CAUTION: These devices are sensitive to electrostatic discharge. Users should follow proper I.C. Handling Procedures.

Copyright

©

Harris Corporation 1994

1

S E M I C O N D U C T O R

Description

The Harris HIP7010, J1850 Byte Level Interface Circuit, is a

member of the Harris family of low-cost multiplexed wiring

ICs. The integrated functions of the HIP7010 provide the

system designer with components key to building a “Class

B” multiplexed communications network interface, which

fully conforms to the VPW Multiplexed Wiring protocol

specified in the SAE J1850 Standard. The HIP7010 is

designed to interface with a wide variety of Host

microcontrollers via a standard three wire, high-speed

(1MHz), synchronous, serial interface. The HIP7010

automatically produces properly framed VPW messages,

appending the Start of Frame (SOF) symbol and calculating

and appending the CRC check byte. All circuitry needed to

decode incoming messages, to validate CRC bytes, and to

detect Breaks, End of Data (EOD), Idle bus, and illegal

symbols is included. In-Frame Responses (IFRs) are fully

supported for Type 1, Type 2, and Type 3 messages, with

the appropriate Normalization Bit automatically generated.

The HCMOS design allows proper operation at various input

frequencies from 2MHz to 12MHz. Connection to the J1850

Bus is via a Harris HIP7020.

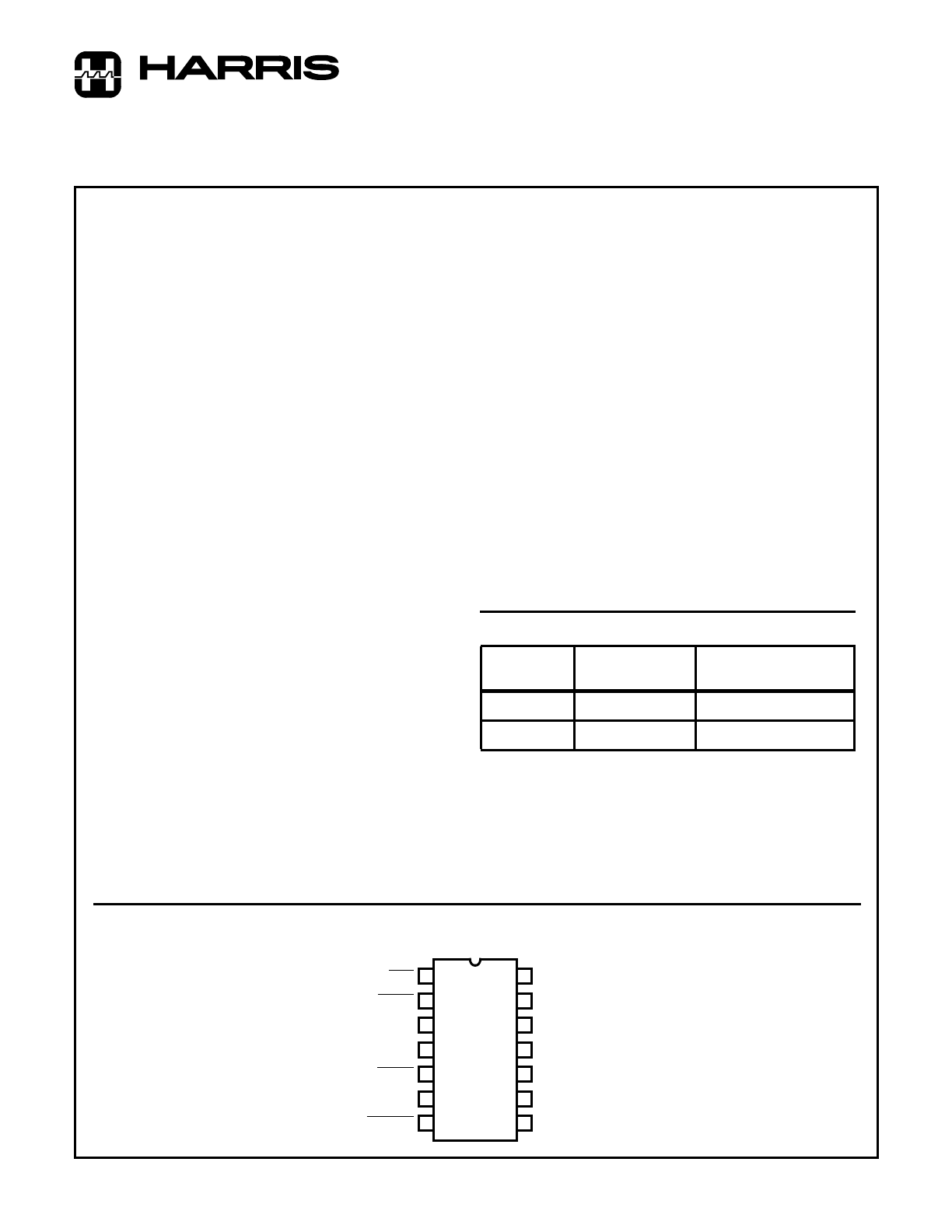

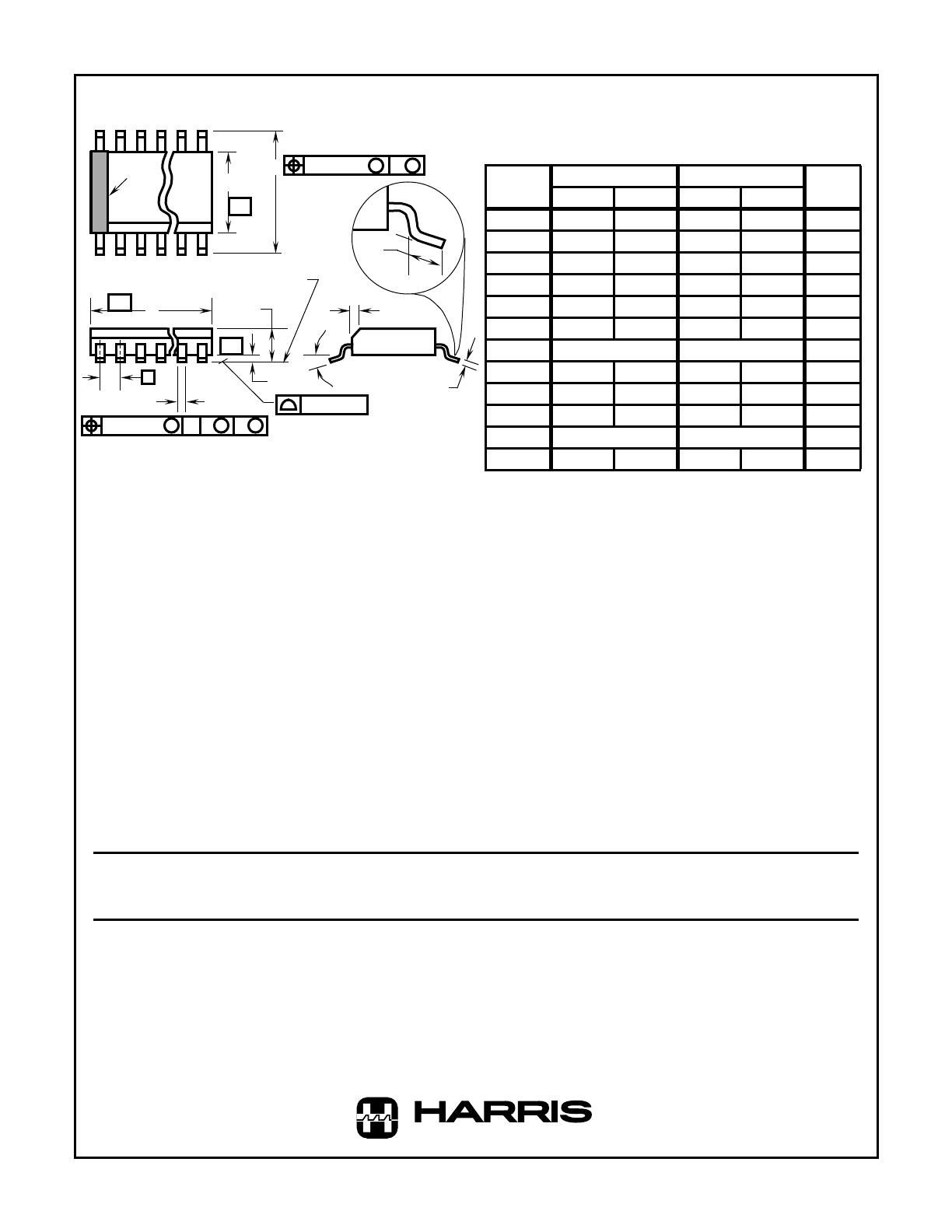

Ordering Information

PART

NUMBER

TEMPERATURE

RANGE

PACKAGE

HIP7010P

-40

o

C +125

o

C

14 Lead Plastic DIP

HIP7010B

-40

o

C +125

o

C

14 Lead Plastic SOIC (N)

HIP7010

J1850 Byte Level Interface Circuit

Features

• Fully Supports VPW (Variable Pulse Width) Messaging

Practices of SAE J1850 Standard for Class B Data

Communications Network Interface

- 3-Wire, High-Speed, Synchronous, Serial Interface

• Reduces Wiring Overhead

• Directly Interfaces with 68HC05 and 68HC11 Style SPI

Ports

• 1MHz, 8-Bit Transfers Between Host and HIP7010 Min-

imize Host Service Requirements

• Automatically Transmits Properly Framed Messages

• Prepends SOF to First Byte and Appends CRC to Last

Byte

• Fail-Safe Design Including, Slow Clock Detection

Circuitry, Prevents J1850 Bus Lockup Due to System

Errors or Loss of Input Clock

• Automatic Collision Detection

• End of Data (EOD), Break, Idle Bus, and Invalid Symbol

(Noise/Illegal Symbols) Detection

• Supports In-Frame Responses with Generation of

Normalization Bits (NB) for Type 1, Type 2, and Type 3

Messages

• Wait-For-Next-Idle Mode Reduces Host Overhead During

Non-Applicable Messages

• Status Register Flags Provide Information on Current

Status of J1850 Bus

• Serial I/O Pins are Active Only During Transfers - Bus

Available for Other Devices 95% of the Time

• High Speed (4X) Receive Mode for Production and

Diagnostic Testing/Programming

• TEST Pin Provides Built-in-Test Capabilities for In-

System Diagnostics and Factory Testing

• Operates with Wide Range of Input Clock Frequencies

• Power-Saving Power-Down Mode

• Full -40

o

C to +125

o

C Operating Range

• Single 3.0V to 6.0V Supply

File Number

3644.1

ADVANCE INFORMATION

November 1994

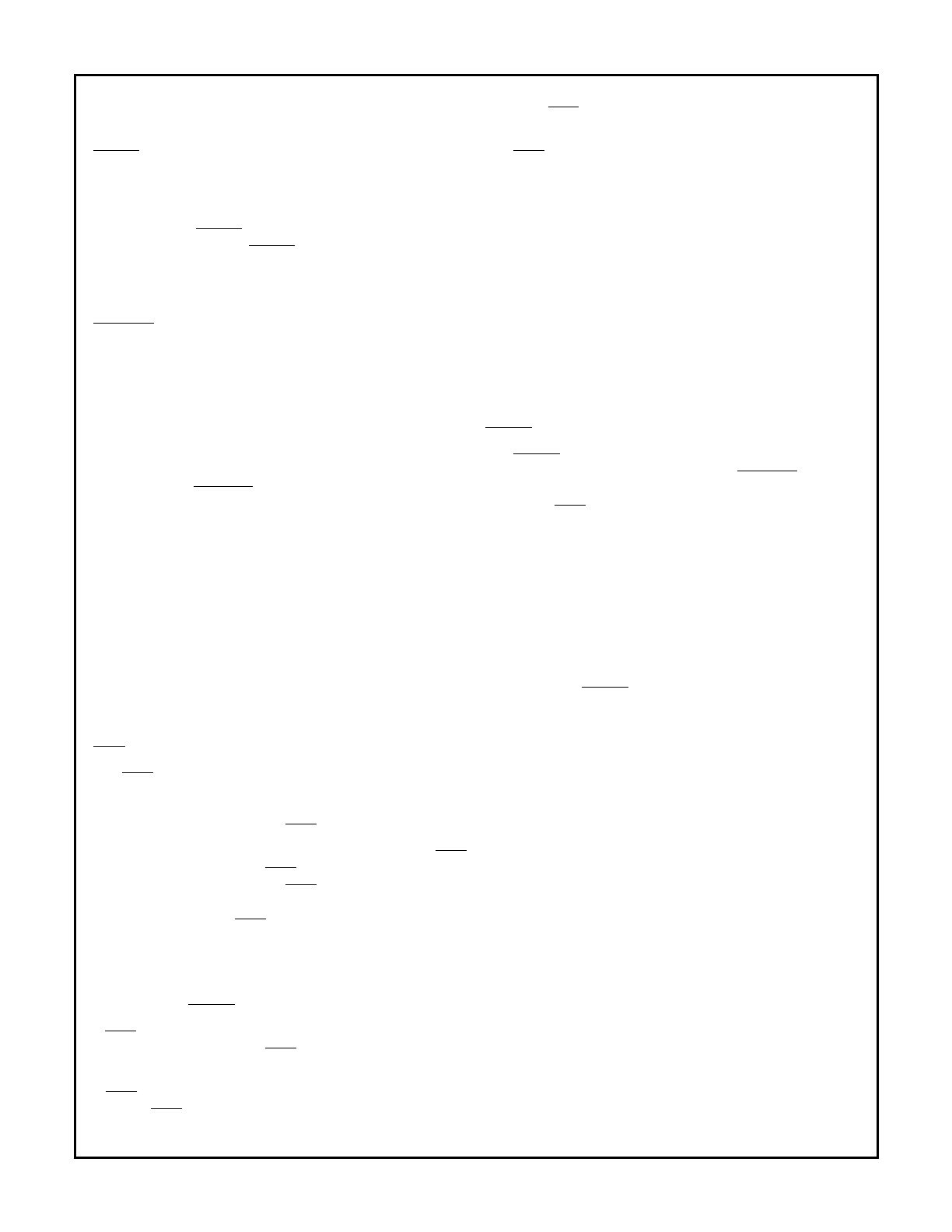

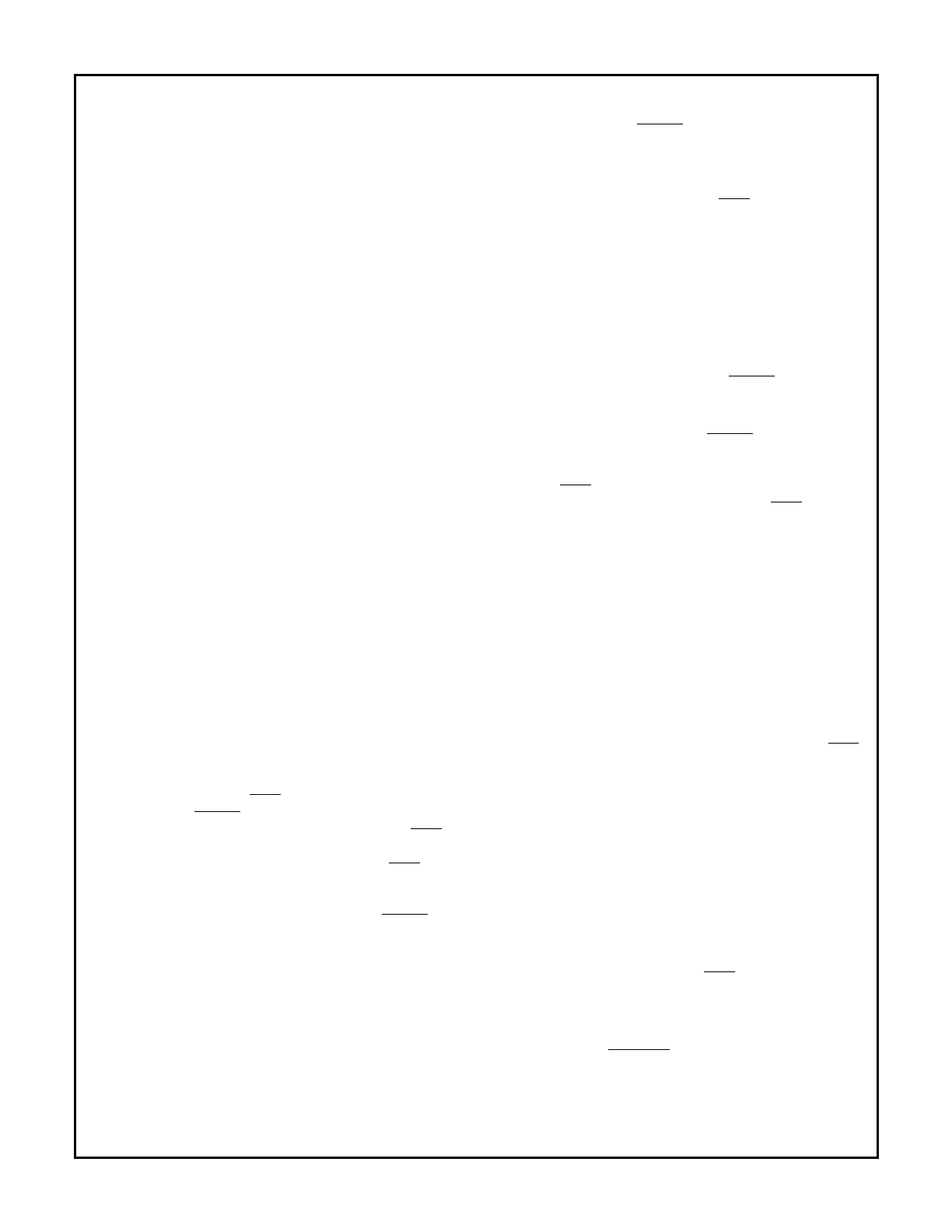

Pinout

HIP7010 (SOIC, PDIP)

