Copyright

©

Harris Corporation 1996

10-91

Harris Semiconductor

No. AN9334.1

October 1996

Harris Linear

Improving Start-up Time at 32kHz for the HA7210 Low Power

Crystal Oscillator

Author: Robert Rood

The HA7210 is a very low power crystal-controlled oscillator

that can be programmed to operate between 10kHz and

10MHz. In the lowest frequency range setting (FREQ 1 = 1,

FREQ 2 = 1), at 32kHz with a 5V supply and a 40pF load, the

HA7210 will draw a mere 10

µ

A. In this range (10kHz to

100kHz), the low power consumption may result in extended

oscillator start-up time. In higher frequency ranges, power

consumption gradually increases and start-up time is not an

issue. Several approaches to address low frequency start-up

time will be presented.

The first approach is to use the Enable/Disable Mode Pin.

This pin, when pulled low, will switch the output to a high

impedance state while an internal inverter continues to drive

the crystal in normal oscillation. This will result in a power

savings because very often a majority of the power dissipation

is used to drive the output load. In the disabled mode the

HA7210 will draw only 5

µ

A of standby current as compared to

10

µ

A above. This small amount of standby current gives the

benefit of instant start-up of a reliable and stable clock. The

Enable Time of the HA7210 is typically 800ns.

For applications where the voltage supply is removed from the

circuit or standby mode is not desired, the time from power

being applied until a stable square wave is generated can be

unexpectedly long. It should be noted that 32kHz crystal

parameters vary significantly from vendor to vendor and can

greatly affect the HA7210 (or any Pierce Oscillator) start-up

characteristic. Of particular importance is the Effective Series

Resistance (ESR) of the crystal, with lower ESR generally

providing faster start-up times (32kHz crystals with ESR

greater than 50k

Ω

should be avoided). Using the circuit in Fig-

ure 1 the start-up characteristic of a 32.768kHz crystal, set in

the recommended lowest frequency range (FREQ 1 = 1,

FREQ 2 = 1) has a delay of 1.9s as shown in Figure 2.

