1

TechnicalInformation

2LS20017E42W36702

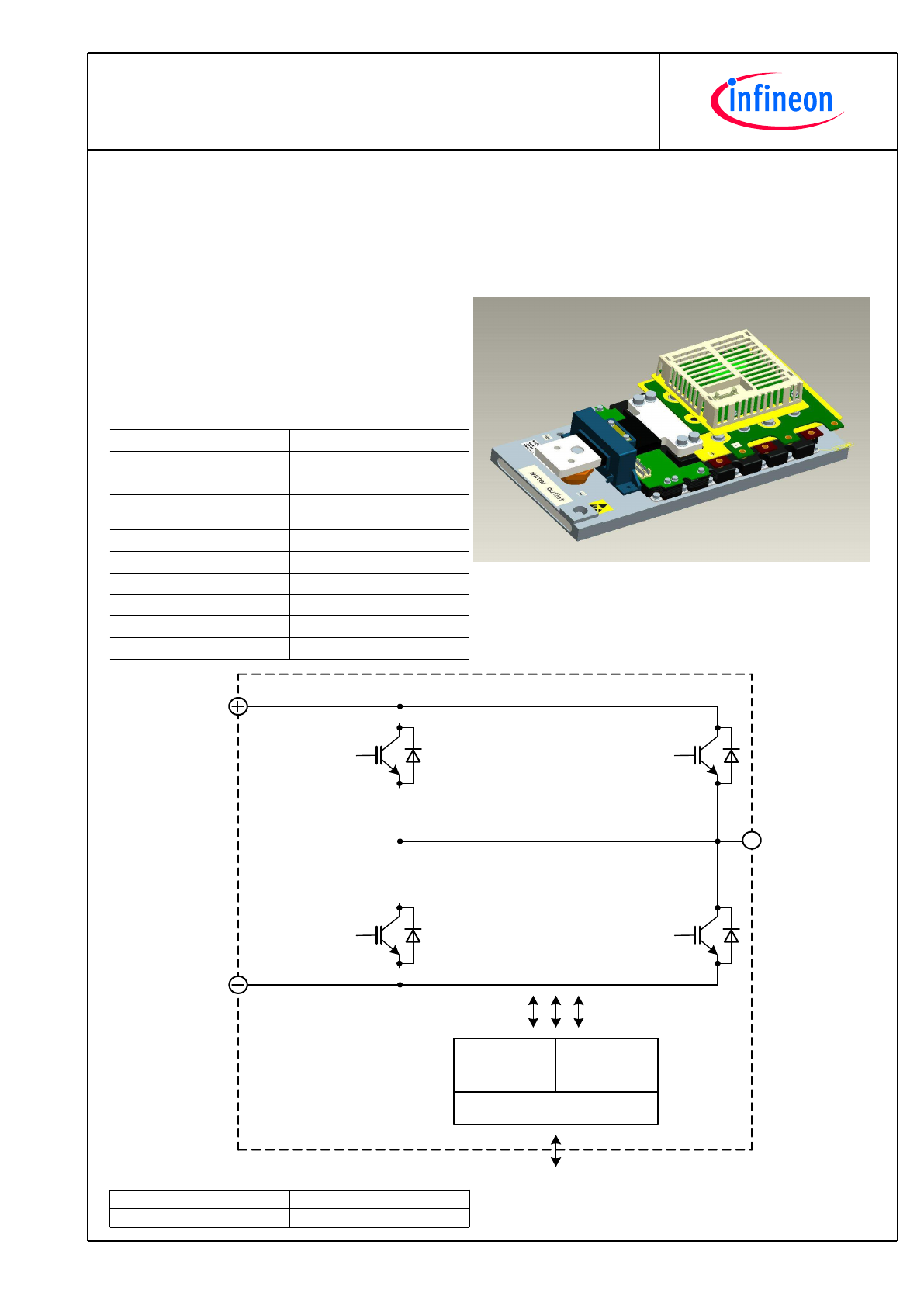

ModSTACK™

preparedby:OW

approvedby:AR

dateofpublication:2013-10-08

revision:2.2

Preliminarydata

Generalinformation

IGBTStackfortypicalvoltagesofupto690V

RMS

Ratedoutputcurrent1520A

RMS

· High power converter

· Wind power

· Motor drives

· PrimePACK

TM

3 module

· Extended operational temperature

· Low V

cesat

Topology

1

/

2

B2I

Application

Inverter

Load type

Resistive, inductive

Semiconductor (Inverter

Section)

2x FF1000R17IE4

Heatsink

Water cooled

Implemented sensors

Current, temperature

Driver signals IGBT

Electrical

Design standards

EN 50178

Sales - name

2LS20017E42W36702

SP - No.

SP000934308

~

Inverter Section

Signal

conditioning

& monitor

Driver

1 phase

Electrical interface

2

TechnicalInformation

2LS20017E42W36702

ModSTACK™

preparedby:OW

approvedby:AR

dateofpublication:2013-10-08

revision:2.2

Preliminarydata

Absolutemaximumratedvalues

Collector-emitter voltage

IGBT; T

vj

= 25°C

V

CES

1700

V

Repetitive peak reverse voltage Diode; T

vj

= 25°C

V

RRM

1700

V

DC link voltage

V

DC

1250

V

Insulation management

according to installation height of 2000 m

V

line

690

V

RMS

Insulation test voltage

V

ISOL

2.5

kV

RMS

Repetitive peak collector

current inverter section (IGBT)

t

p

= 1 ms

I

CRM2

2500

A

Repetitive peak forward current

inverter section (Diode)

t

p

= 1 ms

I

FRM2

2500

A

Continuous current inverter

section

I

AC2

1660

A

RMS

Junction temperature

under switching conditions

T

vjop

150

°C

Switching frequency inverter

section

f

sw2

4

kHz

Notes

Further maximum ratings are specified in the following dedicated sections

Characteristicvalues

InverterSection

min.

typ.

max.