TOP VIEW

IDLE

VPWIN

VPWOUT

V

DD

RESET

TEST

SACTIVE

RDY

STAT

CLK

V

SS

SIN

SOUT

SCK

1

2

3

4

5

6

7

14

13

12

11

10

9

8

2

HIP7010

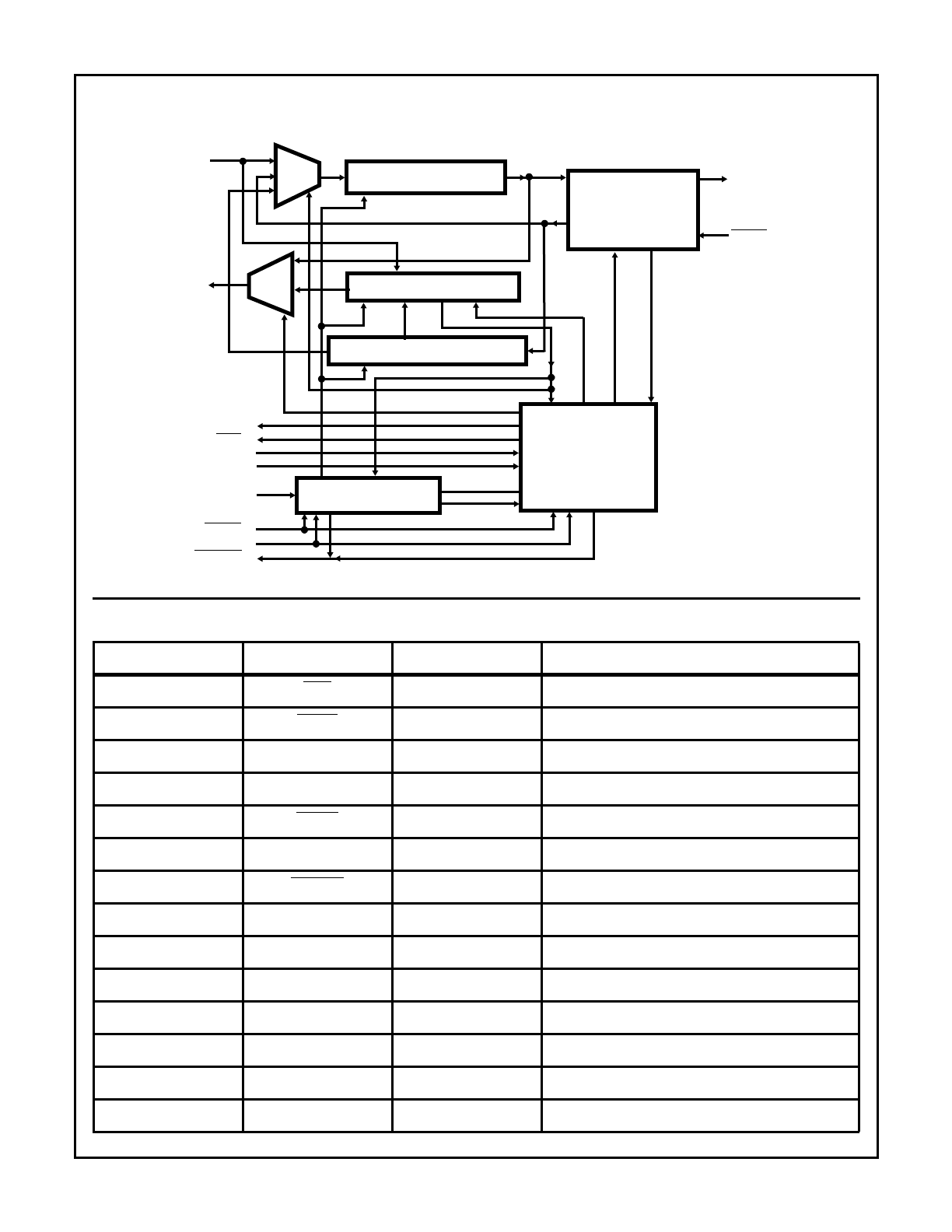

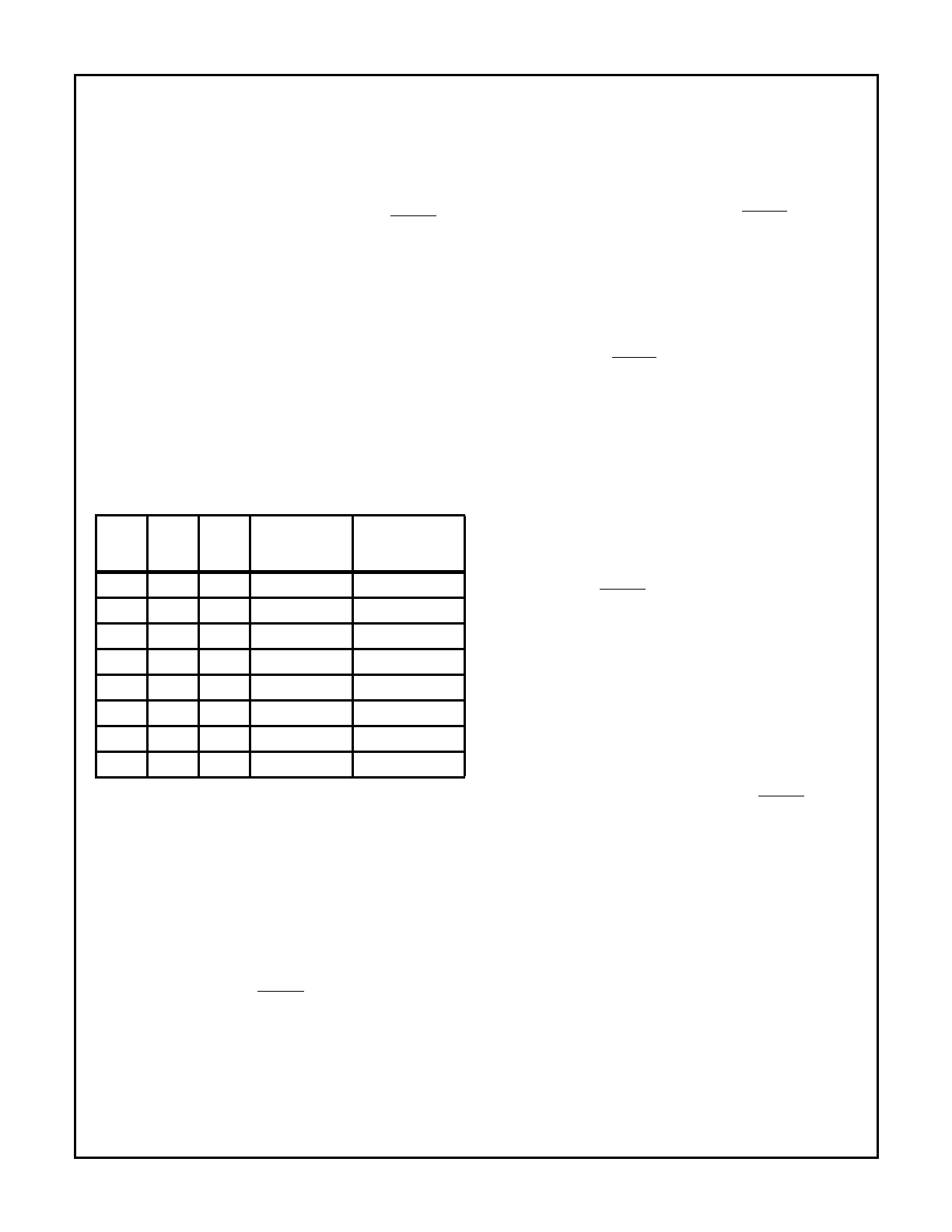

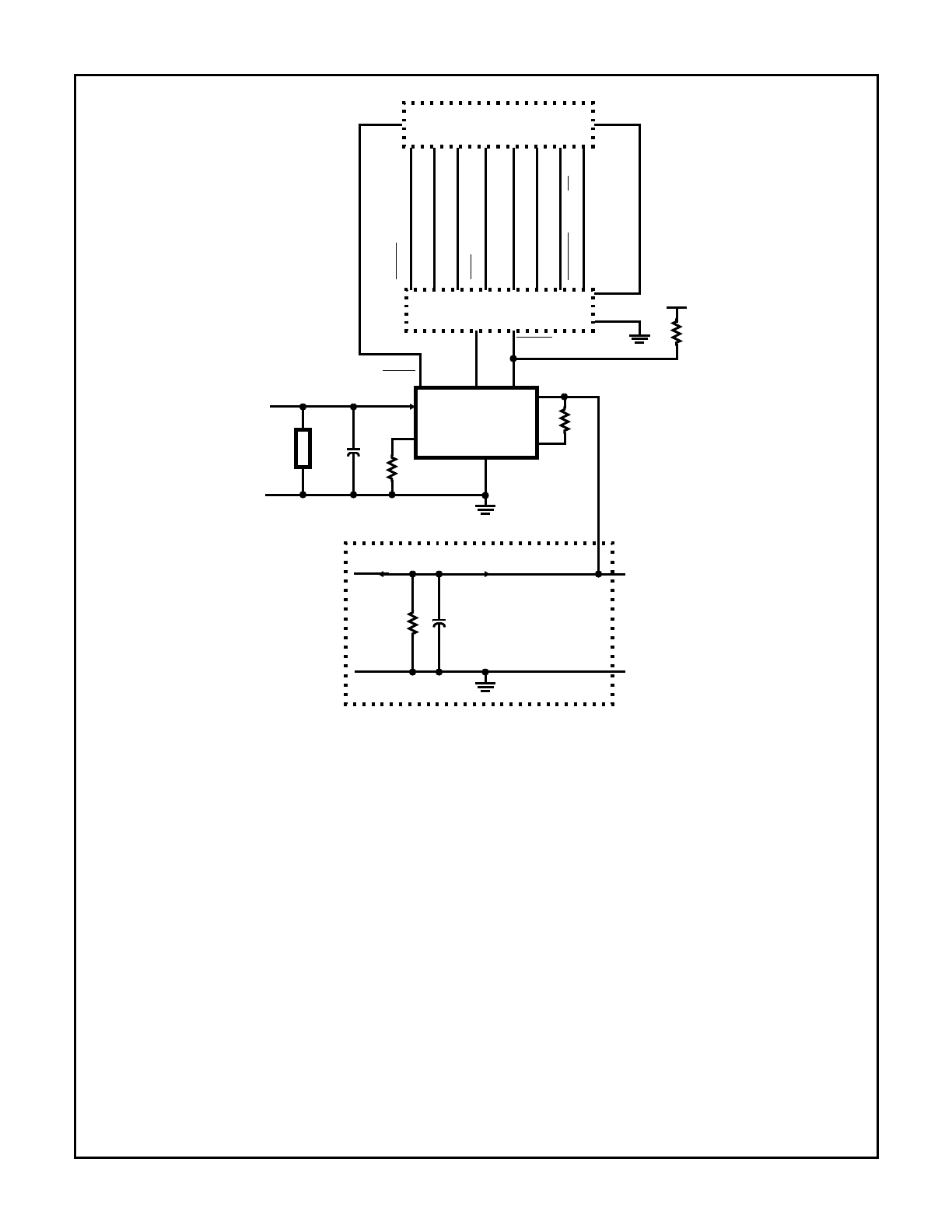

Block Diagram

Pin Description

PIN NUMBER

PIN NAME

IN/OUT

PIN DESCRIPTION

1

IDLE

OUT

CMOS Output

2

VPWIN

IN

CMOS Schmitt (No V

DD

Diode)

3

VPWOUT

OUT

CMOS Output

4

V

DD

-

Power Supply

5

RESET

IN

CMOS Schmitt (No V

DD

Diode)

6

TEST

IN

CMOS Input with Pull-Down

7

SACTIVE

OUT

CMOS Output

8

SCK

OUT

Three-State with Pull-Down

9

SOUT

OUT

Three-State with Pull-Down

10

SIN

IN

CMOS Input with Pull-Down

11

V

SS

-

Ground

12

CLK

IN

CMOS Schmitt (No V

DD

Diode)

13

STAT

IN

CMOS Input with Pull-Down

14

RDY

IN

CMOS Input with Pull-Down

10

9

SOUT

SIN

7

6

5

12

TEST

V

SS

11

CLK

13

14

1

8

STAT

RDY

SCK

2

3

VPWOUT

GENERATOR

TIMING

STATE MACHINE

AND CONTROL LOGIC

DECODED VPW IN

OUTPUT DATA

J1850 VPW SYMBOL

ENCODER/DECODER

LSB

MSB

STATUS/CONTROL BYTE

V

DD

4

A

B

C

MUX

CRC GENERATOR/CHECKER

A

C

MUX

DATA SHIFT REGISTER

IDLE

RESET

SACTIVE

VPWIN

3

Specifications HIP7010

Absolute Maximum Ratings

Thermal Information

Supply Voltage (V

DD

) . . . . . . . . . . . . . . . . . . . . . . . . .-0.3V to +7.0V

Input or Output Voltage

Pins with V

DD

Diode . . . . . . . . . . . . . . . . . . . . -0.3V to V

DD

+0.3V

Pins without V

DD

Diode. . . . . . . . . . . . . . . . . . . . .-0.3V to +10.0V

ESD Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Class 2

Gate Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +2500 Gates

Thermal Resistance

θ

JA

Plastic DIP Package . . . . . . . . . . . . . . . . . . . . . . . . . .+100

o

C/W

SOIC Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .+120

o

C/W

Maximum Package Power Dissipation at +125

o

C

DIP Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250mW

SOIC Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200mW

Operating Temperature Range (T

A

) . . . . . . . . . . . .-40

o

C to +125

o

C

Storage Temperature Range (T

STG

) . . . . . . . . . . . .-65

o

C to +150

o

C

Junction Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +150

o

C

Lead Temperature (Soldering, 10s). . . . . . . . . . . . . . . . . . . . +265

o

C

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation

of the device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

Operating Conditions

Operating Voltage Range . . . . . . . . . . . . . . . . . . . . . +3.0V to +5.5V

Operating Temperature Range . . . . . . . . . . . . . . . . -40

o

C to +125

o

C

Input Low Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0V to +0.8V

Input High Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . .(0.8V

DD

) to V

DD

Input Rise and Fall Time

CMOS Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100ns Max

CMOS Schmitt Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . .Unlimited

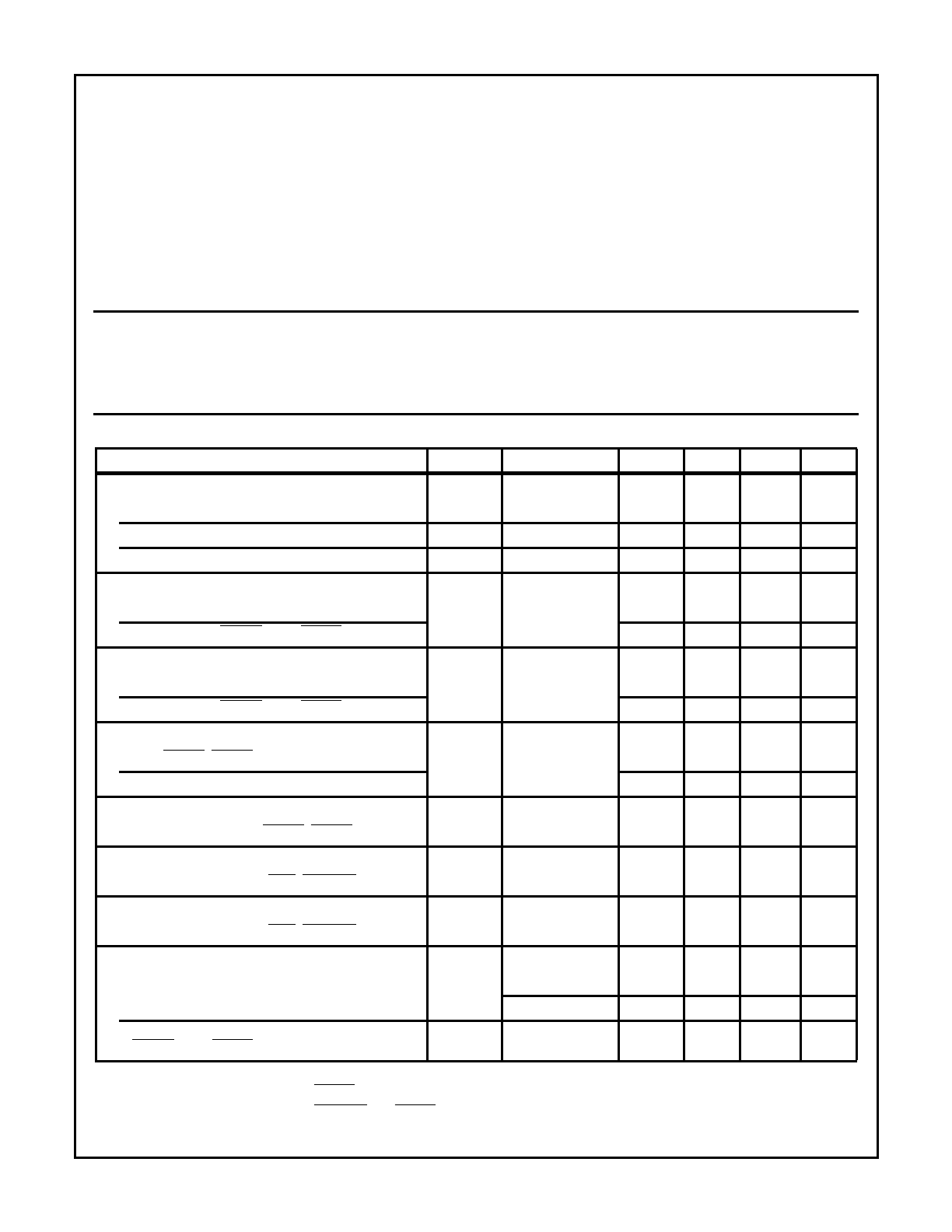

Electrical Specifications

T

A

= -40

o

C to +125

o

C, V

DD

= 5V

DC

±

10%, Unless Otherwise Specified

PARAMETERS

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNITS

Supply Current

Operating Current

I

OP

CLK = 2.0 MHz

-

1.0

-

mA

Power-Down Mode (Note 1)

