July 16, 2014 | DATASHEET V3.3

1

IR3553

40A Integrated PowIRstage®

FEATURES

Peak efficiency up to 93.2% at 1.2V

Integrated driver, control MOSFET, synchronous

MOSFET and Schottky diode

Input voltage (VIN) operating range up to 15V

Output voltage range from 0.25V to Vcc-2.5V, or to

5.5V if internal current sense amplifier is not used

Output current capability of 40A DC

Operation up to 1.0MHz

Integrated current sense amplifier

VCC under voltage lockout

Thermal flag

Body-Braking® load transient support

Diode-emulation high efficiency mode

Compatible with 3.3V PWM logic and VCC tolerant

Compliant with Intel DrMOS V4.0

PCB footprint compatible with IR3550 and IR3551

Efficient dual sided cooling

Small 4mm x 6mm x 0.9mm PQFN package

Lead free RoHS compliant package

APPLICATIONS

Voltage Regulators for CPUs, GPUs, and DDR

memory arrays

High current, low profile DC-DC converters

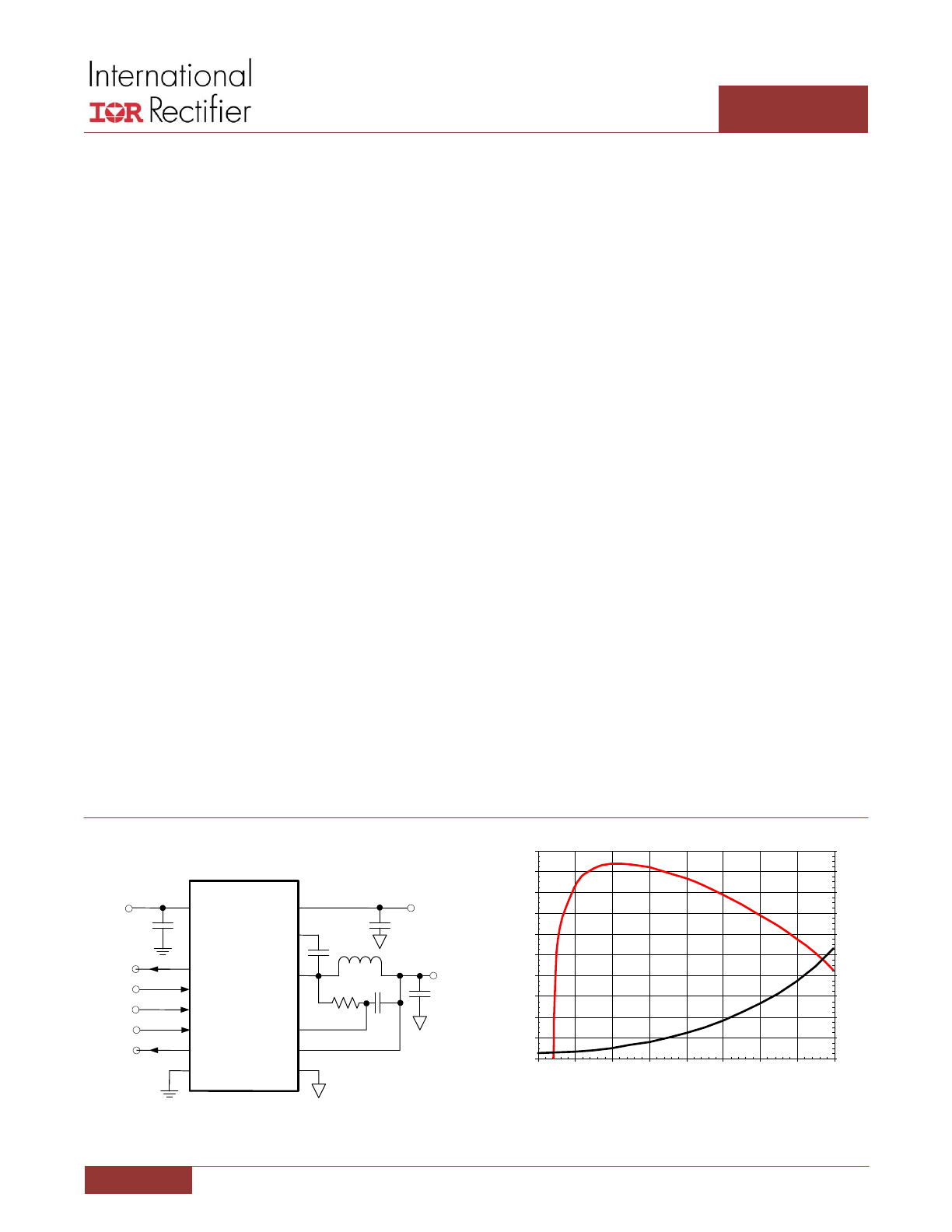

BASIC APPLICATION

SW

PWM

VIN

PGND

VCC

VCC

BOOST

VIN

VOUT

PWM

CSIN+

CSIN-

4.5V to 7V

LGND

IOUT

IOUT

BBRK#

BBRK#

REFIN

REFIN

4.5V to 15V

IR3553

PHSFLT#

PHSFLT#

Figure 1: IR3553 Basic Application Circuit

DESCRIPTION

The IR3553 integrated PowIRstage® is a synchronous buck

gate driver co-packed with a control MOSFET and a

synchronous MOSFET with integrated Schottky diode. It is

optimized internally for PCB layout, heat transfer and

driver/MOSFET timing. Custom designed gate driver and

MOSFET combination enables higher efficiency at lower

output voltages required by cutting edge CPU, GPU and

DDR memory designs.

Up to 1.0MHz switching frequency enables high

performance transient response, allowing miniaturization

of output inductors, as well as input and output capacitors

while maintaining industry leading efficiency. The IR3553’s

superior efficiency enables smallest size and lower solution

cost. The IR3553 PCB footprint is compatible with the

IR3550 (60A) and the IR3551 (50A).

Integrated current sense amplifier achieves superior

current sense accuracy and signal to noise ratio vs. best-in-

class controller based Inductor DCR sense methods.

The IR3553 incorporates the Body- Braking® feature which

enables reduction of output capacitors. Synchronous diode

emulation mode in the IR3553 removes the zero-current

detection burden from the PWM controller and increases

system light-load efficiency.

The IR3553 is optimized specifically for CPU core power

delivery in server applications. The ability to meet the

stringent requirements of the server market also makes

the IR3553 ideally suited to powering GPU and DDR

memory designs and other high current applications.

Figure 2: Typical IR3553 Efficiency & Power Loss

(See Note 2 on Page 8)

74

76

78

80

82

84

86

88

90

92

94

0

5

10

15

20

25

30

35

40

Output Current (A)

Ef

fi

ci

en

cy

(

%

)

0

2

4

6

8

10

12

14

16

18

20

P

o

w

er

L

o

ss

(

W

)

