IRFI4227PbF

Description

This HEXFET

®

Power MOSFET is specifically designed for Sustain; Energy Recovery & Pass switch applications in

Plasma Display Panels. This MOSFET utilizes the latest processing techniques to achieve low on-resistance per silicon

area and low EPULSE rating. Additional features of this MOSFET are 150°C operating junction temperature and high

repetitive peak current capability. These features combine to make this MOSFET a highly efficient, robust and reliable

device for PDP driving applications

1

2017-04-27

Absolute Maximum Ratings

Symbol Parameter

Max.

Units

V

GS

Gate-to-Source Voltage

± 30

V

I

D

@ T

C

= 25°C

Continuous Drain Current, V

GS

@ 10V

26

A

I

D

@ T

C

= 100°C

Continuous Drain Current, V

GS

@ 10V

17

I

DM

Pulsed Drain Current 100

I

RP

@ T

C

= 100°C

Repetitive Peak Current 47

P

D

@T

C

= 25°C

Maximum Power Dissipation

46

W

P

D

@T

C

= 100°C

Maximum Power Dissipation

18

Linear Derating Factor

0.37

W/°C

T

J

Operating Junction and

T

STG

Storage Temperature Range

°C

Soldering Temperature, for 10 seconds (1.6mm from case)

300

Mounting torque, 6-32 or M3 screw

10 lbf•in (1.1N•m)

-40 to + 150

G D S

Gate Drain

Source

Features

Advanced Process Technology

Key Parameters Optimized for PDP Sustain,

Energy Recovery and Pass Switch Applications

Low

E

PULSE

Rating to Reduce Power

Dissipation in PDP Sustain, Energy Recovery

and Pass Switch Applications

Low

Q

G

for Fast Response

High Repetitive Peak Current Capability for

Reliable

Operation

Short Fall & Rise Times for Fast Switching

150°C Operating Junction Temperature for

Improved

Ruggedness

Repetitive Avalanche Capability for Robustness and

Reliability

HEXFET

®

Power MOSFET

TO-220 Full-Pak

Base Part Number

Package Type

Standard Pack

Orderable Part Number

Form Quantity

IRFI4227PbF

TO-220 Full-Pak

Tube

50 IRFI4227PbF

Thermal Resistance

Symbol Parameter

Typ.

Max.

Units

R

JC

Junction-to-Case –––

2.73

R

JA

Junction-to-Ambient

–––

65

°C/W

G

D

S

Key Parameters

V

DS

max 200

V

V

DS (Avalanche)

typ. 240

V

R

DS(ON)

typ. @ 10V

21

m

I

RP

max @ T

C

= 100°C

47

A

T

J

max

150

°C

IRFI4227PbF

2

2017-04-27

Notes:

Repetitive rating; pulse width limited by max. junction temperature.

starting T

J

= 25°C, L = 0.44mH, R

G

= 25

, I

AS

= 16A.

Pulse width

400µs; duty cycle 2%.

R

θ

is measured at T

J

of approximately 90°C.

Half sine wave with duty cycle = 0.25, ton=1μsec.

Electrical Characteristics @ T

J

= 25°C (unless otherwise specified)

Parameter Min.

Typ.

Max.

Units

Conditions

V

(BR)DSS

Drain-to-Source Breakdown Voltage

200

–––

–––

V

V

GS

= 0V, I

D

= 250µA

V

(BR)DSS

/

T

J

Breakdown Voltage Temp. Coefficient

–––

240

––– mV/°C Reference to 25°C, I

D

= 1mA

R

DS(on)

Static Drain-to-Source On-Resistance

–––

21

25

m

V

GS

= 10V, I

D

= 17A

V

GS(th)

Gate Threshold Voltage

3.0

–––

5.0

V

V

GS(th)/

T

J

Gate Threshold Voltage Temp. Coefficient –––

-11

––– mV/°C

I

DSS

Drain-to-Source Leakage Current

––– ––– 20 µA V

DS

= 200V, V

GS

= 0V

––– ––– 1.0 mA V

DS

= 200V,V

GS

= 0V,T

J

=150°C

I

GSS

Gate-to-Source Forward Leakage

–––

–––

100

nA

V

GS

= 20V

Gate-to-Source Reverse Leakage

–––

––– -100

V

GS

= -20V

gfs

Forward Trans conductance

47

–––

–––

S

V

DS

= 25V, I

D

= 17A

Q

g

Total Gate Charge

–––

73

110

nC

I

D

= 17A,V

DS

= 100V

Q

gd

Gate-to-Drain Charge

–––

21

–––

V

GS

= 10V

t

d(on)

Turn-On Delay Time

–––

17

–––

ns

V

DD

= 100V, V

GS

= 10V

t

r

Rise Time

–––

19

–––

I

D

= 17A

t

d(off)

Turn-Off Delay Time

–––

11

–––

R

G

= 2.5

t

f

Fall Time

–––

29

–––

See Fig. 22

t

st

Shoot Through Blocking Time

100

–––

–––

ns V

DD

= 160V,V

GS

= 15V,R

G

= 4.7

E

PULSE

Energy per Pulse

––– 570 –––

µJ

L = 220nH, C = 0.4µF, V

GS

= 15V

V

DD

= 160V, R

G

= 4.7

T

J

= 25°C

––– 910 –––

L = 220nH, C = 0.4µF, V

GS

= 15V

V

DD

= 160V, R

G

= 4.7

T

J

= 100°C

C

iss

Input Capacitance

––– 4600 –––

pF

V

GS

= 0V

C

oss

Output Capacitance

–––

460

–––

V

DS

= 25V

C

rss

Reverse Transfer Capacitance

–––

91

–––

ƒ = 1.0MHz

C

oss

eff.

Effective Output Capacitance

–––

360

–––

V

GS

= 0V, V

DS

= 20V to 160V

L

D

Internal Drain Inductance

–––

4.5

–––

nH

Between lead,

6mm (0.25in.)