I

PD

PD = 1

-

5.0

-

µ

A

Clock Stopped (Note 2)

I

STOP

CLK = V

SS

or V

DD

-

5.0

-

µ

A

Input High Voltage

CMOS Level (SIN, STAT, RDY, TEST)

V

IH

0.7V

DD

-

V

DD

V

Schmitt Trigger (RESET, CLK, VPWIN)

0.8V

DD

-

V

DD

V

Input Low Voltage

CMOS Level (SIN, STAT, RDY, TEST)

V

IL

V

SS

-

0.3V

DD

V

Schmitt Trigger (RESET, CLK, VPWIN)

V

SS

-

0.2V

DD

V

High Level Input Current

(CLK, VPWIN, RESET)

I

IH

V

IN

= V

DD

-1

0.001

1

µ

A

Input Buffer with Pull-down (SIN, TEST, STAT, RDY)

100

TBD

500

µ

A

Low Level Input Current

(SIN, CLK, STAT, RDY, VPWIN, RESET, TEST)

I

IL

V

IN

= V

SS

-1

-0.001

1

µ

A

Output High Voltage

(SCK, SOUT, VPWOUT, IDLE, SACTIVE)

V

OH

I

LOAD

= 0.8 mA

V

DD

-0.8

-

-

V

Output Low Voltage

(SCK, SOUT, VPWOUT, IDLE, SACTIVE)

V

OL

I

LOAD

= -1.6 mA

-

-

0.4

V

High Impedance Leakage Current

Three-State with Pull-down (SCK, SOUT)

I

OZ

V

OUT

= V

DD

100

-0.01

500

µ

A

V

OUT

= V

SS

-10

10

µ

A

Schmitt Trigger Hysteresis Voltage

(RESET, CLK, VPWIN)

V

HYS

0.2

0.5

2.0

V

NOTES:

1. SIN, STAT, RDY, and TEST = V

SS

; VPWIN = V

DD

; CLK = 10MHz

2. SIN, STAT, RDY, and TEST = V

SS

; SACTIVE and VPWIN = V

DD

4

Specifications HIP7010

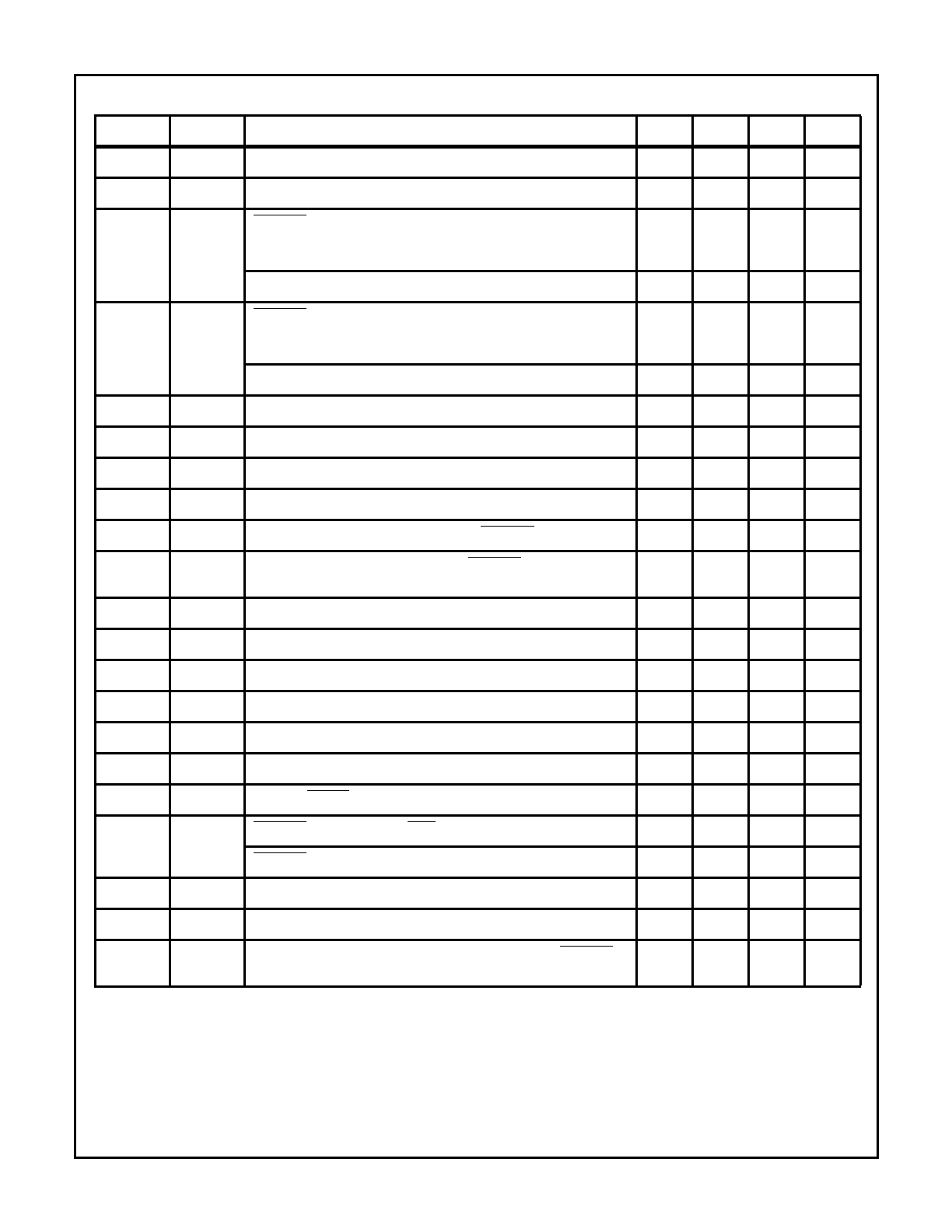

Serial Interface Timing

(See Figure 1- Figure 7) T

A

= -40

o

C to +125

o

C, V

DD

= 5V

DC

±

10%, Unless Otherwise Specified

NUMBER

SYMBOL

PARAMETERS

MIN

TYP

MAX

UNITS

-

-

Operating Frequency

2

8

12

MHz

(1)

t

CYC

SCK Cycle Time

-

1.0

-

MHz

(2)

t

LEAD

SACTIVE Lead Time

Before Status/Control Transfer

450

718

850

ns

Before Data Transfer

1200

1250

1350

ns

(3)

t

LAG

SACTIVE Lag Time

After Status/Control Transfer

650

750

850

ns

After Data Transfer

1200

1250

1350

ns

(4)

t

SCKH

Clock (SCK) HIGH Time

450

500

550

ns

(5)

t

SCKL

Clock (SCK) LOW Time

450

500

550

ns

(6)

t

DVSCK

Required Data In Setup Time (SIN to SCK)

-

10

40

ns

(7)

t

SCKDX

Required Data In Hold Time (SIN after SCK)

-

10

40

ns

(8)

t

DZDA

Data Active from High Impedance Delay (SACTIVE to SOUT Active)

0

10

-

ns

(9)

t

DADZ

Data Active to High Impedance Delay (SACTIVE to SOUT High

Impedance)

-

10

40

ns

(10)

t

SCKDV

Data Out Setup Time (SCK to SOUT)

375

475

-

ns

(11)

t

DXSCK

Data Out Hold Time (SOUT after SCK)

375

475

-

ns

(12)

t

RISE

Output Rise Time (0.3V

DD

to 0.7V

DD

, C

L

= 100pF)

20

50

75

ns

(13)

t

FALL

Output Fall Time (0.7V

DD

to 0.3V

DD

, C

L

= 100pF)

20

50

75

ns

(14)

t

STATH

Required STAT Pulse Width

-

20

75

ns

(15)

t

RDYH

Required RDY Pulse Width

-

20

75

ns

t

RESETL

Required RESET Pulse Width

-

20

75

ns

(16)

t

SACTIVE

SACTIVE Delay from RDY (IDLE = V

SS

)

1150

1750

2350

ns

SACTIVE Delay from STAT (FTU = 0)

5

285

850

ns

(17)

t

RDYSCK

Required RDY Removal Time Prior to Last SCK for Short RDY

-

25

100

ns

(18)

t

SCKRDY

Required RDY Hold Time after Last SCK for Long RDY

-

0

50

ns

(19)

t

REC

Required SERIAL Recovery Time (Minimum Time after SACTIVE

Until Next RDY/STAT)

