March 13, 2013 | FINAL DATASHEET

1

IR3535

Synchronous Buck Converter Driver

FEATURES

• 5V to 7V gate drivers with 6A GATEL sink current

and 4A GATEH sink current

• 4.5V to 14V VIN range

• Local lossless inductor current sensing with

improved noise immunity and accuracy

• Single reference based current reporting output

• Integrated bootstrap synchronous PFET

• Tri‐state PWM diode emulation mode for optimal

light load efficiency

• 7V tolerant PWM input compatible with 3.3V logic

• MOSFET monitoring with PHSFLT output

• Over temperature reporting

• Only four external components per phase

• Self‐calibration of current sense amplifier input

offset to maximize accuracy

• Body‐Braking™ feature with active low logic

• RoHS compliant , small thermally enhanced

16L 3 X 3mm MLPQ package

APPLICATIONS

• Server, notebook and desktop computers

• Game consoles

• Consumer electronics – STB, LCD, TV, printers

• General purpose POL DC‐DC converters

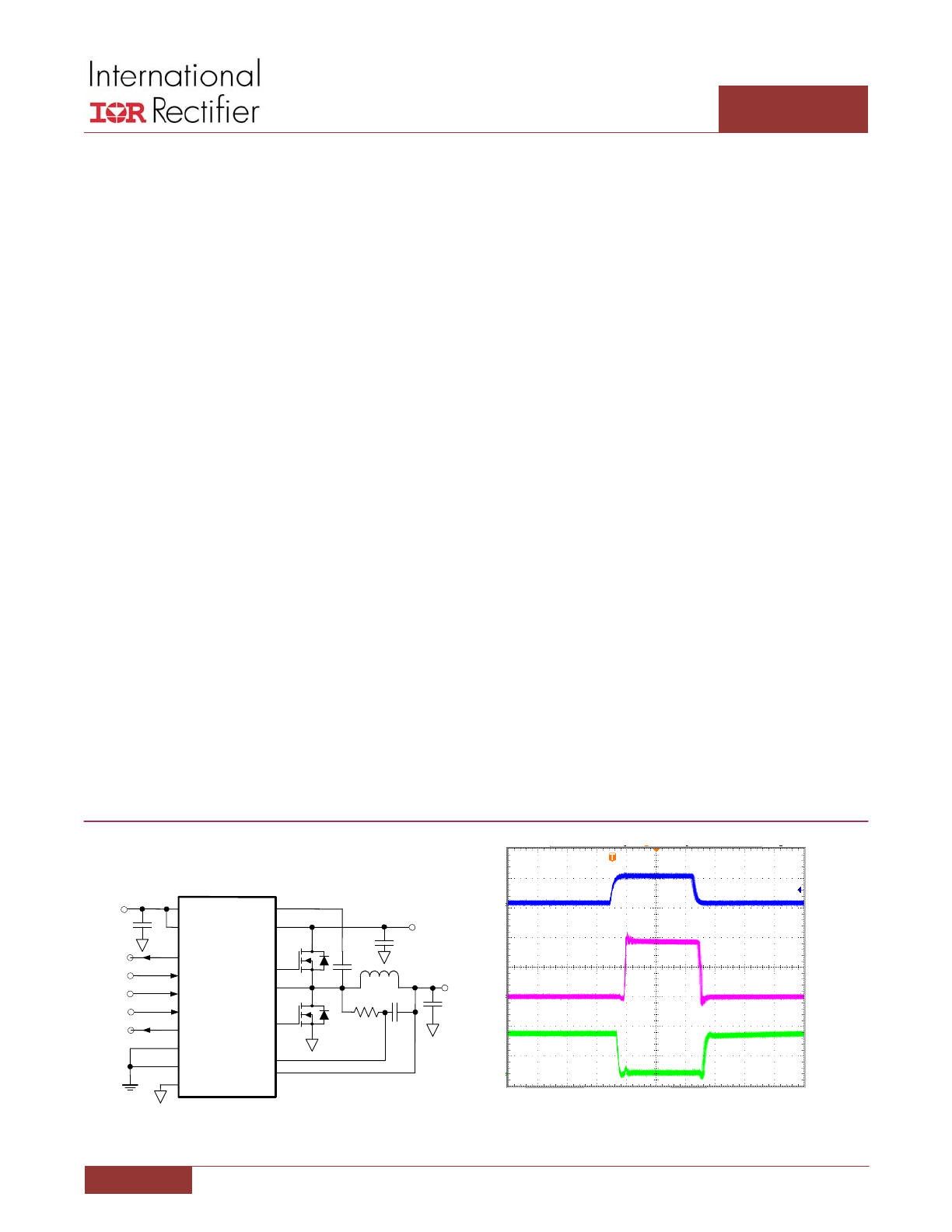

BASIC APPLICATION

SW

PWM

VIN

PGND

VCC

VCC

BOOST

VIN

VOUT

PWM

CSIN+

CSIN‐

4.5V to 7V

LGND

IOUT

IOUT

BBRK#

BBRK#

REFIN

REFIN

4.5V to 14V

IR3535

PHSFLT#

PHSFLT#

GATEL

GATEH

PVCC

TGND

Figure 1: IR3535 Basic Application Circuit

DESCRIPTION

The IR3535 is a high performance, floating N‐channel

MOSFET driver that is optimized for maximum efficiency

delivery of a synchronous buck converter. It is a “Smart”

driver that continually monitors MOSFET conditions,

contains self‐calibrating inductor current sense amplifier,

and provides diode emulation mode with local zero current

detection.

The integrated current sense amplifier achieves superior

current sense accuracy vs. best‐in‐class controller based

inductor DCR sense methods while delivering the clean and

accurate current report information.

The IR patented Body‐Braking

™

feature reduces inductor

to output capacitor energy transfer during load release

which allows the output capacitor bank to be reduced.

Diode emulation mode in the IR3535 alleviates the zero‐

current detection and control burden from the PWM

controller and increases system light load efficiency.

The IR3535 monitors MOSFET conditions and temperature

and reports phase fault if MOSFET short, MOSFET open or

over temperature is detected.

Up to 1.0MHz switching frequency capability enables high

performance transient response, miniaturization of output

inductors, as well as reduced input and output capacitors

while maintaining industry leading efficiency. Solution

size, thermal performance and cost can be optimized by

combining with IR’s DirectFET

™

MOSFETs and utilizing a

dual sided layout.

