512 Kbit / 1 Mbit / 2 Mbit / 4 Mbit 1.8V SPI Serial Flash

SST25WF512 / SST25WF010 / SST25WF020 / SST25WF040

©2014 Silicon Storage Technology, Inc.

DS20005016C

11/14

EOL Data Sheet

www.microchip.com

Features

• Single Voltage Read and Write Operations

– 1.65-1.95V

• Serial Interface Architecture

– SPI Compatible: Mode 0 and Mode 3

• High Speed Clock Frequency

– 40MHz

• Superior Reliability

– Endurance: 100,000 Cycles

– Greater than 100 years Data Retention

• Ultra-Low Power Consumption:

– Active Read Current: 2 mA (typical @ 20MHz)

– Standby Current: 2 µA (typical)

• Flexible Erase Capability

– Uniform 4 KByte sectors

– Uniform 32 KByte overlay blocks

– Uniform 64 KByte overlay blocks

(2 Mbit and 4 Mbit only)

• Fast Erase and Byte-Program:

– Chip-Erase Time: 125 ms (typical)

– Sector-/Block-Erase Time: 62ms (typical)

– Byte-Program Time: 50 µS (typical)

• Auto Address Increment (AAI) Programming

– Decrease total chip programming time over Byte-Pro-

gram operations

• End-of-Write Detection

– Software polling the BUSY bit in Status Register

– Busy Status readout on SO pin

• Reset Pin (RST#) or Programmable Hold Pin

(HOLD#) option

– Hardware Reset pin as default

– Hold pin option to suspend a serial sequence without

deselecting the device

• Write Protection (WP#)

– Enables/Disables the Lock-Down function of the status

register

• Software Write Protection

– Write protection through Block-Protection bits in status

register

• Temperature Range

– Industrial: -40°C to +85°C

• Packages Available

– 8-lead SOIC (150 mils)

– 8-contact WSON (5mm x 6mm)

• All devices are RoHS compliant

SST25WF512 / SST25WF010 / SST25WF020 / SST25WF040 are members of

the Serial Flash 25 Series family and feature a four-wire, SPI-compatible interface

that allows for a low pin-count package which occupies less board space and ulti-

mately lowers total system costs. SPI serial flash memory is manufactured with

SST proprietary, high performance CMOS SuperFlash technology. The split-gate

cell design and thick-oxide tunneling injector attain better reliability and manufac-

turability compared with alternate approaches.

Obsolete Device

Please contact Microchip Sales for replacement information.

©2014 Silicon Storage Technology, Inc.

DS20005016C

11/14

2

512 Kbit / 1 Mbit / 2 Mbit / 4 Mbit 1.8V SPI Serial Flash

SST25WF512 / SST25WF010 / SST25WF020 / SST25WF040

EOL Data Sheet

Product Description

The SST25WF512, SST25WF010, SST25WF020, and SST25WF040 are members of the Serial Flash

25 Series family and feature a four-wire, SPI-compatible interface that allows for a low pin-count pack-

age which occupies less board space and ultimately lowers total system costs. SST25WF512/010/

020/040 SPI serial flash memories are manufactured with SST proprietary, high-performance CMOS

SuperFlash technology. The split-gate cell design and thick-oxide tunneling injector attain better reli-

ability and manufacturability compared with alternate approaches.

The SST25WF512/010/020/040 devices significantly improve performance and reliability, while lower-

ing power consumption. The devices write (Program or Erase) with a single power supply of 1.65-

1.95V for SST25WF512/010/020/040. The total energy consumed is a function of the applied voltage,

current, and time of application. Since for any given voltage range, the SuperFlash technology uses

less current to program and has a shorter erase time, the total energy consumed during any Erase or

Program operation is less than alternative flash memory technologies.

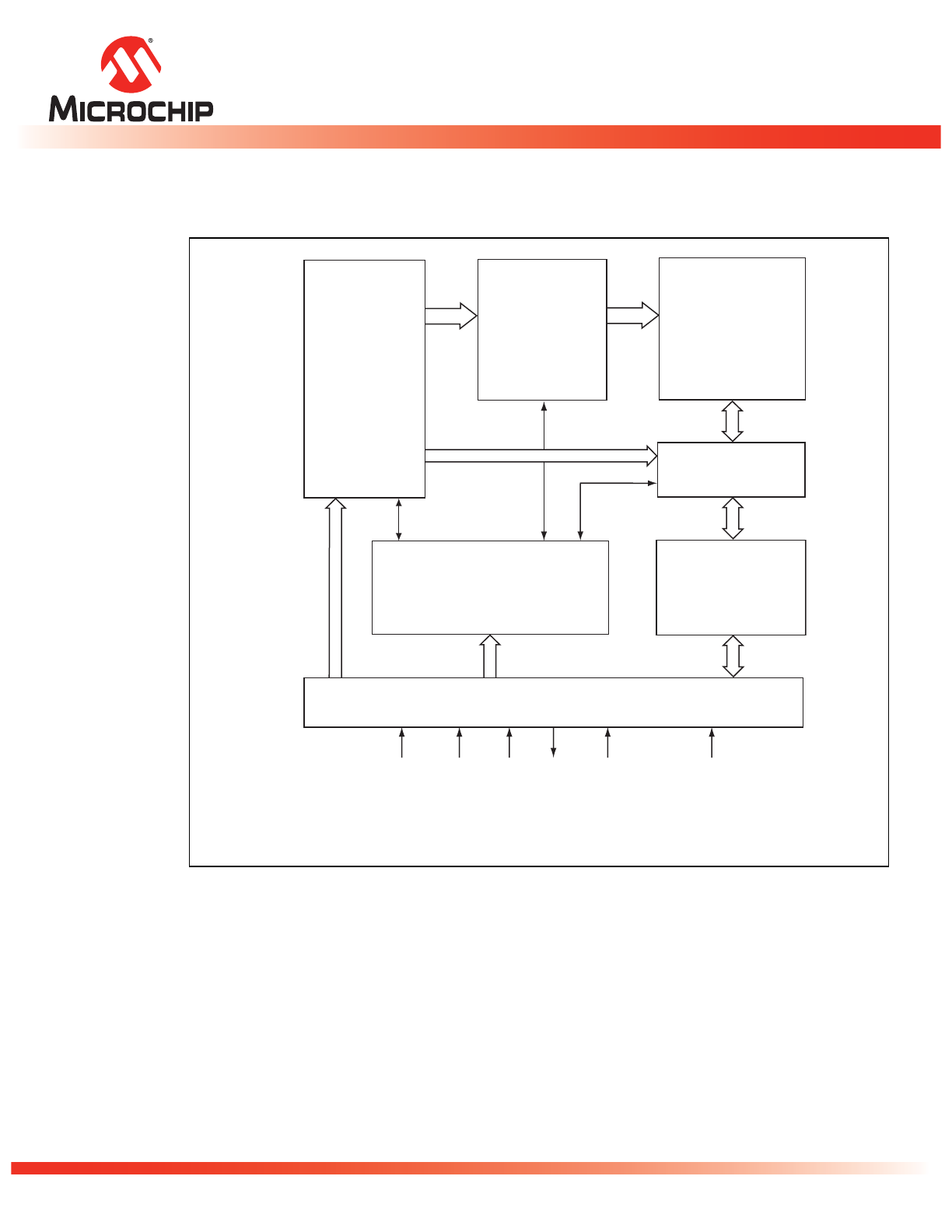

The SST25WF512/010/020/040 devices are offered in both 8-lead SOIC and an 8-contact WSON

packages. See Figure 2 for the pin assignment.

