AUIRF7675M2TR

Base Part Number

Package Type

Standard Pack

Form Quantity

AUIRF7675M2

DirectFET Medium Can

Tape and Reel

4800

AUIRF7675M2TR

Orderable Part Number

AUTOMOTIVE GRADE

V

(BR)DSS

150V

R

DS(on)

typ.

47m

R

g (typical)

1.2

max.

56m

Q

g (typical)

21nC

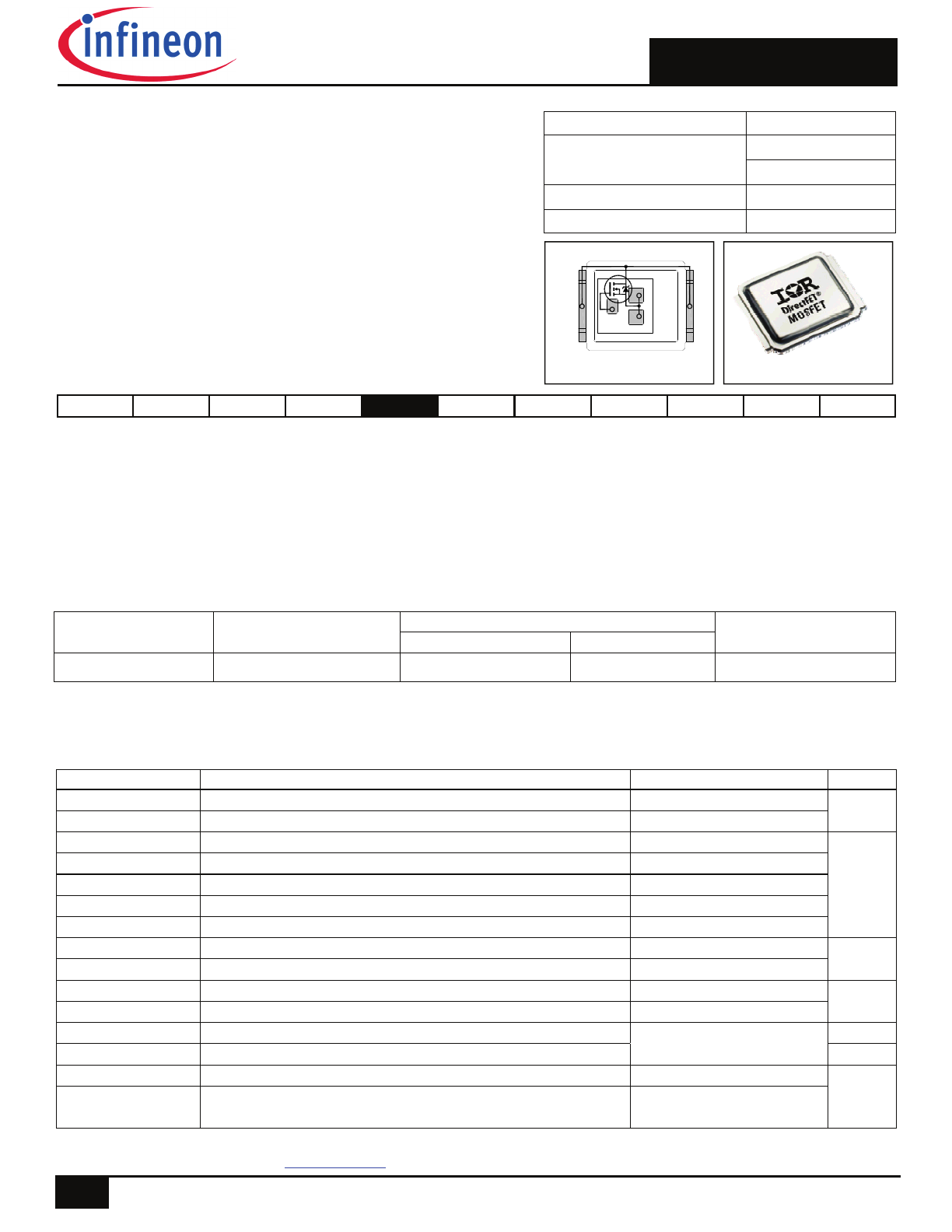

DirectFET

®

ISOMETRIC

M2

Automotive DirectFET

®

Power MOSFET

Applicable DirectFET

®

Outline and Substrate Outline

SB

SC

M2

M4

L4

L6

L8

Description

The AUIRF7675M2TR/TR1 combines the latest Automotive HEXFET® Power MOSFET Silicon technology with the advanced DirectFET packaging

platform to produce a best in class part for Automotive Class D audio amplifier applications. The DirectFET package is compatible with existing layout

geometries used in power applications, PCB assembly equipment and vapor phase, infra-red or convection soldering techniques, when application

note AN-1035 is followed regarding the manufacturing methods and processes. The DirectFET package allows dual sided cooling to maximize thermal

transfer in automotive power systems.

This HEXFET Power MOSFET optimizes gate charge, body diode reverse recovery and internal gate resistance to improve key Class D audio

amplifier performance factors such as efficiency, THD and EMI. Moreover the DirectFET packaging platform offers low parasitic inductance and

resistance when compared to conventional wire bonded SOIC packages which improves EMI performance by reducing the voltage ringing that

accompanies current transients.

These features combine to make this MOSFET a highly desirable component in Automotive Class D audio amplifier systems.

Absolute Maximum Ratings

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only; and

functional operation of the device at these or any other condition beyond those indicated in the specifications is not implied. Exposure to absolute-

maximum-rated conditions for extended periods may affect device reliability. The thermal resistance and power dissipation ratings are measured under

board mounted and still air conditions. Ambient temperature (TA) is 25°C, unless otherwise specified.

Parameter Max.

Units

V

DS

Drain-to-Source Voltage

150

V

V

GS

Gate-to-Source Voltage

±20

I

D

@ T

C

= 25°C

Continuous Drain Current, V

GS

@ 10V (Silicon Limited) 18

A

I

D

@ T

C

= 100°C

Continuous Drain Current, V

GS

@ 10V (Silicon Limited) 13

I

D

@ T

A

= 25°C

Continuous Drain Current, V

GS

@ 10V (Silicon Limited) 4.4

I

DM

Pulsed Drain Current 72

P

D

@T

C

= 25°C

Power Dissipation 45

W

P

D

@T

A

= 25°C

Power Dissipation 2.7

E

AS

Single Pulse Avalanche Energy (Thermally Limited) 59

mJ

E

AS

(Tested)

Single Pulse Avalanche Energy 170

I

AR

Avalanche Current

See Fig. 16, 17, 18a, 18b

A

E

AR

Repetitive Avalanche Energy

mJ

T

P

Peak Soldering Temperature

270

°C

T

J

Operating Junction and

-55 to + 175

T

STG

Storage Temperature Range

I

D

@ T

C

= 25°C

Continuous Drain Current, V

GS

@ 10V (Package Limited)

90

1

2015-12-14

HEXFET® is a registered trademark of Infineon.