L

S

Internal Source Inductance

–––

7.5

–––

from package

and center of die contact

V

DS

= V

GS

, I

D

= 250µA

Diode Characteristics

Parameter

Min. Typ. Max. Units

Conditions

I

S

@ T

C

= 25°C

Continuous Source Current

––– ––– 26

A

MOSFET symbol

(Body Diode)

showing the

I

SM

Pulsed Source Current

––– ––– 100

integral reverse

(Body Diode)

p-n junction diode.

V

SD

Diode Forward Voltage

–––

–––

1.3

V T

J

= 25°C,I

S

= 17A,V

GS

= 0V

t

rr

Reverse Recovery Time

–––

93

140

ns T

J

= 25°C ,I

F

= 17A, V

DD

= 50V

Q

rr

Reverse Recovery Charge

–––

350

520

nC di/dt = 100A/µs

Avalanche Characteristics

Parameter

Typ. Max. Units

E

AS

Single Pulse Avalanche Energy

––– 54

E

AR

Repetitive Avalanche Energy

––– 4.6

V

DS(Avalanche)

Repetitive Avalanche Voltage

240 ––– V

I

AS

Avalanche Current

––– 16 A

mJ

IRFI4227PbF

3

2017-04-27

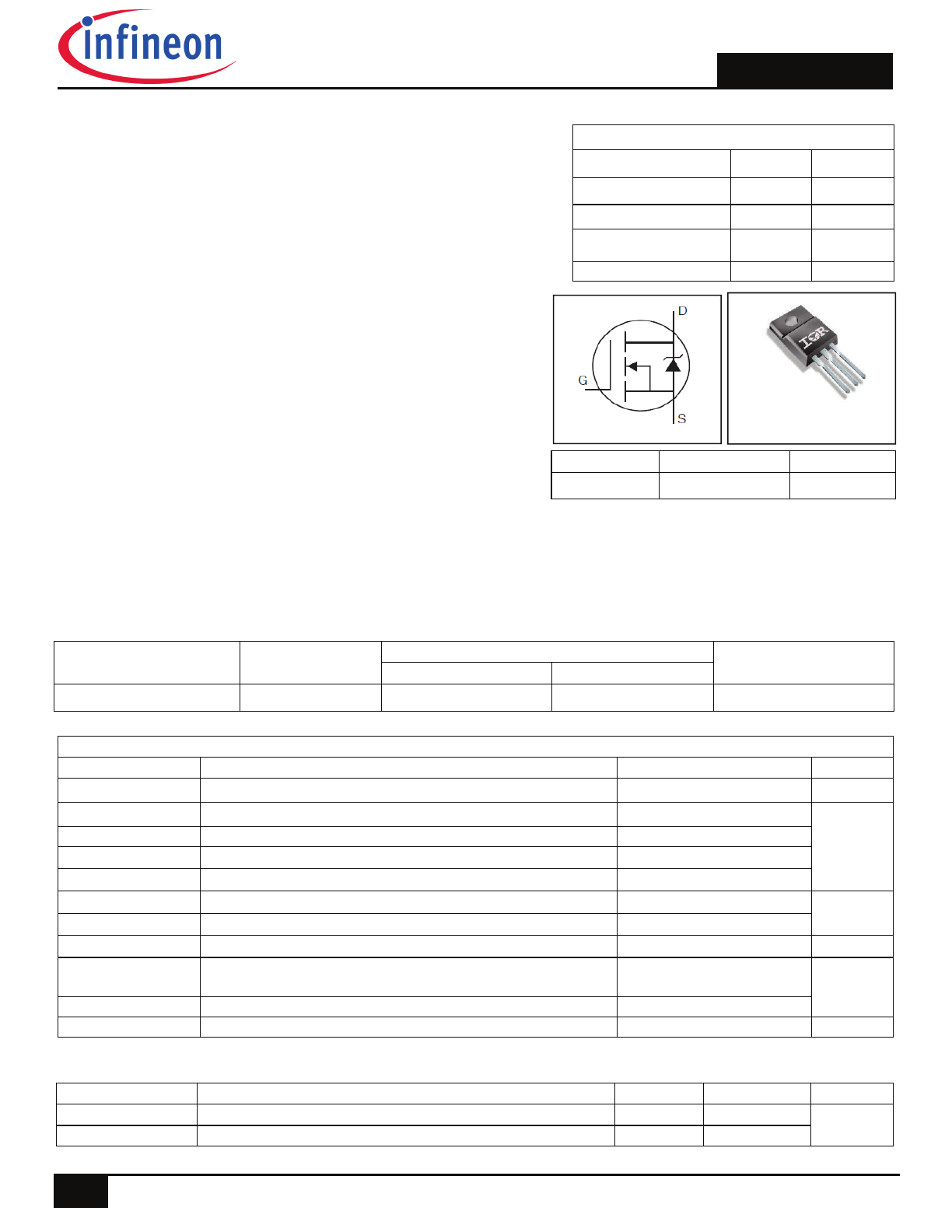

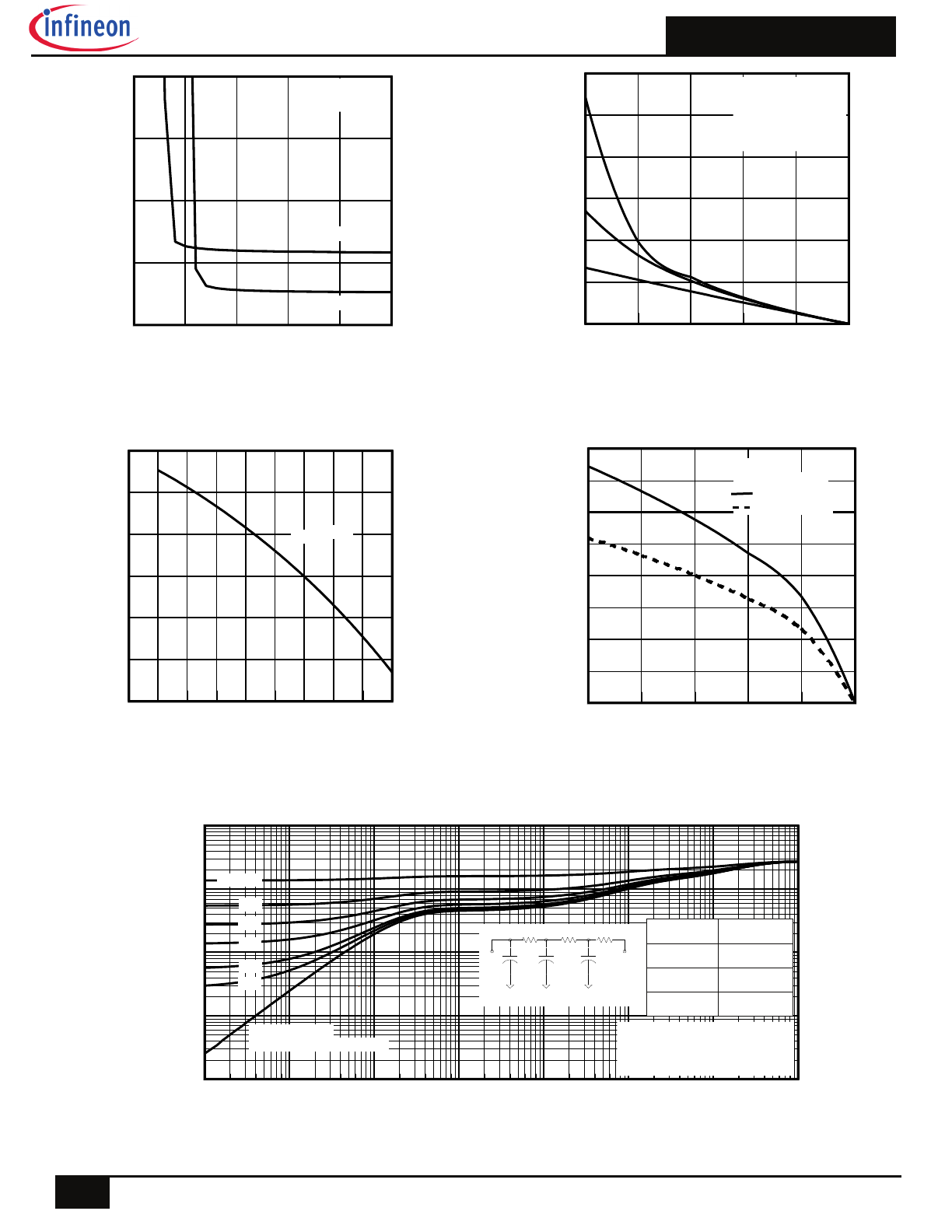

Fig. 2. Typical Output Characteristics

Fig. 3.

Typical Transfer Characteristics

Fig. 4.

Normalized On-Resistance vs. Temperature

Fig. 1. Typical Output Characteristics

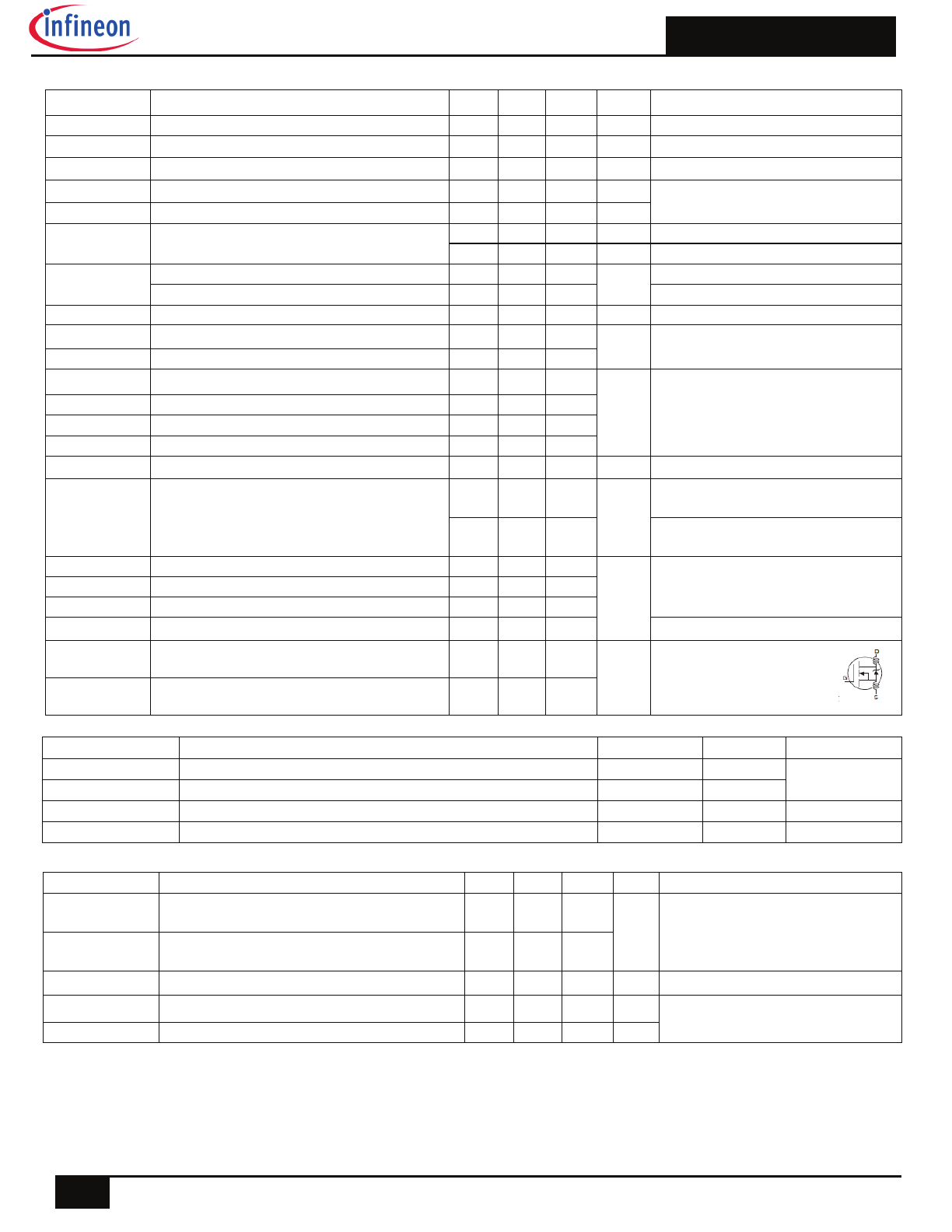

Fig 6. Typical E

PULSE

vs. Drain Current

0.1

1

10

100

VDS, Drain-to-Source Voltage (V)