Figure 2: IR3535 Gate Driver Waveforms

PWM

5V/div

GATEH

10V/div

GATEL

5V/div

100ns/div

March 13, 2013 | FINAL DATASHEET

2

IR3535

Synchronous Buck Converter Driver

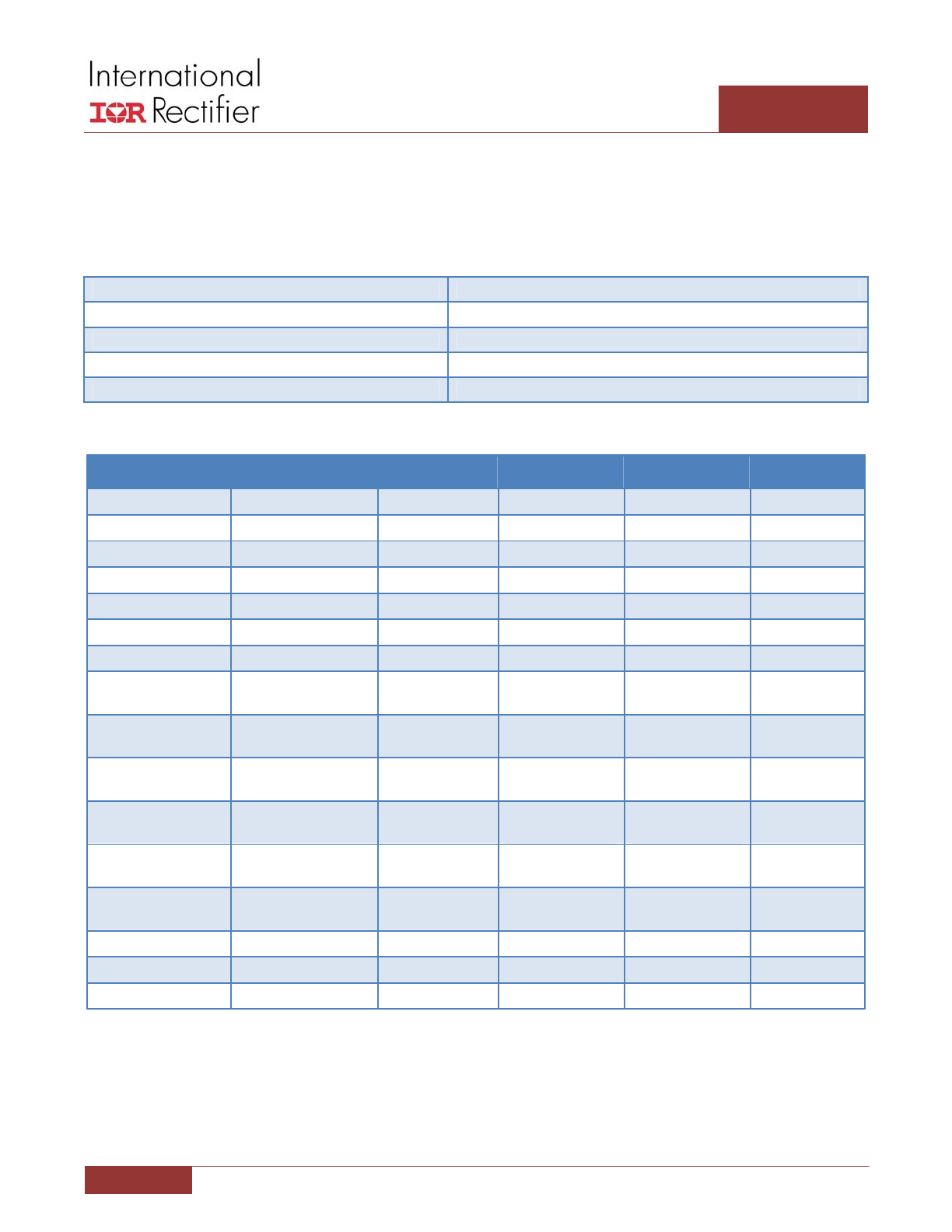

ORDERING INFORMATION

Package

Tape & Reel Qty

Part Number

16 Lead MLPQ

(3 x 3 mm body)

3000

IR3535MTRPBF

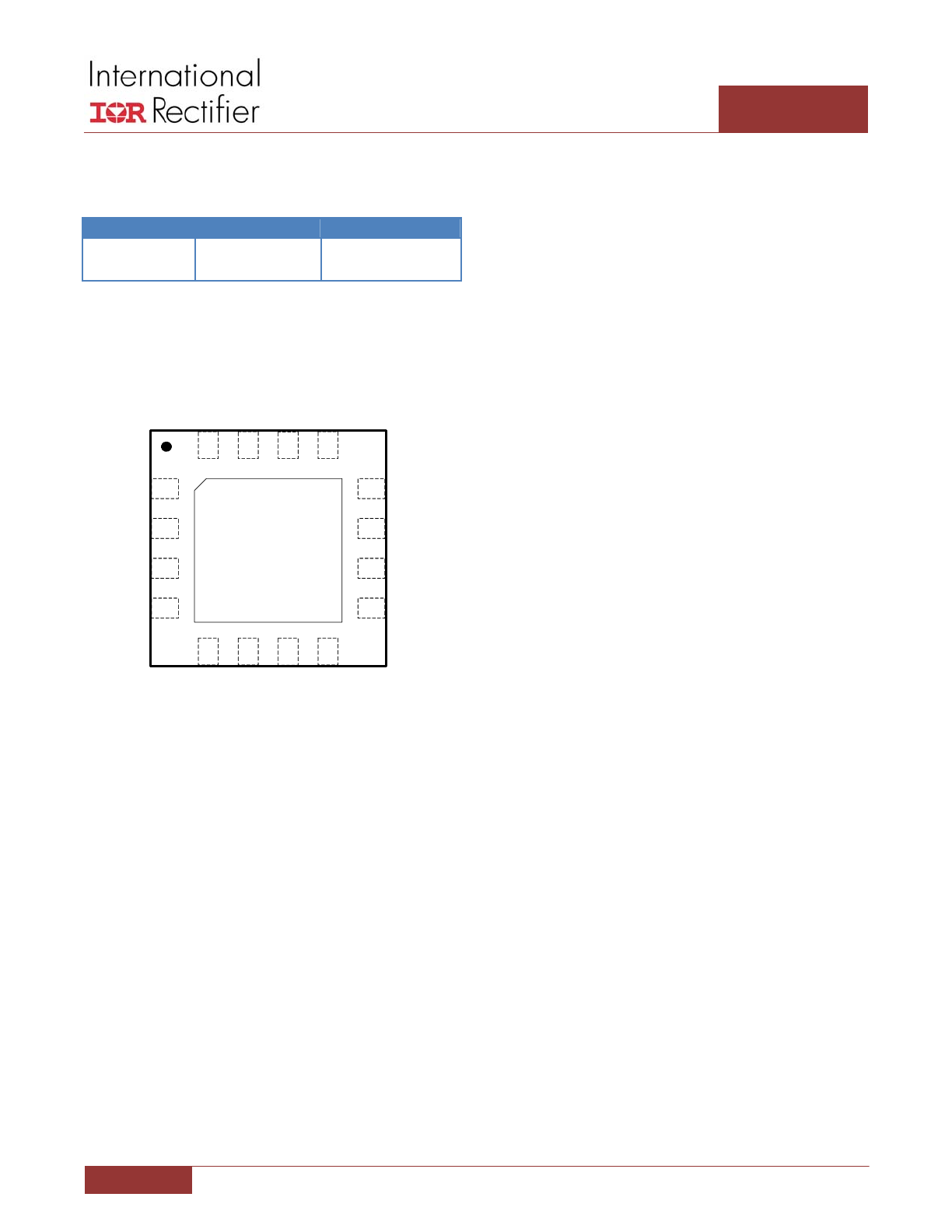

PIN DIAGRAM

BBR#

1

LGND

CS

IN

‐

REFIN

2

3

IOUT

GATEH

SW

PGND

GATEL

4

12

11

10

9

5

6

7

8

16

15

14

13

CS

IN

+

VCC

PV

CC

PW

M

PH

SF

LT

#

VI

N

BOOS

T

IR3535

17

TGND

Figure 3: IR3535 Pin Diagram (Top View)