*Qualification standards can be found at

www.infineon.com

Advanced Process Technology

Optimized for Class D Audio Amplifier Applications

Low Rds(on) for Improved Efficiency

Low Qg for Better THD and Improved Efficiency

Low Qrr for Better THD and Lower EMI

Low Parasitic Inductance for Reduced Ringing and Lower EMI

Delivers up to 250W per Channel into 4

with No Heat sink

Dual Sided Cooling

175°C Operating Temperature

Repetitive Avalanche Capability for Robustness and Reliability

Lead free, RoHS and Halogen free

Automotive Qualified *

D

D

G

S

S

AUIRF7675M2TR

2

2015-12-14

Thermal Resistance

Symbol Parameter

Typ.

Max.

Units

R

JA

Junction-to-Ambient

–––

60

R

JA

Junction-to-Ambient

12.5

–––

R

JA

Junction-to-Ambient

20

–––

R

J-Can

Junction-to-Can –––

3.3

R

J-PCB

Junction-to-PCB Mounted

1.4

–––

Linear Derating Factor 0.3

W/°C

°C/W

Static Electrical Characteristics @ T

J

= 25°C (unless otherwise specified)

Symbol Parameter

Min.

Typ.

Max.

Units

Conditions

V

(BR)DSS

Drain-to-Source Breakdown Voltage

150

–––

–––

V

V

GS

= 0V, I

D

= 250µA

V

(BR)DSS

/

T

J

Breakdown Voltage Temp. Coefficient

––– 0.16

–––

V/°C Reference to 25°C, I

D

= 1.0mA

R

DS(on)

Static Drain-to-Source On-Resistance

––– 47 56 m V

GS

= 10V, I

D

= 11A

V

GS(th)

Gate Threshold Voltage

3.0

4.0

5.0

V

V

DS

= V

GS

, I

D

= 100µA

V

GS(th)

/

T

J

Gate Threshold Voltage Coefficient

–––

-11

––– mV/°C

gfs Forward

Transconductance

16

–––

–––

S

V

DS

= 50V, I

D

= 11A

R

G

Internal Gate Resistance

–––

1.2

5.0

I

DSS

Drain-to-Source Leakage Current

––– ––– 20

µA

V

DS

= 150V, V

GS

= 0V

––– ––– 250

V

DS

= 150V, V

GS

= 0V, T

J

= 125°C

I

GSS

Gate-to-Source Forward Leakage

–––

–––

100

nA

V

GS

= 20V

Gate-to-Source Reverse Leakage

–––

––– -100

V

GS

= -20V

Dynamic Electrical Characteristics @ T

J

= 25°C (unless otherwise specified)

Symbol Parameter

Min.

Typ.

Max.

Units

Conditions

Q

g

Total Gate Charge

–––

21

32

nC

V

DS

= 75V

Q

gs1

Gate-to-Source Charge

–––

5.2

–––

V

GS

= 10V

Q

gs2

Gate-to-Source Charge

–––

1.6

–––

I

D

= 11A

Q

gd

Gate-to-Drain ("Miller") Charge

––– 7.1 –––

See Fig. 6 and 17

Q

godr

Gate Charge Overdrive

–––

7.1

–––

Q

sw

Switch Charge (Q

gs2

+ Q

gd

) –––

8.7

–––

Q

oss

Output Charge

–––

8.8

–––

nC V

DS

= 16V, V

GS

= 0V

t

d(on)

Turn-On Delay Time

–––

10

–––

ns

V

DD

= 75V, V

GS

= 10V

t

r

Rise Time

–––

13

–––

I

D

= 11A

t

d(off)

Turn-Off Delay Time

–––

14

–––

R

G

= 6.8

t

f

Fall Time

–––

7.5

–––

C

iss

Input Capacitance

––– 1360 –––

pF

V

GS

= 0V

C

oss

Output Capacitance

–––

190

–––

V

DS

= 25V

C

rss

Reverse Transfer Capacitance

–––

41

–––

ƒ = 1.0 MHz

C

oss

Output Capacitance

––– 1210 –––

V

GS

= 0V, V

DS

= 1.0V, ƒ = 1.0 MHz

C

oss

Output Capacitance

–––

92

–––

V

GS

= 0V, V

DS

=120V, ƒ = 1.0MHz

Notes through are on page 3

AUIRF7675M2TR

3

2015-12-14

Diode Characteristics

Symbol

Parameter

Min. Typ. Max. Units

Conditions

I

S

Continuous Source Current

––– –––

18

A

MOSFET symbol

(Body Diode)

showing the

I

SM

Pulsed Source Current

––– –––

integral reverse

(Body Diode)

p-n junction diode.

V

SD

Diode Forward Voltage

–––

–––

1.3

V

T

J

= 25°C, I

S

= 11A, V

GS

= 0V

t

rr

Reverse Recovery Time

––– 63 95 ns T

J

= 25°C, I

F

= 11A, V

DD

= 25V

Q

rr

Reverse Recovery Charge

––– 180 270 nC dv/dt = 100A/µs

72

Surface mounted on 1 in.

square Cu board (still air).

Mounted on minimum

footprint full size board with

metalized back and with small

clip heatsink (still air).

Mounted to a PCB with

small clip heatsink (still air)

Click on this section to link to the appropriate technical paper.

Click on this section to link to the DirectFET

®

Website.

Surface mounted on 1 in. square Cu board, steady state.

T

C

measured with thermocouple mounted to top (Drain) of part.

Repetitive rating; pulse width limited by max. junction temperature.

Starting T

J

= 25°C, L = 1.33mH, R

G

= 50

, I

AS

= 11A.

Pulse width

400µs; duty cycle 2%.

Used double sided cooling, mounting pad with large heatsink.

Mounted on minimum footprint full size board with metalized back and with small clip heat sink.

R

is measured at T

J

of approximately 90°C.

