CoolSET

®

-F3R

I C E 3 R B R 4 7 6 5 J Z

O f f - L i n e S M P S C u r r e n t M o d e

C o n t r o l l e r w i t h i n t e g r a t e d 6 5 0 V

C o o l M O S

®

a n d S t a r t u p c e l l

( f r e q u e n c y j i t t e r M o d e ) i n D I P - 7

N e v e r s t o p t h i n k i n g .

P o w e r M a n a g e m e n t & S u p p l y

V e r s i o n 2 . 0 , 7 J u n 2 0 1 3

Edition 2013-6-7

Published by

Infineon Technologies AG,

81726 Munich, Germany,

©

2013 Infineon Technologies AG.

All Rights Reserved.

Legal disclaimer

The information given in this document shall in no event be regarded as a guarantee of conditions or

characteristics. With respect to any examples or hints given herein, any typical values stated herein and/or any

information regarding the application of the device, Infineon Technologies hereby disclaims any and all warranties

and liabilities of any kind, including without limitation, warranties of non-infringement of intellectual property rights

of any third party.

Information

For further information on technology, delivery terms and conditions and prices, please contact your nearest

Infineon Technologies Office (www.infineon.com).

Warnings

Due to technical requirements, components may contain dangerous substances. For information on the types in

question, please contact your nearest Infineon Technologies Office.

Infineon Technologies Components may be used in life-support devices or systems only with the express written

approval of Infineon Technologies, if a failure of such components can reasonably be expected to cause the failure

of that life-support device or system or to affect the safety or effectiveness of that device or system. Life support

devices or systems are intended to be implanted in the human body or to support and/or maintain and sustain

and/or protect human life. If they fail, it is reasonable to assume that the health of the user or other persons may

be endangered.

For questions on technology, delivery and prices please contact the Infineon Technologies Offices in Germany or

the Infineon Technologies Companies and Representatives worldwide: see our webpage at http://

www.infineon.com

CoolMOS

®

, CoolSET

®

are trademarks of Infineon Technologies AG.

ICE3RBR4765JZ

Revision History:

2013-6-7

Version 2.0

Previous Version: 0.0

Page

Subjects (major changes since last revision)

3

add applications

Type

Package

Marking

V

DS

F

OSC

R

DSon

1)

1)

typ @ T

j

=25°C

230VAC ±15%

2)

2)

Calculated maximum input power rating at T

a

=50°C, T

i

=125°C and without copper area as heat sink. Refer to input power curve for other T

a

.

85-265 VAC

2)

