2002-2012 Microchip Technology Inc.

DS21361D-page 1

TC115

Features

• High Efficiency at Low Output Load Currents via

PFM Mode

• Assured Start-up at 0.9V

• 80 µA (Typ) Supply Current

• 85% Typical Efficiency at 100 mA

• 140 mA Typical Output Current @ V

IN

2.0V

• Low Power Shutdown Mode

• No External Switching Transistor Needed

• Space-Saving SOT-89 Package

Applications

• Pagers

• Cellular Phones

• Palmtops

• 1-Cell to 3-Cell Battery Powered Systems

• Cameras, Video Recorders

• Local +3V to +5V Supplies

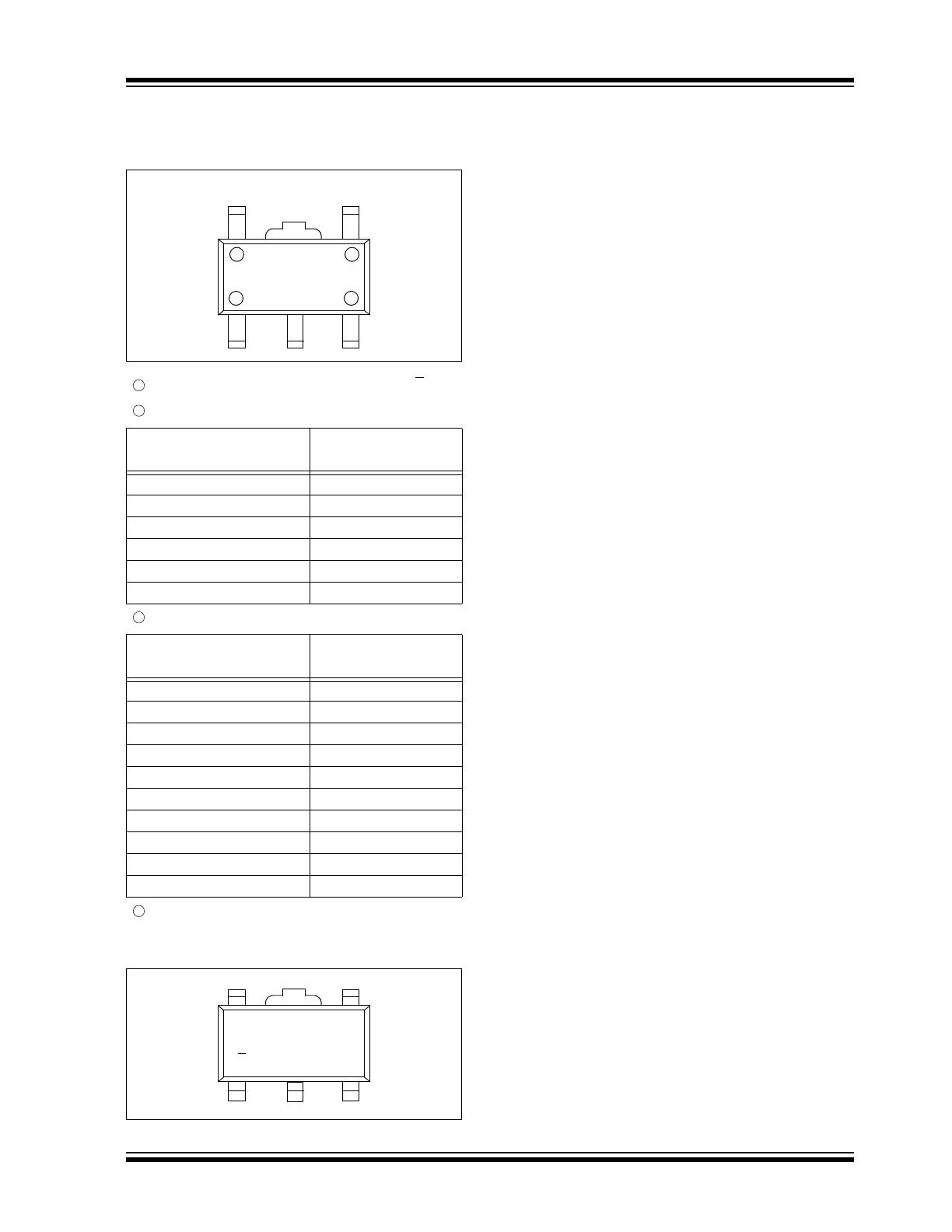

Package Type

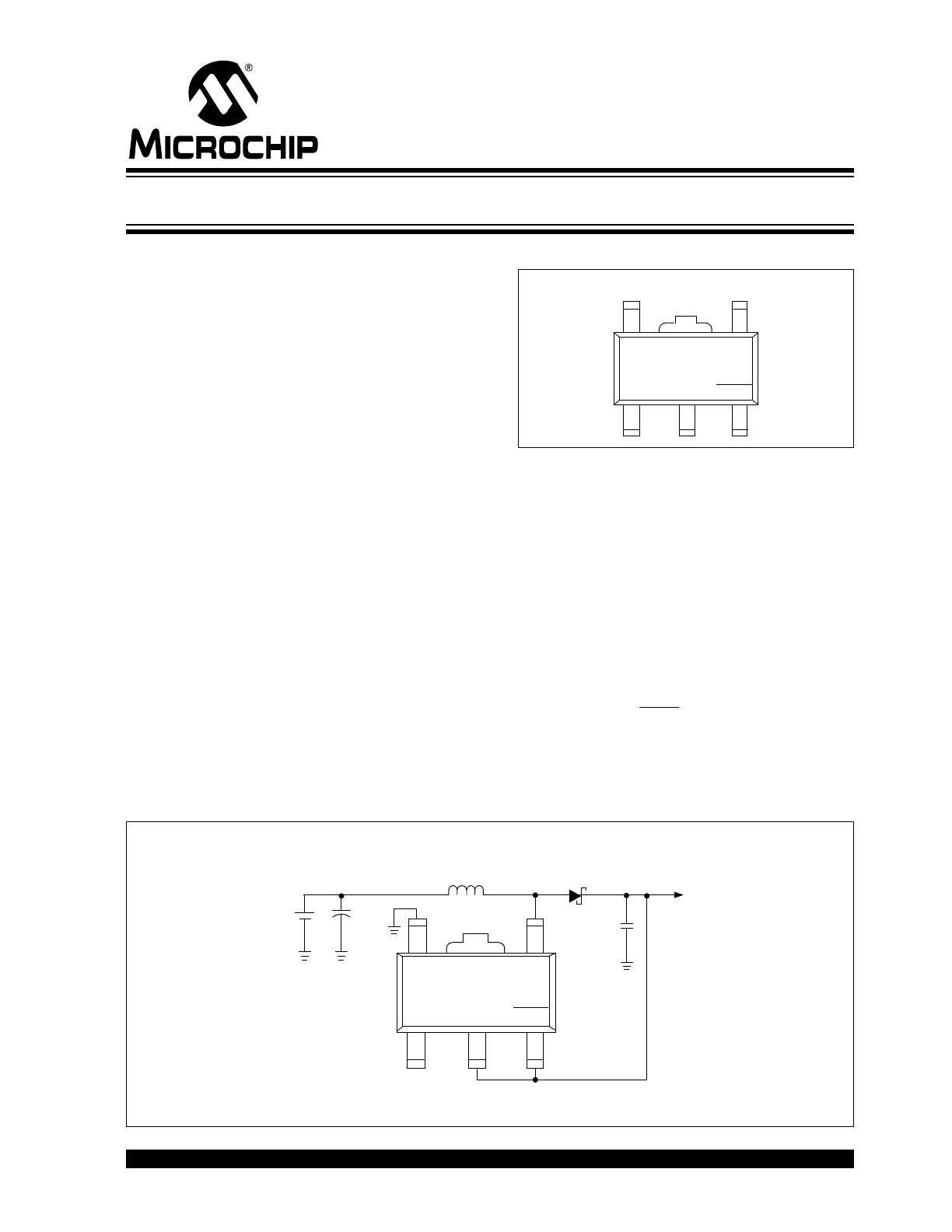

General Description

The TC115 is a high-efficiency step-up DC/DC

converter for small, low input voltage or battery-

powered systems. This device has a start-up voltage

of 0.9V and a typical supply current of 80 µA. Phase

compensation and soft-start circuitry are included on-

chip. Unlike conventional PWM step-up converters,

the TC115 automatically shifts to pulse frequency

modulation (PFM) at low loads, resulting in reduced

supply current and improved efficiency.

The TC115 requires only an external diode, an inductor

and a capacitor, while supporting typical output cur-

rents of 140 mA. Supply current is reduced to less than

0.5 µA (max) when SHDN input is brought low.

Small size, low installed cost and low supply current

make the TC115 step-up converter ideal for use in a

wide range of battery-powered systems.

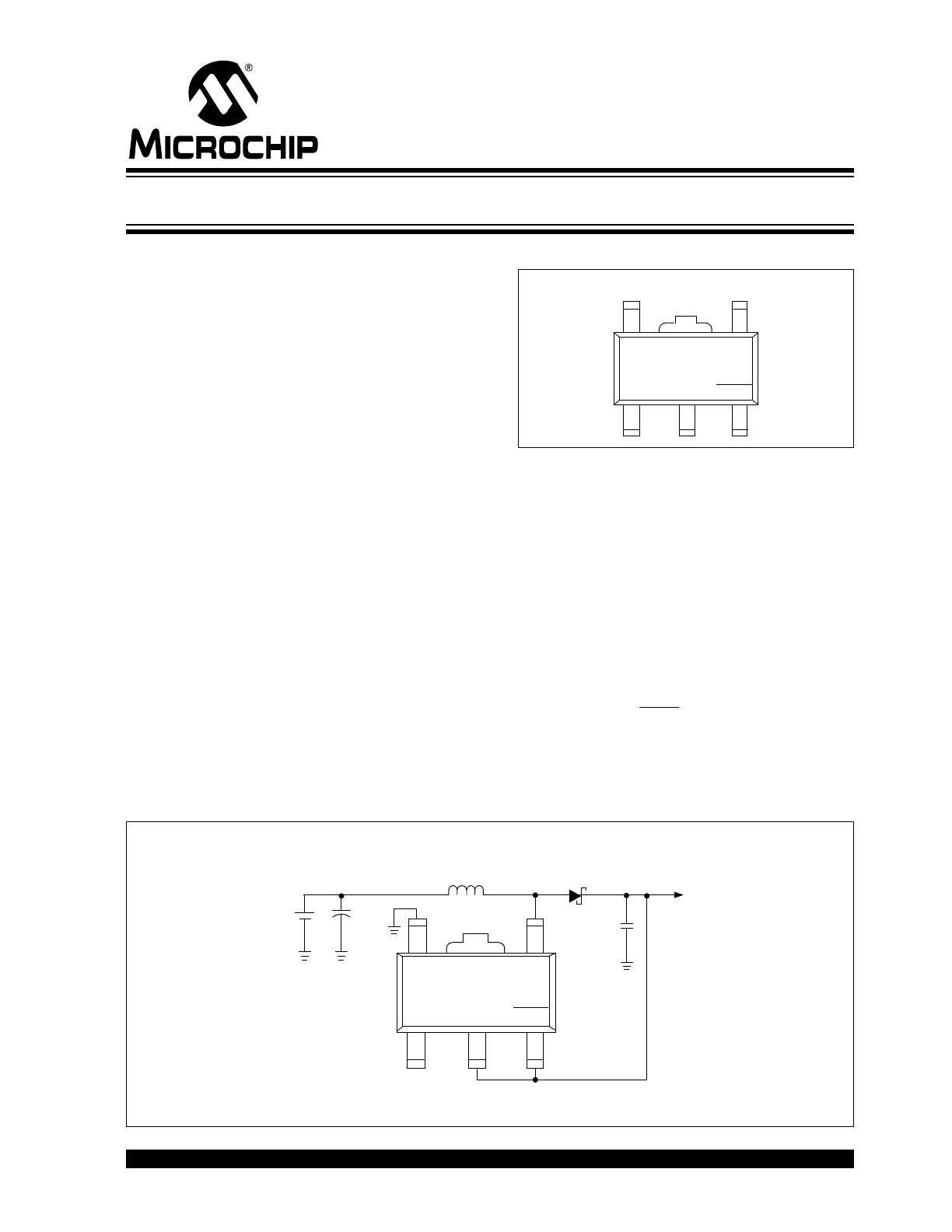

Functional Block Diagram

5

4

TC115

1

3

2

GND

LX

NC

PS

SHDN

SOT-89-5

PS

1.5V

C

1

10 µF

L

1

100 µH

Sumida

®

CD-54

1.5V to +3V, 50 mA Supply

5

4

TC115

1

3

2

SHDN

PS

NC

C

2

47 µF

Tantalum

IN5817

D

1

GND

LX

+3V

OUT

+

+

+

PS

PFM/PWM Step-Up DC/DC Converter

TC115

DS21361D-page 2

2002-2012 Microchip Technology Inc.