10

100

I D

, D

ra

in

-t

o-

S

ou

rc

e

C

ur

re

nt

(

A

)

60µs PULSE WIDTH

Tj = 25°C

7.0V

VGS

TOP 15V

10V

8.0V

BOTTOM

7.0V

0.1

1

10

100

VDS, Drain-to-Source Voltage (V)

10

100

I D

, D

ra

in

-t

o-

S

ou

rc

e

C

ur

re

nt

(

A

)

60µs PULSE WIDTH

Tj = 150°C

7.0V

VGS

TOP 15V

10V

8.0V

BOTTOM

7.0V

3.0

4.0

5.0

6.0

7.0

8.0

VGS, Gate-to-Source Voltage (V)

0.1

1.0

10.0

100.0

1000.0

I D

, D

ra

in

-t

o-

S

ou

rc

e

C

ur

re

nt

)

VDS = 25V

60µs PULSE WIDTH

TJ = 25°C

TJ = 150°C

-60 -40 -20

0

20 40 60 80 100 120 140 160

TJ , Junction Temperature (°C)

0.0

0.5

1.0

1.5

2.0

2.5

3.0

R

D

S

(o

n)

,

D

ra

in

-t

o-

S

ou

rc

e

O

n

R

es

is

ta

nc

e

(

N

or

m

al

iz

ed

)

ID = 17A

VGS = 10V

110

120

130

140

150

160

170

VDS, Drain-to -Source Voltage (V)

100

200

300

400

500

600

700

800

900

1000

E

ne

rg

y

pe

r

pu

ls

e

(µ

J)

L = 220nH

C = 0.4µF

100°C

25°C

Fig 5. Typical E

PULSE

vs. Drain-to-Source Voltage

130

140

150

160

170

180

190

ID, Peak Drain Current (A)

0

200

400

600

800

1000

E

ne

rg

y

pe

r

pu

ls

e

(µ

J)