March 13, 2013 | FINAL DATASHEET

3

IR3535

Synchronous Buck Converter Driver

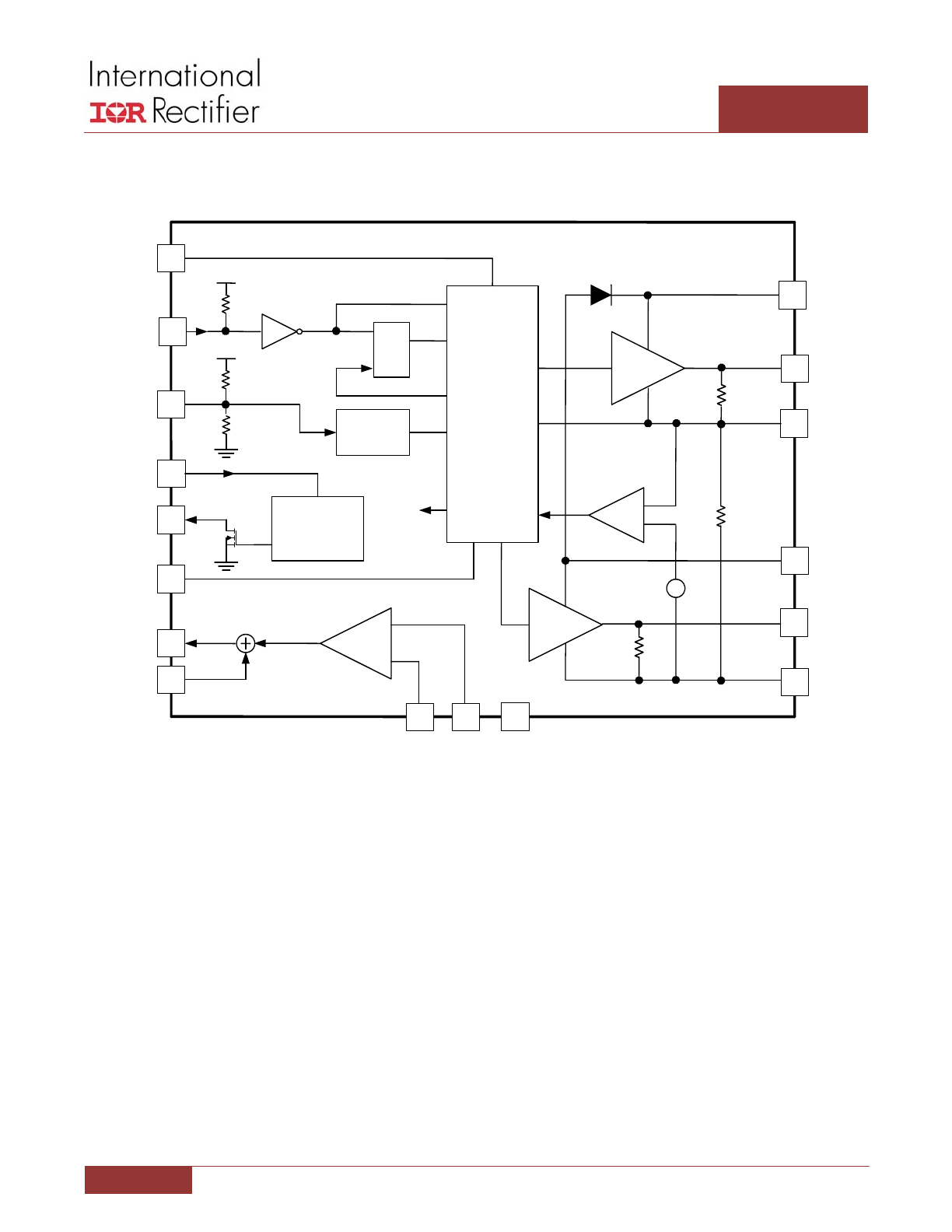

FUNCTIONAL BLOCK DIAGRAM

PWM

11

14

VIN

SW

5

10

CSIN‐

PGND

13 BOOST

Power‐on

Reset

(POR),

3.3V

Reference,

and

Dead‐time

Control

16

IOUT

4

VCC

7

BBR#

1

9

GATEL

Driver

Driver

15

PHSFLT#

6

CSIN+

2

LGND

3

REFIN

Current Sense

Amplifier

MOSFET

& Thermal

Detection

S Q

R

POR

3.3V

VCC

‐

+

3.3V

200k

‐

+

Diode

Emulation

Comparator

IR3535

Offset

‐

+

12 GATEH

8

PVCC

80k

80k

3.3V

Tri‐state

Logic

5.1k

5.1k

X32.5

17

TGND

Figure 4: IR3535 Functional Block Diagram

March 13, 2013 | FINAL DATASHEET

4

IR3535

Synchronous Buck Converter Driver

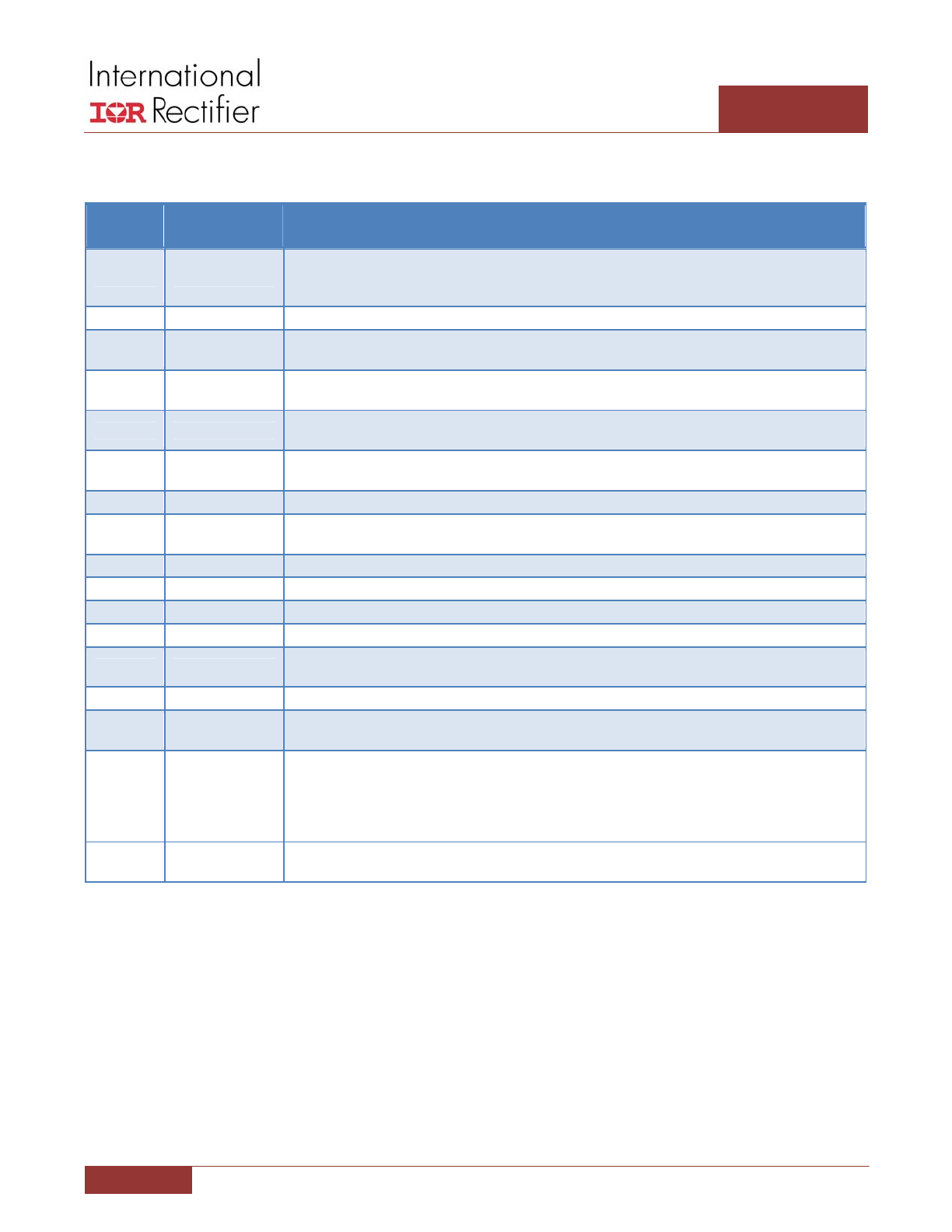

PIN DESCRIPTIONS

PIN #

PIN NAME

PIN DESCRIPTION

1

BBR#

3.3V logic level input, 7V tolerant, with internal weak pull‐up to 3.3V. Logic “Low” to disable both

MOSFETs. Pulling BBR# low momentarily after VCC passes its UVLO threshold activates the Diode

Emulation Mode.