©2014 Silicon Storage Technology, Inc.

DS20005016C

11/14

3

512 Kbit / 1 Mbit / 2 Mbit / 4 Mbit 1.8V SPI Serial Flash

SST25WF512 / SST25WF010 / SST25WF020 / SST25WF040

EOL Data Sheet

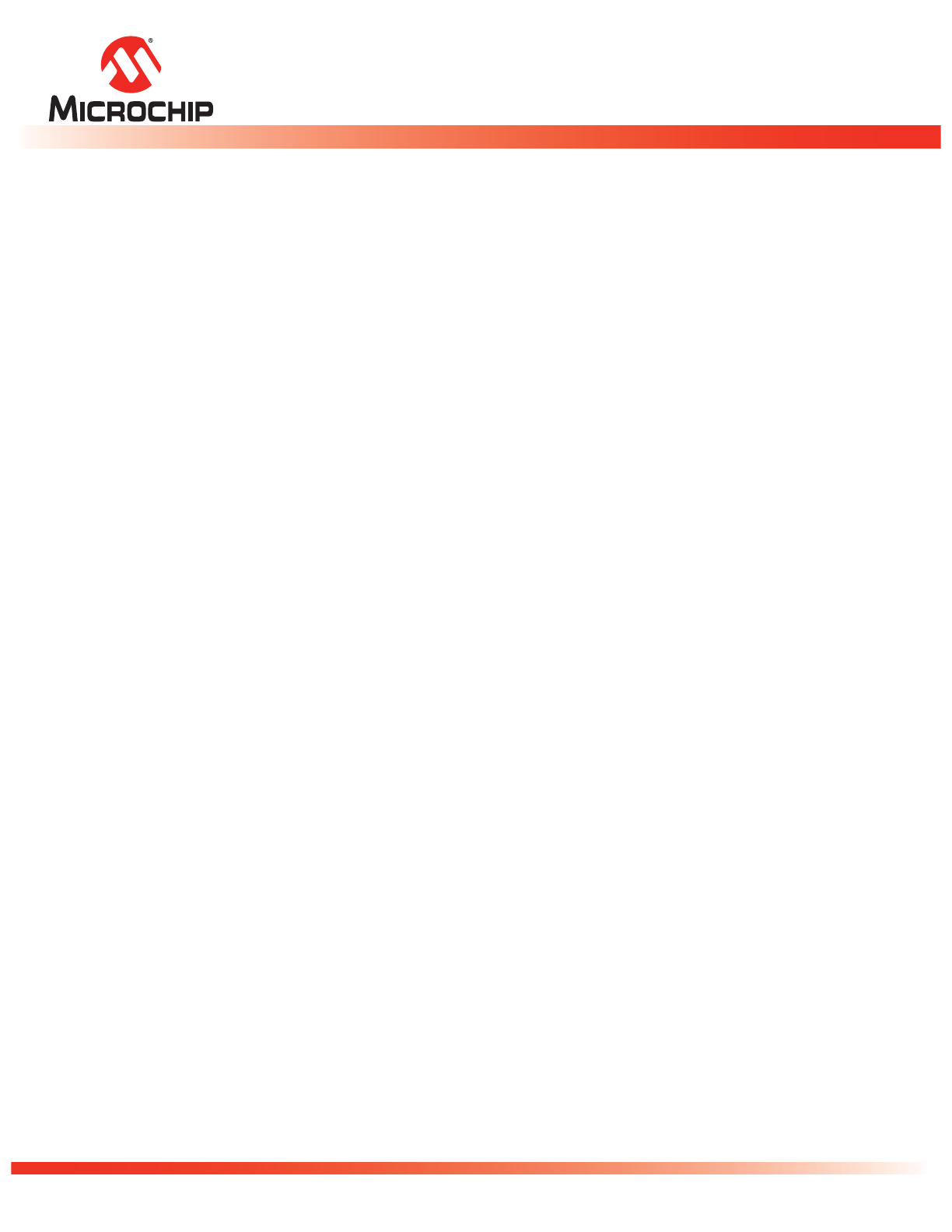

Block Diagram

Figure 1: Functional Block Diagram

1328 F01.0

I/O Buffers

and

Data Latches

SuperFlash

Memory

X - Decoder

Control Logic

Address

Buffers

and

Latches

CE#

Y - Decoder

SCK

SI

SO

WP#

RST#/HOLD#

Serial Interface

Note: In AAI mode, the SO pin functions as an RY/BY# pin when configured as a ready/

busy status pin. See “End-of-Write Detection” on page 16. for more information.

©2014 Silicon Storage Technology, Inc.

DS20005016C

11/14

4

512 Kbit / 1 Mbit / 2 Mbit / 4 Mbit 1.8V SPI Serial Flash

SST25WF512 / SST25WF010 / SST25WF020 / SST25WF040

EOL Data Sheet

Pin Description

Figure 2: Pin Assignment for 8-Lead SOIC and 8-Contact WSON

Table 1: Pin Description

Symbol

Pin Name

Functions

SCK

Serial Clock

To provide the timing of the serial interface.

Commands, addresses, or input data are latched on the rising edge of the

clock input, while output data is shifted out on the falling edge of the clock

input.

SI

Serial Data Input

To transfer commands, addresses, or data serially into the device.

Inputs are latched on the rising edge of the serial clock.

SO

Serial Data Output To transfer data serially out of the device.

Data is shifted out on the falling edge of the serial clock.

Flash busy status pin in AAI mode if SO is configured as a hardware RY/BY#

pin. See “End-of-Write Detection” on page 16. for more information.

CE#

Chip Enable

The device is enabled by a high to low transition on CE#. CE# must remain

low for the duration of any command sequence.

WP#

Write Protect

The Write Protect (WP#) pin is used to enable/disable BPL bit in the status

register.

