Base part number

Standard Pack

Orderable Part Number

Form

Quantity

IRF6648TRPbF

DirectFET

™

Medium Can

Tape and Reel

4800

IRF6648TRPbF

Package Type

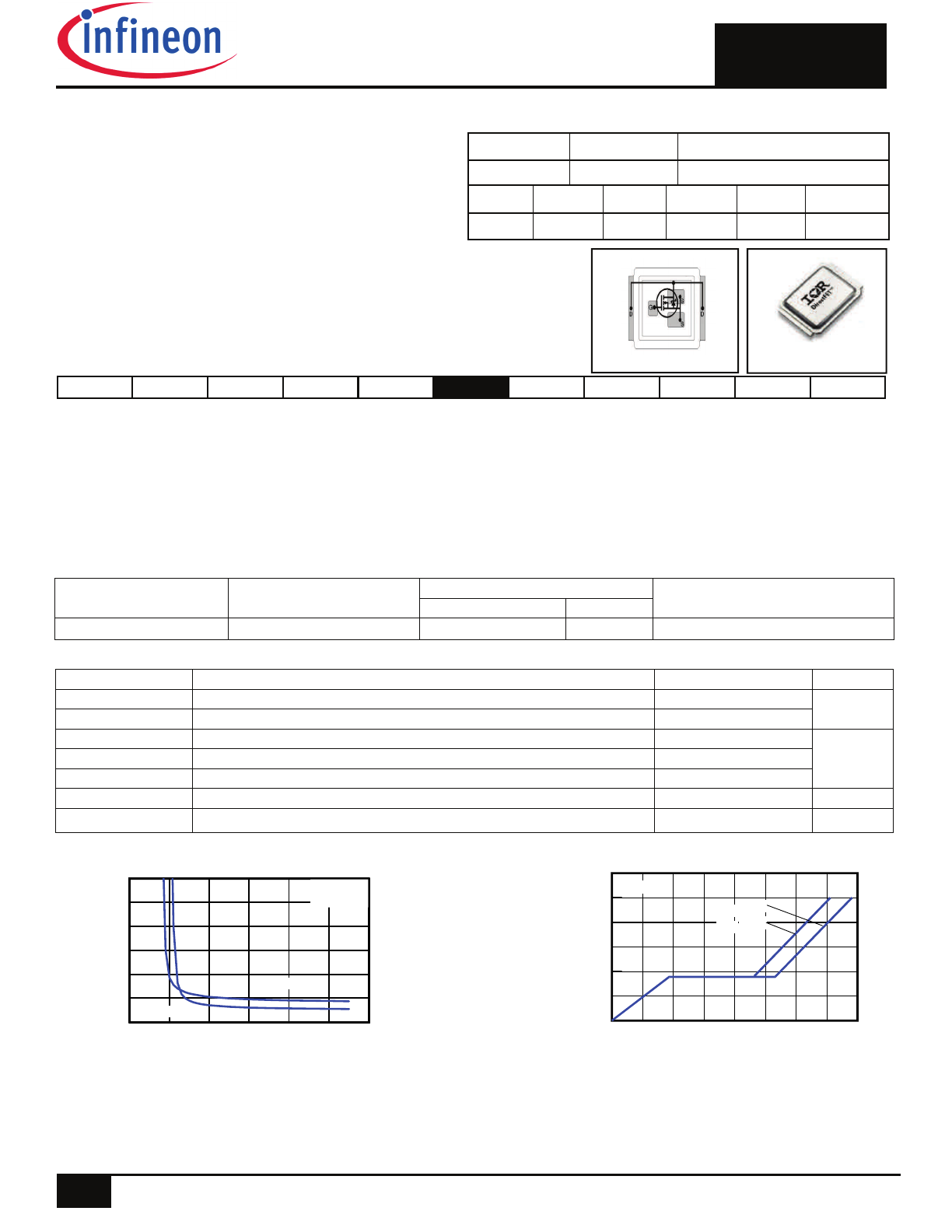

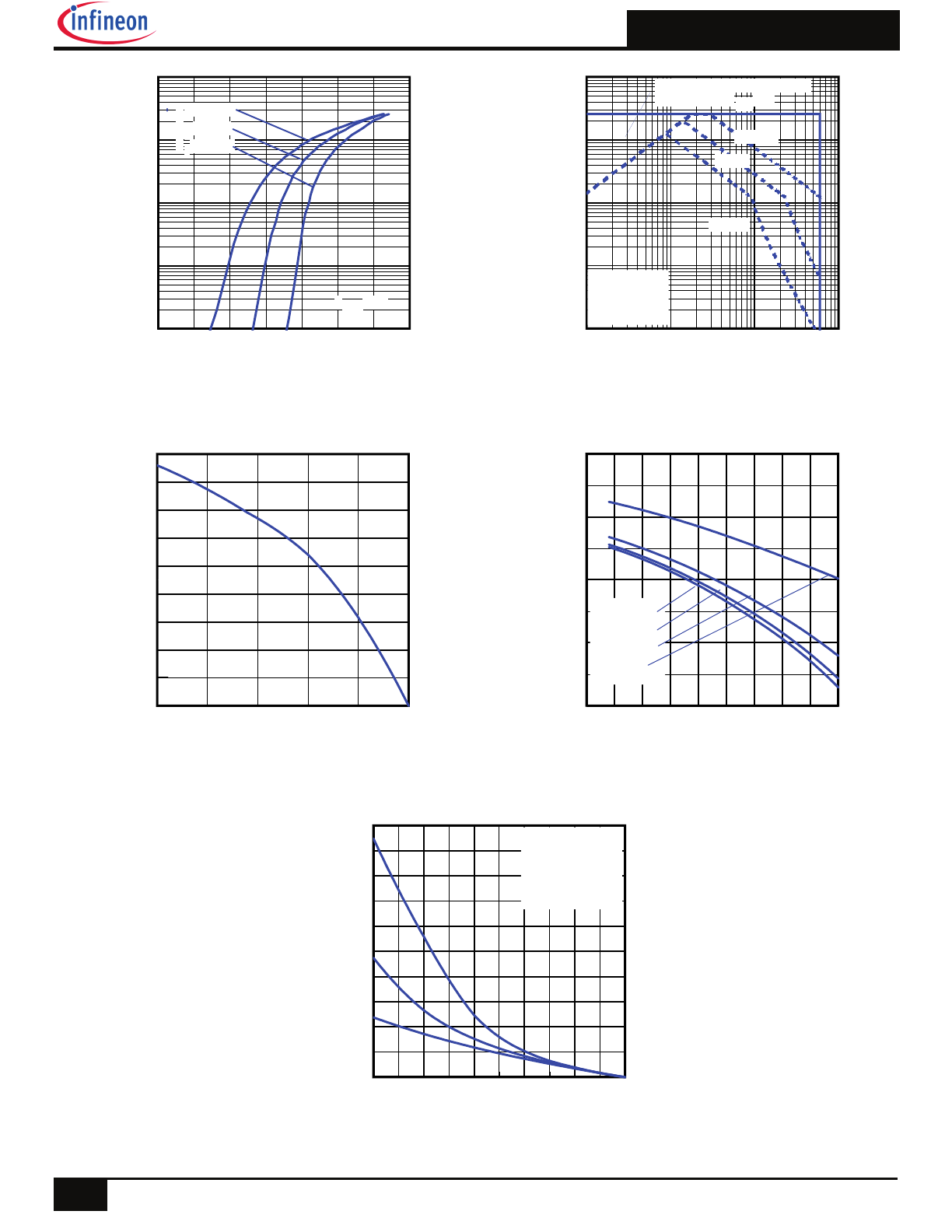

Fig 1. Typical On-Resistance vs. Gate Voltage

DirectFET™ ISOMETRIC

MN

V

DSS

V

GS

R

DS(on)