ICE3RBR4765JZ

PG-DIP-7

3RBR4765JZ

650V

65kHz

4.70

26W

18W

ICE3RBR4765JZ

Version 2.0

3

7 Jun 2013

Off-Line SMPS Current Mode Controller with

integrated 650V CoolMOS

®

and Startup cell

(frequency jitter Mode) in DIP-7

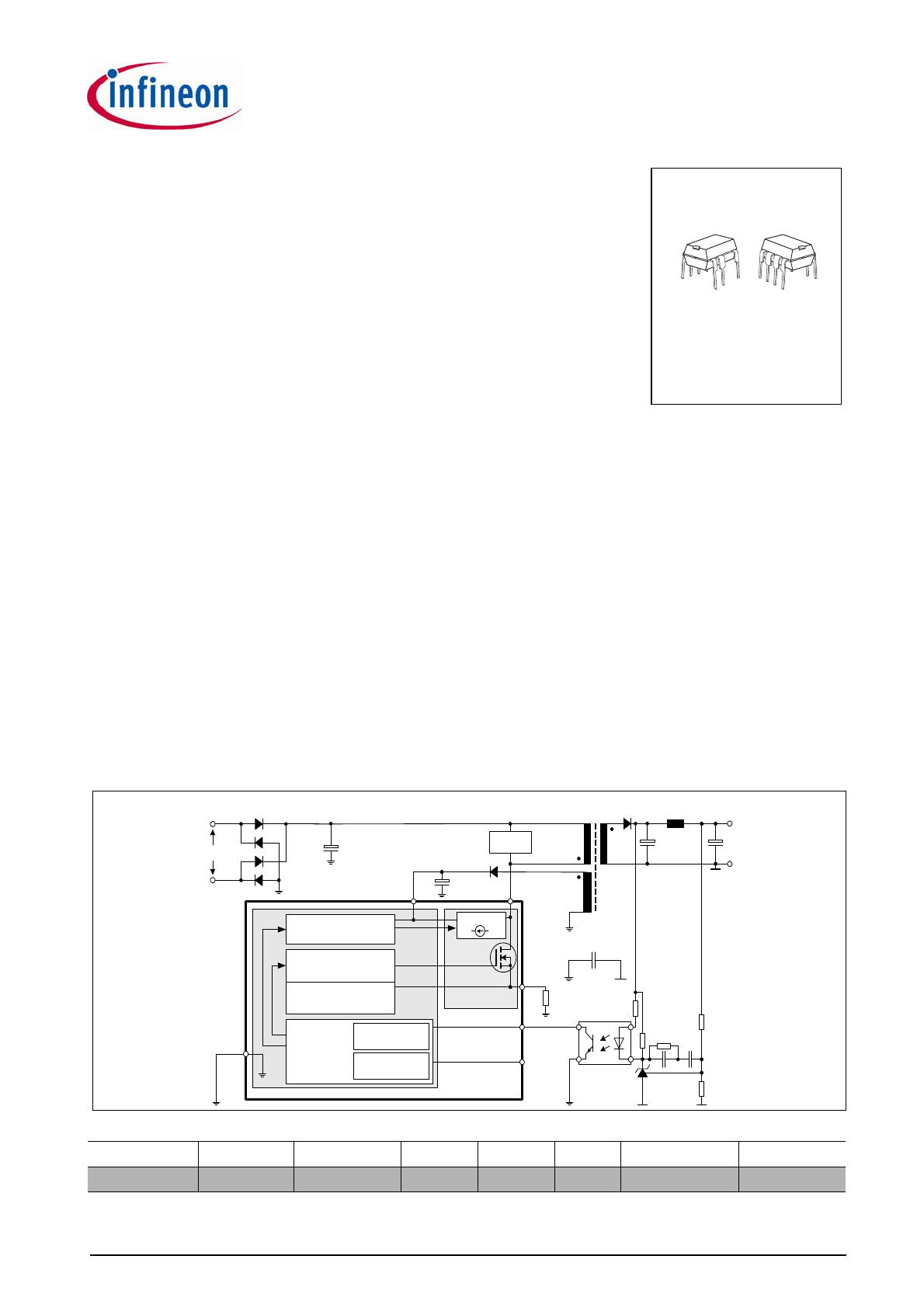

P-DIP-7-1

PG-DIP-7

Description

ICE3RBR4765JZ (ICE3RBRxx65JZ series) is modified

from ICE3BRxx65J in DIP-7 package. It has more robust

design and can work to -40°C. The outstanding

performance includes BiCMOS technology, active burst

mode, built-in frequency jitter, soft gate driving,

propagation delay compensation, built-in soft start time,

built-in blanking time and extendable blanking time for

over load protection, external auto-restart enable feature,

etc.

Applications

•

Adapter/Charger

•

Blue Ray/DVD player, Set-top Box, Digital Photo

Frame

•

Auxiliary power supply for Server, PC, Printer, TV,

Home theater/Audio System, White Goods, etc

Product Highlights

•

Active Burst Mode to reach the lowest Standby Power

Requirements < 50mW

•

Auto Restart protection for overload, overtemperature, overvoltage

•

External auto-restart enable function

•

Built-in soft start and blanking window

•

Extendable blanking Window for high load jumps

•

Built-in frequency jitter and soft driving for low EMI

•

Low Operating temperature down to -40°C

•

Green Mould Compound

•

Pb-free lead plating; RoHS compliant

Features

•

650V avalanche rugged CoolMOS

®

with built-in

Startup Cell

•

Active Burst Mode for lowest Standby Power

•

Fast load jump response in Active Burst Mode

•

65kHz internally fixed switching frequency

•

Auto Restart Protection Mode for Overload, Open

Loop, VCC Undervoltage, Overtemperature &

Overvoltage

•

Built-in Soft Start

•

Built-in blanking window with extendable blanking

time for short duration high current

•

External auto-restart enable pin

•

Max Duty Cycle 75%

•

Overall tolerance of Current Limiting < ±5%

•

Internal PWM Leading Edge Blanking

•

BiCMOS technology provide wide VCC range

•

Built-in Frequency jitter and soft driving for low EMI

C

VCC

C

Bulk

Converter

DC Output

+

Snubber

Power Management

PWM Controller

Current Mode

85 ... 270 VAC

Typical Application

R

Sense

BA

FB

GND

Active Burst Mode

Auto Restart Mode

Control

Unit

-

CS

VCC

Startup Cell

Precise Low Tolerance Peak

Current Limitation

Drain

CoolSET

®

-F3R

(Jitter Mode)

CoolMOS

®

ICE3RBR4765JZ

Table of Contents

Page

Version 2.0

4

7 Jun 2013

1

Pin Configuration and Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.1

Pin Configuration with PG-DIP-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.2

Pin Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2

Representative Blockdiagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.2

Power Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.3

Improved Current Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.3.1

PWM-OP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3.3.2

PWM-Comparator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3.4

Startup Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.5

PWM Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3.5.1

Oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3.5.2

PWM-Latch FF1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3.5.3

Gate Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3.6

Current Limiting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3.6.1

Leading Edge Blanking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

3.6.2

Propagation Delay Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

3.7

Control Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.7.1

Basic and Extendable Blanking Mode . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.7.2

Active Burst Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.7.2.1

Entering Active Burst Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.7.2.2

Working in Active Burst Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

3.7.2.3

Leaving Active Burst Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

3.7.3

Protection Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

3.7.3.1

Auto Restart mode with extended blanking time . . . . . . . . . . . . . . . . .17

3.7.3.2

Auto Restart without extended blanking time . . . . . . . . . . . . . . . . . . .18

4

Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

4.1

Absolute Maximum Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

4.2

Operating Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4.3

Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4.3.1

Supply Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4.3.2

Internal Voltage Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.3.3

PWM Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.3.4

Soft Start time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.3.5

Control Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.3.6

Current Limiting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4.3.7

CoolMOS

®

Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

5

Typical CoolMOS

®

Performance Characteristic . . . . . . . . . . . . . . . . . . .24

ICE3RBR4765JZ

Version 2.0

5

7 Jun 2013

6

Input Power Curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

7

Outline Dimension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

8

Marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

9

Schematic for recommended PCB layout . . . . . . . . . . . . . . . . . . . . . . . .29

Version 2.0

6

7 Jun 2013

ICE3RBR4765JZ

Pin Configuration and Functionality

1

Pin Configuration and Functionality

1.1

Pin Configuration with PG-DIP-7

Figure 1

Pin Configuration PG-DIP-7 (top view)

1.2

Pin Functionality

BA (extended Blanking & Auto-restart enable)

The BA pin combines the functions of extendable

blanking time for over load protection and the external

auto-restart enable. The extendable blanking time

function is to extend the built-in 20 ms blanking time by

adding an external capacitor at BA pin to ground. The

external auto-restart enable function is an external

access to stop the gate switching and force the IC enter

auto-restart mode. It is triggered by pulling down the

BA pin to less than 0.33V.

