Datasheet TLE6280GP

1 2007-07-19

3-Phase Bridge Driver IC

Features

• Compatible to very low ohmic normal

level input N-Channel Mosfets

• Separate input for each MOSFET

• PWM frequency up to 30kHz

• Fulfills specification down to 9V

supply voltage

• Low EMC sensitivity and emission

• Separate Source connection for each MOSFET

• Adjustable dead time

• Adjustable dI/dt limitation

• Short circuit protection with adjustable current limitation

• Driver undervoltage warning

• Reverse polarity protection

• Disable function

• Input with TTL characteristics

• Error flag

• Thermal overload warning for driver IC

• Shoot through protection

• Shoot through option

• Integrated bootstrap diodes

• Green Product (RoHS compliant)

• AEC Qualified

Application

• Dedicated for 3-phase high current motor bridges in PWM control mode. This device fulfills requirements in

12V automotive applications

General Description

3-phase bridge driver IC for MOSFET power stages with multiple protection functions.

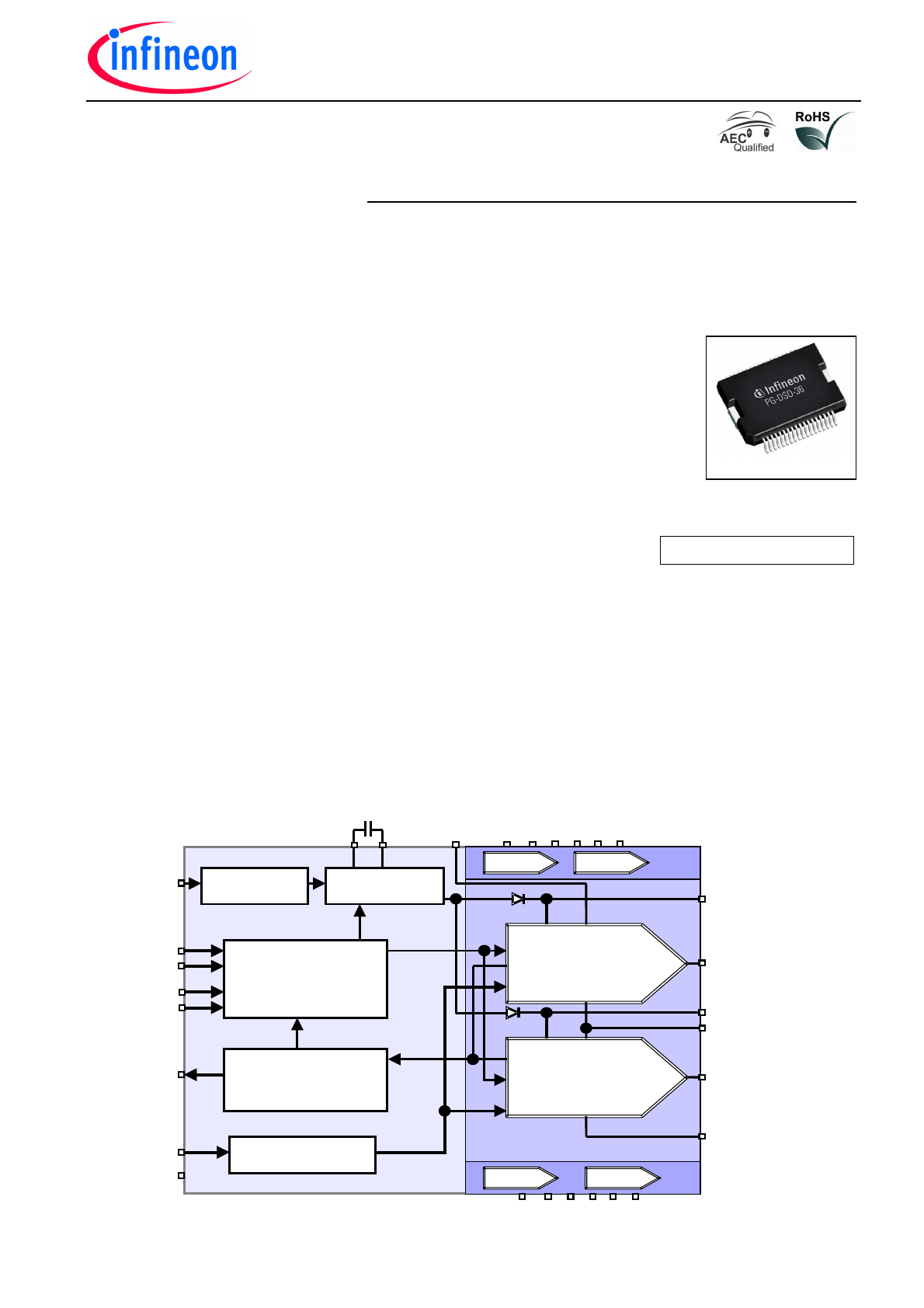

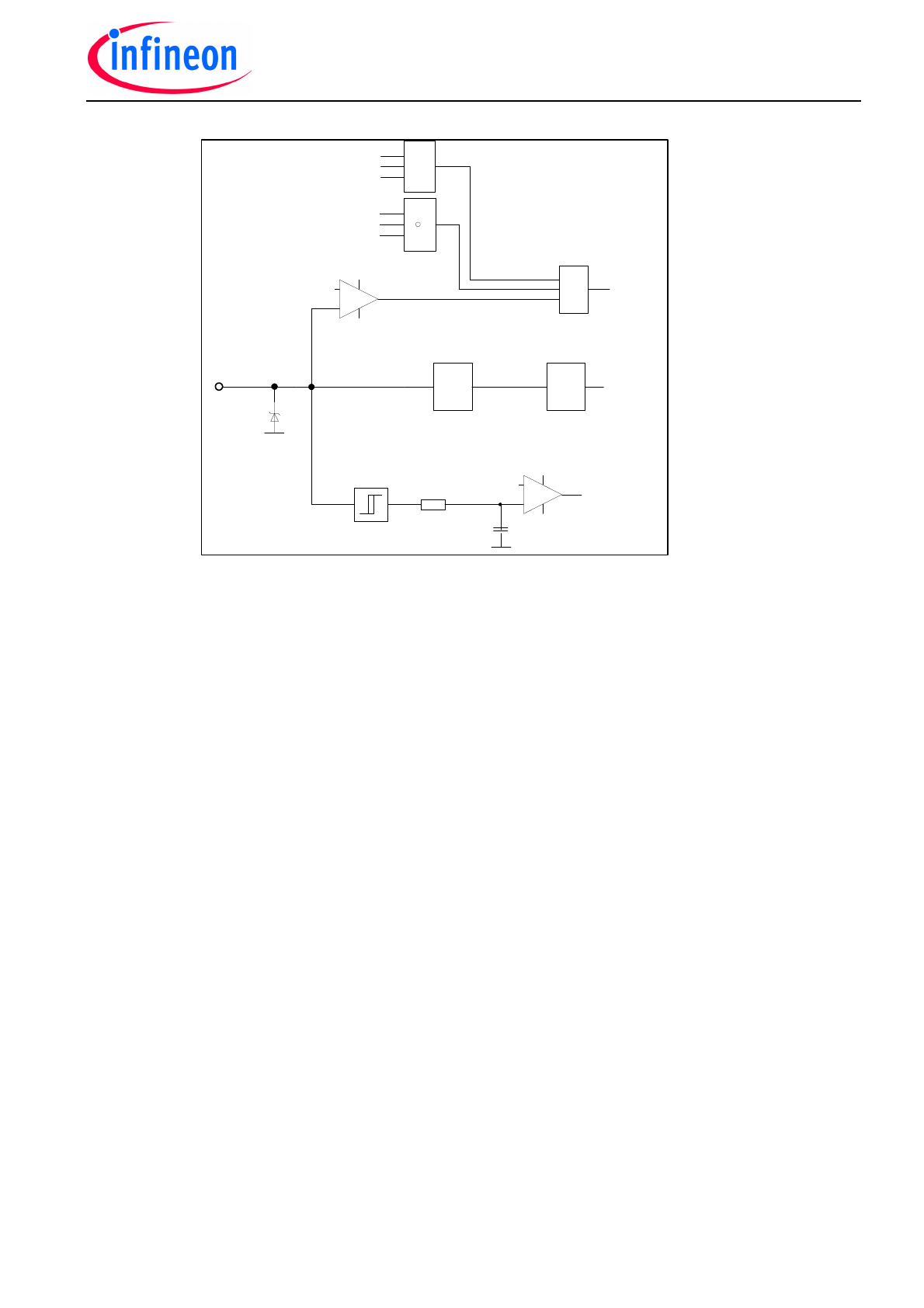

Block Diagram

Product Summary

Turn on current

I

Oxx(on)

0.9 A

Turn off current

I

Oxx(off)

0.85 A

Supply voltage range

V

Vs

8...20 V

Gate Voltage

V

GS

10

V

Temperature range

T

J

-40...+150 °C

PG-DSO36

Input Logic

- Shoot Through Option

- Charge Pump Control

- Programmable Dead Time

Error Logic

- Short Circuit Shut Down

- Under Voltage Warning

- Over Temperature Warning

HS Driver (Channel 2)

- Short Circuit Protection

- Undervoltage Detection

- DI/dt Control

LS Driver (Channel 2)

