1

TechnicalInformation

2PS06017E32G28213

PrimeSTACK™

preparedby:OW

approvedby:AR

dateofpublication:2013-05-03

revision:2.0

Preliminarydata

Keydata

1x325AACat690VAC,forcedair(fannotimplemented)

Generalinformation

Stacksforvariousinverterapplication.Semiconductors,heatsinks,driversandsensorsincluded.

Theseareonlytechnicaldata

Pleasereadcarefullythecompletedocumentationandmaintaintheproperdesignenvironment

EspeciallynotetheEMCenvironmentandthecontroller'sfunctionality.

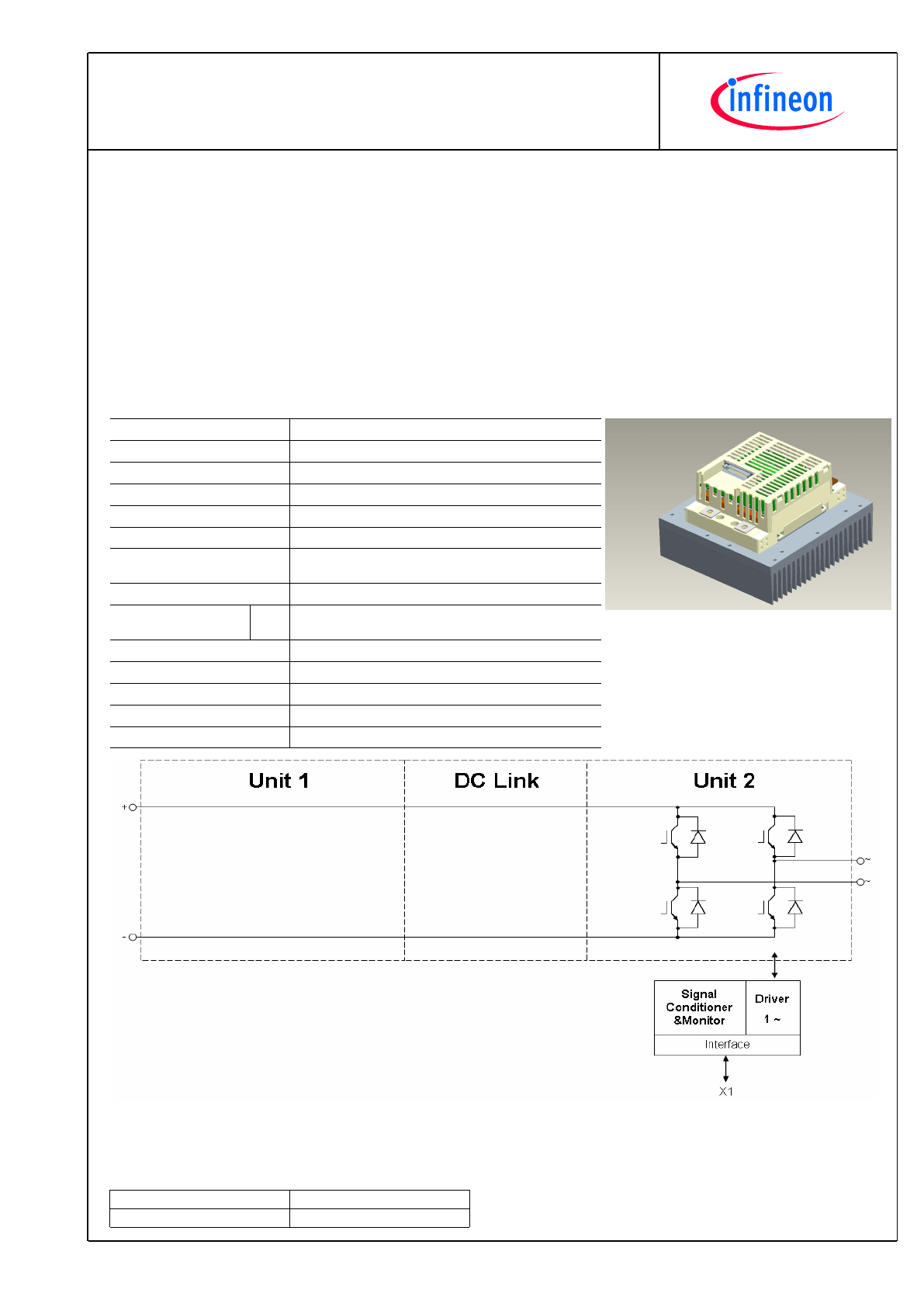

Topology

1/2 B2I

Application / Modulation

Inverter / Sine

Load type

resistive, inductive

Cooling

forced air (fan not implemented)

Market

common industrial, drives, power supply

Implemented sensors

current, temperature

Semicond.