2

LGND

Ground for control logic and analog circuits. IC substrate is connected to this pin.

3

REFIN

Reference voltage input from the PWM controller. The current sense signal is referenced to the

voltage on this pin. Connect to LGND if the current sense amplifier is not used.

4

IOUT

Voltage on this pin is equal to V(REFIN) + 32.5

*

[V(CSIN+) – V(CSIN‐)]. Float this pin if the current

sense amplifier is not used.

5

CSIN‐

Inverting input to the current sense amplifier. Connect to LGND if the current sense amplifier is not

used.

6

CSIN+

Non‐Inverting input to the current sense amplifier. Connect to LGND if the current sense amplifier

is not used.

7

VCC

Bias voltage for control logic and analog functions.

8

PVCC

Voltage for low‐side MOSFET driver. Internal bootstrap synchronous PFET is connected from this

pin to the BOOST pin. Connect a 1uF capacitor between PVCC and PGND.

9

GATEL

Low‐side driver output and input to GATEH non‐overlap comparator.

10

PGND

Return for low side driver and reference for GATEH non‐overlap comparator.

11

SW

Return for high‐side driver and reference for GATEL non‐overlap comparator.

12

GATEH

High‐side driver output and input to GATEL non‐overlap comparator.

13

BOOST

Supply for high‐side driver. Internal bootstrap synchronous PFET is connected between this pin

and the PVCC pin. Connect a minimum 0.22µF 16Vdc capacitor from BOOST to SW pin.

14

VIN

Power rail input for phase fault detection.

15

PHSFLT#

Open collector output of the phase fault comparators. 7V tolerant, connect to an external

pull‐up resistor. Output is low when a MOSFET fault or over temperature condition is detected.

16

PWM

3.3V logic level Tri‐state PWM input, 7V tolerant. “High” turns the control MOSFET on, and “Low”

turns the synchronous MOSFET on.

“Tri‐state” turns the control MOSFET off without delay.

Depending on the mode the IR3535,

“Tri‐state” either turns the synchronous MOSFET off without

delay in Body‐Braking™ mode or turns synchronous MOEFET off when the current reaches zero in

diode emulation mode. See “Theory of Operation” section for further details.

17

TGND

Ground pad for thermal dissipation. Connected to IC substrate. Connect this pad to ground planes

through four vias.

March 13, 2013 | FINAL DATASHEET

5

IR3535

Synchronous Buck Converter Driver

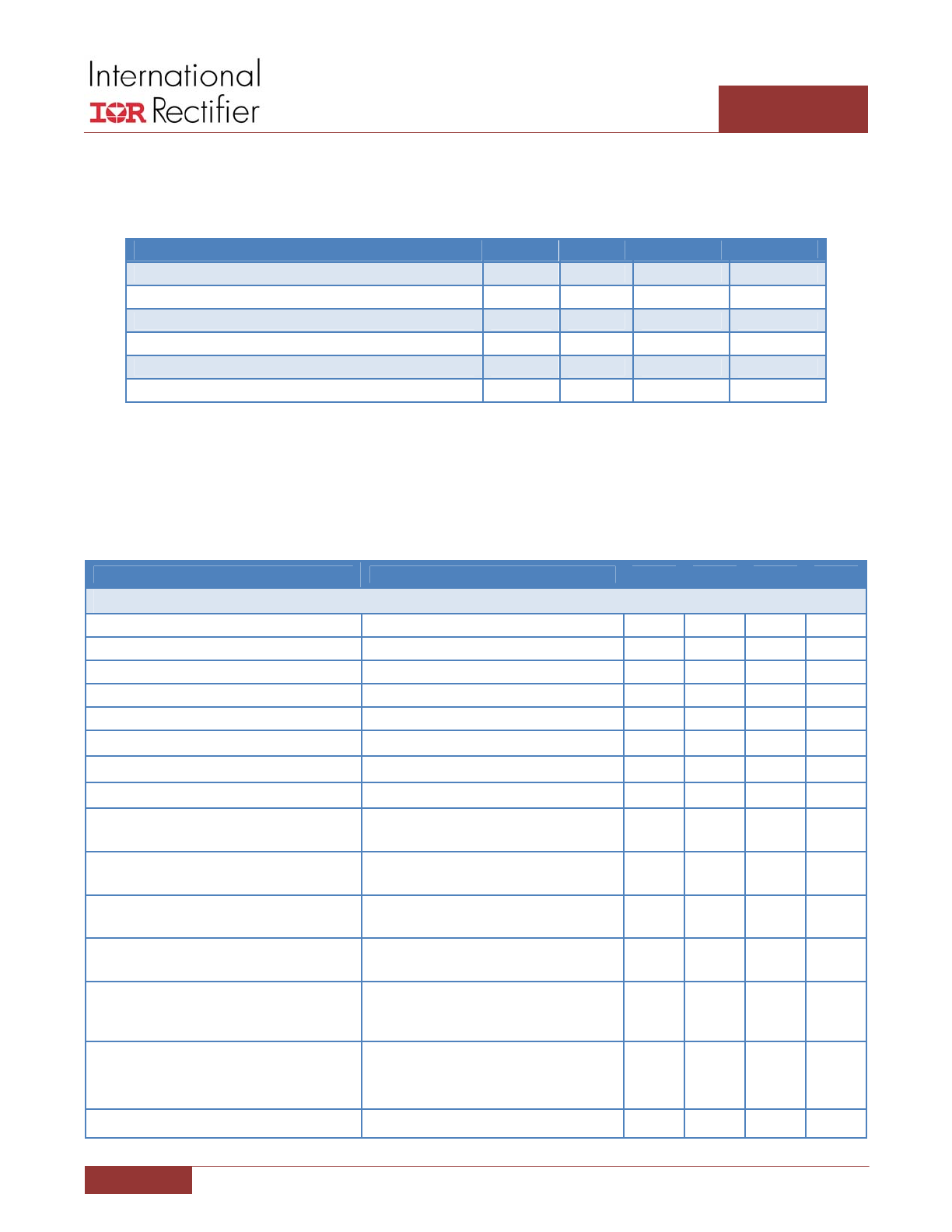

ABSOLUTE MAXIMUM RATINGS

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are

stress ratings only and functional operation of the device at these or any other conditions beyond those indicated in the

operational sections of the specifications are not implied.