- Short Circuit Protection

- Undervoltage Detection

- DI/dt Control

Reverse Polarity

Protection

Voltage Regulator

Charge Pump

DI/dt Limitation

HS Driver 3

LS Driver 3

HS Driver 1

LS Driver 1

VDH

CH

CL

DIDT

ERR

DT

MFP

ILx

IHx

BH2

GH2

BL2

SH2

GL2

SL2

VS

BH1 GH1 SH1 BL1

GL1 SL1

BH3

GH3 SH3 BL3 GL3

SL3

GND

- Shoot Through Protection

Marking

TLE6280GP

Datasheet TLE6280GP

2 2007-07-19

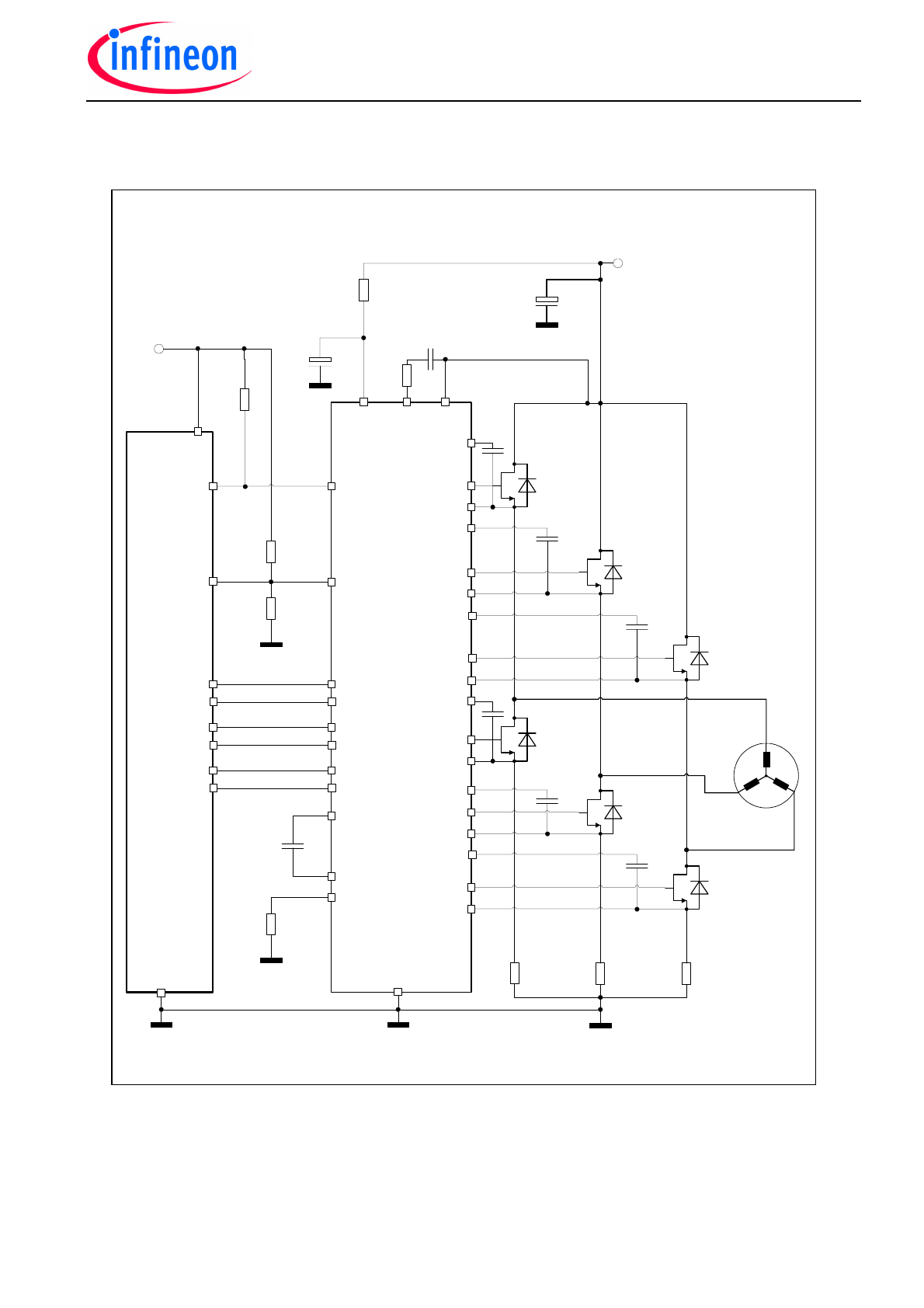

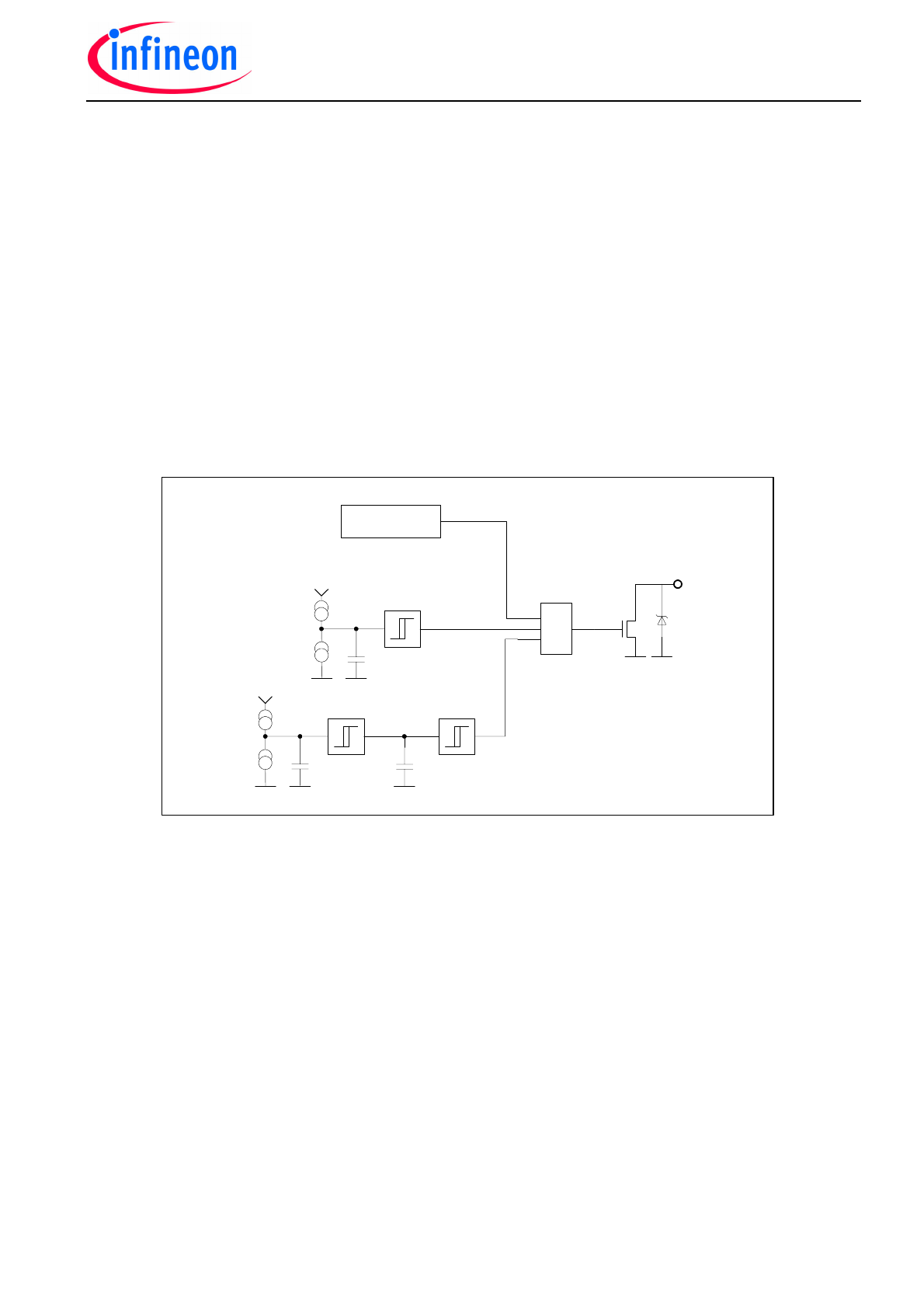

Application Block Diagram

Remark: This application diagram is one possible implementation of this driver IC. There is, e.g., the

possibility to link all three BLx pins and use only one capacitor.