D

S

G

AUIRF7675M2TR

4

2015-12-14

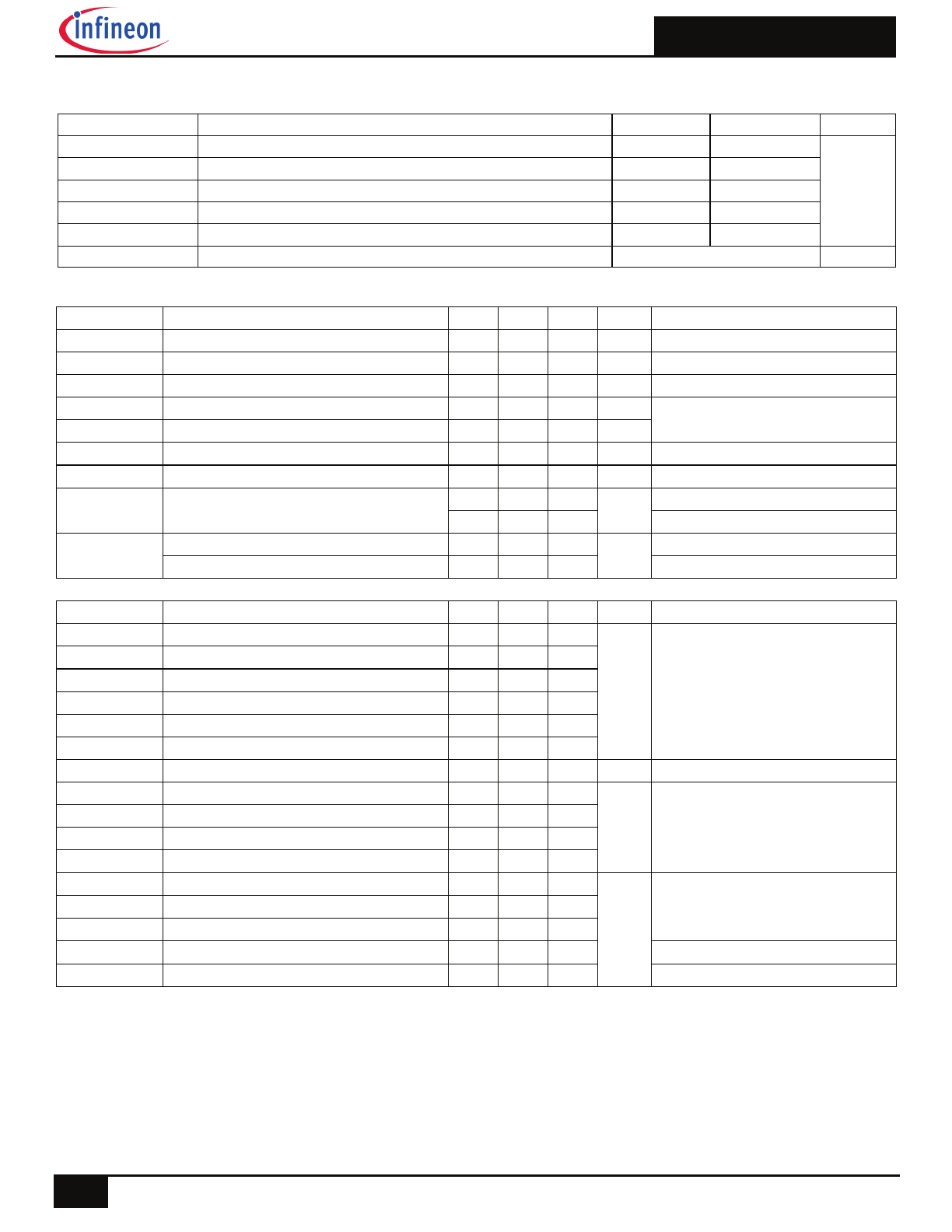

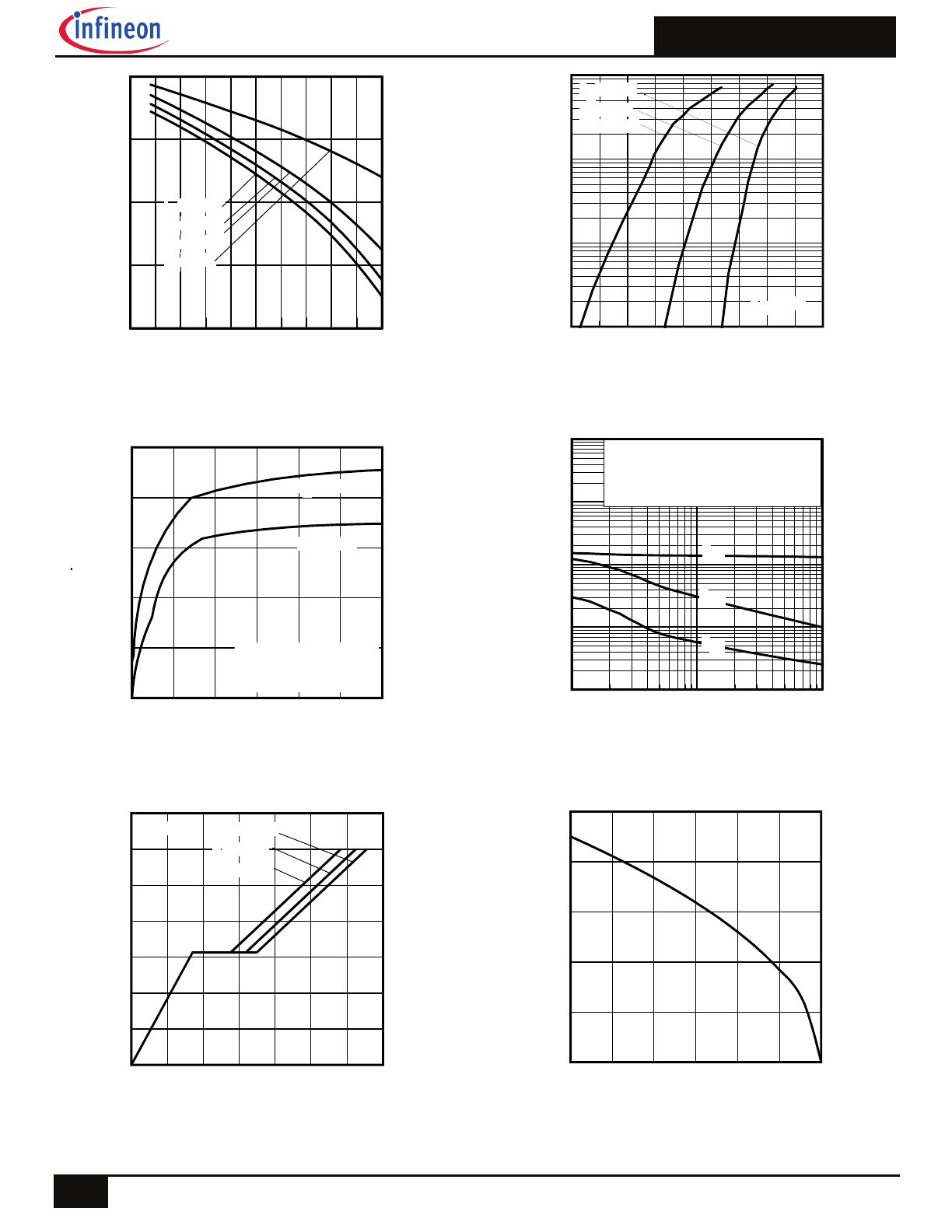

Fig. 3

Typical On-Resistance vs. Gate Voltage

Fig. 1 Typical Output Characteristics

Fig 5. Transfer Characteristics

Fig 6. Normalized On-Resistance vs. Temperature

Fig. 2 Typical Output Characteristics

0.1

1

10

100

VDS, Drain-to-Source Voltage (V)

0.1

1

10

100

I D

, D

ra

in

-t

o-

S

ou

rc

e

C

ur

re

nt

(

A

)

60µs PULSE WIDTH

Tj = 25°C

5.0V

VGS

TOP 15V

10V

8.0V

7.0V

6.5V

6.0V

5.5V

BOTTOM

5.0V

0.1

1

10

100

VDS, Drain-to-Source Voltage (V)

0.1

1

10

100

I D

, D

ra

in

-t

o-

S

ou

rc

e

C

ur

re

nt

(

A

)

60µs PULSE WIDTH

Tj = 175°C

5.0V

VGS

TOP 15V

10V

8.0V

7.0V

6.5V

6.0V

5.5V

BOTTOM

5.0V

6

8

10

12

14

16

18

20

VGS, Gate -to -Source Voltage (V)

40

60

80

100

120

140

R

D

S

(o

n)

,

D

ra

in

-t

o

-S

ou

rc

e

O

n

R

es

is

ta

n

ce

(

m

)

ID = 11A

TJ = 25°C

TJ = 125°C

0

10

20

30

40

50

60

ID, Drain Current (A)

40

80

120

160

200

R

D

S

(o

n)

,

D

ra

in

-t

o

-S

ou

rc

e

O

n

R

es

is

ta

nc

e

(

m

)

