C C M - P F C

I C E 2 P C S 0 6

I C E 2 P C S 0 6 G

S t a n d a l o n e P o w e r F a c t o r

C o r r e c t i o n ( P F C ) C o n t r o l l e r i n

C o n t i n u o u s C o n d u c t i o n M o d e

( C C M ) w i t h I n p u t B r o w n - O u t

P r o t e c t i o n

N e v e r

s t o p

t h i n k i n g .

V e r s i o n 1 . 1 , M a r 2 0 1 0

Power Management & Supply

Edition 2010-03-22

Published by

Infineon Technologies AG

81726 München, Germany

©

2007 Infineon Technologies AG

All Rights Reserved.

Legal Disclaimer

The information given in this document shall in no event be regarded as a guarantee of conditions or

characteristics. With respect to any examples or hints given herein, any typical values stated herein and/or any

information regarding the application of the device, Infineon Technologies hereby disclaims any and all warranties

and liabilities of any kind, including without limitation, warranties of non-infringement of intellectual property rights

of any third party.

Information

For further information on technology, delivery terms and conditions and prices please contact your nearest

Infineon Technologies Office (

www.infineon.com

).

Warnings

Due to technical requirements components may contain dangerous substances. For information on the types in

question please contact your nearest Infineon Technologies Office.

Infineon Technologies Components may be used in life-support devices or systems only with the express written

approval of Infineon Technologies, if a failure of such components can reasonably be expected to cause the failure

of that life-support device or system, or to affect the safety or effectiveness of that device or system. Life support

devices or systems are intended to be implanted in the human body, or to support and/or maintain and sustain

and/or protect human life. If they fail, it is reasonable to assume that the health of the user or other persons may

be endangered.

For questions on technology, delivery and prices please contact the Infineon Technologies Offices in Germany or

the Infineon Technologies Companies and Representatives worldwide: see our webpage at http://

www.infineon.com

CCM-PFC

Revision History:

Datasheet

Previous Version: V1.0

Page

Subjects(major changes since last version)

18&19

Package outline change

CCM-PFC

ICE2PCS06

ICE2PCS06G

Version 1.1

3

Mar 2010

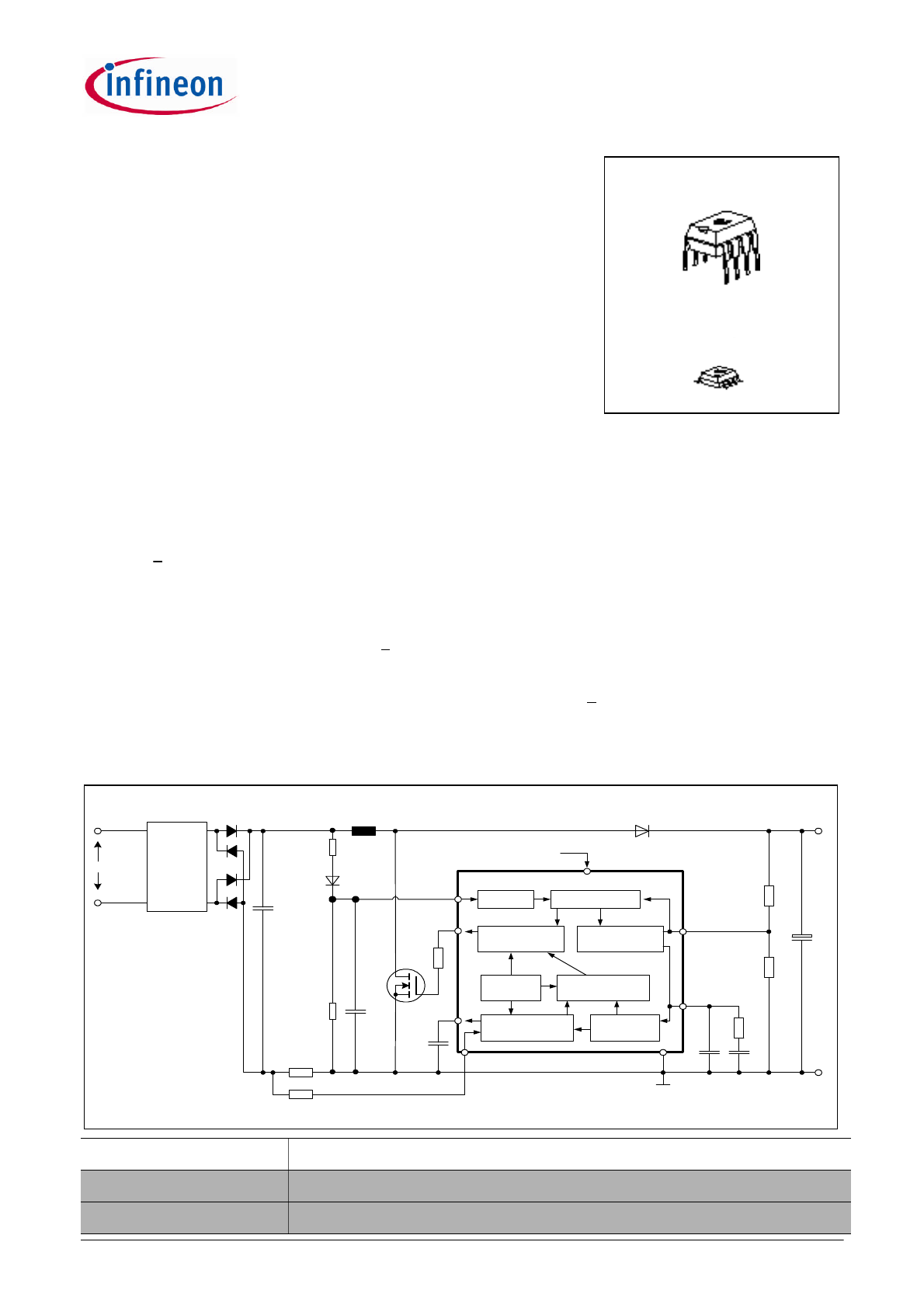

Type

Package

ICE2PCS06

PG-DIP-8

ICE2PCS06G

PG-DSO-8

Standalone Power Factor Correction (PFC)

