C o o l S E T

®

-Q1

I C E 2 Q R 4 7 6 5

O f f - L i n e S M P S Q u a s i - R e s o n a n t

P W M C o n t r o l l e r w i t h i n t e g r a t e d

6 5 0 V C o o l M O S

®

a n d s t a r t u p c e l l i n

D I P - 8

N e v e r s t o p t h i n k i n g .

P o w e r M a n a g e m e n t & S u p p l y

D a t a s h e e t , V e r s i o n 2 . 3 , N o v e m b e r 1 4 , 2 0 1 2

Edition 2012-11-14

Published by

Infineon Technologies AG

81726 München, Germany

©

Infineon Technologies AG 11/14/12.

All Rights Reserved.

Attention please!

The information given in this data sheet shall in no event be regarded as a guarantee of conditions or

characteristics (“Beschaffenheitsgarantie”). With respect to any examples or hints given herein, any typical values

stated herein and/or any information regarding the application of the device, Infineon Technologies hereby

disclaims any and all warranties and liabilities of any kind, including without limitation warranties of

non-infringement of intellectual property rights of any third party.

Information

For further information on technology, delivery terms and conditions and prices please contact your nearest

Infineon Technologies Office (

www.infineon.com

).

Warnings

Due to technical requirements components may contain dangerous substances. For information on the types in

question please contact your nearest Infineon Technologies Office.

Infineon Technologies Components may only be used in life-support devices or systems with the express written

approval of Infineon Technologies, if a failure of such components can reasonably be expected to cause the failure

of that life-support device or system, or to affect the safety or effectiveness of that device or system. Life support

devices or systems are intended to be implanted in the human body, or to support and/or maintain and sustain

and/or protect human life. If they fail, it is reasonable to assume that the health of the user or other persons may

be endangered.

For questions on technology, delivery and prices please contact the Infineon Technologies Offices in Germany or

the Infineon Technologies Companies and Representatives worldwide: see our webpage at http://

www.infineon.com

CoolMOS

®

, CoolSET

®

are trademarks of Infineon Technologies AG.

CoolSET

®

-Q1

ICE2QR4765

Revision History:

November 14, 2012

Datasheet

Previous Version:

2.2

Page

Subjects (major changes since last revision)

20

Revised outline dimension.

21

Add marking

Type

Package

Marking

V

DS

R

DSon

1)

1)

typ @ T=25°C

230VAC ±15%

2)

2)

Calculated maximum input power rating at T

a

=50°C, T

i

=125°C and without copper area as heat sink.

85-265 VAC

2)