Vgs = 10V

TJ = 25°C

TJ = 125°C

3

4

5

6

7

8

9

VGS, Gate-to-Source Voltage (V)

0.01

0.1

1

10

100

I D

, D

ra

in

-t

o-

S

ou

rc

e

C

ur

re

nt

(

A

)

TJ = -40°C

TJ = 25°C

TJ = 175°C

VDS = 50V

60µs PULSE WIDTH

-60 -40 -20 0 20 40 60 80 100120140160180

TJ , Junction Temperature (°C)

0.5

1.0

1.5

2.0

2.5

3.0

R

D

S

(o

n)

,

D

ra

in

-t

o-

S

ou

rc

e

O

n

R

es

is

ta

nc

e

(

N

or

m

al

iz

ed

)

ID = 11A

VGS = 10V

Fig. 4

Typical On-Resistance vs. Drain Current

AUIRF7675M2TR

5

2015-12-14

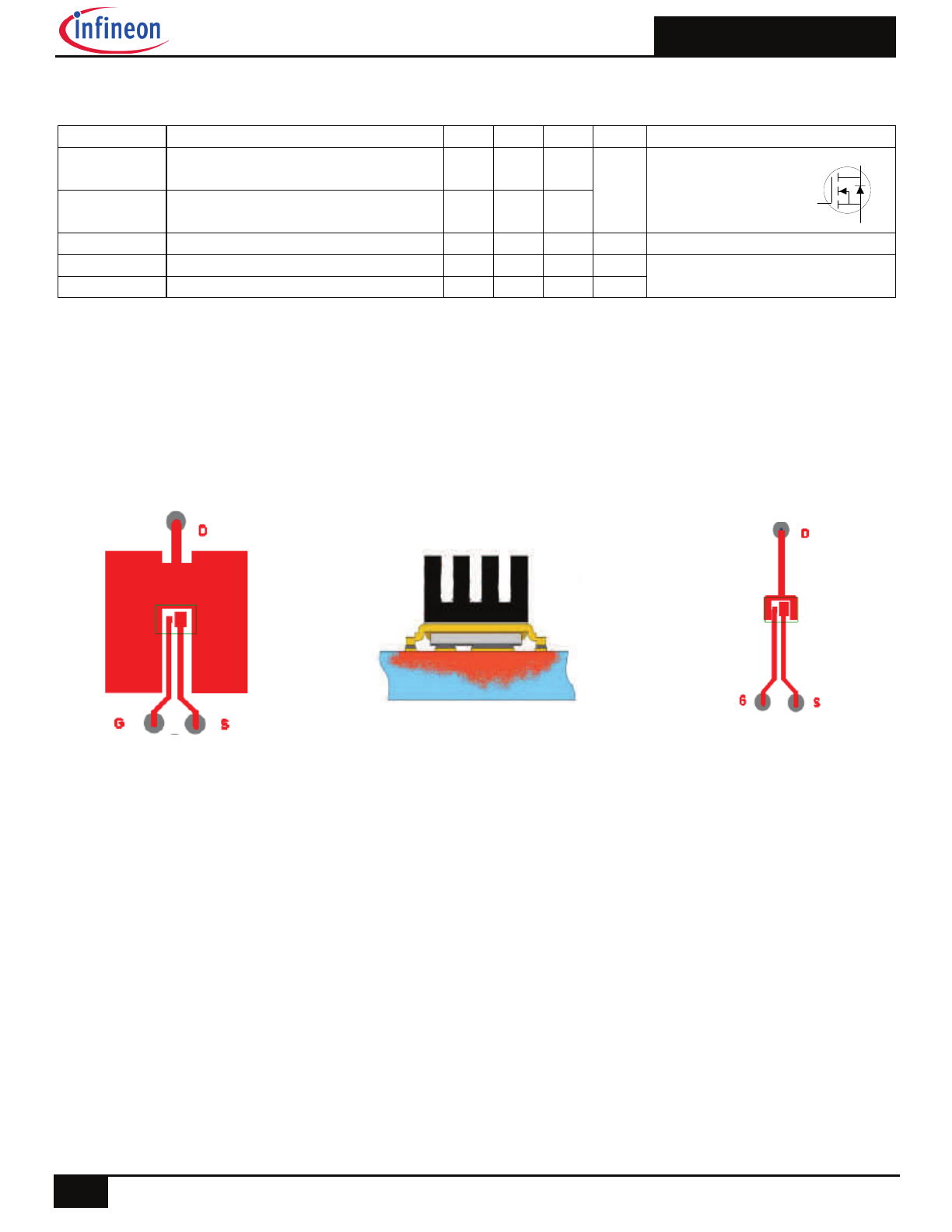

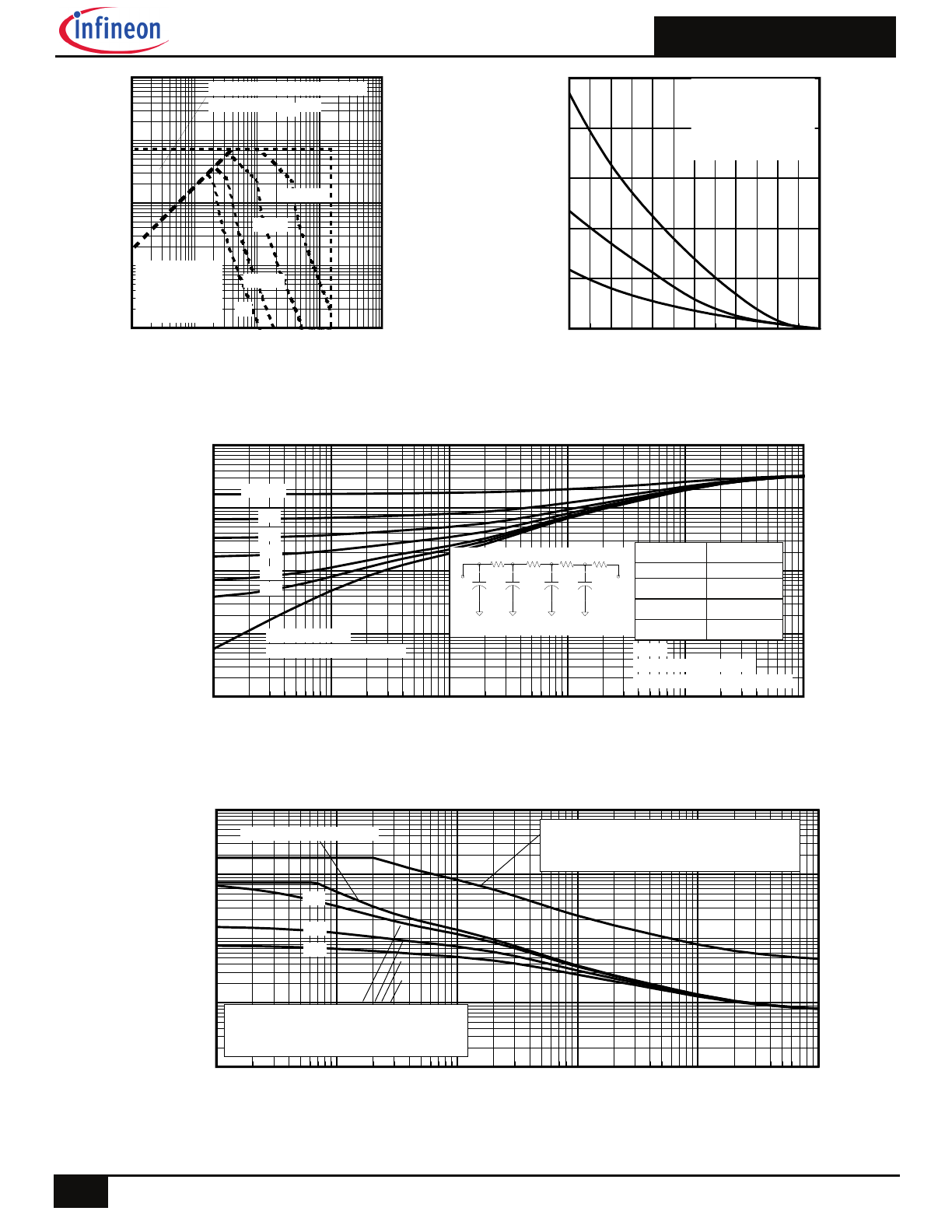

Fig 10. Typical Capacitance vs. Drain-to-Source Voltage

Fig 9. Typical Forward Trans conductance vs. Drain Current

-75 -50 -25 0

25 50 75 100 125 150 175

TJ , Temperature ( °C )

1.5

2.5

3.5

4.5

5.5

V

G

S

(t

h)

,

G

at

e

th

re

sh

ol

d

V

ol

ta

ge

(

V

)

ID = 100µA

ID = 250µA

ID = 1.0mA

ID = 1.0A

0.2

0.4

0.6

0.8

1.0

VSD, Source-to-Drain Voltage (V)

0.1

1

10

100

I S

D

, R

ev

er

se

D

ra

in

C

ur

re

nt

(

A

)

TJ = -40°C

TJ = 25°C

TJ = 175°C

VGS = 0V

0

4

8

12

16

20

24

ID,Drain-to-Source Current (A)

0

10

20

30

40

50

G

fs

, F

or

w

ar

d

T

ra

ns

co

nd

uc

ta

nc

e

(S

)

TJ = 25°C

TJ = 175°C

VDS = 10V

380µs PULSE WIDTH

Fig. 7 Typical Threshold Voltage vs.

Junction Temperature

1

10

100

VDS, Drain-to-Source Voltage (V)

10

100

1000

10000

100000

C

, C

ap

ac

ita

nc

e

(p

F

)

VGS = 0V, f = 1 MHZ

Ciss = Cgs + Cgd, C ds SHORTED

Crss = Cgd

Coss = Cds + Cgd

Coss

Crss

Ciss

Fig 8. Typical Source-Drain Diode Forward Voltage

0

4

8

12

16

20

24

28

QG, Total Gate Charge (nC)

0

2

4

6

8

10

12

14

V

G

S

, G

at

e-

to

-S

ou

rc

e

V

ol

ta

ge

(

V

)

VDS= 120V

VDS= 75V

VDS= 30V

ID= 11A

Fig 11. Typical Gate Charge vs.

Gate-to-Source Voltage

25

50

75

100

125

150

175

TC , Case Temperature (°C)

0

4

8

12

16

20

I D

,

D

ra

in

C

ur

re

nt

(

A

)