Controller in Continuous Conduction Mode

(CCM) with Input Brown-Out Protection

ICE2PCS06

PG-DIP-8

ICE2PCS06G

PG-DSO-8

Product Highlights

•

Leadfree DIP and DSO Package

•

Wide Input Range

•

Direct sensing, Input Brown-Out Detection

•

Optimized for applications which require fast Startup

•

Output Power Controllable by External Sense Resistor

•

Fast Output Dynamic Response during Load Jumps

•

Trimmed, internal fixed Switching Frequency (65kHz)

Features

•

Ease of Use with Few External Components

•

Supports Wide Input Range

•

Average Current Control

•

External Current and Voltage Loop Compensation

for Greater User Flexibility

•

Trimmed internal fixed Switching Frequency

(65kHz+5% at 25

o

C)

•

Direct sensing, Input Brown-Out Detection

with Hysteresis

•

Short Startup(SoftStart) duration

•

Max Duty Cycle of 95% (at 25

o

C)

•

Trimmed Internal Reference Voltage (3V+2% at

25

o

C)

•

VCC Under-Voltage Lockout

•

Cycle by Cycle Peak Current Limiting

•

Output Over-Voltage Protection

•

Open Loop Detection

•

Soft Overcurrent Protection

•

Enhanced Dynamic Response

•

Fulfills Class D Requirements of IEC 1000-3-2

Description

The ICE2PCS06/G is a 8-pin wide input range controller

IC for active power factor correction converters. It is de-

signed for converters in boost topology, and requires few

external components. Its power supply is recommended

to be provided by an external auxiliary supply which will

switch on and off the IC.

The IC operates in the CCM with average current control,

and in DCM only under light load condition. The switching

frequency is trimmed and fixed internally at 65kHz. Both

current and voltage loop compensations are done exter-

nally to allow full user control.

There are various protection features incorporated to en-

sure safe system operation conditions. The internal refer-

ence is trimmed (3V+2%) to ensure precise protection and

output control level.

85 ... 265 V A C

E M I-Filter

V oltage Loop

C om pensation

P rotection U nit

Fixed

O scillator

C urrent Loop

C om pensation

P W M Logic

D river

IC E 2P C S 02 /G

C C M P FC

V C C

A uxiliary S upply

V

O U T

Typ ical A p plication

R am p

G enerator

IC O M P

V S E N S E

V C O M P

IS E N S E

G N D

N onlinear

G ain

G A TE

V IN S

B row n-out

d

CCM-PFC

ICE2PCS06/G

Version 1.1

4

Mar 2010

1

Pin Configuration and Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1

Pin Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2

Pin Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2

Representative Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3

Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.4

System Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.4.1

Input Brown-Out Protection (IBOP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.4.2

Soft Over Current Control (SOC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.4.3

Peak Current Limit (PCL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.4.4

Open Loop Protection (OLP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.4.5

Over-Voltage Protection (OVP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.5

Fixed Switching Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.6

Average Current Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.6.1

Complete Current Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.6.2

Current Loop Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.6.3

Pulse Width Modulation (PWM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.6.4

Nonlinear Gain Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.7

PWM Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.8

Voltage Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.8.1

Voltage Loop Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.8.2

Enhanced Dynamic Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.9

Output Gate Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4

Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1

Absolute Maximum Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2

Operating Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.3

Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.3.1

Supply Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.3.2

PWM Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.3.3

System Protection Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.3.4

Current Loop Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.3.5

Voltage Loop Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.3.6

Driver Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5

Outline Dimension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Version 1.1