-

0

100

ns

5

HIP7010

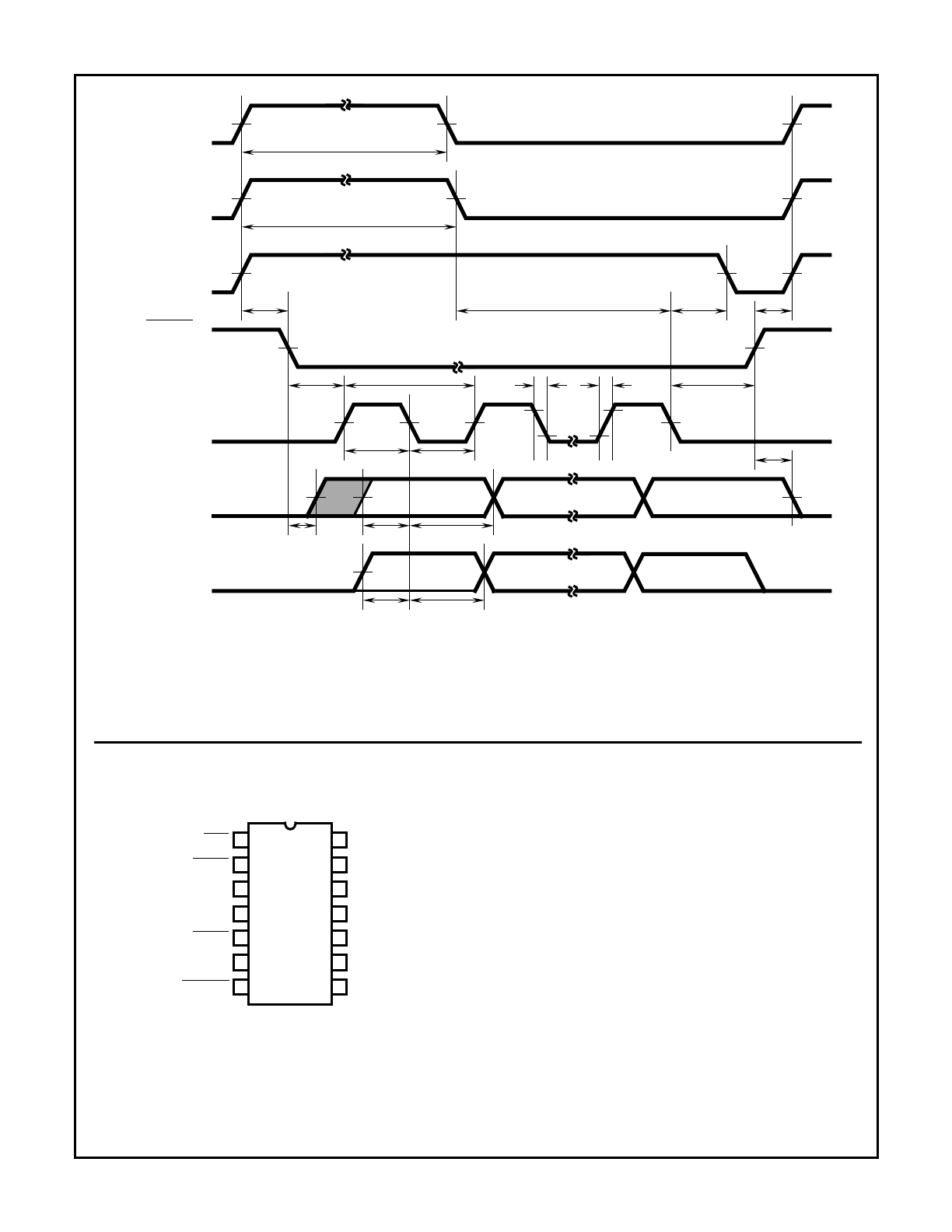

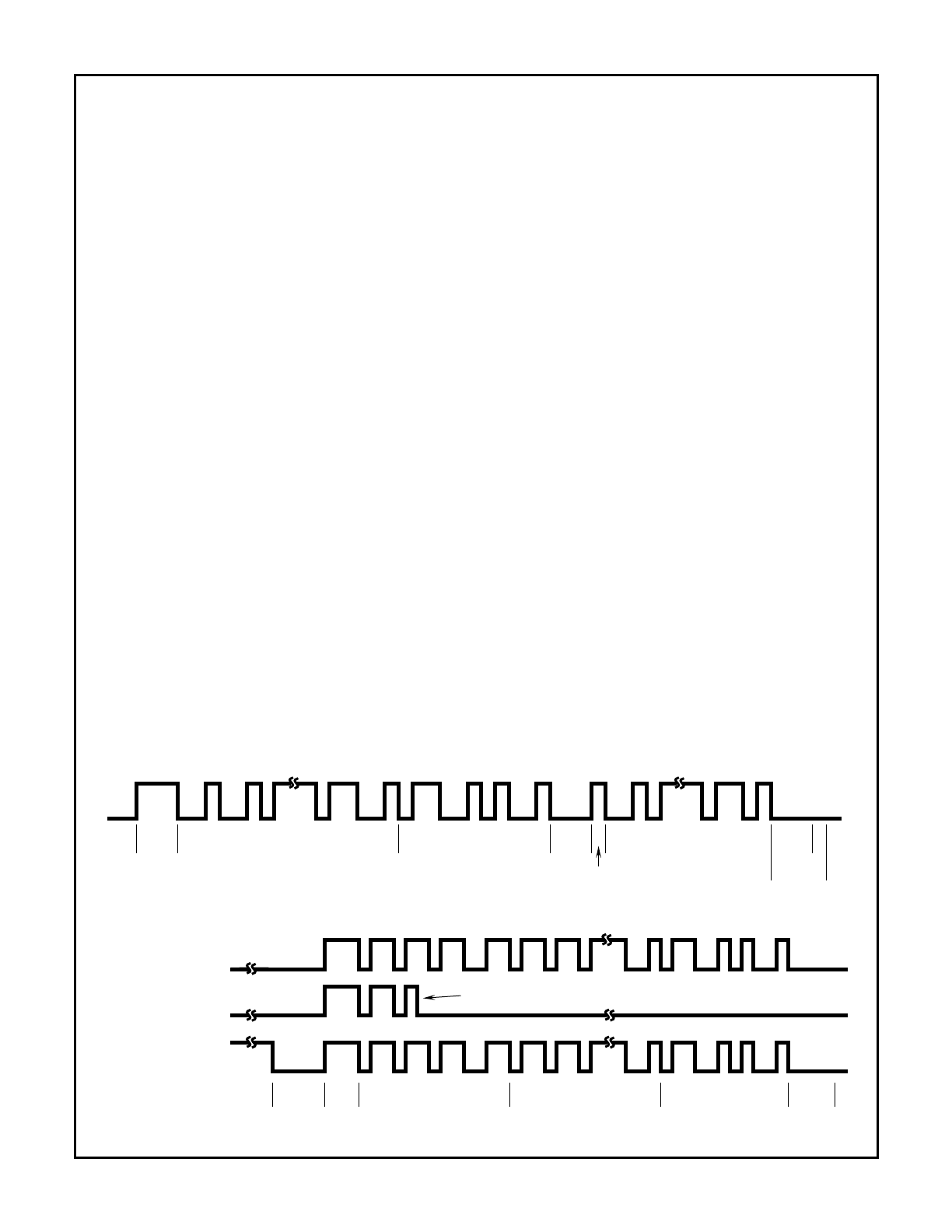

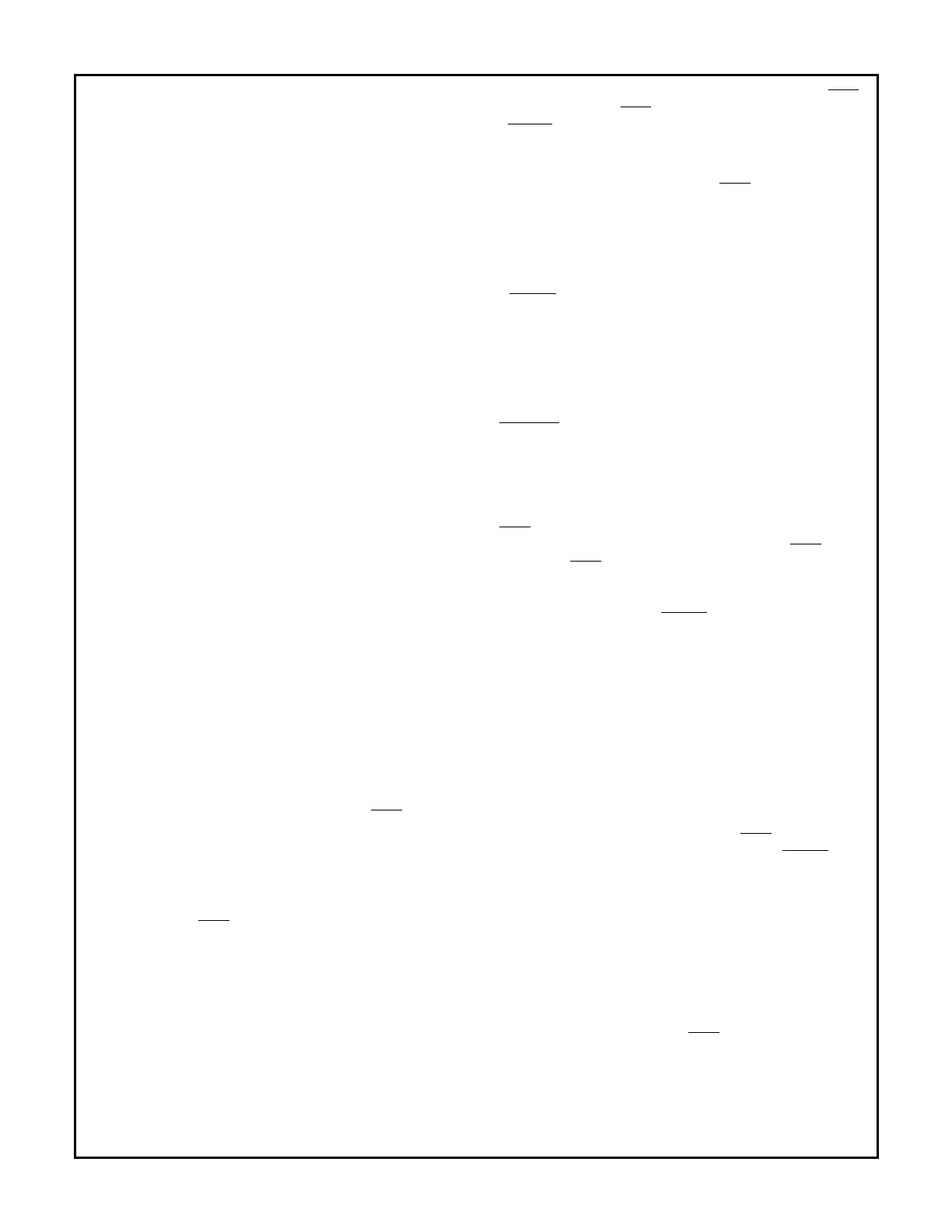

FIGURE 1. SERIAL INTERFACE TIMING DIAGRAM

NOTES:

1. Measurement points are from V

DD

/2, except 12 and 13 which are measured between V

IL

and V

IH.

2. All timings assume proper CLK frequency and Divide Select values to generate 1MHz SCK.

(OUTPUT)

SCK

(OUTPUT)

SIN

(INPUT)

SOUT

(OUTPUT)

D7I

D6I

D0I

D7O

D6O

D0O

(6)

(11)

(8)

(5)

(12)

(13)

(1)

(4)

(7)

SACTIVE

(INPUT)

RDY (LONG)

(INPUT)

RDY (SHORT)

STAT

(INPUT)

(2)

(10)

(9)

(3)

(14)

(15)

(16)

(17)

(18)

(19)

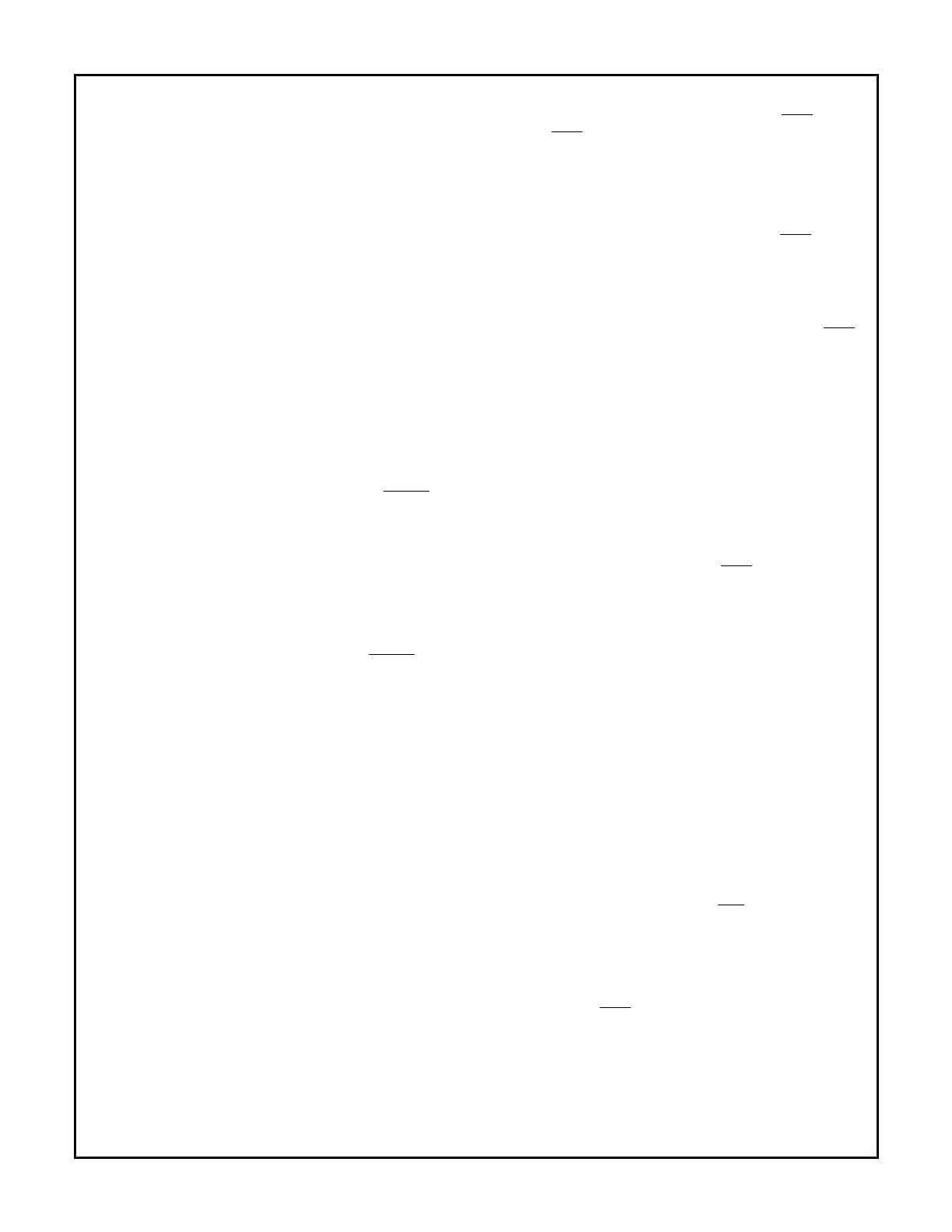

Functional Pin Description

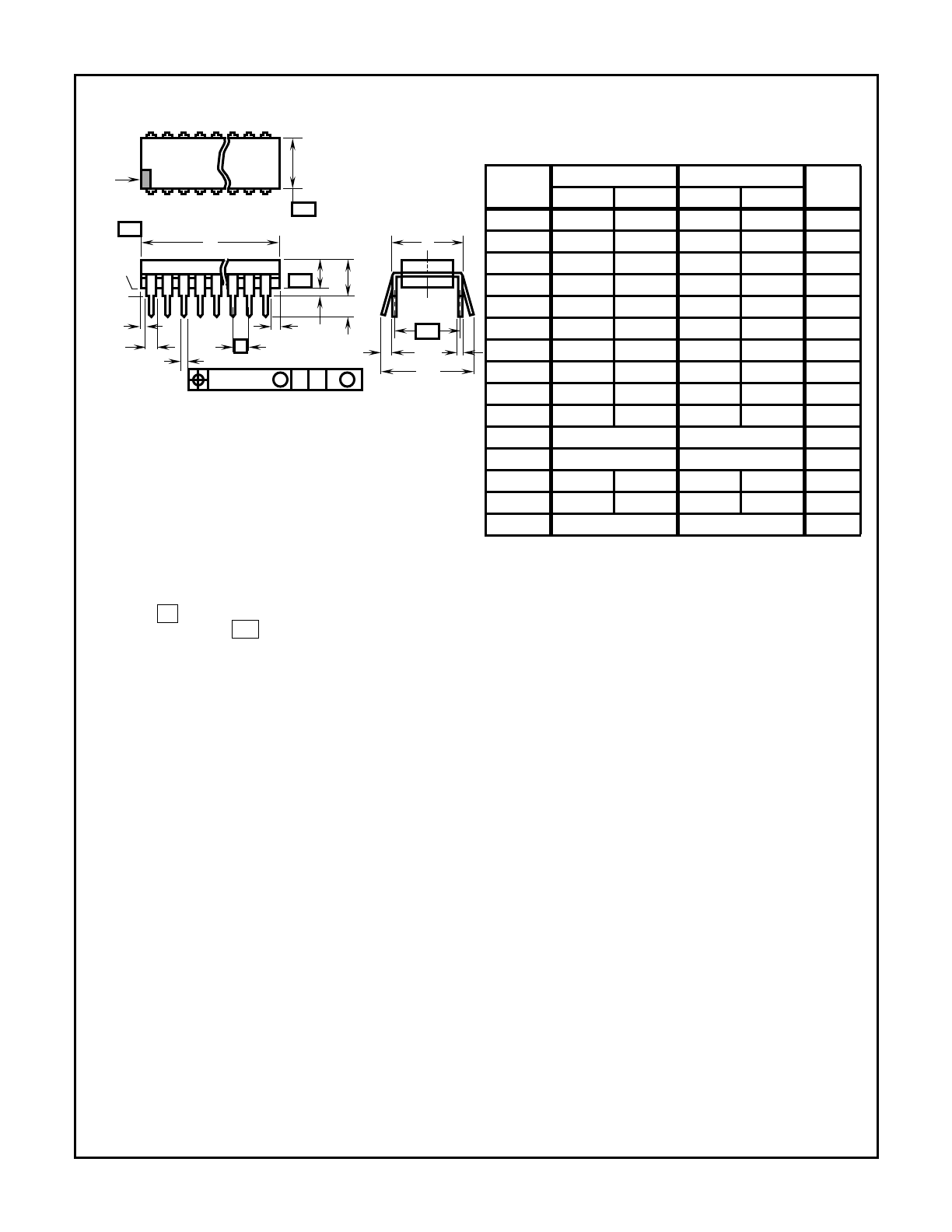

This section provides a description of each of the 14 pins of

the HIP7010 as shown in Figure 2.

FIGURE 2. 14 PIN DIP AND SO TERMINAL ASSIGNMENTS

V

DD

and V

SS

(Power)

Power is supplied to the HIP7010 using these two pins. V

DD

is connected to the positive supply and V

SS

is connected to

the negative supply.

IDLE

VPWIN

VPWOUT

V

DD

RESET

TEST

SACTIVE

RDY

STAT

CLK

V

SS

SIN

SOUT

SCK

1

2

3

4

5

6

7

14

13

12

11

10

9

8

CLK (Clock - Input)

The Clock input (CLK) provides the basic time base reference for

all J1850 symbol detection and generation. Serial Bus transfers

between the HIP7010 and the Host microcontroller are also

timed based on the Clock input. Proper VPW symbol detection

and generation requires a 2MHz clock which is internally derived

from the CLK input. Various CLK input frequencies can be

accommodated via the Divide Select bits in the Status/Control

Register (see Status/Control Register for details).

An internal Slow Clock Detect circuit monitors the CLK input

signal and generates a HIP7010 reset if the clock is inactive

for more than 2

µ

s. This is a safety mechanism to prevent

blocking the J1850 and Serial busses in the event of a clock

failure. The Slow Clock Detect reset can also be intentionally

invoked by externally inhibiting CLK input transitions.

Power can be reduced under Host control via the Power-

Down bit in the Status/Control Register (see Status/Control

Register for details). Setting the Power-Down bit effectively

stops internal clocking of the HIP7010.

6

HIP7010

For enhanced noise immunity, the CLK input is a CMOS Schmitt

trigger input. See Electrical Specifications for input levels.

VPWOUT (Variable Pulse Width Out - Output),

VPWIN (Variable Pulse Width In - Input)

These two lines are used to interface to a J1850 bus trans-

ceiver, such as the Harris HIP7020. VPWOUT is the variable

pulse width modulated output of the HIP7010’s symbol

encoder circuit. VPWIN is the inverted input to the symbol

decoder of the HIP7010. VPWIN is a schmitt input.

SIN (Serial In - Input),

SOUT (Serial Out - Output),

SCK (Serial Clock - Output),

SACTIVE (Serial Bus Active - Output)

These four lines constitute the synchronous Serial Interface

(SERIAL) interface of the HIP7010. See the Serial Interface

(SERIAL) System for details. SIN, SOUT, and SCK provide

the three principal connections to the Host controller. SIN is a

CMOS input. SOUT and SCK are three-state outputs which

are only activated during serial transfers. The SIN, SOUT, and

SCK pins contain integrated pull-down load devices which

provide termination on the bus whenever it is in a high imped-

ance state. The SACTIVE pin is a CMOS output, which pulls

low when the HIP7010 is communicating on the serial bus.

See Serial Interface (SERIAL) System and Applications

Information for more details.

RDY (Byte Ready - Input)

The Byte Ready (RDY) line is a “handshaking” input from the

Host. Each rising edge on the RDY pin signifies that the Host has

loaded a byte into its SERIAL transmit register and the HIP7010

can retrieve it (by generating clocks on SCK) when the HIP7010

is ready for the data. See Serial Interface (SERIAL) System

and Applications Information for more details.

The RDY pin contains an integrated pull-down load device

which will hold the pin low if it is left unconnected.

IDLE (Idle/Service Request - Output)

The IDLE output pin indicates that the J1850 Bus has been

in a passive state for at least 300

µ

s and is now idle. If the

bus has been passive for a minimum of 239

µ

s and another

node initiates a new message, IDLE will pulse low for 1

µ

s.