Fig 12. Maximum Drain Current vs. Case Temperature

AUIRF7675M2TR

6

2015-12-14

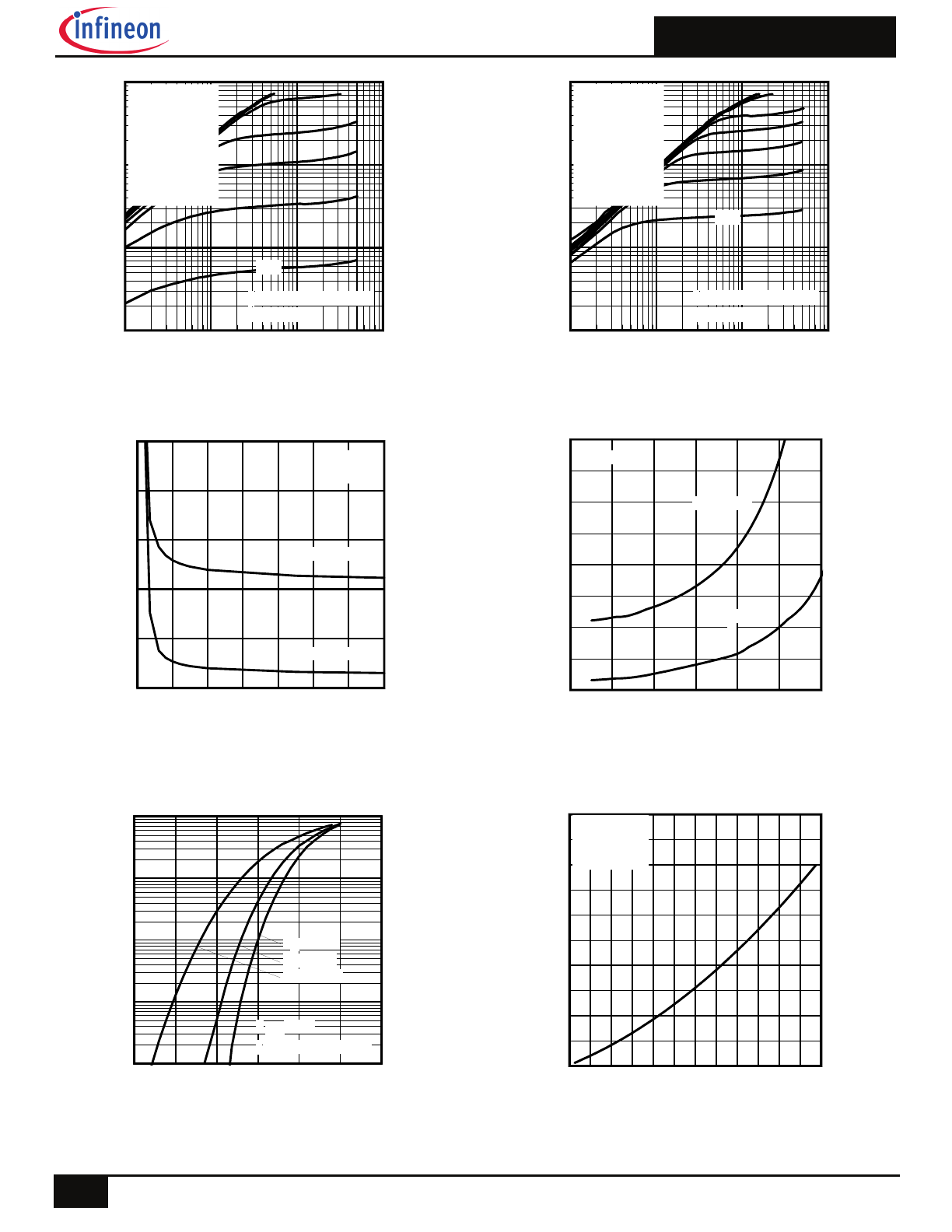

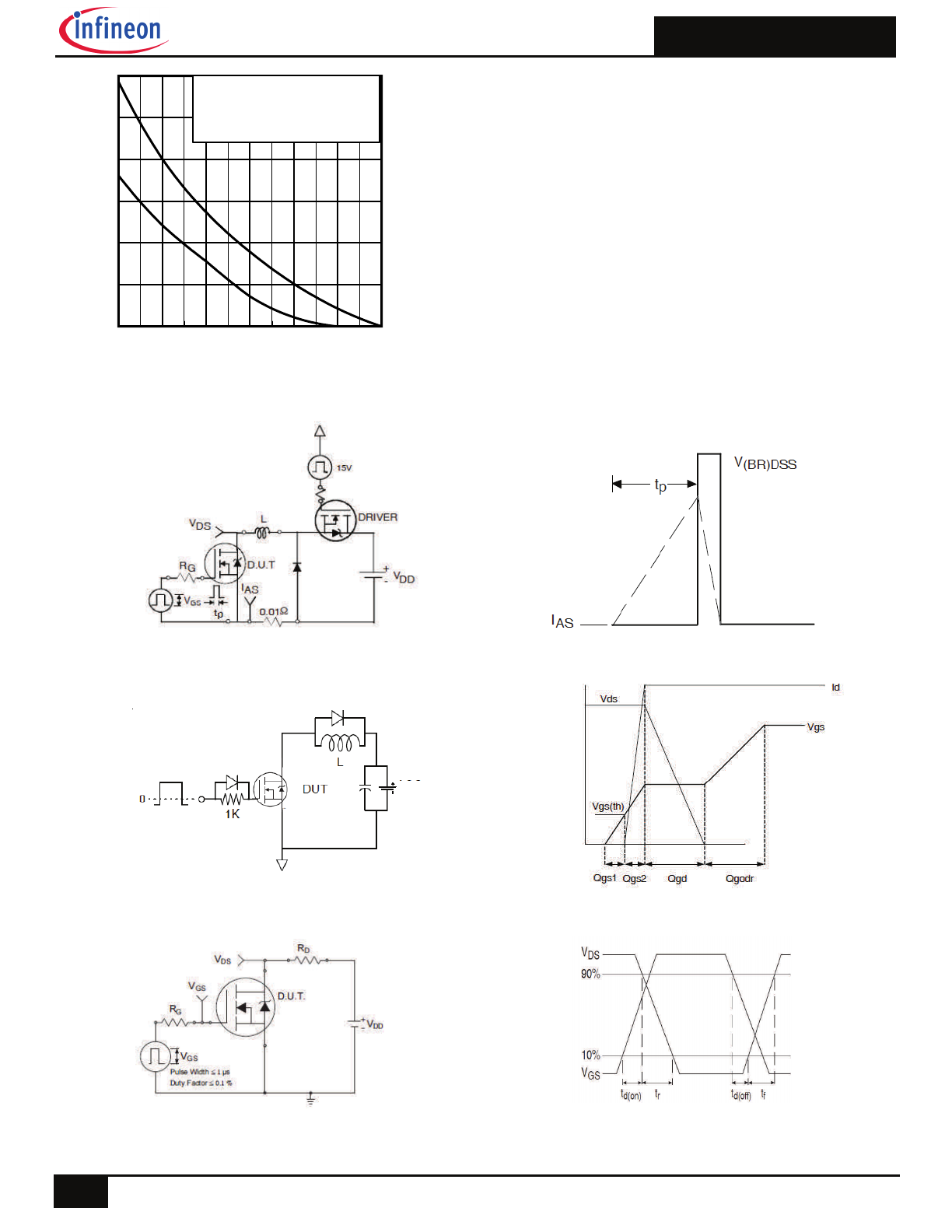

Fig 16. Typical Avalanche Current vs. Pulse Width

Fig 15. Maximum Effective Transient Thermal Impedance, Junction-to-Case

Fig 14. Maximum Avalanche Energy vs. Temperature

Fig 13. Maximum Safe Operating Area

0.1

1

10

100

1000

VDS , Drain-toSource Voltage (V)

0.1

1

10

100

1000

I D

,

D

ra

in

-t

o-

S

ou

rc

e

C

ur

re

nt

(

A

)

Tc = 25°C

Tj = 175°C

Single Pulse

1msec

10msec

OPERATION IN THIS AREA

LIMITED BY RDS(on)

100µsec

DC

25

50

75

100

125

150

175

Starting TJ , Junction Temperature (°C)

0

50

100

150

200

250

E A

S

,

S

in

gl

e

P

ul

se

A

va

la

nc

he

E

ne

rg

y

(m

J)

ID

TOP 2.2A

4.5A

BOTTOM 11A

1E-006

1E-005

0.0001

0.001

0.01

0.1

t1 , Rectangular Pulse Duration (sec)

0.001

0.01

0.1

1

10

T

he

rm

al

R

es

po

ns

e

(

Z

th

JC

)

°C

/W

0.20

0.10

D = 0.50

0.02

0.01

0.05

SINGLE PULSE

( THERMAL RESPONSE )

Notes:

1. Duty Factor D = t1/t2

2. Peak Tj = P dm x Zthjc + Tc

J

J

1

1

2

2

3

3

R

1

R

1

R

2

R

2

R

3

R

3

Ci=

iRi

Ci=

iRi

C

C

4

4

R

4

R

4

1.381063

0.007407

1.312033