ICE2QR4765

PG-DIP-8

ICE2QR4765

650V

4.7

30W

19W

CoolSET

®

-Q1

ICE2QR4765

Version 2.3

3

November 14, 2012

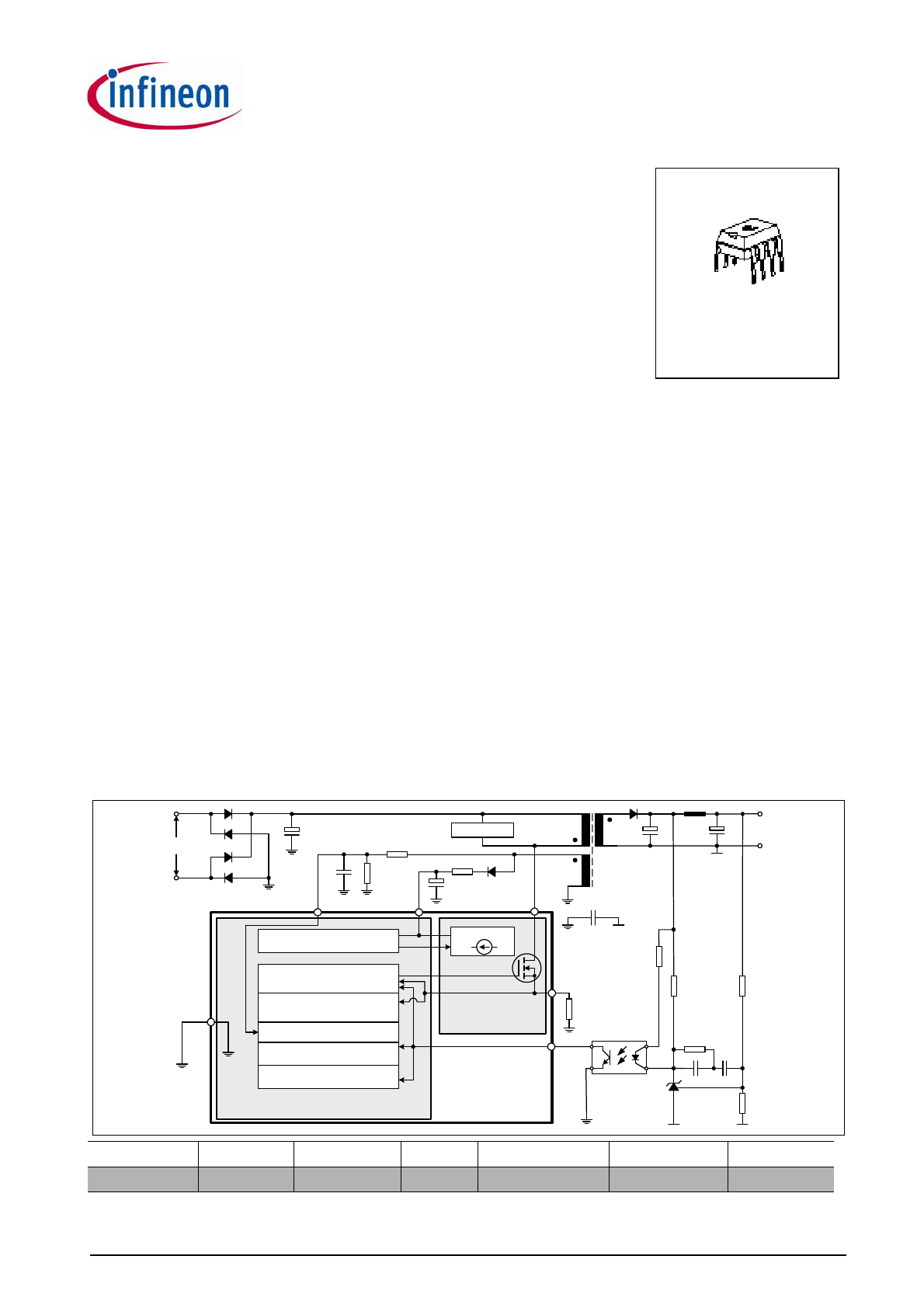

Off-Line SMPS Quasi-Resonant PWM

Controller with integrated 650V CoolMOS

®

and startup cell in DIP-8

PG-DIP-8

Description

The CoolSET

®

-Q1 series (ICE2QRxx65) is the first

generation of quasi-resonant integarted power ICs. It is

optimized for off-line switch mode power supply

applications such as LCD monitor, DVD R/W, DVD

Combo, Blue-ray DVD, set top box, etc. Operting the

MOSFET switch in quasi-resonant mode, lower EMI,

higher efficiency and lower voltage stress on secondary

diodes are expected for the SMPS. Based on the

BiCMOS technology, the CoolSET

®

-Q1 series has a

wide operation range (up to 25V) of IC power supply

and lower power consumption. It also offers many

advantages such as: a quasi-resonant operation till very

low load increasing the average system efficiency

compared to other conventional solutions; the Active

Burst Mode operation enables an ultra-low power

consumption at standby mode with small and

controllable output voltage ripple.

Product Highlights

•

Active Burst Mode to reach the lowest standby power requirement

<100mW@no load

•

Quasi resonant operation

•

Digital frequency reduction for better overall system efficiency

•

Integrated 650V startup cell

Features

•

650V avalanche rugged CoolMOS

®

with built-in

startup cell

•

Quasiresonant operation till very low load

•

Active burst mode operation for low standby input

power (< 0.1W)

•

Digital frequency reduction with decreasing load for

reduced switching loss

•

Built-in digital soft-start

•

Foldback point correction and cycle-by-cycle peak

current limitation

•

Maximum on time limitation

•

Auto restart mode for VCC Overvoltage and

Undervoltage protections

•

Auto restart mode for overload protection

•

Auto restart mode for overtemperature protection

•

Latch-off mode for adjustable output overvoltage

protection and transformer short-winding protection

85 ~ 265 VAC

Snubber

C

bus

D

r1

~D

r4

R

CS

TL431

Optocoupler

R

b1

R

b2

R

c1

C

c1

C

c2

R

ovs2

R

ovs1

C

VCC

D

VCC

D

O

C

O

L

f

C

f

V

O

C

PS

Startup Cell

CoolSET

®

-Q1

Depl. CoolMOS

®

Power Cell

W

p

W

s

W

a

R

VCC

C

ZC

R

ZC2

R

ZC1

Drain

Zero Crossing Block

Power Management

Cycle-by-Cycle

current limitation

Active Burst Mode

PWM controller

Current Mode Control

Protections

VCC

CS

Control Unit

ZC

FB

GND

CoolSET

®

- Q1

ICE2QR4765

Table of Contents

Page

Version 2.3

4

November 14, 2012

1

Pin Configuration and Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.1

Pin Configuration with PG-DIP-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.2

Package PG-DIP-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.3

Pin Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2

Representative Blockdiagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3.1

VCC Pre-Charging and Typical VCC Voltage During Start-up . . . . . . . . . . .7

3.2

Soft-start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3.3

Normal Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3.3.1

Digital Frequency Reduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3.3.1.1

Up/down counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.3.1.2

Zero crossing (ZC counter) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.3.1.3

Ringing suppression time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.3.2

Switch Off Determination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.4

Current Limitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.4.1

Foldback Point Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.5

Active Burst Mode Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3.5.1

Entering Active Burst Mode Operation . . . . . . . . . . . . . . . . . . . . . . . . . .10

3.5.2

During Active Burst Mode Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3.5.3

Leaving Active Burst Mode Operation . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3.6