1.0

ELECTRICAL

CHARACTERISTICS

Absolute Maximum Ratings†

Power Supply Voltage (PS) ...............................................12V

Power Dissipation ......................................................500 mW

LX Sink Current......................................................400 mA pk

SHDN Input Voltage ..........................................................12V

Operating Temperature Range........................-40°C to +85°C

Storage Temperature Range .........................-40°C to +125°C

† Stresses above those listed under "Absolute Maximum

Ratings" may cause permanent damage to the device. These

are stress ratings only and functional operation of the device

at these or any other conditions above those indicated in the

operation sections of the specifications is not implied.

Exposure to Absolute Maximum Rating conditions for

extended periods may affect device reliability.

PIN FUNCTION TABLE

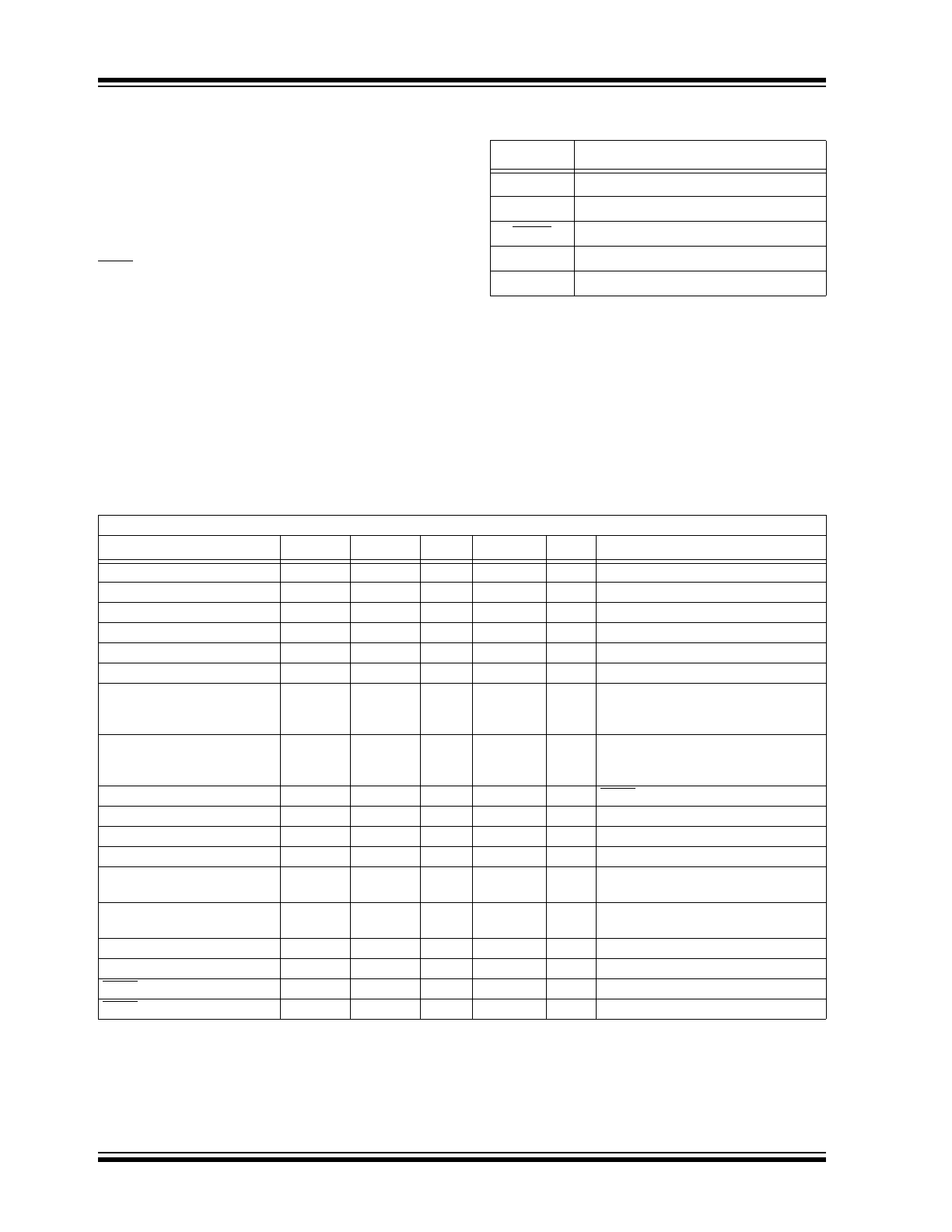

DC CHARACTERISTICS

Symbol

Description

NC

Not connected

PS

Power and voltage sense input

SHDN

Shutdown input

LX

Inductor switch output

GND

Ground terminal

Electrical Specifications: Unless otherwise noted, V

OUT

= 5V, T

A

= +25°C. Circuit configuration is illustrated in Figure 5-1.

Parameters

Sym

Min

Typ

Max

Units

Conditions

Operating Supply Voltage

V

IN

0.9

—

10.0

V

Note 5

Start-Up Supply Voltage

V

START

—

—

0.9

V

I

OUT

= 1 mA

LX Maximum Sink Current

I

LX

MAX

—

—

350

mA

LX Limit Frequency

f

LIM

—

200

—

kHz

V

LX

= VLX

LIM

LX Limit Voltage

VLX

LIM

0.7

—

1.3

V

Note 2

No Load Supply Current

I

DD

—

13

26

µA

I

OUT

= 0, V

IN

= V

OUT

x 0.8 (Note 3)

Boost Mode Supply Current

I

CC

—

80

135

µA

No external components,

V

IN

= (0.95 x V

OUT

) applied to PS (or

V

DD

) input

Standby Supply Current

I

STBY

—

9

17

µA

No external components,

V

IN

= (1.1 x V

OUT

) applied to PS

(or V

DD

) input

Shutdown Supply Current

I

SD

—

—

0.5

µA

SHDN = 0V

Oscillator Frequency

f

OSC

85

100

115

kHz

Note 2, Note 4

Output Voltage

V

OUT

V

R

x 0.975

V

R

V

R

x 1.025

V

V

IN

= 2.2V minimum (Note 1)

LX Output ON Resistance

Rswon

—

1.4

2.4

V

LX

= 0.4V

Duty Cycle

(PFM Operating Mode)

PFMDUTY

10

17

25

%

No external components

Maximum Duty Cycle

MAX-

DUTY

80

87

92

%

Note 4

Soft Start Time

t

SS

4

10

20

msec

Efficiency

h

—

85

—

%

SHDN Input Logic High

V

IH

0.75

—

—

V

SHDN Input Logic Low

V

IL

—

—

0.20

V

Note

1:

V

R

is the nominal factory-programmed output voltage setting.

2:

VLX

LIM

is the voltage on the LX pin (with internal switch ON) that will cause the oscillator to run at twice nominal

frequency in to limit the switch current through the internal N-channel switching transistor.

3:

Measured with D

1

= MA735 (reverse current < 1 µA at a reverse voltage of 10V).

4:

With TC115 operating in PWM mode.

5:

See Section 4.4, “Behavior When V

IN

is Greater Than the Factory-Programmed V

OUT

Setting”.

2002-2012 Microchip Technology Inc.