FB (Feedback)

The information about the regulation is provided by the

FB Pin to the internal Protection Unit and to the internal

PWM-Comparator to control the duty cycle. The FB-

Signal is the only control signal in case of light load at

the Active Burst Mode.

CS (Current Sense)

The Current Sense pin senses the voltage developed

on the series resistor inserted in the source of the

integrated CoolMOS

®

If voltage in CS pin reaches the

internal threshold of the Current Limit Comparator, the

Driver output is immediately switched off. Furthermore

the current information is provided for the PWM-

Comparator to realize the Current Mode.

Drain (Drain of integrated CoolMOS

®

)

Drain pin is the connection to the Drain of the

integrated CoolMOS

®

.

VCC (Power Supply)

VCC pin is the positive supply of the IC. The operating

range is between 10.5V and 25V.

GND (Ground)

GND pin is the ground of the controller.

Pin

Symbol

Function

1

BA

extended Blanking & Auto-restart

enable

2

FB

FeedBack

3

CS

Current Sense/

650V

1)

CoolMOS

®

Source

1)

at T

j

=110°C

4

n.c.

not connected

5

Drain

650V

1)

CoolMOS

®

Drain

6

n.c. Not

connected

7

VCC

Controller Supply Voltage

8

GND

Controller GrouND

Package PG-DIP-7

1

7

8

4

3

2

5

GND

BA

FB

CS

VCC

n.c.