Storage Temperature Range

‐65°C to 150°C

Operating Junction Temperature

0°C to 150°C

ESD Rating

HBM Class 1C JEDEC Standard

MSL Rating

2

Reflow Temperature

260°C

PIN Number

PIN NAME

V

MAX

V

MIN

I

SOURCE

I

SINK

1

BBR#

8V

‐0.3V

1mA

1mA

2

LGND

n/a

n/a

n/a

n/a

3

REFIN

3.5V

‐0.3V

1mA

1mA

4

IOUT

8V

‐0.3V

5mA

5mA

5

CSIN‐

8V

‐0.3V

1mA

1mA

6

CSIN+

8V

‐0.3V

1mA

1mA

7

VCC

8V

‐0.3V

n/a

15mA

8

PVCC

8V

‐0.3V

n/a

5A for 100ns,

100mA DC

9

GATEL

8V

‐0.3V DC,

‐5V for 100ns

5A for 100ns,

200mA DC

7A for 100ns,

200mA DC

10

PGND

0.3V

‐0.3V

7A for 100ns,

200mA DC

n/a

11

SW

25V

‐0.3V DC,

‐10V for 100ns

5A for 100ns,

100mA DC

n/a

12

GATEH

33V

‐0.3V DC,

‐10V for 100ns

5A for 100ns,

100mA DC

5A for 100ns,

100mA DC

13

BOOST

33V

‐0.3V

1A for 100ns,

100mA DC

3A for 100ns,

100mA DC

14

VIN

16V

‐0.3V

n/a

1mA

15

PHSFLT#

8V

‐0.3V

1mA

20mA

16

PWM

8V

‐0.3V

1mA

1mA

Note:

1. Maximum GATEH – SW = 8V

2.

Maximum BOOST – GATEH = 8V

March 13, 2013 | FINAL DATASHEET

6

IR3535

Synchronous Buck Converter Driver

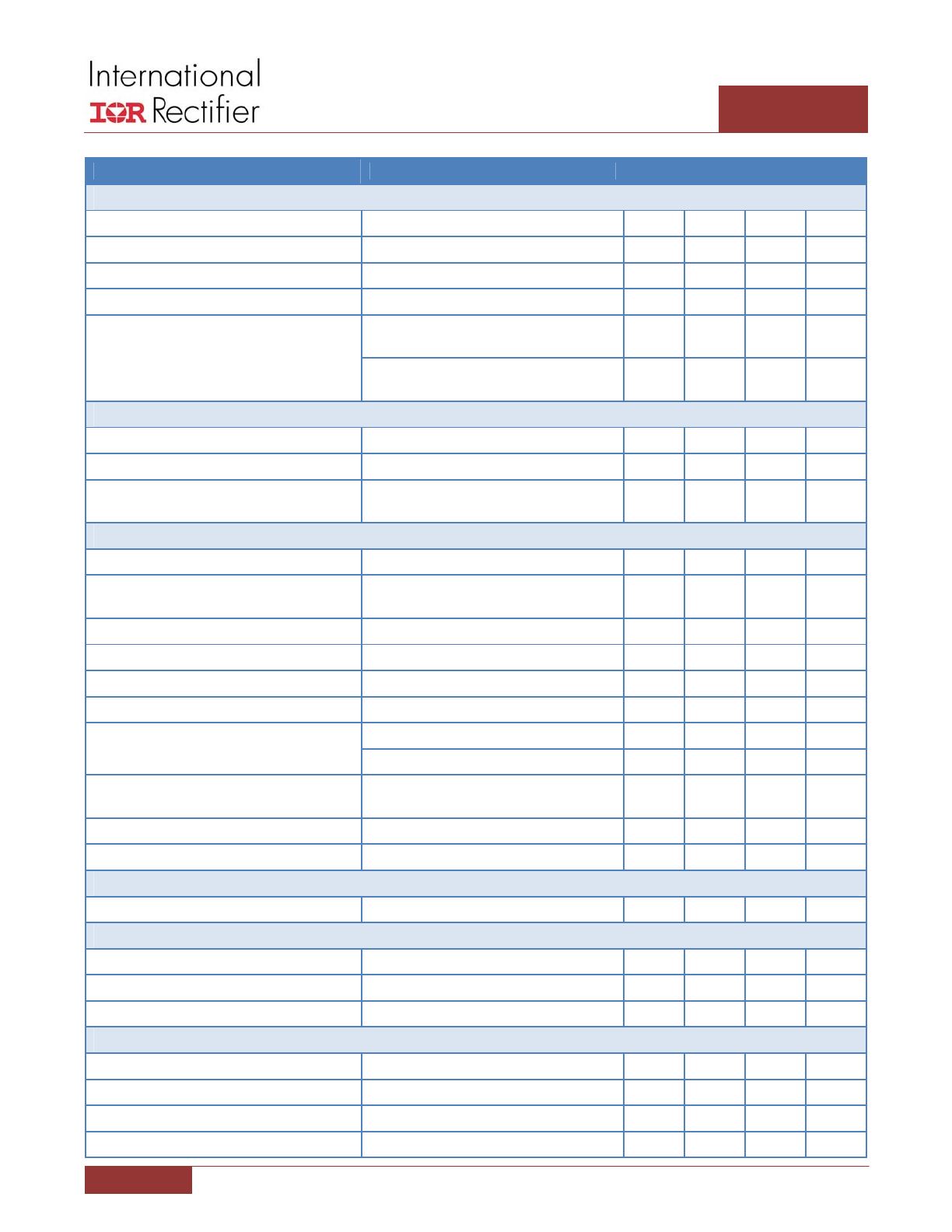

ELECTRICAL SPECIFICATIONS

RECOMMENDED OPERATING CONDITIONS FOR RELIABLE OPERATION WITH MARGIN

SYMBOL

MIN

MAX

UNITS

Recommended VIN Range

VIN

4.5

14

V

Recommended VCC Range

VCC

4.5

7

V

Recommended REFIN Range (V

CC

= 4.5V to 5.5V)

REFIN

0.25

2.0

V

Recommended REFIN Range (V

CC

= 5.5V to 7V)

REFIN

0.25

3.3

V

Recommended Switching Frequency

F

SW

200

1000

kHz

Recommended Operating Junction Temperature

T

J

0

125

°C

ELECTRICAL CHARACTERISTICS

The electrical characteristics involve the spread of values guaranteed within the recommended operating conditions.

Typical values represent the median values, which are related to 25°C.

C

GATEH

= 3.3nF, C

GATEL

= 6.8nF (unless otherwise specified).