Rated continuous current

V

DC

= 1100 V, V

AC

= 690 V

RMS

, cos(

ϕ

) = 0.85,

f

AC sine

= 50 Hz, f

sw

= 2000 Hz, T

inlet

= 40°C, T

j

≤

150 °C

I

AC

1520

A

RMS

Continuous current at low

frequency

V

DC

= 1100 V, V

AC

= 690 V

RMS

, f

AC sine

= 0 Hz,

f

sw

= 2000 Hz, T

inlet

= 40 °C, T

j

≤

150 °C

I

AC low

770

A

RMS

Rated continuous current for

150% overload capability

I

AC 150%

= 1660 A

RMS

, t

on over

= 3 s, T

j

≤

150 °C

I

AC over1

1110

A

RMS

Over current shutdown

within 15 µs

I

AC OC

4200

A

peak

Power losses

I

AC

= 1520 A, V

DC

= 1100 V, V

AC

= 690 V

RMS

,

cos(

ϕ

) = 0.85, f

AC sine

= 50 Hz, f

sw

= 2000 Hz,

T

inlet

= 40 °C, T

j

≤

150 °C

P

loss

6700

W

Controllerinterface

Driver and interface board

ref. to separate Application Note

DR240

min.

typ.

max.

Auxiliary voltage

V

aux

18

24

30

V

Auxiliary power requirement

V

aux

= 24 V

P

aux

40

W

Digital input level

resistor to GND 1.8 k

Ω

, capacitor to GND 4 nF,

logic high = on, min. 15 mA

V

in low

0

4

V

V

in high

11

15

V

Digital output level

open collector, logic low = no fault, max. 15 mA

V

out low

0

1.5

V

V

out high

15

V

Analog current sensor output

inverter section

load max 1 mA, @ 1520 A

RMS

V

IU ana2

V

IV ana2

V

IW ana2

3.3

3.4

3.5

V

Analog temperature sensor

output inverter section (NTC)

load max 1 mA, @T

NTC

= 66 °C,

corresponds to T

j

= 150 °C at rated conditions

V

Theta NTC2

6.4

6.5

6.6

V

Over temperature shutdown

inverter section

load max 1 mA, @T

NTC

= 75 °C

V

Error OT2

8.6

V

3

TechnicalInformation

2LS20017E42W36702

ModSTACK™

preparedby:OW

approvedby:AR

dateofpublication:2013-10-08

revision:2.2

Preliminarydata

Systemdata

min.

typ.

max.

EMC robustness

according to IEC 61800-3 at named

interfaces

V

Burst

2

kV

power

V

Burst

1

kV

control

V

surge

1

kV

aux (24V)

Storage temperature

T

stor

-40

80

°C

Operational ambient

temperature

PCB, bus bar, excluding cooling medium

T

op amb

-25

55

°C

Humidity

no condensation

Rel. F

0

95

%

Vibration

5

m/s²

Shock

40

m/s²

Protection degree

IP00

Pollution degree

2

Dimensions

width x depth x height

205

400

117

mm

Weight

9

kg

Heatsinkwatercooled

min.

typ.

max.