5

Mar 2010

CCM-PFC

ICE2PCS06/G

Pin Configuration and Functionality

1

Pin Configuration and Functionality

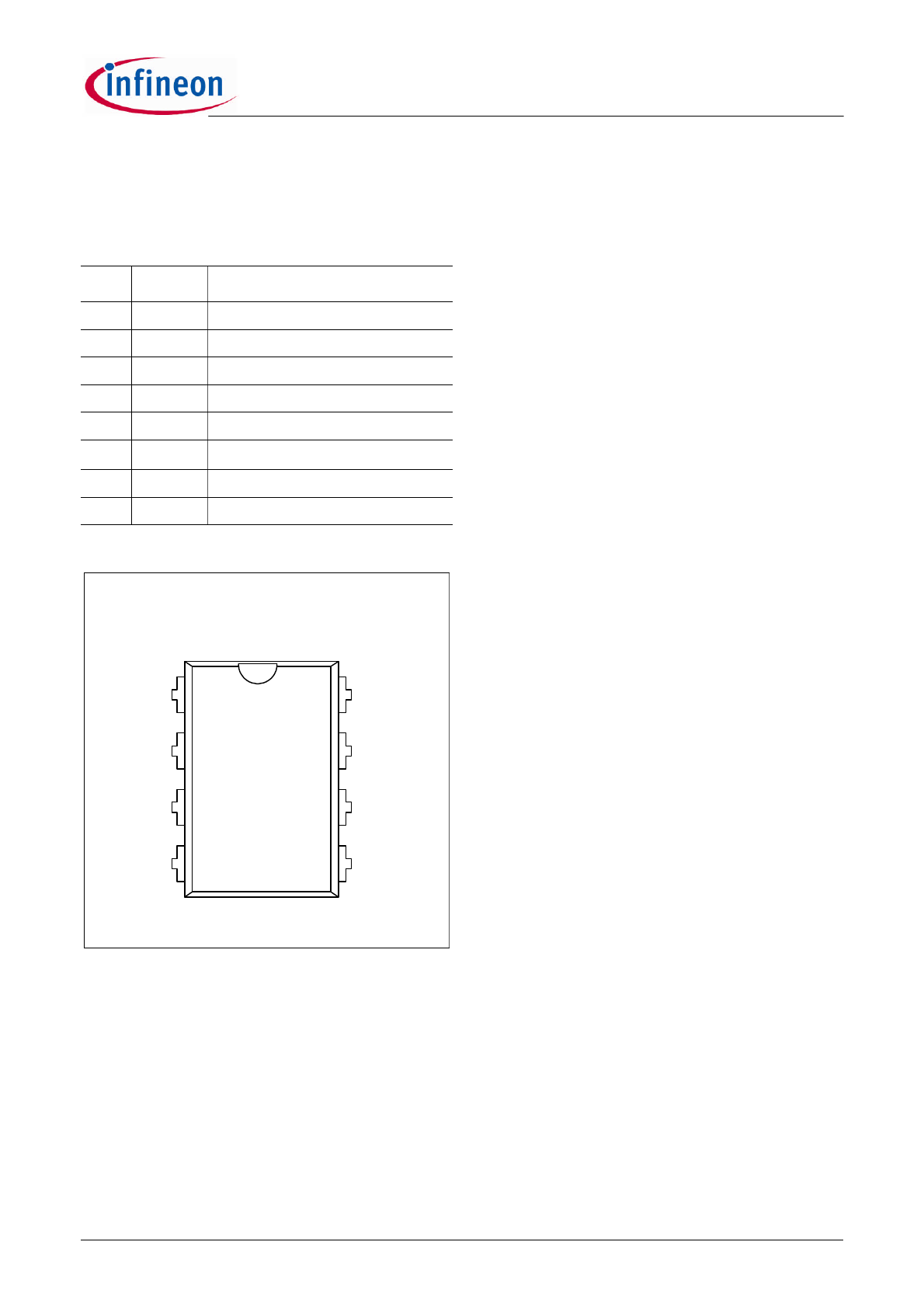

1.1

Pin Configuration

Figure 1

Pin Configuration (top view)

1.2

Pin Functionality

GND (Ground)

The ground potential of the IC.

ICOMP (Current Loop Compensation)

Low pass filter and compensation of the current control

loop. The capacitor which is connected at this pin

integrates the output current of OTA2 and averages the

current sense signal.

ISENSE (Current Sense Input)

The ISENSE Pin senses the voltage drop at the

external sense resistor (R1). This is the input signal for

the average current regulation in the current loop. It is

also fed to the peak current limitation block.

During power up time, high inrush currents cause high

negative voltage drop at R1, driving currents out of pin

3 which could be beyond the absolute maximum

ratings. Therefore a series resistor (R2) of around

220

W is recommended in order to limit this current into

the IC.

VINS (Brown-out Sense Input)

This VINS pin senses a filtered input voltage divider

and detects for the input voltage Brown-out condition.

A Brown-out condition of VINS<0.71V, shuts down the

IC. The IC turns on at VINS>1.5V.

VSENSE (Voltage Sense/Feedback)

The output bus voltage is sensed at this pin via a

resistive divider. The reference voltage for this pin is

3V.

VCOMP (Voltage Loop Compensation)

This pin provides the compensation of the output

voltage loop with a compensation network to ground

(see Figure 2).

VCC (Power Supply)

The VCC pin is the positive supply of the IC and should

be connected to an external auxiliary supply. The

operating range is between 11V and 26V. The turn-on

threshold is at 11.8V and under voltage occurs at 11V.

There is no internal clamp for a limitation of the power

supply.

GATE

The GATE pin is the output of the internal driver stage.

Its gate drive voltage is internally clamped at 15.0V

(typically).