RST#/

HOLD#

Reset

To reset the operation of the device and the internal logic. The device powers

on with RST# pin functionality as default.

Hold

To temporarily stop serial communication with SPI Flash memory while

device is selected. This is selected by an instruction sequence which is

detailed in “Reset/Hold Mode” on page 6.

V

DD

Power Supply

To provide power supply voltage: 1.65-1.95V for SST25WF512/010/020/040

V

SS

Ground

T1.0 20005016

1

2

3

4

8

7

6

5

CE#

SO

WP#

V

SS

V

DD

RST#/HOLD#

SCK

SI

Top View

1328.25WF 08-soic-P0.0

1

2

3

4

8

7

6

5

CE#

SO

WP#

VSS

Top View

VDD

RST#/HOLD#

SCK

SI

1328 08-wson P2.0

8-Lead SOIC

8-Contact WSON

©2014 Silicon Storage Technology, Inc.

DS20005016C

11/14

5

512 Kbit / 1 Mbit / 2 Mbit / 4 Mbit 1.8V SPI Serial Flash

SST25WF512 / SST25WF010 / SST25WF020 / SST25WF040

EOL Data Sheet

Memory Organization

The SST25WF512/010/020/040 SuperFlash memory arrays are organized in uniform 4 KByte with 16

KByte, 32 KByte, and 64 KByte (2 Mbit and 4 Mbit Only) overlay erasable blocks.

Device Operation

The SST25WF512/010/020/040 are accessed through the SPI (Serial Peripheral Interface) bus com-

patible protocol. The SPI bus consist of four control lines; Chip Enable (CE#) is used to select the

device, and data is accessed through the Serial Data Input (SI), Serial Data Output (SO), and Serial

Clock (SCK).

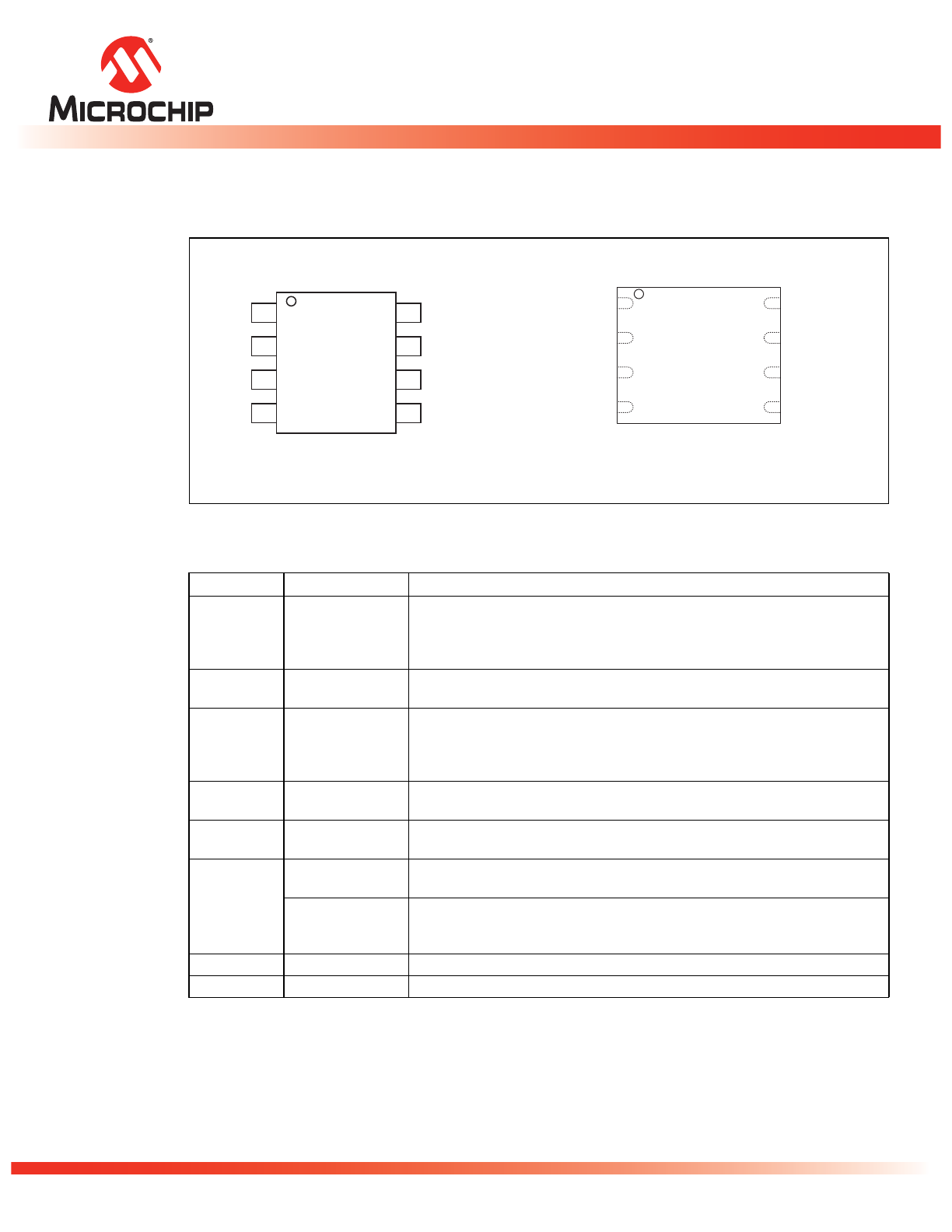

The SST25WF512/010/020/040 support both Mode 0 (0,0) and Mode 3 (1,1) of SPI bus operations.

The difference between the two modes, as shown in Figure 3, is the state of the SCK signal when the

bus master is in Stand-by mode and no data is being transferred. The SCK signal is low for Mode 0

and SCK signal is high for Mode 3. For both modes, the Serial Data In (SI) is sampled at the rising

edge of the SCK clock signal and the Serial Data Output (SO) is driven after the falling edge of the

SCK clock signal.

Figure 3: SPI Protocol

1328 F03.0

MODE 3

SCK

SI

SO

CE#

MODE 3

DON T CARE

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

MODE 0

MODE 0

HIGH IMPEDANCE

MSB

MSB

©2014 Silicon Storage Technology, Inc.