60V min

±20V max

5.5m

@ 10V

Applicable DirectFET Outline and Substrate Outline (see p.7,8 for details)

SH

SJ

SP MZ

MN

Description

The IRF6648PbF combines the latest HEXFET® Power MOSFET Silicon technology with the advanced DirectFET™ packaging to achieve

the lowest on-state resistance in a package that has the footprint of a SO-8 and only 0.7 mm profile. The DirectFET™ package is compati-

ble with existing layout geometries used in power applications, PCB assembly equipment and vapor phase, infra-red or convection soldering

techniques. Application note AN-1035 is followed regarding the manufacturing methods and processes. The DirectFET™ package allows

dual sided cooling to maximize thermal transfer in power systems, improving previous best thermal resistance by 80%.

The IRF6648PbF is an optimized switch for use in synchronous rectification circuits with 5-12Vout, and is also ideal for use as a primary

side switch in 24Vin forward converters. The reduced total losses in the device coupled with the high level of thermal performance enables

high efficiency and low temperatures, which are key for system reliability improvements, and makes this device ideal for high performance.

Absolute Maximum Ratings

Parameter Max.

Units

V

DS

Drain-to-Source Voltage

60

V

V

GS

Gate-to-Source Voltage

±20

I

D

@ T

C

= 25°C

Continuous Drain Current, V

GS

@ 10V (Silicon Limited) 86

A

I

D

@ T

C

= 70°C

Continuous Drain Current, V

GS

@ 10V (Silicon Limited) 69

I

DM

Pulsed Drain Current 260

E

AS

Single Pulse Avalanche Energy 47

mJ

I

AR

Avalanche Current 34

A

Notes

Click on this section to link to the appropriate technical paper.

Click on this section to link to the DirectFET Website.

Surface mounted on 1 in. square Cu board, steady state.

TC measured with thermocouple mounted to top (Drain) of part.

Repetitive rating; pulse width limited by max. junction temperature.

Starting T

J

= 25°C, L = 0.082mH, R

G

= 25

, I

AS

= 34A.

Fig 2. Typical Total Gate Charge vs. Gate-to-Source Voltage

IRF6648PbF

IRF6648TRPbF

Typical values (unless otherwise specified)

Q

g tot

Q

gd

Q

gs2

Q

rr

Q

oss

V

gs(th)

36nC 14nC 2.7nC 37nC 11nC 4.0V

RoHs Compliant

Lead-Free (Qualified up to 260°C Reflow)

Application Specific MOSFETs

Optimized for Synchronous Rectification for

5V to 12V outputs

Low Conduction Losses

Ideal for 24V input Primary Side Forward Converters

Low Profile (<0.7mm)

Dual Sided Cooling Compatible

Compatible with existing Surface Mount Techniques

DirectFET™ Power MOSFET

1

2017-04-06

4

6

8

10

12

14

16

VGS, Gate -to -Source Voltage (V)

0

10

20

30

40

50

60

T

yp

ic

a

l R

D

S

(o

n)

(

m

)

ID = 17A

TJ = 25°C

TJ = 125°C

0

5

10

15

20

25

30

35

40

QG, Total Gate Charge (nC)

0.0

2.0

4.0

6.0

8.0

10.0

12.0

V

G

S

, G

at

e-

to

-S

ou

rc

e

V

ol

ta

ge

(

V

)

VDS= 48V

VDS= 30V

ID= 17A

IRF6648TRPbF

2

2017-04-06

Static @ T

J

= 25°C (unless otherwise specified)

Parameter Min.

Typ.

Max.

Units

Conditions

BV

DSS

Drain-to-Source Breakdown Voltage

60

––– –––

V

V

GS

= 0V, I

D

= 250µA

V

DSS

/

T

J

Breakdown Voltage Temp. Coefficient

––– 0.076 –––

V/°C Reference to 25°c, I

D

= 1mA

R

DS(on)

Static Drain-to-Source On-Resistance

–––

5.5

7.0

m

V

GS

= 10V, I

D

= 17A

V

GS(th)

Gate Threshold Voltage

3.0

4.0

4.9

V

V

DS

= V

GS

, I

D

= 150µA

V

GS(th)

/

T

J

Gate Threshold Voltage Temp. Coefficient

–––

-11 ––– mV/°C

I

DSS

Drain-to-Source Leakage Current

––– ––– 20

V

DS

= 60 V, V

GS

= 0V

––– ––– 250

V

DS

= 48 V, V

GS

= 0V, T

J

= 125°C

I

GSS

Gate-to-Source Forward Leakage

–––

––– 100

nA

V

GS

= 20V

Gate-to-Source Reverse Leakage

–––

––– -100

V

GS

= -20V

gfs Forward

Transconductance

31

–––

–––

S

V

DS

= 10V, I

D

= 17A

Q

g

Total Gate Charge

–––

36

50

nC

Q

gs1

Pre– Vth Gate-to-Source Charge

–––

7.5

–––

V

DS

= 30V

Q

gs2

Post– Vth Gate-to-Source Charge

–––

2.7

–––

V

GS

= 10V

Q

gd

Gate-to-Drain Charge

–––

14

21

I

D

= 17A

Q

godr

Gate Charge Overdrive

–––

12

–––

See Fig 15

Q

sw

Switch Charge (Q

gs2 +

Q

gd)

––– 17 –––

Q

oss

Output Charge

–––

21

–––

nC

V

DS

= 16V, V

GS

= 0V

R

G(Internal)

Gate Resistance

–––

1.0

–––

t

d(on)

Turn-On Delay Time

–––

16

–––

ns

V

DD

= 30V, V

GS

= 10V

t

r

Rise Time

–––

29

–––

I

D

= 17A

t

d(off)

Turn-Off Delay Time

–––

28

–––

R

G

= 6.2

t

f

Fall Time

–––

13

–––

See Fig 16 & 17

C

iss

Input Capacitance

––– 2120 –––

pF

V

GS

= 0V

C

oss

Output Capacitance

–––

600 –––

V

DS

= 25V

C

rss

Reverse Transfer Capacitance

–––

170 –––

ƒ = 1.0MHz

Diode Characteristics

Parameter

Min. Typ. Max. Units

Conditions

I

S

Continuous Source Current

––– ––– 81

A

MOSFET symbol

(Body Diode)

showing the

I

SM

Pulsed Source Current

––– ––– 260

integral reverse

(Body Diode)

p-n junction diode.