Pin

Symbol

Function

1

GND

IC Ground

2

ICOMP

Current Loop Compensation

3

ISENSE

Current Sense Input

4

VINS

Brown-out Sense Input

5

VCOMP

Voltage Loop Compensation

6

VSENSE V

OUT

Sense (Feedback) Input

7

VCC

IC Supply Voltage

8

GATE

Gate Drive Output

Package PG-DIP-8 / PG-DSO-8

1

6

7

8

4

3

2

5

GATE

GND

ICOMP

ISENSE

VCC

VSENSE

VINS

VCOMP

CCM-PFC

ICE2PCS06/G

Representative Block diagram

Version 1.1

6

Mar 2010

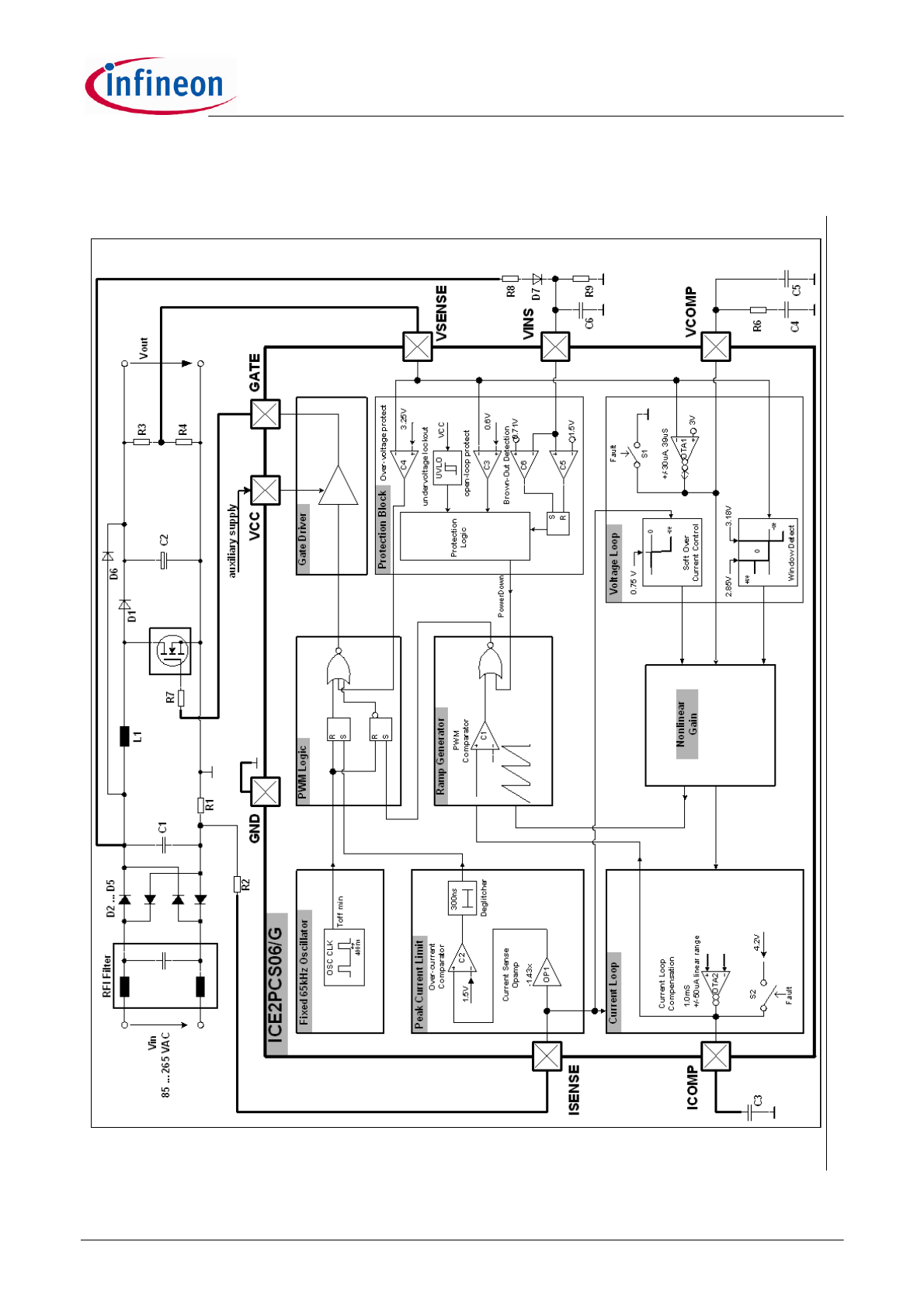

2

Representative Block diagram

Figure 2

Representative Block diagram

CCM-PFC

ICE2PCS06/G

Functional Description

Version 1.1

7

Mar 2010

3.1

General

The ICE2PCS06/G is a 8 pin control IC for power factor

correction converters. It comes in both DIP and DSO

packages and is suitable for wide range line input

applications from 85 to 265 VAC. The IC supports

converters in boost topology and it operates in

continuous conduction mode (CCM) with average

current control.

It is a design derivative from the ICE2PCS01/G with the

differences in the supporting functions, namely the

input brown-out detection and internal fixed switching

frequency 65kHz.

The IC operates with a cascaded control; the inner

current loop and the outer voltage loop. The inner

current loop of the IC controls the sinusoidal profile for

the average input current. It uses the dependency of

the PWM duty cycle on the line input voltage to

determine the corresponding input current. This means

the average input current follows the input voltage as

long as the device operates in CCM. Under light load

condition, depending on the choke inductance, the

system may enter into discontinuous conduction mode

(DCM) resulting in a higher harmonics but still meeting

the Class D requirement of IEC 1000-3-2.

The outer voltage loop controls the output bus voltage.

Depending on the load condition, OTA1 establishes an

appropriate voltage at VCOMP pin which controls the

amplitude of the average input current.

The IC is equipped with various protection features to

ensure safe operating condition for both the system

and device.

3.2

Power Supply

An internal under voltage lockout (UVLO) block

monitors the VCC power supply. As soon as it exceeds

11.8V and both voltages at pin 6 (VSENSE) >0.6V and

pin 4 (VINS) >1.5V, the IC begins operating its gate

drive and performs its Startup as shown in Figure 3.

.