Water flow

according to coolant specification from Infineon

∆

V/

∆

t

15

dm³/min

Water pressure

8

bar

Water pressure drop

∆

p

60

mbar

Coolant inlet temperature

T

inlet

-40

55

°C

Notes

Composition of coolant: Water and 52 vol. % Antifrogen N

Overviewofoptionalcomponents

Unit 1

Inverter

Section

Unit 3

Parallel interface board

Optical interface board

Voltage sensor

Current sensor

×

Temperature sensor

×

Temperature simulation

DC link capacitors

Data cable for control signals

Collector for water cooled heatsink

Collector-emitter Active Clamping

×

Notes

Setting of Active Clamping TVS-Diodes: V

Z

= 1280 V

4

TechnicalInformation

2LS20017E42W36702

ModSTACK™

preparedby:OW

approvedby:AR

dateofpublication:2013-10-08

revision:2.2

Preliminarydata

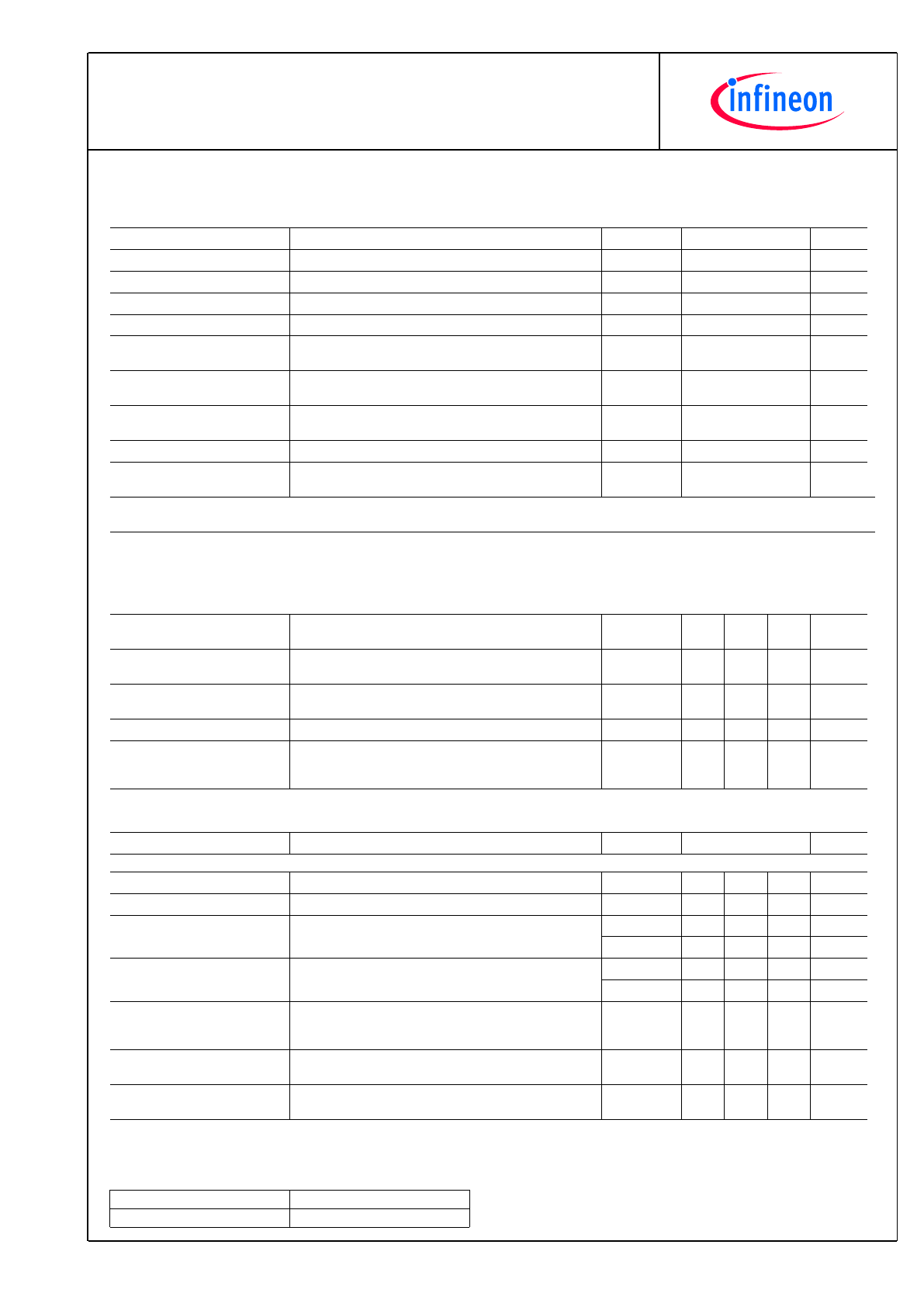

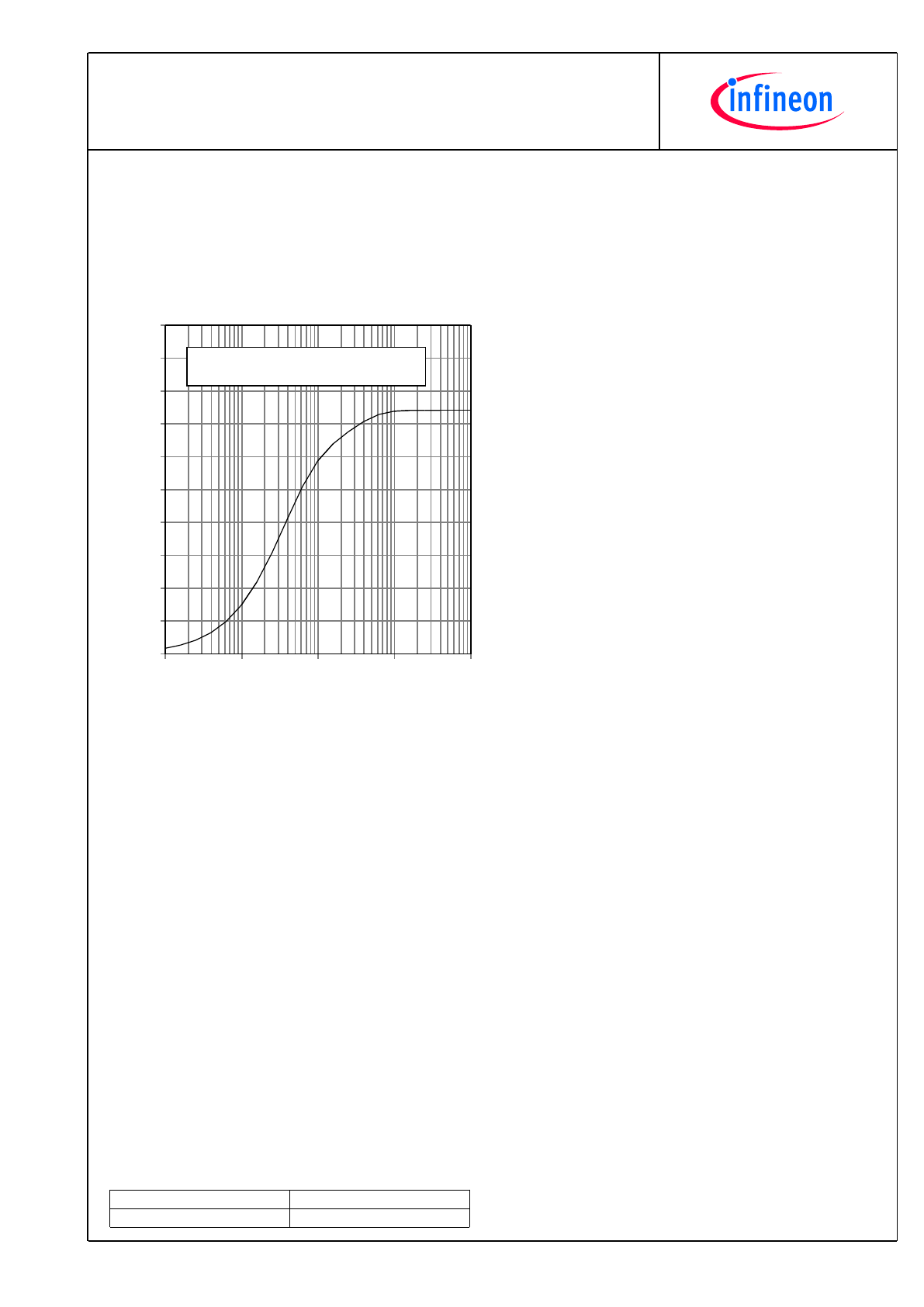

f

AC sine

- derating curve IGBT (motor), Diode (generator)

V

DC

= 1100 V, V

AC

= 690 V

RMS

, f

sw

= 2 kHz, cos

ϕ

= ±0.85,

T

inlet

= 40 °C and nom. cooling conditions

f