V

SD

Diode Forward Voltage

–––

–––

1.3

V

T

J

= 25°C, I

S

= 17A, V

GS

= 0V

t

rr

Reverse Recovery Time

–––

31

47

ns T

J

= 25°C, I

F

= 17A,V

DD

= 30V

Q

rr

Reverse Recovery Charge

–––

37

56

nC di/dt = 100A/µs See Fig. 18

µA

C

oss

Output Capacitance

2450

V

GS

= 0V, V

DS

= 1.0V, f =1.0MHz

C

oss

Output Capacitance

440

V

GS

= 0V, V

DS

= 48V, f =1.0MHz

D

S

G

Notes:

Repetitive rating; pulse width limited by max. junction temperature.

Pulse width ≤ 400µs; duty cycle ≤ 2%.

IRF6648TRPbF

3

2017-04-06

Absolute Maximum Ratings

Symbol Parameter

Max.

Units

P

D

@T

A

= 25°C

Power Dissipation

2.8

P

D

@T

A

= 70°C

Power Dissipation

1.8

W

P

D

@T

C

= 25°C Power Dissipation 89

T

P

Peak Soldering Temperature

270

T

J

Operating Junction and

-40 to + 150

°C

T

STG

Storage Temperature Range

Thermal Resistance

Symbol Parameter Typ.

Max.

Units

R

JA

Junction-to-Ambient

––– 45

R

JA

Junction-to-Ambient

12.5 –––

°C/W

R

JC

Junction-to-Can

–––

1.4

R

JA-PCB

Junction-to-PCB Mounted

1.0

–––

Linear Derating Factor

0.022

W/°C

.