July 16, 2014 | DATASHEET V3.3

2

IR3553

40A Integrated PowIRstage®

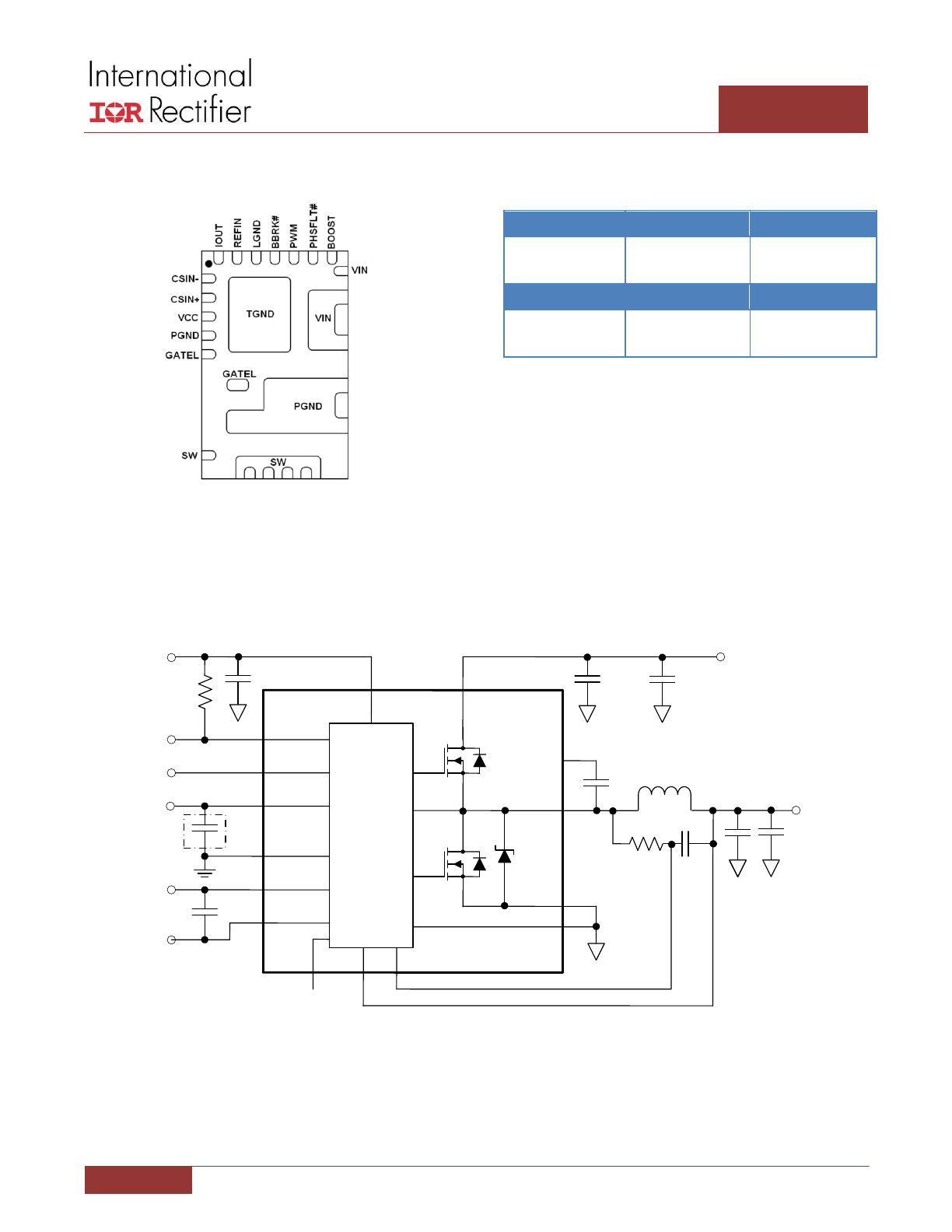

PINOUT DIAGRAM

Figure 3: IR3553 Pin Diagram, Top View

ORDERING INFORMATION

Package

Tape & Reel Qty

Part Number

PQFN, 25 Lead

4mm x 6mm

3000

IR3553MTRPBF

Package

Qty

Part Number

PQFN, 25 Lead

4mm x 6mm

100

IR3553MPBF

TYPICAL APPLICATION DIAGRAM

SW

PWM

VIN

PGND

Gate

Drivers

and

Current

Sense

Amplifier

LGND

VCC

PHSFLT#

IOUT

VCC

BOOST

VIN

PWM

IOUT

PHSFLT#

BBRK#

BBRK#

REFIN

REFIN

CSIN-

CSIN+

IR3553

4.5V to 7V

4.5V to 15V

C2

10uF x 2

C5

0.22uF

C3

1uF

R1

10k

C4

0.22uF

R2

2.49k

L1

150nH

3

14-16

17

18

19

20

22

21

23

1

2

12, 13

6-11

C1

0.22uF

PGND 4

24

TGND

No Connect

C8

1nF

C9

22nF

Optional for

diode emulation

setup

VOUT

C7

470uF

C6

22uF

Figure 4: Application Circuit with Current Sense Amplifier

July 16, 2014 | DATASHEET V3.3

3

IR3553

40A Integrated PowIRstage®

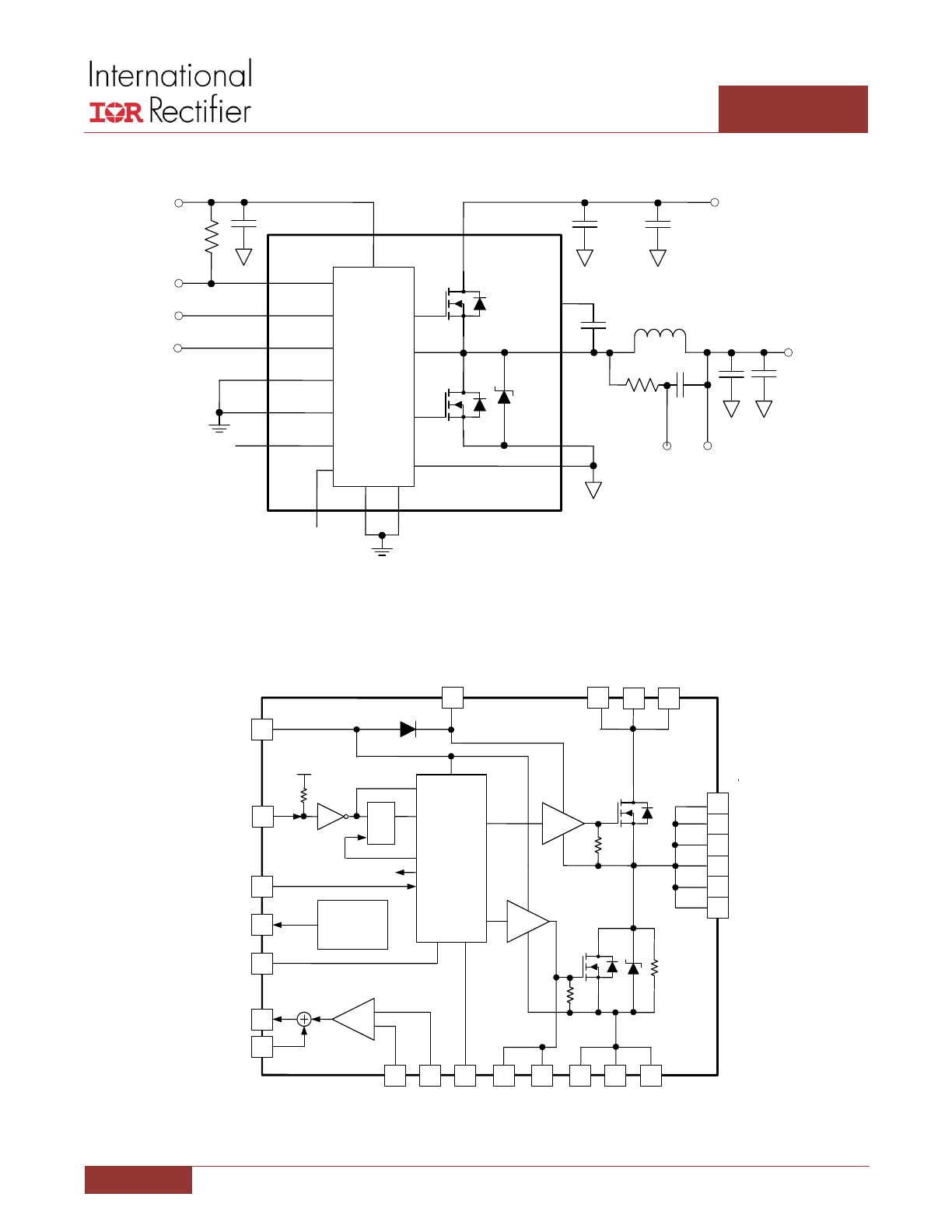

TYPICAL APPLICATION DIAGRAM (CONTINUED)