0.039921

0.104573

2.1E-05

0.501388

0.000741

Ri (°C/W)

i (sec)

1.0E-06

1.0E-05

1.0E-04

1.0E-03

1.0E-02

1.0E-01

tav (sec)

0.01

0.1

1

10

100

A

va

la

nc

he

C

ur

re

nt

(

A

)

0.05

Duty Cycle = Single Pulse

0.10

Allowed avalanche Current vs avalanche

pulsewidth, tav, assuming

j = 25°C and

Tstart = 150°C.

0.01

Allowed avalanche Current vs avalanche

pulsewidth, tav, assuming

Tj = 150°C and

Tstart =25°C (Single Pulse)

AUIRF7675M2TR

7

2015-12-14

Notes on Repetitive Avalanche Curves , Figures 16, 17:

(For further info, see AN-1005 at www.infineon.com)

1. Avalanche failures assumption:

Purely a thermal phenomenon and failure occurs at a temperature far in

excess of T

jmax

. This is validated for every part type.

2. Safe operation in Avalanche is allowed as long as T

jmax

is not exceeded.

3. Equation below based on circuit and waveforms shown in Figures 18a, 18b.

4. P

D (ave)

= Average power dissipation per single avalanche pulse.

5. BV = Rated breakdown voltage (1.3 factor accounts for voltage increase

during

avalanche).

6. I

av

= Allowable avalanche current.

7.

T

=

Allowable rise in junction temperature, not to exceed

T

jmax

(assumed as

25°C in Figure 16, 17).

t

av =

Average time in avalanche.