DS21361D-page 3

TC115

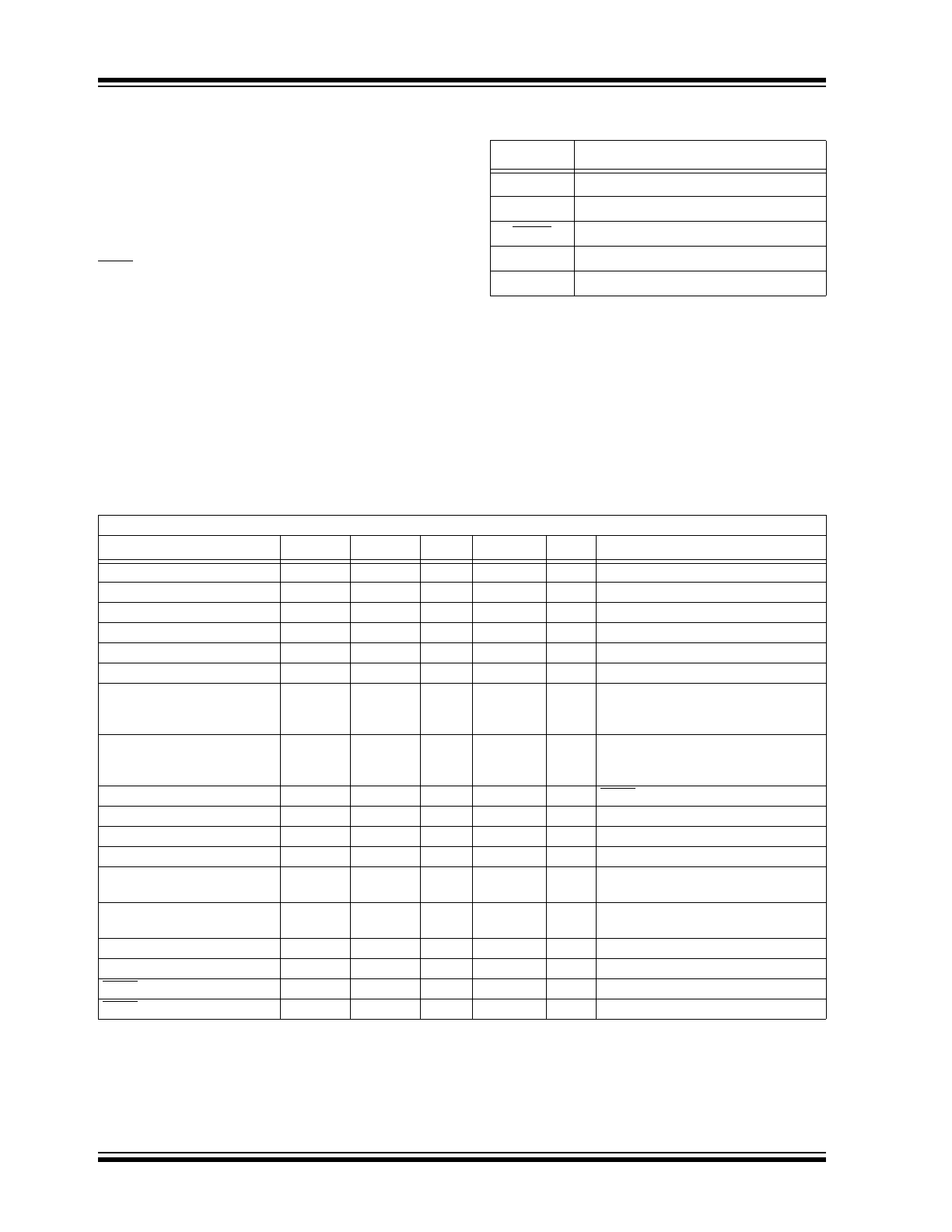

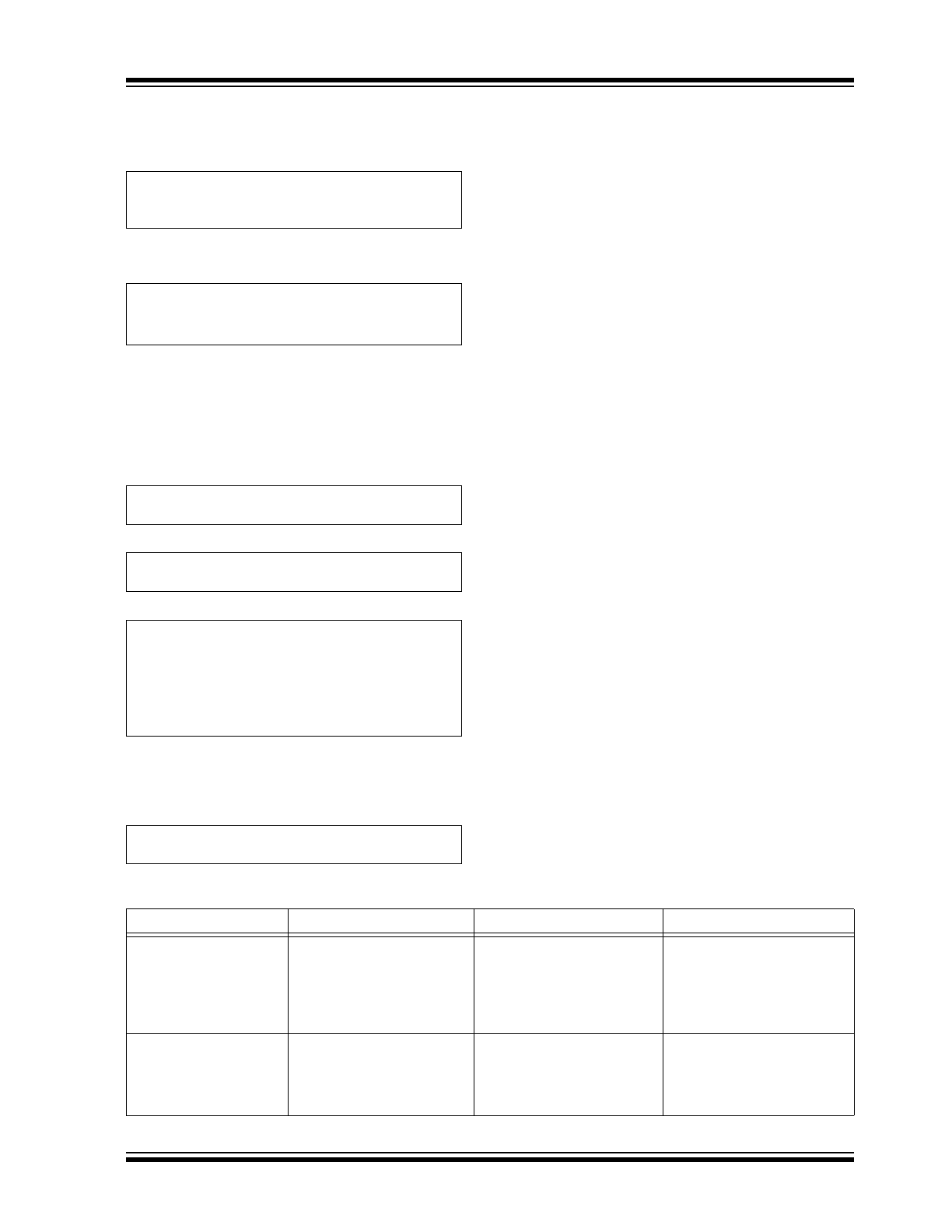

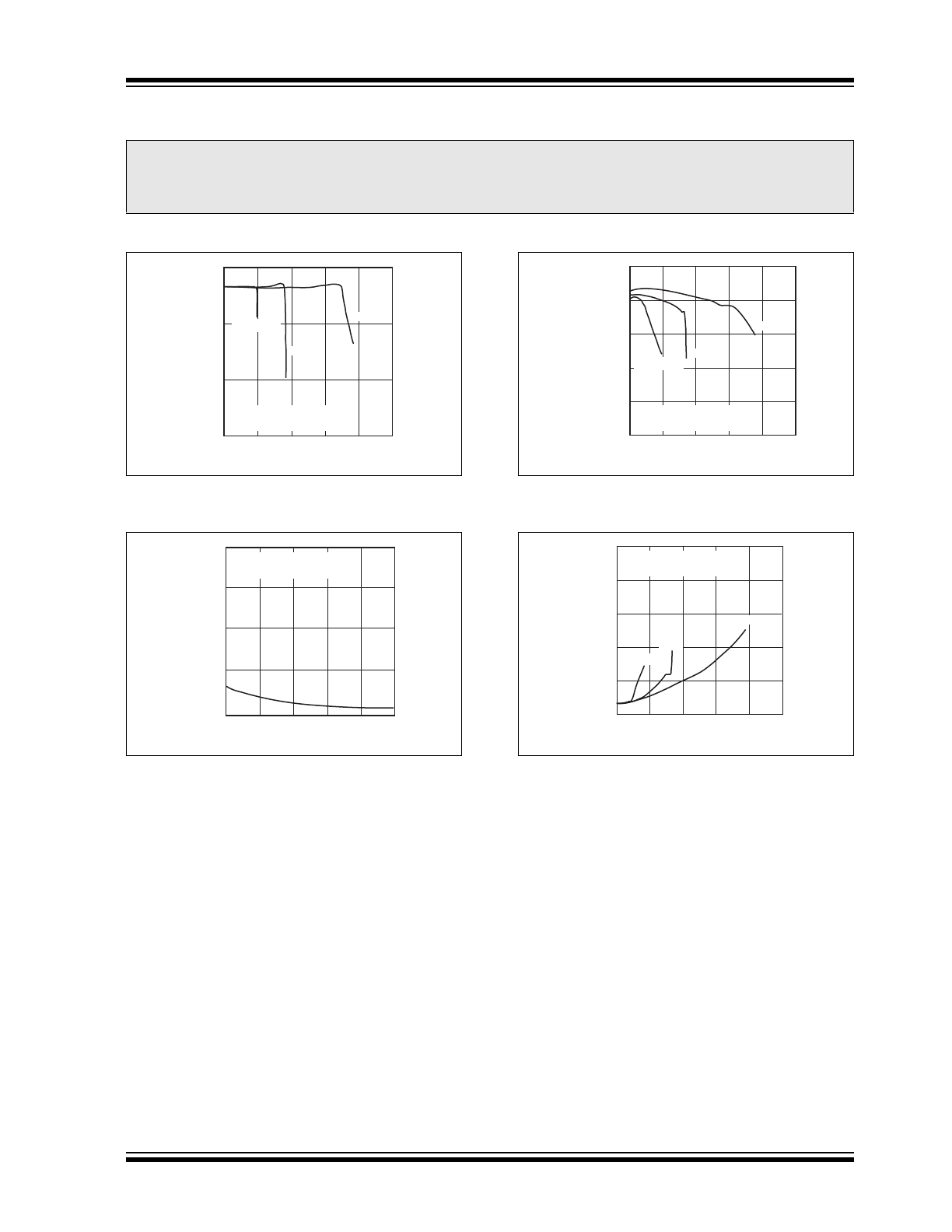

2.0

TYPICAL PERFORMANCE CURVES

Note: Unless otherwise indicated, V

OUT

= 5V, T

A

= +25°C.

FIGURE 2-1:

Output Voltage vs. Output

Current.

FIGURE 2-2:

No Load Input Current vs.

Input Voltage.

FIGURE 2-3:

Efficiency vs. Output

Current.

FIGURE 2-4:

Ripple Voltage vs. Output

Current.

Note:

The graphs and tables provided following this note are a statistical summary based on a limited number of

samples and are provided for informational purposes only. The performance characteristics listed herein

are not tested or guaranteed. In some graphs or tables, the data presented may be outside the specified

operating range (e.g., outside specified power supply range) and therefore outside the warranted range.

OUTPUT CURRENT I

OUT

(mA)

OUTPUT VOLTAGE V

OUT

(V)

0

40

80

120

160

200

3.1

2.9

2.7

2.5

1.5V

V

IN

= 1.0V

L

1

= 100

µH

C2 = 47

µF (Tantalum)

2.0V

1.0

1.2

1.4

1.6

1.8

2.0

INPUT VOLTAGE V

IN

(V)

200

INPUT CURRENT I

IN

(

µ

A) 150

100

50

0

L

1 = 100

µH

C2 = 47

µF (Tantalum)

OUTPUT CURRENT I

OUT

(mA)

EFFICIENCY (%)

0

40

80

120

160

200

100

80

60

40

20

0

V

IN

= 1.0V

1.5V

2.0V

L

1 = 100

µH

C2 = 47

µF (Tantalum)

OUTPUT CURRENT I

OUT

(mA)

RIPPLE VOLTAGE Vr(mVp-p)

0

40

80

120

160

200

100

80

60

40

10

0

L

1 = 100

µH

C2 = 47

µF (Tantalum)

2.0V

1.5V

V

IN

= 1.0V

TC115

DS21361D-page 4

2002-2012 Microchip Technology Inc.

3.0

PIN DESCRIPTIONS

The descriptions of the pins are listed in Table 3-1.

TABLE 3-1:

PIN FUNCTION TABLE

3.1

Power and Voltage Sense Input

(PS)

PS is a dual function input that provides both feedback

voltage sensing and internal chip power. It should be

connected to the regulator output (See Section 5.0,

“Applications”).

3.2

Shutdown Input (SHDN)

A logic-low on SHDN suspends device operation and

supply current is reduced to less than 0.5 µA. The

device resumes normal operation when SHDN is again

brought high.

3.3

Inductor Switch Output (LX)

LX is the drain of an internal N-channel switching tran-

sistor. This terminal drives the external inductor, which

ultimately provides current to the load.

3.4

Ground Terminal (GND)

Connect to circuit ground.

3.5

No Connect (NC)

No internal connection.

Pin No.

Symbol

Description

1

NC

Not connected

2

PS

Power and voltage sense input

3

SHDN

Shutdown input

4

LX

Inductor switch output

5

GND

Ground terminal

2002-2012 Microchip Technology Inc.

DS21361D-page 5

TC115

4.0

DETAILED DESCRIPTION

The TC115 is a combination PFM/PWM step-up

(boost) regulator. It is particularly useful in battery-pow-

ered 1, 2 and 3 cell applications where the required out-

put current is 140 mA or less, and size/cost issues are

a concern. The device operates in PWM mode when

the output load is sufficient to demand a 10% (or

greater) duty cycle. While in PWM mode, the TC115

behaves as any other PWM switching regulator to a

maximum duty cycle of 92%. At low output loads (i.e.,

output loads requiring < 10% duty cycle to support), the

TC115 automatically switches to pulse frequency mod-

ulation (PFM) operating mode with a fixed duty cycle of

25% (max) (17%, typical). While in PFM mode, the

inductor is modulated with individual fixed width pulses

only as needed to maintain output voltage. This action

reduces supply current, thereby improving power

efficiency at low output loads.

4.1

Input Power and Sensing

The TC115 is powered from the PS input, which must

be connected to the regulated output, as shown in

Figure 5-1. PS also senses output voltage for closed-

loop regulation. Start-up current is furnished through

the inductor when input voltage is initially applied. This

action starts the oscillator, causing the voltage at the

PS input to rise, bootstrapping the regulator into full

operation.

4.2

Output Diode

For best results, use a Schottky diode, such as the

MA735, 1N5817, EC10 or equivalent. Connect the

diode between the PS and LX pins as close to the IC as

possible. While ultra fast diodes can be used, lower effi-

ciency will result due to their higher forward voltage

drop. Ordinary rectifiers should be avoided because of

their slow recovery characteristics.

4.3

Low Power Shutdown Mode

The TC115 enters a low power shutdown mode when

SHDN is brought low. While in shutdown, the oscillator

is disabled and the internal switch is shut off. Normal

regulator operation resumes when SHDN is brought

high. SHDN may be tied to the input supply if not used.

4.4

Behavior When V

IN

is Greater

Than the Factory-Programmed

V

OUT

Setting

The TC115 is designed to operate as a step-up

regulator only. As such, V

IN

is assumed to always be

less than the factory-programmed V

OUT

setting (V

R

).

Operating the TC115 with V

IN

> V

R

causes regulating

action to be suspended (and corresponding supply

current reduction to 9 µA, typical) until V

IN

is again less

than V

R

. While regulating action is suspended, V

IN

is

connected to V

OUT

through the series combination of

the inductor and Schottky diode. Care must be taken to

add the appropriate isolation (MOSFET output switch

or post LDO with shutdown) during system design if

this V

IN

/V

OUT

leakage path is problematic.

Note:

Because the TC115 uses an external

diode, a leakage path between the input

voltage and the output node (through the

inductor and diode) exists while the regu-

lator is in shutdown. Care must be taken in

system design to assure the input supply

is isolated from the load during shutdown.

TC115

DS21361D-page 6

2002-2012 Microchip Technology Inc.