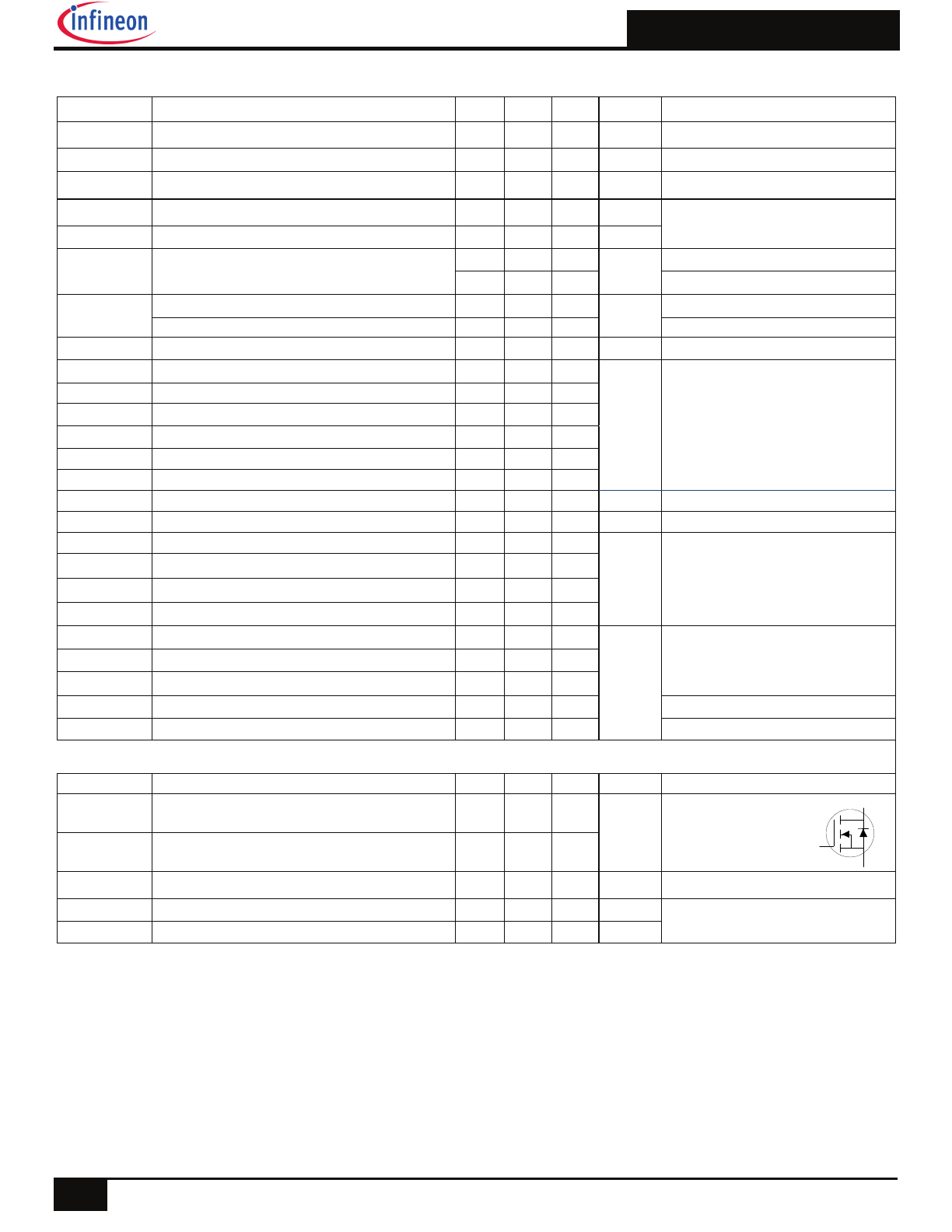

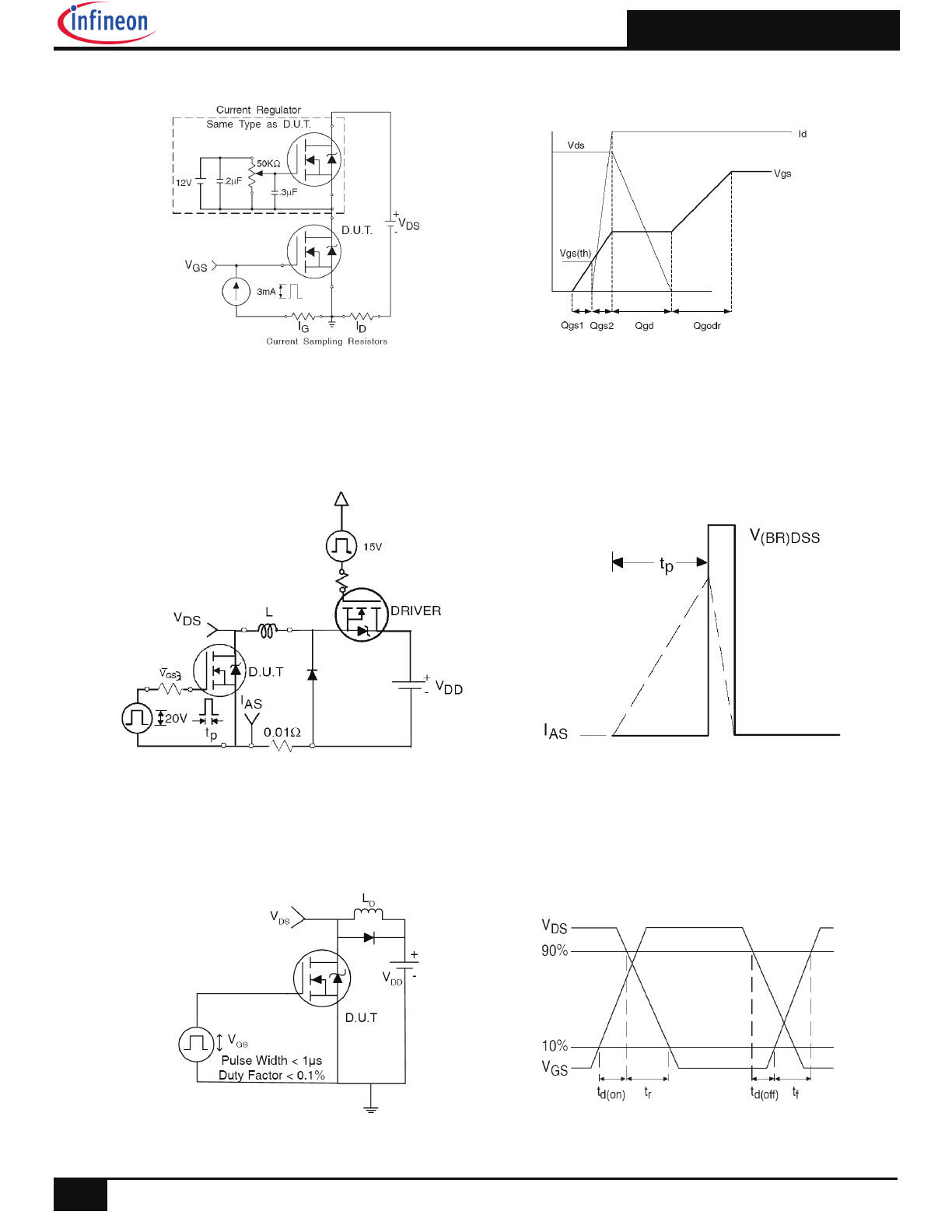

Fig 3. Maximum Effective Transient Thermal Impedance, Junction-to-Case

Notes:

Surface mounted on 1 in. square Cu board, steady state.

T

C

measured with thermocouple incontact with top (Drain) of part.

Surface mounted on 1 in. square Cu

board (still air).

Mounted to a PCB with small clip

heatsink (still air)

Used double sided cooling, mounting pad with large heatsink.

Mounted on minimum footprint full size board with metalized

back and with small clip heatsink.

R

is measured at T

J

of approximately 90°C.

Mounted on minimum footprint full size board with metalized

back and with small clip heatsink (still air)

1E-006

1E-005

0.0001

0.001

0.01

0.1

t1 , Rectangular Pulse Duration (sec)

0.001

0.01

0.1

1

10

T

he

rm

al

R

es

po

ns

e

(

Z

th

JC

)

0.20

0.10

D = 0.50

0.02

0.01

0.05

SINGLE PULSE

( THERMAL RESPONSE )

Notes:

1. Duty Factor D = t1/t2

2. Peak Tj = P dm x Zthjc + Tc

Ri (°C/W)

i (sec)