FREQUENCY SELECTION TRUTH TABLE

ENABLE

FREQ 1

FREQ 2

OUTPUT RANGE

1

1

1

10kHz to 100kHz

1

1

0

100kHz to 1MHz

1

0

1

1MHz to 5MHz

1

0

0

5MHz to 10MHz

0

X

X

High-Z

V

DD

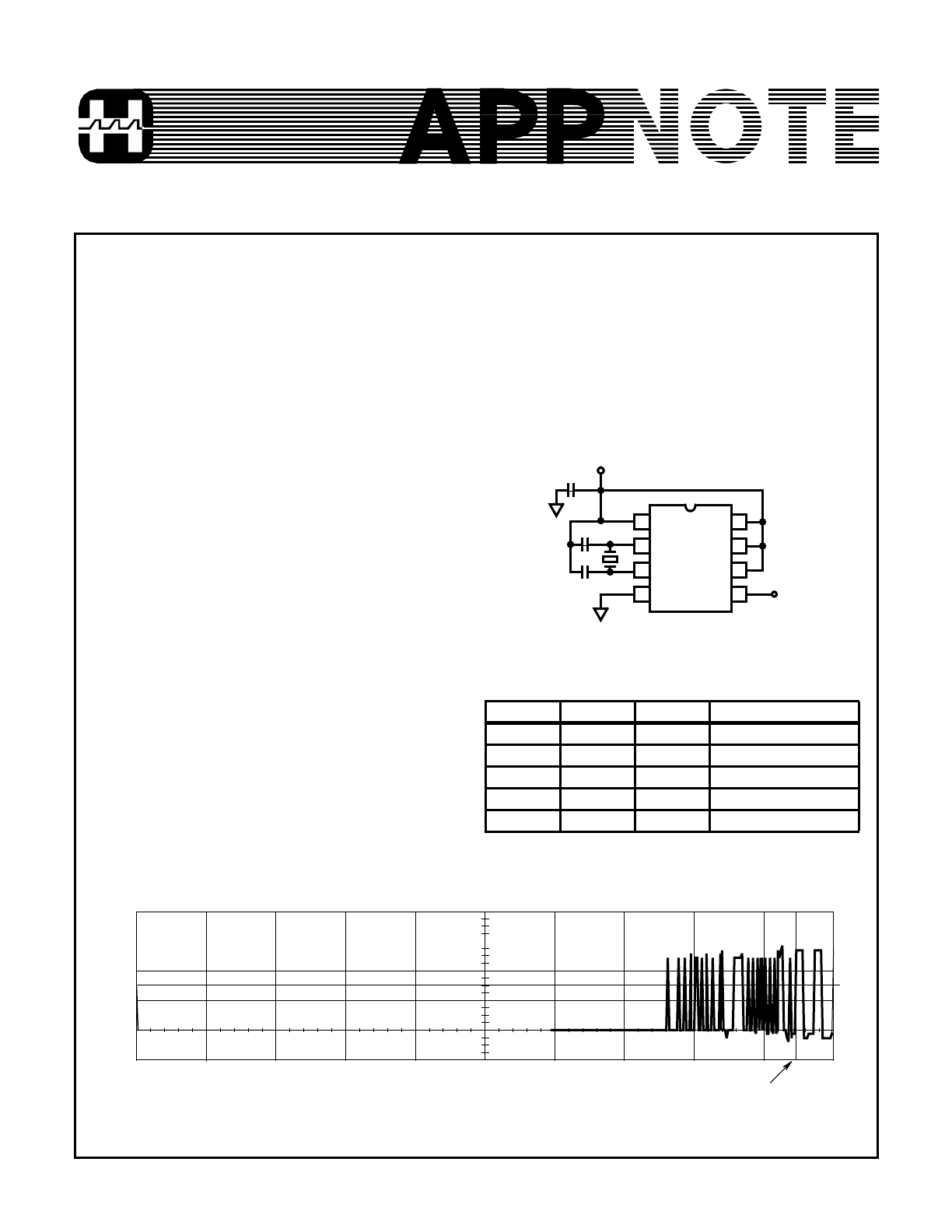

1

2

3

4

8

7

6

5

HA7210

32.768kHz

CLOCK

0.1

µ

F

ENABLE

FREQ 2

FREQ 1

10pF

10pF

32.768kHz

CRYSTAL

C

1

C

2

FIGURE 1. TYPICAL APPLICATION CIRCUIT

0.0s

1.0s

1.892s

2.0s

0V

V

DD

= 5V, C

1

= 10pF, C

2

= 10pF, FREQ 1 = 1, FREQ 2 = 1, CRYSTAL = EPSON (C-001R 32.768K-A)

2V/DIV.

200ms/DIV.

FIGURE 2. START-UP CHARACTERISTIC AT 32kHz WITH FREQ 1 = 1 AND FREQ 2 = 1

10-92

The start-up time can be improved by switching to the next

higher frequency range setting, where FREQ 1 = 1 and FREQ

2 = 0. In this setting the voltage that is internally applied to the

oscillating inverter increases from 1.4V to 2.2V providing more

power and higher transconductance. This increased power

comes at the expense of increased supply current. For a 32kHz

crystal, with V

DD

= 5V and a 40pF load the FREQ 1 = 1,

FREQ 2 = 0 setting will draw 30MA as compared to 10MA for

the FREQ 1 = 1, FREQ 2 = 1 range setting. Another concern

when using the next higher range is that the internal 15pF crys-

tal loading capacitors are disconnected. This means that the

user must provide external crystal loading capacitors for the

crystal to start properly in the higher range. The minimum val-

ues for C

1

and C

2

to provide reliable start-up was found to be

10pF each. The start-up time in the FREQ 1 = 1, FREQ 2 = 0

mode is shown in Figure 3 at 528ms, significantly faster than

the FREQ 1 = 1, FREQ 2 = 1 setting.

How can the benefits of faster start-up be gained without the

penalty of increased supply current? A solution to this prob-

lem is provided with the addition of a single capacitor C

F2

as

shown in Figure 4.

The digital inputs (ENABLE, FREQ 1, FREQ 2) provide internal

pull-up devices. These P-Channel devices provide 0.4

µ

A of

current to insure that an input will go to the “1” state if left open.

This pull-up current is used to charge a 0.22

µ

F capacitor (C

F2

)

connected to the FREQ 2 pin. At power-up C

F2

has zero

charge and holds FREQ 2 “low”, (FREQ 1 = 1, FREQ 2 = 0) so

that the HA7210 will give a fast start-up. Then the 0.4

µ

A pull-up

current will slowly charge C

F2

until it reaches a “high” state

(FREQ 1 = 1, FREQ 2 = 1) and the part draws lower supply cur-

rent. The FREQ 2 pin must be held low until the oscillation has

fully started to insure a start-up time improvement. The digital

input threshold is about 1.5V, providing a delay determined by:

The results are shown in Figure 5. Notice that CH 2 doesn’t

go all the way to 5V as expected. This is due to the 10M

Ω

scope probe loading the 0.4

µ

A current source. This probe

loading also causes CH 2 (FREQ 2 pin) to have an RC

shape rather that the expected linear trace.

In summary, start-up time is an important consideration in the

design and crystal selection for low frequency crystal oscilla-

tors. This Application Note describes several alternatives to

improve start-up time utilizing unique features of the HA7210

while taking advantage of its extremely low supply current.