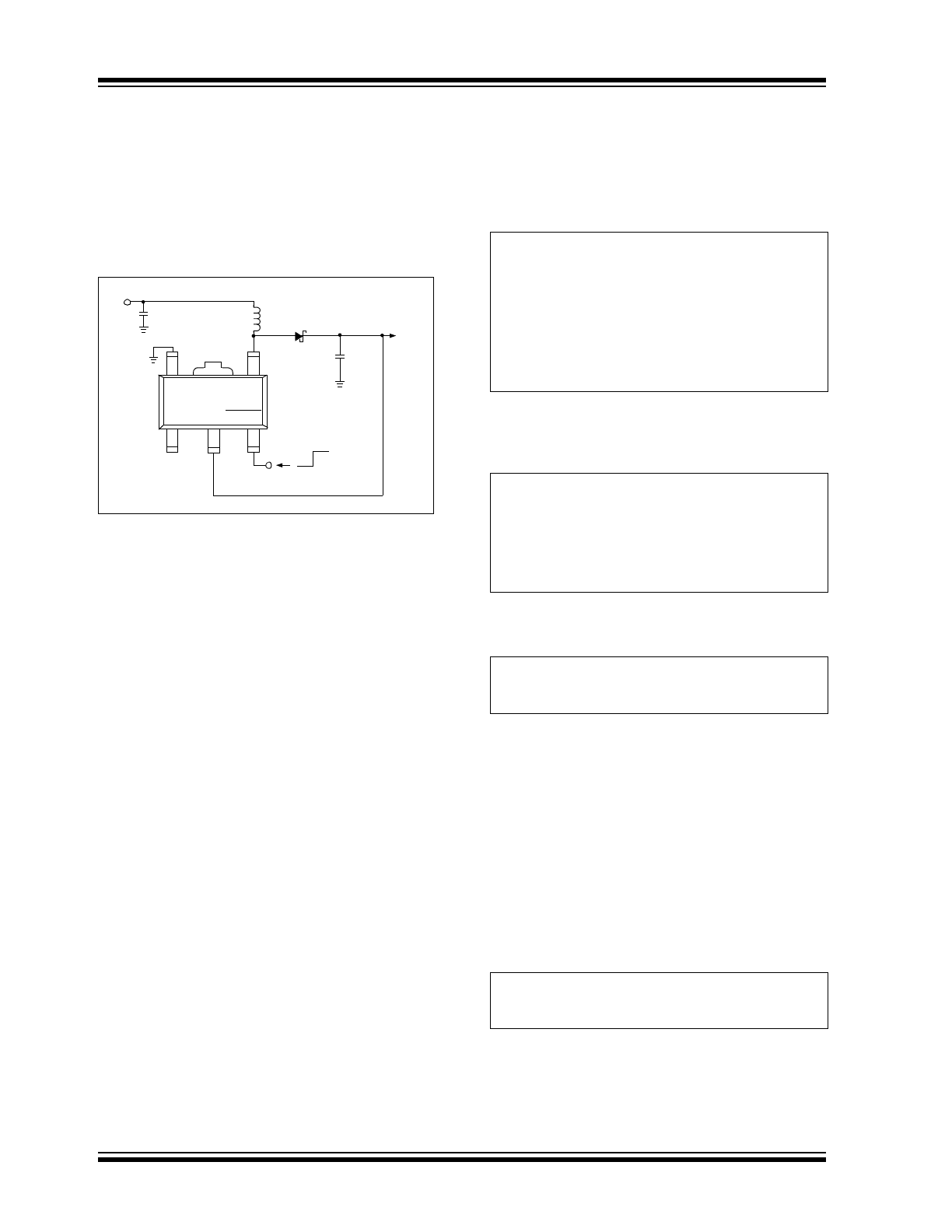

5.0

APPLICATIONS

5.1

Input Bypass Capacitors

Using an input bypass capacitor reduces peak current

transients drawn from the input supply and reduces the

switching noise generated by the regulator. The source

impedance of the input supply determines the size of

the capacitor that should be used.

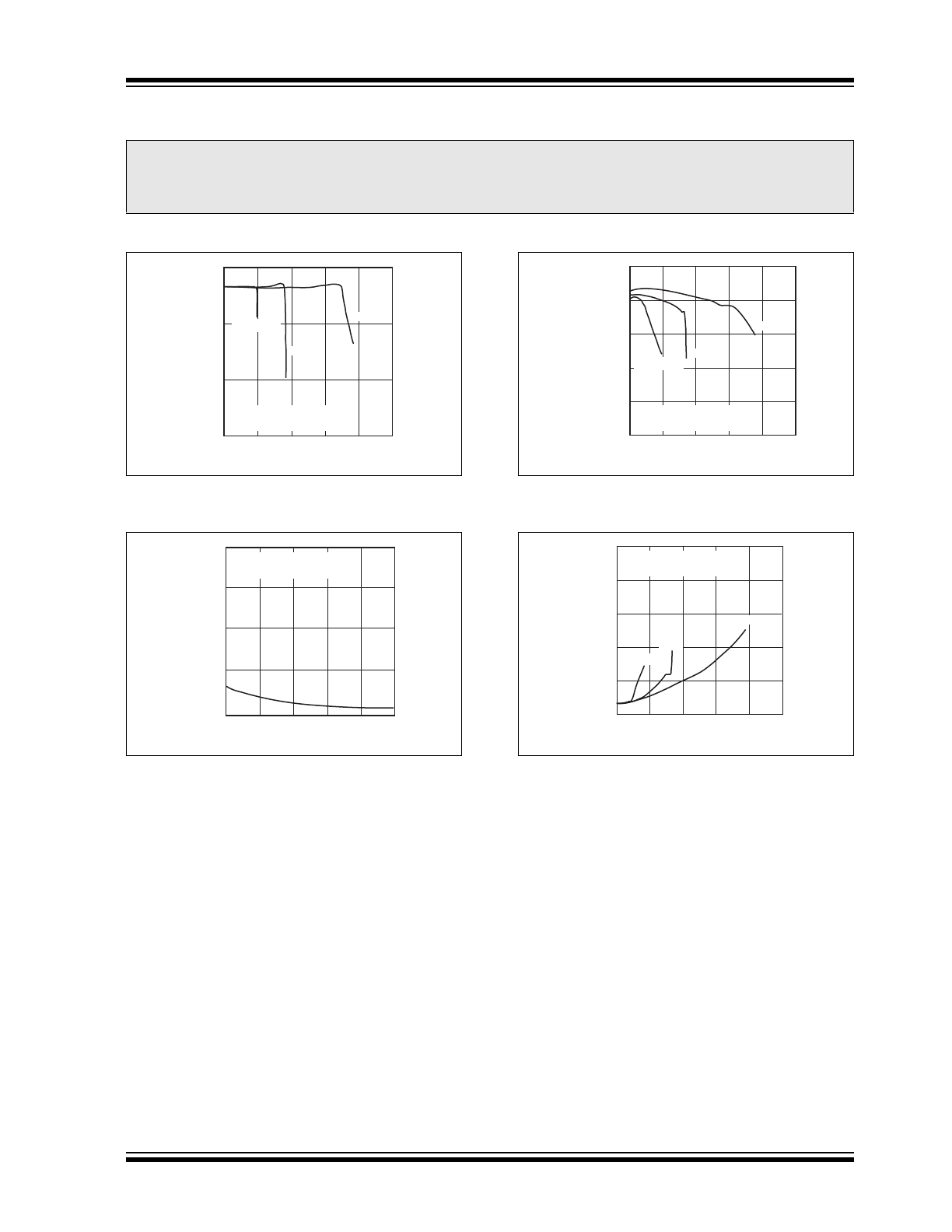

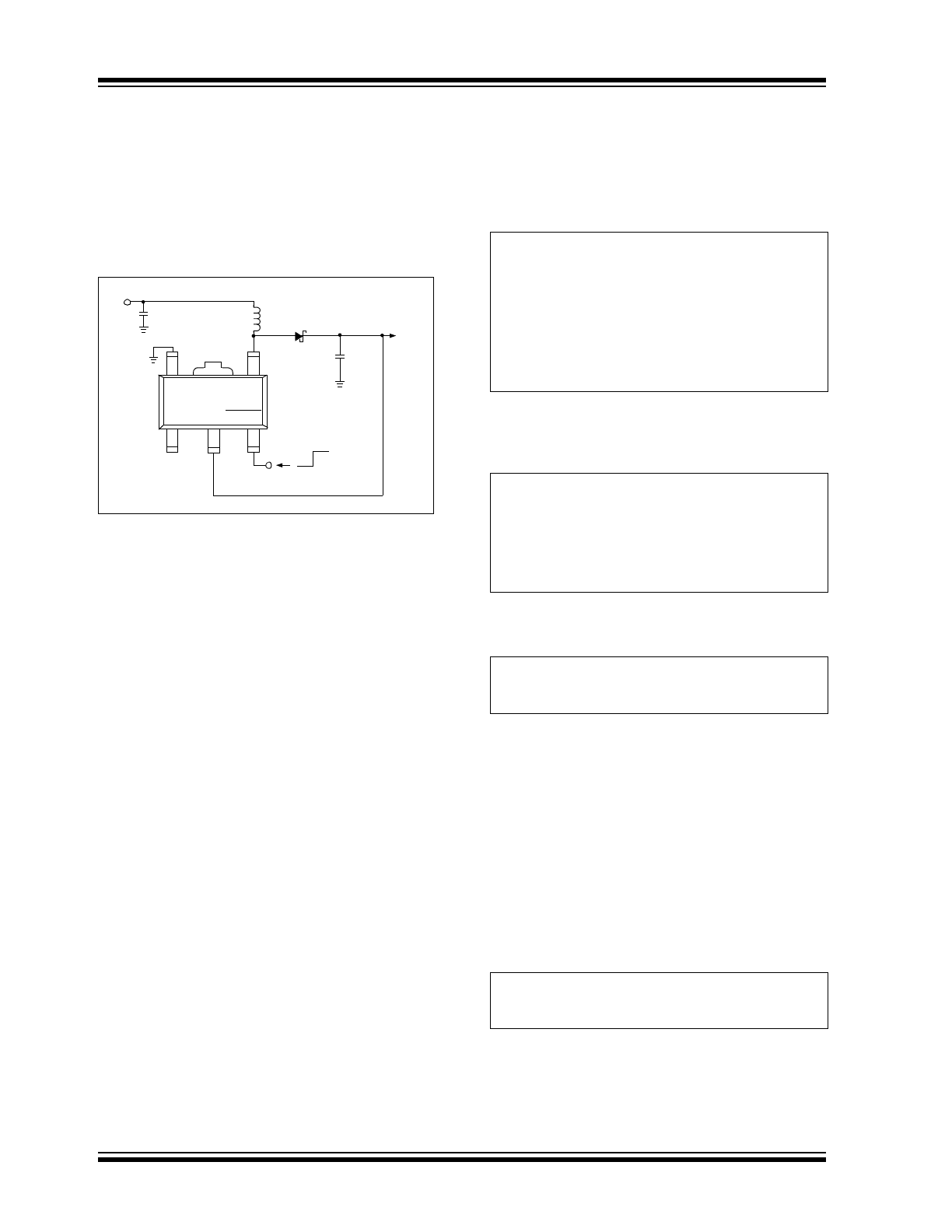

FIGURE 5-1:

TC115 Typical Application.

5.2

Inductor Selection

Selecting the proper inductor value is a trade-off

between physical size and power conversion require-

ments. Lower value inductors cost less, but result in

higher ripple current and core losses. They are also

more prone to saturate since the coil current ramps to

a higher value. Larger inductor values reduce both

ripple current and core losses, but are larger in physical

size and tend to increase the start-up time slightly.

Practical inductor values, therefore, range from 50 µH

to 300 µH. Inductors with a ferrite core (or equivalent)

are recommended. For highest efficiency, use an

inductor with a series resistance less than 0.1

).

The inductor value directly affects the output ripple

voltage. Equation 5-3 is derived as shown below, and

can be used to calculate an inductor value, given the

required output ripple voltage (V

RIPPLE

) and output

capacitor series resistance:

EQUATION 5-1:

Expressing di in terms of switch ON resistance and

time:

EQUATION 5-2:

Solving for L:

EQUATION 5-3:

Care must be taken to ensure the inductor can handle

peak switching currents, which can be several times

load currents. Exceeding rated peak current will result

in core saturation and loss of inductance. The inductor

should be selected to withstand currents greater than

I

PK

(Equation 5-10) without saturating.

