C

B

E

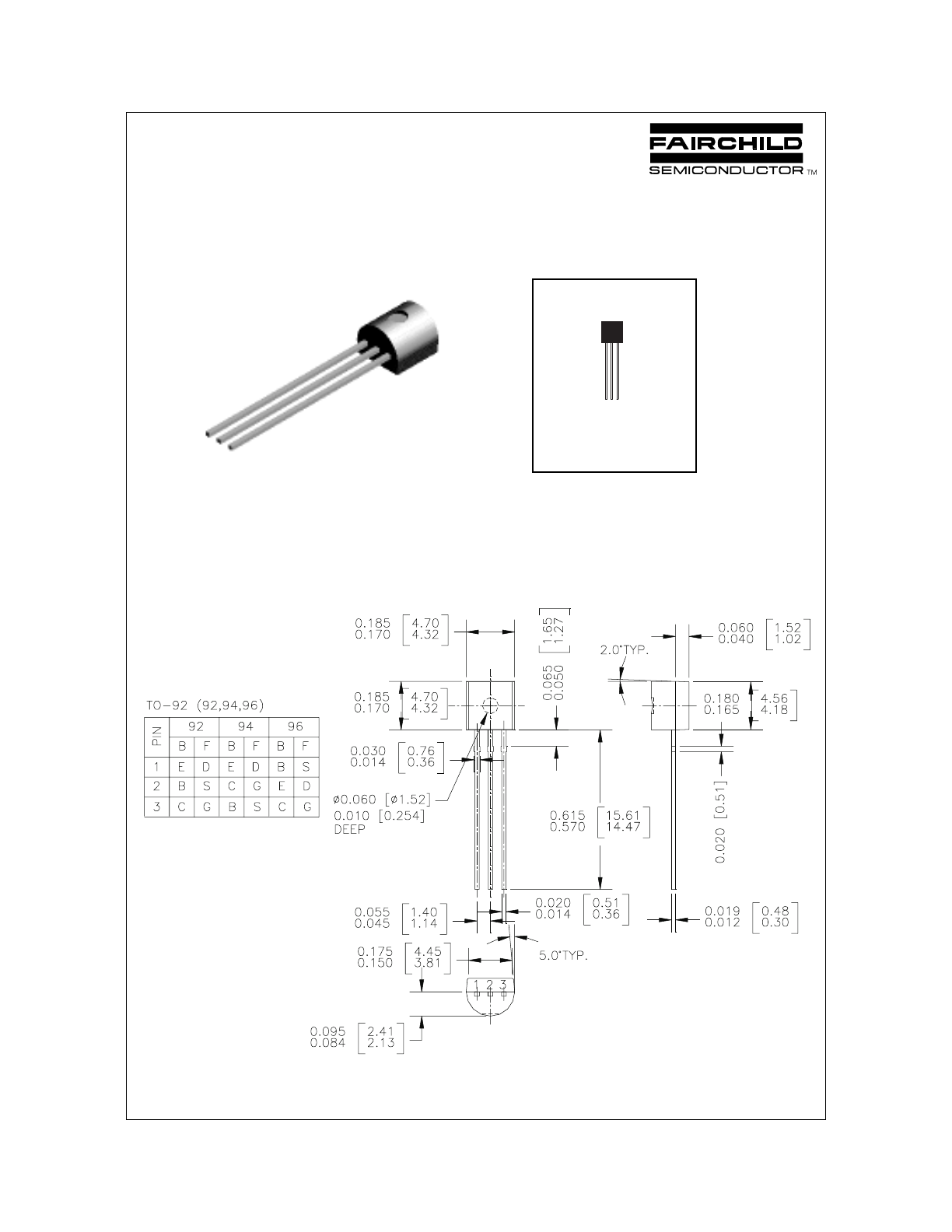

TO-92

C

B

E

B

C

C

SOT-223

E

PNP General Purpose Amplifier

This device is designed for general purpose amplifier and switching

applications at collector currents of 10

µ

A to 100 mA.

Absolute Maximum Ratings*

T

A

= 25°C unless otherwise noted

*

These ratings are limiting values above which the serviceability of any semiconductor device may be impaired.