Protection Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

4

Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4.1

Absolute Maximum Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4.2

Operating Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4.3

Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4.3.1

Supply Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4.3.2

Internal Voltage Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4.3.3

PWM Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.3.4

Current Sense . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.3.5

Soft Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.3.6

Foldback Point Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.3.7

Digital Zero Crossing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.3.8

Active Burst Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.3.9

Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.3.10

CoolMOS® Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

5

Typical CoolMOS

®

Performance Characteristic . . . . . . . . . . . . . . . . . . .17

6

Input power curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

7

Outline Dimension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

8

Marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Version 2.3

5

November 14, 2012

CoolSET

®

- Q1

ICE2QR4765

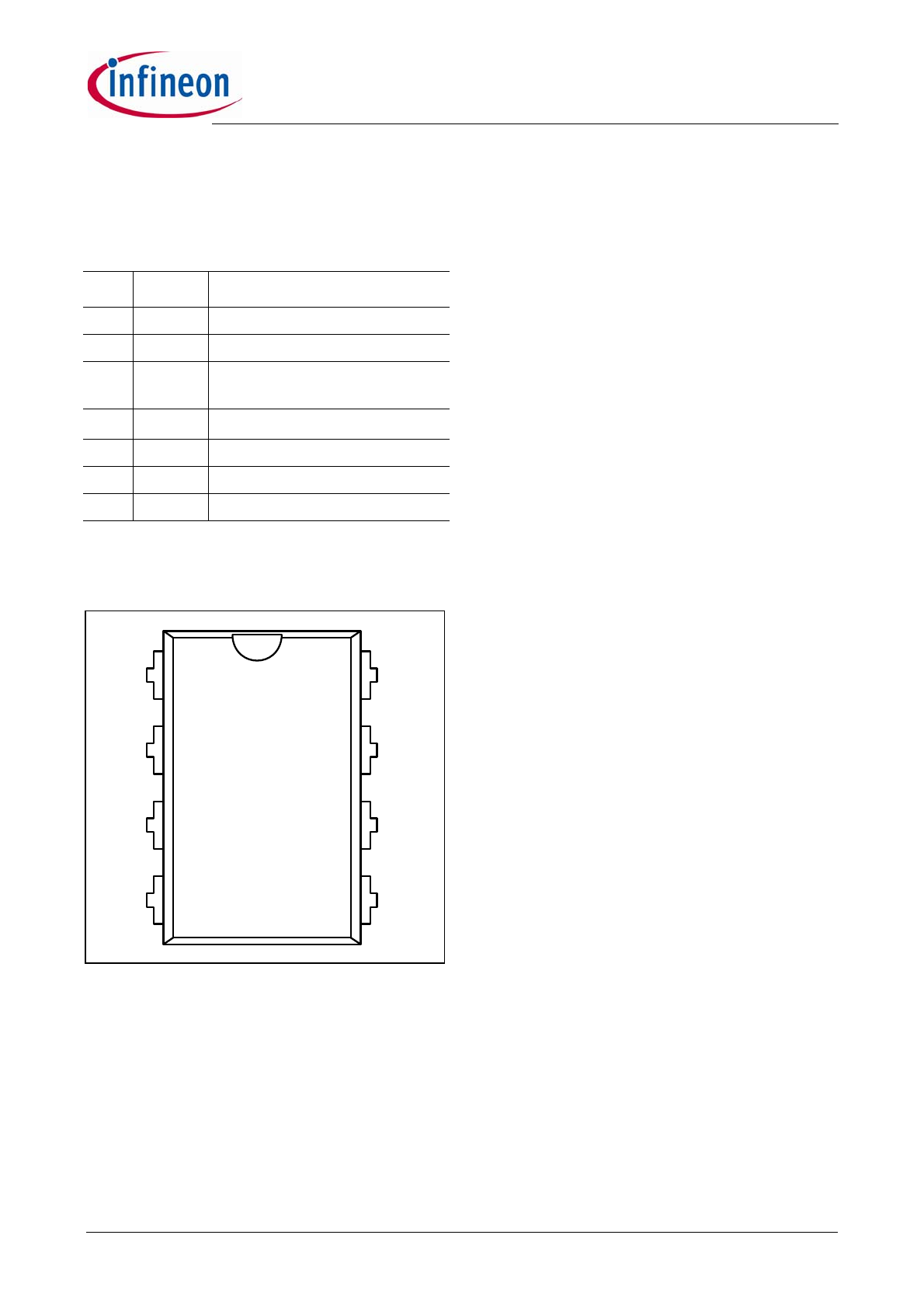

Pin Configuration and Functionality

1

Pin Configuration and Functionality

1.1

Pin Configuration with PG-DIP-8

1.2

Package PG-DIP-8

Figure 1

Pin Configuration PG-DIP-8 (top view)

Note: Pin 4 and 5 are shorted

1.3

Pin Functionality

ZC (Zero Crossing)

At this pin, the voltage from the auxiliary winding after

a time delay circuit is applied. Internally, this pin is

connected to the zero-crossing detector for switch-on

determination. Additionally, the output overvoltage

detection is realized by comparing the voltage Vzc with

an internal preset threshold.

FB (Feedback)

Normally, an external capacitor is connected to this pin

for a smooth voltage V

FB

. Internally, this pin is

connected to the PWM signal generator for switch-off

determination (together with the current sensing

signal), the digital signal processing for the frequency

reduction with decreasing load during normal

operation, and the Active Burst Mode controller for

entering Active Burst Mode operation determination

and burst ratio control during Active Burst Mode

operation. Additionally, the open-loop / over-load

protection is implemented by monitoring the voltage at

this pin.

CS (Current Sense)

This pin is connected to the shunt resistor for the

primary current sensing, externally, and the PWM

signal generator for switch-off determination (together

with the feedback voltage), internally. Moreover, short-

winding protection is realised by monitoring the voltage

V

cs

during on-time of the main power switch.

Drain (Drain of integrated Depl. CoolMOS

®

)

Drain pin is the connection to the drain of the internal

CoolMOS

®.

VCC (Power supply)

VCC pin is the positive supply of the IC. The operating

range is between V

VCCoff

and V

VCCOVP

.

GND (Ground)

This is the common ground of the controller.

Pin

Symbol

Function

1

ZC

Zero Crossing

2

FB

Feedback

3

CS

Current Sense/

650V

1)

CoolMOS

®

Source

1)

at T

j

=110°C

4, 5

Drain

650V

1)

CoolMOS

®

Drain

6

n.c. Not

connected

7

VCC

Controller Supply Voltage

8

GND

Controller Ground

1

6

7

8

4

3

2

5

GND

ZC

FB

CS

VCC

n.c.