SW

PWM

VIN

PGND

Gate

Drivers

and

Current

Sense

Amplifier

IOUT

VCC

PHSFLT#

VCC

BOOST

VIN

PWM

REFIN

PHSFLT#

BBRK#

BBRK#

CS+

LGND

CSIN-

CSIN+

IR3553

4.5V to 7V

4.5V to 15V

C2

10uF x 2

C5

0.22uF

C3

0.22uF

R1

10k

C4

0.22uF

R2

2.49k

L1

150nH

3

14-16

17

18

19

20

21

23

22

1

2

12, 13

6-11

C1

0.22uF

PGND 4

24

TGND

No Connect

CS-

VOUT

C7

470uF

C6

22uF

Figure 5: Application Circuit without Current Sense Amplifier

FUNCTIONAL BLOCK DIAGRAM

PW M

6

7

8

9

10

11

14

15

16

VIN

VIN

VIN

SW

SW

SW

SW

SW

SW

1

4

12

13

CSIN -

PG N D

PG N D

PG N D

17

BO O ST

Pow er-on

Reset

(PO R),

3.3V

Reference,

and

D ead-tim e

Control

19

IO U T

23

VCC

3

BBRK#

20

25

5

G ATEL G ATEL

D river

D river

18

PH SFLT#

2

CSIN +

21

LG N D

22

REFIN

Current Sense

Am plifier

M O SFET

& Therm al

D etection

S Q

R

PO R

3.3V

VCC

-

+

3.3V

24

TG N D

Figure 6: IR3553 Functional Block Diagram

July 16, 2014 | DATASHEET V3.3

4

IR3553

40A Integrated PowIRstage®

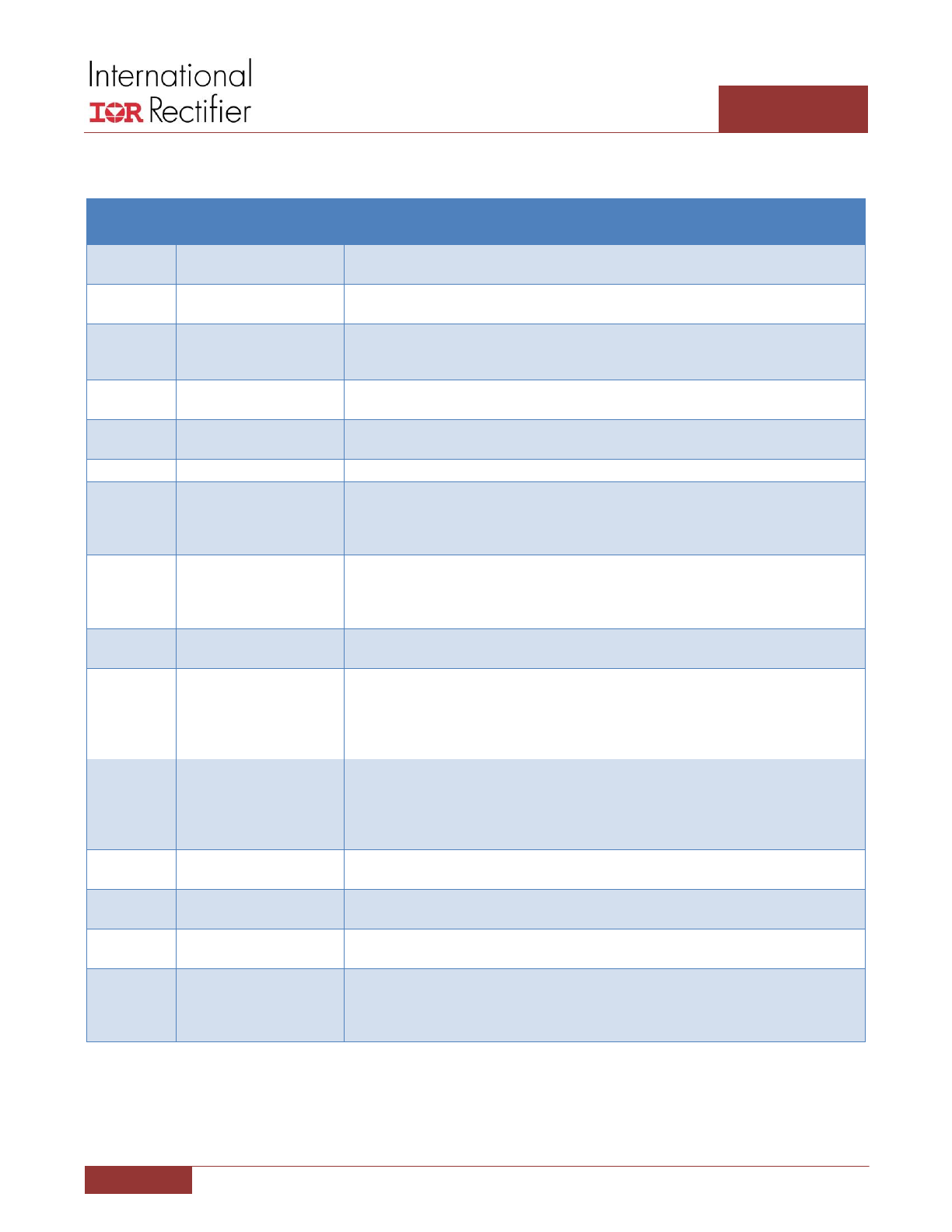

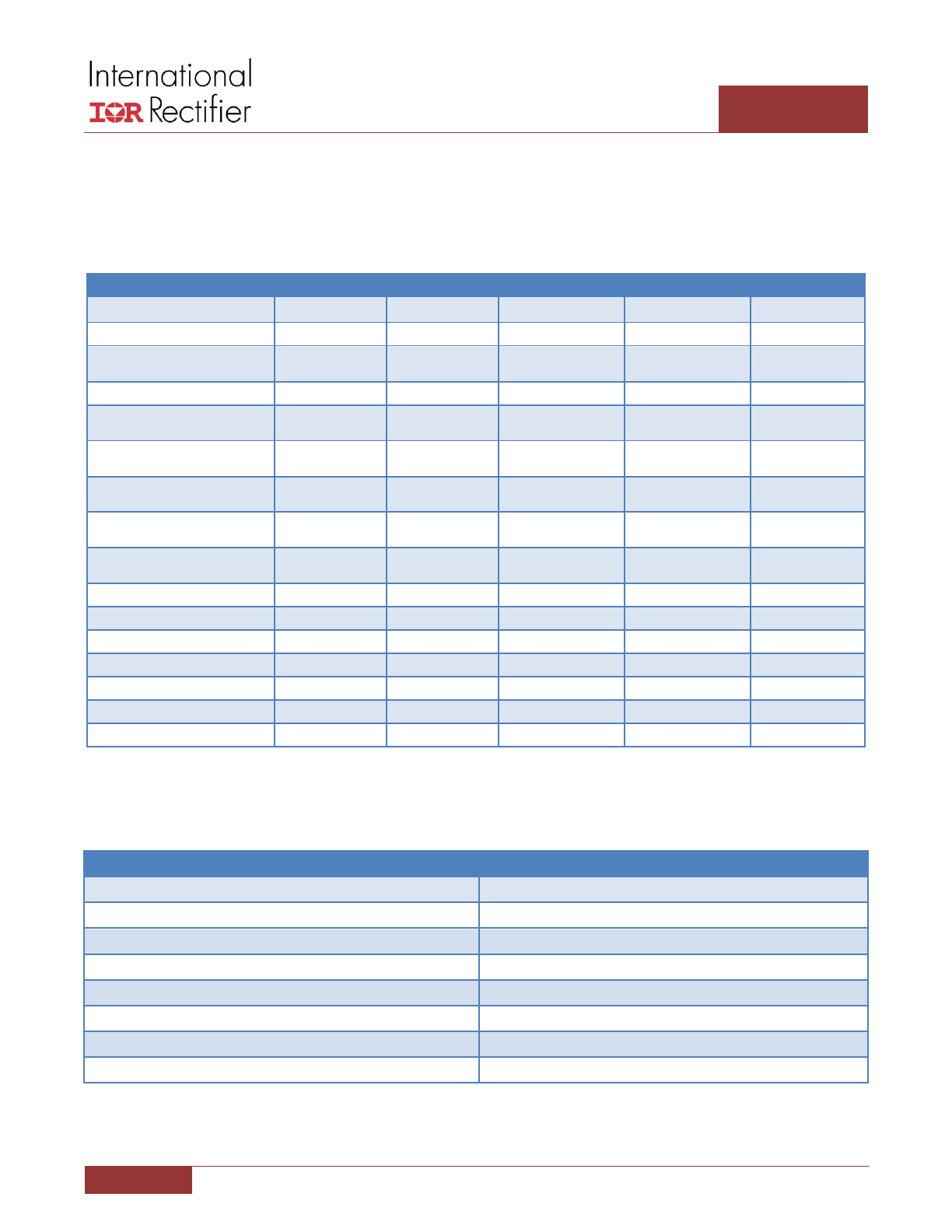

PIN DESCRIPTIONS

PIN #

PIN NAME

PIN DESCRIPTION

1

CSIN-

Inverting input to the current sense amplifier. Connect to LGND if the current sense

amplifier is not used.

2

CSIN+

Non-Inverting input to the current sense amplifier. Connect to LGND if the current sense

amplifier is not used.

3

VCC

Bias voltage for control logic. Connect a minimum 1uF cap between VCC and PGND (pin

4) if current sense amplifier is used. Connect a minimum 0.22uF capacitor between VCC

and PGND (pin 4) if current sense amplifier is not used.

4, 12, 13

PGND

Power ground of MOSFET driver and the synchronous MOSFET. MOSFET driver signal is

referenced to this pin.

5, 25

GATEL

Low-side MOSFET driver pins that can be connected to a test point in order to observe

the waveform.

6 – 11

SW

Switch node of synchronous buck converter.

14 – 16

VIN

High current input voltage connection. Recommended operating range is 4.5V to 15V.

Connect at least two 10uF 1206 ceramic capacitors and a 0.22uF 0402 ceramic

capacitor. Place the capacitors as close as possible to VIN pins and PGND pins (12-13).

The 0.22uF 0402 capacitor should be on the same side of the PCB as the IR3553.

17

BOOST

Bootstrap capacitor connection. The bootstrap capacitor provides the charge to turn on