DS20005016C

11/14

6

512 Kbit / 1 Mbit / 2 Mbit / 4 Mbit 1.8V SPI Serial Flash

SST25WF512 / SST25WF010 / SST25WF020 / SST25WF040

EOL Data Sheet

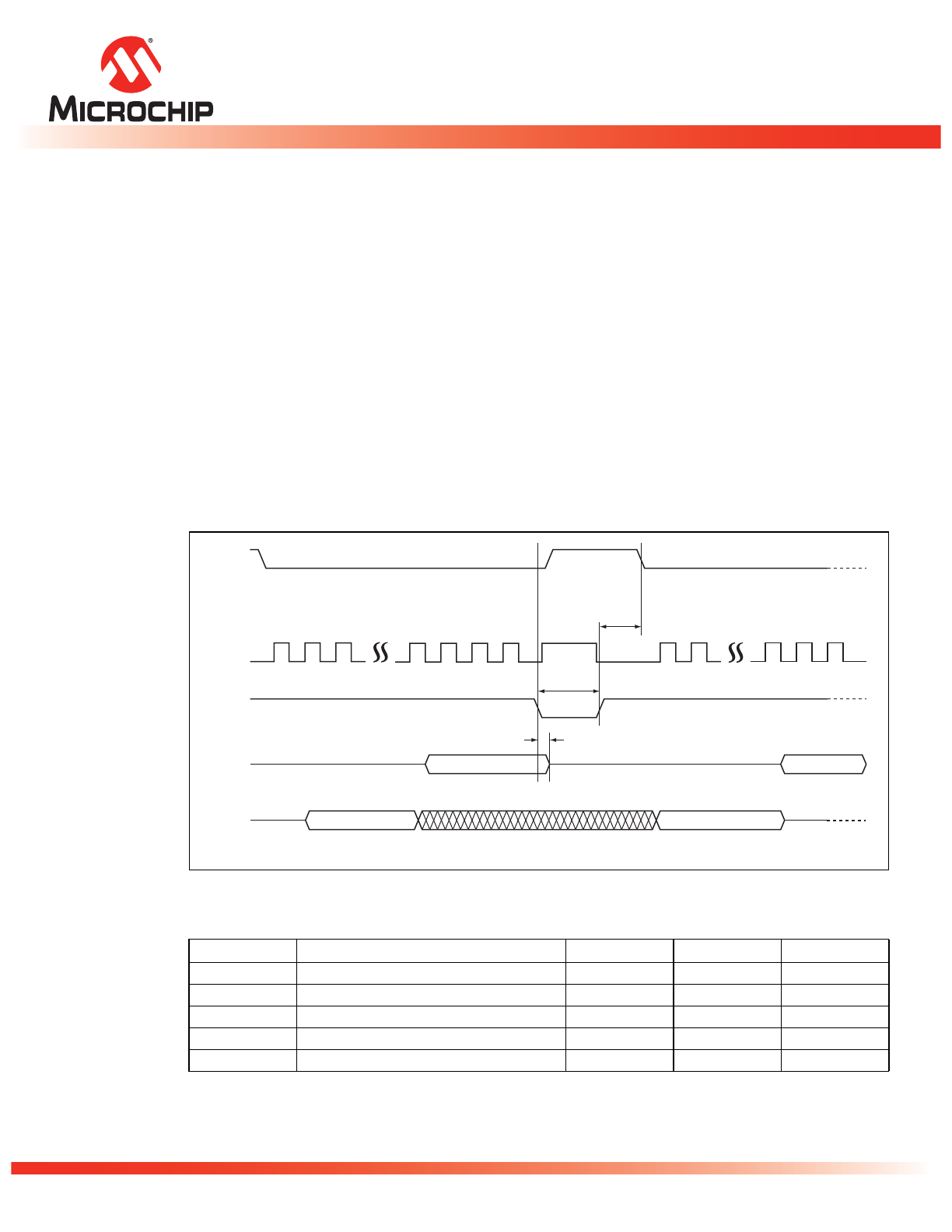

Reset/Hold Mode

The RST#/HOLD# pin provides either a hardware reset or a hold pin. From power-on, the RST#/

HOLD# pin defaults as a hardware reset pin (RST#). The Hold mode for this pin is a user selected

option where an Enable-Hold instruction enables the Hold mode. Once selected as a hold pin

(HOLD#), the RST#/HOLD# pin will be configured as a HOLD# pin, and goes back to RST# pin only

after a power-off and power-on sequence.