Symbol

Parameter

Value

Units

V

CEO

Collector-Emitter Voltage

40

V

V

CBO

Collector-Base Voltage

40

V

V

EBO

Emitter-Base Voltage

5.0

V

I

C

Collector Current - Continuous

200

mA

T

J

, T

stg

Operating and Storage Junction Temperature Range

-55 to +150

°

C

2001 Fairchild Semiconductor Corporation

Thermal Characteristics

T

A

= 25°C unless otherwise noted

Symbol

Characteristic

Max

Units

2N3906

*MMBT3906

**PZT3906

P

D

Total Device Dissipation

Derate above 25

°

C

625

5.0

350

2.8

1,000

8.0

mW

mW/

°

C

R

θ

JC

Thermal Resistance, Junction to Case

83.3

°

C/W

R

θ

JA

Thermal Resistance, Junction to Ambient

200

357

125

°

C/W

*

Device mounted on FR-4 PCB 1.6" X 1.6" X 0.06."

**

Device mounted on FR-4 PCB 36 mm X 18 mm X 1.5 mm; mounting pad for the collector lead min. 6 cm

2

.

2N3906

MMBT3906

SOT-23

Mark: 2A

PZT3906

2N3906 / MMBT3906 / PZT3906

NOTES:

1) These ratings are based on a maximum junction temperature of 150 degrees C.

2) These are steady state limits. The factory should be consulted on applications involving pulsed or low duty cycle operations.

3) All voltages (V) and currents (A) are negative polarity for PNP transistors.

2N3906/MMBT3906/PZT3906, Rev A

Electrical Characteristics

T

A

= 25°C unless otherwise noted

Symbol

Parameter

Test Conditions

Min

Max

Units

OFF CHARACTERISTICS

ON CHARACTERISTICS

SMALL SIGNAL CHARACTERISTICS

SWITCHING CHARACTERISTICS

V

(BR)CEO

Collector-Emitter Breakdown Voltage*

I

C

= 1.0 mA, I

B

= 0

40

V

V

(BR)CBO

Collector-Base Breakdown Voltage

I

C

= 10

µ

A, I

E

= 0

40

V

V

(BR)EBO

Emitter-Base Breakdown Voltage

I

E

= 10

µ

A, I

C

= 0

5.0

V

I

BL

Base Cutoff Current

V

CE

= 30 V, V

BE

= 3.0 V

50

nA

I

CEX

Collector Cutoff Current

V

CE

= 30 V, V

BE

= 3.0 V

50

nA

h

FE

DC Current Gain *

I

C

= 0.1 mA, V

CE

= 1.0 V

I

C

= 1.0 mA, V

CE

= 1.0 V

I

C

= 10 mA, V

CE

= 1.0 V

I

C

= 50 mA, V

CE

= 1.0 V

I

C

= 100 mA, V

CE

= 1.0 V

60

80

100

60

30

300

V

CE(sat)

Collector-Emitter Saturation Voltage

I

C

= 10 mA, I

B

= 1.0 mA

I

C

= 50 mA, I

B

= 5.0 mA

0.25

0.4

V

V

V

BE(sat)

Base-Emitter Saturation Voltage

I

C

= 10 mA, I

B

= 1.0 mA

I

C

= 50 mA, I

B

= 5.0 mA

0.65

0.85

0.95

V

V

f

T

Current Gain - Bandwidth Product

I

C

= 10 mA, V

CE

= 20 V,

f = 100 MHz

250

MHz

C

obo

Output Capacitance

V

CB

= 5.0 V, I

E

= 0,

f = 100 kHz

4.5

pF

C

ibo

Input Capacitance

V

EB

= 0.5 V, I

C

= 0,

f = 100 kHz

10.0

pF

NF

Noise Figure

I

C

= 100

µ

A, V

CE

= 5.0 V,

R

S

=1.0k

Ω

,f=10 Hz to 15.7 kHz

4.0

dB

t

d

Delay Time

V

CC

= 3.0 V, V

BE

= 0.5 V,

35

ns

t

r

Rise Time

I

C

= 10 mA, I

B1

= 1.0 mA

35

ns

t

s

Storage Time

V

CC

= 3.0 V, I

C

= 10mA

225

ns

t

f

Fall Time

I

B1

= I

B2

= 1.0 mA

75

ns

Spice Model

PNP (Is=1.41f Xti=3 Eg=1.11 Vaf=18.7 Bf=180.7 Ne=1.5 Ise=0 Ikf=80m Xtb=1.5 Br=4.977 Nc=2 Isc=0 Ikr=0