Calculating the peak inductor current is straightforward.

Inductor current consists of an AC (sawtooth) current

centered on an average DC current (i.e., input current).

Equation 5-6 calculates the average DC current. Note

that minimum input voltage and maximum load current

values should be used:

EQUATION 5-4:

C

1

L

1

5

4

TC115

1

3

2

SHDN

PS

NC

C

2

D

1

GND

LX

V

OUT

V

IN

OFF ON

(Tie to V

IN

or V

OUT

if not used)

+

+

Where:

ESR: the equivalent series resistance of the

output filter capacitor; V

RIPPLE

is in

volts.

di: represents the peak to peak ripple

current in the inductor.

V

RIPPLE

ESR di

V

RIPPLE

V

IN

V

SW

–

t

ON

L

--------------------------------------------

Where:

V

SW

= voltage drop across the switch.

T

ON

= the amount of time the switch is ON.

L

V

IN

V

SW

–

t

ON

V

R IP PLE

--------------------------------------------

Input Power

Output Power

Efficiency

---------------------------------

=

2002-2012 Microchip Technology Inc.

DS21361D-page 7

TC115

Rewriting in terms of input and output currents and volt-

ages:

EQUATION 5-5:

Solving for input current:

EQUATION 5-6:

The sawtooth current is centered on the DC current

level, swinging equally above and below the DC current

calculated in Equation 5-6. The peak inductor current is

the sum of the DC current plus half the ac current. Note

that minimum input voltage should be used when

calculating the ac inductor current (Equation 5-9).

EQUATION 5-7:

EQUATION 5-8:

EQUATION 5-9:

Combining the DC current calculated in Equation 5-6,

with half the peak ac current calculated in Equation 5-9,

the peak inductor current is given by:

EQUATION 5-10:

5.3

Internal Transistor Switch

The LX pin has a typical ON resistance of 1.4

.

Therefore, peak switch current is given by (V

IN

/1.4).

The internal transistor switch has a maximum design

rating of 350 mA. An oscillator frequency doubling cir-

cuit is an included guard against high switching cur-

rents. Should the voltage on the LX pin rise above 1.3V

(max) while the internal N-channel switch is ON, the

oscillator frequency automatically doubles to minimize

ON time. Although reduced, switch current still flows

because the PWM remains in operation. Therefore, the

LX input is not internally current-limited and care must

be taken never to exceed the 350 mA maximum limit.

Failure to observe this will result in damage to the

regulator.

5.4

Output Capacitor

The effective series resistance of the output capacitor

directly affects the amplitude of the output voltage

ripple (The product of the peak inductor current and the

ESR determines output ripple amplitude). Therefore, a

capacitor with the lowest possible ESR should be

selected. Smaller capacitors are acceptable for light

loads (or in applications where ripple is not a concern).

The Sprague

®

595D series of tantalum capacitors are

among the smallest of all low ESR surface mount

capacitors available. Table 5-1 lists suggested

components and suppliers.

5.5

Board Layout Guidelines

As with all inductive switching regulators, the TC115

generates fast switching waveforms which radiate

noise. Interconnecting lead lengths should be

minimized to keep stray capacitance, trace resistance

and radiated noise as low as possible. In addition, the

GND pin, input bypass capacitor and output filter

capacitor ground leads should be connected to a single

point.

TABLE 5-1:

SUGGESTED COMPONENTS AND SUPPLIERS

V

IN

M IN

I

IN

M A X

V

OUT

MA X

I

OUT

M AX

Efficiency

---------------------------------------------------

=

I

IN

M A X

V

OUT

M A X

I

OUT

MA X

Efficiency

V

IN

M IN

----------------------------------------------------

=

V

L

L di dt

=

di

V

L

di dt

=

di

V

IN

M IN

V

SW

–

t

ON

L

----------------------------------------------

=

Where:

V

SW

= The voltage drop across the internal

N-channel MOSFET.

I

P K

I

IN

M A X

0.5 di

+

=

Type

Inductors

Capacitors

Diodes

Surface Mount

Sumida

®

CD54 Series

CDR125 Series

Coiltronics™

CTX Series

Matsuo

®

267 Series

Sprague

®

595D Series

Nichicon™

F93 Series

Nihon

EC10 Series

Matsushita™

MA735 Series

Through-Hole

Sumida

®

RCH855 Series

RCH110 Series

Renco

®

RL1284-12

Sanyo™

OS-CON Series

Nichicon™

PL Series

ON Semiconductor

®

1N5817 - 1N5822

TC115

DS21361D-page 8

2002-2012 Microchip Technology Inc.