Drain

ICE3RBR4765JZ

Representative Blockdiagram

Version 2.0

7

7 Jun 2013

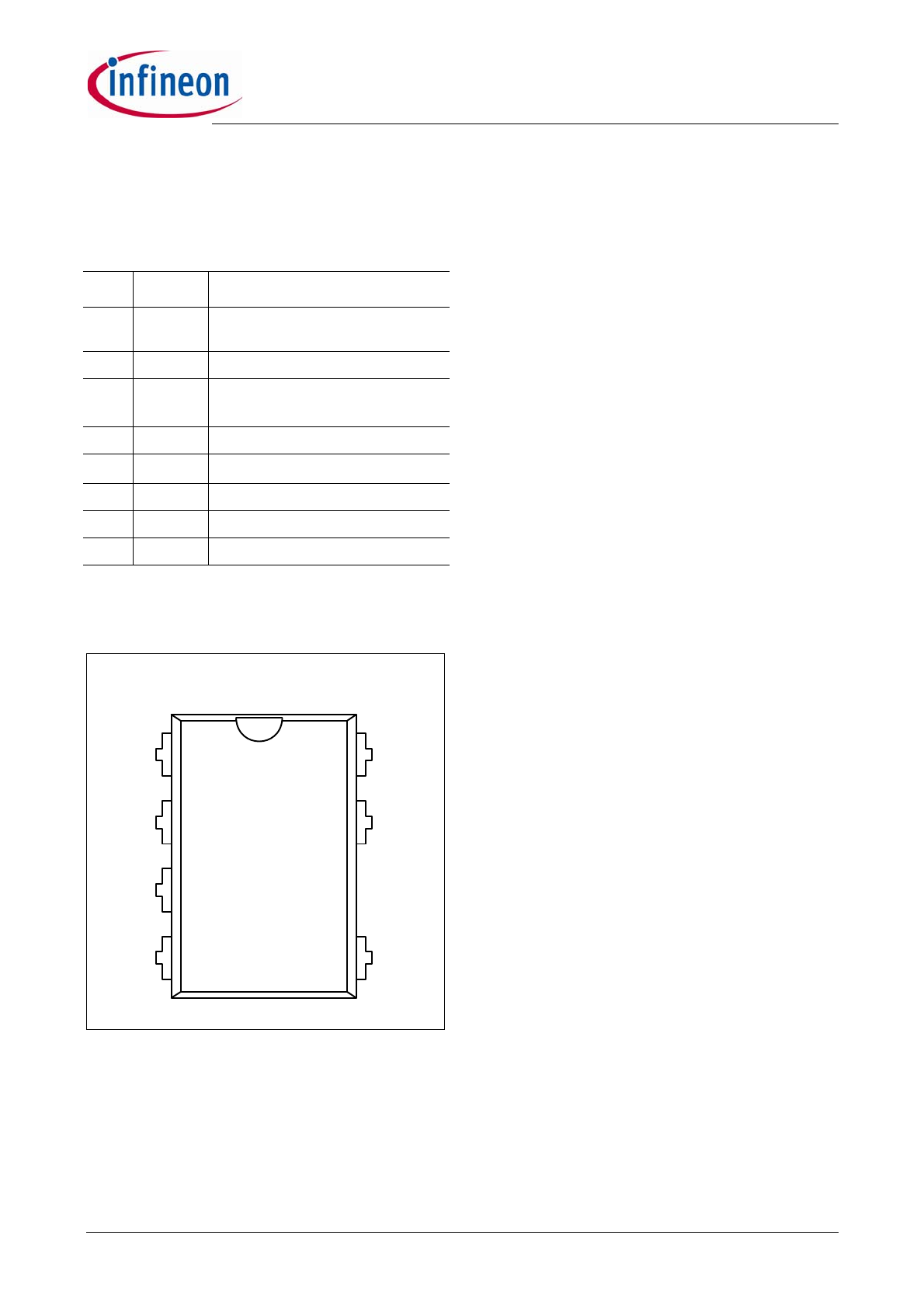

2

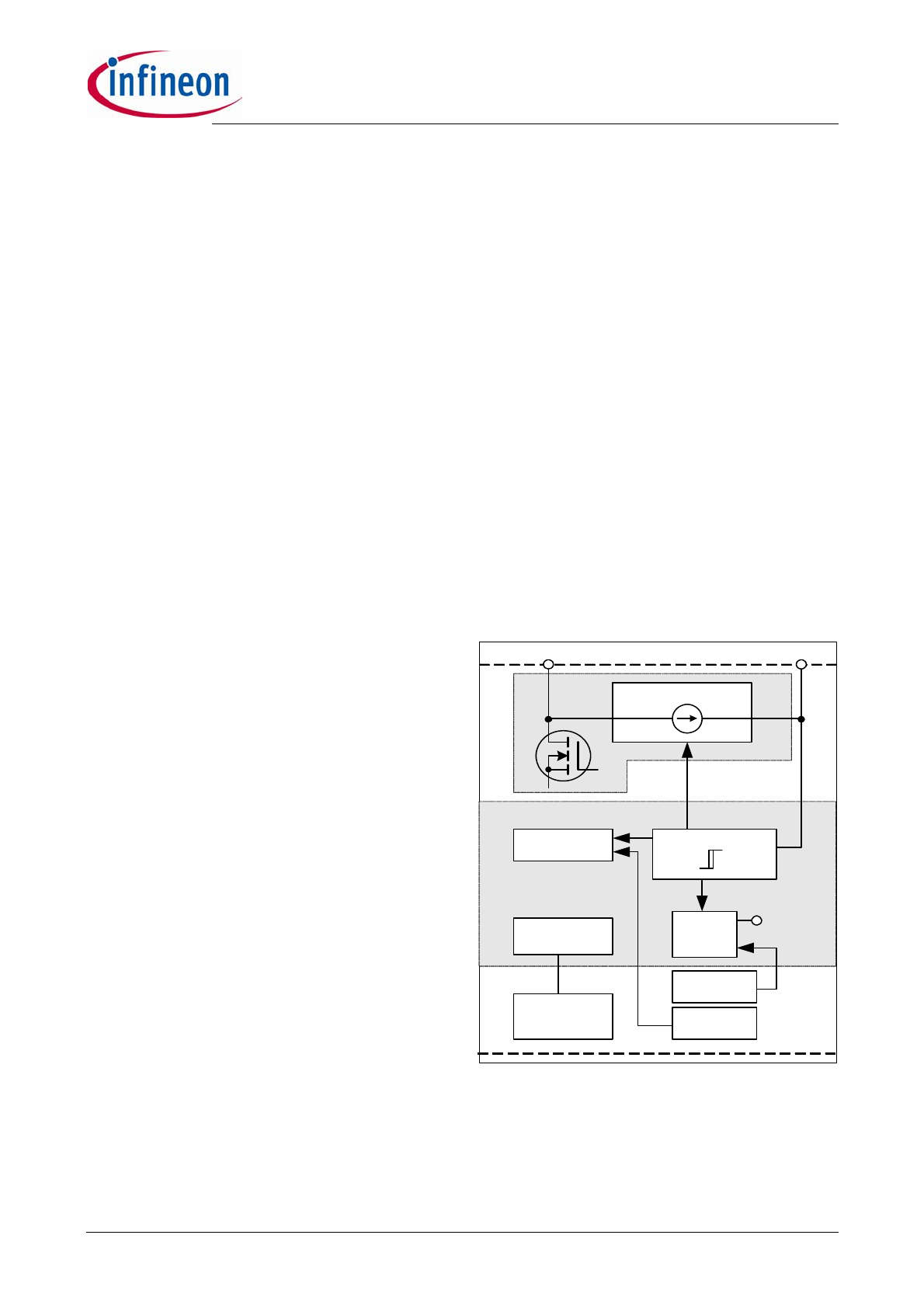

Representative Blockdiagram

Figure 2

Representative Blockdiagram

In

te

rn

a

l

B

ia

s

Vo

lt

a

g

e

Re

fe

re

n

c

e

O

s

c

illa

to

r

Du

ty

Cy

c

le

ma

x

x3

.2

C

u

rr

e

n

t

L

im

it

in

g

PWM

O

P

C

u

rre

n

t

M

o

d

e

So

ft

S

ta

rt

C2

C1

20.

5V

25.

5V

R

FB

P

o

w

e

r

M

an

ag

em

en

t

C

BK

C

VC

C

85

..

.

27

0

V

A

C

C

Bu

lk

+

Co

n

v

e

rt

e

r

DC

O

u

tp

u

t

V

OU

T

PWM

C

o

mp

ar

at

o

r

C3

4.

0

V

C4

4.

0

V

Ga

te

Dr

iv

e

r

0.

72

Cl

o

c

k

R

Se

n

se

10k

D1

C6

a

3.

0

V

C5

1.

3

5

V

C1

0

R

S

Q

Au

to

R

e

st

a

rt

Mo

de

&

G7

&

G5

&

G9

1

G8

& G1

T

her

ma

l

S

hu

td

o

w

n

0.

9

V

S1

1

P

o

w

e

r-D

ow

n

R

e

se

t

CS

BA

GND

VC

C

C7

C8

FB

PWM

Se

c

ti

o

n

C

o

nt

ro

l

U

ni

t

FF

1

C1

2

&

0.

