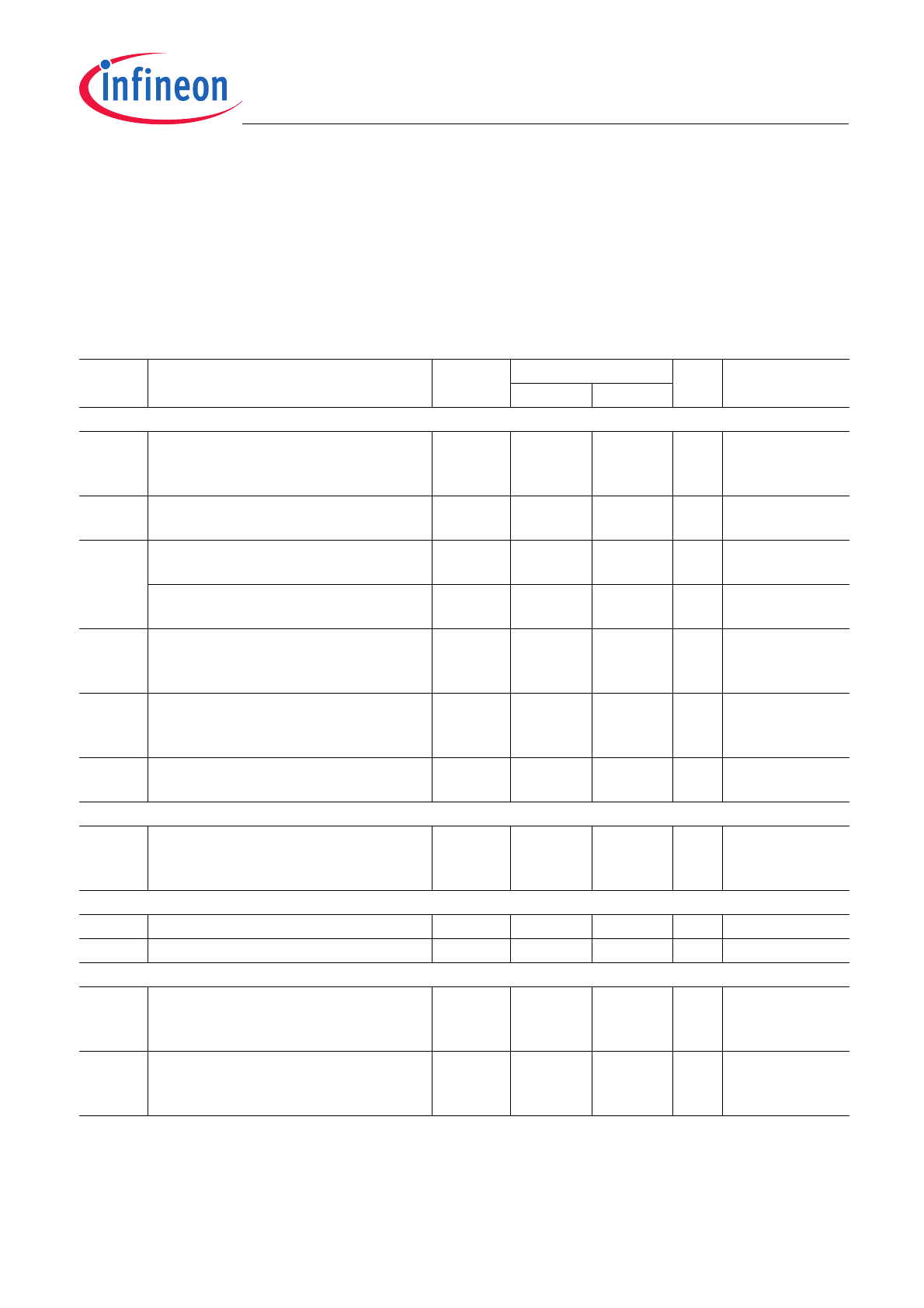

Absolute Maximum Ratings

Attention: Stresses above the ones listed here may cause permanent damage to the device. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

Absolute Maximum Ratings

1)

T

j

= -40

⋅C to +150 ⋅C; all voltages with respect to ground, positive current flowing into pin

(unless otherwise specified)

1) Not subject to production test, specified by design.