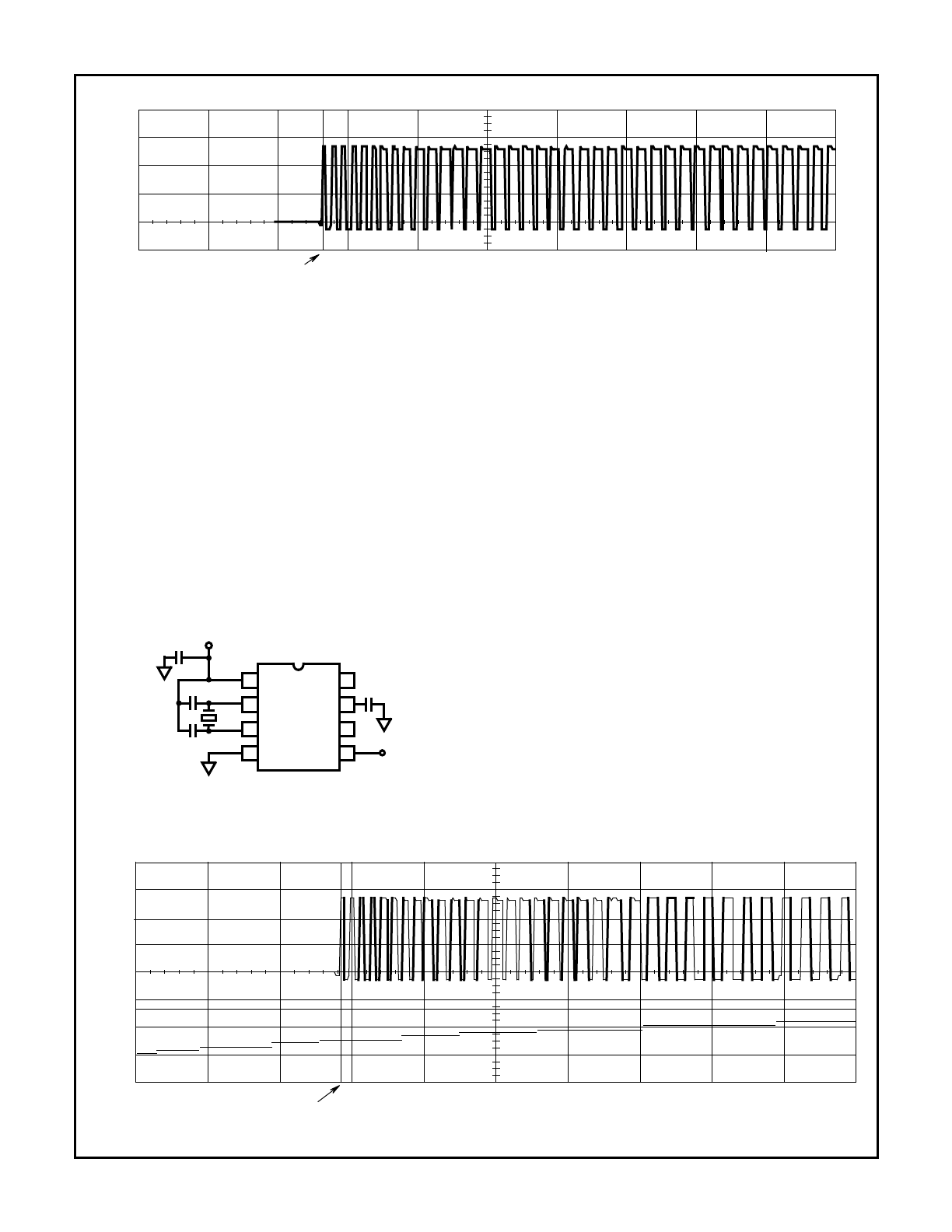

528ms

1.0s

0.0s

2.0s

0V

V

DD

= 5V, C

1

= 10pF, C

2

= 10pF, FREQ 1 = 1, FREQ 2 = 0, CRYSTAL = EPSON (C-001R 32.768K-A)

2V/DIV.

200ms/DIV.

FIGURE 3. START-UP CHARACTERISTIC AT 32kHz WITH FREQ 1 = 1 AND FREQ 2 = 0

V

DD

1

2

3

4

8

7

6

5

HA7210

32.768kHz

CLOCK

0.1

µ

F

ENABLE

FREQ 2

FREQ 1

10pF

10pF

32.768kHz

CRYSTAL

OUTPUT

0.22

µ

F

C

1

C

2

C

F2

FIGURE 4. FAST START-UP AT 32kHz WITH NO SUPPLY

CURRENT PENALTY

i

C

dv

dt

-------

=

dt

0.22

µ

F

(

)

1.5V

(

)

0.4

µ

A

----------------------------------------------

=

0.825s

=

568ms

0.0s

1.0s

2.0s

0V

0V

CH1

CH2

2V/DIV

200ms/DIV

FIGURE 5. START-UP CHARACTERISTIC AT 32kHz WITH SPEED-UP CIRCUIT

Application Note 9334