34V

Le

ad

in

g

Ed

g

e

B

lan

k

ing

22

0ns

25

k

2pF

5.

0V

G1

0

1p

F

P

ropa

ga

ti

on

-D

e

lay

Co

m

p

e

n

s

a

ti

o

n

5.

0

V

U

n

d

e

rv

ol

ta

ge

Lo

c

k

o

u

t

V

cs

th

G2

-

ICE3

RBR

x

x

6

5

J

/

CoolSET

®

-F3

R

(

J

itte

r

M

ode

)

S

n

ubb

er

VCC

Dr

a

in

Coo

lM

O

S

®

St

a

rt

u

p

C

ell

C6

b

&

G6

3.

5V

&

G1

1

Ac

ti

v

e

Bu

rs

t

Mo

de

0.

6V

10

.5

V

18

V

#1

#

:

op

tion

al

e

x

te

rn

al

com

pon

ents

;

#1

:

C

BK

is

u

s

ed

to

e

x

te

nd

th

e

B

la

nk

in

g

T

im

e

#2

:

T

AE

is

us

ed

to

ena

ble

the

e

x

te

rn

al

A

u

to-

re

star

t

feat

ur

e

F

re

q

.

jit

te

r

20

ms

B

lan

k

ing

Ti

m

e

20m

s

B

la

nk

in

g

Ti

m

e

12

0us

B

lan

k

ing

T

im

e

So

ft

St

a

rt

Bl

o

c

k

S

o

ft

-S

ta

rt

C

o

mp

ar

at

o

r

Sp

ik

e

B

lank

in

g

30

us

T2

3.

25k

5.

0

V

T1

T3

0.

6

V

I

BK

VC

C

A

u

to

-r

es

ta

rt

En

a

b

le

S

ig

nal

T

AE

C9

0.

3

3

V

1m

s

co

u

n

te

r

T

j

>

1

30°

C

#2

Version 2.0

8

7 Jun 2013

ICE3RBR4765JZ

Functional Description

3

Functional Description

All values which are used in the functional description

are typical values. For calculating the worst cases the

min/max values which can be found in section 4

Electrical Characteristics have to be considered.

3.1

Introduction

ICE3RBR4765JZ (ICE3RBRxx65JZ series) is derived

from ICE3BRxx65J in DIP-7 package. It has more

robust design and can work to -40°C.

A high voltage Startup Cell is integrated into the IC

which is switched off once the Undervoltage Lockout

on-threshold of 18V is exceeded. This Startup Cell is

part of the integrated CoolMOS

®

. The external startup

resistor is no longer necessary as this Startup Cell is

connected to the Drain. Power losses are therefore

reduced. This increases the efficiency under light load

conditions drastically.

The particular features are the active burst mode,

propagation delay compensation, modulated gate

driving, auto-restart protection for Vcc overvoltage,

over temperature, over load, open loop, built-in soft

start, blanking window and frequency jitter. It provides

the flexibility to increase the blanking window by simply

addition of a capacitor in BA pin. In order to further

increase the flexibility of the protection feature, an

external auto-restart enable features are added.

The intelligent Active Burst Mode can effectively obtain

the lowest Standby Power at light load and no load

conditions. After entering the burst mode, there is still a

full control of the power conversion to the output

through the optocoupler, that is used for the normal

PWM control. The response on load jumps is optimized

and the voltage ripple on V

out

is minimized. The V

out

is

on well controlled in this mode.

The usually external connected RC-filter in the

feedback line after the optocoupler is integrated in the

IC to reduce the external part count.

Adopting the BiCMOS technology, it can increase the

design flexibility as the Vcc voltage range is increased

to 25V.

It has a built-in 20ms soft start function.

There are 2 modes of blanking time for high load

jumps; the basic mode and the extendable mode. The

blanking time for the basic mode is set at 20ms while

the extendable mode will increase the blanking time by

adding an external capacitor at the BA pin in addition to

the basic mode blanking time. During this blanking time

window the system can give the maximum power to the

loading.

In order to increase the robustness and safety of the

system, the IC provides Auto Restart protection. The

Auto Restart Mode reduces the average power

conversion to a minimum level under unsafe operating

conditions. This is necessary for a prolonged fault

condition which could otherwise lead to a destruction of

the SMPS over time. Once the malfunction is removed,

normal operation is automatically retained after the

next Start Up Phase. To make the protection more

flexible, an external auto-restart enable pin is provided.

When the pin is triggered, the switching pulse at gate

will stop and the IC enters the auto-restart mode after

the pre-defined spike blanking time.

The internal precise peak current control reduces the

costs for the transformer and the secondary diode. The

influence of the change in the input voltage on the

maximum power limitation can be avoided together

with the integrated Propagation Delay Compensation.

Therefore the maximum power is nearly independent

on the input voltage, which is required for wide range

SMPS. Thus there is no need for the over-sizing of the

SMPS, e.g. the transformer and the output diode.

Furthermore, it implements the frequency jitter mode to

the switching clock such that the EMI noise will be

effectively reduced.