SH1

V

S

=12V

C

1000µF

C

DI/DT

12nF

µC

GH1

R

Q

50 k

Ω

SH2

GH2

BH2

GL1

GL2

VS

V

CC

ERR

MFP

R

Q

82 k

Ω

IL1

IH1

C

BH1

220nF

C

BH2

220nF

C

VS

1µF

R

VS

10

Ω

GND

BH1

SL1

SH3

GH3

BH3

C

BH3

220nF

SL2

GL3

SL3

DI/DT

R

DI/DT

100

Ω

R

Q

20 k

Ω

V

5

=5V

IL2

IH2

IL3

IH3

GND

CH

CL

C

CP

1.5µF

VDH

DT

R

DT

50 k

Ω

BH3

C

BL3

220nF

BL2

C

BL2

220nF

BL1

C

BL1

220nF

TLE6280GP

P-GND

P-GND

Fig. 1 : Application circuit

Datasheet TLE6280GP

3 2007-07-19

Pin

Symbol Function

1;18;19:36 GND

Logic

Ground

8 VS

Voltage

supply

20

21

CL

CH

Charge pump - capacitor

9

11

13

IH1

IH2

IH3

Control inputs for high-side switches 1 to 3

(low active)

10

12

14

IL1

IL2

IL3

Control inputs for low-side switches 1 to 3

(high active)

15

MFP

Multi function pin:

a) Disable the complete device by V

MFP

<1V

b) Program pin for output voltage level under short

circuit condition (V

Gxx

–V

Sxx

= 2xV

MFP

)

c) Enable shoot through option by V

MFP

>4.5V

17

DT

Program pin for dead time

35

DIDT

Program pin dI/dt limitation

34

VDH

Sense pin for drain voltage of the high-side Mosfets

16

ERR

Error flag for driver supply under voltage, over-

temperature and short circuit (open drain output)

2

28

22

BH1

BH2

BH3

Bootstrap supply high-side switches 1 to 3

5

31

25

BL1

BL2

BL3

Backup capacitor connection low switches 1 to 3

3

29

23

GH1

GH2

GH3

Output to gate high-side switches 1 to 3

6

32

26

GL1

GL2

GL3

Output to gate low-side switches 1 to 3

4

30

24

SH1

SH2

SH3

Connection to source high-side switches 1 to 3

7

33

27

SL1

SL2

SL3

Connection to source low-side switches 1 to 3

Datasheet TLE6280GP

4 2007-07-19

Functional description

General

In the automotive sector there are more and more applications requiring high performance

motor drives, such as electro-hydraulic or electric power steering. In these applications

3-phase motors, synchronous and asynchronous, are used, combining high output perform-

ance, low space requirements and high reliability.

The TLE6280GP is a driver IC dedicated to control the 6 to 12 external Mosfets forming the

converter for high current 3 phase motor drives in the automotive sector. It incorporates fea-

tures like short circuit detection, diagnosis and high output performance and combines it with

typical automotive specific requirements like full functionality even at low battery voltages. Its

3 high-side and 3 low-side output stages are powerful enough to drive Mosfets with 250nC

gate charge with approx. 300ns fall and rise times.

Typical applications are cooling fan, water pump, electro-hydraulic and electric power steer-

ing. The TLE6280GP is designed for a 12V power net.

Use in 24V application is possible as well. Limiting factor could be the power dissipation.

This datasheet describes all functionality of this device. Additional application tips are given

in an application note available on the Internet.

Output stages

The 3 low-side and 3 high-side powerful push-pull output stages are all floating blocks, each

with its own Source pin. This allows the direct connection of the output stage to the Source

of each single Mosfet, allowing a perfect control of each Gate-Source voltage even when

200A are driven in the bridge with rise and fall times clearly below 1µs.

All 6 output stages have the same output power and, due to the use of the bootstrap princi-

ple, they can be switched all up to 30kHz.

Its output stages are powerful enough to drive Mosfets with 250nC gate charge with approx.

300ns fall and rise times, or even to run 12 such Mosfets with fall and rise times of approx.

600ns.

Maximum allowed power dissipation and the need to refresh the bootstrap capacitors with a

minimum refresh pulse limit the divice use for higher frequencies.

Fig. 2 shows the supply structure of TLE6280GP. The bootstrap capacitors are charged by

the charge pump capacitor C

CP

via the CH pin and diodes.

The exact value for this minimum refresh pulse is given by the RC time constant formed by

the impedance between the CH pin and Bxx pin, and the capacitor formed by the external

Mosfet (C

Mosfet

=Q

Gate-total

/ V

GS

). The size of the bootstrap capacitor has to be adapted to the

external Mosfet that the driver IC has to drive. Usually the bootstrap capacitor is about 10-20

times bigger than C

Mosfet

. External components, such as R-C networks, at the Vs Pin have to

be considered, too.

Operation at Vs<12V – integrated charge pump

The TLE6280GP provides a feature tailored to the requirements of 12V automotive applica-

tions. Often the operation of an application has to be assured even at 9V-supply voltage or

lower. Normally bridge driver ICs provide in such conditions clearly less than 9V to the Gate

of the external Mosfet, increasing its RDSon and associated the power dissipation.

The supply structure of the device is shown in fig.2. The TLE 6280GP has a built-in voltage

regulator with charge pump control to generate an internal supply voltage of 13V within a

supply voltage range of 8-40V. Operation below 8V is possible as well and will result in a re-

duced Gate voltage. The charge pump works with an external capacitor C

CP

connected be-

tween the CL and CH pins. It provides more than 13V at the CH pin and guarantees high

supply voltage for the bootstrap capacitors C

Bx

.