AC sine

[Hz]

I

AC

/I

nom

[%]

0

5

10

15

20

25

30

35

40

45

50

0

10

20

30

40

50

60

70

80

90

100

110

IGBT, cos

ϕ

= 0.85 (100% = 1520 A)

Diode, cos

ϕ

= -0.85 (100% = 1510 A)

f

sw

- derating curve IGBT (motor), Diode (generator)

V

DC

= 1100 V, V

AC

= 690 V

RMS

, f

AC sine

= 50 Hz, cos

ϕ

= ±0.85,

T

inlet

= 40 °C and nom. cooling conditions

f

sw

[Hz]

I

AC

/I

nom

[%]

1000

2000

3000

4000

0

10

20

30

40

50

60

70

80

90

100

110

120

IGBT, cos

ϕ

= 0.85 (100% = 1520 A)

Diode, cos

ϕ

= -0.85 (100% = 1510 A)

T

inlet

- derating curve IGBT (motor), Diode (generator)

V

DC

= 1100 V, V

AC

= 690 V

RMS

, f

sw

= 2 kHz, f

AC sine

= 50 Hz,

cos

ϕ

= ±0.85 and nom. cooling conditions

T

inlet

[°C]

I

AC

/I

nom

[%]

-25

-15

-5

5

15

25

35

45

55

0

10

20

30

40

50

60

70

80

90

100

110

120

IGBT, cos

ϕ

= 0.85 (100% = 1520 A)

Diode, cos

ϕ

= -0.85 (100% = 1510 A)

Analog temperature sensor output V

Theta NTC

Sensing NTC of IGBT module

T

NTC

[°C]

V

Theta NTC

[V]