the control MOSFET. Connect a minimum 0.22µF capacitor from BOOST to SW pin. Place

the capacitor as close to BOOST pin as possible and minimize parasitic inductance of

PCB routing from the capacitor to SW pin.

18

PHSFLT#

Open drain output of the phase fault circuits. Connect to an external pull-up resistor.

Output is low when a MOSFET fault or over temperature condition is detected.

19

PWM

3.3V logic level tri-state PWM input and 7V tolerant. “High” turns the control MOSFET

on, and “Low” turns the synchronous MOSFET on. “Tri-state” turns both MOSFETs off in

Body-Braking® mode. In diode emulation mode, “Tri-state” activates internal diode

emulation control. See “PWM Tri-state Input” Section for further details about the PWM

Tri-State functions.

20

BBRK#

3.3V logic level input and 7V tolerant with internal weak pull-up to 3.3V. Logic low

disables both MOSFETs. Pull up to VCC directly or by a 4.7kΩ resistor if Body-Braking® is

not used. The second function of the BBRK# pin is to select diode emulatiom mode.

Pulling BBRK# low at least 20ns after VCC passes its UVLO threshold selects internal

diode emulation control. See “Body-Braking

®

Mode” Section for further details.

21

LGND

Signal ground. Driver control logic, analog circuits and IC substrate are referenced to

this pin.

22

REFIN

Reference voltage input from the PWM controller. IOUT signal is referenced to the

voltage on this pin. Connect to LGND if the current sense amplifier is not used.

23

IOUT

Current output signal. Voltage on this pin is equal to V(REFIN) + 32.5 * [V(CSIN+) –

V(CSIN-)]. Float this pin if the current sense amplifier is not used.

24

TGND

This pin is connected to internal power and signal ground of the driver. For best

performance of the current sense amplifier, TGND must be electrically isolated from

Power Ground (PGND) and Signal Ground (LGND) in the PCB layout. Connect to PGND if

the current sense amplifier is not used.

July 16, 2014 | DATASHEET V3.3

5

IR3553

40A Integrated PowIRstage®

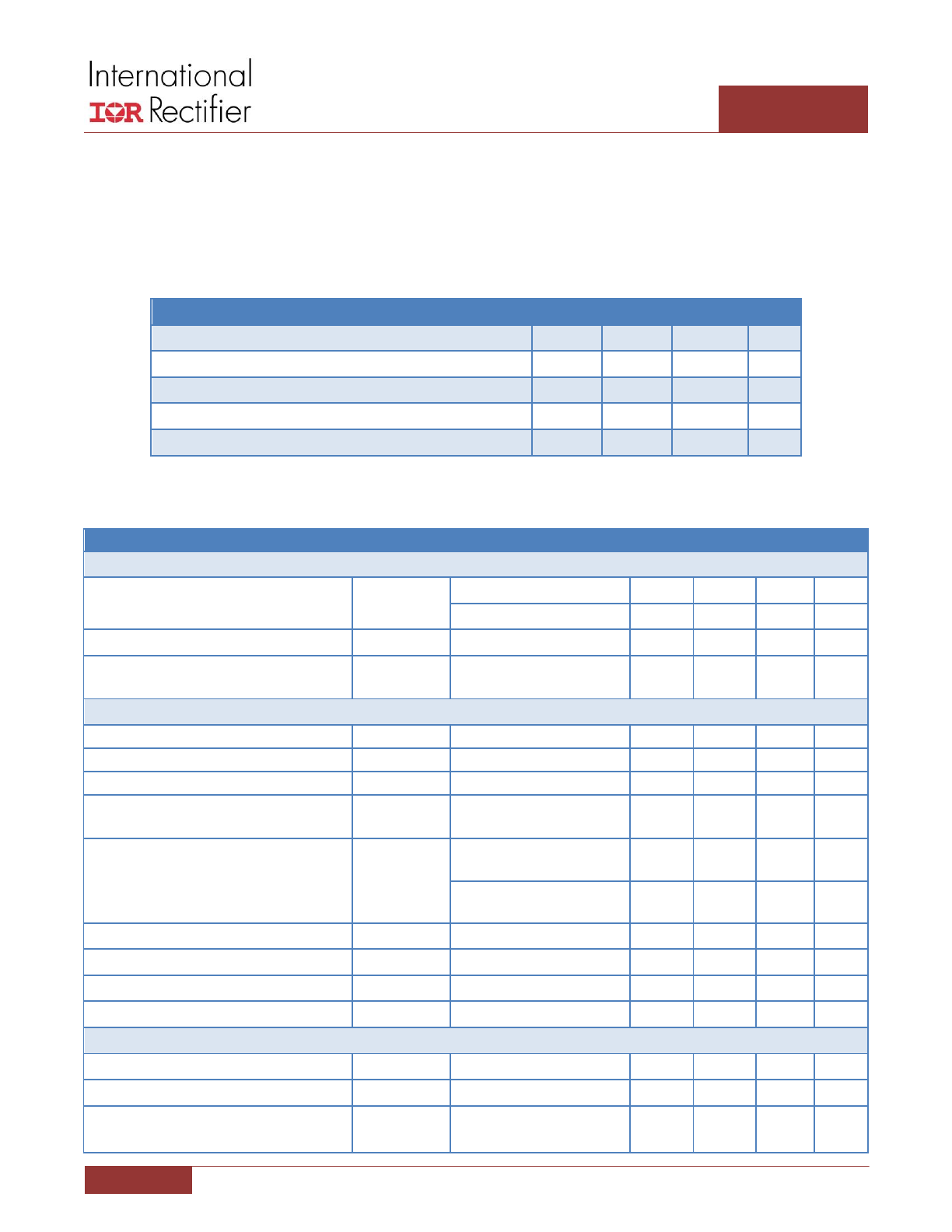

ABSOLUTE MAXIMUM RATINGS

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are

stress ratings only and functional operation of the device at these or any other conditions beyond those indicated in the

operational sections of the specifications are not implied.