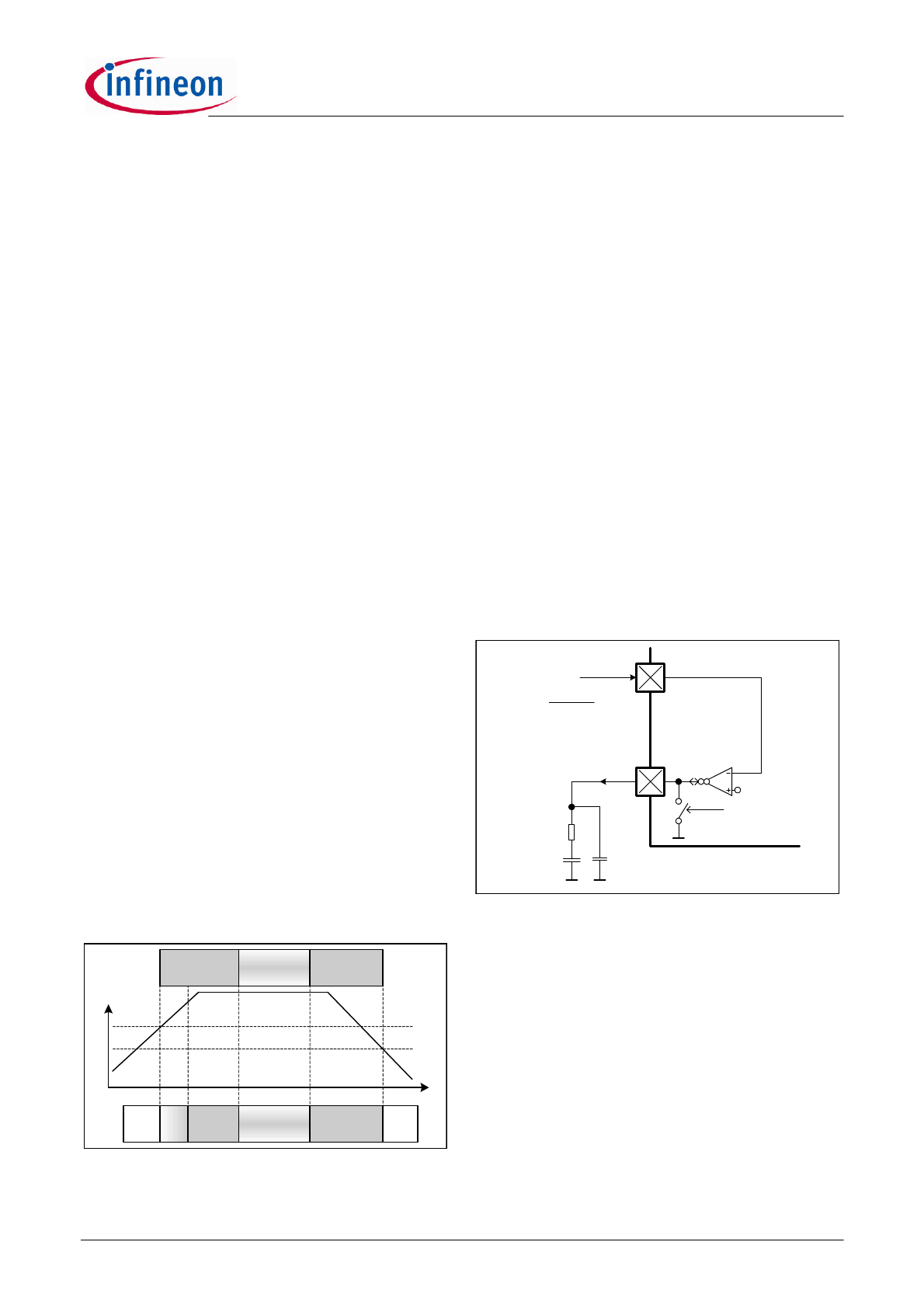

Figure 3

State of Operation respect to VCC

If VCC drops below 11V, the IC is off. The IC will then

be consuming typically 300

mA, whereas consuming

10mA during normal operation.

The IC can be turned off and forced into standby mode

by pulling down the voltage at pin 6 (VSENSE) to lower

than

0.6V.

In

this

standby

mode,

the

current

consumption is reduced to 300

mA. Other condition that

can result in the standby mode is when a Brown-out

condition occurs, ie pin 4 (VINS) <0.71V.

3.3

Start-up

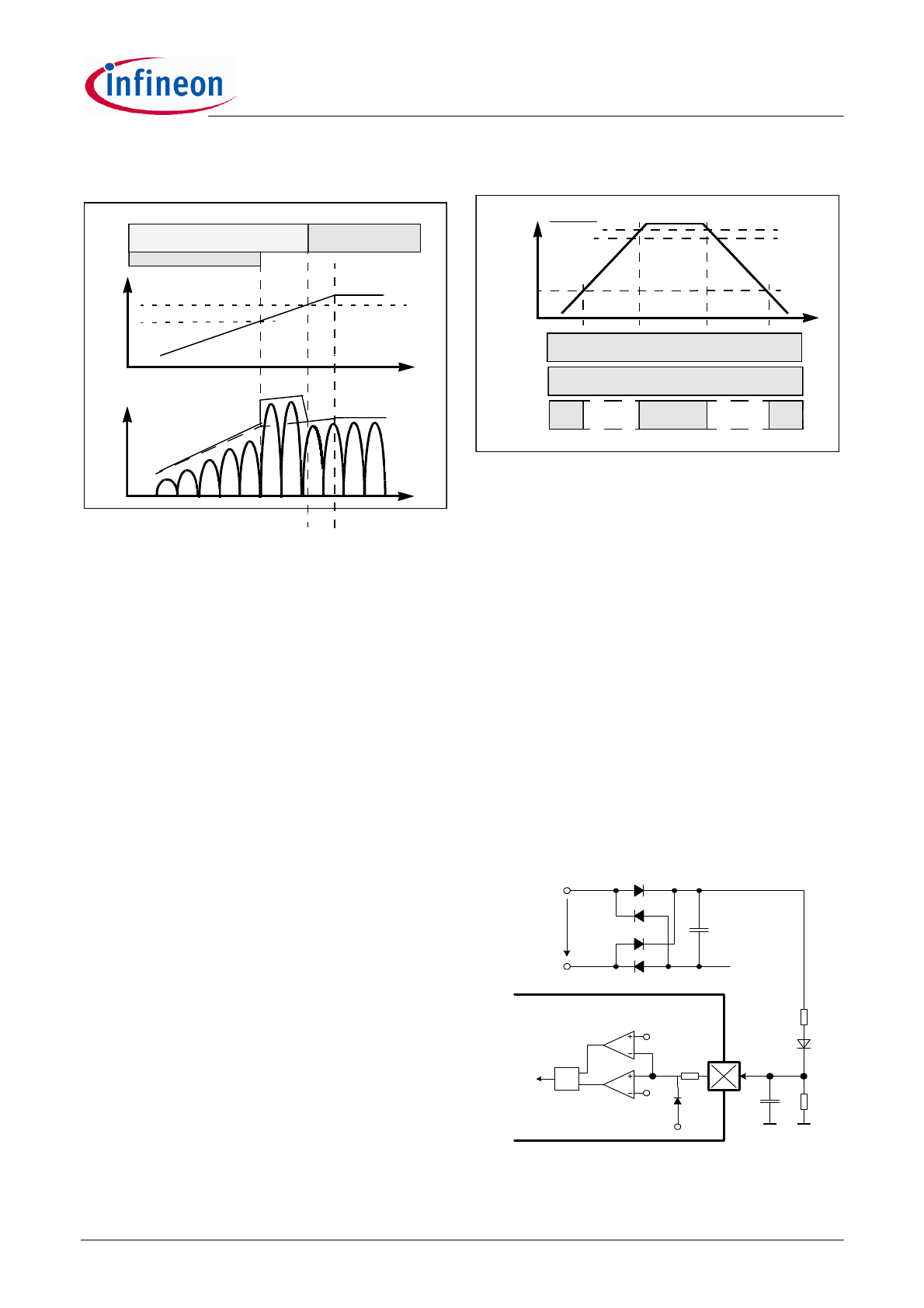

Figure 4 shows the operation of voltage loop’s OTA1

during startup. The VCOMP pin is pull internally to

ground via switch S1 during UVLO and other fault

conditions (see later section on “System Protection”).