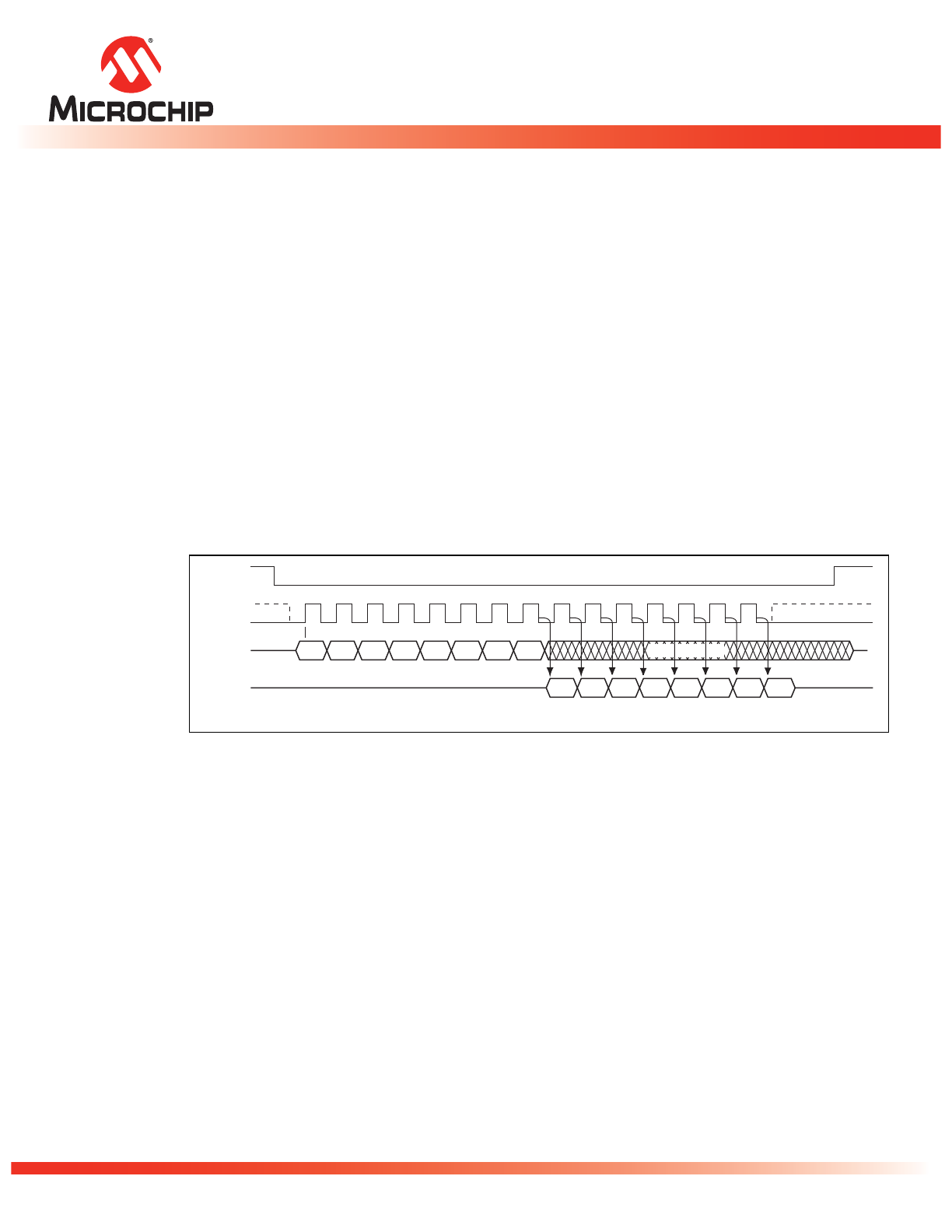

Reset

If the RST#/HOLD# pin is used as a reset pin, RST# pin provides a hardware method for resetting the

device. Driving the RST# pin high puts the device in normal operating mode. The RST# pin must be

driven low for a minimum of T

RST

time to reset the device. The SO pin is in high impedance state while

the device is in reset. A successful reset will reset the status register to its power-up state. See Table 4

for default power-up modes. A device reset during an active Program or Erase operation aborts the

operation and data of the targeted address range may be corrupted or lost due to the aborted erase or

program operation. The device exits AAI Programming Mode in progress and places the SO pin in high

impedance state.

Figure 4: Reset Timing Diagram

Table 2: Reset Timing Parameters

Symbol

Parameter

Min

Max

Units

T

RST

Reset Pulse Width

100

ns

T

RHZ

Reset to High-Z Output

107

ns

T

RECR

Reset Recovery from Read

100

ns

T

RECP

Reset Recovery from Program

10

µs

T

RECE

Reset Recovery from Erase

1

ms

T2.20005016

1328 Fx4.0

CE#

SO

SI

SCK

RST#

T

RECR

T

RECP

T

RECE

T

RST

T

RHZ

©2014 Silicon Storage Technology, Inc.

DS20005016C

11/14

7

512 Kbit / 1 Mbit / 2 Mbit / 4 Mbit 1.8V SPI Serial Flash

SST25WF512 / SST25WF010 / SST25WF020 / SST25WF040

EOL Data Sheet

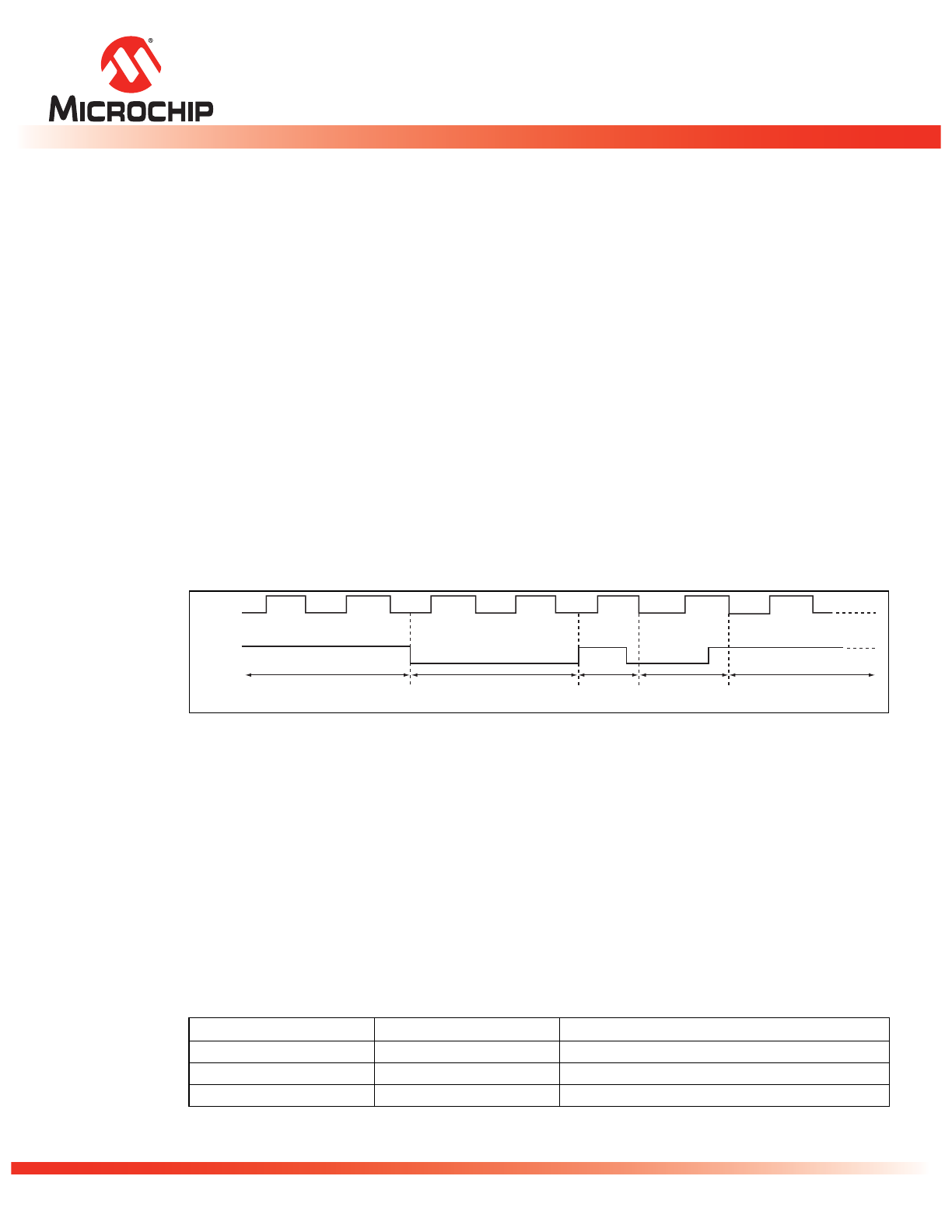

Hold

The Hold operation enables the hold pin functionality of the RST#/HOLD# pin. Once set to hold pin

mode, the RST#/HOLD# pin continues functioning as a hold pin until the device is powered off and

then powered on. After a power-off and power-on, the pin functionality returns to a reset pin (RST#)

mode. See “Enable-Hold (EHLD)” on page 22 for detailed timing of the Hold instruction.