(Unit 1)

none

DC Link

none

Semicond.

(Unit 2)

2x FF300R17KE3

IGBT

Driver signals IGBT

electrical CMOS

Standards

EN50178, UL94, prepared for UL508C

Internal ID

28213

Mechanical drawing number

38000028

Electrical drawing number

2PS-C2-V

2

TechnicalInformation

2PS06017E32G28213

PrimeSTACK™

preparedby:OW

approvedby:AR

dateofpublication:2013-05-03

revision:2.0

Preliminarydata

Notes

Overvoltage shutdown:

It must be realized by the customer.

Overvoltage and Overcurrent shutdown reaction time:

This parameter refers to the customers controller.

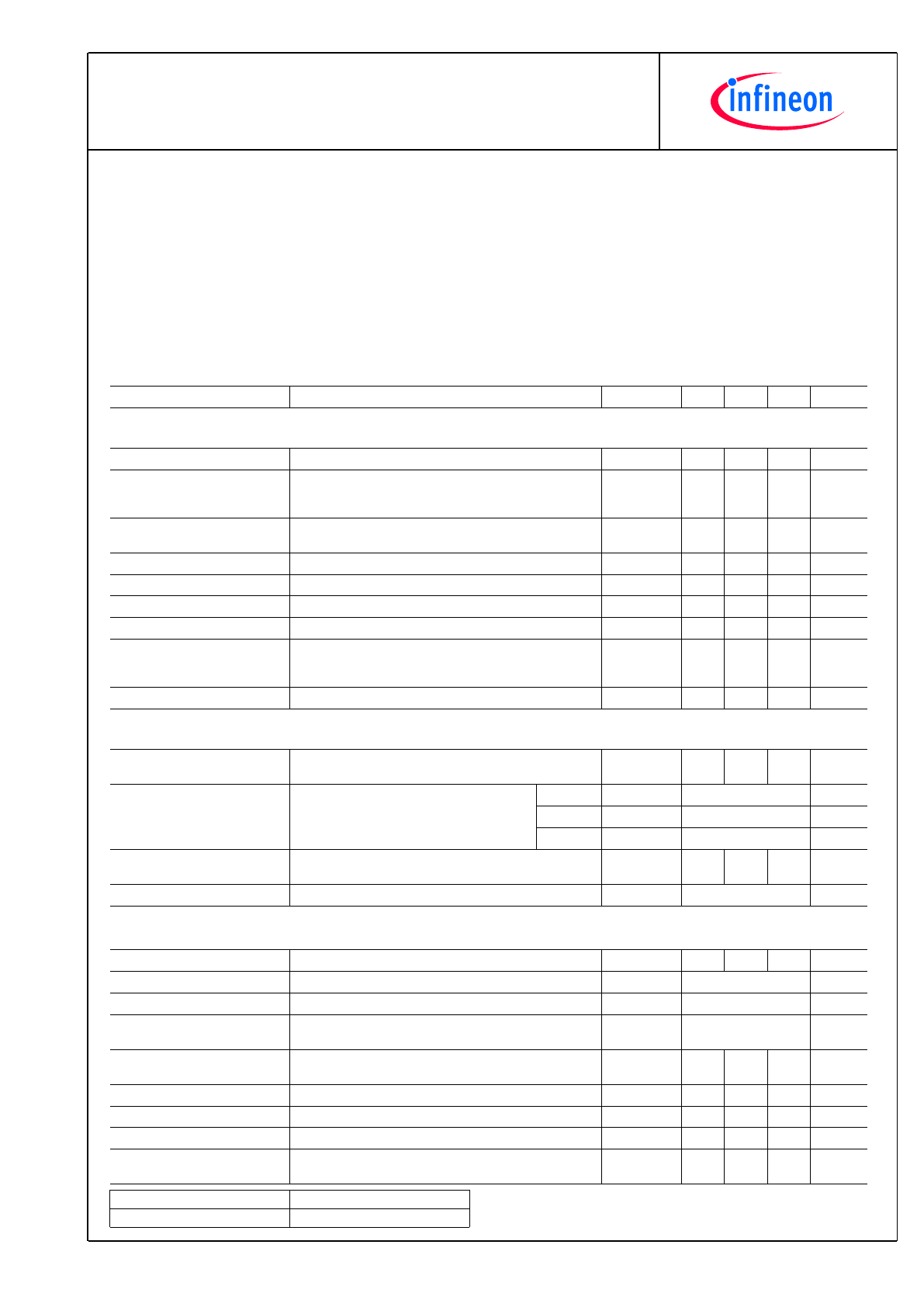

Electricaldata

DCLink

min

typ

max

units

Voltage

V

DC

1100

1200

V

Unit2AC

min

typ

max

units

Voltage

V

Unit2

690

V

RMS

Continuous current

V

Unit2

= 690V

RMS

, V

DC

= 1100V, T

inlet

= 40°C,

T

J

≤

125°C, f

Unit2

= 50Hz, f

sw2

= 2000Hz,

cos(phi) = 0,85

I

Unit2

325

A

RMS

Continuous current overload

cap.

T

inlet

= 40°C, for overload capability 150% for 60s

231

A

RMS

Short time current

T

inlet

= 40°C, 10s, every 180s, initial load = 283A

RMS

I

Unit2

354

A

RMS

DC current

no rotating field, T

inlet

= 40°C

I

Unit2 DC

162,0

A

av

within 15µs

930

A

peak

Overcurrent shutdown

Switching frequency

f

sw2

20000

Hz

Power losses

V

Unit2

= 690V, V

DC

= 1100V, T

inlet

= 40°C,

T

J

≤

125°C, f

Unit2

= 50Hz, f

sw2

= 2000Hz,

cos(phi) = 0,85, I

Unit2

= 325A

RMS

P

loss2

3770

W

Power factor

cos(phi)

Unit2

-1,00

1,00

Generaldata

min

typ

max

units

Power losses

(PCB)

P

loss aux

40

W

V

Burst

2

kV

power

V

Burst

1

kV

control

V

Surge

1

kV