Datasheet TLE6280GP

5 2007-07-19

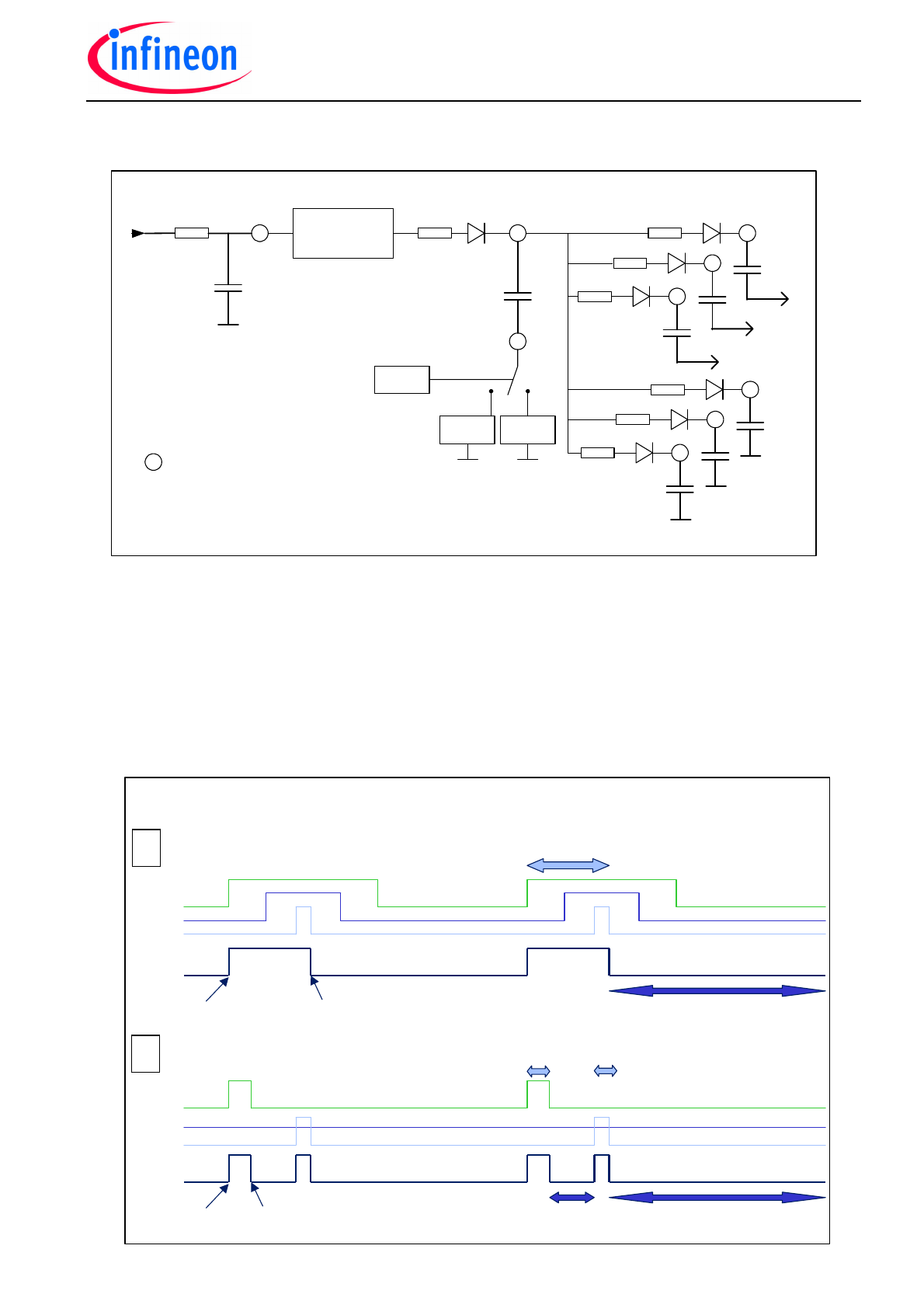

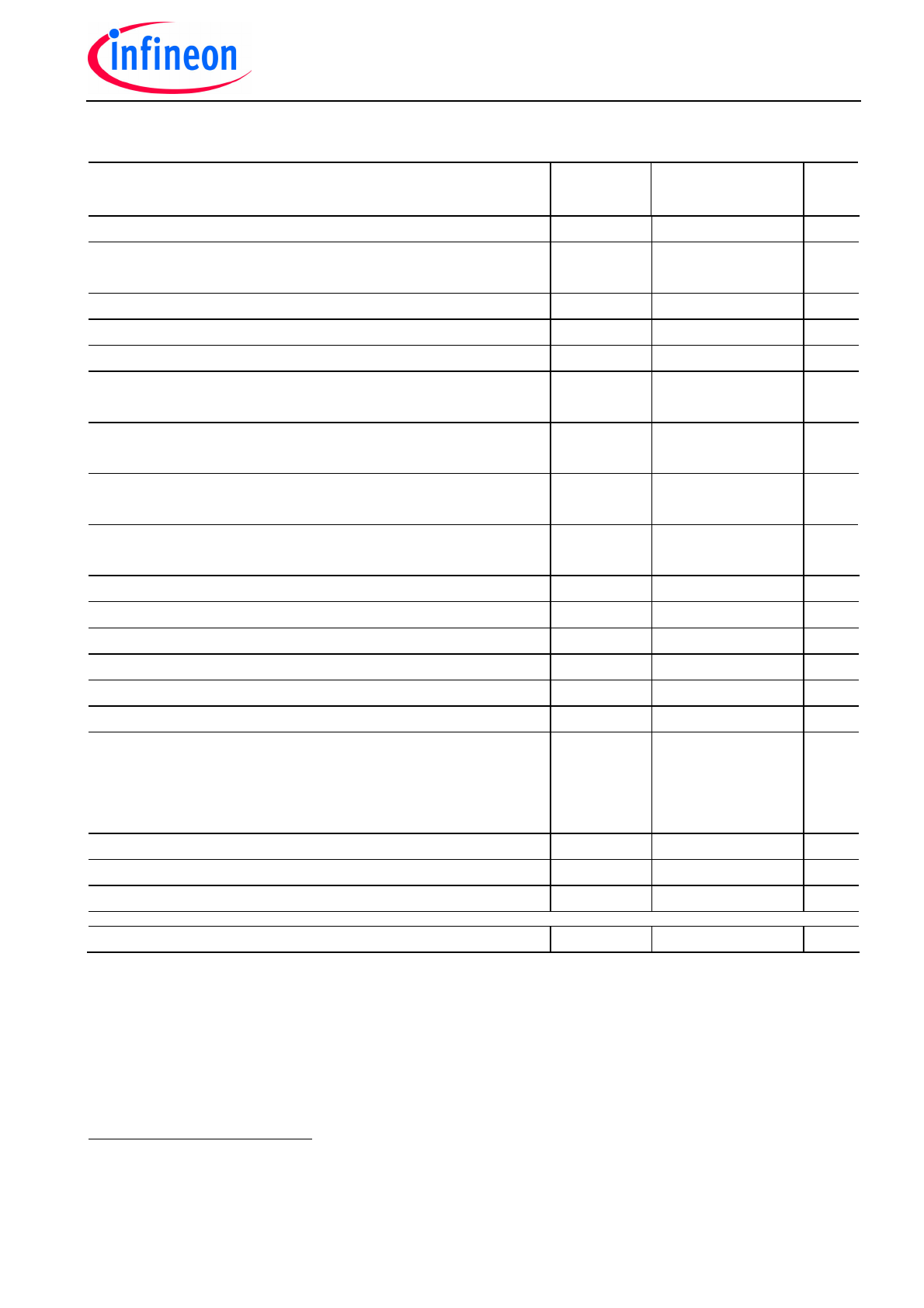

The Input Low-side pins ILx (see Fig. 3) trigger the charge pump. As soon as the first exter-

nal low-side Mosfet is switched on and the corresponding bootstrap capacitor is connected

to GND, the C

CP

is pushed to high and provides about 13V at the CH pin. C

CP

can now di-

rectly feed the low-side output stages and recharge the bootstrap capacitors connected to

GND.

As soon as the first of the 3 external low-side Mosfets is switched off, the C

CP

will be pulled

down to be re-charged.

This synchronous operation with the output stages has the benefit that the electromagnetic

emissions generated by the charge pump can be filtered by the same filter necessary to filter

the EME of the converter itself. At the same time it is assured that the high voltage at the CH

pin is available just in time to charge the high-side bootstrap.