PIN Number

PIN NAME

V

MAX

V

MIN

I

SOURCE

I

SINK

1

CSIN-

VCC + 0.3V

-0.3V

1mA

1mA

2

CSIN+

VCC + 0.3V

-0.3V

1mA

1mA

3

VCC

8V

-0.3V

NA

5A for 100ns,

200mA DC

4

PGND

0.3V

-0.3V

15mA

15mA

5, 25

GATEL

VCC + 0.3V

-3V for 20ns,

-0.3V DC

1A for 100ns,

200mA DC

1A for 100ns,

200mA DC

6-11

SW

2

25V

-5V for 20ns,

-0.3V DC

45A RMS,

60A Peak

20A RMS,

25A Peak

12, 13

PGND

NA

NA

20A RMS,

25A Peak

45A RMS,

60A Peak

14-16

VIN

2

25V

-0.3V

5A RMS

15A RMS,

20A Peak

17

BOOST

1

33V

-0.3V

1A for 100ns,

100mA DC

5A for 100ns,

100mA DC

18

PHSFLT#

VCC + 0.3V

-0.3V

1mA

20mA

19

PWM

VCC + 0.3V

-0.3V

1mA

1mA

20

BBRK#

VCC + 0.3V

-0.3V

1mA

1mA

21

LGND

0.3V

-0.3V

15mA

15mA

22

REFIN

3.5V

-0.3V

1mA

1mA

23

IOUT

VCC + 0.3V

-0.3V

5mA

5mA

24

TGND

0.3V

-0.3V

NA

NA

Note:

1. Maximum BOOST – SW = 8V.

2.

Maximum VIN – SW = 25V.

3. All the maximum voltage ratings are referenced to PGND (Pins 12 and 13).

THERMAL INFORMATION

Thermal Resistance, Junction to Top (θ

JC_TOP

)

23.2 °C/W

Thermal Resistance, Junction to PCB (pin 13) (θ

JB

)

2.5 °C/W

Thermal Resistance (θ

JA

)

1

22.2 °C/W

Maximum Operating Junction Temperature

-40 to 150°C

Maximum Storage Temperature Range

-65°C to 150°C

ESD rating

HBM Class 1B JEDEC Standard

MSL Rating

3

Reflow Temperature

260°C

Note:

1. Thermal Resistance (θ

JA

) is measured with the component mounted on a high effective thermal conductivity test board in free air.

Refer to International Rectifier Application Note AN-994 for details.

July 16, 2014 | DATASHEET V3.3

6

IR3553

40A Integrated PowIRstage®

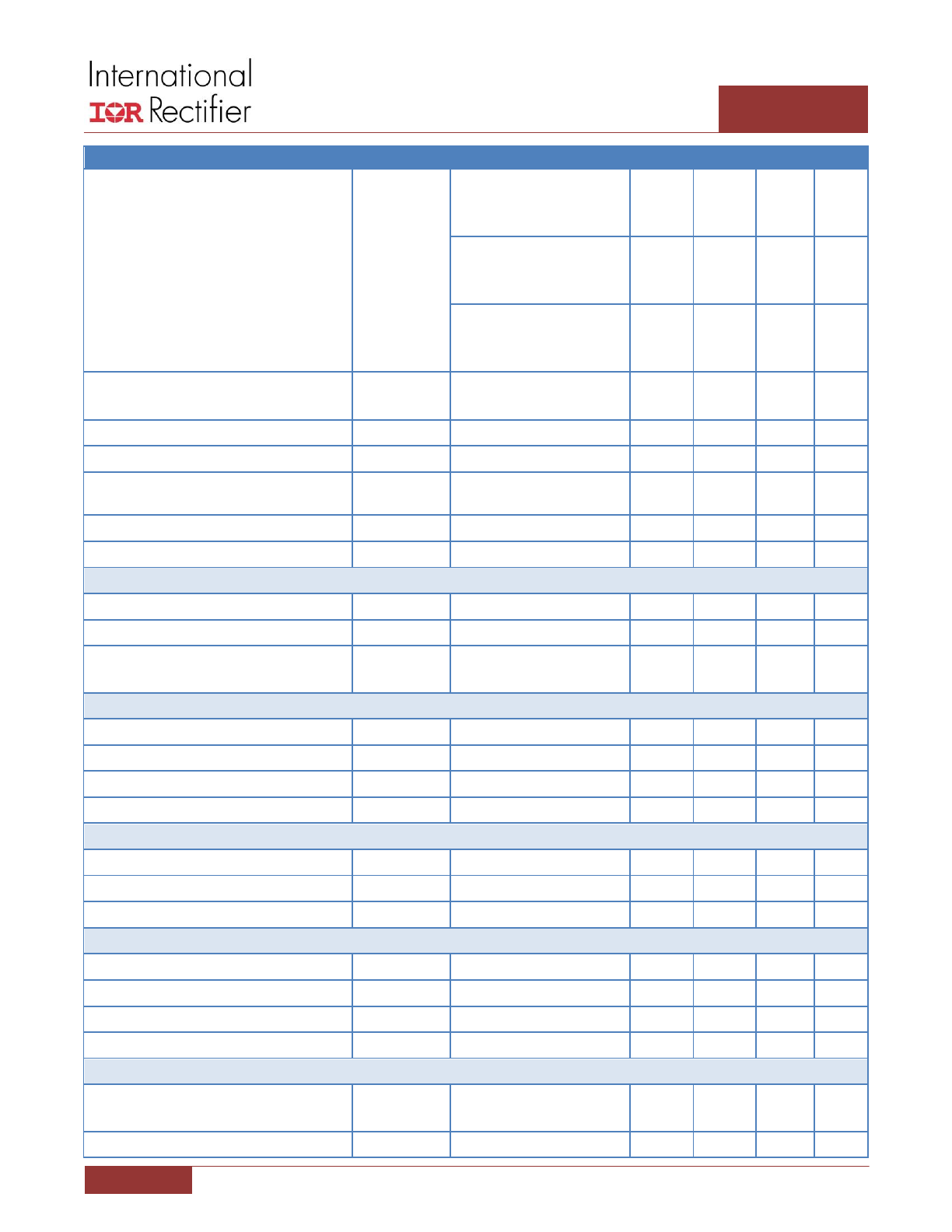

ELECTRICAL SPECIFICATIONS

The electrical characteristics involve the spread of values guaranteed within the recommended operating conditions.

Typical values represent the median values, which are related to 25°C.

RECOMMENDED OPERATING CONDITIONS FOR RELIABLE OPERATION WITH MARGIN

PARAMETER

SYMBOL

MIN

MAX

UNIT

Recommended VIN Range

VIN

4.5

15

V

Recommended VCC Range

VCC

4.5

7

V

Recommended REFIN Range

REFIN

0.25

VCC – 2.5

V

Recommended Switching Frequency

ƒ

SW

200

1000

kHz

Recommended Operating Junction Temperature

T

J

-40

125

°C

ELECTRICAL CHARACTERISTICS

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNIT

Efficiency and Maximum Current

IR3553 Peak Efficiency

Note 1

η

Note 2. See Figure 2.