0.67673

0.001660

0.54961

0.007649

0.17199

0.000044

J

J

1

1

2

2

3

3

R

1

R

1

R

2

R

2

R

3

R

3

C

C

Ci=

iRi

Ci=

iRi

IRF6648TRPbF

4

2017-04-06

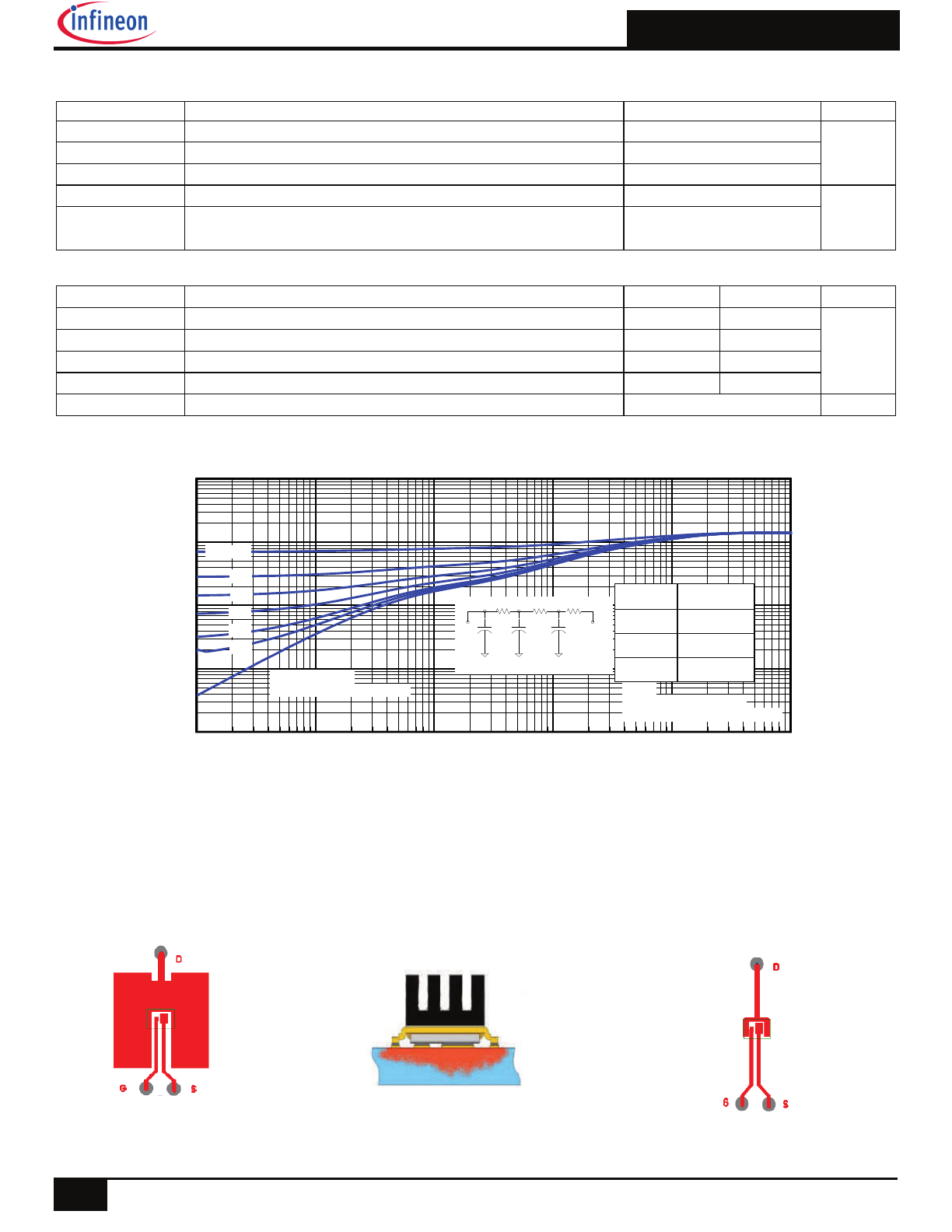

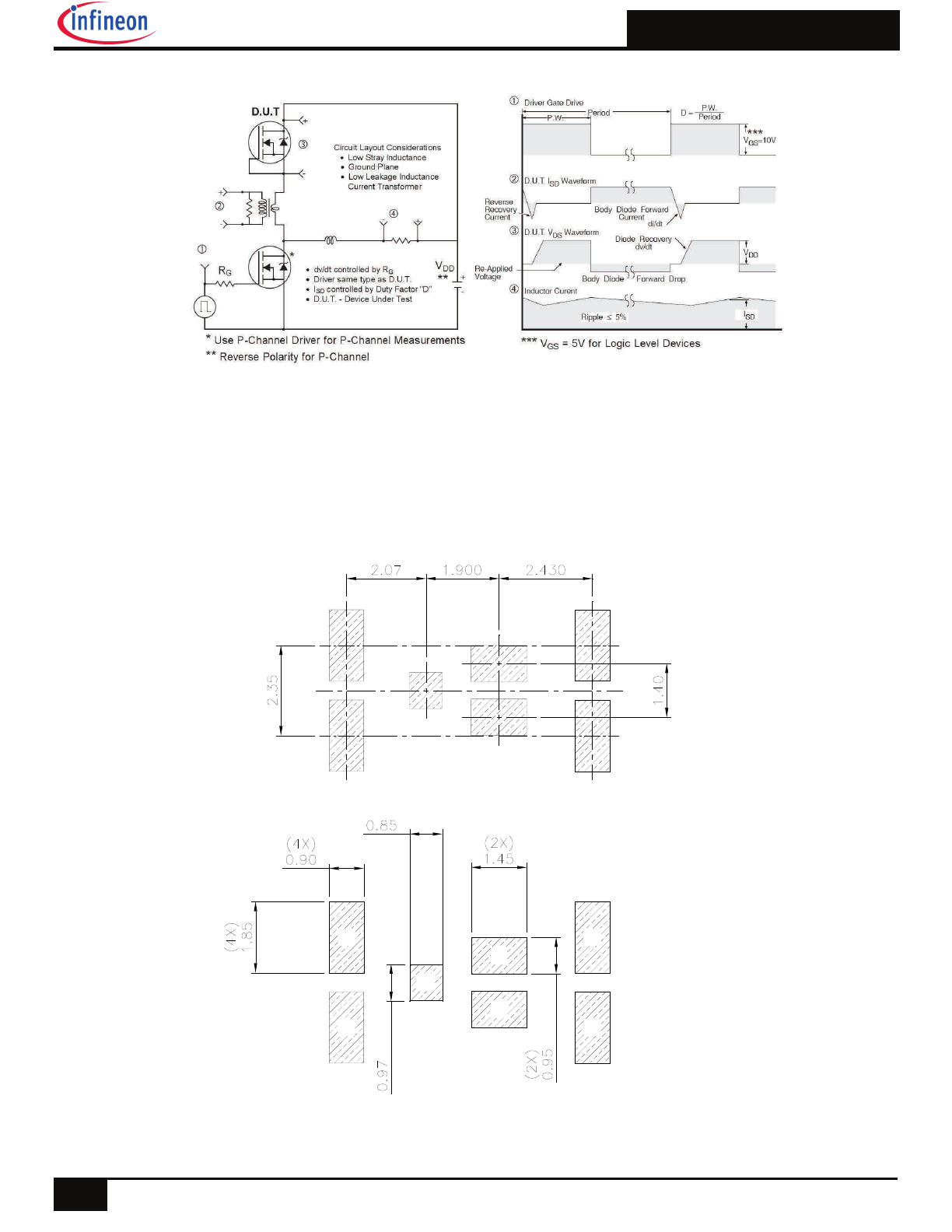

Fig 4. Typical Output Characteristics

Fig 7. Normalized On-Resistance vs. Temperature

Fig 8. Typical Capacitance vs. Drain-to-Source Voltage

Fig 6. Typical Transfer Characteristics

Fig 5. Typical Output Characteristics

0.1

1

10

VDS, Drain-to-Source Voltage (V)

1

10

100

1000

I D

, D

ra

in

-t

o-

S

ou

rc

e

C

ur

re

nt

(

A

)

VGS

TOP 15V

10V

8.0V

7.0V

BOTTOM

6.0V

60µs PULSE WIDTH

Tj = 25°C

6.0V

0.1

1

10

VDS, Drain-to-Source Voltage (V)

1

10

100

1000

I D

, D

ra

in

-t

o-

S

ou

rc

e

C

u

rr

en

t (

A

)

6.0V

60µs PULSE WIDTH

Tj = 150°C

VGS

TOP 15V

10V

8.0V

7.0V

BOTTOM

6.0V

2

4

6

8

10

VGS, Gate-to-Source Voltage (V)

0.1

1

10

100

1000

I D

, D

ra

in

-t

o-

S

ou

rc

e

C

ur

re

nt

(

A

)

TJ = 150°C

TJ = 25°C

TJ = -40°C

VDS = 10V

60µs PULSE WIDTH

-60 -40 -20 0 20 40 60 80 100 120 140 160

TJ , Junction Temperature (°C)

0.5

1.0

1.5

2.0

T

yp

ic

al

R

D

S

(o

n)

(

N

or

m

al

iz

ed

)

ID = 86A

VGS = 10V

1

10

100

VDS, Drain-to-Source Voltage (V)

100

1000

10000

C

, C

ap

ac

ita

nc

e

(p

F

)

VGS = 0V, f = 1 MHZ

Ciss = Cgs + Cgd, C ds SHORTED

Crss = Cgd

Coss = Cds + Cgd

Coss

Crss

Ciss

0

20

40

60

80

100

ID, Drain Current (A)

0

5

10

15

20

25

30

T

yp

ic

al

R

D

S

(o

n)

(

m

)