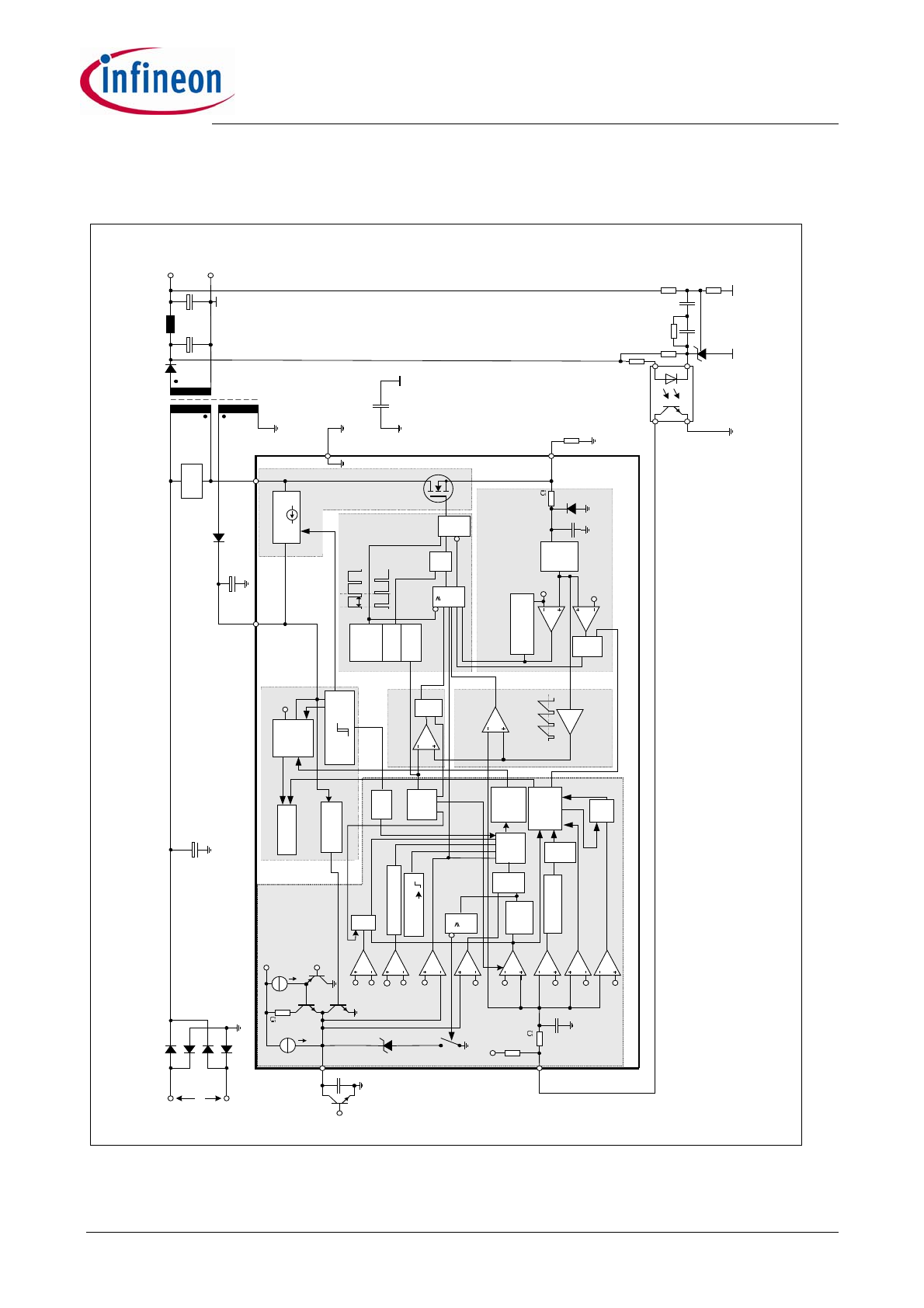

3.2

Power Management

Figure 3

Power Management

The Undervoltage Lockout monitors the external

supply voltage V

VCC

. When the SMPS is plugged to the

main line the internal Startup Cell is biased and starts

to charge the external capacitor C

VCC

which is

connected to the VCC pin. This VCC charge current is

Internal Bias

Voltage

Reference

Power Management

5.0V

Undervoltage Lockout

18V

10.5V

Power-Down Reset

Active Burst

Mode

Auto Restart

Mode

Startup Cell

VCC

Drain

CoolMOS

®

Soft Start block

ICE3RBR4765JZ

Functional Description

Version 2.0

9

7 Jun 2013

controlled to 0.9mA by the Startup Cell. When the V

VCC

exceeds the on-threshold V

CCon

=18V the bias circuit

are switched on. Then the Startup Cell is switched off

by the Undervoltage Lockout and therefore no power

losses present due to the connection of the Startup Cell

to the Drain voltage. To avoid uncontrolled ringing at

switch-on, a hysteresis start up voltage is implemented.

The switch-off of the controller can only take place

when V

VCC

falls below 10.5V after normal operation

was entered. The maximum current consumption

before the controller is activated is about 150

μA.

When V

VCC

falls below the off-threshold V

CCoff

=10.5V,

the bias circuit is switched off and the soft start counter

is reset. Thus it is ensured that at every startup cycle

the soft start starts at zero.

The internal bias circuit is switched off if Auto Restart

Mode is entered. The current consumption is then

reduced to 150

μA.

Once the malfunction condition is removed, this block

will then turn back on. The recovery from Auto Restart

Mode does not require re-cycling the AC line.

When Active Burst Mode is entered, the internal Bias is

switched off most of the time but the Voltage Reference

is kept alive in order to reduce the current consumption

below 450

μA.