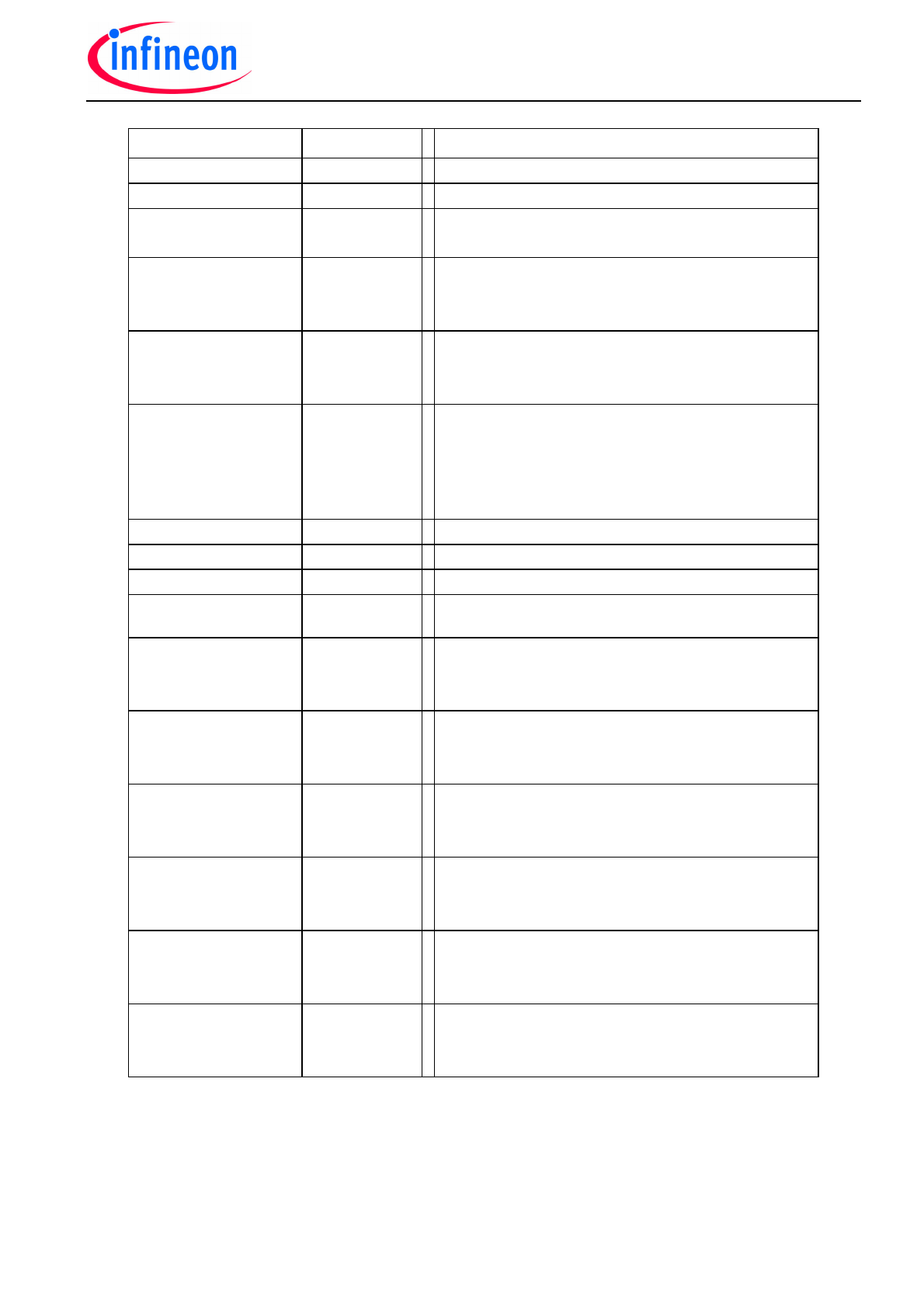

Fig. 3: Trigger timing of charge pump caused by changing input signals

Vreg1 13V

+13 ... +8V

CH

CL

BH

1

BH

2

BH

3

BL

1

BL

2

BL

3

Vreg2=6V

Vreg3 =

Vreg1-8V

Triggered

by ILx

VS

C

CP

C

BH1

C

BL1

Phase A

Phase B

Phase C

= Pin

Bold line = external component

C

VS

from battery

R

VS

Fig. 2: Supply structure with external components (compare to Fig. 1)

IL1

IL2

Timing of charge pump - Examples

1

2

1. ILx high

1. ILx low

IL3

CH

Charge of bootstrap

capacitors

Charge of charge pump

capacitor

IL2

1. ILx high

1. ILx low

CH

Charge of bootstrap capacitors

IL1

IL3

Charge of charge pump capacitor

Datasheet TLE6280GP

6 2007-07-19

The size of the C

Bxx

and C

CP

capacitors depends upon the gate charge of the Mosfet.

(See “output stages”). C

CP

is usually 6 times larger then C

Bxx

.

Dead Time and Shoot through option.

In bridge applications it has to be assured that the external high-side and low-side Mosfets

are not “on” at the same time, such that the battery voltage is directly connected to GND.

This is usually assured by the integration of delays in a driver IC, generating a so-called

dead time between switching off the external Mosfet and switching on the other Mosfet of the

same half-bridge.

The dead times generated in the TLE6280GP are adjustable. The dead time generated by

the TLE6280GP can be varied from 100ns to 4µs by connecting an external resistor from the

DT pin to GND. The dead time has to be long enough to avoid a short between battery and

GND, while the dead time should be as short as possible to reduce extra power dissipation

in the external Mosfets.

In addition to this adjustable delay, the TLE6280GP provides a locking mechanism, prevent-

ing both external Mosfets of one half-bridge from being switched on at the same time. This

functionality is called shoot through protection.

If the command to switch on both high and low-side switches in the same half-bridge is given

at the input pins, the command will be ignored. (See dead time diagrams, fig. 6-8)

This shoot through protection can be deactivated by setting the MFP-pin to 5V.

Short circuit protection / current limitation

The TLE6280GP provides a short circuit protection for the external Mosfets, by monitoring

the Drain-Source voltage of the external Mosfets. As soon as this voltage is higher than the

short circuit detection limit, the Gate-Source voltage of this Mosfet will be limited to twice the

voltage at the MFP-Pin, providing a current limitation.

The short circuit detection level is dependent upon the voltage of the MFP pin as well (see

diagrams).

After a delay of about 11µs all external Mosfets will be switched off until the driver is reset by

the MFP pin. The error flag is set.

The Drain-Source voltage monitoring of the short circuit detection for certain external Mos-