92.7

%

Note 3. See Figure 7.

92.2

%

IR3553 Maximum DC Current

Note 1

I

DC_MAX

Note 2.

40

A

IR3553 Maximum Peak Current

Note 1

I

PK_MAX

Note 4. 5ms load pulse

width, 10% load duty cycle.

60

A

PWM Comparator

PWM Input High Threshold

V

PWM_HIGH

PWM Tri-state to High

2.5

V

PWM Input Low Threshold

V

PWM_LOW

PWM Tri-state to Low

0.8

V

PWM Tri-state Float Voltage

V

PWM_TRI

PWM Floating

1.2

1.65

2.1

V

Hysteresis

V

PWM_HYS

Active to Tri-state or Tri-

state to Active, Note 1

65

76

100

mV

Tri-state Propagation Delay

t

PWM_DELAY

PWM Tri-state to Low

transition to GATEL >1V

38

ns

PWM Tri-state to High

transition to GATEH >1V

18

ns

PWM Sink Impedance

R

PWM_SINK

3.67

5.1

8.70

kΩ

PWM Source Impedance

R

PWM_SOURCE

3.67

5.1

8.70

kΩ

Internal Pull up Voltage

V

PWM_PULLUP

VCC > UVLO

3.3

V

Minimum Pulse Width

t

PWM_MIN

Note 1

41

58

ns

Current Sense Amplifier

CSIN+/- Bias Current

I

CSIN_BIAS

-100

0

100

nA

CSIN+/- Bias Current Mismatch

I

CSIN_BIASMM

-50

0

50

nA

Calibrated Input Offset Voltage

V

CSIN_OFFSET

Self-calibrated offset,

0.5V ≤ V(REFIN) ≤ 2.25V

±450

µV

July 16, 2014 | DATASHEET V3.3

7

IR3553

40A Integrated PowIRstage®

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNIT

Gain

G

CS

0.5V ≤ V(REFIN) ≤ 2.25V,

-5mV ≤ *V(CSIN+) –V(CSIN-)]

≤ 25mV, 0°C ≤ T

J

≤ 125°C

30.0

32.5

35.0

V/V

0.5V ≤ V(REFIN) ≤ 2.25V,

-5mV ≤ *V(CSIN+) – V(CSIN-)]

≤ 25mV

30.0

33.0

36.0

V/V

0.8V ≤ V(REFIN) ≤ 2.25V,

-10mV ≤*V(CSIN+)–V(CSIN-)]

≤ 25mV

28.0

31.5

35.0

V/V

Unity Gain Bandwidth

f

BW

C(IOUT) = 10pF. Measure at

IOUT. Note 1

4.8

6.8

8.8

MHz

Slew Rate

S

R

6

V/µs

Differential Input Range

V

D_IN

0.8V ≤ V(REFIN) ≤ 2.25V,

-10

25

mV

Common Mode Input Range

V

C_IN

0

VCC-

2.5

V

Output Impedance (IOUT)