In its role as a Service Request pin, a reset forces IDLE

high. Following the reset, IDLE remains high for 17 CLK

cycles and is then driven low. IDLE will remain low until 40

CLK cycles +1.5

µ

s after completion of the first Status/Con-

trol byte transfer. The IDLE pin will then resume its normal

role, remaining high until a 300

µ

s lull (or 239

µ

s plus a pas-

sive to active transition) has been detected on the J1850

bus. This provides a handshake mechanism to ensure the

Host will reinitialize the HIP7010 each time the HIP7010 is

reset via POR, RESET, or Slow Clock Detect.

If IDLE is low when an echo failure causes the ERR bit to be

set in the Status byte, the IDLE pin will pulse high for 2

µ

s

and then return low (see Status/Control Register).

If IDLE is low when the host sets the NXT bit in the control

byte, the IDLE pin will pulse high for 2

µ

s and then return low

(see Status/Control Register).

In general a Status/Control byte transfer should be performed

each time IDLE goes low. See Effects of Resets and Power-

Down and Applications Information for more details.

The IDLE pin is an active low CMOS output. See Operation

of the HIP7010 for more details.

STAT (Request Status/Control - Input)

The Request Status/Control (STAT) input pin is used by the

Host microcontroller to initiate an exchange of the Host’s con-

trol byte and the HIP7010’s status byte. A low to high transi-

tion on the STAT input signals the HIP7010 that the Host has

placed a control word in it’s SERIAL output register and is

ready to exchange it with the HIP7010’s status word. The

HIP7010 controls the exchange by generating the 8 SCKs

required. See Serial Interface (SERIAL) System and Appli-

cations Information for more details.

The STAT pin contains an integrated pull-down load device

which will hold the pin low if it is left unconnected.

RESET (Reset - Input)

The RESET input is a low level active input, which resets the

HIP7010. Resetting the HIP7010 forces SACTIVE high, dis-

ables the SOUT and SCK pins, forces the VPWOUT output

low, drives IDLE high, and returns the internal state machine

to its initial state. Following reset, the HIP7010 is inhibited

from transmitting or receiving J1850 messages until a Sta-

tus/Control Register transfer has been completed (see

Effects Of Resets And Power-Down for more details).

The HIP7010 is also reset during initial power-on, by an

internal power-on-reset (POR) circuit.

Loss of a clock on the CLK input will cause a reset as

described previously under CLK.

If not used, the RESET pin should be tied to V

DD

.

For enhanced noise immunity, the CLK input is a CMOS Schmitt

trigger input. See Electrical Specifications for input levels.

TEST (Test Mode - Input)

The TEST input provides a convenient method to test the

HIP7010 at the component level. Raising the TEST pin to a

high level causes the HIP7010 to enter a special TEST mode.

In the TEST mode, a special portion of the state machine is

activated which provides access to the Built-in-Test and diag-

nostic capabilities of the HIP7010 (see Test Mode for more

details).

The TEST pin contains an integrated pull-down load device

which will hold the pin low if it is left unconnected. In many

applications the TEST pin will be left unconnected, to allow

access via a board level ATE tester.

J1850 VPW Messaging

This section provides an introduction to J1850 multiplexed

communications. It is assumed that the user is or will

become familiar with the appropriate documents published

by the Society of Automotive Engineering (SAE). The follow-

ing discussion is not comprehensive.

7

HIP7010

Overview

The SAE J1850 Standard (Note 1) (J1850) establishes the

requirements for communications on a Class B multiplexed

wiring network for automotive applications. The J1850 docu-

ment details the requirements in a three layer description

which separately specifies the characteristics of the

physical

layer, the data link layer, and the application layer. There are

several options within each layer which allows vehicle manu-

facturers to customize the network while still maintaining a

level of universality.

NOTE:

1. SAE J1850 Standard, Class B Data Communication Network

Interface, May 1994, Society of Automotive Engineers Inc.

The hardware of the Harris HIP7010 provides features which

facilitate implementation of the 10.4Kbps Variable Pulse

Width Modulated (VPW) physical layer option of J1850. In

combination with a bus transceiver, such as the Harris J1850

Bus Transceiver HIP7020, and appropriate software algo-

rithms the HIP7010 circuitry enables the designer to com-

pletely implement a 10.4Kbps VPW Class B

Communications Network Interface per J1850. Features of

such an implementation include:

• Single Wire 10.4Kbps Communications

• Bit-by-Bit Bus Arbitration

• Industry Standard Protocol

• Message Acknowledgment (“In-Frame Response”) Capa-

bilities

• Exceptionally Tolerant of Clock Skew, System Noise, and

Ground Offsets

• Meets CARB and EPA Diagnostic Requirements

• Supports up to 32 Nodes

• Low Error Rates

• Excellent EMC Levels (when interfaced via Harris J1850

Bus Transceiver HIP7020)

In addition to the standard J1850 features, the HIP7010 hard-

ware provides a high speed mode, (intended for receive only

use) which can significantly enhance vehicle maintenance

capabilities. The high speed mode provides a 41.6Kbps com-

munications path to any node built with the HIP7010.

Anatomy of a J1850 VPW Message

All messages in a J1850 VPW system are sent along a single

wire, shared bus. At any given moment the bus can be in

either of two states:

active (high) or passive (low). Multiple

nodes are connected to the bus as a “wired-OR” network in

which the bus is high if

any one (or more) node is generating

an active output. The bus is only low when

no nodes are gen-

erating active outputs. It follows that, when no communica-

tions are taking place the bus will rest in the passive state. A

message begins when the bus is first driven to the high state.

Each succeeding state transition (i.e. - a change from active to

passive or passive to active) transfers one bit of information

(

symbol) until the message is complete and the bus once

again rests at the passive state. The interpretation of each

symbol in the message is dependent on its duration (and

state), hence the descriptor Variable Pulse Width (VPW).

Each message has a beginning and an end, the span of

which encompasses the entire

message or frame (refer to

Figure 3). A frame consists of an active

start of frame (SOF)

symbol and a passive

end of frame (EOF) symbol sandwiched

around a series of byte sized (8-bit) groups of symbols. The

first byte of the frame contents is always a

header byte, fol-

lowed by possibly additional header bytes, followed by one or

more

data bytes, followed by an integrity check byte (CRC

byte), followed by a passive

end of data (EOD) symbol, fol-

lowed by possibly one or more

in-frame-response (IFR) bytes.

To keep waiting times low, messages are limited to 12 bytes

total (including header, data, check, and IFR bytes). All mes-

sage bytes are transmitted most significant bit (MSB) first.

VPW Symbol Definitions

Within the J1850 scheme, symbols are defined in terms of both

duration and state (passive or active). The duration is mea-

sured as the time between successive transitions. There is one

transition per symbol and one symbol per transition. The end of

one symbol marks the beginning of the next. Since the bus is

passive when a message begins and must return to that same

state when the message completes, all frames have an even

number of transitions and hence an even number of symbols.

There are unique definitions for data bit symbols (all the sym-

bols which occur within the header, data, and check bytes) and

protocol symbols (including SOF, EOD, and EOF). The duration

of each symbol is expressed in terms of VPW Timing Pulses

(TV values). Table 1 summarizes the TV definitions. Each TV is

specified in terms of a

nominal (or ideal) duration and a mini-

mum and maximum duration. The span between the minimum

and maximum limits accommodates system noise sources

such as node to node clock skew, ground offsets, clock jitter,

and electromechanical noise. There are no dead zones

between the maximum of one TV and the minimum of the next.

FIGURE 3. TYPICAL J1850 VPW MESSAGE FRAME

SOF

HEADER

DATA 1

DATA 2

CRC

EOD

EOF

8

HIP7010

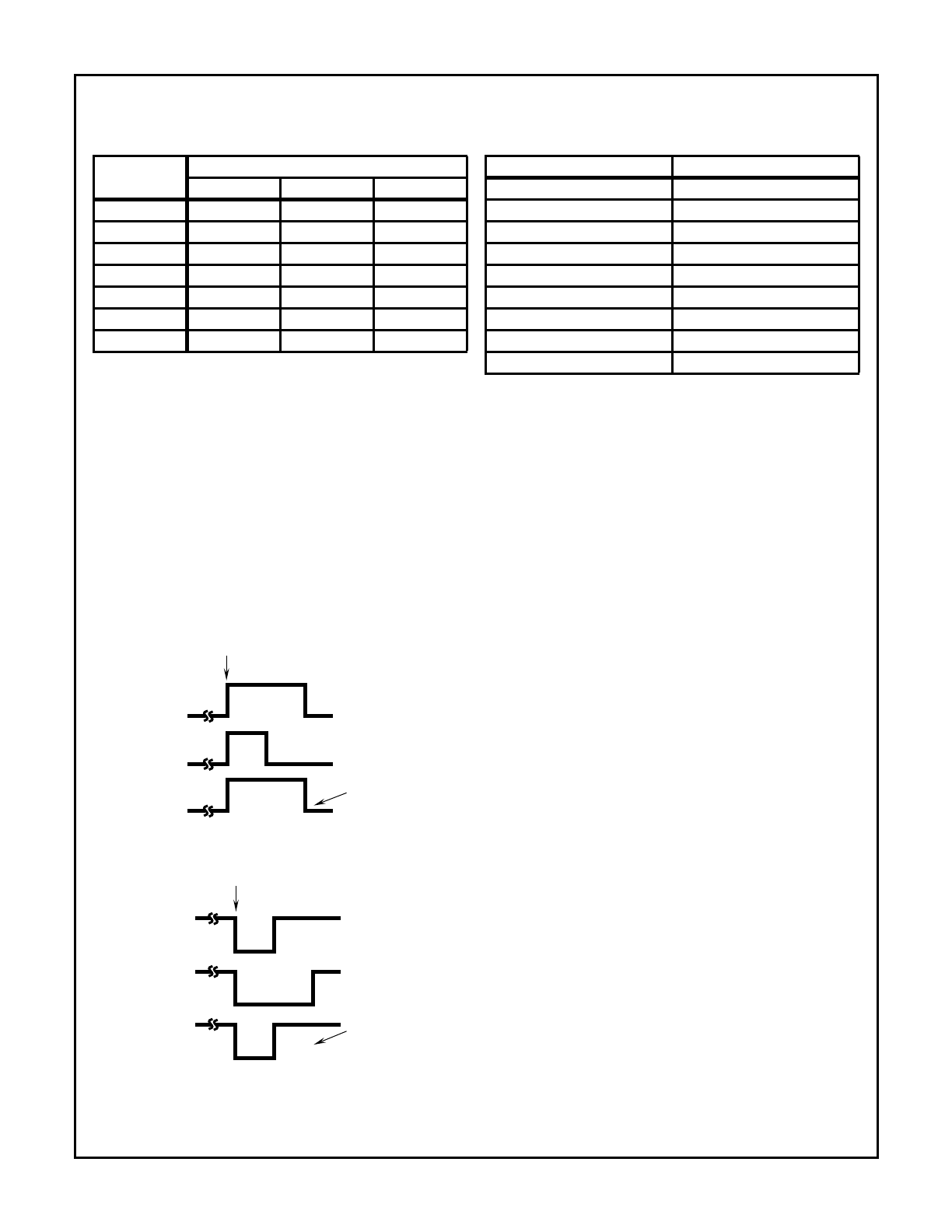

The terms

short and long are often used to refer to pulses of

duration TV1 and TV2 respectively.

VPW is a non-return-to-zero (NRZ) protocol in which each

transition represents a complete bit of information. Accord-

ingly, a

0 data bit will sometimes be transmitted as a passive

pulse and sometimes as an active pulse. Similarly, a

1 data

bit will sometimes be transmitted as a passive pulse and

sometimes as an active pulse. In order to accommodate

arbitration (see Bus Arbitration) a

long active pulse repre-

sents a 0 data bit and a

short active pulse represents a 1

data bit. Complementing this fact, a

short passive pulse rep-

resents a 0 and a

long passive pulse represents a 1. Starting

from a transition to the active state, a 0 data bit will maintain

the active level longer than a 1. Similarly, starting from a

transition to the passive state, a 0 data bit will return to the

active level quicker than a 1. These facts give rise to the

dominance of 0’s over 1’s on the J1850 bus as depicted in

Figure 4. See Bus Arbitration for additional details.

FIGURE 4A. DOMINANCE OF ACTIVE 0 DATA BIT

FIGURE 4B. DOMINANCE OF PASSIVE 0 DATA BIT

FIGURE 4.

TABLE 1. J1850 TV DEFINITIONS

TV ID

DURATION (ALL TIMES IN

µ

s)

MINIMUM

NOMINAL

MAXIMUM

Illegal

0

NA

≤

34

TV1

>34

64

≤

96

TV2

>96

128

≤

163

TV3

>163

200

≤

239

TV4

>239

280

NA

TV5

>239

300

NA

TV6

>280

300

NA

BIT

DATA

0

BIT

DATA

1

BUS

J1850

SYNCHRONIZED

PULSE (0)

LONGER ACTIVE

0

0

1

CONTROLS THE BUS

BIT

DATA

0

BIT

DATA

1

BUS

J1850

SYNCHRONIZED

PULSE (0)

SHORTER PASSIVE

0

0

1

CONTROLS THE BUS

Table 2 summarizes the complete set of symbol definitions

based on duration and state.

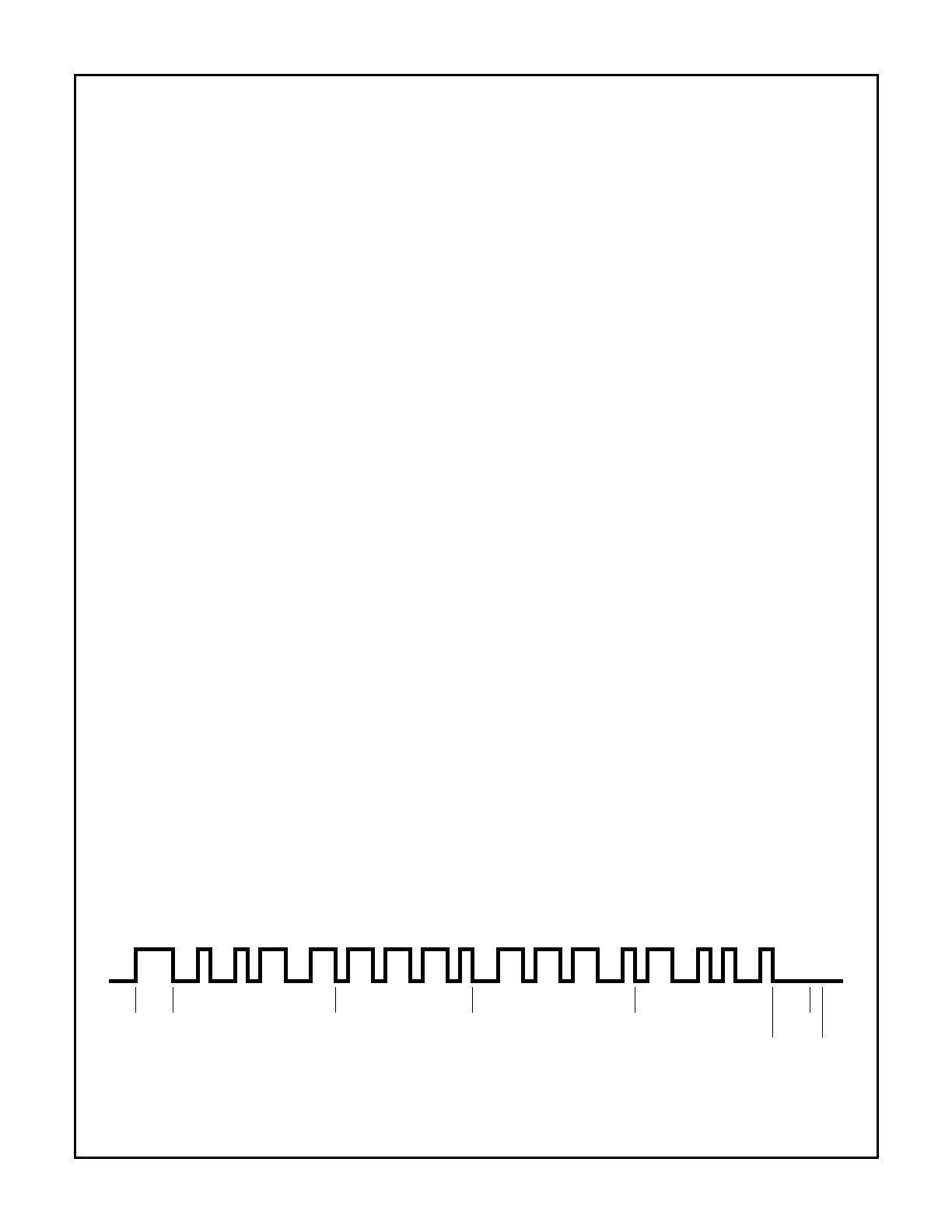

In Frame Response (IFR)

The distinction between two of the passive symbols, EOD and

EOF, is subtle but important (refer to Figure 5). The EOD (TV3)

interval signifies that the originator of the message is done

broadcasting and any nodes which have been requested to

respond (i.e. - to acknowledge receipt of the message) can now

do so. The EOD interval begins when the transmitting node has

completed sending the eighth bit of the check byte. The trans-

mitter simply releases the bus and allows it to revert to a pas-

sive state. In the course of normal messaging, no node can

seize the bus until an EOD time has been detected. Once an

EOD has elapsed, any nodes which are scheduled to produce

an IFR will arbitrate for control of the bus (see Bus Arbitration)

and respond appropriately. If no responses are forthcoming the

bus remains in the passive state until an EOF (TV4) interval

has elapsed. After the EOF has been generated, the frame is

considered closed and the next communications on the bus will

represent a totally new message.