3.3

Improved Current Mode

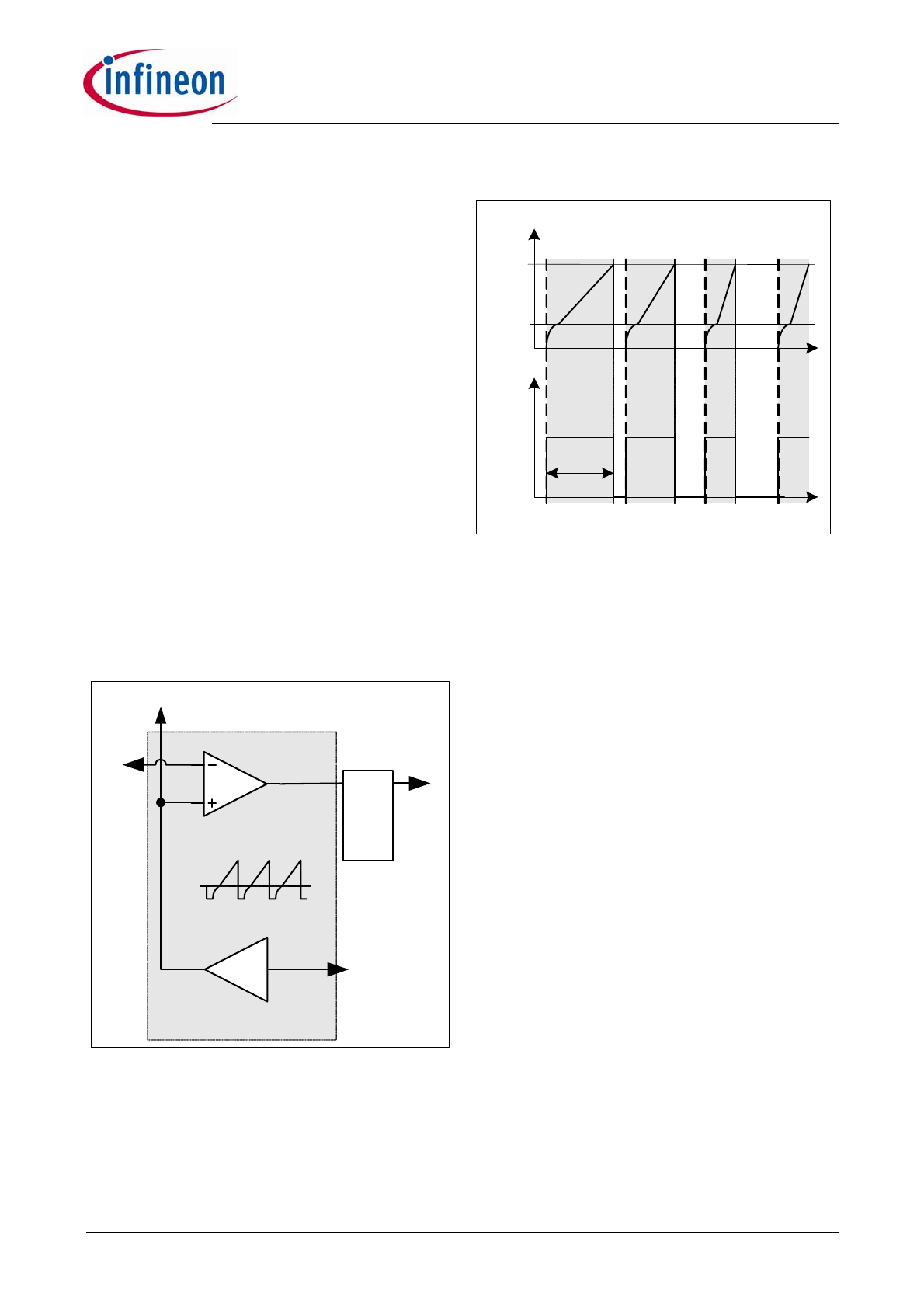

Figure 4

Current Mode

Current Mode means the duty cycle is controlled by the

slope of the primary current. This is done by comparing

the FB signal with the amplified current sense signal.

Figure 5

Pulse Width Modulation

In case the amplified current sense signal exceeds the

FB signal the on-time T

on

of the driver is finished by

resetting the PWM-Latch (see Figure 5).

The primary current is sensed by the external series

resistor R

Sense

inserted in the source of the integrated

CoolMOS

®

. By means of Current Mode regulation, the

secondary output voltage is insensitive to the line

variations. The current waveform slope will change with

the line variation, which controls the duty cycle.

The external R

Sense

allows an individual adjustment of

the maximum source current of the integrated

CoolMOS

®

.

To improve the Current Mode during light load

conditions the amplified current ramp of the PWM-OP

is superimposed on a voltage ramp, which is built by

the switch T2, the voltage source V1 and a resistor R1

(see Figure 6). Every time the oscillator shuts down for

maximum duty cycle limitation the switch T2 is closed

by V

OSC

. When the oscillator triggers the Gate Driver,

T2 is opened so that the voltage ramp can start.

In case of light load the amplified current ramp is too

small to ensure a stable regulation. In that case the

Voltage Ramp is a well defined signal for the

comparison with the FB-signal. The duty cycle is then

controlled by the slope of the Voltage Ramp.