During power up when V

OUT

is less than 83% of the

rated level, OTA1 sources an output current, maximum

30

mA into the compensation network at pin 5 (VCOMP)

causing the voltage at this pin to rise linearly. This

results in a controlled linear increase of the input

current from 0A thus reducing the stress on the

external component.

Figure 4

Startup Circuit

As V

OUT

has not reached within 5% from the rated

value, VCOMP voltage is level-shifted by the window

detect block as shown in Figure 5, to ensure there is

fast boost up output voltage.

When V

OUT

approaches its rated value, OTA1’s

sourcing current drops and so does the level shift of the

window detect block is removed. The normal voltage

loop then takes control.

V

CC

(V

VSENSE

> 0.6 V)

AND (V

VINS

> 1.5 V)

11.8 V

11.0 V

t

OFF

Start

Up

Open loop/

Standby

Normal

Operation

IC's

State

OFF

Normal

Operation

(V

VSENSE

< 0.6 V)

OR (V

VINS

< 0.8 V)

(V

VSENSE

> 0.6 V)

AND (V

VINS

> 1.5 V)

VCOMP

C5

C4

VSENSE

OTA1

3V

ICE2PCS06/G

protect

R3 + R4

R4

x V

OUT

)

(

R6

S1

3

Functional Description

CCM-PFC

ICE2PCS06/G

Functional Description

Version 1.1

8

Mar 2010

.

Figure 5

Startup with controlled maximum current

3.4

System Protection

The IC provides several protection features in order to

ensure the PFC system in safe operating range:

•

VCC Undervoltage Lockout (UVLO)

•

Input Brown-out Detection (IBOP)

•

Soft Over Current Control (SOC)

•

Peak Current Limit (PCL)

•

Open-Loop Detection (OLP)

•

Output Over-Voltage Protection (OVP)

After the system is supplied with the correct level of

VCC and V

IN

, the system will enter into its normal mode

of operation. Figure 6 shows situation when these

protections features are active, as a function of the

output voltage V

OUT

.

An activation of the UVLO, IBOP and OLP results in the

internal fault signal going high and brings the IC into the

standby mode.

As the function of UVLO has already described in the

earlier “Power Supply” section, the following sections

continue

to

describe

the

functionality

of

these

protection features.

Figure 6

Protection Features

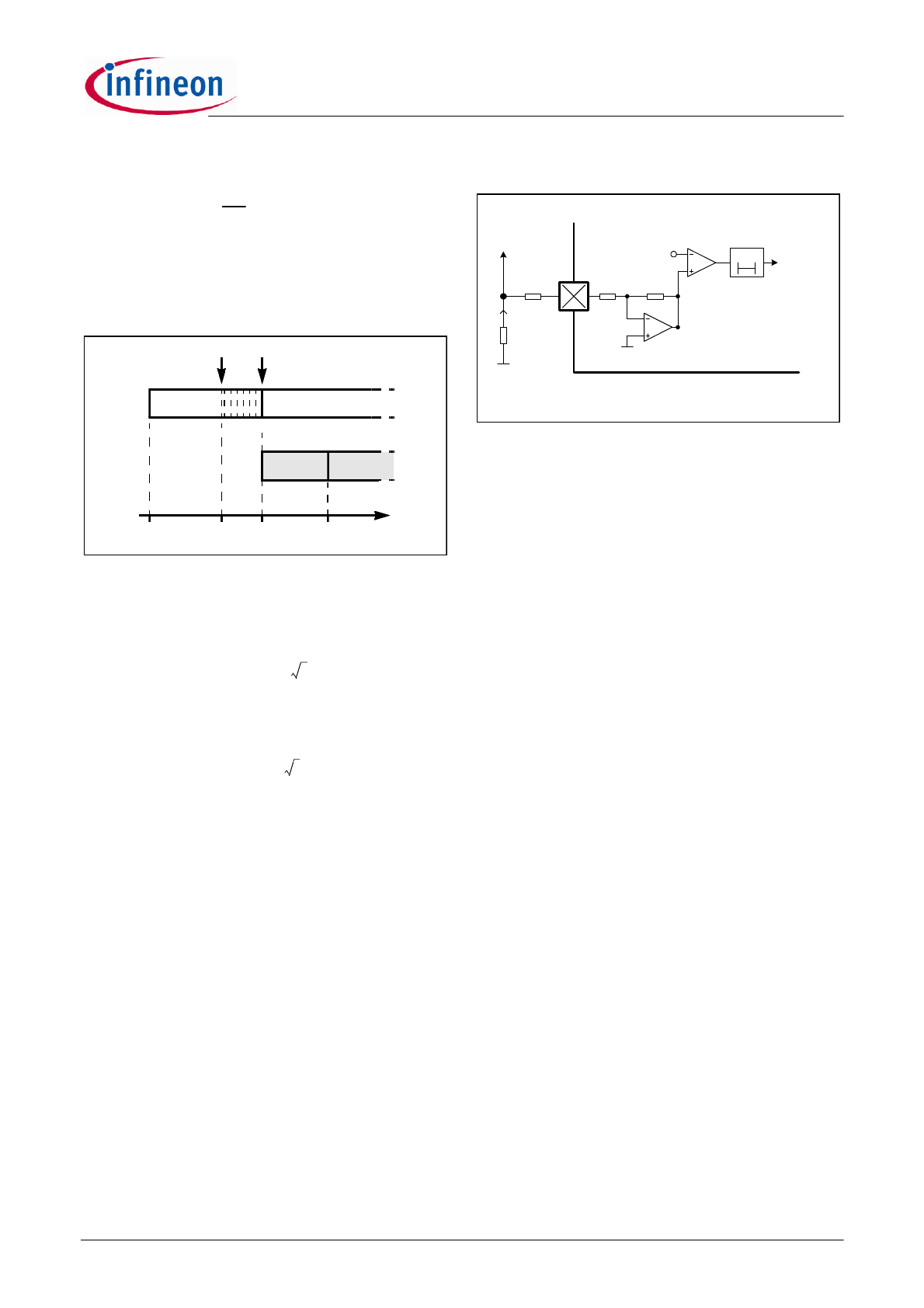

3.4.1

Input Brown-Out Protection (IBOP)

Brown-out occurs when the input voltage V

IN

falls below

the minimum input voltage of the design (i.e. 85V for

universal input voltage range) and the VCC has not

entered into the V

CCUVLO

level yet. For a system without

IBOP, the boost converter will increasingly draw a

higher current from the mains at a given output power

which may exceed the maximum design values of the

input current.