Rc=2.5 Cjc=9.728p Mjc=.5776 Vjc=.75 Fc=.5 Cje=8.063p Mje=.3677 Vje=.75 Tr=33.42n Tf=179.3p Itf=.4 Vtf=4

Xtf=6 Rb=10)

*

Pulse Test: Pulse Width

≤

300

µ

s, Duty Cycle

≤

2.0%

NOTE: All voltages (V) and currents (A) are negative polarity for PNP transistors.

2N3906 / MMBT3906 / PZT3906

PNP General Purpose Amplifier

(continued)

2N3906 / MMBT3906 / PZT3906

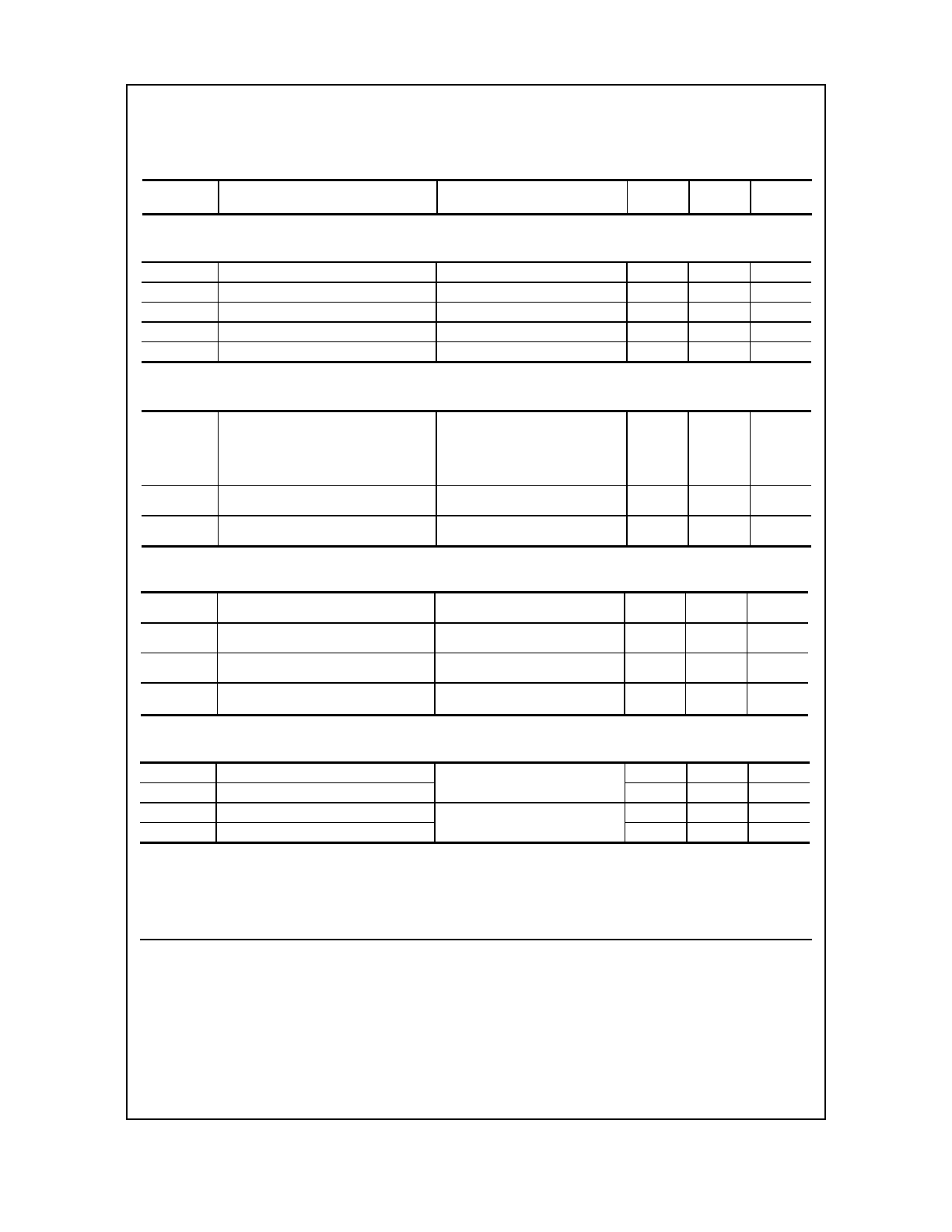

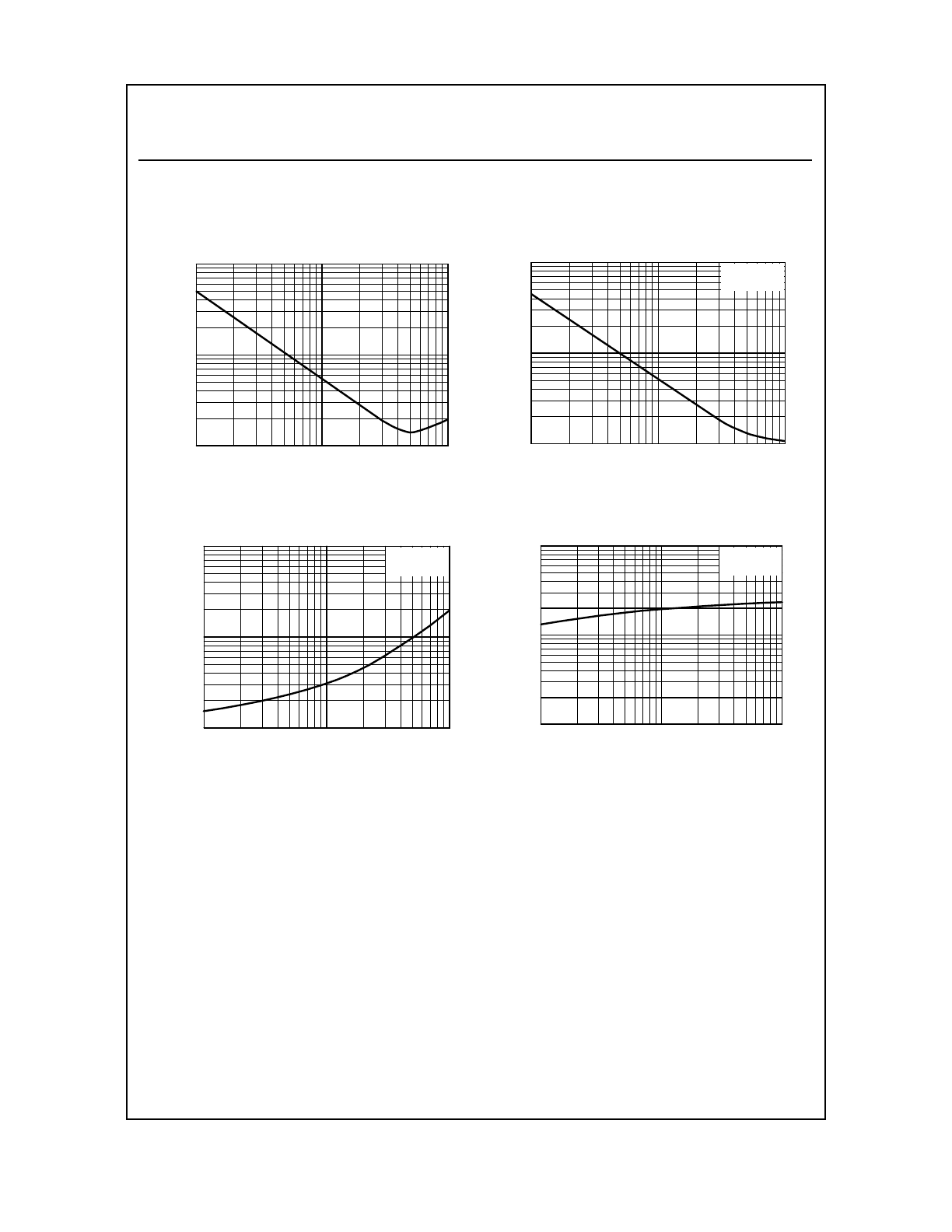

Typical Characteristics

Common-Base Open Circuit

Input and Output Capacitance

vs Reverse Bias Voltage

0.1

1

10

0

2

4

6

8

10

REVERSE BIAS VOLTAGE (V)