L = 220nH

C = Variable

100°C

25°C

IRFI4227PbF

4

2017-04-27

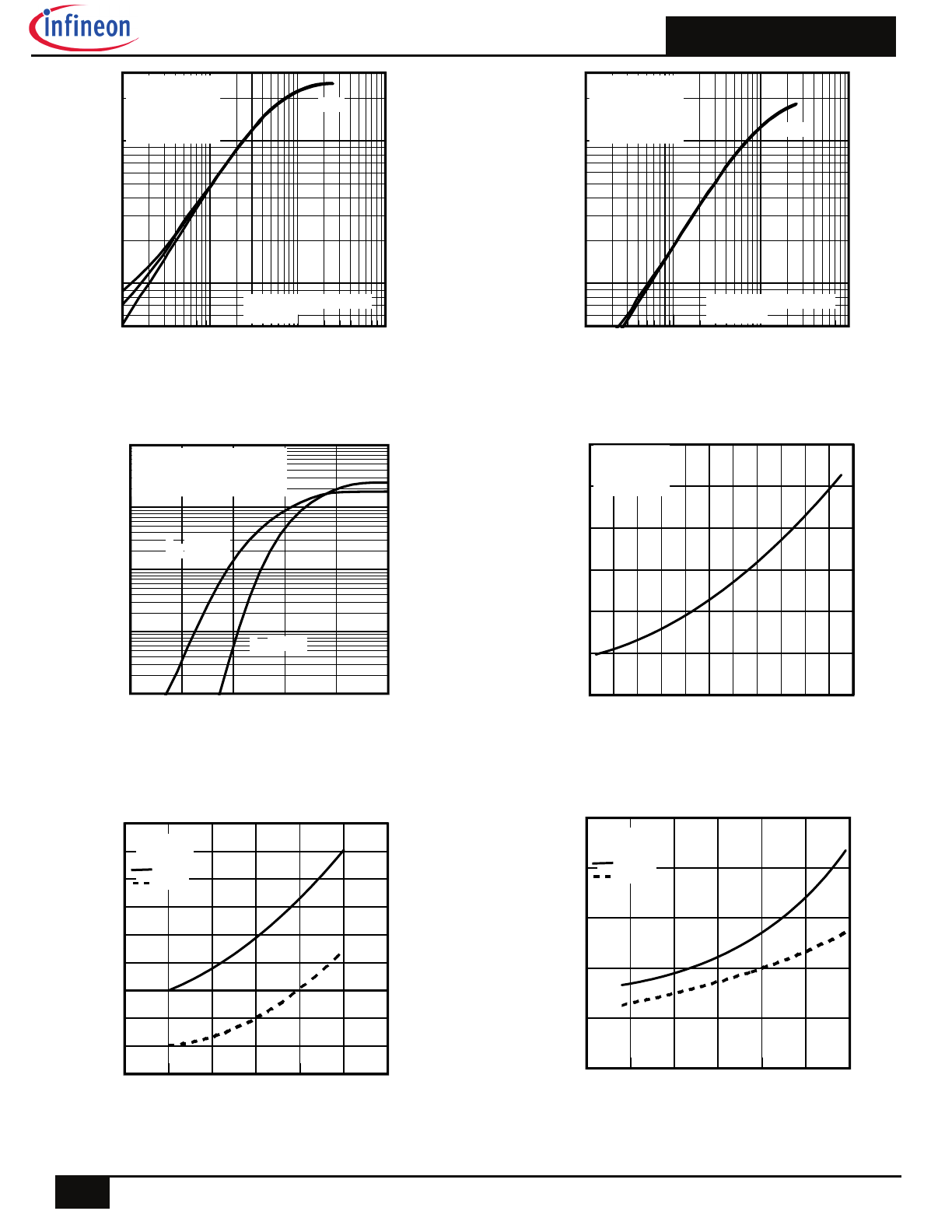

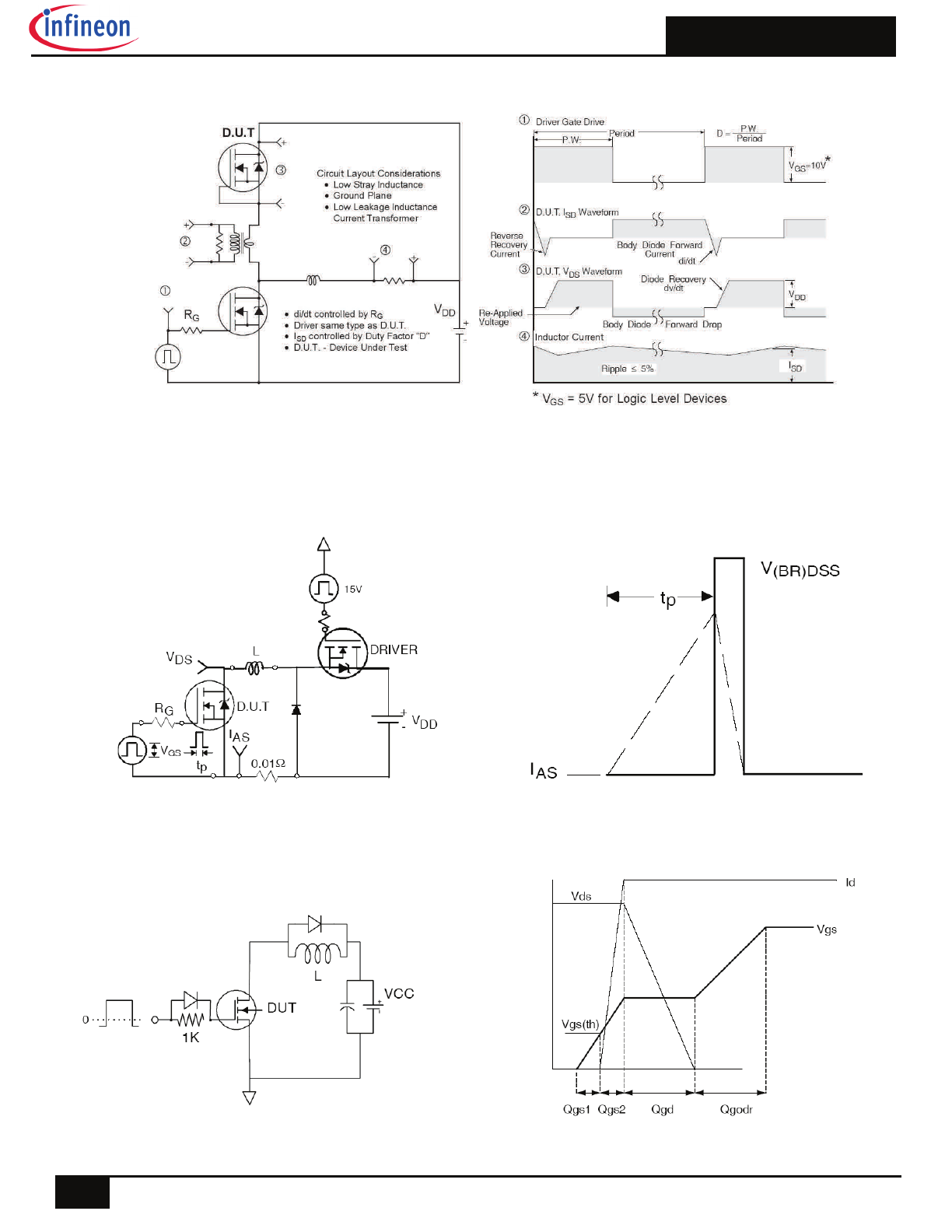

Fig 11. Maximum Drain Current vs. Case Temperature

Fig 9. Typical Capacitance vs.Drain-to-Source Voltage

Fig 12. Maximum Safe Operating Area

Fig. 7. Typical E

PULSE

vs. Temperature

25

50

75

100

125

150

Temperature (°C)

0

200

400

600

800

1000

1200

1400

E

ne

rg

y

pe

r

pu

ls

e

(µ

J)

L = 220nH

C= 0.4µF

C= 0.3µF

C= 0.2µF

0.2

0.4

0.6

0.8

1.0

1.2

1.4

VSD, Source-to-Drain Voltage (V)

0.1

1.0

10.0

100.0

1000.0

I S

D

,

R

ev

er

se

D

ra

in

C

ur

re

nt

(

A

)

TJ = 25°C

TJ = 150°C

VGS = 0V

1

10

100

1000

VDS, Drain-to-Source Voltage (V)

0

2000

4000

6000

8000

C

, C

ap

ac

ita

nc

e

(p

F

)

Coss

Crss

Ciss

VGS = 0V, f = 1 MHZ

Ciss = Cgs + Cgd, Cds SHORTED

Crss = Cgd

Coss = Cds + Cgd

0

20

40

60

80

100

120

QG Total Gate Charge (nC)

0

4

8

12

16

20

V

G

S

, G

at

e-

to

-S

ou

rc

e

V

ol

ta

ge

(

V

)

VDS= 160V

VDS= 100V

VDS= 40V

ID= 17A

Fig 8. Typical Source-Drain Diode Forward Voltage

25

50

75

100

125

150

TC , CaseTemperature (°C)

0

10

20

30

I D

, D

ra

in

C

ur

re

nt

(

A

)

1

10

100

1000

VDS , Drain-to-Source Voltage (V)

0.1

1

10

100

1000

I D

,

D

ra

in

-t

o-

S

ou

rc

e

C

ur

re

nt

(

A

)

Tc = 25°C

Tj = 150°C

Single Pulse

1µsec

10µsec

OPERATION IN THIS AREA

LIMITED BY R DS(on)