Drain

Drain

CoolSET

®

- Q1

ICE2QR4765

Representative Blockdiagram

Version 2.3

6

November 14, 2012

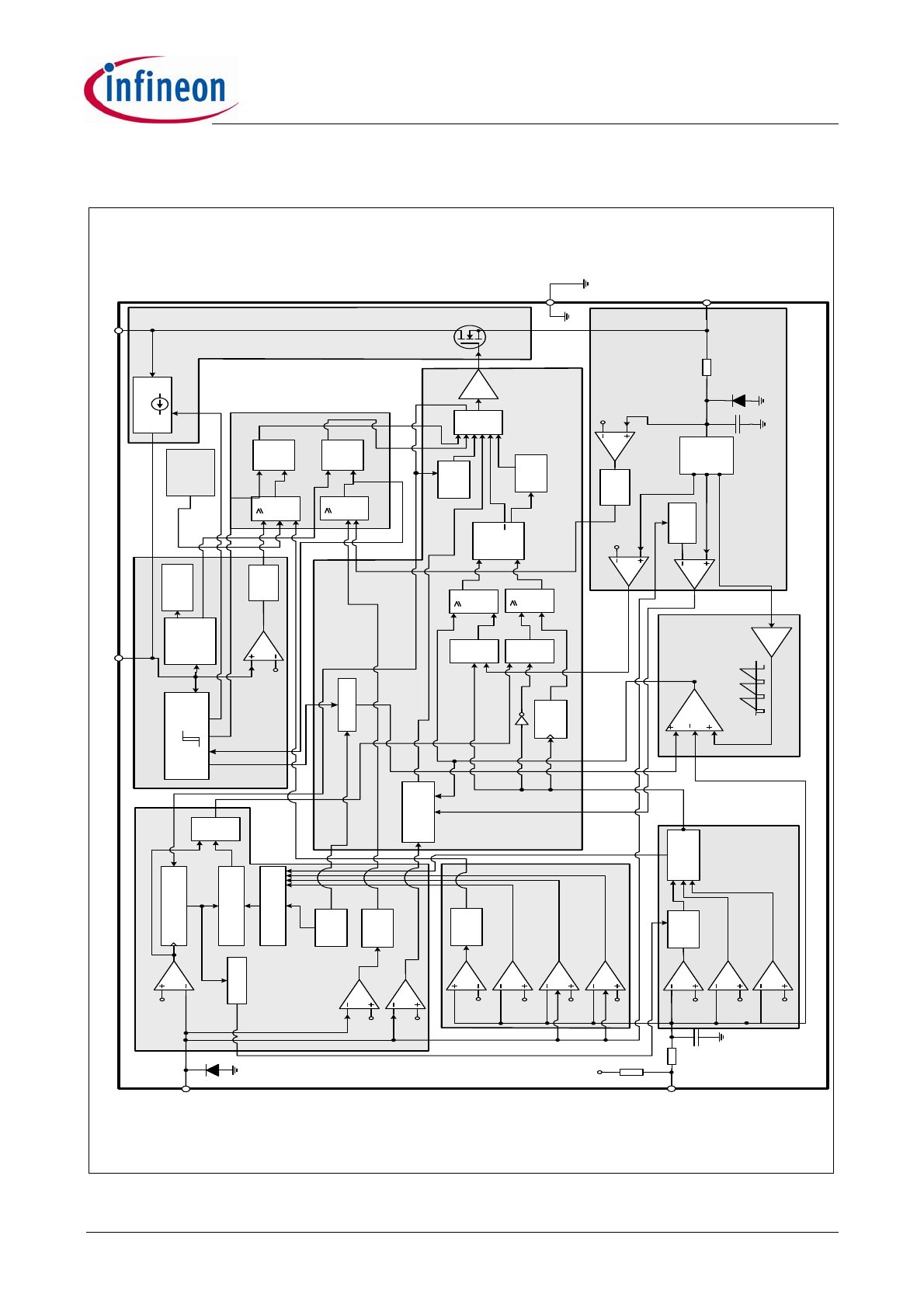

2

Representative Blockdiagram

Figure 2

Representative Block diagram

1

G2

1

G7

R

SQ

la

tc

hed

P

rot

ec

t

R

SQ

Au

to

re

st

ar

t

Pr

ot

ec

t

P

ro

tect

io

n

R

FB

1

G3

25

kO

2pF

D1

&

G1

&

G5

1

G4

t

BE

B

&

G6

A

ctiv

e B

ur

st B

lo

ck

FB

C8

V

FB

E

B

C9

V

FB

B

O

n

C1

0

V

FB

B

O

ff

C3

V

ZC

R

S

C2

V

ZC

O

V

P

De

la

y

t

ZC

O

V

P

f

sB

OS

C

Ac

tiv

e

Bu

rs

t M

od

e

t

CO

UN

T

C1

V

ZC

C

ZC

U

p/

dow

n c

ount

er

ZC

c

ount

er

cl

k

C

om

par

at

or

So

ft-

st

ar

t

R

ingi

ng

S

uppr

es

si

on

C

oun

t=

7

V

REF

R

S

Q

G8

&

G9

St

ar

tu

p C

el

l

Dr

ai

n

CS

VC

C

Ga

te

Dr

iv

e

G

PW

M

PW

M

O

P

C

urre

nt

M

od

e

PW

M

C

om

par

at

or

V

PW

M

q

V

ol

tage

R

ef

er

enc

e

U

nde

rv

ol

ta

ge

Lo

ck

ou

t

18

V

10.