D = Duty cycle in avalanche = t

av

·f

Z

thJC

(D, t

av

) = Transient thermal resistance, see Figures 15)

P

D (ave)

= 1/2 ( 1.3·BV·I

av

) =

T/ Z

thJC

I

av

= 2

T/ [1.3·BV·Z

th

]

E

AS (AR)

= P

D (ave)

·t

av

Fig 18a. Unclamped Inductive Test Circuit

Fig 18b. Unclamped Inductive Waveforms

Fig 19a. Gate Charge Test Circuit

Fig 19b. Gate Charge Waveform

VDD

Fig 20a. Switching Time Test Circuit

Fig 20b. Switching Time Waveforms

25

50

75

100

125

150

175

Starting TJ , Junction Temperature (°C)

0

10

20

30

40

50

60

E A

R

,

A

va

la

nc

he

E

ne

rg

y

(m

J)

TOP Single Pulse

BOTTOM 1% Duty Cycle

ID = 11A

Fig 17. Maximum Avalanche Energy vs. Temperature

AUIRF7675M2TR

8

2015-12-14

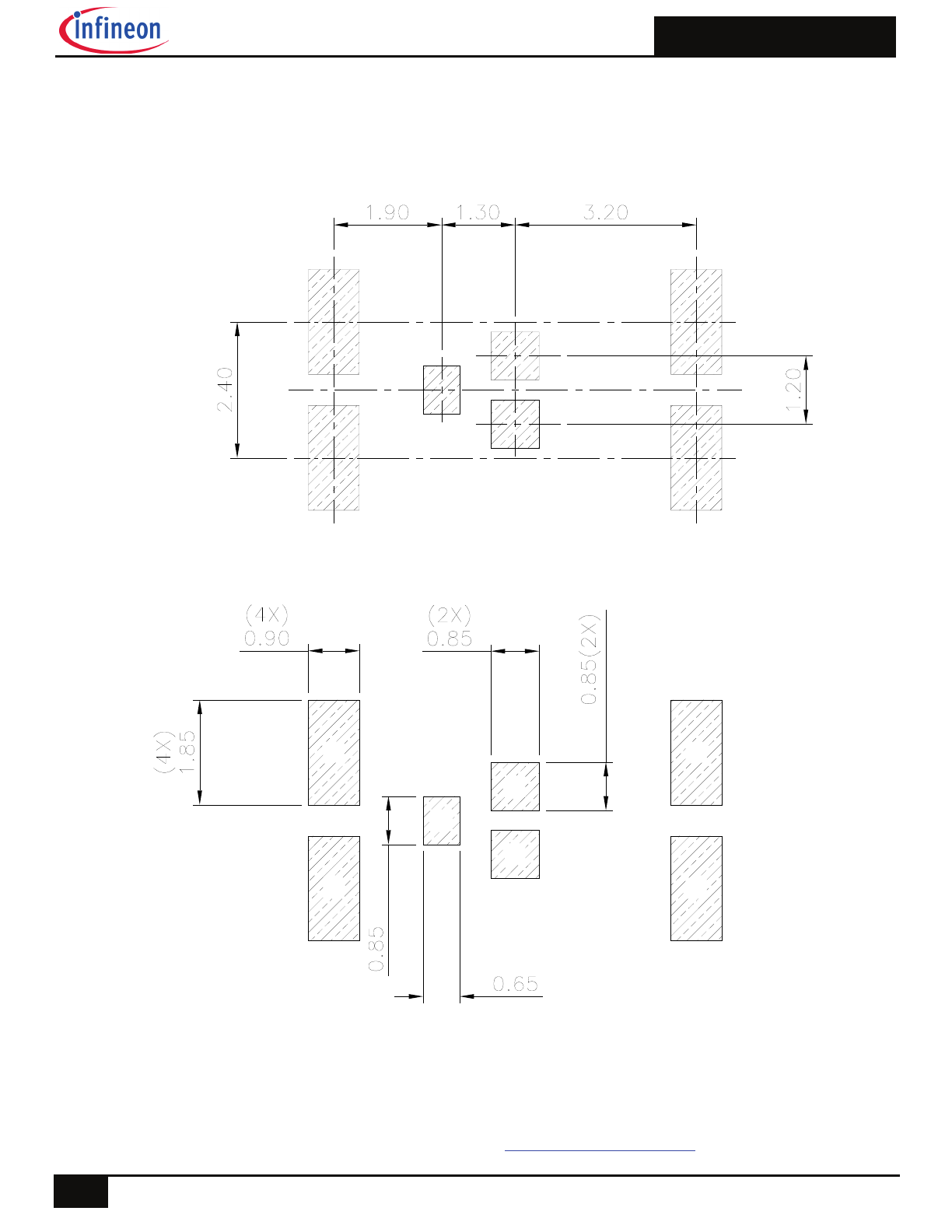

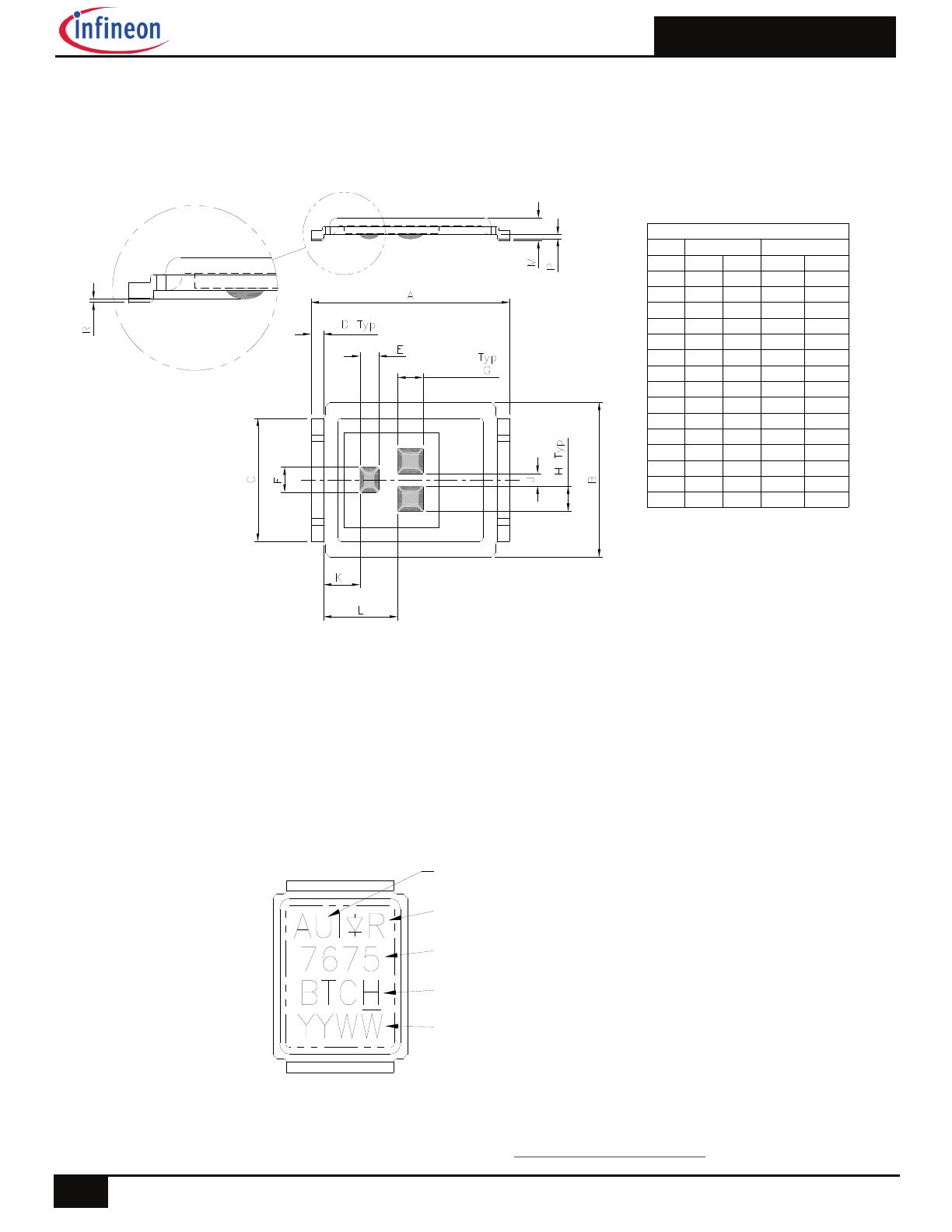

DirectFET

®

Board Footprint, M2 (Medium Size Can).