100µsec

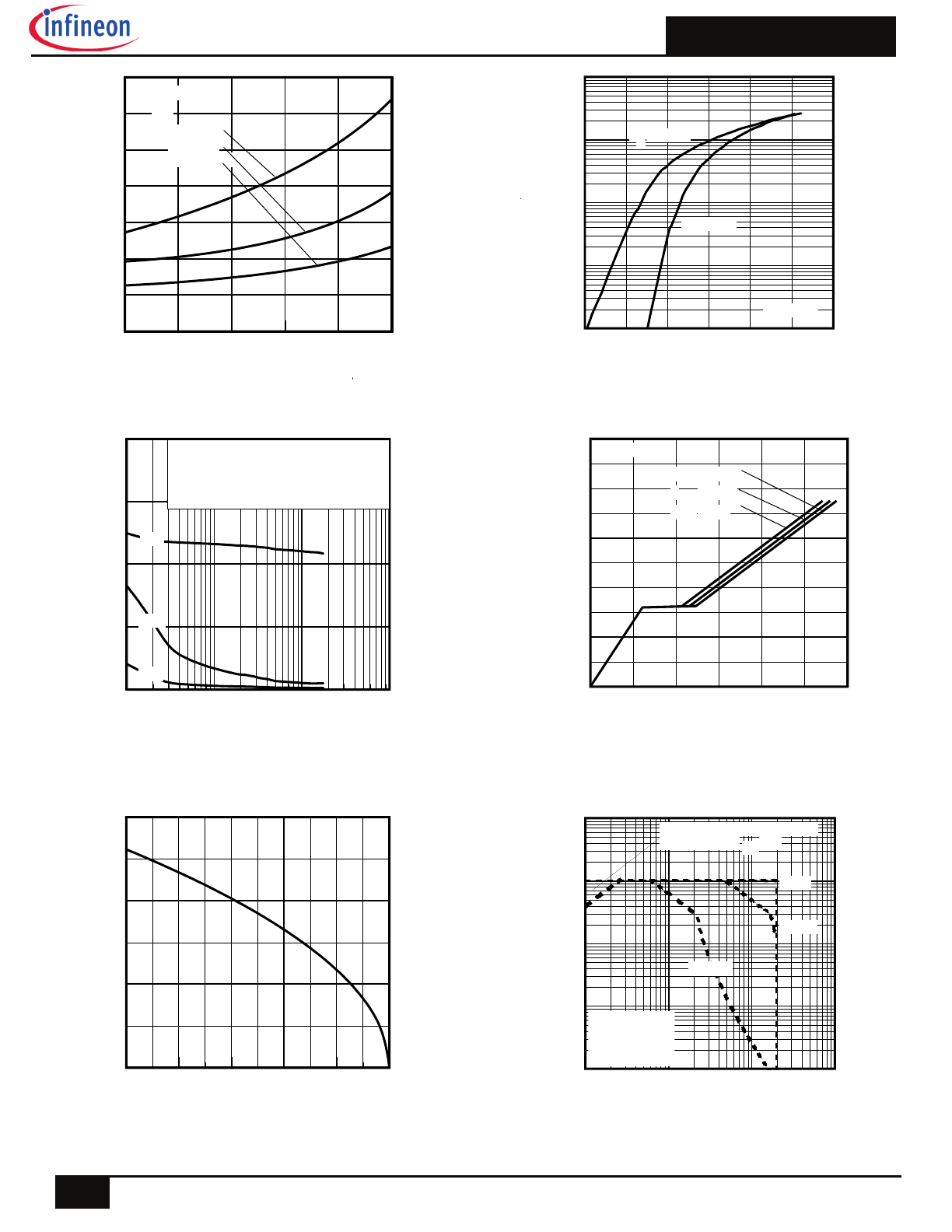

Fig 10. Typical Gate Charge vs. Gate-to-Source Voltage

IRFI4227PbF

5

2017-04-27

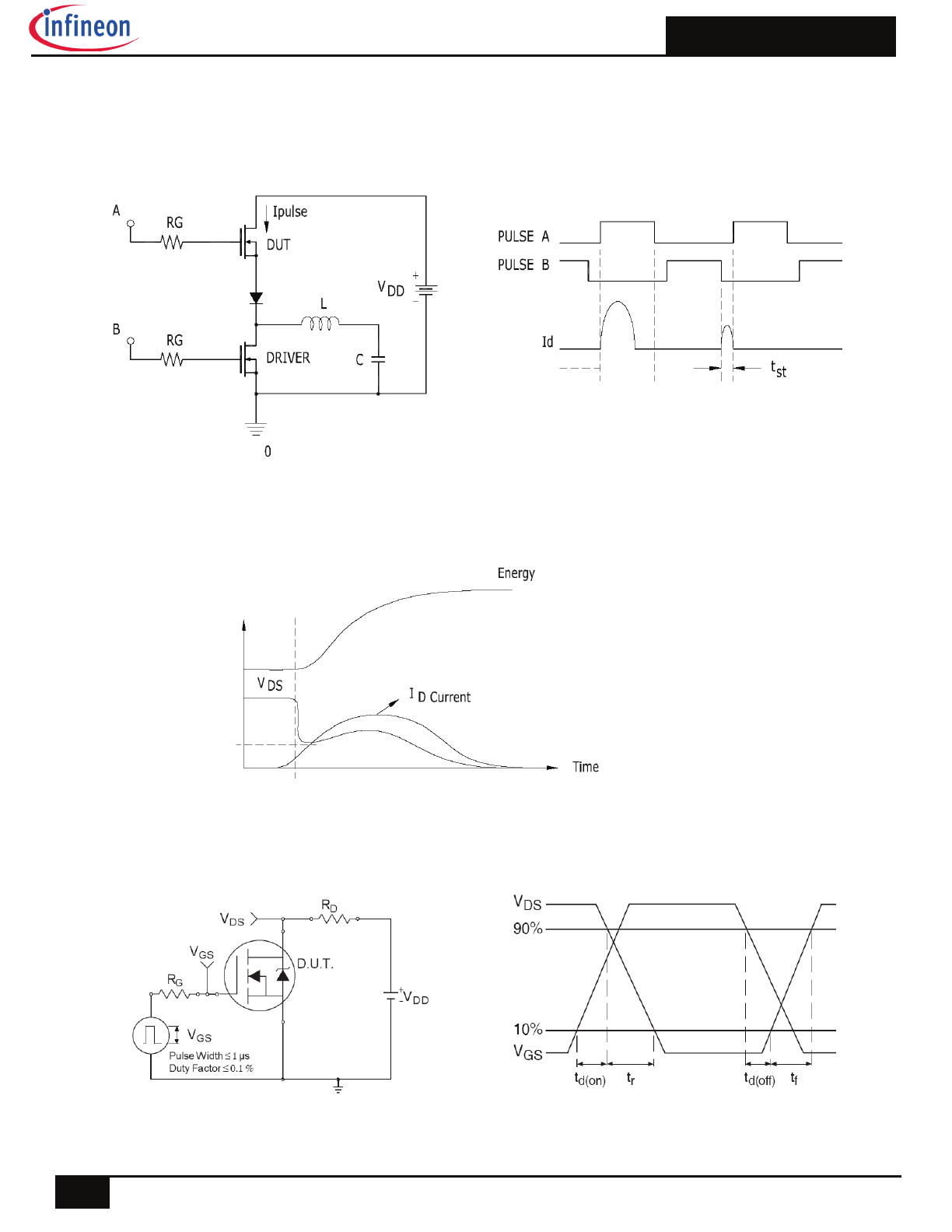

Fig. 14. Maximum Avalanche Energy Vs. Temperature

Fig. 15. Threshold Voltage vs. Temperature

Fig. 13. On-Resistance Vs. Gate Voltage

5

6

7

8

9

10

VGS, Gate-to-Source Voltage (V)

0.00

0.04

0.08

0.12

0.16

R

D

S

(o

n)

,

D

ra

in

-t

o

-S

ou

rc

e

O

n

R

es

is

ta

nc

e

(

)

TJ = 25°C

TJ = 125°C

ID = 17A

25

50

75

100

125

150

Starting TJ, Junction Temperature (°C)

0

40

80

120

160

200

240

E

A

S

,

S

in

gl

e

P

ul

se

A

va

la

nc

he

E

ne

rg

y

(m

J)

ID

TOP

2.5A

3.0A

BOTTOM

16A

-75

-50

-25

0

25

50

75

100 125 150

TJ , Temperature ( °C )

2.0

2.5

3.0

3.5

4.0

4.5

5.0

V

G

S

(t

h)

G

at

e

th

re

sh

ol

d

V

ol

ta

ge

(

V

)

ID = 250µA

25

50

75

100

125

150

Case Temperature (°C)

0

20

40

60

80

R

ep

et

iti

ve

P

ea

k

C

ur

re

nt

(

A

)

ton= 1µs

Duty cycle = 0.25

Half Sine Wave

Square Pulse

1E-006

1E-005

0.0001

0.001

0.01

0.1

1

10

t1 , Rectangular Pulse Duration (sec)

0.001

0.01

0.1

1

10

T

he

rm

al

R

es

po

ns

e

(

Z

th

JC

)

0.20

0.10

D = 0.50

0.02

0.01

0.05

SINGLE PULSE

( THERMAL RESPONSE )

Notes:

1. Duty Factor D = t1/t2

2. Peak Tj = P dm x Zthjc + Tc

Fig. 16. Typical Repetitive peak Current vs.

Case temperature

Fig 17. Maximum Effective Transient Thermal Impedance, Junction-to-Case

J

J

1

1

2

2

3

3

R

1

R

1

R

2

R

2

R

3

R

3

C

C

Ci=

iRi

Ci=

iRi

Ri (°C/W)

i (sec)