R

CS_OUT

62

200

Ω

IOUT Sink Current

I

CS_SINK

Driving external 3 kΩ

0.5

0.8

1.1

mA

Diode Emulation Mode Comparator

Input Offset Voltage

V

IN_OFFSET

Note 1

-12

-3

3

mV

Leading Edge Blanking Time

t

BLANK

V(GATEL)>1V Starts Timer

50

150

200

ns

Negative Current Time-Out

t

NC_TOUT

PWM = Tri-State,

V(SW) ≤ -10mV

12

28

46

µs

Digital Input – BBRK#

Input voltage high

V

BBRK#_IH

2.0

V

Input voltage low

V

BBRK#_IL

0.8

V

Internal Pull Up Resistance

R

BBRK#_PULLUP

VCC > UVLO

69

200

338

kΩ

Internal Pull Up Voltage

V

BBRK#_PULLUP

VCC > UVLO

3.3

V

Digital Output – PHSFLT#

Output voltage high

V

PHASFLT#_OH

VCC

V

Output voltage low

V

PHASFLT#_OL

4mA

150

300

mV

Input current

I

PHASFLT#_IN

V(PHSFLT#) = 5.5V

0

1

µA

Phase Fault Detection

Control MOSFET Short Threshold

V

CM_SHORT

Measure from SW to PGND

3.3

V

Synchronous MOSFET Short Threshold

V

SM_SHORT

Measure from SW to PGND

150

200

250

mV

Synchronous MOSFET Open Threshold

V

SM_OPEN

Measure from SW to PGND

-250

-200

-150

mV

Propagation Delay

t

PROP

PWM High to Low Cycles

15

Cycle

Thermal Flag

Rising Threshold

T

RISE

PHSFLT# Drives Low,

Note 1

160

°C

Falling Threshold

T

FALL

Note 1

135

°C

July 16, 2014 | DATASHEET V3.3

8

IR3553

40A Integrated PowIRstage®

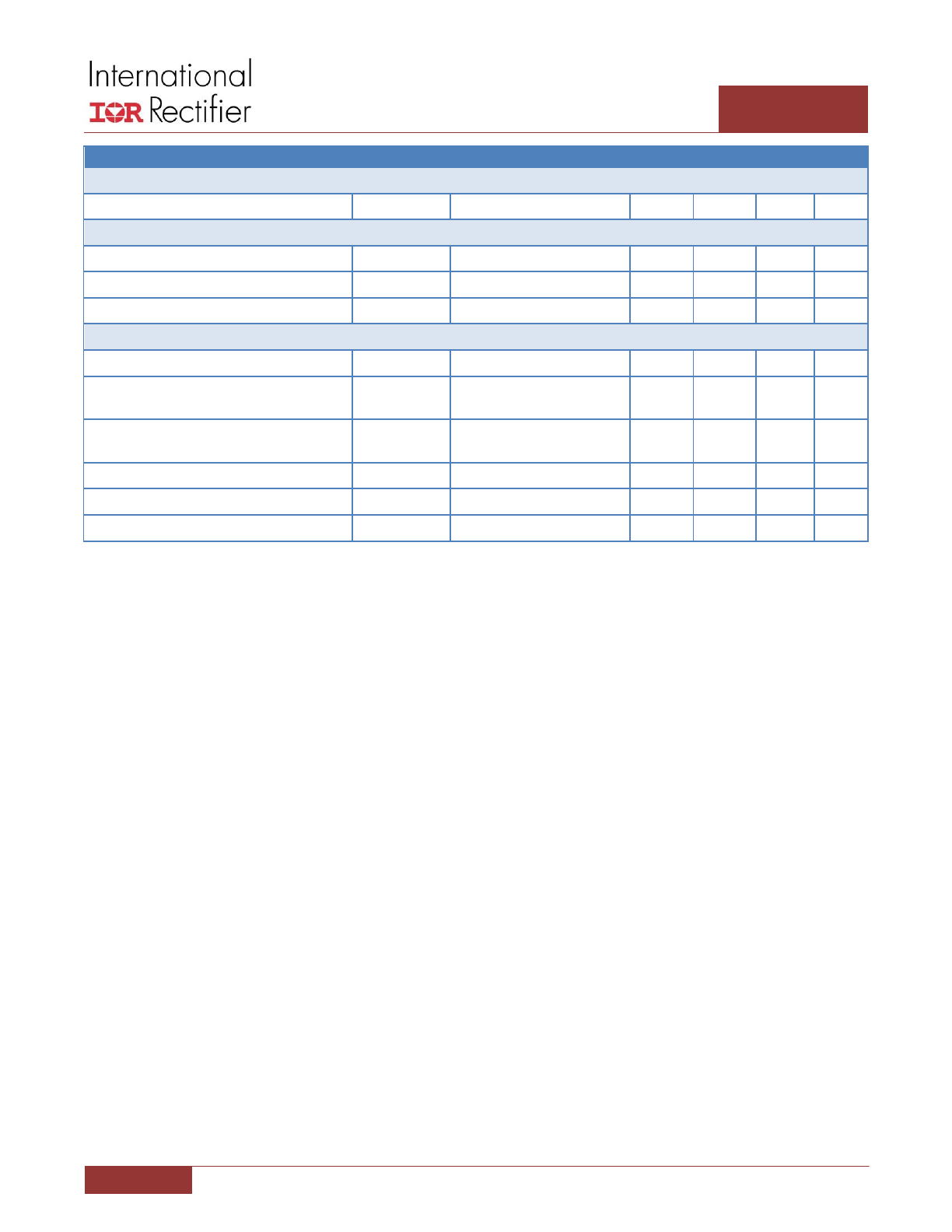

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNIT

Bootstrap Diode

Forward Voltage

V

FWD

I(BOOST) = 30mA, VCC=6.8V

360

520

920

mV

VCC Under Voltage Lockout

Start Threshold

V

VCC_START

3.3

3.7

4.1

V

Stop Threshold

V

VCC_STOP

3.0

3.4

3.8

V

Hysteresis

V

VCC_HYS

0.2

0.3

0.4

V

General

VCC Supply Current

I

VCC

VCC = 4.5V to 7V

4

8

12

mA

VIN Supply Leakage Current

I

VIN

VIN = 20V, 125C, V(PWM) =

Tri-State

1

µA

BOOST Supply Current

I

BOOST

4.75V < V(BOOST)-V(SW) <

8V

0.5

1.5

3.0

mA

REFIN Bias Current

I

REFIN

-1.5

0

1

µA

SW Floating Voltage

V

SW_FLOAT

V(PWM) = Tri-State

0.2

0.4

V

SW Pull Down Resistance

R

SW_PULLDOWN

BBRK# is Low or VCC = 0V

18

kΩ

Notes

1. Guaranteed by design but not tested in production

2. V

IN

=12V, V

OUT

=1.2V, ƒ

SW

= 300kHz, L=210nH (0.2mΩ), VCC=6.8V, C

IN

=47uF x 4, C

OUT

=470uF x3, 400LFM airflow, no heat sink, 25°C

ambient temperature, and 8-layer PCB of 3.7” (L) x 2.6” (W). PWM controller loss and inductor loss are not included.

3. V

IN

=12V, V

OUT

=1.2V, ƒ

SW

= 400kHz, L=150nH (0.29mΩ), VCC=7V, C

IN

=47uF x 4, C

OUT

=470uF x3, no airflow, no heat sink, 25°C ambient

temperature, and 8-layer PCB of 3.7” (L) x 2.6” (W). PWM controller loss and inductor loss are not included.

4. V

IN

=12V, V

OUT

=1.2V, ƒ

SW

= 400kHz, L=210nH (0.2mΩ, 13mm x 13mm x 8mm), VCC=6.8V, C

IN

=47uF x 4, C

OUT

=470uF x3, no heat sink,

25°C ambient temperature, 8-layer PCB of 3.7” (L) x 2.6” (W), 5ms load pulse width, 10% load duty cycle, and IR3553 junction

temperature below 125°C.

July 16, 2014 | DATASHEET V3.3

9

IR3553

40A Integrated PowIRstage®

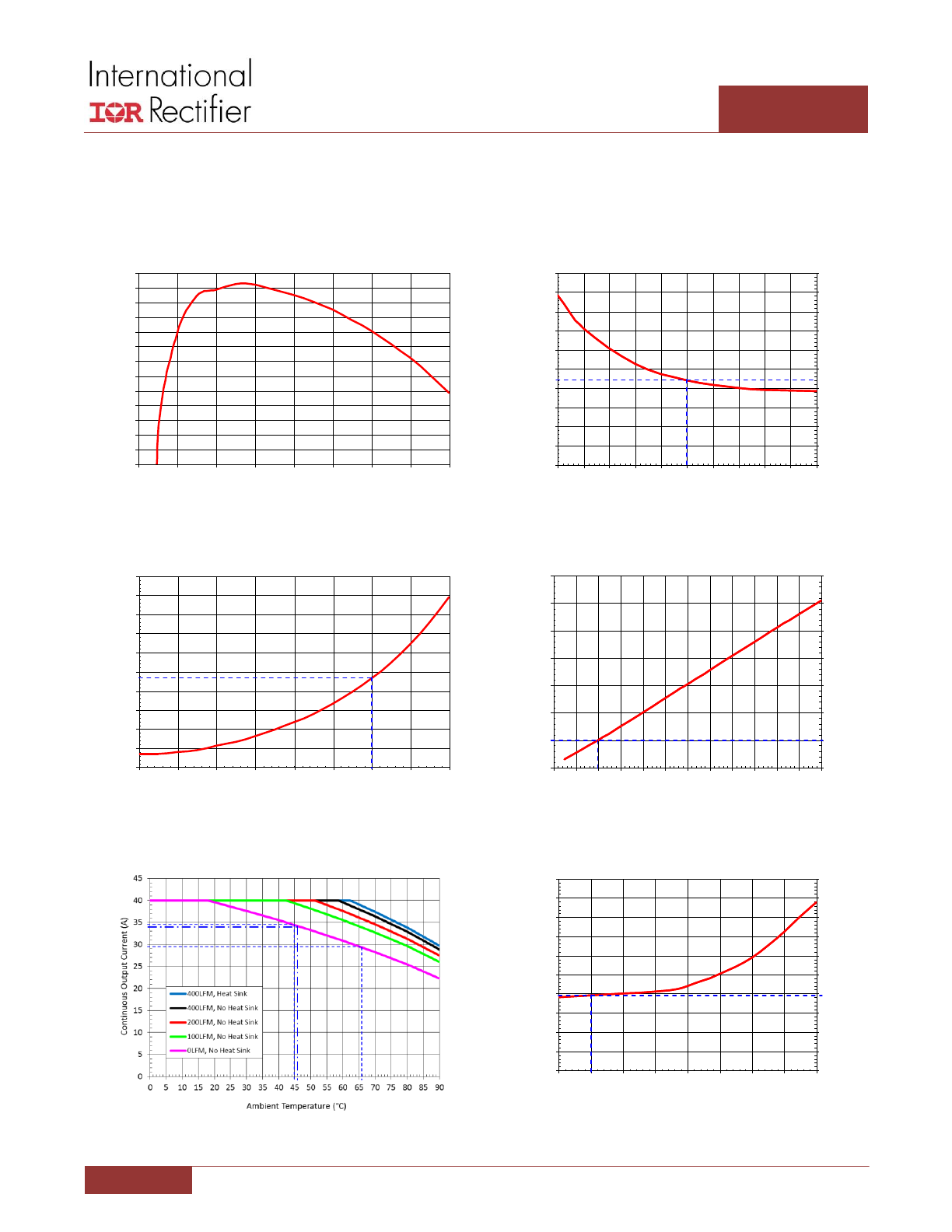

TYPICAL OPERATING CHARACTERISTICS

Circuit of Figure 32, V

IN

=12V, V

OUT

=1.2V, ƒ

SW

= 400kHz, L=150nH (0.29mΩ), VCC=7V, T

AMBIENT

= 25°C, no heat sink, no air flow,

8-layer PCB board of 3.7” (L) x 2.6” (W), no PWM controller loss, no inductor loss, unless specified otherwise.