5

10us

In

te

rn

al

Bi

as

P

ow

er

M

an

age

m

ent

D

epl

. C

ool

M

O

S

®

T

On

M

ax

C7

V

FB

ZL

C6

V

FB

ZH

C5

V

FB

R

1

C4

V

FB

O

LP

t

OL

P

_B

R

egul

at

io

n

C

ur

re

nt L

im

iti

ng

10

kO

D2

Lea

di

ng

E

dge

B

lank

ing

t

LE

B

1p

F

Fo

ld

bac

k

C

orre

ct

io

n

De

la

y

t

CSS

W

C1

3

V

CSB

C1

4

V

CSS

W

C1

5

PW

M

C

ont

ro

l

Ze

ro

C

ros

si

ng

Ga

te

D

ri

ve

r

GN

D

en

C1

2

V

VCCO

V

P

T

O

ffM

ax

OT

P

Version 2.3

7

November 14, 2012

CoolSET

®

- Q1

ICE2QR4765

Functional Description

3

Functional Description

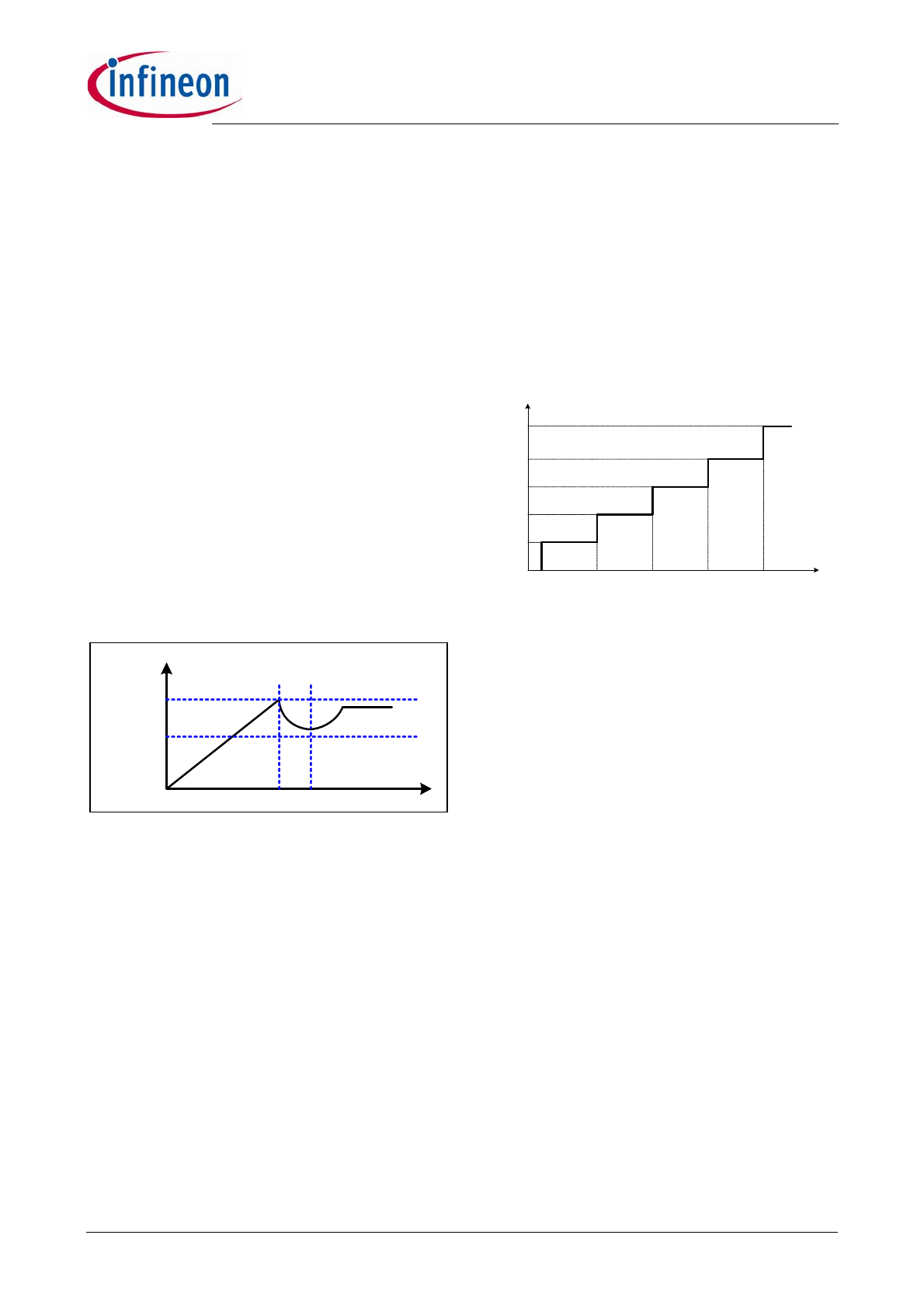

3.1

VCC Pre-Charging and Typical

VCC Voltage During Start-up

In ICE2QR4765, a startup cell is integrated into the

CoolMOS

®

. As shown in Figure 2, the start cell consists

of a high voltage device and a controller, whereby the

high voltage device is controlled by the controller. The

startup cell provides a pre-charging of the VCC

capacitor till VCC voltage reaches the VCC turned-on

threshold V

VCCon

and the IC begins to operate.

Once the mains input voltage is applied, a rectified

voltage shows across the capacitor C

bus

. The high

voltage device provides a current to charge the VCC

capacitor C

vcc

. Before the VCC voltage reaches a

certain value, the amplitude of the current through the

high voltage device is only determined by its channel

resistance and can be as high as several mA. After the

VCC voltage is high enough, the controller controls the

high voltage device so that a constant current around

1mA is provided to charge the VCC capacitor further,

until the VCC voltage exceeds the turned-on threshold

V

VCCon

. As shown as the time phase I in Figure 3, the

VCC voltage increase near linearly and the charging

speed is independent of the mains voltage level.

Figure 3

VCC voltage at start up

The time taking for the VCC pre-charging can then be

approximately calculated as:

[1]

where I

VCCcharge2

is the charging current from the

startup cell which is 1.05mA, typically.

Exceeds the VCC voltage the turned-on threshold

V

VCCon

of at time t

1

, the startup cell is switched off, and

the IC begins to operate with a soft-start. Due to power

consumption of the IC and the fact that still no energy

from the auxiliary winding to charge the VCC capacitor

before the output voltage is built up, the VCC voltage

drops (Phase II). Once the output voltage is high

enough, the VCC capacitor receives then energy from

the auxiliary winding from the time point t

2

on. The VCC

then will reach a constant value depending on output

load.

3.2

Soft-start

At the time t

on

, the IC begins to operate with a soft-start.

By this soft-start the switching stresses for the switch,

diode and transformer are minimised. The soft-start

implemented in ICE2QR4765 is a digital time-based

function. The preset soft-start time is 12ms with 4

steps. If not limited by other functions, the peak voltage

on CS pin will increase step by step from 0.32V to 1V

finally.

Figure 4

Maximum current sense voltage during

softstart

3.3

Normal Operation

The PWM controller during normal operation consists

of a digital signal processing circuit including an up/

down counter, a zero-crossing counter (ZC counter)

and a comparator, and an analog circuit including a

current measurement unit and a comparator. The

switch-on and -off time points are each determined by

the digital circuit and the analog circuit, respectively. As

input information for the switch-on determination, the

zero-crossing input signal and the value of the up/down

counter are needed, while the feedback signal V

FB

and

the current sensing signal V

CS

are necessary for the

switch-off determination. Details about the full

operation of the PWM controller in normal operation

are illustrated in the following paragraphs.

3.3.1

Digital Frequency Reduction

As mentioned above, the digital signal processing

circuit consists of an up/down counter, a ZC counter

and a comparator. These three parts are key to

implement digital frequency reduction with decreasing

load. In addition, a ringing suppression time controller

is implemented to avoid mistriggering by the high

frequency oscillation, when the output voltage is very

low under conditions such as soft start or output short

circuit . Functionality of these parts is described as in

the following.

V

VCCon

V

VCC

V

VCCoff

t1

t

t2

i

ii

iii

t

1

V

VCCon

C

vcc

⋅

I

VCCch

e2

arg

------------------------------------------

=

t

on

3

6

9

12

0.32

0.49

0.66

0.83

1.00

Vcs_sst

(V)

Time(ms)