fets is active as soon as the corresponding input is set to “on” and the dead time is expired.

This feature provides a 2-step switch-on behavior for each regular switching-on of a Mosfet.

Description of MFP pin (Multi functional pin)

The MFP pin has multiple tasks:

1) Reset the device.

2) Adjust the short circuit detection level of the external Mosfet and define the gate voltage

limitation for current limitation in case of short circuit

3) Deactivate the shoot-through protection

Fig 4. shows the internal structure of the MFP pin.

Condition of MFP pin

Function

0 – 1.1V

Disable the driver. All external Mosfets will be actively

switched off

2.5 – 4.0 V

Adjustable short circuit detection level combined with adjust-

able gate voltage limitation for current limitation. Shoot-

through protection is active.

> 4.5V

Shoot-through protection deactivated.

Datasheet TLE6280GP

7 2007-07-19

Shoot through protection / option

As already mentioned, the device has a built-in shoot-through protection, to avoid a simulta-

neous activation of high- and low-side switch in one half-bridge.

In case there is a short circuit in the bridge, the driver will switch off all external Mosfets. If

there is still current flowing in the motor, it is possible for the user to override this shoot

through protection.

By setting the ILx to “high”, the IHx to “low” and MFP to a level above 4.5V, all external Mos-

fets will be turned on simultaneously to blow a well-dimensioned fuse. The application will be

finally disconnected in this way from battery, and thus guarantee that the motor does not ap-

ply any uncontrolled torque.

Undervoltage warning:

If the voltage of a bootstrap capacitor C

Bxx

reaches the undervoltage warning level the error

flag is set and will remain set until the voltage of the bootstrap capacitor has recovered.

The error signal can be seen as awarning that an undervoltage shut-down could occur soon,

and the user can take appropriate measures to avoid this. Such measures could be the

change of the duty cycle to a range of 10-90% or the ramp down of the motor.

Undervoltage shut down:

The TLE6280GP has an integrated undervoltage shut-down, to guarantee that the behavior

of the device is predictable in all voltage ranges.

If the voltage of a bootstrap capacitor C

Bxx

reaches the undervoltage shut-down level, the

Gate-Source voltage of the affected external Mosfet will be actively pulled to low. In this

situation the short circuit detection of this output stage is deactivated to avoid a complete

&

&

NAND

Vmfp x 2

MFP

Shoot

Through

80ns

1.45 /

1.7V

Gate

control

4.5V

IHx

ILx

Levelshifter

Dissable

=

Reset

Fig. 4: Block diagram of internal structure of MFP pin

Datasheet TLE6280GP

8 2007-07-19

shut down of the driver. This allows continued operation of the motor in case of undervoltage

shut-down for a short period of time.