In the hold mode, serial sequences underway with the SPI Flash memory are paused without resetting

the clocking sequence. To activate the HOLD# mode, CE# must be in active low state. The HOLD#

mode begins when the SCK active low state coincides with the falling edge of the HOLD# signal. The

Hold mode ends when the rising edge of the HOLD# signal coincides with the SCK active low state. If

the falling edge of the HOLD# signal does not coincide with the SCK active low state, then the device

enters Hold mode when the SCK next reaches the active low state. Similarly, if the rising edge of the

HOLD# signal does not coincide with the SCK active low state, then the device exits Hold mode when

the SCK next reaches the active low state. See Figure 5 for Hold Condition waveform.

Once the device enters Hold mode, SO will be in high-impedance state while SI and SCK can be V

IL

or V

IH.

If CE# is driven active high during a Hold condition, the device returns to standby mode. The device

can then be re-initiated with the command sequences listed in Tables 9 and 10. As long as HOLD# sig-

nal is low, the memory remains in the Hold condition. To resume communication with the device,

HOLD# must be driven active high, and CE# must be driven active low. See Figure 5 for Hold timing.

Figure 5: Hold Condition Waveform

Write Protection

SST25WF512/010/020/040 provide software Write protection. The Write Protect pin (WP#) enables or

disables the lock-down function of the status register. The Block-Protection bits (BP2, BP1, BP0, and

BPL) in the status register provide Write protection to the memory array and the status register. See

Table 5 for the Block-Protection description.

Write Protect Pin (WP#)

The Write Protect (WP#) pin enables the lock-down function of the BPL bit (bit 7) in the status register.

When WP# is driven low, the execution of the Write-Status-Register (WRSR) instruction is determined by

the value of the BPL bit (see Table 3). When WP# is high, the lock-down function of the BPL bit is disabled.

Table 3: Conditions to execute Write-Status-Register (WRSR) Instruction

WP#

BPL

Execute WRSR Instruction

L

1

Not Allowed

L

0

Allowed

H

X

Allowed

T3.0 20005016

Active

Hold

Active

Hold

Active

1328 Fx5.0

SCK

HOLD#

©2014 Silicon Storage Technology, Inc.

DS20005016C

11/14

8

512 Kbit / 1 Mbit / 2 Mbit / 4 Mbit 1.8V SPI Serial Flash

SST25WF512 / SST25WF010 / SST25WF020 / SST25WF040

EOL Data Sheet

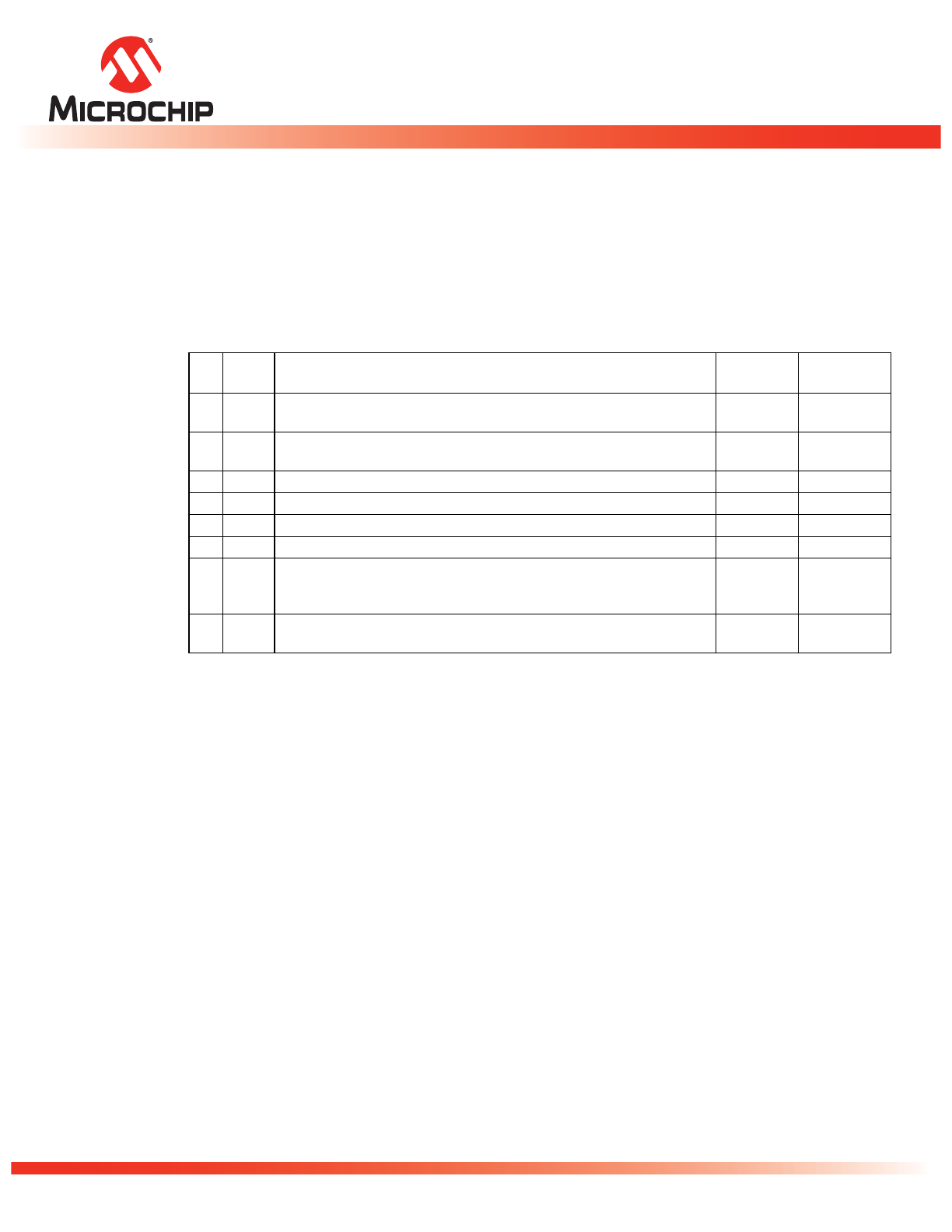

Status Register

The software status register provides status on whether the flash memory array is available for any

Read or Write operation, whether the device is Write enabled, and the state of the Memory Write pro-

tection. During an internal Erase or Program operation, the status register may be read only to deter-

mine the completion of an operation in progress. Table 4 describes the function of each bit in the

software status register.

Busy

The Busy bit determines whether there is an internal Erase or Program operation in progress. A ‘1’ for

the Busy bit indicates the device is busy with an operation in progress. A ‘0’ indicates the device is

ready for the next valid operation.