IFRs can consist of multiple bytes from a single respondent,

one byte from a single respondent, or one byte from multiple

respondents. In all cases the first response byte must be pre-

ceded by a

normalization bit (NB) which serves as a start of

response symbol and places the bus in an active state so that

following the IFR byte(s) the bus will be left in the passive state.

The NB symbol is by definition active, but can be either TV1

or TV2 in duration. The long variety (TV2) signifies the IFR

contains a CRC byte. The short variety (TV1) precedes an

IFR without CRC.

Message Types

Messages are classified into one of four

Types according to

whether the message has an IFR and what kind of IFR it is.

The definitions are:

• Type 0 - No IFR

• Type 1 - One byte IFR from a single respondent

(no CRC byte)

• Type 2 - One byte IFRs from multiple respondents

(no CRC byte)

• Type 3 - Multiple byte IFR from a single respondent

(CRC appended)

TABLE 2. J1850 SYMBOL DEFINITIONS

SYMBOL

DEFINITION

0 Data

Passive TV1 or Active TV2

1 Data

Active TV1 or Passive TV2

SOF (Start of Frame)

Active TV3

EOD (End of Data)

Passive TV3

EOF (End of Frame)

Passive TV4

IFS (Inter-Frame Separation)

Passive TV6

IDLE (Idle Bus)

Passive >TV6 Nominal

NB (Normalization Bit)

ActiveTV1 or Active TV2

BRK (Break)

Active TV5

9

HIP7010

Bus Arbitration

The nature of multiplexed communications leads to contention

issues when two or more nodes attempt to transmit on the bus

simultaneously. Within J1850 VPW systems, messages are

assigned varying levels of priority which allows implementa-

tion of an arbitration scheme to resolve potential contentions.

The specified arbitration is performed on a symbol by symbol

basis throughout the duration of every message.

Arbitration begins with the rising edge of the SOF pulse. No

node should attempt to issue an SOF until an Idle bus has

been detected (i.e. - an

Inter-Frame Separation (IFS) symbol

with a period of TV6 has been received). If multiple nodes are

ready to access the bus and are all waiting for an IFS to

elapse, invariable skews in timing components will cause one

arbitrary node to detect the Idle condition before all others and

start transmission first. For this reason, all nodes waiting for

an IFS will consider an IFS to have occurred if either:

1. An IFS nominal period has elapsed

or

2. An EOF minimum period has elapsed

and a rising edge

has been detected

Arbitrating devices will all be synchronized during the SOF.

Beginning with the first data bit and continuing to the EOF,

every transmitting device is responsible for verifying that the

symbol it sent was the symbol which appeared on the bus.

Each transition, every transmitting node must decode the

symbol, verify the received symbol matches the one sent, and

begin timing of the next symbol. Since timing of the next sym-

bol begins with the last transition detected on the bus, all

transmitters are re-synchronized each symbol. When the

received symbol doesn’t match the symbol sent, a conflict (

bit

collision) occurs. Any device detecting a collision will assume

it has lost arbitration and immediately relinquish the bus. Typi-

cally, after losing arbitration, a device will attempt retransmis-

sion of the message when the bus once again becomes idle.

The definition of 1 and 0 data bits (see Table 2 and discussion

under VPW Symbol Definitions) leads to 0’s having priority

over 1’s in this arbitration scheme. Header bytes are generally

assigned such that arbitration is completed before the first

data byte is transmitted. Because of the dominance of 0 bits

and the MSB first bit order, a header with the hexadecimal

value $00 will have highest priority, then $01, $02, $03, etc.

An example of two nodes arbitrating for control of the bus is

shown in Figure 6.

Arbitration also takes place during the IFR portion of a mes-

sage, if more than one node is attempting to generate a

response. Arbitration begins with the NB symbol, which fol-

lows the EOD and precedes the first IFR byte.

For Type 1 and Type 3 messages only, the respondent which

successfully arbitrates for control of the bus produces an IFR.

All other respondents abort their IFRs.

For Type 2 messages, all respondents which lose arbitration

must count symbols and re-attempt transmission at the end of

each byte. Each node, which successfully responds, elimi-

nates itself from the subsequent arbitration until all nodes

have responded. This arbitration scheme limits each respon-

dent to a single byte during a Type 2 IFR.

Break

To force a message to be aborted before EOF is reached, a

break (BRK) symbol can be transmitted by any node. The

BRK symbol is an active pulse of duration TV5. Reception of a

break causes all nodes to reset to a

ready-to-receive state

and to re-arbitrate for control following an IFS.

HIP7010 Architectural Overview

The HIP7010 consists of three major functional blocks: the

Serial Interface System (SERIAL) block; the State Machine

(STATE) block; and the Symbol Encoder/Decoder (SENDEC)

block. Transfers between the Host and the HIP7010 are con-

trolled by the SERIAL block, while transfers between the

J1850 bus and the HIP7010 are handled by the SENDEC

FIGURE 5. J1850 MESSAGE WITH IN-FRAME-RESPONSE

FIGURE 6. TWO NODES ARBITRATING FOR CONTROL OF J1850 BUS

SOF

HEADER

. . . . DATA N

CRC

IN FRAME RESPONSE

EOD

NB

EOD

EOF

SOF

0

0

0

0

0

0

0

1

1

0

0

HEADER

COLLISION DETECTED BY B

J1850

TRANSMITTER

B

TRANSMITTER

A

DATA 1 . . . DATA N

CRC

EOF

IFS

BUS

10

HIP7010

block. The STATE block controls the flow of all data between

the SERIAL and SENDEC blocks. The STATE block also con-

trols Host/HIP7010 handshaking, automatic J1850 bus arbi-

tration, break recognition, CRC checking, and many other

features. In addition to the three major blocks the HIP7010

includes CRC generator/checker hardware, a Status/Control

Register, and a Timing generator.

Timing Generator

The timing generator, as its name suggests, generates all

internal timing pulses required for the SERIAL, SENDEC,

STATE, and CRC circuits. The CLK input pin is appropriately

divided to produce an internal 2MHz clock which results in a

1MHz SERIAL transfer rate and VPW J1850 symbol timing

with 1

µ

s accuracy. The CLK pin of the HIP7010 can be driven

with a variety of common microcontroller frequencies. Fre-

quency selection is accomplished via three bits in the Status/

Control register. See Status/Control Register for more

details.

The Serial Interface (SERIAL) System

Overview

The SERIAL system handles all interface between the Host

microcontroller and the HIP7010. The SERIAL system is

designed to interface directly with the Serial Peripheral Inter-

face (SPI) systems of the Harris CDP68HC05 family of micro-

controllers. Identical interfaces are found on the 68HC11 and

HC16 families. Compatible systems are found on most popu-

lar microcontrollers.

Serial data words are simultaneously transmitted and

received over the SOUT/SIN lines, synchronized to the SCK

clock stream. The word size is fixed at 8-bits. A series of

eight clocks is required to transfer one word. With the excep-

tion of Status/Control Register transfers (described later), all

SERIAL transfers use a single eight bit shift register within

the HIP7010. The serial bits are “shifted out” on the SOUT

pin, most significant bit (MSB) first, from the shift register. As

each bit shifts out one end of the shift register, the data on

the SIN input pin is, usually, shifted into the other end of the

same shift register. After eight clocks, the original contents of

the shift register have been entirely transmitted on the SOUT

pin and replaced by the byte received on the SIN pin.

Most Host micros which include a synchronous serial inter-

face, operate their interface in a manner compatible with the

HIP7010s implementation. The result of each 8-bit SERIAL

transfer is that the contents of the HIP7010s shift register

and the Host’s shift register have effectively been “swapped”.

SERIAL Bus Timing

The SCK output of the HIP7010 is used to synchronize the

movement of data both into and out of the device on its SIN

and SOUT lines. As stated above, the Host and the HIP7010

are capable of exchanging a byte of information during a

sequence of eight clocks generated on the SCK pin. The

relationship between the clock signal on SCK and the data

on SIN and SOUT is shown in Figure 7.

Approximately 750ns prior to each series of eight clocks, the

SACTIVE output of the HIP7010 is driven low. SACTIVE

remains low until a minimum of 1200ns after the last clock

transition. When interfacing to a CDP68HC05 SPI compatible

Host, the SACTIVE output would normally be connected to

the SS input of the Host. The trailing edge of the SACTIVE

signal can also be used as a flag to Hosts which don’t auto-

matically recognize the transfer of a serial byte.

The quiescent state of SCK is low. Once a transfer is initiated, the

rising edge of each SCK pulse places the next bit on the SOUT

line and the falling edge is used to latch the bit input on SIN.

The Host must adhere to this same timing, by meeting the input

setup time requirements of SIN valid before the trailing edge of

SCK (see Electrical Specification for details) and latching

the SOUT data on the same edge. When interfacing the

HIP7010 to a CDP68HC05 SPI compatible Host, the SPI inter-

face should be programmed with CPHA = 1 and CPOL = 0.

At all times, other than during an actual SERIAL transfer

between the HIP7010 and its Host, the SCK and SOUT pins

are held in a high impedance state. This allows other devices

connected to the Host via the SERIAL bus to be accessed

when the HIP7010 is not transferring data. Utilization of the

SERIAL bus by the HIP7010 is less than 5%, leaving signifi-

cant bandwidth for other transfers. When held in the high

impedance state, a pair of integrated pull-down devices on the

SCK and SOUT pull the pins to ground, if they are not driven

by another source. See Applications Information for a

detailed discussion of SERIAL bus utilization.

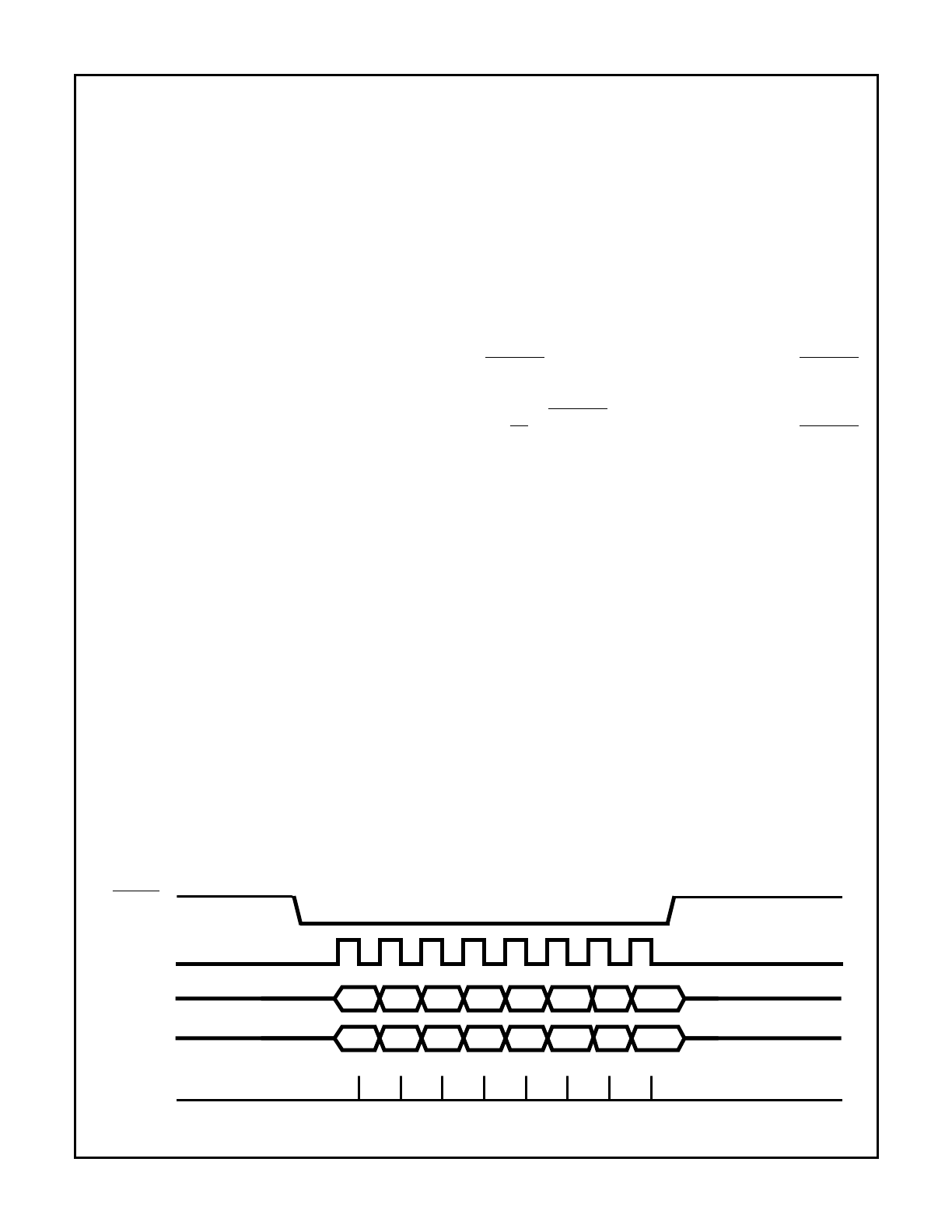

FIGURE 7. SERIAL BUS TIMING

SCK

SOUT

SIN

SACTIVE

SCK NORMALLY LOW

MSB

MSB

6

6

5

5

4

4

3

3

2

2

1

1

LSB

LSB

INTERNAL STROBE FOR LATCHING DATA IN HIP7010

MSB

6

5

4

3

2

1

LSB

11

HIP7010

SERIAL Bus Transfers

The HIP7010 is always configured as a SERIAL “master”. As

a master, the HIP7010 generates the transfer-synchronizing

clock on the SCK pin, transmits data on the SOUT pin, and

receives data on the SIN pin.

Whenever the HIP7010 receives a complete byte from the

J1850 bus via the VPWIN line, it automatically initiates an

unsolicited SERIAL transfer. The unsolicited transfer trans-

mits the received (or reflected) byte to the Host and, if in the

midst of transmitting a message, retrieves the next byte from

the Host. While these unsolicited transfers are, strictly

speaking, asynchronous to the Host’s activities, there are

well defined rules which govern the minimum time between

unsolicited transfers (i.e. - no two unsolicited transfers can

occur in less time than it takes to transfer one J1850 byte (8

x 64 = 512

µ

s). See Applications Information for more

details.

In addition to the unsolicited transfers which are based on

receipt of incoming J1850 messages, the Host can initiate

certain transfers in a more synchronous fashion.

Handshak-

ing between the Host and the HIP7010 is provided by the

Byte Ready (RDY) and Request Status (STAT) pins. These

two pins are driven by the Host and trigger the HIP7010 to

initiate one of the two, unique,

solicited SERIAL transfers.

The Byte Ready (RDY) line is the first of two handshaking

inputs from the Host. Each rising edge on the RDY pin signi-

fies that the Host has loaded a byte into its serial transmit

register and the HIP7010 can retrieve it. If the J1850 bus is

available (i.e. - IFS has elapsed) the rising edge of RDY is

interpreted as signalling the first byte of a new message. The

HIP7010 immediately performs a solicited SERIAL transfer

to load the first byte. Prior to performing the transfer, the

HIP7010 drives the J1850 bus high to initiate an SOF sym-

bol. The SOF is then followed by the eight symbols which

represent the transferred byte. If a J1850 message is

already in progress, the rising edge of RDY is interpreted as

signalling that the next byte of the message or of an IFR is

ready to be transferred from the Host. The HIP7010 will ini-

tiate the transfer, as an unsolicited transfer, when conditions

on the J1850 bus warrant the transfer (i.e. - when the previ-

ously retrieved byte has been completely transmitted on the

J1850 bus or after EOD for an IFR).

While the rising edge of RDY is used to notify the HIP7010

that the Host is ready to supply the next byte, the level of

RDY following the actual serial transfer provides additional

information. Figure 1 depicts the use of RDY. By driving the

RDY line high and returning it low before the transfer has

been completed, the HIP7010 will detect a low. This is

referred to as a

short RDY. If the RDY line is brought high

and held high until the transfer is complete, a high level is

detected by the HIP7010. This is referred to as a long

RDY.