CoolSET

®

- Q1

ICE2QR4765

Functional Description

Version 2.3

8

November 14, 2012

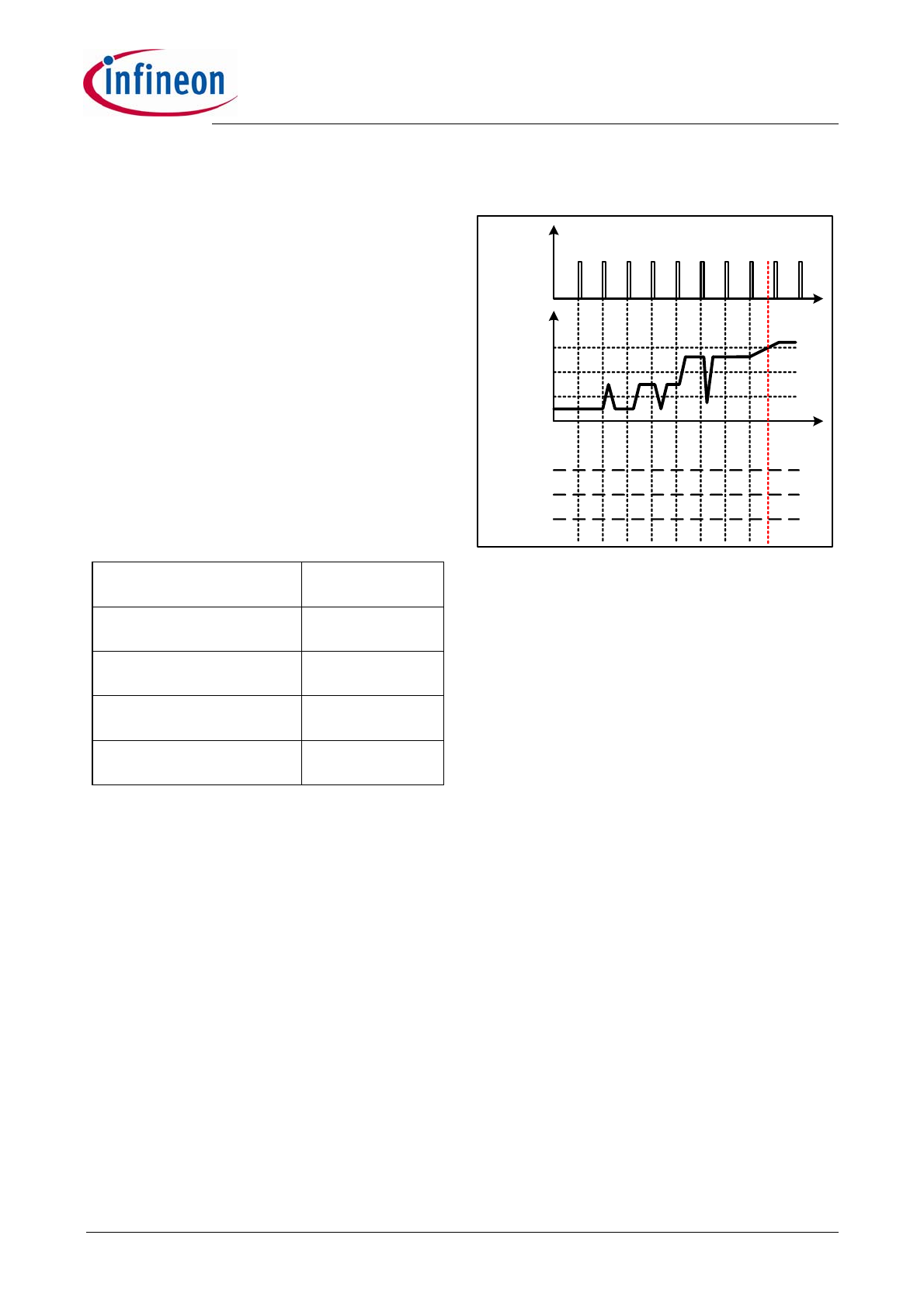

3.3.1.1

Up/down counter

The up/down counter stores the number of the zero

crossing to be ignored before the main power switch is

switched on after demagnetisation of the transformer.

This value is fixed according to the feedback voltage,

V

FB

, which contains information about the output

power. Indeed, in a typical peak current mode control,

a high output power results in a high feedback voltage,

and a low output power leads to a low regulation

voltage. Hence, according to V

FB

, the value in the up/

down counter is changed to vary the power MOSFET

off-time according to the output power. In the following,

the variation of the up/down counter value according to

the feedback voltage is explained.

The feedback voltage V

FB

is internally compared with

three threshold voltages V

RL

, V

RH

and V

RM

, at each

clock period of 48ms. The up/down counter counts then

upward, keep unchanged or count downward, as

shown in Table 1.

Table 1

Operation of the up/down counter

In the ICE2QR4765, the number of zero crossing is

limited to 7. Therefore, the counter varies between 1

and 7, and any attempt beyond this range is ignored.

When V

FB

exceeds V

FBR1

voltage, the up/down counter

is initialised to 1, in order to allow the system to react

rapidly to a sudden load increase. The up/down

counter value is also intialised to 1 at the start-up, to

ensure an efficient maximum load start up.

Figure 5

shows some examples on how up/down counter is

changed according to the feedback voltage over time.

The use of two different thresholds V

FBZL

and V

FBZH

to

count upward or downward is to prevent frequency

jittereing when the feedback voltage is close to the

threshold point. However, for a stable operation, these

two thresholds must not be affected by the foldback

current limitation (see Section 3.4.1), which limits the

V

CS

voltage. Hence, to prevent such situation, the

threshold voltages, V

FBZL

and V

FBZH

, are changed

internally depending on the line voltage levels.

Figure 5

Up/down counter operation

3.3.1.2

Zero crossing (ZC counter)

In the system, the voltage from the auxiliary winding is

applied to the zero-crossing pin through a RC network,

which provides a time delay to the voltage from the

auxiliary winding. Internally, this pin is connected to a

clamping network, a zero-crossing detector, an output

overvoltage detector and a ringing suppression time

controller.

During on-state of the power switch a negative voltage

applies to the ZC pin. Through the internal clamping

network, the voltage at the pin is clamped to certain

level.

The ZC counter has a minimum value of 0 and

maximum value of 7. After the internal MOSFET is

turned off, every time when the falling voltage ramp of

on ZC pin crosses the 100mV threshold, a zero

crossing is detected and ZC counter will increase by 1.

It is reset every time after the DRIVER output is

changed to high.

The voltage v

ZC

is also used for the output overvoltage

protection. Once the voltage at this pin is higher than

the threshold V

ZCOVP

during off-time of the main switch,

the IC is latched off after a fixed blanking time.