TJ = 25°C

Vgs = 7.0V

Vgs = 8.0V

Vgs = 10V

Vgs = 15V

Fig 9. Normalized Typical On-Resistance vs. Drain

Current and Gate Voltage

IRF6648TRPbF

5

2017-04-06

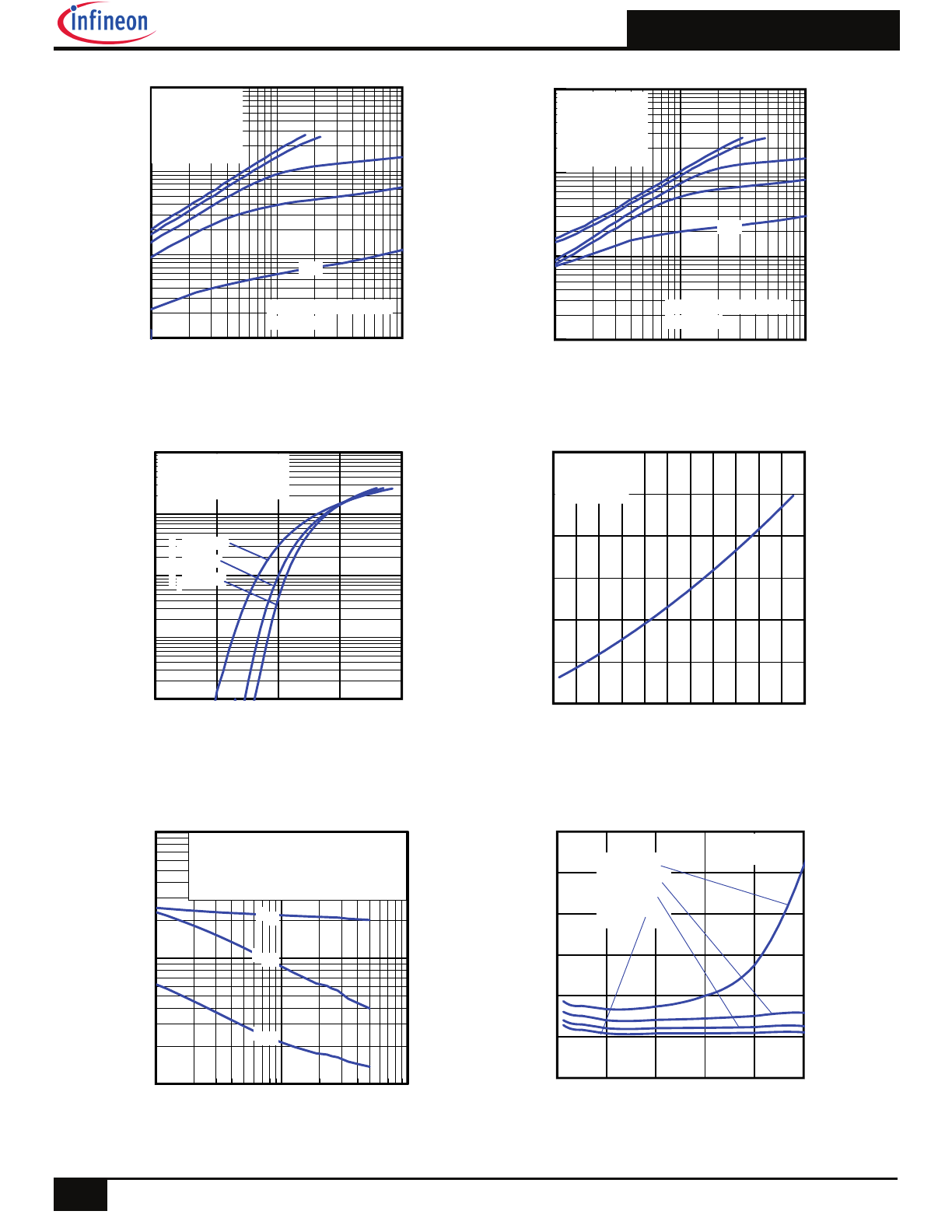

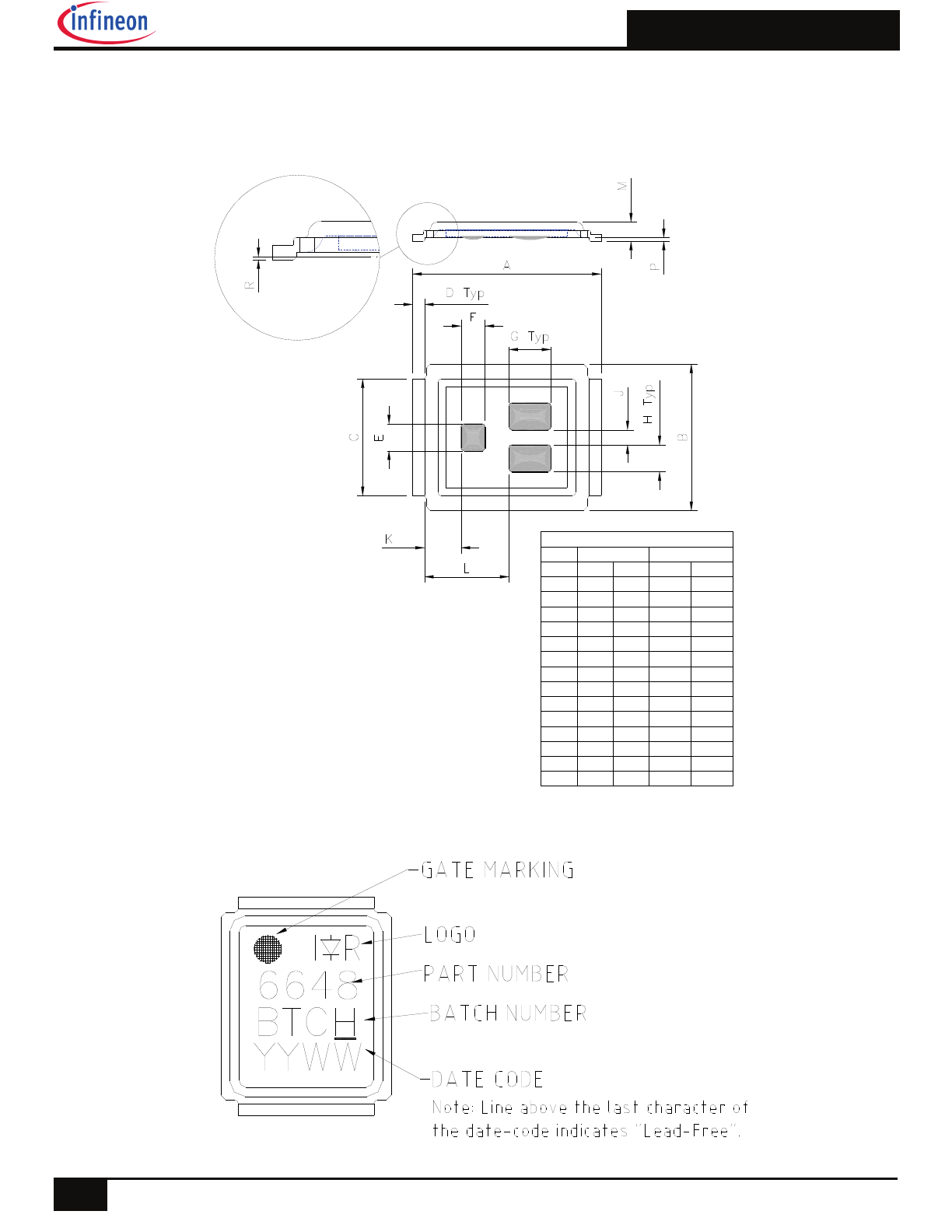

Fig 11. Maximum Safe Operating Area

Fig 14. Maximum Avalanche Energy vs. Drain Current

Fig 10. Typical Source-Drain Diode Forward Voltage

Fig 12. Maximum Drain Current vs. Case Temperature

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

VSD, Source-to-Drain Voltage (V)

0

1

10

100

1000

I S

D

, R

ev

er

se

D

ra

in

C

ur

re

nt

(

A

)

TJ = 150°C

TJ = 25°C

TJ = -40°C

VGS = 0V

0

1

10

100

VDS, Drain-to-Source Voltage (V)

0.1

1

10

100

1000

I D

,

D

ra

in

-t

o-

S

ou

rc

e

C

ur

re

nt

(

A

)