ICE2PCS06/G provides a new IBOP feature whereby it

senses directly the input voltage for Input Brown-Out

condition

via

an

external

resistor/capacitor/diode

network as shown in Figure 7. This network provides a

filtered value of V

IN

which turns the IC on when the

voltage at pin 4 (VINS) is more than 1.5V. The IC enters

into the standby mode when VINS goes below 0.71V.

The hysteresis prevents the system to oscillate

between normal and standby mode. Note also that V

IN

needs to at least 20% of the rated V

OUT

in order to

overcome OLP and powerup the system.

Figure 7

Input Brown-Out Protection (IBOP)

av(I

IN

)

V

OUT

t

V

OUT

=rated

95%rated

Window Detect

Normal Control

t

Max Vcomp current

83%rated

VCOMP

Level-shifted VCOMP

t

V

OUT

PCL / SOC

20%

100%

OLP

OLP

108%

OVP

V

OUT,Rated

UVLO / IBOP

Supply

related

Current

related

Output

related

ICE2PCS06/G

85 ... 265 VAC

Vin

C1

D2 ... D5

VINS

C4

C5

R

S

1.5V

0.71V

Brow n-Out Detection

R8

R9

C6

D7

brown-out

80k

3.5V

CCM-PFC

ICE2PCS06/G

Functional Description

Version 1.1

9

Mar 2010

3.4.2

Soft Over Current Control (SOC)

The IC is designed not to support any output power

that corresponds to a voltage lower than -0.75V at the

ISENSE pin. A further increase in the inductor current,

which results in a lower ISENSE voltage, will activate

the Soft Over Current Control (SOC). This is a soft

control as it does not directly switch off the gate drive.

It acts on the nonlinear gain block to result in a reduced

PWM duty cycle.

Figure 8

SOC and PCL Protection as function of

V

ISENSE

The rated output power with a minimum V

IN

(V

INMIN

) is

Due to the internal parameter tolerance, the maximum

power with V

INMIN

is

3.4.3

Peak Current Limit (PCL)

The IC provides a cycle by cycle peak current limitation

(PCL). It is active when the voltage at pin 3 (ISENSE)

reaches -1.04V. This voltage is amplified by OP1 by a

factor of -1.43 and connected to comparator C2 with a

reference voltage of 1.5V as shown in Figure 9. A

deglitcher with 300ns after the comparator improves

noise immunity to the activation of this protection.

Figure 9

Peak Current Limit (PCL)

3.4.4

Open Loop Protection (OLP)

Whenever VSENSE voltage falls below 0.6V, or

equivalently V

OUT

falls below 20% of its rated value, it

indicates an open loop condition (i.e. VSENSE pin not

connected) or an insufficient input voltage V

IN

for

normal operation. In this case, most of the blocks within

the IC will be shutdown. It is implemented using

comparator C3 with a threshold of 0.6V as shown in the

IC block diagram in Figure 2.

3.4.5

Over-Voltage Protection (OVP)

Whenever V

OUT

exceeds the rated value by 5%, the

over-voltage protection OVP is active as shown in

Figure 6. This is implemented by sensing the voltage at

pin VSENSE with respect to a reference voltage of

3.15V. A VSENSE voltage higher than 3.15V will

immediately reduce the output duty cycle, bypassing

the normal voltage loop control. This results in a lower

input power to reduce the output voltage V

OUT

. A

VSENSE voltage higher than 3.25V will immediately

turn off the gate, thereby preventing damage to bus

capacitor.

3.5

Fixed Switching Frequency

ICE2PCS06/G

has

an

internally

fixed

switching

frequency as opposed to the ICE2PCS01/G which can

be externally set. This frequency is trimmed to 65kHz

with an accuracy ±5% at 25

o

C.

V

ISENSE

-0.61V -0.75V

-1.04V

Normal

Operation

SOC

PCL

P

OUT

(rated)

IC’s

State

0

P

OUT

(max)

P

OUT

rated

(

)

V

IN MIN

0.61

R1

2

×

-------------------

´

=

P

OUT

ma x

(

)