CA

P

A

CI

T

A

NCE (

p

F

)

C obo

C ibo

PNP General Purpose Amplifier

(continued)

Ty pical Pulsed Current Gain

v s Collector Current

0.1

0.2

0.5

1

2

5

10

20

50

100

50

100

150

200

250

I - COLLECTOR CURRE NT (mA)

h

-

T

YPI

C

A

L

P

U

L

SED

C

U

R

R

EN

T

G

A

IN

C

FE

125 °C

25 °C

- 40 °C

V = 1 .0V

CE

Collector-Emitter Saturation

Voltage vs Collector Current

1

10

100

200

0

0.05

0.1

0.15

0.2

0.25

0.3

I - COLLECTOR CURRE NT (mA)

V

-

C

O

L

L

E

C

T

O

R

E

M

IT

T

E

R

V

O

L

TA

G

E

(

V

)

C

CE

S

A

T

25 °C

- 40 °C

125°C

β

= 10

Base-Emitter Saturation

Voltage vs Collector Current

1

10

100

200

0

0.2

0.4

0.6

0.8

1

I - COLLECTOR CURRE NT (mA)

V

-

B

A

S

E

E

M

IT

T

E

R

V

O

L

T

A

G

E

(

V

)

C

BE

S

A

T

β

= 10

25 °C

- 40 °C

125 °C

Base Emitter ON Voltage vs

Collector Current

0.1

1

10

25

0

0.2

0.4

0.6

0.8

1

I - COLLECTOR CURRE NT (mA)

V

-

B

A

S

E

E

M

IT

T

E

R

O

N

V

O

L

T

A

G

E

(

V

)

C

BE

(

O

N

)

V = 1V

CE

25 °C

- 40 °C

125 °C

Collector-Cutoff Current

vs Ambient Temperature

25

50

75

100

125

0.01

0.1

1

10

100

T - AMBIE NT TEMP ERATURE ( C)

I

- C

O

L

LE

C

T

O

R

CU

RR

E

N

T

(

n

A)

A

CBO

°

V = 25V

CB

Power Dissipation vs

Ambient Temperature

0

25

50

75

100

125

150

0

0.25

0.5

0.75

1

TEMPERATURE ( C)

P

-

PO

W

E

R

D

ISSI

P

A

TI

O

N

(

W

)