OPERATION IN THIS AREA

LIMITED BY R DS(on)

Tc = 25°C

Tj = 150°C

Single Pulse

100µsec

1msec

10msec

25

50

75

100

125

150

TC , Case Temperature (°C)

0

10

20

30

40

50

60

70

80

90

I D

,

D

ra

in

C

ur

re

nt

(

A

)

-75 -50 -25

0

25

50

75 100 125 150

TJ , Temperature ( °C )

2.0

3.0

4.0

5.0

6.0

T

yp

ic

al

V

G

S

(t

h)

, G

at

e

th

re

sh

ol

d

V

ol

ta

ge

(

V

)

ID = 150µA

ID = 250µA

ID = 1.0mA

ID = 1.0A

25

50

75

100

125

150

Starting TJ , Junction Temperature (°C)

0

20

40

60

80

100

120

140

160

180

200

E

A

S

,

S

in

gl

e

P

ul

se

A

va

la

nc

he

E

ne

rg

y

(m

J)

ID

TOP 12A

18A

BOTTOM 34A

Fig 13. Typical Threshold Voltage vs. Junction Temperature

IRF6648TRPbF

6

2017-04-06

Fig 15a. Gate Charge Test Circuit

Fig 15b. Gate Charge Waveform

Fig 16a. Unclamped Inductive Test Circuit

Fig 16b. Unclamped Inductive Waveforms

Fig 17a. Switching Time Test Circuit

Fig 17b. Switching Time Waveforms

IRF6648TRPbF

7

2017-04-06

DirectFET™ Substrate and PCB Layout, MN Outline

(Medium Size Can, N-Designation).

Please see DirectFET application note AN-1035 for all details regarding the assembly of DirectFET. This includes all rec-

ommendations for stencil and substrate designs.

Fig 18. Diode Reverse Recovery Test Circuit for HEXFET® Power MOSFETs

G

D

G=GATE

D=DRAIN

S=SOURCE

S

D

D

D

S

IRF6648TRPbF

8

2017-04-06

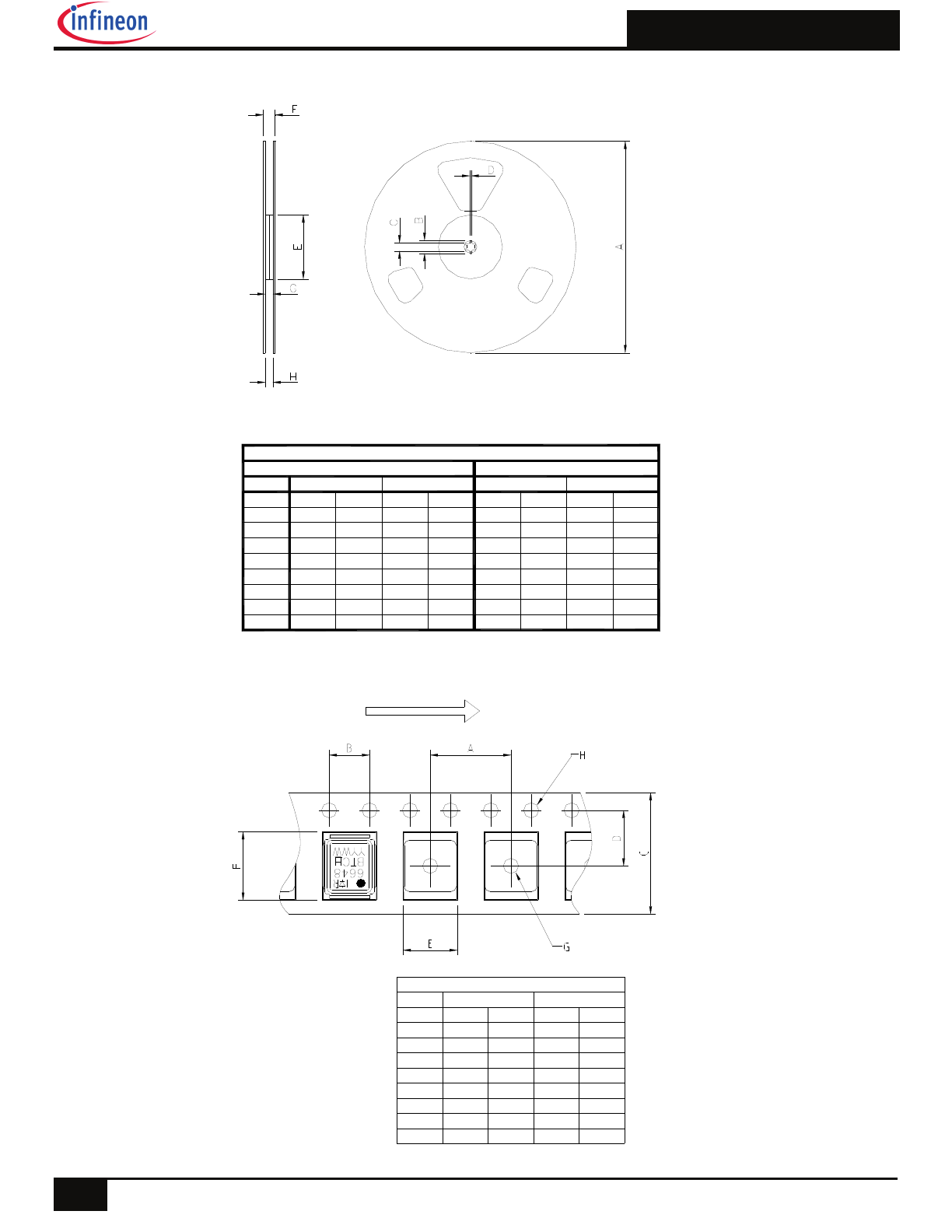

DirectFET™ Outline Dimension, MN Outline

(Medium Size Can, N-Designation).

Please see DirectFET application note AN-1035 for all details regarding the assembly of DirectFET. This includes all

recommendations for stencil and substrate designs.