aux (24V)

EMC test

according to IEC61800-3 at named

interfaces

Insulation management is

designed for

V

Line

690

V

RMS

Insulation test voltage

according to EN50178, f = 50Hz, t = 60s

V

isol

2,5

kV

RMS

Controllerinterfacedata

min

typ

max

units

Auxiliary voltage

V

aux

18

24

30

V

av

Auxiliary power requirement

V

aux

= 24V

av

P

aux

40

W

Driver and interface board

see separate technical information

DR240

Driver core

EiceDRIVER

2ED300C17-S

Digital input level

resistor to GND 10,0k

Ω

, capacitor to GND 1nF, high =

on, min 15mA

V

in

0,0

15,0

V

Digital output level

open collector, low = ok, max 15mA

V

out

0,0

30,0

V

3,43

3,50

3,60

Analog current outputs Unit 2

load max 1mA; at 325A

V

ana out

V

Analog temperature output

load max 1mA; at T

NTC

= 77°C correspond to T

j

= 125°C

V

T out

8,90

9,10

9,30

V

Overcurrent shutdown

reaction time

afterovercurrentmessagebyPrimeSTACK™interface

10

µs

3

TechnicalInformation

2PS06017E32G28213

PrimeSTACK™

preparedby:OW

approvedby:AR

dateofpublication:2013-05-03

revision:2.0

Preliminarydata

Heatsinkaircooled/Thermaldata

min

typ

max

units

Airflow

∆

V/

∆

t

Air

500

m³/h

Air pressure drop

∆

p

Air

110

Pa

T

Air

= 20°C, Pair = 1013hPa, dry- and dust free,

measured on side of heat sink. according to DIN 41882

heat sink temperature > -25°C

-25

Cooling air inlet temperature

T

inlet

40

°C

Environmentalconditions

min

typ

max

units

Storage temperature

T

stor

-40

85

°C

Ambient temperature

T

amb

-25

55

°C

Operating temperature

see chapter Heat sink air cooled / Thermal data

Cooling air velocity

(PCB)