Pos.

Parameter

Symbol

Limit Values

Unit

PIN / Conditions

Min.

Max.

Voltages

3.1.1

Power Supply Voltage 1 static

dynamic: 1 min. 25

°C

dynamic: Test cond. see

Figure 3

V

B

V

B

V

B

-0.3

–

–

20

24

40

V

DOUT1-3

DOUT1-3

2)

DOUT1-3

2)

2) As long as max. junction temperature

T

j

is not exceeded.

3.1.2

Power Supply Voltage 2

V

CC

V

DO

-0.3

7

V

VCC

VDO

3.1.3

Continuous Drain Source Voltage

(lowside configuration)

V

DSL

–

40

V

DOUT - SOUT

(channel 4 to 6)

Continuous Source Voltage

(highside configuration)

V

SH

-9

V

B

V

SOUT - GND

(channel 4 to 6)

3.1.4

Input Voltage

V

IN

-0.3

V

CC

+ 0.3 V

IN1-6, Reset,

FSIN, CS, SCLK,

SI, CLKProg

3.1.5

Output Voltage

V

OUT

-0.3

V

CC

+ 0.3 V

Fault

DIAG1-6

SO

3.1.6

Output Voltage

V

CP

–

V

B

+ 10

V

VCP; no voltage

must be applied

Currents

3.1.7

Reverse Current (1 ms)

I

rev

-4

–

A

between DOUT

and SOUT;

Channel 4 to 6

Temperatures

3.1.8

Operating Temperature

T

j

-40

+150

°C

–

3.1.9

Storage Temperature

T

stg

-55 +150

°C

–

ESD Susceptibility

3.1.10

ESD (Human Body Model)

C

= 100 pF,

R

= 1.5 k

Ω

Applied to all terminals 3 times

V

ESDb

–

2000

V

–

3.1.11

ESD (Machine Model)