MAX

0.250

0.201

0.156

0.018

0.036

0.032

0.056

0.036

0.020

0.051

0.115

0.0274

0.0031

0.007

MIN

0.246

0.189

0.152

0.014

0.034

0.031

0.054

0.034

0.019

0.046

0.109

0.0235

0.0008

0.003

MAX

6.35

5.05

3.95

0.45

0.92

0.82

1.42

0.92

0.52

1.29

2.91

0.676

0.080

0.17

MIN

6.25

4.80

3.85

0.35

0.88

0.78

1.38

0.88

0.48

1.16

2.74

0.616

0.020

0.08

CODE

A

B

C

D

E

F

G

H

J

K

L

M

R

P

DIMENSIONS

METRIC

IMPERIAL

DirectFET

™

Part Marking

IRF6648TRPbF

9

2017-04-06

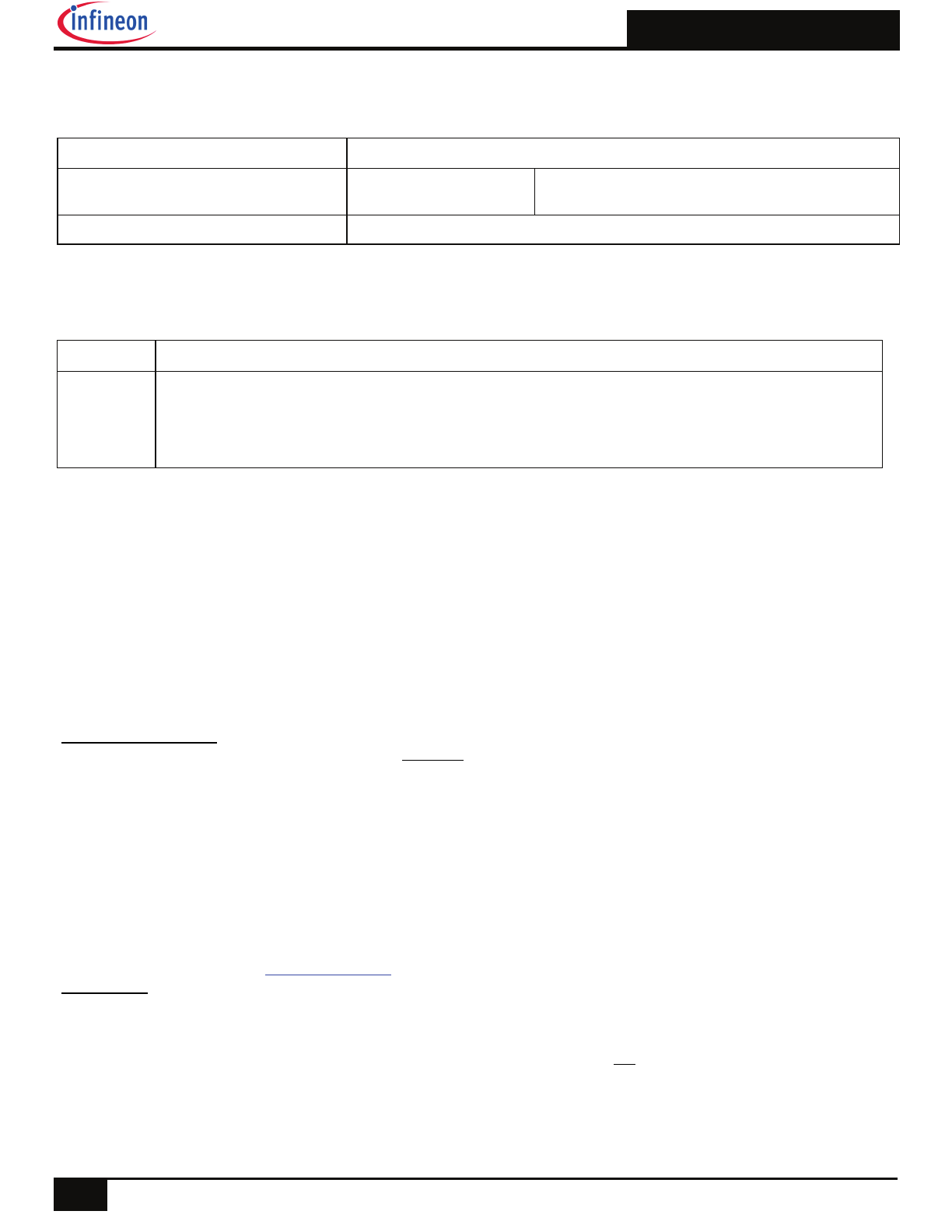

DirectFET

™

Tape & Reel Dimension (Showing component orientation).

STANDARD OPTION (QTY 4800)

MIN

330.0

20.2

12.8

1.5

100.0

N.C

12.4

11.9

CODE

A

B

C

D

E

F

G

H

MAX

N.C

N.C

13.2

N.C

N.C

18.4

14.4

15.4

MIN

12.992

0.795

0.504

0.059

3.937

N.C

0.488

0.469

MAX

N.C

N.C

0.520

N.C

N.C

0.724

0.567

0.606

METRIC

IMPERIAL

TR1 OPTION (QTY 1000)

IMPERIAL

MIN

6.9

0.75

0.53

0.059

2.31

N.C

0.47

0.47

MAX

N.C

N.C

12.8

N.C

N.C

13.50

12.01

12.01

MIN

177.77

19.06

13.5

1.5

58.72

N.C

11.9

11.9

METRIC

MAX

N.C

N.C

0.50

N.C

N.C

0.53

N.C

N.C

REEL DIMENSIONS

NOTE: Controlling dimensions in mm

Std reel quantity is 4800 parts. (ordered as IRF6648TRPBF). For 1000 parts on 7"

reel, order IRF6648TR1PBF

MIN

7.90

3.90

11.90

5.45

5.10

6.50

1.50

1.50

CODE

A

B

C

D

E

F

G

H

MAX

8.10

4.10

12.30

5.55

5.30

6.70

N.C

1.60

MIN

0.311

0.154

0.469

0.215

0.201

0.256

0.059

0.059

MAX

0.319

0.161

0.484

0.219

0.209

0.264

N.C

0.063

DIMENSIONS

METRIC

IMPERIAL

LOADED TAPE FEED DIRECTION

IRF6648TRPbF

10

2017-04-06

Qualification Information

Qualification Level

Consumer

†

Moisture Sensitivity Level

DirectFET

®

Medium Can

MSL1

(per JEDEC J-STD-020D

†)

RoHS Compliant

Yes

† Applicable version of JEDEC standard at the time of product release.

Revision History

Date Comment

04/06/2017

Changed datasheet with Infineon logo - all pages.

Added Orderable table on page 1.

Corrected PCB layout on page 7

Added Qualification table on page 10.

Added disclaimer on last page.

Published by

Infineon Technologies AG

81726 München, Germany

©

Infineon Technologies AG 2015

All Rights Reserved.

IMPORTANT NOTICE

The information given in this document shall in no event be regarded as a guarantee of conditions or characteristics

(“Beschaffenheitsgarantie”). With respect to any examples, hints or any typical values stated herein and/or any

information regarding the application of the product, Infineon Technologies hereby disclaims any and all warranties and

liabilities of any kind, including without limitation warranties of non-infringement of intellectual property rights of any third

party.

In addition, any information given in this document is subject to customer’s compliance with its obligations stated in this

document and any applicable legal requirements, norms and standards concerning customer’s products and any use of

the product of Infineon Technologies in customer’s applications.

The data contained in this document is exclusively intended for technically trained staff. It is the responsibility of

customer’s technical departments to evaluate the suitability of the product for the intended application and the

completeness of the product information given in this document with respect to such application.

For further information on the product, technology, delivery terms and conditions and prices please contact your nearest

Infineon Technologies office (

www.infineon.com

).

WARNINGS

Due to technical requirements products may contain dangerous substances. For information on the types in question

please contact your nearest Infineon Technologies office.

Except as otherwise explicitly approved by Infineon Technologies in a written document signed by authorized

representatives of Infineon Technologies, Infineon Technologies’ products may not be used in any applications where a

failure of the product or any consequences of the use thereof can reasonably be expected to result in personal injury.