To achieve the switch-on at voltage valley, the voltage

from the auxiliary winding is fed to a time delay network

(the RC network consists of D

zc

, R

zc1

, R

zc2

and C

zc

as

shown in typical application circuit) before it is applied

to the zero-crossing detector through the ZC pin. The

needed time delay to the main oscillation signal

Δt

should be approximately one fourth of the oscillation

period (by transformer primary inductor and drain-

source capacitor) minus the propagation delay from

v

FB

up/down counter

action

Always lower than V

FBZL

Count upwards till

7

Once higher than V

FBZL

, but

always lower than V

FBZH

Stop counting, no

value changing

Once higher than V

FBZH

, but

always lower than V

FBR1

Count downwards

till 1

Once higher than V

FBR1

Set up/down

counter to 1

1

Case 3

Case 2

Case 1

Up/down

counter

n

n+1

n+2

n+2

n+2

n+2

n+1

n

n-1

4 5 6 6 6 6 5 4 3

1

1

2 3 4 4 4 4 3 2 1

7 7 7 7 7 7 6 5 4

t

t

V

FB

V

FBR1

V

FBZH

V

FBZL

clock

T=48ms

1

CoolSET

®

- Q1

ICE2QR4765

Functional Description

Version 2.3

9

November 14, 2012

thedetected zero-crossing to the switch-on of the main

switch t

delay

, theoretically:

[2]

This time delay should be matched by adjusting the

time constant of the RC network which is calculated as:

[3]

3.3.1.3

Ringing suppression time

After MOSFET is turned off, there will be some

oscillation on V

DS

, which will also appear on the voltage

on ZC pin. To avoid that the MOSFET is turned on

mistriggerred by such oscillations, a ringing

suppression timer is implemented. The time is

dependent on the voltage v

ZC

. When the voltage v

ZC

is

lower than the threshold V

ZCRS

, a longer preset time

applies, while a shorter time is set when the voltage v

ZC

is higher than the threshold.

3.3.1.4

Switch on determination

After the gate drive goes to low, it can not be changed

to high during ring suppression time.

After ring suppression time, the gate drive can be

turned on when the ZC counter value is higher or equal

to up/down counter value.

However, it is also possible that the oscillation between

primary inductor and drain-source capacitor damps

very fast and IC can not detect enough zero crossings

and ZC counter value will not be high enough to turn on

the gate drive. In this case, a maximum off time is

implemented. After gate drive has been remained off

for the period of T

OffMax

, the gate drive will be turned on

again regardless of the counter values and V

ZC

. This

function can effectively prevent the switching

frequency from going lower than 20kHz, otherwise

which will cause audible noise, during start up.

3.3.2

Switch Off Determination

In the converter system, the primary current is sensed

by an external shunt resistor, which is connected

between low-side terminal of the main power switch

and the common ground. The sensed voltage across

the shunt resistor v

CS

is applied to an internal current

measurement unit, and its output voltage V

1

is

compared with the regulation voltage V

FB

. Once the

voltage V

1

exceeds the voltage V

FB

, the output flip-flop

is reset. As a result, the main power switch is switched

off. The relationship between the V

1

and the v

CS

is

described by:

[4]

To avoid mistriggering caused by the voltage spike

across the shunt resistor at the turn on of the main

power switch, a leading edge blanking time, t

LEB

, is

applied to the output of the comparator. In other words,

once the gate drive is turned on, the minimum on time

of the gate drive is the leading edge blanking time.

In addition, there is a maximum on time, t

OnMax

,

limitation implemented in the IC. Once the gate drive

has been in high state longer than the maximum on

time, it will be turned off to prevent the switching

frequency from going too low because of long on time.

3.4

Current Limitation

There is a cycle by cycle current limitation realized by

the current limit comparator to provide an overcurrent

detection. The source current of the MOSFET is

sensed via a sense resistor R

CS

. By means of R

CS

the

source current is transformed to a sense voltage V

CS

which is fed into the pin CS. If the voltage V

CS

exceeds

an internal voltage limit, adjusted according to the

Mains voltage, the comparator immediately turns off

the gate drive.

To prevent the Current Limitation process from

distortions caused by leading edge spikes, a Leading

Edge Blanking time (t

LEB

) is integrated in the current

sensing path.

A further comparator is implemented to detect

dangerous current levels (V

CSSW

) which could occur if

one or more transformer windings are shorted or if the

secondary diode is shorted. To avoid an accidental

latch off, a spike blanking time of t

CSSW

is integrated in

the output path of the comparator .

3.4.1

Foldback Point Correction

When the main bus voltage increases, the switch on

time becomes shorter and therefore the operating

frequency is also increased. As a result, for a constant

primary current limit, the maximum possible output

power is increased, which the converter may have not

been designed to support.

To avoid such a situation, the internal foldback point

correction circuit varies the V

CS

voltage limit according

to the bus voltage. This means the V

CS

will be

decreased when the bus voltage increases. To keep a

constant maximum input power of the converter, the

Δt

T

osc

4

------------

t

delay

–

=

τ

td

C

zc

R

zc1

R

zc2

⋅

R

zc1

R

zc2

+

---------------------------------

⋅

=

V

1

3.3 V

cs

⋅

0.7

+

=

CoolSET

®

- Q1

ICE2QR4765

Functional Description

Version 2.3

10

November 14, 2012

required maximum V

CS

versus various input bus

voltage can be calculated, which is shown in

Figure 6

.