PARAMETER

CONDITIONS

MIN

TYP

MAX

UNIT

Gate Drivers

GATEH Source Resistance

BOOST – SW = 7V

670

MΩ

GATEH Sink Resistance

BOOST – SW = 7V

670

MΩ

GATEL Source Resistance

PVCC – PGND = 7V

670

MΩ

GATEL Sink Resistance

PVCC – PGND = 7V

300

MΩ

GATEH Source Current

BOOST = 7V, GATEH = 2.5V, SW = 0V

3

A

GATEH Sink Current

BOOST = 7V, GATEH = 2.5V, SW = 0V

4

A

GATEL Source Current

PVCC = 7V, GATEL = 2.5V, SW = 0V

4

A

GATEL Sink Current

PVCC = 7V, GATEL = 2.5V, SW = 0V

6

A

GATEH Rise Time

BOOST – SW = 7V, measure 1V to 4V

transition time

5

10

ns

GATEH Fall Time

BOOST – SW = 7V, measure 4V to 1V

transition time

4

8

ns

GATEL Rise Time

PVCC – PGND = 7V, measure 1V to 4V

transition time

10

20

ns

GATEL Fall Time

PVCC – PGND = 7V, measure 4V to 1V

transition time

5

10

ns

GATEL Low to GATEH High Delay

BOOST = PVCC = 7V, SW = PGND = 0V,

measure time from GATEL falling to 1V to

GATEH rising to 1V

10

15

30

ns

GATEH Low to GATEL High Delay

BOOST = PVCC = 7V, SW = PGND = 0V,

measure time from GATEH falling to 1V to

GATEL rising to 1V

10

15

30

ns

Disable Pull Down Resistance

GATEH to SW, GATEL to PGND

30

80

130

KΩ

March 13, 2013 | FINAL DATASHEET

7

IR3535

Synchronous Buck Converter Driver

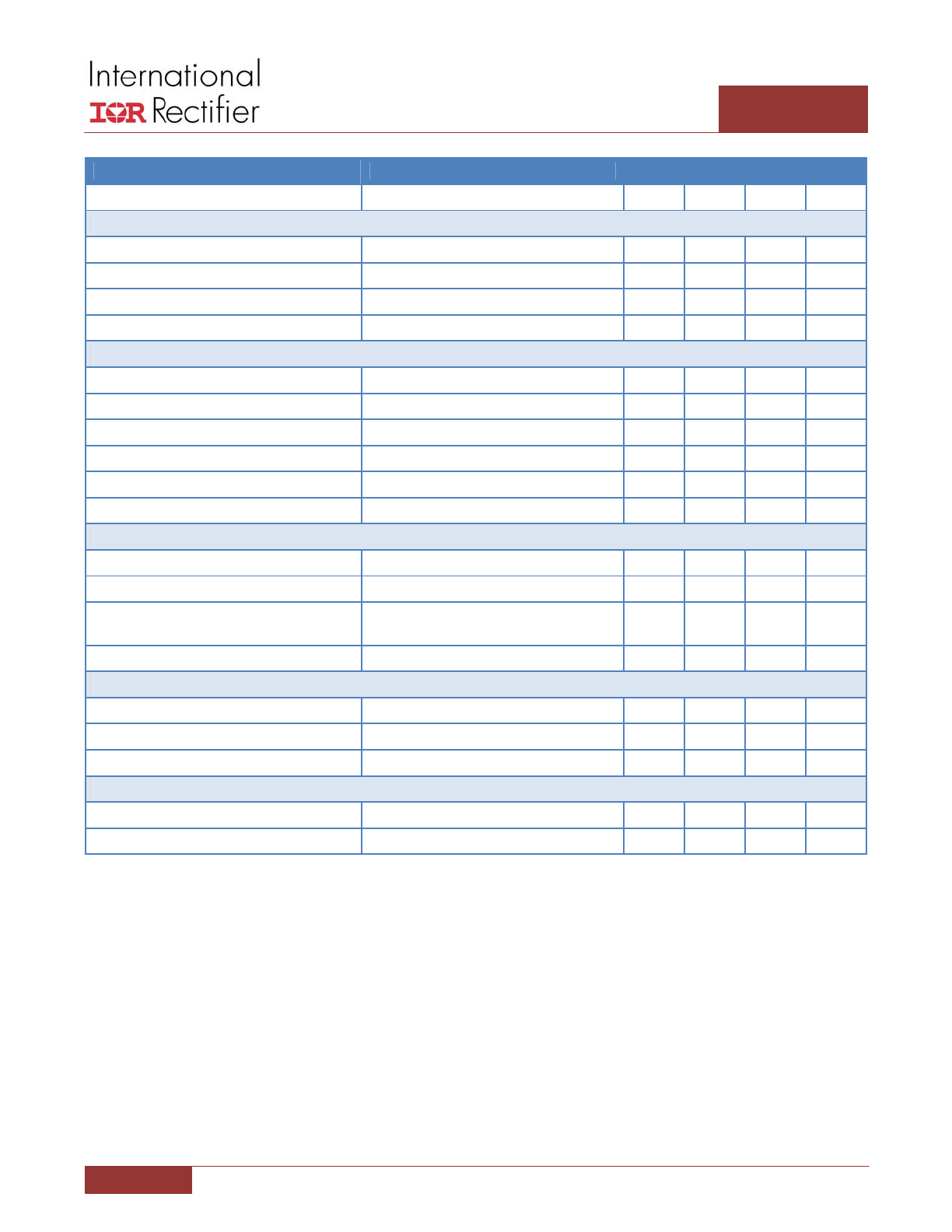

PARAMETER

CONDITIONS

MIN

TYP

MAX

UNIT

PWM Comparator

High Side Switch Threshold

PWM Low or PWM Tri‐State to High

2.5

V

Low Side Switch Threshold

PWM High or PWM Tri‐State to Low

0.8

V

PWM Tri‐State Float Voltage

Floating

1.2

1.65

2.1

V

Hysteresis

Active to Tri‐State to Active, Note 1

65

76

100

mV

Tri‐State Propagation Delay Time

C

PWM

= 20pF, measure from V(PWM) = 0V

to GATEL < 1V

190

ns

C

PWM

= 20pF, measure from V(PWM) = 5V

release to GATEH < 1V

380

ns

PWM Input

Sinking Impedance

3.67

5.1

8.7

KΩ

Source Impedance

3.67

5.1

8.7

KΩ

GATEH Turn‐Off Propagation Delay

Measure from V(PWM) falling edge to

GATEH < 1V

25

45

ns

Current Sense Amplifier

CSIN+/‐ Bias Current

‐100

0

100

nA

Input Offset Voltage

CSIN+ = CSIN‐ = REFIN, measure input

referred offset from REFIN

‐750

750

µV

Calibrated Input Offset Voltage

Self‐calibrated offset, Note 1

‐450

0

450

µV

Gain

0.5V ≤ V(REFIN) < 2.25

30

32.5

35

V/V

Unity Gain Bandwidth

C(IOUT) = 10pF, measure at IOUT. Note 1

4.8

6.8

8.8

MHz

Slew Rate

6

V/µs

Differential Input Range

0.8V ≤ V(REFIN) ≤ 2.25V, Note 1

‐10

25

mV

0.25V ≤ V(REFIN) ≤ 0.8V, Note 1

‐5

25

mV

Common Mode Input Range

0

VCC –

2.5

V

Output Impedance

62

200

Ω

IOUT Sink Current

Driving external 3 kΩ

0.5

0.8

1.1

mA

Bootstrap Diode

Forward Voltage

I(BOOST) = 30mA, VCC = 6.8V

360

520

960

mV

Digital Output ― Phase Fault

VOH

HIGH Level Pull‐Up Voltage

7

V

VOL

I(PHSFLT#) = 4mA

150

300

mV

Leakage Current

V(PHSFLT#) = 5.5V

0

1

µA

Phase Fault Detection

Top Side Threshold

Measure from Vin to SW

1.9

2.2

2.5

V

Bottom Side Threshold

150

200

250

mV

Bottom FET Open Threshold

‐250

‐215

‐180

mV

Propagation Delay

PWM High to PWM Low Cycles

15

Cycles

March 13, 2013 | FINAL DATASHEET

8

IR3535

Synchronous Buck Converter Driver

PARAMETER

CONDITIONS

MIN

TYP

MAX

UNIT

Operating Bias Voltage

4.5

7

V

Digital Input ― BBR#

VIL

Input Low Threshold

0.8

V

VIH

Input High Threshold

2.0

V

Internal Pull Up Resistance

VCC > UVLO

69

200

340

KΩ

Internal Pull Up Voltage

VCC > UVLO

3.3

V

General

VCC Supply Current

4

8

12

mA

VIN Supply Curent

4.5 ≤ V(VIN) ≤ 14V

0.05

0.15

0.4

mA

Switch Node Bias Current

5

mA

BOOST Supply Current

4.75 ≤ V(BOOST) – V(SW) ≤ 7V

0.5

1.5

3