C

= 200 pF,

R

= 0

Ω

Applied to all terminals 3 times

V

ESDm

–

250

V

–

Data Sheet

9

Rev. 2.5, 2010-10-11

TLE6288R

General Product Characteristics

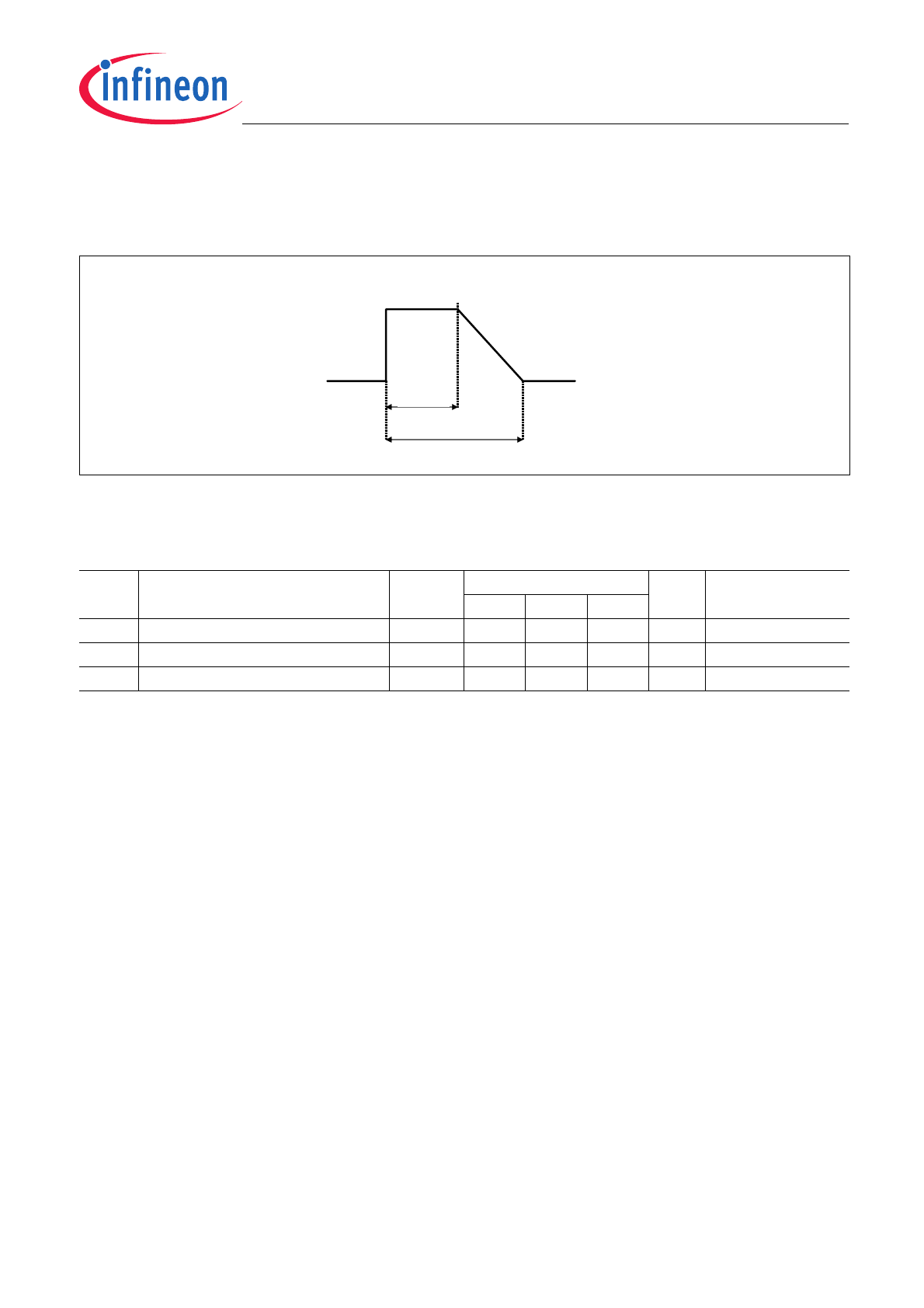

Attention: Integrated protection functions are designed to prevent IC destruction under fault conditions

described in the data sheet. Fault conditions are considered as “outside” normal operating

range. Protection functions are not designed for continuous repetitive operation.

Figure 3

Test Condition

3.2

Thermal Resistance

Pos.

Parameter

Symbol

Limit Values

Unit

Conditions

Min.

Typ.

Max.

3.2.1

–

3.2.2

Junction to Case

1)

1) Not subject to production test, specified by design.

R

thjC

1

K/W

2)

2) Channel 1-6 continously turned on, 0.8W power dissipation per channel

3.2.3

Junction to ambient

1)

R

thjA

15.5

K/W

2)

3)

3) Specified

R

thjA

value is according to Jedec JESD51-2,-5,-7 at natural convection on FR4 2s2p board ; The Product

(Chip+Package) was simulated on a 76.2 x 114.3 x 1.5 mm board with 2 inner copper layers (2 x 70

μm Cu, 2 x 35μm Cu).

Where applicable a thermal via array under the exposed pad contacted the first inner copper layer.

Further informations can be found in Chapter 7.2

12V

40V

10 times

(once/ 30sec)

160ms

350ms

TLE6288R

Description

Data Sheet

10

Rev. 2.5, 2010-10-11

4

Description

4.1

General Functional Description

Channel 1 to 3

•

High Side Configuration with Charge Pump

•

On / off Current Control

•

Peak & Hold Current Control with fixed off time, values adjustable by SPI

•

Type of current control can be selected by SPI

•

Peak Current,Peak Time, Hold Current and Off-Time can be selected by SPI to set average and ripple current

for a given load (refer to

Figure 6

)

Channel 4 to 6

•

Configurable as either High or Low Side switch (by SPI)

•

On / Off operation

4.1.1

Output Stage Control: Parallel Control and SPI Control

A Boolean operation (either AND or OR) is performed on each of the parallel inputs IN 1 … 6 and respective SPI

data bits, in order to determine the states of the respective outputs. The type of Boolean operation performed is

programmed via the serial interface. Both, parallel inputs and respective SPI databits are high active.