20

30

40

50

60

70

80

90

100

0

1

2

3

4

5

6

7

8

9

10

11

12

5

TechnicalInformation

2LS20017E42W36702

ModSTACK™

preparedby:OW

approvedby:AR

dateofpublication:2013-10-08

revision:2.2

Preliminarydata

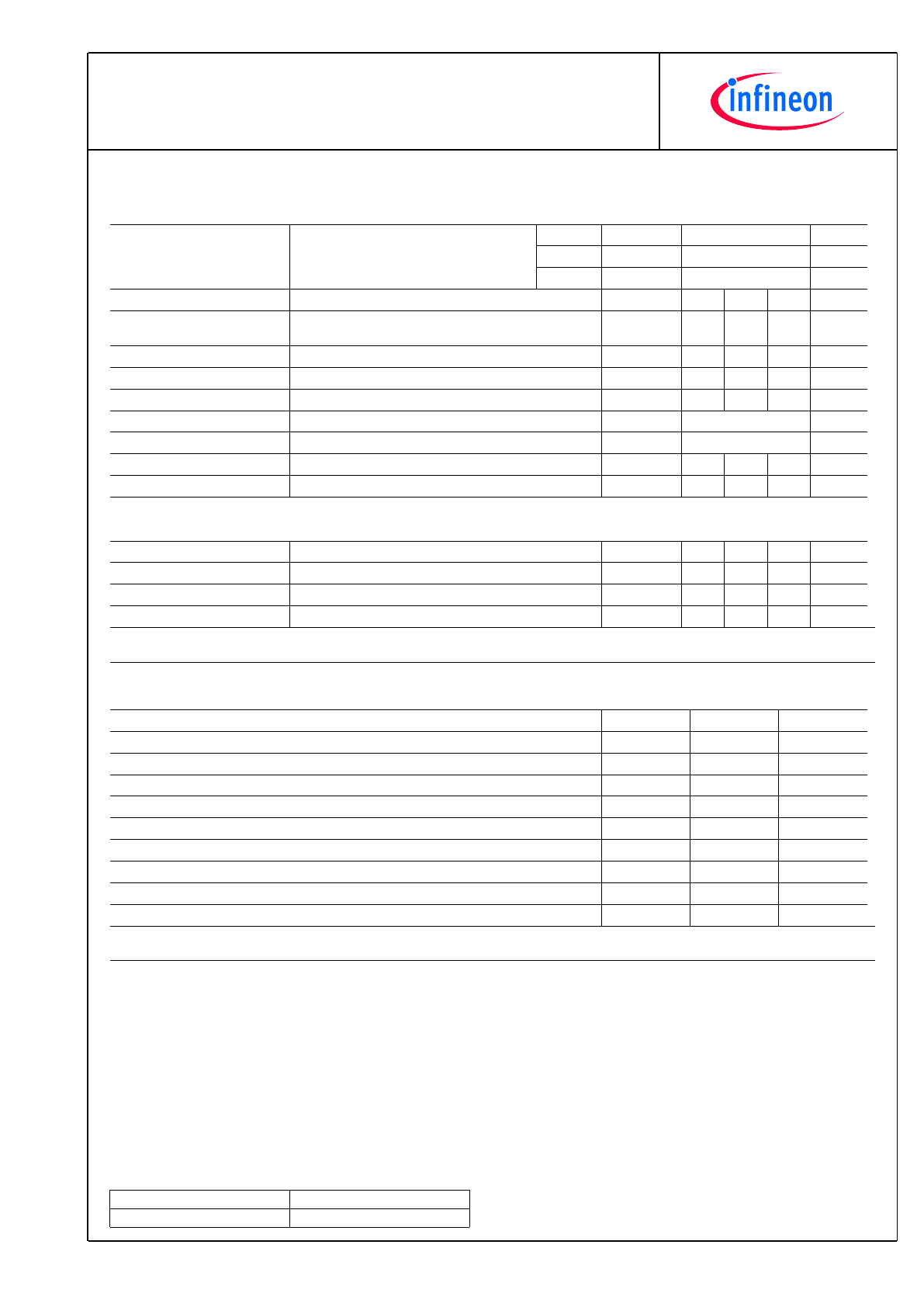

Z

th,ha

- thermal impedance heatsink to ambient per switch

nom. cooling conditions

t [s]

Z

th,ha

[K/W]

0.1

1

10

100

1000

0.000

0.005

0.010

0.015

0.020

0.025

0.030

0.035

0.040

0.045

0.050

i:

r

i

[K/W]:

τ

i

[s]:

1

0.000006

0.000001403

2

0.000006

0.00000451

3

0.0274

3.381

4

0.00964

22.97

6

TechnicalInformation

2LS20017E42W36702

ModSTACK™

preparedby:OW

approvedby:AR

dateofpublication:2013-10-08

revision:2.2

Preliminarydata

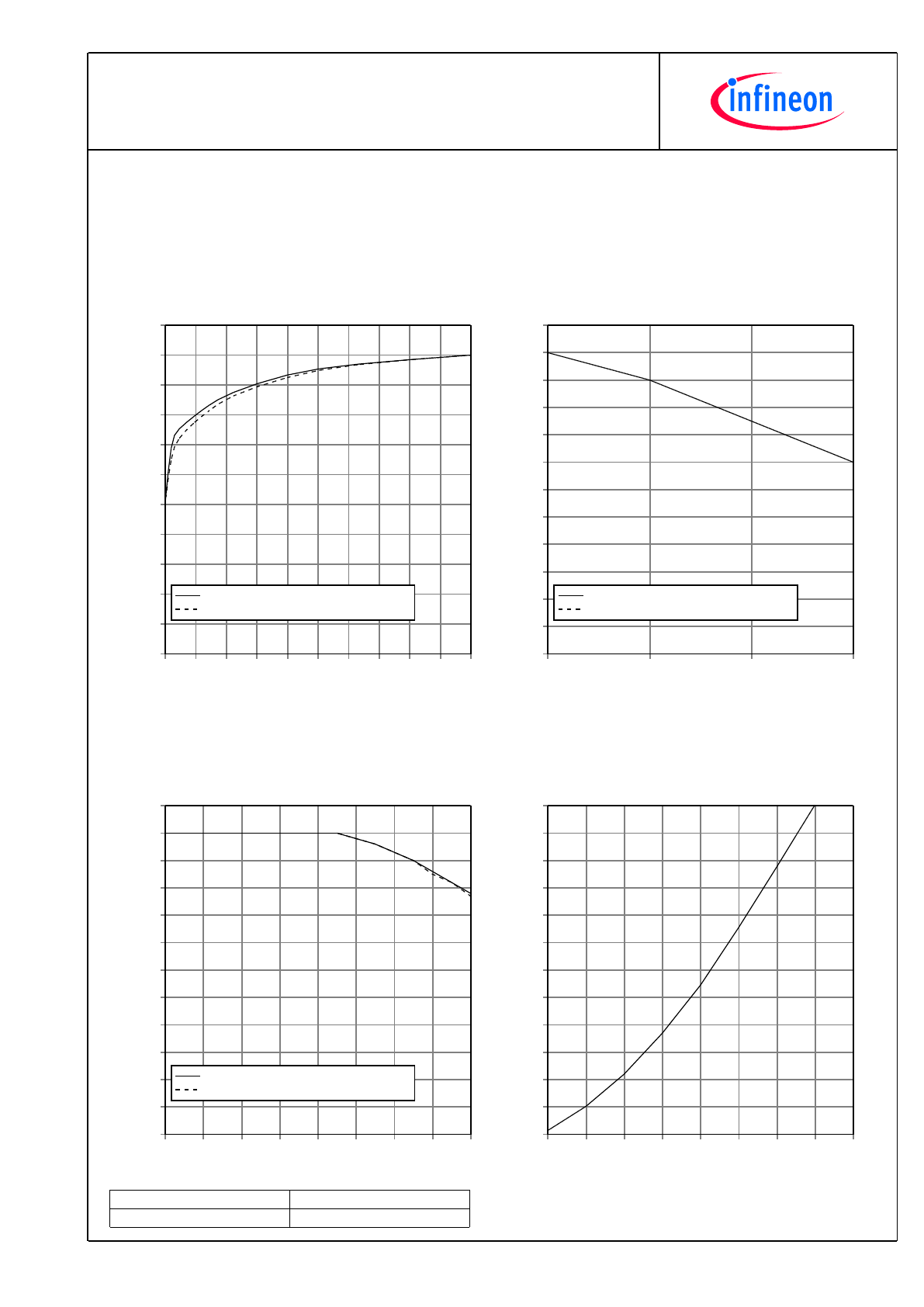

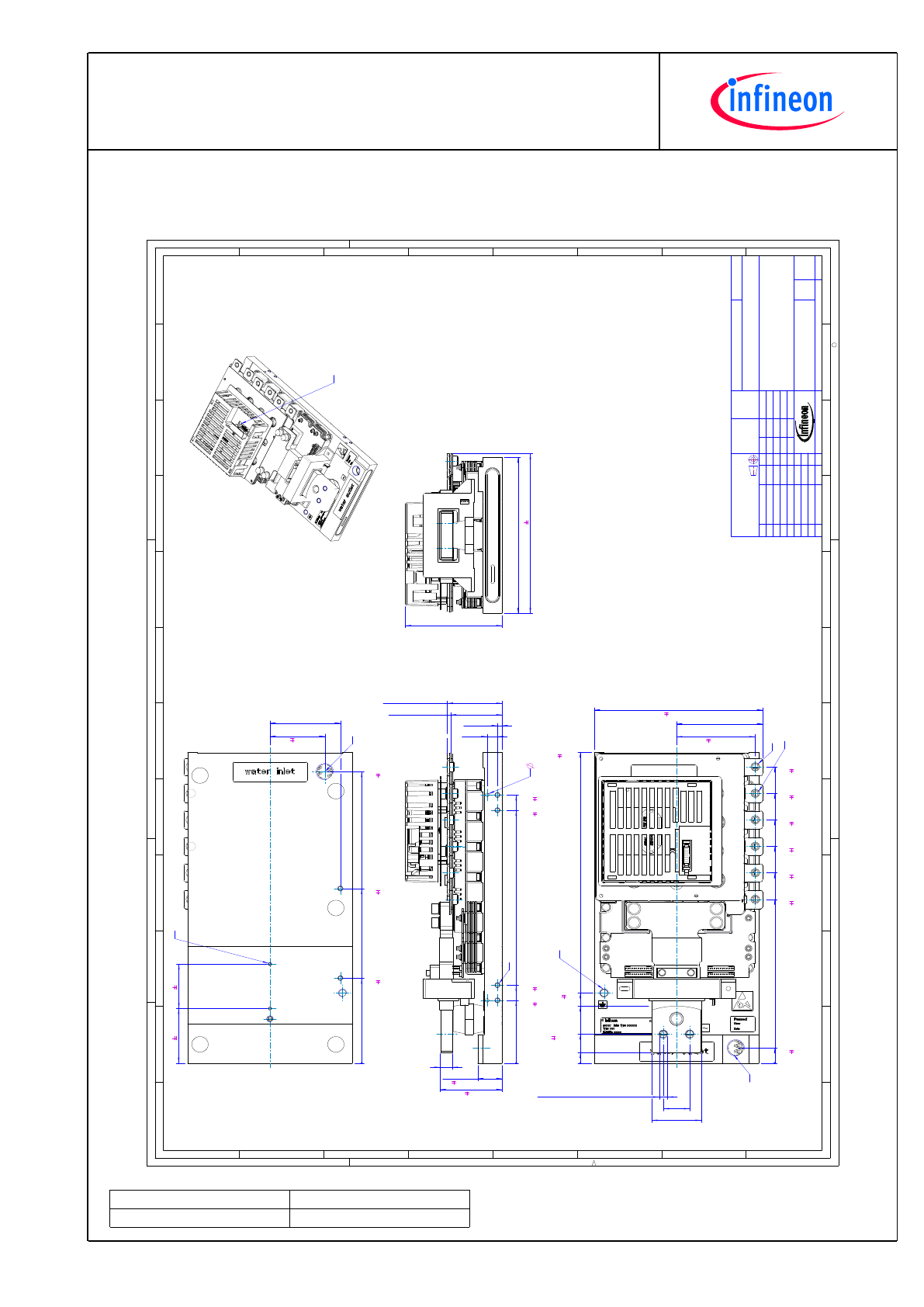

Mechanicaldrawing

1

H

2

3

4

5

6

7

8

9

10

11

12

1

2

3

4

5

6

8

7

G

F

E

D

C

B

A

H

G

F

E

D

C

B

A

9

10

11

12

C

op

yr

ig

ht

IN

FI

N

E

O

N

T

E

C

H

N

O

LO

G

IE

S

A

G

,A

ll

rig

ht

s

re

se

rv

ed

c

A

2

Do

ku

me

nts

ta

tu

ss

ie

he

SA

P-D

oku

me

nte

nve

rw

altu

ng

32

2x

M

,A

C-c

on

ne

ctin

po

in

t

to

rq

ue

:m

ax

32

Nm

10

95

.6

5

0.8

60

15

10

4.6

5

70

0.

5

57

0.

15

85

.5

66

.6

0.5

10

9

0.5

22

4

0.5

37

4

0.5

0

20

0

+0

.5

-1

.5

20

4.

65

1

117

.3

+1

-2

29

.5

0.5

75

.2

0.5

80

.5

0.1

5

10

0

0.1

5

32

4.5

0.1

5

34

4

0.1

5

0

DC

-P

lu

s

62

.5

DC

-M

in

us

66

.5

20

4.6

5

1

13

.1

5

37

.1

5

0.8

73

.1