As soon as the bootstrap voltage recovers, the output stage condition will be aligned to the

input patterns by the next changing input signal at the corresponding input pin.

Diagnosis

The ERR pin is an open collector output and has to be pulled up with external pull-up resis-

tors to 5V. In normal conditions the ERR signal is high. In case of an error the ERR pin is

pulled down. There are 3 different causes for an error signal:

1) Short circuit of an external Mosfet – all external Mosfets are switched off. The driver has

to be reset to start again.

2) Undervoltage warning: at least one of the external capacitors connected to Bxx pins has

a voltage below the warning level.

3) Over-temperature warning: The device works normally but is out of the maximum ratings.

Immediate actions have to be taken to reduce the thermal load. The error flag will be re-

moved when the driver reached temperatures below the over temperature warning level.

dI/dt control

In all high current PWM applications, transient overvoltages and electro-magnetic emmisions

are critical items. The dI/dt regulation of the TLE6280GP helps to reduce transient overvolt-

age as well as electro-magnetic emissions.

Each real bridge configuration has stray inductance in each half-bridge. When the Mosfets in

the bridge are switching and load current is flowing, the stray inductance together with the

dI/dt in the halfbridge causies transient overvoltages. These transient overvoltages can be

feed to the DIDT pin of the gate driver by a high pass filter. Voltages exceeding 2 to 5V or –2

to –5V at this pin will strongly reduce the gate current of the actually switched Mosfet, result-

ing in an increased switching time in the Miller plateau of the Mosfet, and reducing the

switching speed exactly and only in the critical area of the switching process. Through this

regulation over-voltages are reduced and a smoother dI/dt in the bridge is obtained.

For more detailed information please refer to application note.

Fig. 5: Block diagram of ERR functionality

OR

ERR

Iscp (VMFP)

3.3µA

0.3µA

10pF

Temperature

Sensor

I undervoltage

τ approx. 1µs

Datasheet TLE6280GP

9 2007-07-19

Estimation of power dissipation within the driver IC

The power dissipation within the driver IC is strongly dependent upon the use of the driver

and the external components. Nevertheless, a rough estimation of the worst case power dis-

sipation is possible.

Worst case calculation is:

P

D

= (Q

gate

*n*const* f

PWM

+ I

VS(open)

) * V

Vs

- P

RGate

With:

P

D

= Power dissipation in the driver IC

f

PWM

= Switching frequency

Q

gate

= Total gate charge of used MOSFET at 10V V

GS

n

= number of switched Mosfets

const

= constant considering some leakage current in the driver and the power dissipa-

tion caused by the charge pump (nominally = 2)

I

VS(open)

= Current consumption of driver without connected Mosfets during switching

V

VS

= Voltage at Vs

P

RGate

= Power dissipation in the external gate resistors

This value can be reduced dramatically by the use of external gate resistors.

Recommended start up procedure

To assure the driver to be active and functional, a special initialization procedure is required

whenever the gate drive is enabled (V

MFP

is changed from LO to HI). Every time the driver is

enabled, after 10

µs or later, positive-going transition signals at all ILx pins are required in or-

der to ensure proper start-up of the output driver. This procedure assures a proper wake up

the device and allowes to fill the bootstrap capacitors. Not filling the bootstrap capacitors

might lead to low Gate-Source voltages mainly in highside and can cause a short circuit de-

tection when the highside switches are activated. Not changing the ILx input signal after

enabling the device may cause the lowside outputs to stay in off conditions.

Datasheet TLE6280GP

10 2007-07-19

Maximum ratings

Parameter and Conditions Symbol

Values

Unit

at T

j

= -40 … +150 °C, unless otherwise specified

Supply voltage

1

V

S

-4 ... 45V

V

Operating temperature range

Storage temperature range

T

j

T

stg

-40 ...+150

-55 ...+150

°C

Max. voltage range at Ixx, MFP, DT; ERR

-0.3 ...+7

V

Max. voltage range at SLx

2

V

SLx

-7 ...+7

V

Max. voltage range at SHx

3

V

SHx

-7 ...+45

V

Max. voltage range at GLx

2

V

GLx

-7 ...+18

V

Max. voltage range at GHx

3

V

GHx

-7 ...+55

V

Max. voltage range at BHx

3

V

BHx

-0.3 ...+55

V

Max. voltage range at VDH

4

V

VDH

-4 ...+55

V

Max. voltage difference Bxx - Sxx

V

Bxx

-V

Sxx

-0.3 ...+15

V

Max. voltage difference Gxx - Sxx

V

Gxx

-V

Sxx

-0.3...+11

V

Max. voltage range at CL

V

CL

-0.3 ...+10

V

Max. voltage range at CH

V

CH

-0.3 ...+18

V

Max. voltage range at DIDT

V

DIDT

-7 ...+7

V

Power dissipation (DC) @ T

C

=125°C

P

tot

1.2

W

ESD voltage (Human Body Model)

JESD22-A114-B

@ all pins

@ all pins excluding Gxx

V

ESD

1

2

kV

DIN humidity category, DIN 40 040

E

IEC climatic category, DIN IEC 68-1

40/150/56

Jedec Level

3

Thermal resistance junction-case

R

thJC

≤5 K/W

1

With external resistor (

≥10 Ω ) and capacitor – see fig.1

2

The min value -7V is reduced to –(Vs - 0.5V) if Vs<7.5V

3

The min value -7V is reduced to –(V

BHx

-V

SHx

-1V) if bootstrap voltages <8V

4

The min value -4V is increased to –( V

BHx

- V

SHx

) if bootstrap voltages <4V