Please see DirectFET

®

application note AN-1035 for all details regarding the assembly of DirectFET

®

.

This includes all recommendations for stencil and substrate designs.

G

D

S

D

D

D

S

G = GATE

D = DRAIN

S = SOURCE

Note: For the most current drawing please refer to IR website at

http://www.irf.com/package/

AUIRF7675M2TR

9

2015-12-14

DirectFET

®

Outline Dimension, M2 Outline (Medium Size Can).

Please see DirectFET

®

application note AN-1035 for all details regarding the assembly of DirectFET

®

. This includes

all recommendations for stencil and substrate designs.

DirectFET

®

Part Marking

CODE

A

B

C

D

E

F

G

H

J

K

L

R

0.003

0.047

0.094

0.156

0.032

0.018

0.024

MAX

0.250

0.02

1.10

2.30

3.85

0.78

0.35

0.58

MIN

6.25

4.80

0.08

1.20

2.40

3.95

0.82

0.45

0.62

MAX

6.35

5.05

0.001

0.090

0.043

0.152

0.031

0.023

0.014

MIN

0.189

0.246

METRIC

IMPERIAL

DIMENSIONS

I

N/A

N/A

0.78

0.82

N/A

N/A

0.032

0.031

0.032

0.78

0.82

0.031

0.015

0.017

0.38

0.42

M

P

0.029

0.007

0.68

0.09

0.74

0.17

0.027

0.003

0.199

PART NUMBER

LOGO

BATCH NUMBER

DATE CODE

Line above the last character of

the date code indicates "Lead-Free"

"AU" = GATE AND

AUTOMOTIVE MARKING

Note: For the most current drawing please refer to IR website at

http://www.irf.com/package/

AUIRF7675M2TR

10

2015-12-14

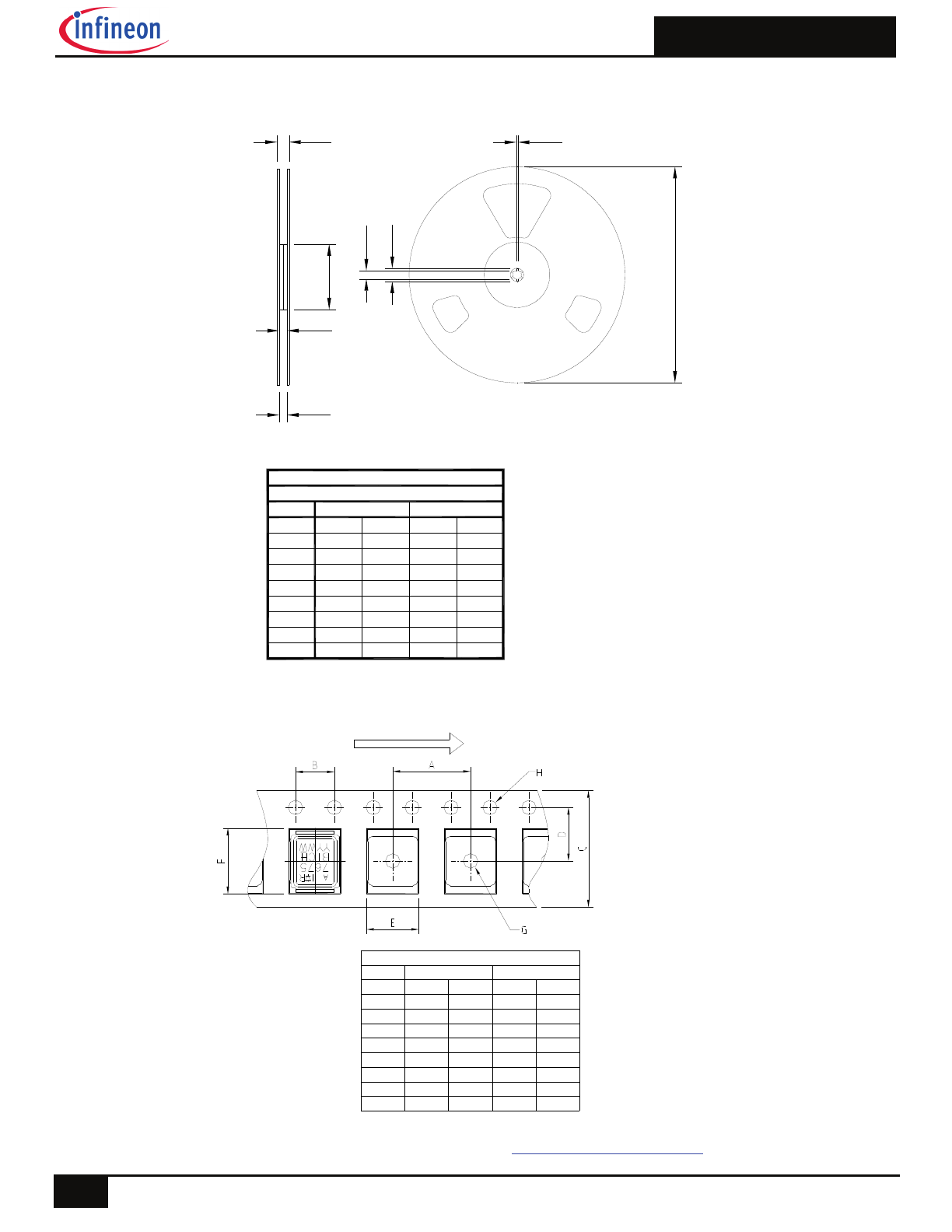

DirectFET

®

Tape &

Reel Di-

Note: For the most current drawing please refer to IR website at

http://www.irf.com/package/

REEL DIMENSIONS

NOTE: Controlling dimensions in mm

Std reel quantity is 4800 parts, order as AUIRF7675M2TR.

B

C

MAX

N.C

N.C

0.520

N.C

N.C

0.724

0.567

0.606

IMPERIAL

H

MIN

330.0

20.2

12.8

1.5

100.0

N.C

12.4

11.9

STANDARD OPTION (QTY 4800)

CODE

A

B

C

D

E

F

G

H

MAX

N.C

N.C

13.2

N.C

N.C

18.4

14.4

15.4

MIN

12.992

0.795

0.504

0.059

3.937

N.C

0.488

0.469

METRIC

G

E

F

A

D

Loaded Tape Feed Direction

MIN

7.90

3.90

11.90

5.45

5.10

6.50

1.50

1.50

NOTE: CONTROLLING

DIMENSIONS IN MM

CODE

A

B

C

D

E

F

G

H

MAX

0.319

0.161

0.484

0.219

0.209

0.264

N.C

0.063

MIN

0.311

0.154

0.469

0.215

0.201

0.256

0.059

0.059

MAX

8.10

4.10

12.30

5.55

5.30

6.70

N.C

1.60

DIMENSIONS

METRIC

IMPERIAL

U