Write Enable Latch (WEL)

The Write-Enable-Latch bit indicates the status of the internal Write-Enable-Latch memory. If the WEL

bit is set to ‘1’, it indicates the device is Write enabled. If the bit is set to ‘0’ (reset), it indicates the

device is not Write enabled and does not accept any Write (Program/Erase) commands. The Write-

Enable-Latch bit is automatically reset under the following conditions:

•

Device Reset

•

Power-up

•

Write-Disable (WRDI) instruction completion

•

Byte-Program instruction completion

•

Auto Address Increment (AAI) programming is completed or reached its highest unpro-

tected memory address

•

Sector-Erase instruction completion

•

Block-Erase instruction completion

•

Chip-Erase instruction completion

•

Write-Status-Register instructions

Table 4: Software Status Register

Bit

Name

Function

Default at

Power-up

Read/Write

0

BUSY

1 = Internal Write operation is in progress

0 = No internal Write operation is in progress

0

R

1

WEL

1 = Device is memory Write enabled

0 = Device is not memory Write enabled

0

R

2

BP0

Indicate current level of block write protection (See Tables 5 through 8)

1

R/W

3

BP1

Indicate current level of block write protection (See Tables 5 through 8)

1

R/W

4

BP2

Indicate current level of block write protection (See Tables 5 through 8)

1

R/W

5

RES

Reserved for future use

0

N/A

6

AAI

Auto Address Increment Programming status

1 = AAI programming mode

0 = Byte-Program mode

0

R

7

BPL

1 = BP1 and BP0 are read-only bits

0 = BP1 and BP0 are read/writable

0

R/W

T4.1 20005016

©2014 Silicon Storage Technology, Inc.

DS20005016C

11/14

9

512 Kbit / 1 Mbit / 2 Mbit / 4 Mbit 1.8V SPI Serial Flash

SST25WF512 / SST25WF010 / SST25WF020 / SST25WF040

EOL Data Sheet

Auto Address Increment (AAI)

The Auto Address Increment Programming-Status bit provides status on whether the device is in AAI

programming mode or Byte-Program mode. The default at power up is Byte-Program mode.

Block-Protection (BP2, BP1, BP0)

The Block-Protection (BP1, BP0) bits define the size of the memory area to be software protected

against any memory Write (Program or Erase) operation, see Tables 5-7. The Write-Status-Register

(WRSR) instruction is used to program the BP1 and BP0 bits as long as WP# is high or the Block-Pro-

tect-Lock (BPL) bit is ‘0’. Chip-Erase can only be executed if Block-Protection bits are all ‘0’. After

power-up, BP2, BP1, and BP0 are set to defaults. See Table 4 for defaults at power-up.

Block Protection Lock-Down (BPL)

When the WP# pin is driven low (V

IL

), it enables the Block-Protection-Lock-Down (BPL) bit. When BPL is

set to ‘1’, it prevents any further alteration of the BPL, BP1, and BP0 bits. When the WP# pin is driven high

(V

IH

), the BPL bit has no effect and its value is ‘Don’t Care’. After power-up, the BPL bit is reset to ‘0’.

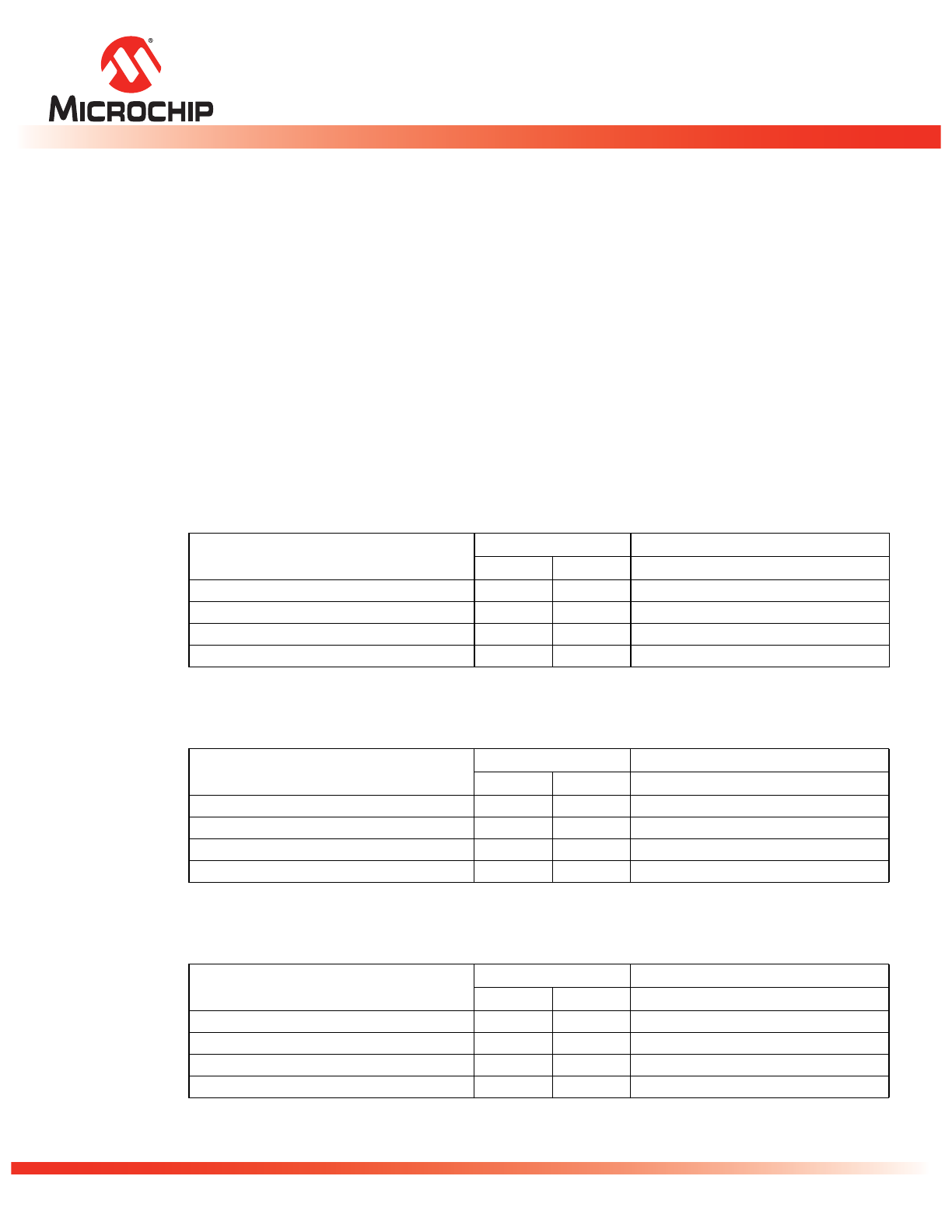

Table 5: Software Status Register Block Protection for SST25WF512

Protection Level

Status Register Bit

Protected Memory Address

BP1

1

1. Default at power-up for BP1 and BP0 is ‘11’.

BP0

512 Kbit

None

0

0

None

1 (Upper Quarter Memory)