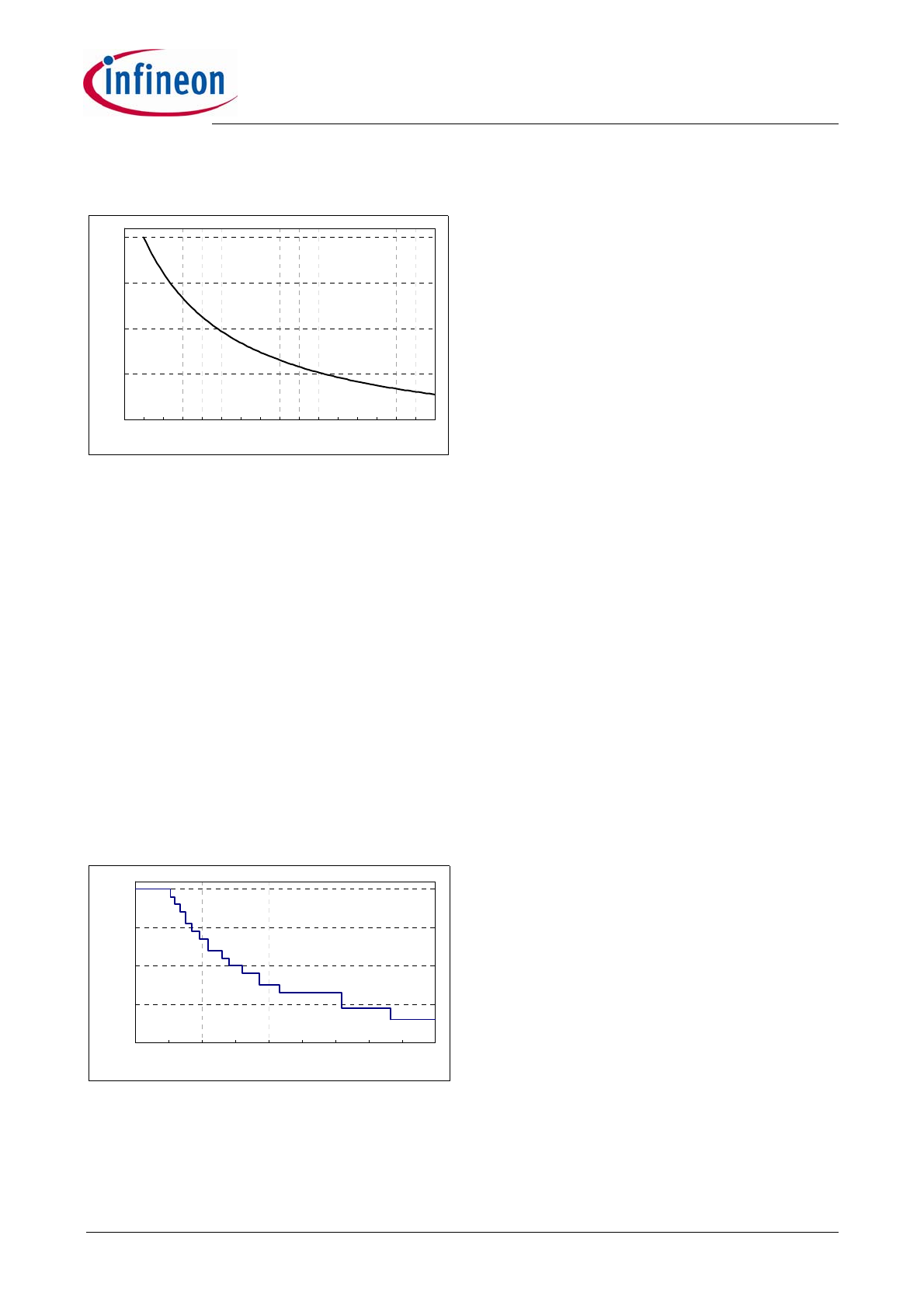

Figure 6

Variation of the VCS limit voltage according

to the IZC current

According to the typical application circuit, when

MOSFET is turned on, a negative voltage proportional

to bus voltage will be coupled to auxiliary winding.

Inside CoolSET

®

-Q1, an internal circuit will clamp the

voltage on ZC pin to nearly 0V. As a result, the current

flowing out from ZC pin can be calculated as

[5]

When this current is higher than I

ZC_1

, the amount of

current exceeding this threshold is used to generate an

offset to decrease the maximum limit on V

CS

. Since the

ideal curve shown in

Figure 6

is a nonlinear one, a

digital block in CoolSET

®

-Q1 is implemented to get a

better control of maximum output power. Additional

advantage to use digital circuit is the production

tolerance is smaller compared to analog solutions. The

typical maximum limit on V

CS

versus the ZC current is

shown in

Figure 7

.

Figure 7

V

CS-max

versus I

ZC

3.5

Active Burst Mode Operation

At light load condition, the IC enters Active Burst Mode

operation to minimize the power consumption. Details

about Active Burst Mode operation are explained in the

following paragraphs.

3.5.1

Entering Active Burst Mode Operation

For determination of entering Active Burst Mode

operation, three conditions apply:

•

the feedback voltage is lower than the threshold of

V

FBEB

(1.25V). Accordingly, the peak current sense

voltage across the shunt resistor is 0.17;

•

the up/down counter is 7; and

•

a certain blanking time (t

BEB

).

Once all of these conditions are fulfilled, the Active

Burst Mode flip-flop is set and the controller enters

Active Burst Mode operation. This multi-condition

determination for entering Active Burst Mode operation

prevents mistriggering of entering Active Burst Mode

operation, so that the controller enters Active Burst

Mode operation only when the output power is really

low during the preset blanking time.

3.5.2

During Active Burst Mode Operation

After entering the Active Burst Mode the feedback

voltage rises as V

OUT

starts to decrease due to the

inactive PWM section. One comparator observes the

feedback signal if the voltage level V

BH

(3.6V) is

exceeded. In that case the internal circuit is again

activated by the internal bias to start with swtiching.

Turn-on of the power MOSFET is triggered by the

timer. The PWM generator for Active Burst Mode

operation composes of a timer with a fixed frequency of

52kHz, typically, and an analog comparator. Turn-off is

resulted by comparison of the voltage signal v

1

with an

internal threshold, by which the voltage across the

shunt resistor V

csB

is 0.34V, accordingly. A turn-off can

also be triggered by the maximal duty ratio controller

which sets the maximal duty ratio to 50%. In operation,

the output flip-flop will be reset by one of these signals

which come first.

If the output load is still low, the feedback signal

decreases as the PWM section is operating. When

feedback signal reaches the low threshold V

BL

(3.0V),

the internal bias is reset again and the PWM section is

disabled until next time regultaion siganl increases

beyond the V

BH

threshold. If working in Active Burst

Mode the feedback signal is changing like a saw tooth

between 3.0V and 3.6V shown in

Figure 8

.

3.5.3

Leaving Active Burst Mode Operation

The feedback voltage immediately increases if there is

a high load jump. This is observed by one comparator.

As the current limit is 34% during Active Burst Mode a

certain load is needed so that feedback voltage can

exceed V

LB

(4.5V). After leaving active busrt mode,

maximum current can now be provided to stabilize V

O

.

In addition, the up/down counter will be set to 1

0.6

0.7

0.8

0.9

1

80

100 120 140 160 180 200 220 240 260 280 300 320 340 360 380 400

Vin(V)

Vc

s

-m

a

x

(V)

I

ZC

V

BUS

N

a

R

ZC1

N

P

------------------------

=

0.6

0.7

0.8

0.9

1

300

500

700

900

1100

1300

1500

1700

1900

2100

Iz c(uA)

Vc

s

-m

a

x

(V)