V

Air PCB

0,3

m/s

Air pressure

standard atmosphere

p

Air

900

1100

hPa

Humidity

no condensation

Rel. F

5

85

%

Installation height

0

1000

m

Vibration

according to IEC60721

5

m/s²

Shock

according to IEC60721

40

m/s²

Protection degree

IP00

Pollution degree

2

Torque at DC Terminals

M

DC

6,0

10,0

Nm

Torque at AC Terminals

M

AC

16,0

20,0

Nm

Dimensions

width × depth × height

216

200

167

mm

Weight with heat sink

approximation

6,3

kg

Weight without heat sink

approximation

1,9

kg

4

TechnicalInformation

2PS06017E32G28213

PrimeSTACK™

preparedby:OW

approvedby:AR

dateofpublication:2013-05-03

revision:2.0

Preliminarydata

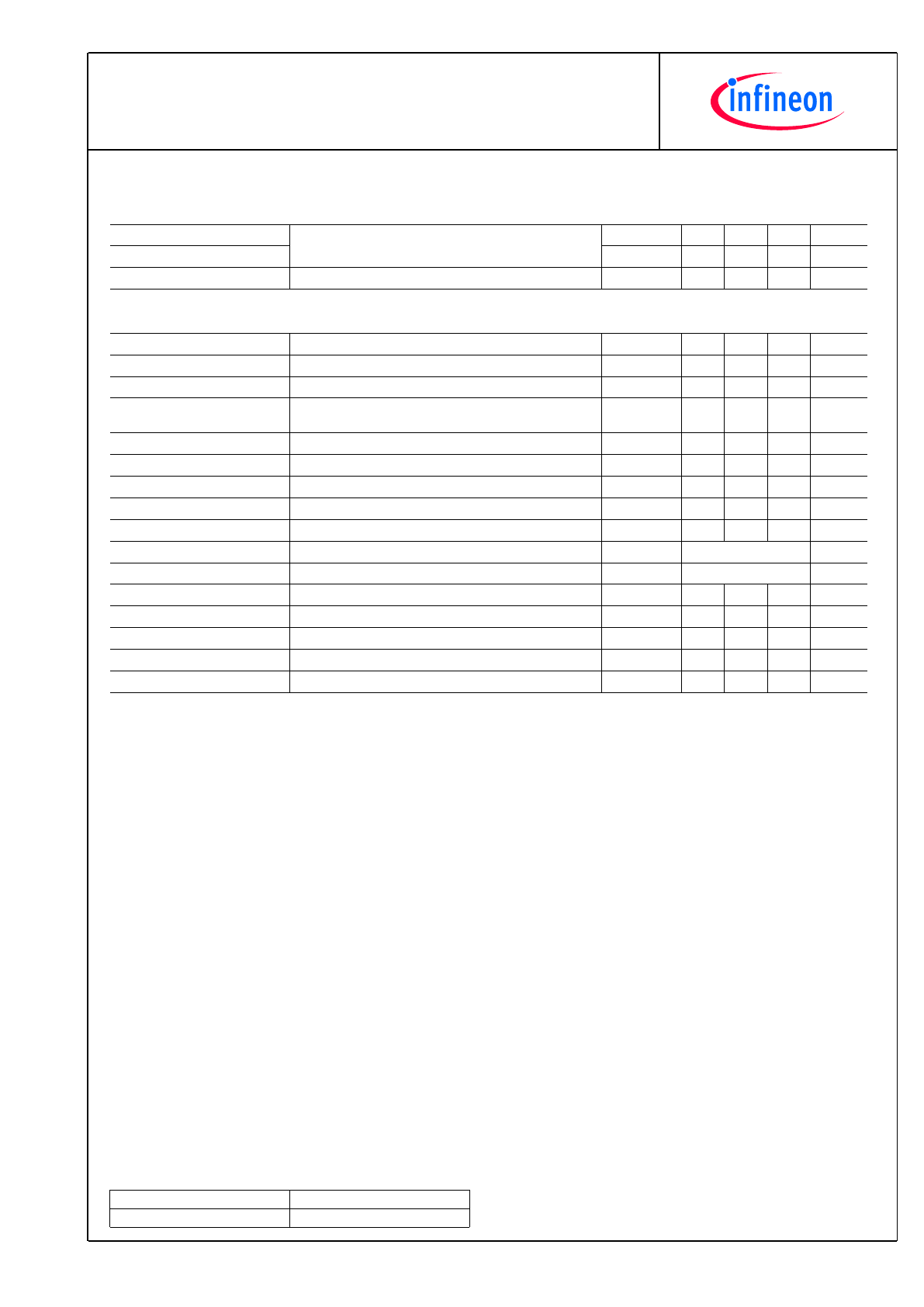

fo - derating curve IGBT (motor)

cos(phi) = 0,85

T

cool medium

= 40°C

f

0

[Hz]