5

90

0.8

39

9

0.8

0

19

.5

0.8

21

0.1

5

0.8

24

4.1

5

0.8

27

8.1

5

0.8

31

2.1

5

0.8

34

6.1

5

0.8

38

0.1

5

0.8

0

5.5

12

.5

P

ar

t-

N

o.

ge

ne

ra

lT

ol

er

an

ce

S

ur

fa

ce

S

ca

le

1:

2

A

ss

em

bl

y-

N

o.

D

IN

IS

O

27

68

-v

-

M

at

er

ia

l

M

at

er

ia

l-N

o.

D

at

e

N

am

e

D

es

ci

pt

io

n

A

ge

nt

6.

03

.1

2

P

ap

en

fo

rt

O

ut

lin

e

C

he

ck

ed

6.

03

.1

2

ge

z.

V

ol

ke

N

or

m

M

od

S

TA

C

K

C

G

ra

ph

-N

o.

V

er

si

on

S

he

et

36

70

2

M

b

0

Ve

rs

.

R

ev

is

io

n

D

at

e

N

am

e

O

rig

in

C

on

st

ru

ct

ed

fo

r

co

nn

ec

tin

g

po

in

ts

A

C

an

d

D

C

ar

e

tin

pl

at

ed

re

co

m

m

en

de

tt

or

qu

e:

D

C

+

an

d

D

C

-

M

8

:2

0N

m

+-

10

%

A

C

M

10

:3

2N

m

+-

10

%

M

6-

10

de

pt

h

4.

5-

5d

ep

th

3:

10

X

1:

ID

C

co

nn

ec

to

r

14

po

le

3x

M

8

D

C

-M

in

us

3x

M

8

D

C

-P

lu

s

G

1/

2"

w

at

er

ou

tle

t

M

10

,e

ar

th

gr

ou

nd

G

1/

2"