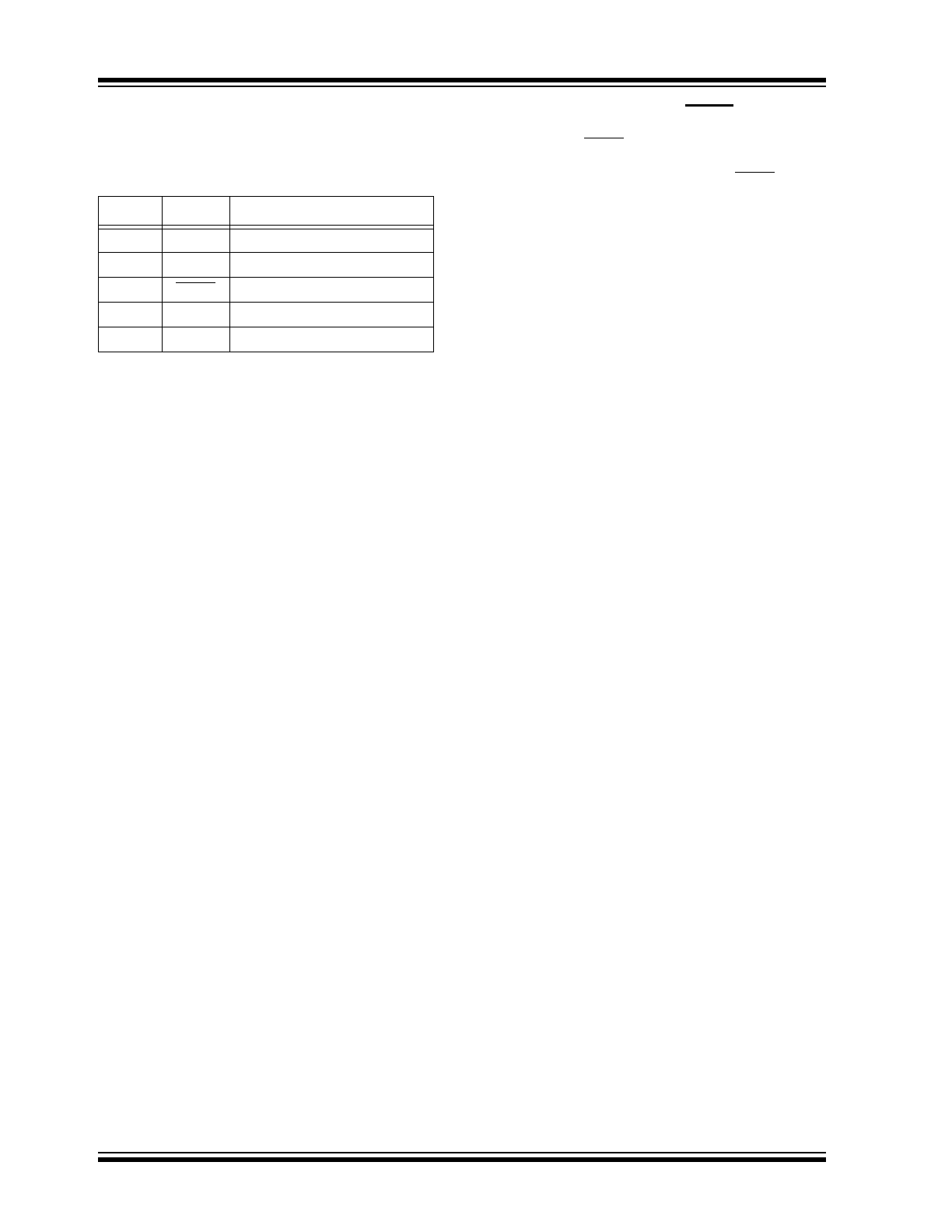

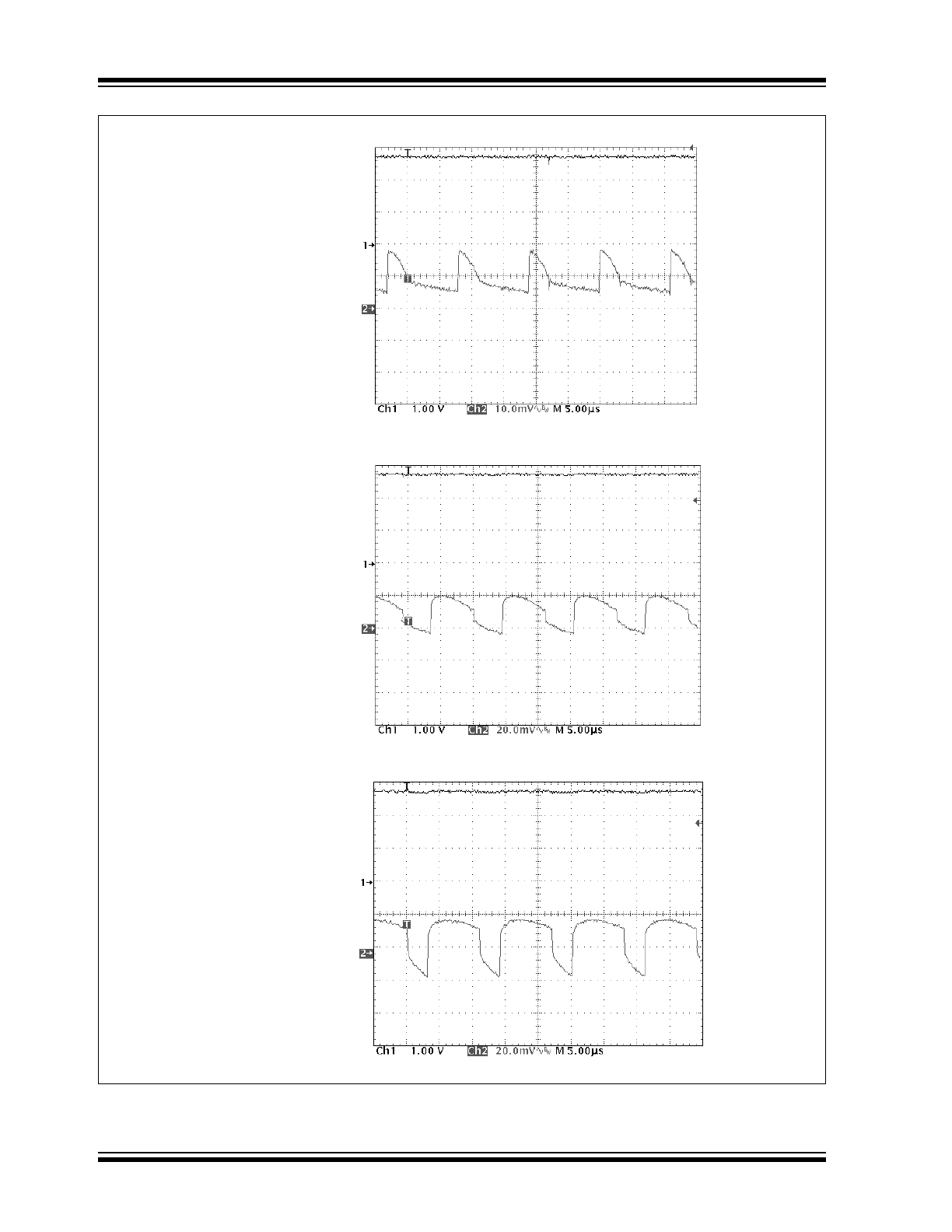

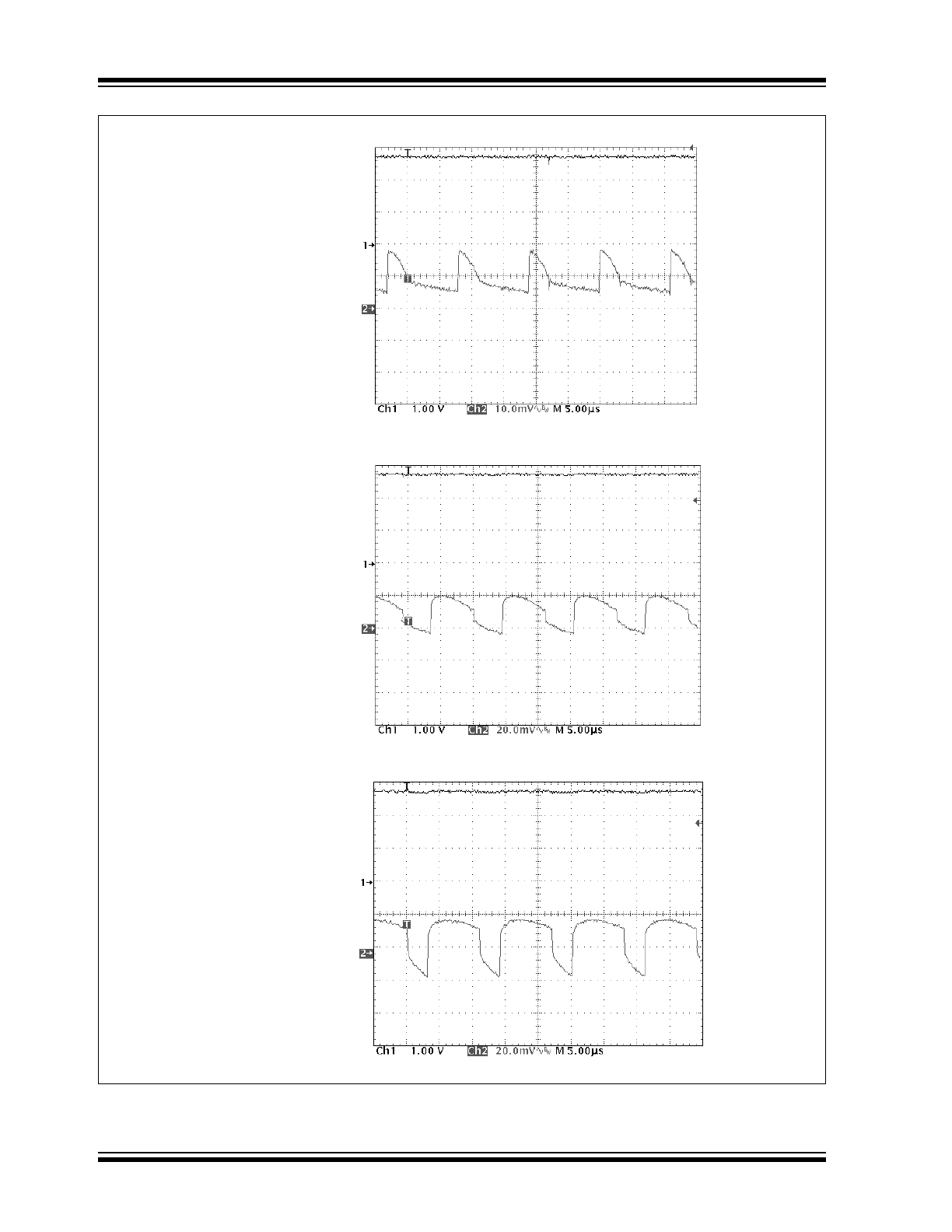

FIGURE 5-2:

Typical Ripple Waveforms.

TC115301

V

IN

= 2.5V

I

LOAD

= 80 mA

CH1: V

OUT

(DC)

CH2: V

OUT

(AC Ripple)

L = 100

µH

C = 47

µF

D1 = MA735

TC115301

V

IN

= 2.0V

I

LOAD

= 40 mA

CH1: V

OUT

(DC)

CH2: V

OUT

(AC Ripple)

L = 100

µH

C = 47

µF

D1 = MA735

TC115301

V

IN

= 1.0V

I

LOAD

= 10 mA

CH1: V

OUT

(DC)

CH2: V

OUT

(AC Ripple)

L = 100

µH

C = 47

µF

D1 = MA735

2002-2012 Microchip Technology Inc.

DS21361D-page 9

TC115

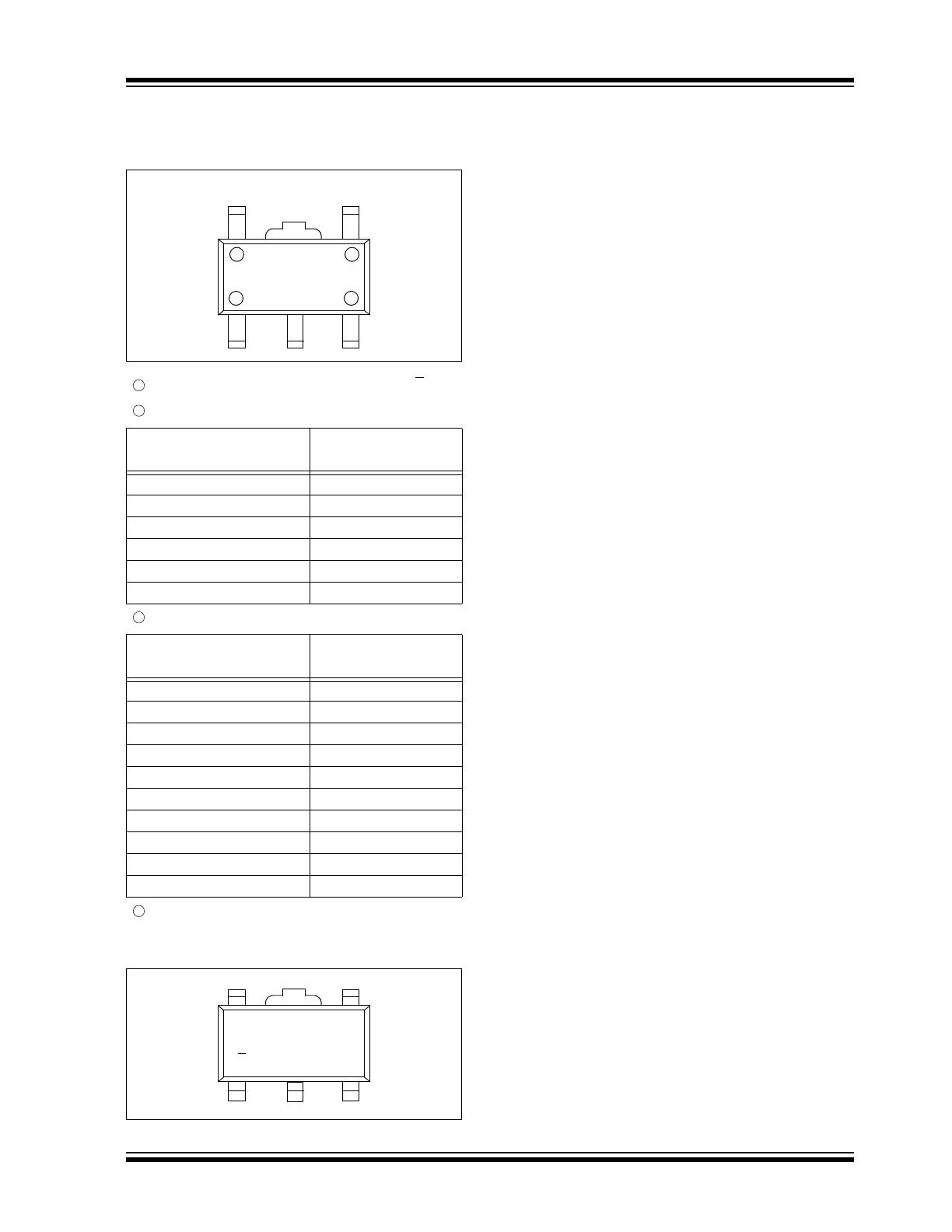

6.0

PACKAGING INFORMATION

6.1

Package Marking Information

Example: For TC115331, the marking code is:

Symbol

(100 kHz)

Voltage

1

1.

2

2.

3

3.

4

4.

5

5.

6

6.

Symbol

(100 kHz)

Voltage

0

.0

1

.1

2

.2

3

.3

4

.4

5

.5

6

.6

7

.7

8

.8

9

.9

5

4

1

3

2

SOT-89-5

4

1

3

2

1

represents product classification; TC115 = 1

2

represents first integer of voltage and frequency

3

represents first decimal of voltage and frequency

4

represents production lot ID code

3

X

1

3

TC115

DS21361D-page 10

2002-2012 Microchip Technology Inc.

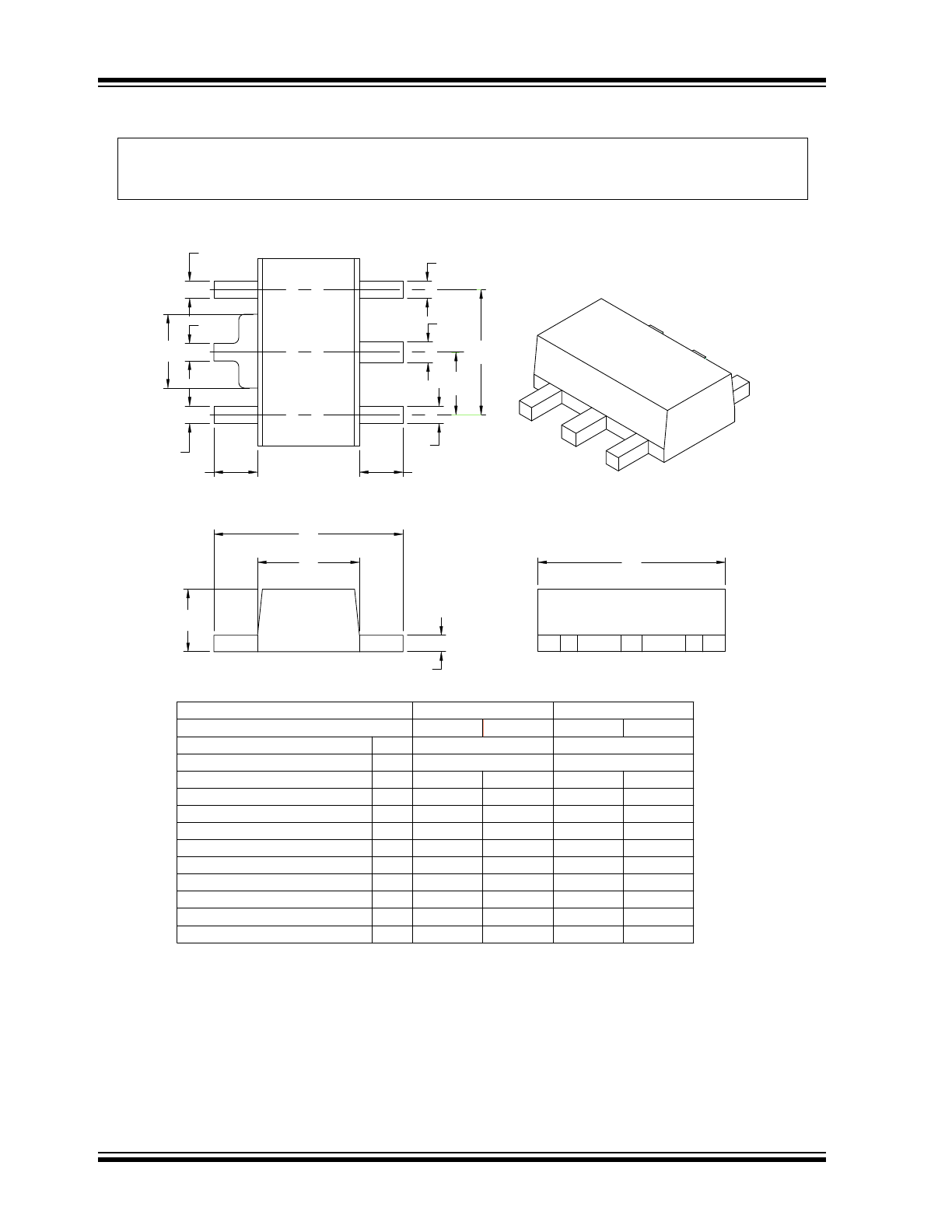

5-Lead Plastic Small Outline Transistor Header (MT) (SOT-89)

0.53

0.41

.021

.016

B

Lead 2 Width

0.44

0.37

.017

.015

c

Lead Thickness

1.80

1.40

.071

.055

D1

Tab Width

4.60

4.40

.181

.173

D

Overall Length

4.50

.177

H

Overall Width

1.60

1.40

.063

.055

A

Overall Height

3.00 BSC

.118 BSC

p1

Outside lead pitch (basic)

1.50 BSC

.059 BSC

p

Pitch

MAX

MIN

MAX

MIN

Dimension Limits

MILLIMETERS*

INCHES

Units

exceed .005" (0.127mm) per side.