D

o

SOT-223

SOT-23

TO-92

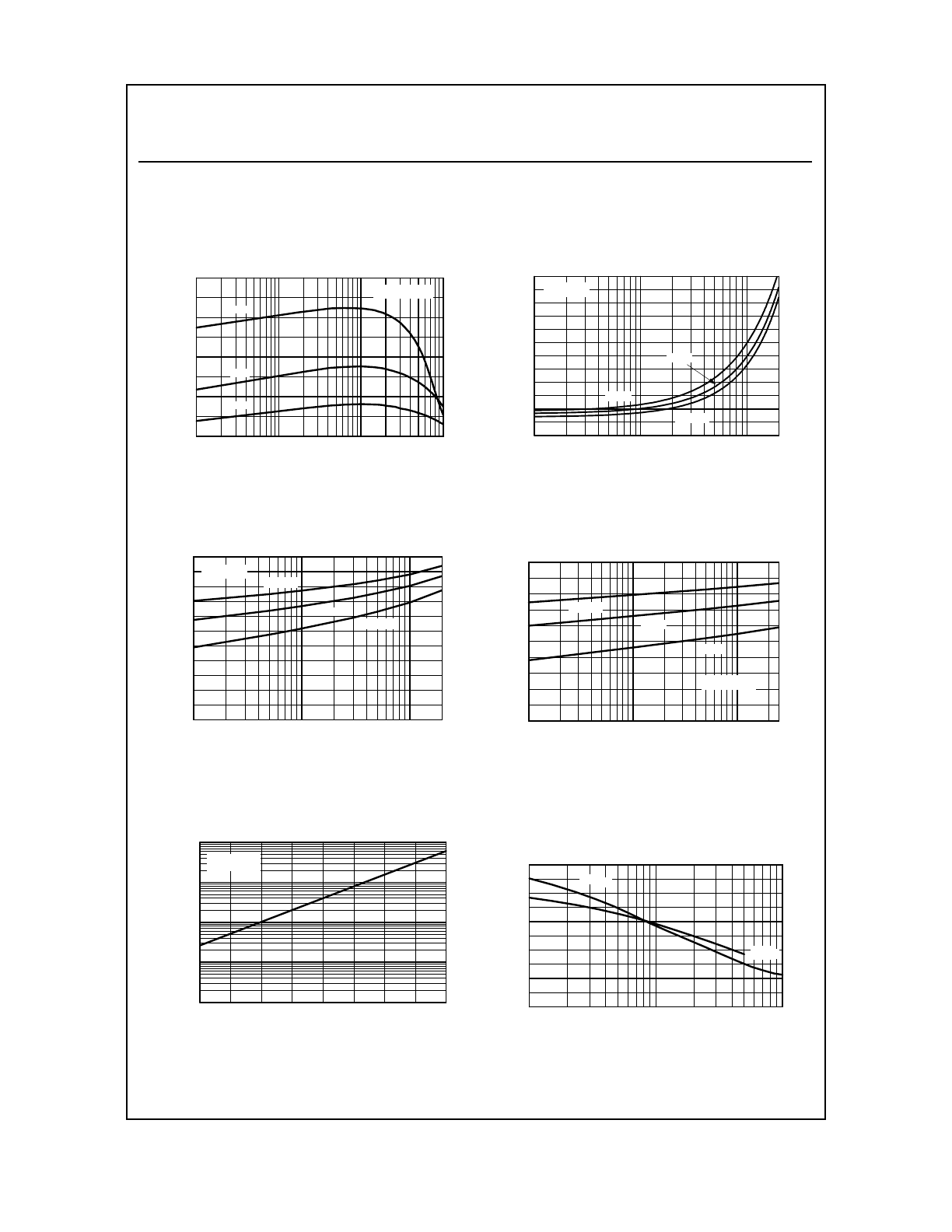

Typical Characteristics

(continued)

Noise Figure vs Frequency

0.1

1

10

100

0

1

2

3

4

5

6

f - FREQUENCY (kHz)

NF

-

NO

IS

E

F

IG

U

R

E

(

d

B)

I = 100

µ

A, R = 200

Ω

C

V = 5.0V

CE

S

I = 100

µ

A, R = 2.0 k

Ω

C

S

I = 1.0 mA, R = 200

Ω

C

S

Noise Figure vs Source Resistance

0.1

1

10

100

0

2

4

6

8

10

12

R - SOURCE RESISTANCE ( )

NF

-

NO

IS

E

F

IG

U

RE

(

d

B)

k

Ω

I = 100

µ

A

C

V = 5.0V

f = 1.0 kHz

CE

I = 1.0 mA

C

S

Switching Times

vs Collector Current

1

10

100

1

10

100

500

I - COLLECTOR CURRENT (mA)

T

IME

(n

S

)

I = I =

t r

t

s

B1

C

B2

I

c

10

t f

t d

Turn On and Turn Off Times

vs Collector Current

1

10

100

1

10

100

500

I - COLLECTOR CURRENT (mA)

TI

M

E

(n

S

)

I = I =

t

off

B1

B2

I

c

10

t

on

V = 0.5V

BE(OFF)

t

I =

on

t

off

B1

I

c

10

2N3906 / MMBT3906 / PZT3906

PNP General Purpose Amplifier

(continued)

2N3906 / MMBT3906 / PZT3906

Typical Characteristics

(continued)

PNP General Purpose Amplifier

(continued)

Input Impedance

0.1

1

10

0.1

1

10

I - COLLECTOR CURRENT (mA)

h

-

I

N

PU

T I

M

PED

ANC

E

(k

)

V = 10 V

CE

C

ie

f = 1.0 kHz

Ω

Output Admittance

0.1

1

10

10

100

1000

I - COLLECTOR CURRENT (mA)

h

-

O

U

TPU

T

A

D

M

IT

T

A

N

C

E

(

m

h

os

)