A short RDY signals a normal transfer, but a long RDY has

special significance. A long RDY indicates that the byte cur-

rently sitting within the Host is the last byte of a message or of

an IFR. When transmitting the body of a message or a Type 3

IFR the HIP7010 will automatically append the CRC after the

byte for which the long RDY was used. When responding with

a Type 1 or Type 2 IFR the response is a single byte, and as

such it is always the last byte. For sake of consistency the

HIP7010 requires a long RDY for Type 1 and Type 2 IFRs.

See Status/Control Register and Application Information

for more details.

The other handshaking input is the Request Status/Control

(STAT) input pin. STAT is used by the Host microcontroller to

initiate an exchange of the Host’s

control byte and the

HIP7010’s

status byte. A low to high transition on the STAT

input signals the HIP7010 that the Host has placed a control

word in it’s serial output register and is ready to exchange it

with the HIP7010’s status word. The HIP7010 will generate

the eight SCKs for the solicited transfer as soon as feasible.

To avoid confusion with the transfer of a received J1850

byte, STAT should generally be pulsed shortly after receiving

each data byte from the HIP7010. This technique is safe,

because once a J1850 message byte has been received

from or sent to the HIP7010, another unsolicited transfer is

guaranteed not to happen for at least 500

µ

s. A Control/Sta-

tus byte transfer should also be performed in response to

each high to low transition on the IDLE line. See Applica-

tion Information for more details.

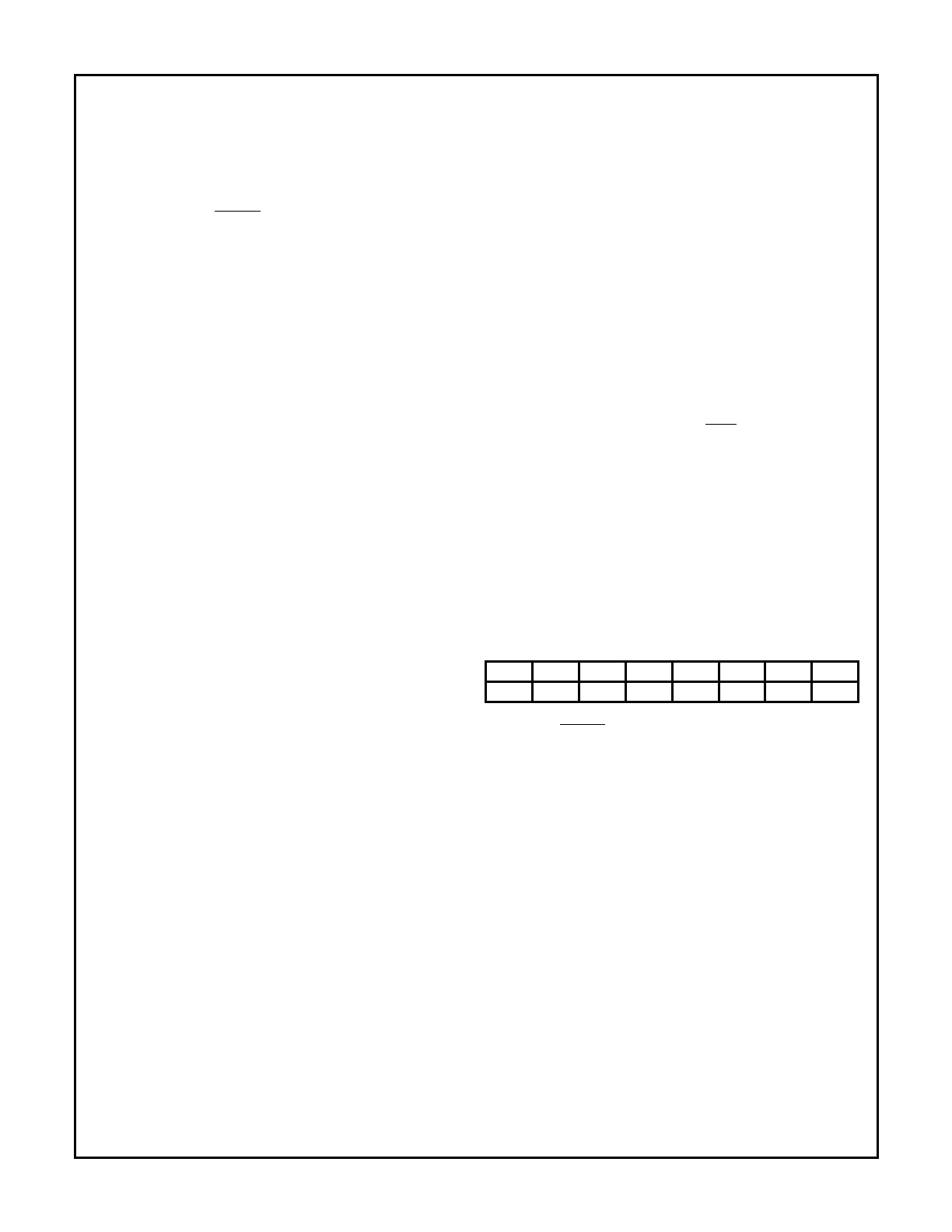

Status/Control Register

The Status/Control Register is actually a pair of registers:

the Status Register and the Control Register. When the Host

initiates a Status/Control Register transfer by raising the

STAT input, the HIP7010 sends the contents of the Status

Register to the Host and simultaneously loads the Control

register with the byte received from the Host.

Status Register

The Status Register contains eight, read-only, status bits.

7

6

5

4

3

2

1

0

EOD

MACK

0

FTU

4X

CRC

ERR

BRK

B7, EOD

When an EOD symbol has been received on

VPWIN and an IFR byte is received from the

J1850 bus, the End-of-Data flag (EOD) is set,

during the unsolicited transfer of the byte from the

HIP7010 to the Host. EOD remains set, until the

unsolicited transfer of the first byte of the next

frame.

EOD can be used to distinguish the IFR portion

of a frame from the message portion.

EOD is cleared by reset.

B6, MACK If MACK (Multi-byte ACKnowledge) is high,

either the MACK control bit has been set during

a previous Status/Control Register transfer or a

long normalization bit has been received follow-

ing an EOD. When both MACK is set and the

EOD flag (see B7, EOD) is set, the most recent

data byte transferred is part of a Type 3 IFR.

The value of MACK is only relevant if EOD = 1.

MACK remains set until the unsolicited transfer

of the first byte of the next frame.

MACK is cleared by reset.

B5, 0

Bit 5 of the Status byte is not used and will

always read as a 0.

12

HIP7010

B4, FTU

When First Time Up (FTU) is high, it indicates

that a reset has occurred since the last Status/

Control Register transfer. FTU is high during the

first Status/Control Register transfer after a reset

and low thereafter.

FTU can be used to recognize that a Slow Clock

Detect reset has occurred or to insure that a

Status/Control Register transfer has been suc-

cessfully completed since the last reset.

B3, 4X

The 4X status flag indicates that the 4X mode bit

has been set in the Control Register. This bit

reflects the contents of the Control Register not

the current mode of the HIP7010’s SENDEC.

The SENDEC only changes modes synchro-

nously with an edge detected on the VPWIN pin.

4X is cleared by reset.

B2, CRC

The CRC Error flag (CRC) is set when a CRC

error has been detected in the current frame.

CRC is cleared by reset and at the conclusion of

the Status/Control Register transfer.

B1, ERR

The Error flag (ERR) is set when an illegal sym-

bol or other, non-CRC error has been detected on

the VPWIN pin. Following are some of the many

errors which will cause ERR to be set: 1. An illegal

symbol, (i.e. - a symbol other than a TV1, TV2, or

Break in the middle of a data byte); 2. Receipt of a

truncated byte (i.e. - less than 8 symbols); 3. The

Host attempting to initiate a message more than

96

µ

s after the IDLE line goes high; 4. An improp-

erly framed message (i.e. - SOF not equal to

TV3, wrong EOD, EOF, or NB widths); 5. Failure

by the Host to use the long form of RDY to indi-

cate the last byte of a message; 6. An attempt by

the Host to transmit a single byte (Type 1 or Type

2) IFR by setting ACK but without using the long

form of RDY for the byte transfer; 7. Setting the

Host asserting STAT during a data byte transfer;

8. A transition has occurred on the VPWOUT pin

and the reflected transition has not been

detected on VPWIN (echo fail).

ERR is cleared by a reset and at the conclusion

of the Status/Control Register transfer.

B0, BRK

The break flag (BRK) is set on the first rising

edge of VPWIN after a BRK symbol has been

detected on the J1850 bus. If the Host was

transmitting or has a message to transmit, it

should re-arbitrate for the bus following an IFS

(IDLE goes low).

BRK automatically clears the 4X mode of the

SENDEC and resets the 4X bit in the Status byte.

BRK is cleared by a reset or at the conclusion of

the Status/Control Register transfer.

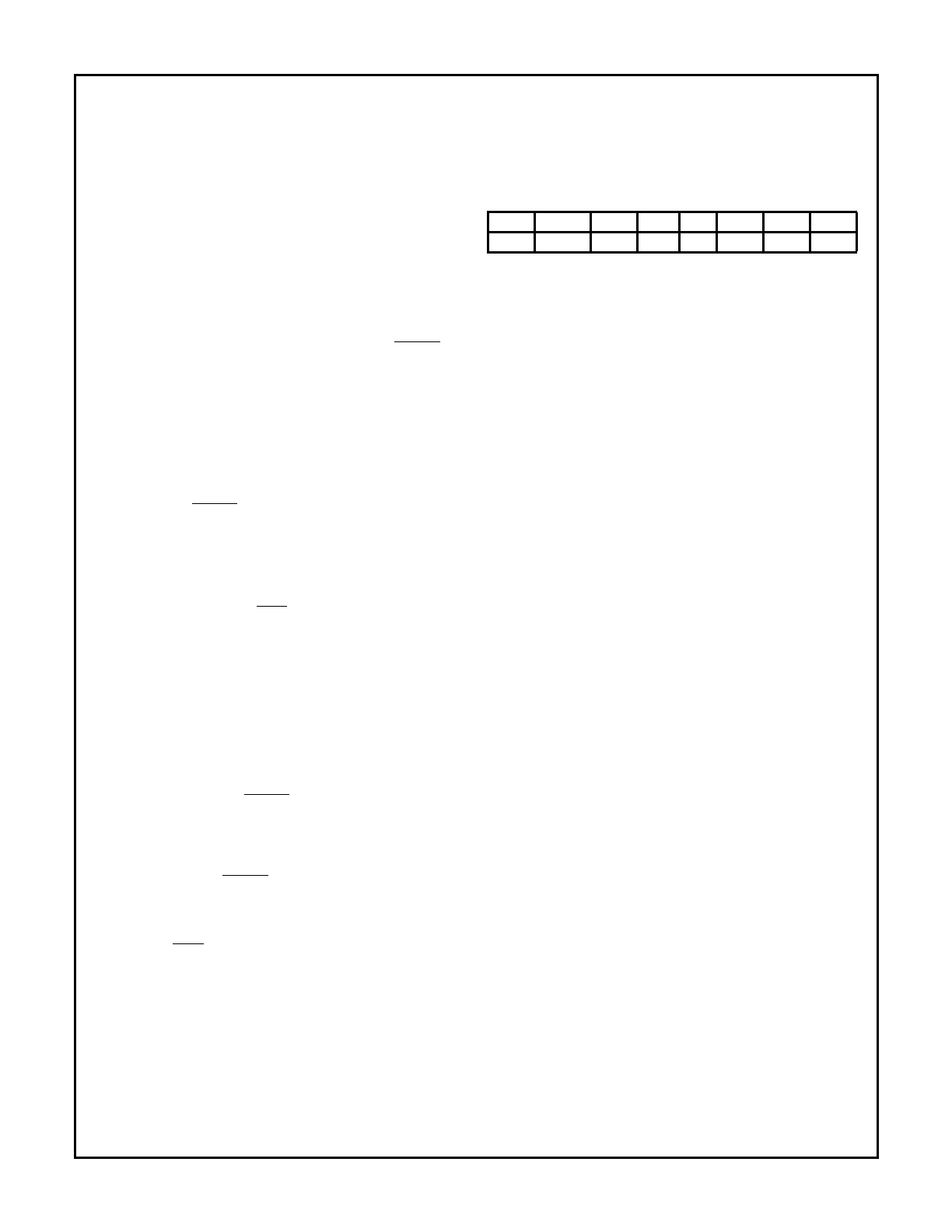

Control Register

The Control Register contains eight, write-only, control bits.

The PD, NXT, MACK, and ACK bits can only be set high

they are cleared by hardware under specific conditions. The

other four bits can be both set and reset by the Host. All bits

in the Control Register are cleared by reset.

7

6

5

4

3

2

1

0

ACK

MACK

NXT

PD

4X

DS2

DS1

DS0

B7, ACK

Setting the Acknowledgment (ACK) bit signals

the HIP7010 that, following the EOD, an IFR

response is to be sent. Once set, the ACK bit

cannot be cleared by the Host. ACK is cleared

upon successful transmission of the IFR or at

the next Idle.

The ACK bit can be set anytime prior to 135

µ

s

after the final byte (the CRC) of a message. The

first IFR byte must be loaded into the Host’s

serial output register, and the RDY line set after

the HIP7010 transfers the next-to-last byte to

the Host, and before the HIP7010 transfers the

last byte (CRC) of the J1850 message to the

Host. When the CRC byte is sent to the Host

from the HIP7010, the IFR byte will be simulta-

neously loaded into the HIP7010.

To send a single byte (Type 1 or Type 2) IFR the

Host must leave MACK (B6 of the Control Regis-

ter) low and use the long RDY line format.

When sending a single byte (Type 1 or Type 2)

IFR, the possibility of losing arbitration exists. In

the case of a Type 1 IFR no further action should

be taken. The standard protocol for handling

loss of arbitration during a Type 2 IFR is to re-

attempt the transmission until successful. To

ensure proper transmission of the IFR the Host

must repeatedly load it’s serial output register

with the desired IFR byte, and set RDY (using

the short format), until the IFR has been prop-

erly received back. There is no danger of inad-

vertently sending the IFR byte twice. The

HIP7010 monitors the arbitration results and will

transmit the IFR byte only once. The ACK bit is

automatically cleared upon the first successful

transmission thus preventing a second transmis-

sion. The Host controls when the ACK bit is set.

During normal operation the Host must only set

ACK once per IFR.

To send a Type 3 IFR the Host must set MACK

high and use the short format of the RDY for all

bytes except the last, when the long format is

used. A CRC will automatically be appended to

the last byte of a Type 3 IFR. A Type 3 IFR, con-

sisting of a single byte plus CRC, can be created

by setting MACK high and using the long RDY

line format for loading the single data byte.

13

HIP7010

When sending a Type 3 IFR, the possibility of

losing arbitration during the IFR also exists. In

the case of Type 3 IFRs, once arbitration has

been lost the Host no longer needs to continue

transmitting bytes. As in the case of Type 2

IFRs, the Host cannot know arbitration has been

lost until after the next byte to transmit has been

loaded. Again, there is no danger of sending

extra bytes because the HIP7010 automatically

suspends transmissions once arbitration is lost.

B6, MACK The Multi-byte Acknowledge (MACK) bit, in con-

junction with the ACK bit, signals the HIP7010

that, following the EOD, a Type 3 IFR with CRC

response is to be sent. Once set, the MACK bit

cannot be cleared by the Host. MACK is cleared

upon detection of an Idle following the transmis-

sion of the IFR. Setting MACK without also set-

ting ACK will result in no IFR being transmitted.

The MACK bit can be set anytime prior to 135

µ

s

after the final byte (the CRC) of a message. The

first IFR byte must be loaded into the Host’s

serial output register, and the RDY line set after

the HIP7010 transfers the next-to-last byte to

the Host, and before the HIP7010 transfers the

last byte (CRC) of the J1850 message to the

Host. When the CRC byte is sent to the Host

from the HIP7010, the first IFR byte will be

simultaneously loaded into the HIP7010. To

send a Type 3 IFR the Host uses the short for-

mat of the RDY for all bytes except the last,

when the long format is used.

Setting the MACK bit in the Control Register is

not immediately reflected in the MACK bit of the

Status Register. The status bit is updated follow-

ing each data transfer.

B5, NXT

If the Wait for Next Idle (NXT) bit is asserted

high during a Status/Control Register transfer,

the HIP7010 State Machine is re-initialized to a

“wait for Idle” state. The VPWOUT pin is driven

low and the IDLE pin is reset high. Activity on

the VPWIN pin is ignored until a valid Idle is

detected. When NXT is asserted the IDLE pin

will go high for a minimum of 6

µ

s. If the bus is

Idle at the end of the 6

µ

s period, IDLE will be

driven low and the HIP7010 will be ready to

transmit or receive a J1850 message. If the bus

is not Idle, current activity on the VPWIN pin is

ignored until a new Idle is detected.

The NXT bit enables the Host to ignore the bal-

ance of the current message. Unsolicited trans-

fers from the HIP7010 are guaranteed not to

occur until the next Idle occurs. Transfers

resume following the first byte of the next mes-

sage.