I/I

norm

[%]

-5

0

5

10 15 20 25 30 35 40 45 50 55

0

10

20

30

40

50

60

70

80

90

100

110

120

130

fsw - derating curve IGBT (motor)

cos(phi) = 0,85

T

cool medium

= 40°C

f

sw

[Hz]

I/I

norm

[%]

0

1000

2000

3000

4000

5000

6000

7000

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

Transient thermal impedance per switch

T

cool medium

= 40°C

time [s]

Zth heat sink to ambient [K/W]

0.1

1

10

100

1000

0.00

0.02

0.04

0.06

0.08

0.10

0.12

0.14

0.16

0.18

0.20

i:

r

i

[K/W]:

τ

i

[s]:

1

0.03136

2.869

2

0.08562

41.23

3

0.03032

145.58

4

0.02254

145.58

5

TechnicalInformation

2PS06017E32G28213

PrimeSTACK™

preparedby:OW

approvedby:AR

dateofpublication:2013-05-03

revision:2.0

Preliminarydata

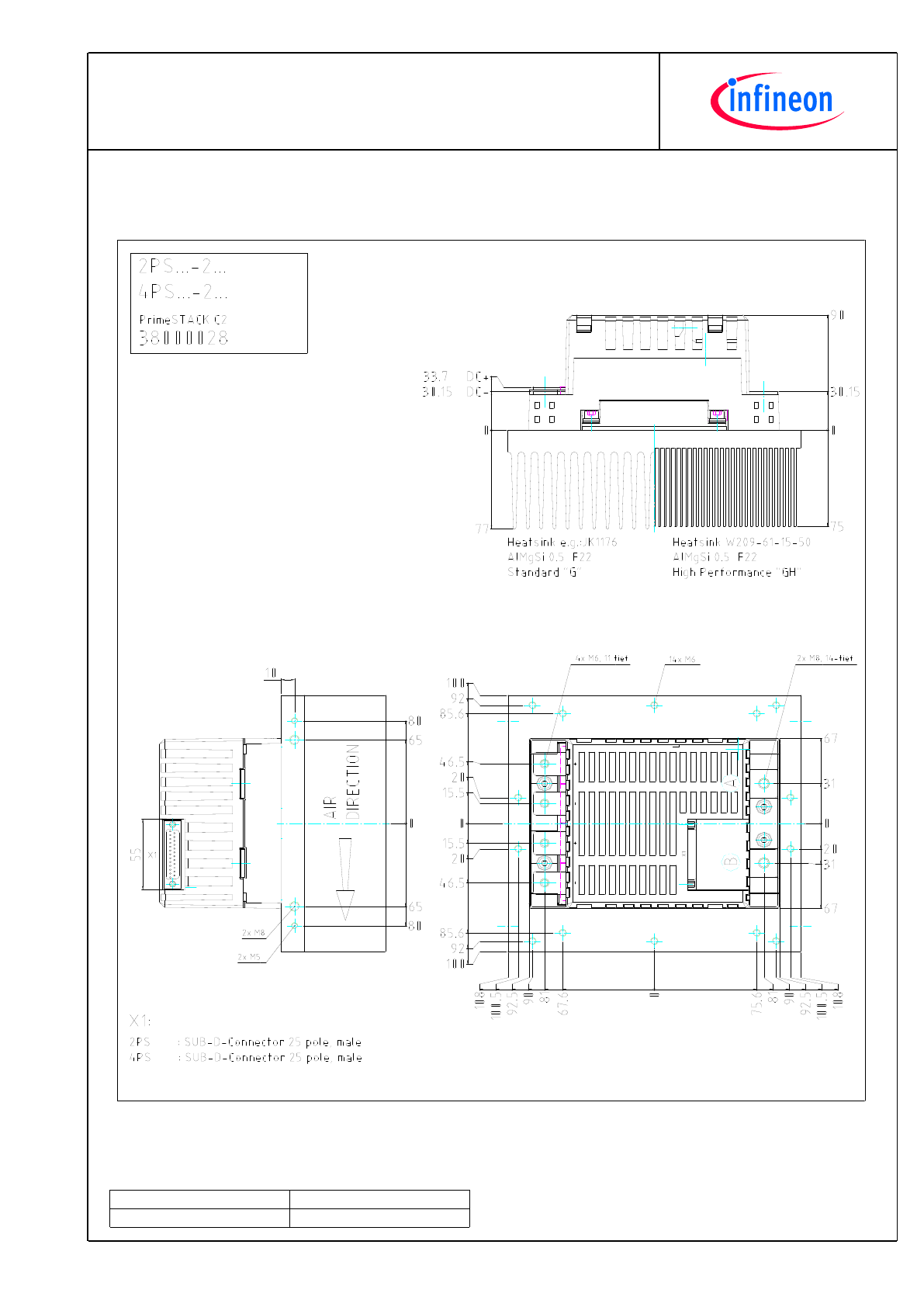

Mechanicaldrawing

6

TechnicalInformation

2PS06017E32G28213

PrimeSTACK™

preparedby:OW

approvedby:AR

dateofpublication:2013-05-03

revision:2.0

Preliminarydata

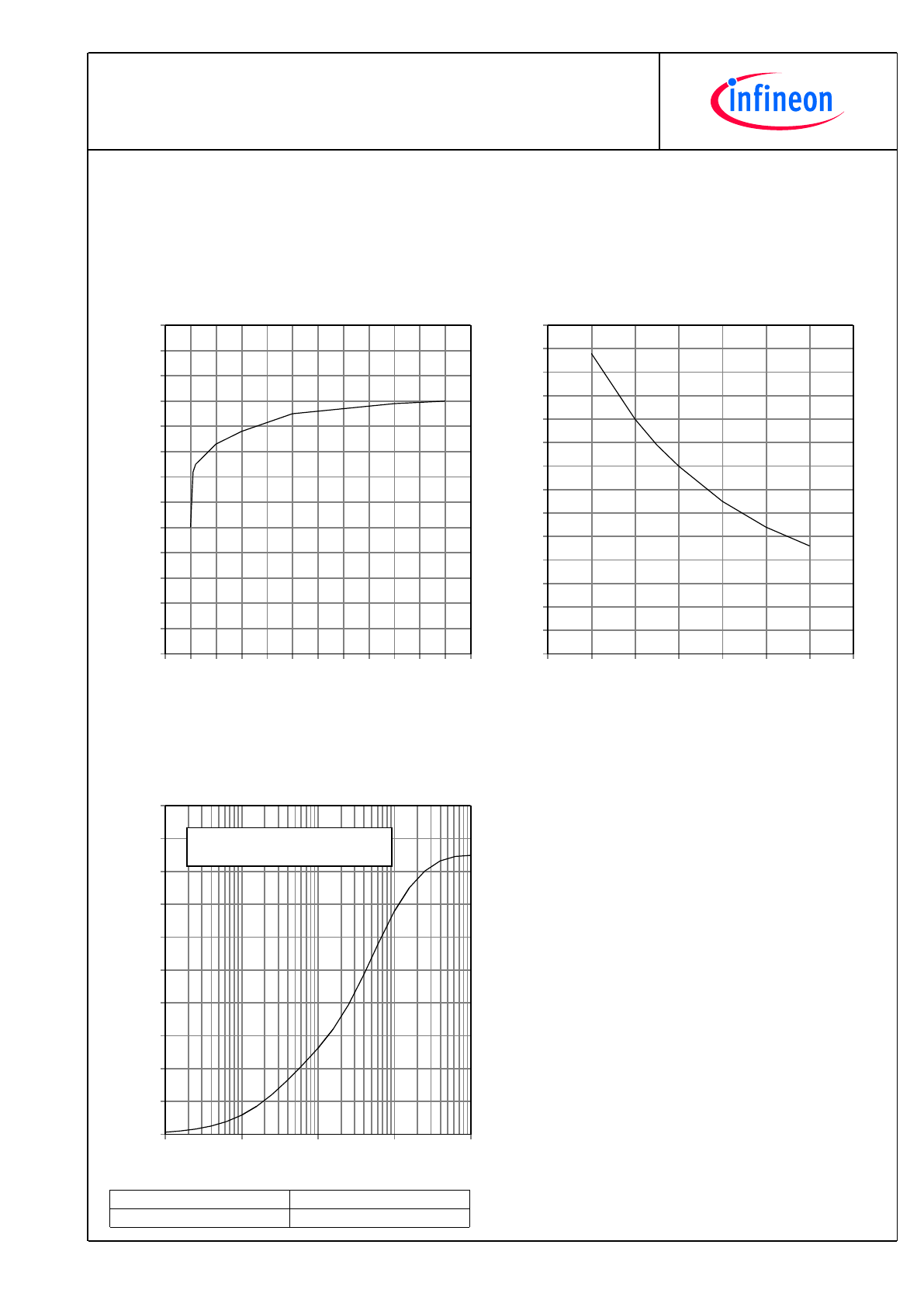

Circuitdiagram

+

-

A

+

-

B

IGBT BOT

Output

Input

14

15 IGBT TOP

2 Error

3

22

Temp. error

Voltage error

13

25

GND digital

GND digital

Digita

l circuit

12

23

10

11

24

NC

NC

NC

NC

1 True earth/shield

Anal

og

circ

uit

20

19

21

Current

Temperature

Voltage DC-Link

7

8

9

GND analog

GND analog

GND analog

Output

Power

sup

ply

6

18

4

16

13V÷30V

GND

GND

13V÷30V

In

Out

15V/50mA

15V/50mA