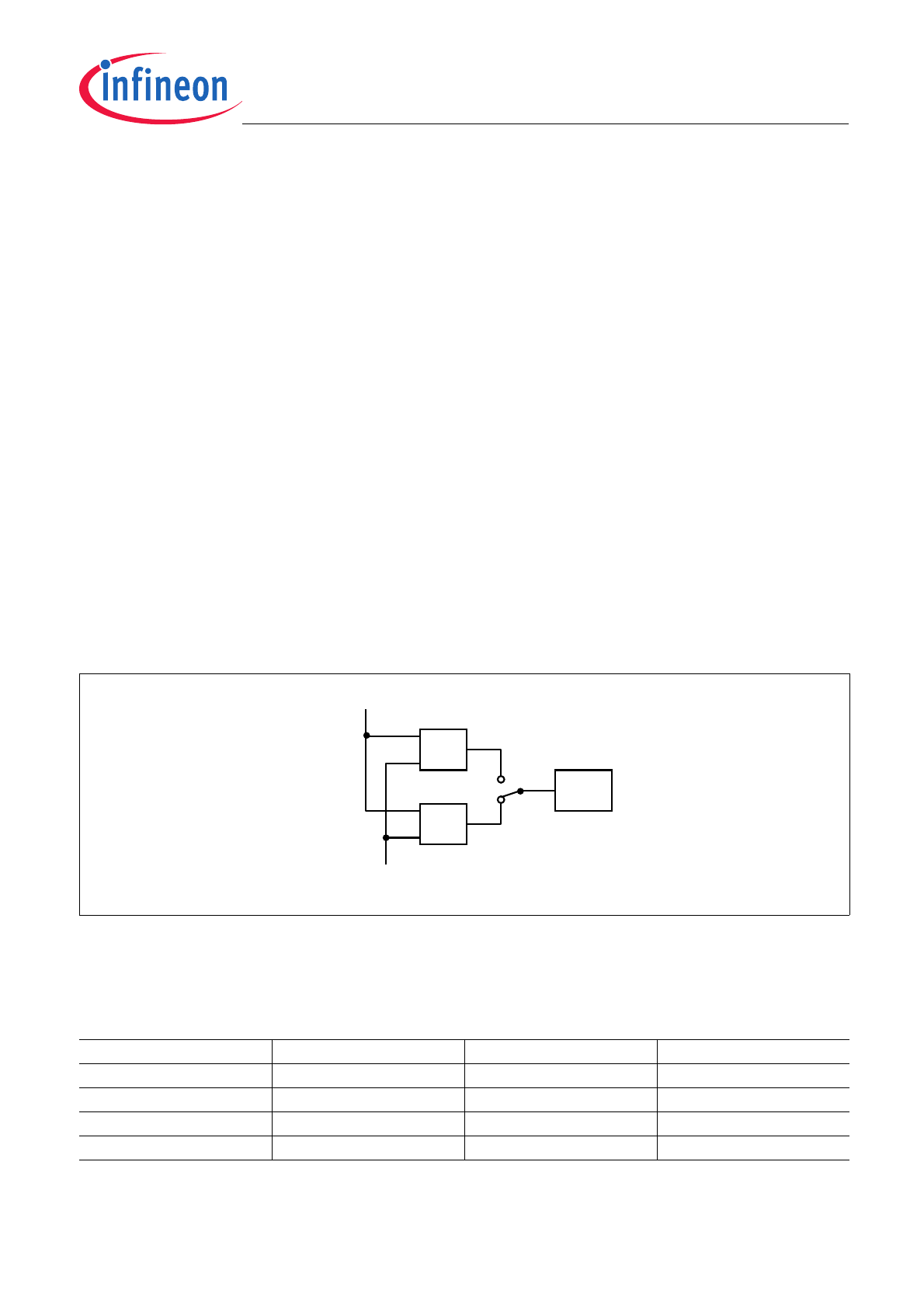

Figure 4

Serial Input Bits 6-11 of Command “Channels on/off”

Each output is independently controlled by an output latch and a common reset line FSIN, which disables all

outputs. A logic high input ‘data bit’ turns the respective output channel ON, a logic low ‘data bit’ turns it OFF.

Table 2

Truth Table

Parallel Input

SPI Bit

Output OR

Output AND

0

0

OFF

OFF

0

1

ON

OFF

1

0

ON

OFF

1

1

ON

ON

OR

AND

Output

Driver

IN 1…6

Serial Input bits 6 -11 of command

„Channels on / off „