2x

M

4-

8d

ep

th

7

TechnicalInformation

2LS20017E42W36702

ModSTACK™

preparedby:OW

approvedby:AR

dateofpublication:2013-10-08

revision:2.2

Preliminarydata

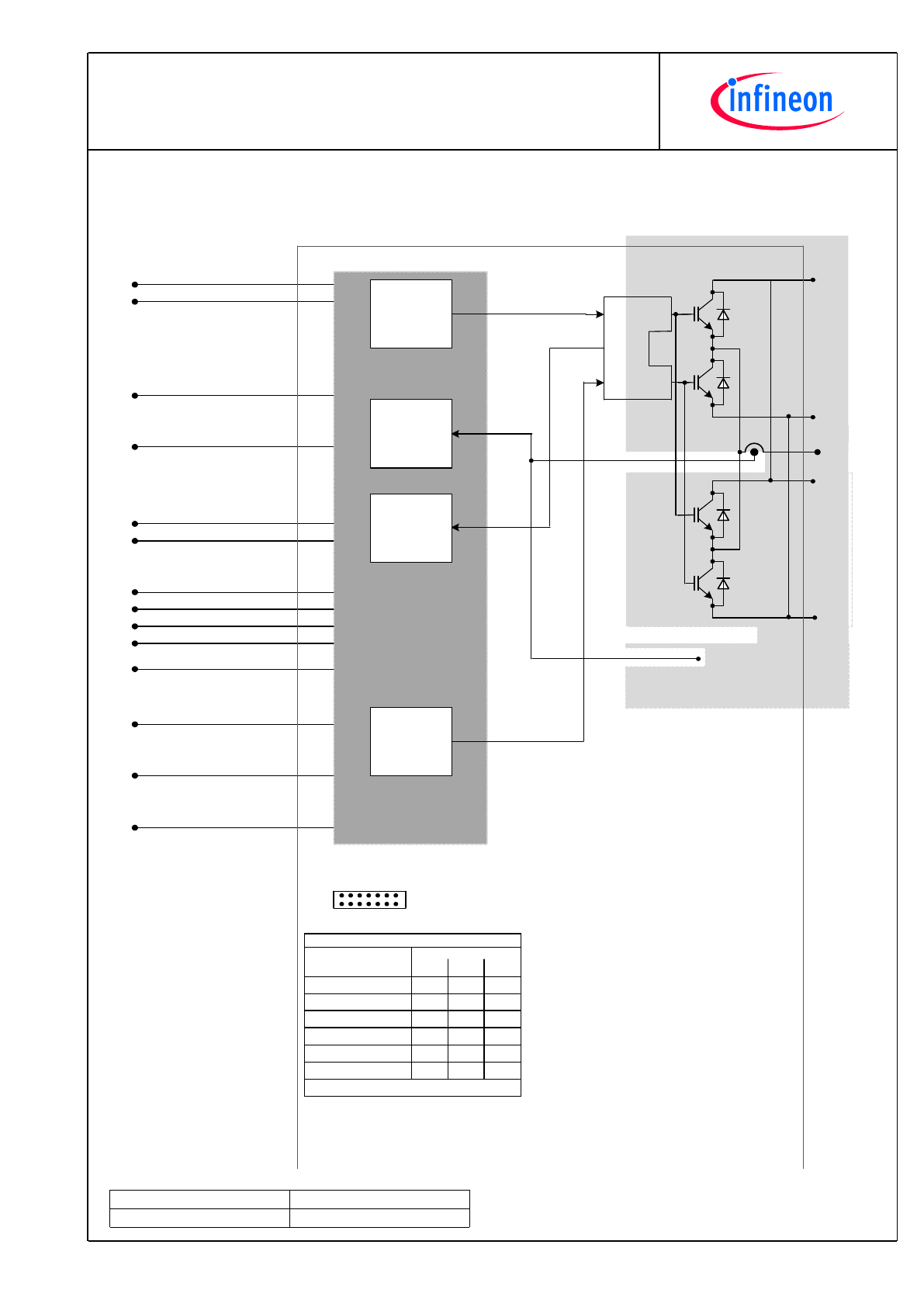

Circuitdiagram

Top

Bottom

E

ic

eD

R

IV

E

R

T

M

AC

DC-

DC+

Signal

conditioning

&

Gate signals

Sensor

signals

Failure

management

Power

supply

DR240

Low voltage domain

1

X1 (IDC Connector)

14 pole male

X1:2

PWM BOT

X1:4

PWM TOP

X1:3

Fault

X1:5

OT Error

X1:8

P15 (50mA)

X1:9

P15 (50mA)

X1:6

P24

X1:7

P24

X1:10

GND

X1:11

GND

X1:14

V

I ana

X1:12

V

Theta NTC

X1:13

GND

analog

X1:1

TE, Shield

High voltage domain

T

NTC

Error Table

Error outputs (open collector)

X1:3

X1:5

Error driver core

Over temp. output stage

Over temperature PCB

Over voltage DC Link

Under voltage power supply

X = high level with external pull up resistor

Over current

x

x

x

x

x

x

M

od

S

T

A

C

K

T

M

DC+

DC-

8

TechnicalInformation

2LS20017E42W36702

ModSTACK™

preparedby:OW

approvedby:AR

dateofpublication:2013-10-08

revision:2.2

Preliminarydata

Terms&Conditionsofusage

Thedatacontainedinthisproductdatasheetisexclusivelyintendedfortechnicallytrainedstaff.Youandyourtechnical

departmentswillhavetoevaluatethesuitabilityoftheproductfortheintendedapplicationandthecompletenessoftheproduct

datawithrespecttosuchapplication.

Thisproductdatasheetisdescribingthecharacteristicsofthisproductforwhichawarrantyisgranted.Anysuchwarrantyis

grantedexclusivelypursuantthetermsandconditionsofthesupplyagreement.Therewillbenoguaranteeofanykindforthe

productanditscharacteristics.

Shouldyourequireproductinformationinexcessofthedatagiveninthisproductdatasheetorwhichconcernsthespecific

applicationofourproduct,pleasecontactthesalesoffice,whichisresponsibleforyou(seewww.infineon.com,sales&contact).

Forthosethatarespecificallyinterestedwemayprovideapplicationnotes.

Duetotechnicalrequirementsourproductmaycontaindangeroussubstances.Forinformationonthetypesinquestionplease

contactthesalesoffice,whichisresponsibleforyou.

ShouldyouintendtousetheProductinaviationapplications,inhealthorliveendangeringorlifesupportapplications,please

notify.Pleasenote,thatforanysuchapplicationsweurgentlyrecommend

-toperformjointRiskandQualityAssessments;

-theconclusionofQualityAgreements;

-toestablishjointmeasuresofanongoingproductsurvey,

andthatwemaymakedeliverydependedontherealization

ofanysuchmeasures.

Ifandtotheextentnecessary,pleaseforwardequivalentnoticestoyourcustomers.

Changesofthisproductdatasheetarereserved.

SafetyInstructions

Priortoinstallationandoperation,allsafetynoticesandwarningsandallwarningsignsattachedtotheequipmenthavetobe

carefullyread.Makesurethatallwarningsignsremaininalegibleconditionandthatmissingordamagedsignsarereplaced.To

installationandoperation,allsafetynoticesandwarningsandallwarningsignsattachedtotheequipmenthavetobecarefully

read.Makesurethatallwarningsignsremaininalegibleconditionandthatmissingordamagedsignsarereplaced.