5

17

Overcurrent

HB A

Overcurrent

HB B

Und

ervolta

ge

Overtemp

. output

stage

Overtemp

. PCB

Overvolta

ge

DC

-Link

Error

me

ssages

Error

me

ssages

Option V

Voltage measurement

V

CE(sat)

/ supply

PTC

X= high level with required external pull up resistor.

Error Table

X

Undervoltage power supply

X

X

Overvoltage DC-Link (Option)

X

Overtemperature PCB

X

X

Overtemperature output stage

X

Overcurrent

X

Error Driver Core

Voltage

Pin 22

Temp.

Pin 3

Error

Pin 2

Error outputs (open collector)

Mana

For detailed technical information please refer the PrimeSTACK manual.

safety separation between

high voltage area and

low voltage area

2PS

-C2

-V

-Re

v03

SUB-D-Connector

25pole male

front view

female thread

UNC4/40

1

NC

High voltage

area in grey

J

BOT

TOP

Eic

eDRIV

ER

™

Option DC link capacitors

+

-

7

TechnicalInformation

2PS06017E32G28213

PrimeSTACK™

preparedby:OW

approvedby:AR

dateofpublication:2013-05-03

revision:2.0

Preliminarydata

Terms&Conditionsofusage

Thedatacontainedinthisproductdatasheetisexclusivelyintendedfortechnicallytrainedstaff.Youandyourtechnical

departmentswillhavetoevaluatethesuitabilityoftheproductfortheintendedapplicationandthecompletenessoftheproduct

datawithrespecttosuchapplication.

Thisproductdatasheetisdescribingthecharacteristicsofthisproductforwhichawarrantyisgranted.Anysuchwarrantyis

grantedexclusivelypursuantthetermsandconditionsofthesupplyagreement.Therewillbenoguaranteeofanykindforthe