Figure 7: Typical IR3553 Efficiency

Figure 8: Typical IR3553 Power Loss

Figure 9: Thermal Derating Curve, T

CASE

<= 125°C

Figure 10: Normalized Power Loss vs. Input Voltage

Figure 11: Normalized Power Loss vs. Output Voltage

Figure 12: Normalized Power Loss vs. Switching Frequency

80

81

82

83

84

85

86

87

88

89

90

91

92

93

0

5

10

15

20

25

30

35

40

Output Current (A)

Ef

fi

ci

en

cy

(

%

)

0

1

2

3

4

5

6

7

8

9

10

0

5

10

15

20

25

30

35

40

Output Current (A)

P

o

w

er

L

o

ss

(

W

)

0.80

0.85

0.90

0.95

1.00

1.05

1.10

1.15

1.20

1.25

1.30

5

6

7

8

9

10

11

12

13

14

15

Input Voltage (V)

N

o

rm

a

liz

ed

P

o

wer

L

o

ss

-6.0

-4.5

-3.0

-1.5

0.0

1.5

3.0

4.5

6.0

7.5

9.0

C

a

se

T

em

p

er

a

tu

re

A

d

ju

st

m

en

t

(°

C

)

0.8

0.9

1.0

1.1

1.2

1.3

1.4

1.5

0.8

0.9

1

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

2

Output Voltage (V)

N

o

rm

a

liz

ed

P

o

wer

L

o

ss

-6

-3

0

3

6

9

12

15

C

a

se

T

em

p

er

a

tu

re

A

d

ju

st

m

en

t

(°

C

)

0.80

0.85

0.90

0.95

1.00

1.05

1.10

1.15

1.20

1.25

1.30

200

300

400

500

600

700

800

900

1000

Switching Frequency (kHz)

N

o

rma

liz

ed

P

o

w

er

L

o

ss

-6.0

-4.5

-3.0

-1.5

0.0

1.5

3.0

4.5

6.0

7.5

9.0

C

a

se

T

em

p

er

a

tu

re

A

d

ju

st

m

en

t

(°

C

)

July 16, 2014 | DATASHEET V3.3

10

IR3553

40A Integrated PowIRstage®

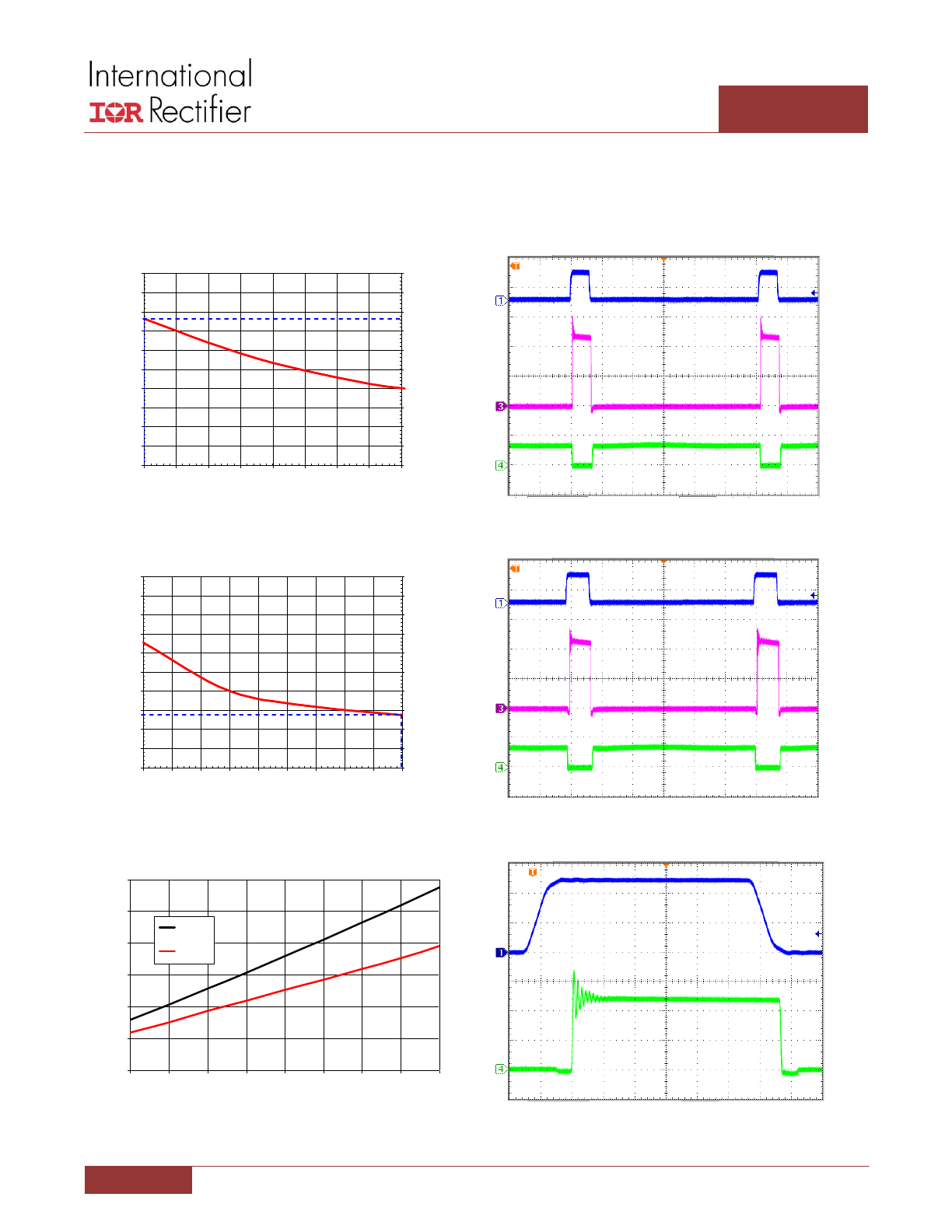

TYPICAL OPERATING CHARACTERISTICS (CONTINUED)

Circuit of Figure 32, V

IN

=12V, V

OUT

=1.2V, ƒ

SW

= 400kHz, L=150nH (0.29mΩ), VCC=7V, T

AMBIENT

= 25°C, no heat sink, no air flow,

8-layer PCB board of 3.7” (L) x 2.6” (W), no PWM controller loss, no inductor loss, unless specified otherwise.

Figure 13: Normalized Power Loss vs. VCC Voltage

Figure 14: Power Loss vs. Output Inductor

Figure 15: VCC Current vs. Switching Frequency

Figure 16: Switching Waveform, I

OUT

= 0A

Figure 17: Switching Waveform, I

OUT

= 40A

Figure 18: PWM to SW Delays, I

OUT

= 10A

PWM

2V/div

SW

5V/div

40ns/div

PWM

5V/div

SW

5V/div

GATEL

10V/div

400ns/div

PWM

5V/div

SW

5V/div

GATEL

10V/div

400ns/div

0

10

20

30

40

50

60

200

300

400

500

600

700

800

900

1000

fsw (kHz)

V

CC

Cu

rr

en

t

(mA

)

Vcc=6.8V

Vcc=5V

0.80

0.85

0.90

0.95

1.00

1.05

1.10

1.15

1.20

1.25

1.30

5.00

5.25

5.50

5.75

6.00

6.25

6.50

6.75

7.00

VCC Voltage (V)

N

o

rma

liz

ed

P

o

w

er

L

o

ss

-6.0

-4.5

-3.0

-1.5

0.0

1.5

3.0

4.5

6.0

7.5

9.0

Ca

se

T

emp

er

atu

re

A

d

ju

stme

n

t

(°

C)

0.80

0.85

0.90

0.95

1.00

1.05

1.10

1.15

1.20

1.25

1.30

120

130

140

150

160

170

180

190

200

210

Output Inductor (nH)

N

o

rma

liz

ed

P

o

w

er

L

o

ss

-6.0

-4.5

-3.0

-1.5

0.0

1.5

3.0

4.5

6.0

7.5

9.0

Ca

se

T

emp

er

atu

re

A

d

ju

stme

n

t

(°

C)