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not

Notes:

Drawing No. C04-030

*Controlling Parameter

Foot Length

L

.031

0.80

Leads 1,3, 4 & 5 Width

B1

.014

.019

0.36

0.48

Molded Package Width

E

.090

.102

2.29

2.60

-

-

-

-

Tab Lead Width

B2

.013

.019

0.32

0.48

D1

H

L

B1

B

B1

p

p1

E

C

A

1

2

2

3

L

B1

B1

4

5

B2

D

Note:

For the most current package drawings, please see the Microchip Packaging Specification located

at http://www.microchip.com/packaging

2002-2012 Microchip Technology Inc.

DS21361D-page 1

TC115

Features

• High Efficiency at Low Output Load Currents via

PFM Mode

• Assured Start-up at 0.9V

• 80 µA (Typ) Supply Current

• 85% Typical Efficiency at 100 mA

• 140 mA Typical Output Current @ V

IN

2.0V

• Low Power Shutdown Mode

• No External Switching Transistor Needed

• Space-Saving SOT-89 Package

Applications

• Pagers

• Cellular Phones

• Palmtops

• 1-Cell to 3-Cell Battery Powered Systems

• Cameras, Video Recorders

• Local +3V to +5V Supplies

Package Type

General Description

The TC115 is a high-efficiency step-up DC/DC

converter for small, low input voltage or battery-

powered systems. This device has a start-up voltage

of 0.9V and a typical supply current of 80 µA. Phase

compensation and soft-start circuitry are included on-

chip. Unlike conventional PWM step-up converters,

the TC115 automatically shifts to pulse frequency

modulation (PFM) at low loads, resulting in reduced

supply current and improved efficiency.

The TC115 requires only an external diode, an inductor

and a capacitor, while supporting typical output cur-

rents of 140 mA. Supply current is reduced to less than

0.5 µA (max) when SHDN input is brought low.

Small size, low installed cost and low supply current

make the TC115 step-up converter ideal for use in a

wide range of battery-powered systems.

Functional Block Diagram

5

4

TC115

1

3

2

GND

LX

NC

PS

SHDN

SOT-89-5

PS

1.5V

C

1

10 µF

L

1

100 µH

Sumida

®

CD-54

1.5V to +3V, 50 mA Supply

5

4

TC115

1

3

2

SHDN

PS

NC

C

2

47 µF

Tantalum

IN5817

D

1

GND

LX

+3V

OUT

+

+

+

PS

PFM/PWM Step-Up DC/DC Converter

TC115

DS21361D-page 2

2002-2012 Microchip Technology Inc.

1.0

ELECTRICAL

CHARACTERISTICS

Absolute Maximum Ratings†

Power Supply Voltage (PS) ...............................................12V

Power Dissipation ......................................................500 mW

LX Sink Current......................................................400 mA pk

SHDN Input Voltage ..........................................................12V

Operating Temperature Range........................-40°C to +85°C

Storage Temperature Range .........................-40°C to +125°C

† Stresses above those listed under "Absolute Maximum

Ratings" may cause permanent damage to the device. These

are stress ratings only and functional operation of the device

at these or any other conditions above those indicated in the

operation sections of the specifications is not implied.

Exposure to Absolute Maximum Rating conditions for

extended periods may affect device reliability.

PIN FUNCTION TABLE

DC CHARACTERISTICS

Symbol

Description

NC

Not connected

PS

Power and voltage sense input

SHDN

Shutdown input

LX

Inductor switch output

GND

Ground terminal

Electrical Specifications: Unless otherwise noted, V

OUT

= 5V, T

A

= +25°C. Circuit configuration is illustrated in Figure 5-1.

Parameters

Sym

Min

Typ

Max

Units

Conditions

Operating Supply Voltage

V

IN

0.9

—

10.0

V

Note 5

Start-Up Supply Voltage

V

START

—

—

0.9

V

I

OUT

= 1 mA

LX Maximum Sink Current

I

LX

MAX

—

—

350

mA

LX Limit Frequency

f

LIM

—

200

—

kHz

V

LX

= VLX

LIM

LX Limit Voltage

VLX

LIM

0.7

—

1.3

V

Note 2

No Load Supply Current

I

DD

—

13

26

µA

I

OUT

= 0, V

IN

= V

OUT

x 0.8 (Note 3)

Boost Mode Supply Current

I

CC

—

80

135

µA

No external components,

V

IN

= (0.95 x V

OUT

) applied to PS (or

V

DD

) input

Standby Supply Current

I

STBY

—

9

17

µA

No external components,

V

IN

= (1.1 x V

OUT

) applied to PS

(or V

DD

) input

Shutdown Supply Current

I

SD

—

—

0.5

µA

SHDN = 0V

Oscillator Frequency

f

OSC

85

100

115

kHz

Note 2, Note 4

Output Voltage

V

OUT

V

R

x 0.975

V

R

V

R

x 1.025

V

V

IN

= 2.2V minimum (Note 1)

LX Output ON Resistance

Rswon

—

1.4

2.4

V

LX

= 0.4V

Duty Cycle

(PFM Operating Mode)

PFMDUTY

10

17

25

%

No external components

Maximum Duty Cycle

MAX-

DUTY

80

87

92

%

Note 4

Soft Start Time

t

SS

4

10

20

msec

Efficiency

h

—

85

—

%

SHDN Input Logic High

V

IH

0.75

—

—

V

SHDN Input Logic Low

V

IL

—

—

0.20

V

Note

1:

V

R

is the nominal factory-programmed output voltage setting.

2:

VLX

LIM

is the voltage on the LX pin (with internal switch ON) that will cause the oscillator to run at twice nominal

frequency in to limit the switch current through the internal N-channel switching transistor.

3:

Measured with D

1

= MA735 (reverse current < 1 µA at a reverse voltage of 10V).

4:

With TC115 operating in PWM mode.

5:

See Section 4.4, “Behavior When V

IN

is Greater Than the Factory-Programmed V

OUT

Setting”.

2002-2012 Microchip Technology Inc.

DS21361D-page 3

TC115

2.0

TYPICAL PERFORMANCE CURVES

Note: Unless otherwise indicated, V

OUT

= 5V, T

A

= +25°C.

FIGURE 2-1:

Output Voltage vs. Output

Current.

FIGURE 2-2:

No Load Input Current vs.

Input Voltage.

FIGURE 2-3:

Efficiency vs. Output

Current.

FIGURE 2-4:

Ripple Voltage vs. Output

Current.

Note:

The graphs and tables provided following this note are a statistical summary based on a limited number of

samples and are provided for informational purposes only. The performance characteristics listed herein

are not tested or guaranteed. In some graphs or tables, the data presented may be outside the specified

operating range (e.g., outside specified power supply range) and therefore outside the warranted range.

OUTPUT CURRENT I

OUT

(mA)

OUTPUT VOLTAGE V

OUT

(V)

0

40

80

120

160

200

3.1

2.9

2.7

2.5

1.5V

V

IN

= 1.0V

L

1

= 100

µH

C2 = 47

µF (Tantalum)

2.0V

1.0

1.2

1.4

1.6

1.8

2.0

INPUT VOLTAGE V

IN

(V)

200

INPUT CURRENT I

IN

(

µ

A) 150

100

50

0

L

1 = 100

µH

C2 = 47

µF (Tantalum)

OUTPUT CURRENT I

OUT

(mA)

EFFICIENCY (%)

0

40

80

120

160

200

100

80

60

40

20

0

V

IN

= 1.0V

1.5V

2.0V

L

1 = 100

µH

C2 = 47

µF (Tantalum)

OUTPUT CURRENT I

OUT

(mA)

RIPPLE VOLTAGE Vr(mVp-p)

0

40

80

120

160

200

100

80

60

40

10

0

L

1 = 100

µH

C2 = 47

µF (Tantalum)

2.0V

1.5V

V

IN

= 1.0V

TC115

DS21361D-page 4

2002-2012 Microchip Technology Inc.

3.0

PIN DESCRIPTIONS

The descriptions of the pins are listed in Table 3-1.

TABLE 3-1:

PIN FUNCTION TABLE

3.1

Power and Voltage Sense Input

(PS)

PS is a dual function input that provides both feedback

voltage sensing and internal chip power. It should be

connected to the regulator output (See Section 5.0,

“Applications”).

3.2

Shutdown Input (SHDN)

A logic-low on SHDN suspends device operation and

supply current is reduced to less than 0.5 µA. The

device resumes normal operation when SHDN is again

brought high.

3.3

Inductor Switch Output (LX)

LX is the drain of an internal N-channel switching tran-

sistor. This terminal drives the external inductor, which

ultimately provides current to the load.

3.4

Ground Terminal (GND)

Connect to circuit ground.

3.5

No Connect (NC)

No internal connection.

Pin No.

Symbol

Description

1

NC

Not connected

2

PS

Power and voltage sense input

3

SHDN

Shutdown input

4

LX

Inductor switch output

5

GND

Ground terminal

2002-2012 Microchip Technology Inc.

DS21361D-page 5

TC115

4.0

DETAILED DESCRIPTION

The TC115 is a combination PFM/PWM step-up

(boost) regulator. It is particularly useful in battery-pow-

ered 1, 2 and 3 cell applications where the required out-

put current is 140 mA or less, and size/cost issues are

a concern. The device operates in PWM mode when

the output load is sufficient to demand a 10% (or

greater) duty cycle. While in PWM mode, the TC115

behaves as any other PWM switching regulator to a

maximum duty cycle of 92%. At low output loads (i.e.,

output loads requiring < 10% duty cycle to support), the

TC115 automatically switches to pulse frequency mod-

ulation (PFM) operating mode with a fixed duty cycle of

25% (max) (17%, typical). While in PFM mode, the

inductor is modulated with individual fixed width pulses

only as needed to maintain output voltage. This action

reduces supply current, thereby improving power

efficiency at low output loads.

4.1

Input Power and Sensing

The TC115 is powered from the PS input, which must

be connected to the regulated output, as shown in

Figure 5-1. PS also senses output voltage for closed-

loop regulation. Start-up current is furnished through

the inductor when input voltage is initially applied. This

action starts the oscillator, causing the voltage at the

PS input to rise, bootstrapping the regulator into full

operation.

4.2

Output Diode

For best results, use a Schottky diode, such as the

MA735, 1N5817, EC10 or equivalent. Connect the

diode between the PS and LX pins as close to the IC as

possible. While ultra fast diodes can be used, lower effi-

ciency will result due to their higher forward voltage

drop. Ordinary rectifiers should be avoided because of

their slow recovery characteristics.

4.3

Low Power Shutdown Mode

The TC115 enters a low power shutdown mode when

SHDN is brought low. While in shutdown, the oscillator

is disabled and the internal switch is shut off. Normal

regulator operation resumes when SHDN is brought

high. SHDN may be tied to the input supply if not used.

4.4

Behavior When V

IN

is Greater

Than the Factory-Programmed

V

OUT

Setting

The TC115 is designed to operate as a step-up

regulator only. As such, V

IN

is assumed to always be

less than the factory-programmed V

OUT

setting (V

R

).

Operating the TC115 with V

IN

> V

R

causes regulating

action to be suspended (and corresponding supply

current reduction to 9 µA, typical) until V

IN

is again less

than V

R

. While regulating action is suspended, V

IN

is

connected to V

OUT

through the series combination of

the inductor and Schottky diode. Care must be taken to

add the appropriate isolation (MOSFET output switch

or post LDO with shutdown) during system design if

this V

IN

/V

OUT

leakage path is problematic.

Note:

Because the TC115 uses an external

diode, a leakage path between the input

voltage and the output node (through the

inductor and diode) exists while the regu-

lator is in shutdown. Care must be taken in

system design to assure the input supply

is isolated from the load during shutdown.

TC115

DS21361D-page 6

2002-2012 Microchip Technology Inc.