mA

REFIN Bias Current

‐1.5

0

1

µA

SW Floating Voltage

CSIN‐ tied to SW, PWM Tri‐State

0.1

0.3

0.4

V

Diode Emulation Mode Comparator

Input Offset Voltage

Note 2

‐12

‐3

3

mV

Leading Edge Blanking Time

V(GATEL) > 1V Starts Timer, Note 1

100

150

200

ns

Propagation Delay

Blanking Expired, +2.5mV overdrive to

V(GATEL) < 1V, Note 1

41

50

ns

Negative Current Time‐Out

PWM = Tri‐State, V(SW) < = ‐10mV

20

30

45

µs

VCC Under Voltage Lockout

Start

3.3

3.7

4.1

V

Stop

3

3.4

3.8

V

Hysteresis

0.25

0.35

0.45

V

Thermal Flag

Rising Threshold

PHSFLT# Drives Low. Note 1

115

°C

Falling Threshold

Note 1

95

°C

Note:

1. Guaranteed by design but not tested in production

2.

The Diode Emulation Mode (DEM) comparator measures the SW against PGND. The input offset is biased slightly to the negative so

that a slightly positive current in the synchronous MOSFET is treated as zero current to accommodate propagation delays and

untrimmed accuracy.

March 13, 2013 | FINAL DATASHEET

9

IR3535

Synchronous Buck Converter Driver

THEORY OF OPERATION

DESCRIPTION

The IR3535 is a synchronous buck driver which provides

system designers with ease of use and flexibility required

in cutting edge CPU, GPU and memory power delivery

designs. The IR3535 is designed to work with a controller

that provides the PWM signal. The IR3535 incorporates a

continuously self‐calibrated current sense amplifier,

optimized for use with inductor DCR sensing. The current

sense amplifier provides signal gain and noise immunity,

providing multiphase systems with a superior design

toolbox for programmed impedance designs.

The IR3535 also provides a phase fault signal capable of

detecting open or shorted MOSFETs, or an over‐

temperature condition in the vicinity of the driver.

The IR3535 accepts an active low Body‐Braking™ input

which disables the output MOSFETs to enhance transient

performance or provide a high impedance output.

The IR3535 PWM input is compatible with 3.3V logic and

7V tolerant. It accepts 3‐level PWM input signals, with a

diode emulation feature when the PWM signal is floated,

allowing designers to maximize system efficiency at light

loads without compromising transient performance.

BODY‐BRAKING™ MODE

There are two ways to place the IR3535 in Body‐Braking™

mode, in which two MOSFETs are turned off.

Pulling BBR# low forces the IR3535 into Body‐Braking™

mode rapidly, which is used to enhance transient response

after load release or provide a high impedance output.

If the BBR# input is high and has not been low since power

on, the Body‐Braking™ is activated when the PWM input

enters the tri‐state region, which is withing a range around

1.65V. The Body‐Braking™ response is slower due to the

hold‐off time created by the paracitic capacitor with pull‐

up or pull‐down resistor at PWM pin. For better

performance, no more than 100pF parasitic capacitive load

should be present on the PWM line of IR3535.

DIODE EMULATION MODE

An additional feature of the IR3535 is diode emulation

mode. This function improves efficiency by preventing

negative inductor current from flowing in the synchronous

MOSFET.

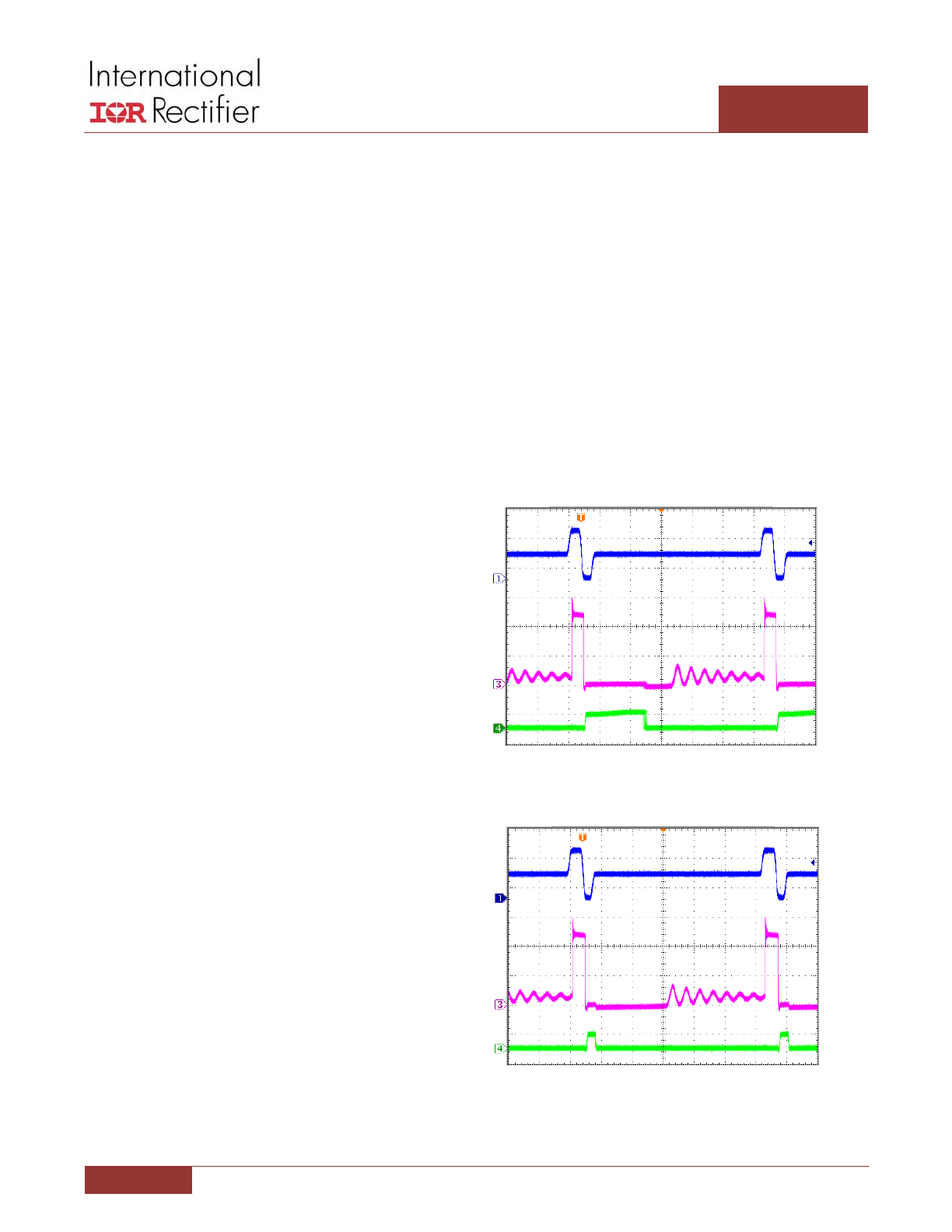

As shown in Figure 5, when the PWM input enters the tri‐

state region the control MOSFET is turned off first, and the

synchronous MOSFET is initially turned on and then is

turned off when the output current reaches zero. If the

sensed output current does not reach zero within a set

amount of time the gate driver will assume that the output

is de‐biased and turn off the synchronous MOSFET,

allowing the switch node to float.