V

INMIN

0.75

R1

2

×

-------------------

´

=

ISENSE

ICE2PCS06/G

R1

R2

I

INDUCTOR

OP1

1.43x

Current Limit

300ns

C2

Deglitcher

Turn Off

Driver

1.5V

Full-wave

Rectifier

CCM-PFC

ICE2PCS06/G

Functional Description

Version 1.1

10

Mar 2010

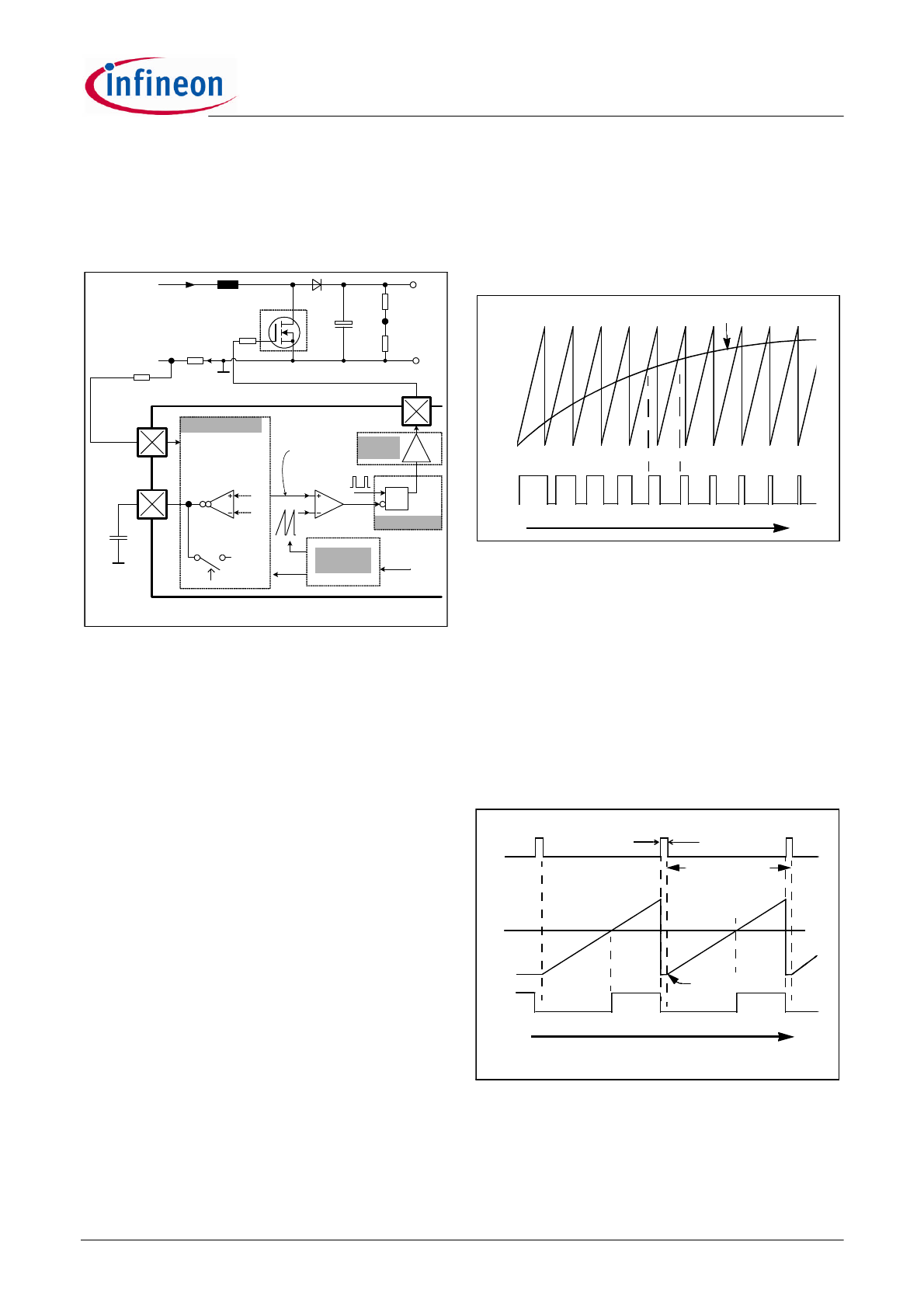

3.6

Average Current Control

3.6.1

Complete Current Loop

The complete system current loop is shown in Figure

10.

Figure 10

Complete System Current Loop

It consists of the current loop block which averages the

voltage at pin ISENSE, resulted from the inductor

current flowing across R1. The averaged waveform is

compared with an internal ramp in the ramp generator

and PWM block. Once the ramp crosses the average

waveform, the comparator C1 turns on the driver stage

through the PWM logic block. The Nonlinear Gain block

defines the amplitude of the inductor current. The

following sections describe the functionality of each

individual blocks.

3.6.2

Current Loop Compensation

The compensation of the current loop is done at the

ICOMP pin. This is the OTA2 output and a capacitor C3

has to be installed at this node to ground (see Figure

10). Under normal mode of operation, this pin gives a

voltage which is proportional to the averaged inductor

current. This pin is internally shorted to 4.2V in the

event of standby mode.

3.6.3

Pulse Width Modulation (PWM)

The IC employs an average current control scheme in

continuous conduction mode (CCM) to achieve the

power factor correction.

Assuming the voltage loop is working and output

voltage is kept constant, the off duty cycle D

OFF

for a

CCM PFC system is given as

From the above equation, D

OFF

is proportional to V

IN

.

The objective of the current loop is to regulate the

average inductor current such that it is proportional to

the off duty cycle D

OFF

, and thus to the input voltage

V

IN

. Figure 11 shows the scheme to achieve the

objective.

Figure 11

Average Current Control in CCM

The PWM is performed by the intersection of a ramp

signal with the averaged inductor current at pin 5

(ICOMP). The PWM cycle starts with the Gate turn off

for a duration of T

OFFMIN

(400ns typ.) and the ramp is

kept discharged. The ramp is then allowed to rise after

T

OFFMIN

expires. The off time of the boost transistor

ends at the intersection of the ramp signal and the

averaged current waveform. This results in the

proportional relationship between the average current

and the off duty cycle D

OFF

.

Figure 12 shows the timing diagrams of T

OFFMIN

and the

PWM waveforms.

Figure 12

Ramp and PWM waveforms

3.6.4

Nonlinear Gain Block

The nonlinear gain block controls the amplitude of the

regulated inductor current. The input of this block is the

R

S

ICE2PCS06/G

Vout

L1

C2

R3

R4

Gate

Driver

D1

From

Full-wave

Retifier

GATE

R1

R2

OTA2

ICOMP

4.2V

Current Loop

Compensation

Current Loop

Nonlinear

Gain

1.0mS

+/-50uA (linear range)

C3

S2

Fault

ISENSE

C1

PWM

Comparator

PWM Logic

Q

Input From

Voltage Loop

voltage

proportional to

averaged

Inductor current

R7

D

O FF

V

I N

V

OUT

--------------

=

t

ave(I

IN

) at ICOMP

ramp profile

GATE

drive

T

OFFMIN

400ns

V

CREF

(1)

V

RAMP

PWM

ramp

released

PWM cycle

(1)

V

CREF

is a function of V

ICOMP

t