0

1

00C000H-00FFFFH

2 (Upper Half Memory)

1

0

008000H-00FFFFH

3 (Full Memory)

1

1

000000H-00FFFFH

T5.1 20005016

Table 6: Software Status Register Block Protection for SST25WF010

Protection Level

Status Register Bit

Protected Memory Address

BP1

1

1. Default at power-up for BP1 and BP0 is ‘11’.

BP0

1 Mbit

None

0

0

None

1 (Upper Quarter Memory)

0

1

018000H-01FFFFH

2 (Upper Half Memory)

1

0

010000H-01FFFFH

3 (Full Memory)

1

1

000000H-01FFFFH

T6.0 20005016

Table 7: Software Status Register Block Protection for SST25WF020

Protection Level

Status Register Bit

Protected Memory Address

BP1

1

1. Default at power-up for BP1 and BP0 is ‘11’.

BP0

2 Mbit

None

0

0

None

1 (Upper Quarter Memory)

0

1

030000H-03FFFFH

2 (Upper Half Memory)

1

0

020000H-03FFFFH

3 (Full Memory)

1

1

000000H-03FFFFH

T7.0 20005016

©2014 Silicon Storage Technology, Inc.

DS20005016C

11/14

10

512 Kbit / 1 Mbit / 2 Mbit / 4 Mbit 1.8V SPI Serial Flash

SST25WF512 / SST25WF010 / SST25WF020 / SST25WF040

EOL Data Sheet

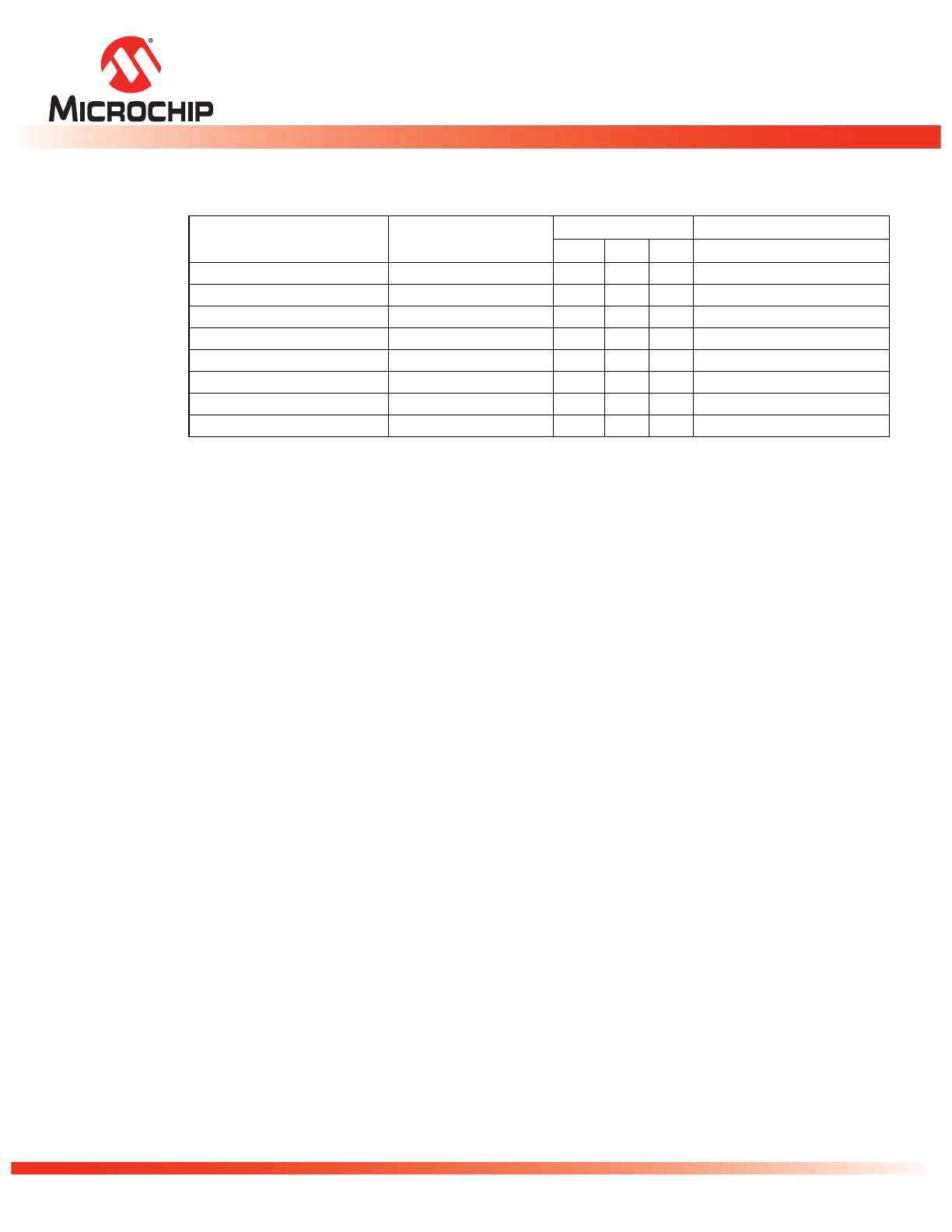

Table 8: Software Status Register Block Protection for SST25WF040

Protection Level

Protected Blocks

Status Register Bit

Protected Memory Address

BP2

1

1. Default at power-up for BP2, BP1, and BP0 is ‘11’.

BP1

BP0

4 Mbit

None

None

0

0

0

None

1 (Upper Eighth Memory)

Blocks 14 through 15

0

0

1

70000H-7FFFFH

2 (Upper Quarter Memory)

Blocks 12 through 15

0

1

0

60000H-7FFFFH

3 (Upper Half Memory)

Blocks 8 through 15

0

1

1

40000H-7FFFFH

4 (Full Memory)

Blocks 0 through 15

1

0

0

00000H-7FFFFH

5 (Full Memory)

Blocks 0 through 15

1

0

1

00000H-7FFFFH

6 (Full Memory)

Blocks 0 through 15

1

1

0

00000H-7FFFFH

7 (Full Memory)

Blocks 0 through 15

1

1

1

00000H-7FFFFH

T8.0 20005016