5.0

APPLICATIONS

5.1

Input Bypass Capacitors

Using an input bypass capacitor reduces peak current

transients drawn from the input supply and reduces the

switching noise generated by the regulator. The source

impedance of the input supply determines the size of

the capacitor that should be used.

FIGURE 5-1:

TC115 Typical Application.

5.2

Inductor Selection

Selecting the proper inductor value is a trade-off

between physical size and power conversion require-

ments. Lower value inductors cost less, but result in

higher ripple current and core losses. They are also

more prone to saturate since the coil current ramps to

a higher value. Larger inductor values reduce both

ripple current and core losses, but are larger in physical

size and tend to increase the start-up time slightly.

Practical inductor values, therefore, range from 50 µH

to 300 µH. Inductors with a ferrite core (or equivalent)

are recommended. For highest efficiency, use an

inductor with a series resistance less than 0.1

).

The inductor value directly affects the output ripple

voltage. Equation 5-3 is derived as shown below, and

can be used to calculate an inductor value, given the

required output ripple voltage (V

RIPPLE

) and output

capacitor series resistance:

EQUATION 5-1:

Expressing di in terms of switch ON resistance and

time:

EQUATION 5-2:

Solving for L:

EQUATION 5-3:

Care must be taken to ensure the inductor can handle

peak switching currents, which can be several times

load currents. Exceeding rated peak current will result

in core saturation and loss of inductance. The inductor

should be selected to withstand currents greater than

I

PK

(Equation 5-10) without saturating.

Calculating the peak inductor current is straightforward.

Inductor current consists of an AC (sawtooth) current

centered on an average DC current (i.e., input current).

Equation 5-6 calculates the average DC current. Note

that minimum input voltage and maximum load current

values should be used:

EQUATION 5-4:

C

1

L

1

5

4

TC115

1

3

2

SHDN

PS

NC

C

2

D

1

GND

LX

V

OUT

V

IN

OFF ON

(Tie to V

IN

or V

OUT

if not used)

+

+

Where:

ESR: the equivalent series resistance of the

output filter capacitor; V

RIPPLE

is in

volts.

di: represents the peak to peak ripple

current in the inductor.

V

RIPPLE

ESR di

V

RIPPLE

V

IN

V

SW

–

t

ON

L

--------------------------------------------

Where:

V

SW

= voltage drop across the switch.

T

ON

= the amount of time the switch is ON.

L

V

IN

V

SW

–

t

ON

V

R IP PLE

--------------------------------------------

Input Power

Output Power

Efficiency

---------------------------------

=

2002-2012 Microchip Technology Inc.

DS21361D-page 7

TC115

Rewriting in terms of input and output currents and volt-

ages:

EQUATION 5-5:

Solving for input current:

EQUATION 5-6:

The sawtooth current is centered on the DC current

level, swinging equally above and below the DC current

calculated in Equation 5-6. The peak inductor current is

the sum of the DC current plus half the ac current. Note

that minimum input voltage should be used when

calculating the ac inductor current (Equation 5-9).

EQUATION 5-7:

EQUATION 5-8:

EQUATION 5-9:

Combining the DC current calculated in Equation 5-6,

with half the peak ac current calculated in Equation 5-9,

the peak inductor current is given by:

EQUATION 5-10:

5.3

Internal Transistor Switch

The LX pin has a typical ON resistance of 1.4

.

Therefore, peak switch current is given by (V

IN

/1.4).

The internal transistor switch has a maximum design

rating of 350 mA. An oscillator frequency doubling cir-

cuit is an included guard against high switching cur-

rents. Should the voltage on the LX pin rise above 1.3V

(max) while the internal N-channel switch is ON, the

oscillator frequency automatically doubles to minimize

ON time. Although reduced, switch current still flows

because the PWM remains in operation. Therefore, the

LX input is not internally current-limited and care must

be taken never to exceed the 350 mA maximum limit.

Failure to observe this will result in damage to the

regulator.

5.4

Output Capacitor

The effective series resistance of the output capacitor

directly affects the amplitude of the output voltage

ripple (The product of the peak inductor current and the

ESR determines output ripple amplitude). Therefore, a

capacitor with the lowest possible ESR should be

selected. Smaller capacitors are acceptable for light

loads (or in applications where ripple is not a concern).

The Sprague

®

595D series of tantalum capacitors are

among the smallest of all low ESR surface mount

capacitors available. Table 5-1 lists suggested

components and suppliers.

5.5

Board Layout Guidelines

As with all inductive switching regulators, the TC115

generates fast switching waveforms which radiate

noise. Interconnecting lead lengths should be

minimized to keep stray capacitance, trace resistance

and radiated noise as low as possible. In addition, the

GND pin, input bypass capacitor and output filter

capacitor ground leads should be connected to a single

point.

TABLE 5-1:

SUGGESTED COMPONENTS AND SUPPLIERS

V

IN

M IN

I

IN

M A X

V

OUT

MA X

I

OUT

M AX

Efficiency

---------------------------------------------------

=

I

IN

M A X

V

OUT

M A X

I

OUT

MA X

Efficiency

V

IN

M IN

----------------------------------------------------

=

V

L

L di dt

=

di

V

L

di dt

=

di

V

IN

M IN

V

SW

–

t

ON

L

----------------------------------------------

=

Where:

V

SW

= The voltage drop across the internal

N-channel MOSFET.

I

P K

I

IN

M A X

0.5 di

+

=

Type

Inductors

Capacitors

Diodes

Surface Mount

Sumida

®

CD54 Series

CDR125 Series

Coiltronics™

CTX Series

Matsuo

®

267 Series

Sprague

®

595D Series

Nichicon™

F93 Series

Nihon

EC10 Series

Matsushita™

MA735 Series

Through-Hole

Sumida

®

RCH855 Series

RCH110 Series

Renco

®

RL1284-12

Sanyo™

OS-CON Series

Nichicon™

PL Series

ON Semiconductor

®

1N5817 - 1N5822

TC115

DS21361D-page 8

2002-2012 Microchip Technology Inc.

FIGURE 5-2:

Typical Ripple Waveforms.

TC115301

V

IN

= 2.5V

I

LOAD

= 80 mA

CH1: V

OUT

(DC)

CH2: V

OUT

(AC Ripple)

L = 100

µH

C = 47

µF

D1 = MA735

TC115301

V

IN

= 2.0V

I

LOAD

= 40 mA

CH1: V

OUT

(DC)

CH2: V

OUT

(AC Ripple)

L = 100

µH

C = 47

µF

D1 = MA735

TC115301

V

IN

= 1.0V

I

LOAD

= 10 mA

CH1: V

OUT

(DC)

CH2: V

OUT

(AC Ripple)

L = 100

µH

C = 47

µF

D1 = MA735

2002-2012 Microchip Technology Inc.

DS21361D-page 9

TC115

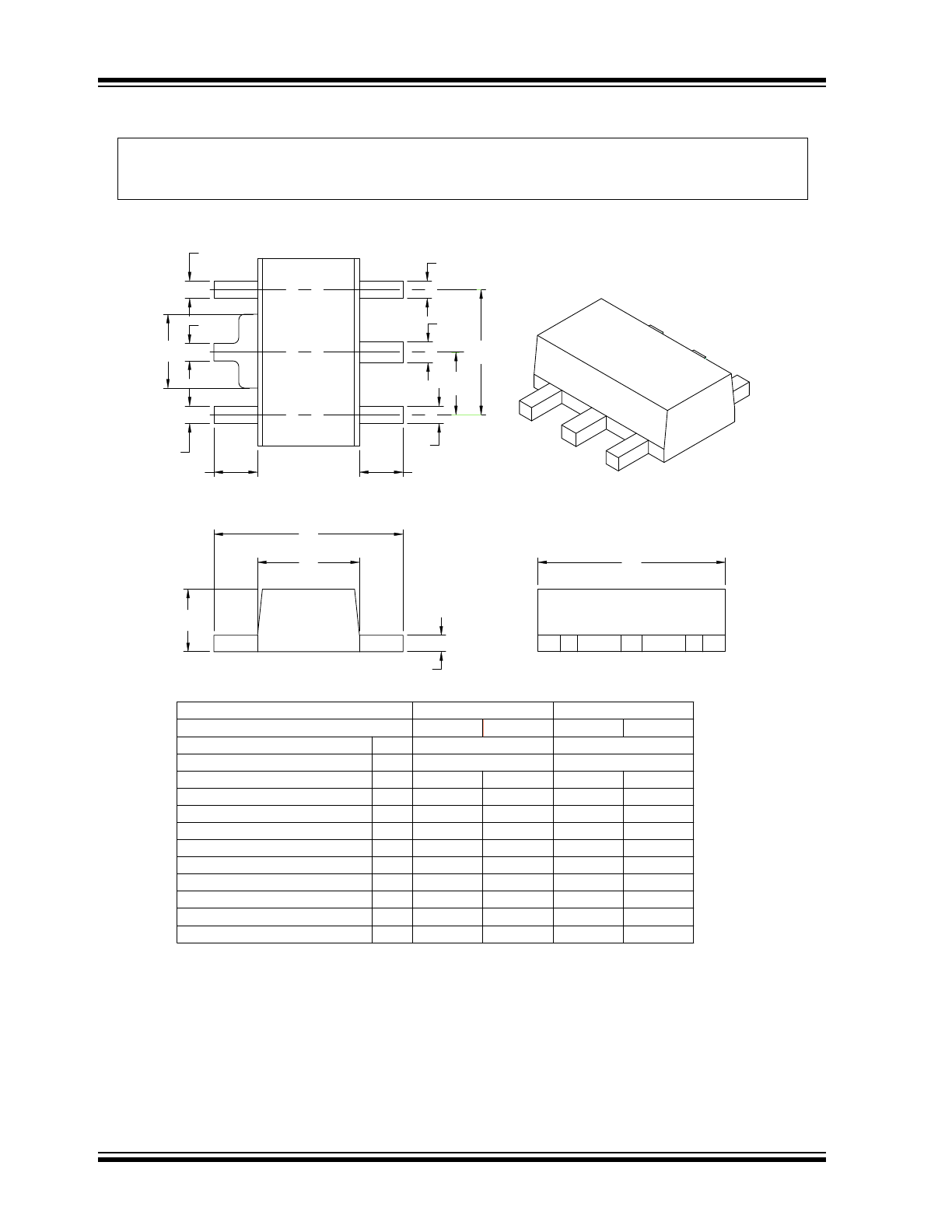

6.0

PACKAGING INFORMATION

6.1

Package Marking Information

Example: For TC115331, the marking code is:

Symbol

(100 kHz)

Voltage

1

1.

2

2.

3

3.

4

4.

5

5.

6

6.

Symbol

(100 kHz)

Voltage

0

.0

1

.1

2

.2

3

.3

4

.4

5

.5

6

.6

7

.7

8

.8

9

.9

5

4

1

3

2

SOT-89-5

4

1

3

2

1

represents product classification; TC115 = 1

2

represents first integer of voltage and frequency

3

represents first decimal of voltage and frequency

4

represents production lot ID code

3

X

1

3

TC115

DS21361D-page 10

2002-2012 Microchip Technology Inc.

5-Lead Plastic Small Outline Transistor Header (MT) (SOT-89)

0.53

0.41

.021

.016

B

Lead 2 Width

0.44

0.37

.017

.015

c

Lead Thickness

1.80

1.40

.071

.055

D1

Tab Width

4.60

4.40

.181

.173

D

Overall Length

4.50

.177

H

Overall Width

1.60

1.40

.063

.055

A

Overall Height

3.00 BSC

.118 BSC

p1

Outside lead pitch (basic)

1.50 BSC

.059 BSC

p

Pitch

MAX

MIN

MAX

MIN

Dimension Limits

MILLIMETERS*

INCHES

Units

exceed .005" (0.127mm) per side.

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not

Notes:

Drawing No. C04-030

*Controlling Parameter

Foot Length

L

.031

0.80

Leads 1,3, 4 & 5 Width

B1

.014

.019

0.36

0.48

Molded Package Width

E

.090

.102

2.29

2.60

-

-

-

-

Tab Lead Width

B2

.013

.019

0.32

0.48

D1

H

L

B1

B

B1

p

p1

E

C

A

1

2

2

3

L

B1

B1

4

5

B2

D

Note:

For the most current package drawings, please see the Microchip Packaging Specification located

at http://www.microchip.com/packaging