B4, PD

The Power-Down (PD) bit is used to halt internal

clocks to the HIP7010 to minimize power. A low

level on the VPWIN, a low to high edge on the

STAT pin, or a high level on the RDY pin will clear

the PD bit and normal HIP7010 functions will

resume.

PD can only be set if the IDLE pin is low or dur-

ing the first Status/Control Register transfer fol-

lowing a reset. The CLK input is internally gated

off at the end of the Status/Control Register

transfer.

There are two situations which can cause the

PD bit to be cleared prematurely: 1. The RDY

input is high during the Status/Control Register

transfer (since this is under control of the Host it

should be avoided); 2. A noise pulse of less than

8

µ

s duration occurs on the VPWIN line.

If either of these situations occur, the PD will be

cleared, the HIP7010 will resume operating and

look for a valid edge on VPWIN, RDY, or STAT. If

no valid edge has occurred the HIP7010 will

recycle to the top of the State Machine, pulsing

IDLE high for a minimum of 2

µ

s. It is the respon-

sibility of the Host to monitor the IDLE pin after

setting PD to ensure that the POWER-DOWN

mode has been successfully entered.

See Effects of Resets and Power-Down for a

detailed discussion of the Power-Down mode.

B3, 4X

Setting the High Speed Mode (4X) bit causes the

HIP7010’s SENDEC to decode symbols received

on the J1850 bus at 0.25X the normal durations.

The 4X mode is designed to allowed receipt of

messages at 4X the normal J1850 rate. It is

intended for manufacturing and diagnostic use, not

normal “down the road” vehicle communications.

Transmission is inhibited while the 4X bit is set.

The 4X bit can only be written to when the IDLE

pin is low or during the first Status/Control trans-

fer following a reset. Setting 4X is inhibited during

the first Status/Control after a Break. The SEN-

DEC begins operating at the 4X rate upon receipt

of the next edge. The system must provide suffi-

cient time for all nodes to detect the Idle, interpret

the “shift to high speed” message, and change

their mode bits before issuing a high speed SOF.

4X is cleared by receipt of a Break symbol on

the J1850 bus and it can also be cleared by per-

forming a Status/Control Register transfer with

the 4X bit low. When cleared via a Status/Con-

trol Register transfer, IDLE must be low. The

SENDEC reverts to operating at the normal rate

upon receipt of the next edge.

4X mode cannot be utilized for transmitting mes-

sages. VPWOUT is disabled in hardware, but

the State Machine will attempt to transmit if RDY

is strobed. It is the Host’s responsibility to refrain

from transmitting in 4X mode.

14

HIP7010

B2, DS2

B1, DS1

B0, DS1

The three Divide Select bits (DS2-DS0) are used

to match the internal clock divider with the input

frequency on the CLK input to produce the

required 2MHz internal time base. Table 3 shows

the clock divide values and nominal input fre-

quency for the eight combinations of DS2-DS0.

During a HIP7010 reset caused by a POR, a

Slow Clock Detect, or a low on the RESET line,

the Clock Divider is inhibited and a fixed divide-by

sixteen clock divider is activated. This is greater

than any selectable divide-by and guarantees

proper operation of the SERIAL interface for all

valid operating frequencies (although the transfer

rate will be below 1MHz). The CLK divide-by

remains at sixteen and operation of the HIP7010

is suspended until the Host performs a Status/

Control Register transfer to set the proper divide

value. The State Machine and SENDEC are held

in a reset state (passive) until the first Status/

Control Register transfer has been completed.

This insures proper setting of the divide selects

prior to generation or receipt of any symbols.

TABLE 3. DS2-DS0 CLOCK DIVIDER SELECTIONS

DS2

DS1

DS0

CLK INPUT

FREQ. (MHZ)

INTERNAL

HIP7010 CLK

DIVIDE-BY

0

0

0

24 (Note 1)

12

0

0

1

12 (Note 1)

6

0

1

0

20

10

0

1

1

10

5

1

0

0

16 (Note 1)

8

1

0

1

8

4

1

1

0

4

2

1

1

1

2

1

NOTE:

1. Objective Specification

Once DS2-DS0 have been set following a reset,

they must not be altered. Each Status/Control

Register transfer must properly reassert the

same DS2-DS0 values to maintain proper clock-

ing. Selecting a DS2-DS0 combination which is

too low for the given CLK frequency can result in

loss of SERIAL communications, due to exces-

sive clocking rates. In such instances the only

recovery mechanism is to force a HIP7010 reset

by pulling the RESET input low, interrupting the

CLK input, or performing a power-on reset. A well

behaved Host will avoid changes to DS2-DS0.

System fault tolerance can be maximized by using

the lowest possible frequency at the CLK input.

Power-down does not reset DS2-DS0, allowing

rapid “wake-up” from the Power-down state.

Symbol Encoder/Decoder (SENDEC)

Operation

The Symbol Encoder/Decoder (SENDEC) hardware inte-

grated in the HIP7010 handles generation and reception of

J1850 messages on a symbol by symbol basis. Symbols are

output from the SENDEC, as a digital signal, on the VPWOUT

pin and input, as a digital signal, on the VPWIN pin. These

two lines must be connected through a bus transceiver (such

as the Harris J1850 Bus Transceiver HIP7020) to the single

wire J1850 bus. The transceiver is responsible for generating

and receiving waveforms consistent with the physical layer

specifications of J1850. In addition, the transceiver is respon-

sible for providing isolation from bus transients.

Every symbol sent out on the VPWOUT is, in effect, inverted and

reflected back on the VPWIN pin after some finite delay through

the transceiver. In actuality. Only active symbols are guaranteed

to be reflected unchanged. If the transmitted symbol is passive

and another node is simultaneously sending an active symbol,

the active symbol will dominate and pull the bus to a high level.

The SENDEC circuitry includes a 3-bit digital filter which effec-

tively filters out noise pulses less than 8

µ

s in duration.

The STATE logic transfers data bits between the SERIAL

system and the SENDEC and handles addition of required

frame elements such as the SOF symbol and the CRC byte.

When transmitting bytes, bits are taken from the SERIAL

shift register and translated into the required symbols, bit by

bit. Timing of each symbol is calculated from the last

transition on the VPWIN line which keeps all nodes on the

J1850 bus “in synch” during arbitration periods.

Decoding of received symbols is automatically performed by

the SENDEC. The decoded symbol is translated to a 0 or 1

value and transferred by the STATE logic into the SERIAL shift

register. As each symbol is decoded it is shifted into the

SERIAL shift register and, if transmitting, the next bit to transmit

on the J1850 bus is shifted out. Once an entire byte has been

loaded into the SERIAL shift register the STATE logic automati-

cally generates an unsolicited transfer of the byte to the Host.

Whenever the SENDEC is transmitting, it is simultaneously

monitoring the “reflected” symbol on the VPWIN line. At

each transition the reflected symbol is read and compared to

the sent one. If the reflected symbol doesn’t match the sym-

bol sent, a collision has occurred and the HIP7010 automati-

cally disables transmissions until the next Idle/IFR period. If

there was no collision, the HIP7010 continues transmitting

until the entire byte has been sent. Once the byte has been

sent, a full byte will also have been reflected and received by

the HIP7010. As discussed above, the HIP7010 initiates a

transfer of the received byte to the Host, which allows the

Host the opportunity to compare the sent and reflected

bytes, and to transfer the next byte of the message.

In addition to features already discussed, the SENDEC

includes, noise detection, Idle bus detection, a wake-up facil-

ity, “no echo” detection, and a high speed receive mode. Sym-

bol timing is based on the main CLK input. The programmable

prescaler, controlled by the DS0-DS2 bits in the Control Reg-

ister, allows proper SENDEC operation with a variety of CLK

input frequencies (see DS2-DS0 under Status/Control Reg-

15

HIP7010

ister for prescaler details). The high speed mode is a J1850

extension which allows production and/or maintenance equip-

ment to transmit messages at 4X the normal 10.4Kbps rate

(see 4X under Status/Control Register for prescaler details).

Software algorithms can be implemented in the Host to pro-

vide message buffering and filtering and other needed fea-

tures to create a complete J1850 VPW node. See the

Applications Information section for typical algorithms.

The State Machine Logic (STATE)

The State Machine Logic (STATE) of the HIP7010, is a

sequential state machine implementation of the J1850 VPW

data link layer. STATE controls data flows within the

HIP7010 and between the Host and the J1850 bus.

When receiving messages, STATE monitors the input from

the SENDEC, building byte sized chunks to send to the

Host. As each byte is assembled, STATE transfers the result

to the Host via the Serial interface, as an unsolicited transfer.

Upon receipt of a complete message (recognized by EOD),

STATE verifies both the CRC and bit counts and sets appro-

priate Status Register flags.

When transmitting messages from the Host to the J1850

bus, STATE waits for the first RDY input transition, after

which it retrieves the first byte from the Host and initiates the

message with an SOF. Each bit of the Host’s message byte

is transferred to the J1850 bus via the SENDEC. When the

transfer of a byte is complete, STATE checks for a new RDY

(if there is one), retrieves the associated byte, and again

transfers the byte via the SENDEC to the J1850 bus. After

retrieving each byte from the Host, STATE checks to see if

the long RDY format was used, which indicates this is the

end of the Host’s message. If the message is complete,

STATE transfers the final byte to the J1850 Bus and then,

automatically, sends the computed CRC to the J1850 bus.

Throughout the transmission of a message from the Host to

the J1850 bus, STATE monitors the symbols reflected back

via the SENDEC and handles all bus conditions such as loss

of arbitration, illegal bits, Break, bad CRC, and missing bits.

STATE also catches Host errors including failure to set the

RDY line in time for the next byte transfer, attempting to ini-

tiate a new message more than 96

µ

s after IDLE has gone

away, and inappropriate use of the STAT line (i.e. - request-

ing a Status/Control Register transfer during an unsolicited

transfer of the reflected data).

In 4X mode VPWOUT is disabled in hardware, but STATE

will attempt to transmit if RDY is strobed. This results in

STATE clearing IDLE and waiting for the leading edge of

SOF. Since VPWOUT is blocked STATE will only recover if

another node’s SOF is received or NXT is set. It is the Host’s

responsibility to refrain from transmitting in 4X mode.

The Control Register bits influence STATE. If ACK is set,

STATE handles sequencing of the requested IFR. The flow

consists of waiting for an EOD, sending the appropriate Nor-

malization Bit (Type 1/2 vs Type 3 IFR), transferring the IFR

byte(s) from the Host to the J1850 bus, handling arbitration,

and finally adding the CRC to Type 3 IFRs. As with normal

transmissions, STATE contains error handling to react

appropriately to all J1850 bus conditions.

Detection of an Idle on the bus causes STATE to set the IDLE

pin. STATE clears the IDLE pin upon receipt of a transition on

the VPWIN line or when the Host initiates a new message.

Detection of a Break on the J1850 bus causes an interrupt

input to STATE which causes the HIP7010 to cease any cur-

rent transmission and enter a

wait for IDLE mode.

Effects of Resets and Power-Down

Resets

A Power-On reset, a Slow Clock Detect reset, and a low on

the RESET pin all have an identical effect on the operation

of the HIP7010. All resets are asynchronous and

immedi-

ately do the following:

• VPWOUT is forced low.

• The HIP7010 is set to

RESTART mode.

• The internal divide-by is set to sixteen and held at that

value until the RESTART mode ends.

• SACTIVE is forced high and SCK and SOUT are set to a

high impedance state.

• The ACK, MACK, NXT, PD, and 4X bits are cleared in the

Control Register.

• All Status Register bits are cleared (except bit 4, FTU,

which is set to a 1).

• IDLE is forced high and held high for 17 CLKs after the

source of the reset is removed. After 17 CLKs, IDLE is

forced low. IDLE Remains low until 40 CLKs +1.5

µ

s after

the first Status/Control Register transfer.

• The SENDEC is reset, holding the symbol timer at a count

of 0 and clearing the 3-bit VPWIN filter to all 0’s, until the

RESTART mode ends.

• STATE is held in a

reset loop until the RESTART mode

ends. While STATE is in the reset loop, transitions on the

RDY pin are ignored.

The RESTART mode is entered by any reset and ends when

the first Status/Control Register transfer has been com-

pleted. Upon exiting the RESTART mode the HIP7010

enters its normal

RUN mode. This is reflected in the clearing

of the FTU bit of the Status Register.

When the RESTART mode ends and the RUN mode begins,

the internal divide-by is set to the value programmed via

DS2-DS0 in the Control Register. The IDLE pin is driven

high after 40 CLKs, the SENDECs counter and VPWIN filter

begin operating, and STATE begins monitoring the outputs

of SENDEC looking for an Idle.

The HIP7010 remains in RUN mode until another reset

occurs or the POWER-DOWN mode is entered.

Power-Down

The

POWER-DOWN mode of the HIP7010 is entered by set-

ting the PD bit in the Control Register (see Control Register

for more information). Setting the PD bit can only be done

when the HIP7010 is driving the IDLE pin low. Once set, the

PD forces the HIP7010 to the POWER-DOWN mode 2

µ

s

after the completion of the Status/Control Register transfer.

While in the POWER-DOWN mode the CLK input is internally

gated off, minimizing power dissipation. The Slow Clock

Detect is inhibited while in the POWER-DOWN mode.

16

HIP7010

A return to the RUN mode from the POWER-DOWN mode is

normally caused by a low level on VPWIN. During POWER-

DOWN the input signal is not filtered via the 7

µ

s digital filter (no

clocks are available to drive the digital filter). Without filtering in

place it is possible for a noise spike, less than 8

µ

s wide, to

wake-up the HIP7010. In such a case the HIP7010 returns to

RUN mode, but the spike is rejected by the now running, digital

filter and the bus continues in the Idle state. To notify the Host

when such spurious wake-ups occur, STATE monitors the out-

put of the digital filter and if, within 12

µ

s after the wake-up, the

digital filter doesn’t indicate VPWIN is low, STATE pulses IDLE

high for 2

µ

s and then drives it low again. The HIP7010 is now in

the RUN mode. It is the responsibility of the Host to recognize

the pulse on the IDLE pin and set PD in the Control Register to

reenter the POWER-DOWN mode. In systems where the Host

directly monitors the VPWIN pin during POWER-DOWN, moni-

toring the IDLE pin may not be necessary.

One of the mechanisms to exit POWER-DOWN is to provide

a high level on the RDY pin. Since this is a level sensitive

event the HOST must ensure that RDY is not already high

when the PD bit is set in the Control Register. A well behaved

Host will control this properly. However, in the event RDY is

high when PD is set, a 12

µ

s time-out will occur similar to that

described for waking-up with a noise pulse on VPWIN. After

the time-out, IDLE will pulse high for 2

µ

s then low again. The

Host should react to this pulse appropriately.

Test Mode

Overview

When the TEST Pin of the HIP7010 is driven high, it modi-

fies the operation of the BLIC in two ways:

1.

It inhibits receipt of bus signals on the VPWIN pin and

internally routes the VPWOUT signal to the VPWIN

input.

During this “loopback” mode of operation the

VPWOUT pin will continue to operate.

2.

The State Machine which controls the operation of the

HIP7010 is extended to include a special TEST Sequence.

The TEST Sequence can only be entered from one loca-

tion in the normal State Machine flow. This point can con-

veniently be reached following reset of the BLIC or by

setting the NXT bit in the BLIC’s Control Register.

Entering the TEST Sequence

Entry into the TEST Sequence of the BLIC’s State Machine

requires that the TEST pin is high and the State Machine is

at it’s “start”. The State Machine will always pass through it’s

starting point at certain identifiable times:

1.

Following the first Status/Control Transfer after a Reset

2.

Following completion of a J1850 message (i.e. after EOD)

3.

Following abortion of a message frame due to noise, bad

symbol, bad CRC, receipt of a Break, etc.

4.

Following setting of the NXT bit in the Control Register

As are all states, the starting point is a transitory state. Once

entered the, State Machine will remain at its start only until

the bus has been low for a TV4 min (i.e. EOF, 239

µ

s). To

ensure proper synchronization, the TEST Sequence should

generally be entered only after a Reset or after setting the

NXT bit in the BLIC’s Control Register.

Test Block 1

Once the TEST Sequence has been entered, IDLE will go

low. Once IDLE has gone low, each time that RDY is pulsed

(with the short form of RDY) it will result in an exchange of

data between the Host’s SPI register and the BLIC’s data

register. Following a reset, the BLIC’s data register will con-

tain $00. For all other exchanges during the TEST sequence

the BLIC will give back to the Host the byte it supplied during

the prior exchange. During each exchange the IDLE pin will

go high and return low when the exchange is complete. Fol-

lowing each exchange the Host should query the BLIC’s Sta-

tus Register by pulsing STAT. All flags should be clear.

This section of the TEST Sequence not only checks proper