This is in contrast to the Body‐Braking® mode shown in

Figure 6, where GATEL follows PWM input. The Schottky

diode in parallel with the synchronous MOSFET conducts

for a longer period of time and therefore lowers the light

load efficiency.

Figure 5: Diode Emulation Mode

Figure 6: Body‐Braking® Mode

PWM

2V/div

SW

5V/div

400ns/div

GAETL

10V/div

PWM

2V/div

SW

5V/div

400ns/div

GATEL

10V/div

March 13, 2013 | FINAL DATASHEET

10

IR3535

Synchronous Buck Converter Driver

The zero current detection circuit in the IR3535 is

independent of the current sense amplifier and therefore

still functions even if the current sense amplifier is not

used. As shown in Figure 4, an offset is added to the diode

emulation comparator so that a slightly positive output

current in the inductor and synchronous MOSFET is treated

as zero current to accommodate propagation delays,

preventing any negative current flowing in the

synchronous MOSFET. This causes the Schottky diode in

parallel with the synchronous MOSFET to conduct before

the inductor current actually reaches zero, and the

conduction time increases with inductance of the output

inductor.

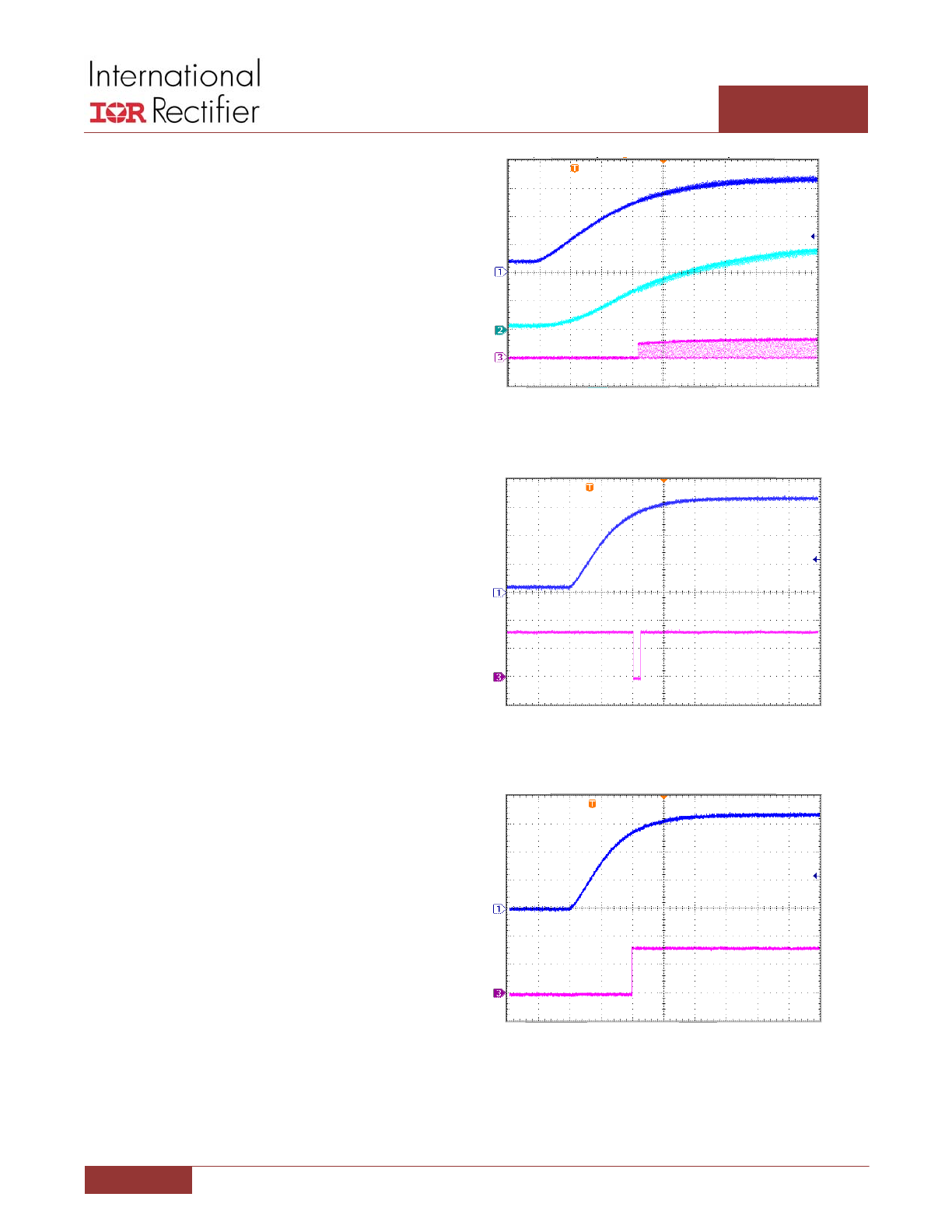

To set the IR3535 in diode emulation mode, the BBR# pin

must be toggled low at least once after the VCC passes its

UVLO threshold during power up. One simple way is to use

the internal BBR# pull‐up resistor (200kΩ typical) with an

external capacitor from BBR# pin to LGND. To ensure the

diode emulation mode is properly set, the BBR# voltage

should be lower than 0.8V when the VCC voltage passes its

UVLO threshold (3.3V minimum and 3.7V typical), as

shown in Figure 7. A digital signal from the PWM controller

can also be used to set the diode emulation mode. The

BBR# signal can either be pulled low for at least 20ns after

the VCC passes its UVLO threshold, as shown in Figure 8, or

be pulled low before VCC power up and then released

after the VCC passes its UVLO threshold, as shown in

Figure 9.

Once the diode emulation mode is set, it cannot be reset

until the VCC power is recycled.

TRI‐STATE GATE DRIVERS

The gate drivers can deliver up to 4A peak current and 6A

sink current for low side driver. An adaptive non‐overlap

circuit monitors the voltage on the internal GATEH and

GATEL pins to prevent MOSFET shoot‐through current

while minimizing body diode conduction. Tri‐state

operation prevents negative inductor current and negative

output voltage during power‐down. The gate driver

incorporates pull down resistors on the MOSFET gates to

prevent spurious turn‐on of the output stage even when

the IC is off and there is a high dV/dt event on the VIN

supply rail. The gate drivers pull low if the supply voltages

are below the normal operating range.

PHASE FAULT CIRCUIT AND THERMAL

FLAG CIRCUIT (PHSFLT#)

The IR3535 phase fault circuit monitors the switch node

with respect to VIN and ground to determine whether

Figure 7: Diode Emulation Setup through BBR# Capacitor

Figure 8: Diode Emulation Setup through BBR# Input

Figure 9: Diode Emulation Setup through BBR# Input

there is a defective MOSFET in the converter. The output

of the PHSFLT# is high during normal operation and

becomes low when there is a fault. The driver monitors the

VCC

2V/div

BBR#

1V/div

2ms/div

SW

10V/div

VCC

2V/div

BBR#

2V/div

4ms/div

VCC

2V/div

BBR#

2V/div

4ms/div