productanditscharacteristics.

Shouldyourequireproductinformationinexcessofthedatagiveninthisproductdatasheetorwhichconcernsthespecific

applicationofourproduct,pleasecontactthesalesoffice,whichisresponsibleforyou(seewww.infineon.com,sales&contact).

Forthosethatarespecificallyinterestedwemayprovideapplicationnotes.

Duetotechnicalrequirementsourproductmaycontaindangeroussubstances.Forinformationonthetypesinquestionplease

contactthesalesoffice,whichisresponsibleforyou.

ShouldyouintendtousetheProductinaviationapplications,inhealthorliveendangeringorlifesupportapplications,please

notify.Pleasenote,thatforanysuchapplicationsweurgentlyrecommend

-toperformjointRiskandQualityAssessments;

-theconclusionofQualityAgreements;

-toestablishjointmeasuresofanongoingproductsurvey,

andthatwemaymakedeliverydependedontherealization

ofanysuchmeasures.

Ifandtotheextentnecessary,pleaseforwardequivalentnoticestoyourcustomers.

Changesofthisproductdatasheetarereserved.

SafetyInstructions

Priortoinstallationandoperation,allsafetynoticesandwarningsandallwarningsignsattachedtotheequipmenthavetobe

carefullyread.Makesurethatallwarningsignsremaininalegibleconditionandthatmissingordamagedsignsarereplaced.To

installationandoperation,allsafetynoticesandwarningsandallwarningsignsattachedtotheequipmenthavetobecarefully

read.Makesurethatallwarningsignsremaininalegibleconditionandthatmissingordamagedsignsarereplaced.