0.9085

0.105329

1.3717

2.0127

0.44978

0.000177

IRFI4227PbF

6

2017-04-27

Fig 19a. Unclamped Inductive Test Circuit

Fig 19b. Unclamped Inductive Waveforms

Fig 20a. Gate Charge Test Circuit

Fig 20b. Gate Charge Waveform

Fig 18. Diode Reverse Recovery Test Circuit for N-Channel HEXFET® Power MOSFETs

IRFI4227PbF

7

2017-04-27

Fig 21a. t

st

and E

PULSE

Test Circuit

Fig 21b. t

st

Test Waveforms

Fig 22a. Switching Time Test Circuit

Fig 22b. Switching Time Waveforms

Fig 21c. E

PULSE

Test Waveforms

IRFI4227PbF

8

2017-04-27

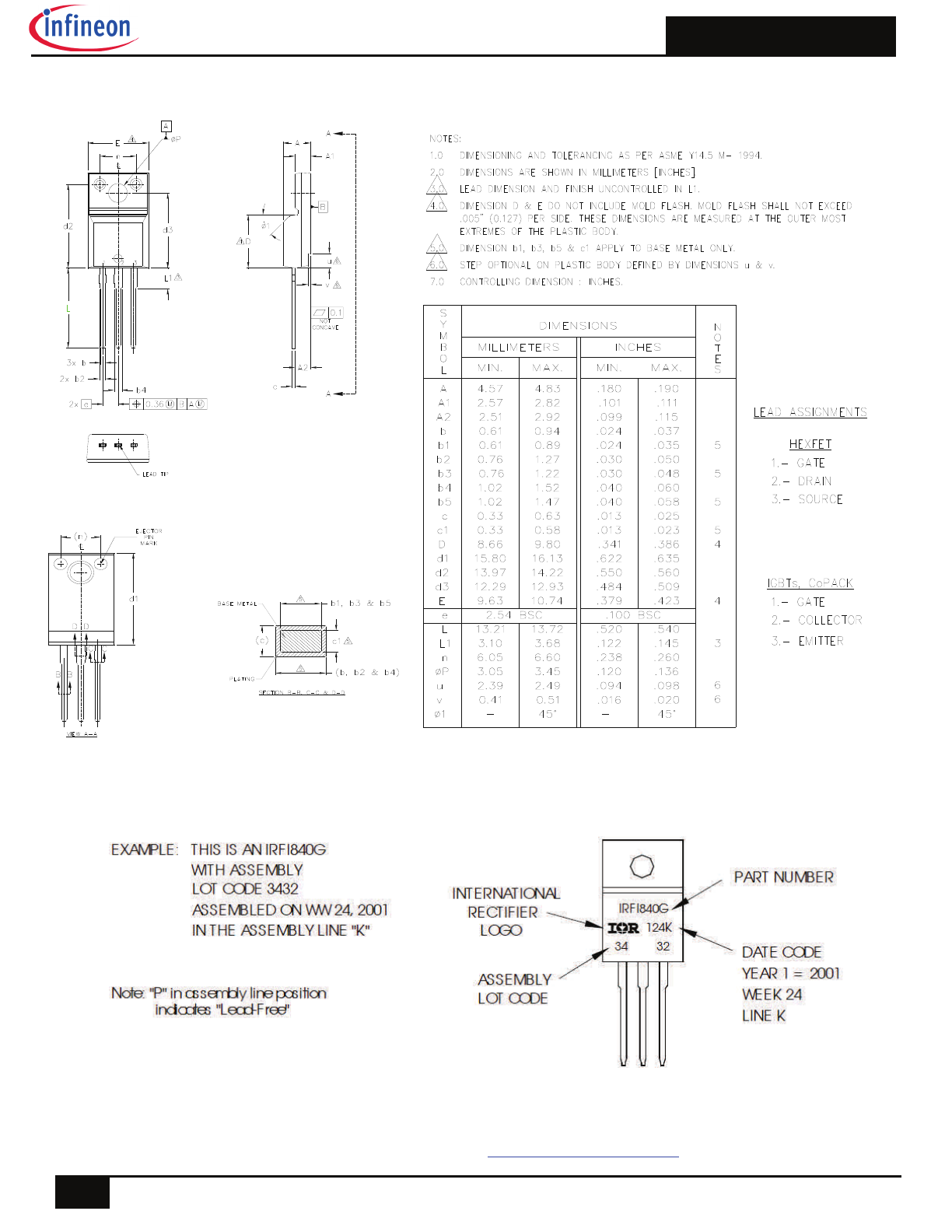

TO-220 Full-Pak Package Outline (Dimensions are shown in millimeters (inches))

TO-220 Full-Pak Part Marking Information

TO-220AB Full-Pak packages are not recommended for Surface Mount Application.

Note: For the most current drawing please refer to website at

http://www.irf.com/package/

IRFI4227PbF

9

2017-04-27

Qualification Information

Qualification Level

Industrial

(per JEDEC JESD47F)

†

TO-220 Full-Pak

N/A

RoHS Compliant

Yes

Moisture Sensitivity Level

† Applicable version of JEDEC standard at the time of product release.

Trademarks of Infineon Technologies AG

µHVIC™, µIPM™, µPFC™, AU-ConvertIR™, AURIX™, C166™, CanPAK™, CIPOS™, CIPURSE™, CoolDP™, CoolGaN™, COOLiR™, CoolMOS™, CoolSET™,

CoolSiC™, DAVE™, DI-POL™, DirectFET™, DrBlade™, EasyPIM™, EconoBRIDGE™, EconoDUAL™, EconoPACK™, EconoPIM™, EiceDRIVER™, eupec™, FCOS™,

GaNpowIR™, HEXFET™, HITFET™, HybridPACK™, iMOTION™, IRAM™, ISOFACE™, IsoPACK™, LEDrivIR™, LITIX™, MIPAQ™, ModSTACK™, my-d™, NovalithIC™,

OPTIGA™, OptiMOS™, ORIGA™, PowIRaudio™, PowIRStage™, PrimePACK™, PrimeSTACK™, PROFET™, PRO-SIL™, RASIC™, REAL3™, SmartLEWIS™, SOLID

FLASH™, SPOC™, StrongIRFET™, SupIRBuck™, TEMPFET™, TRENCHSTOP™, TriCore™, UHVIC™, XHP™, XMC™

Trademarks updated November 2015

Other Trademarks

All referenced product or service names and trademarks are the property of their respective owners.

Edition 2016-04-19

Published by

Infineon Technologies AG

81726 Munich, Germany

© 2016 Infineon Technologies AG.

All Rights Reserved.

Do you have a question about this

document?

Email:

erratum@infineon.com

Document reference

ifx1

IMPORTANT NOTICE

The information given in this document shall in no

event be regarded as a guarantee of conditions or

characteristics (“Beschaffenheitsgarantie”) .

With respect to any examples, hints or any typical

values stated herein and/or any information

regarding the application of the product, Infineon

Technologies hereby disclaims any and all

warranties and liabilities of any kind, including

without limitation warranties of non-infringement

of intellectual property rights of any third party.

In addition, any information given in this

document is subject to customer’s compliance

with its obligations stated in this document and

any applicable legal requirements, norms and

standards concerning customer’s products and

any use of the product of Infineon Technologies in

customer’s applications.

The data contained in this document is exclusively

intended for technically trained staff. It is the

responsibility of customer’s technical

departments to evaluate the suitability of the

product for the intended application and the

completeness of the product information given in

this document with respect to such application.

For further information on the product, technology,

delivery terms and conditions and prices please

contact your nearest Infineon Technologies office

(

www.infineon.com

).

Please note that this product is not qualified

according to the AEC Q100 or AEC Q101 documents

of the Automotive Electronics Council.

WARNINGS

Due to technical requirements products may

contain dangerous substances. For information on

the types in question please contact your nearest

Infineon Technologies office.

Except as otherwise explicitly approved by Infineon

Technologies in a written document signed by

authorized representatives of Infineon

Technologies, Infineon Technologies’ products

may not be used in any applications where a

failure of the product or any consequences of the

use thereof can reasonably be expected to result in

personal injury.

Revision History

Date Comments

04/27/2017

Changed datasheet with Infineon logo - all pages.

Corrected Package Outline on page 8.

Added disclaimer on last page.