By means of the time delay circuit which is triggered by

the inverted V

OSC

signal, the Gate Driver is switched-off

until it reaches approximately 156ns delay time (see

Figure 7). It allows the duty cycle to be reduced

continuously till 0% by decreasing V

FB

below that

threshold.

x3.3

PWM OP

Improved

Current Mode

0.67V

C8

PWM-Latch

CS

FB

R

S

Q

Q

Driver

Soft-Start Comparator

t

FB

Amplified Current Signal

T

on

t

0.67V

Driver

ICE3RBR4765JZ

Functional Description

Version 2.0

10

7 Jun 2013

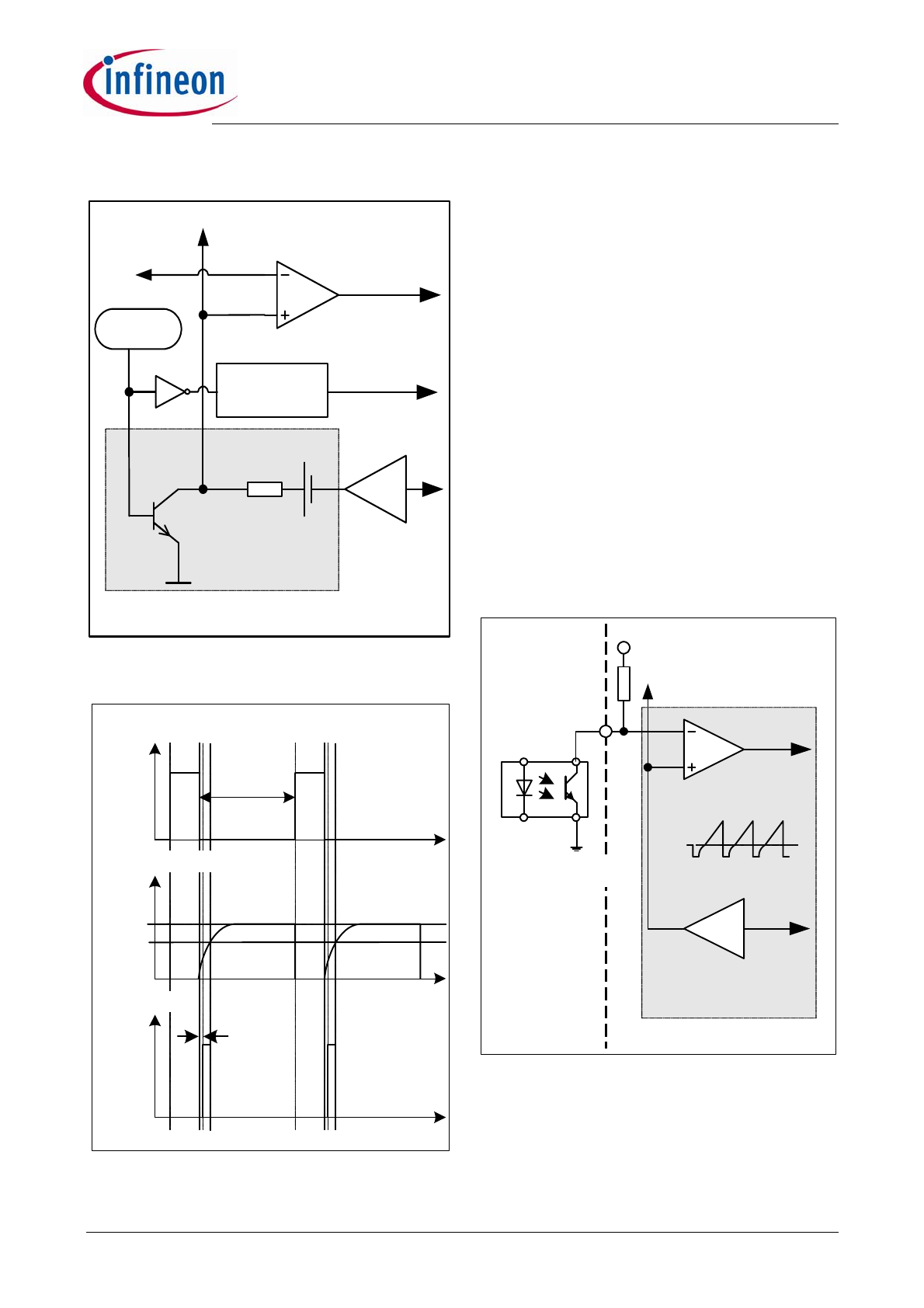

Figure 6

Improved Current Mode

Figure 7

Light Load Conditions

3.3.1

PWM-OP

The input of the PWM-OP is applied over the internal

leading edge blanking to the external sense resistor

R

Sense

connected to pin CS. R

Sense

converts the source

current into a sense voltage. The sense voltage is

amplified with a gain of 3.3 by PWM OP. The output of

the PWM-OP is connected to the voltage source V

1

.

The voltage ramp with the superimposed amplified

current signal is fed into the positive inputs of the PWM-

Comparator C8 and the Soft-Start-Comparator (see

Figure 6).

3.3.2

PWM-Comparator

The PWM-Comparator compares the sensed current

signal of the integrated CoolMOS

®

with the feedback

signal V

FB

(see Figure 8). V

FB

is created by an external

optocoupler or external transistor in combination with

the internal pull-up resistor R

FB

and provides the load

information of the feedback circuitry. When the

amplified current signal of the integrated CoolMOS

®

exceeds the signal V

FB

the PWM-Comparator switches

off the Gate Driver.

Figure 8

PWM Controlling

PWM OP

0.67V

10k

Ω

Oscillator

C8

T

2

R

1

FB

PWM-Latch

V

1

Gate Driver

Voltage Ramp

V

OSC

Soft-Start Comparator

time delay

circuit (156ns)

PWM Comparator

X3.3

t

t

V

OSC

0.67V

FB

t

max.

Duty Cycle

Gate Driver

Voltage Ramp

156ns time delay

X3.3

PWM OP

Improved

Current Mode

PWM Comparator

CS

Soft-Start Comparator

5V

C8

0.67V

FB

Optocoupler

R

FB

PWM-Latch