V = 10 V

CE

C

oe

f = 1.0 kHz

µ

Current Gain

0.1

1

10

10

20

50

100

200

500

1000

I - COLLECTOR CURRENT (mA)

h

- C

U

R

R

E

N

T G

A

IN

V = 10 V

CE

C

fe

f = 1.0 kHz

Voltage Feedback Ratio

0.1

1

10

1

10

100

I - COLLECTOR CURRENT (mA)

h

-

V

O

L

T

A

G

E

F

E

E

D

B

A

C

K

R

A

T

IO

(

x

1

0

)

C

re

_

4

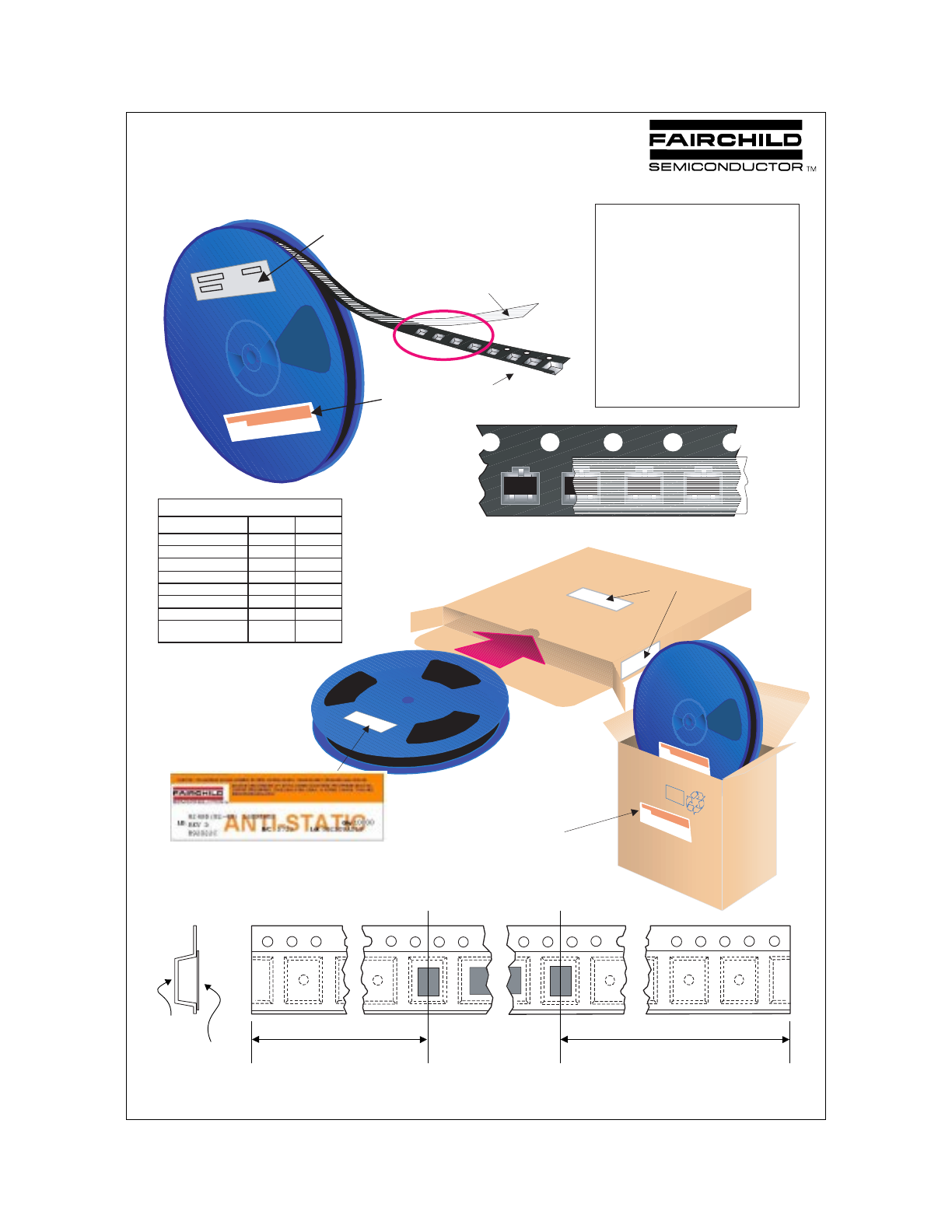

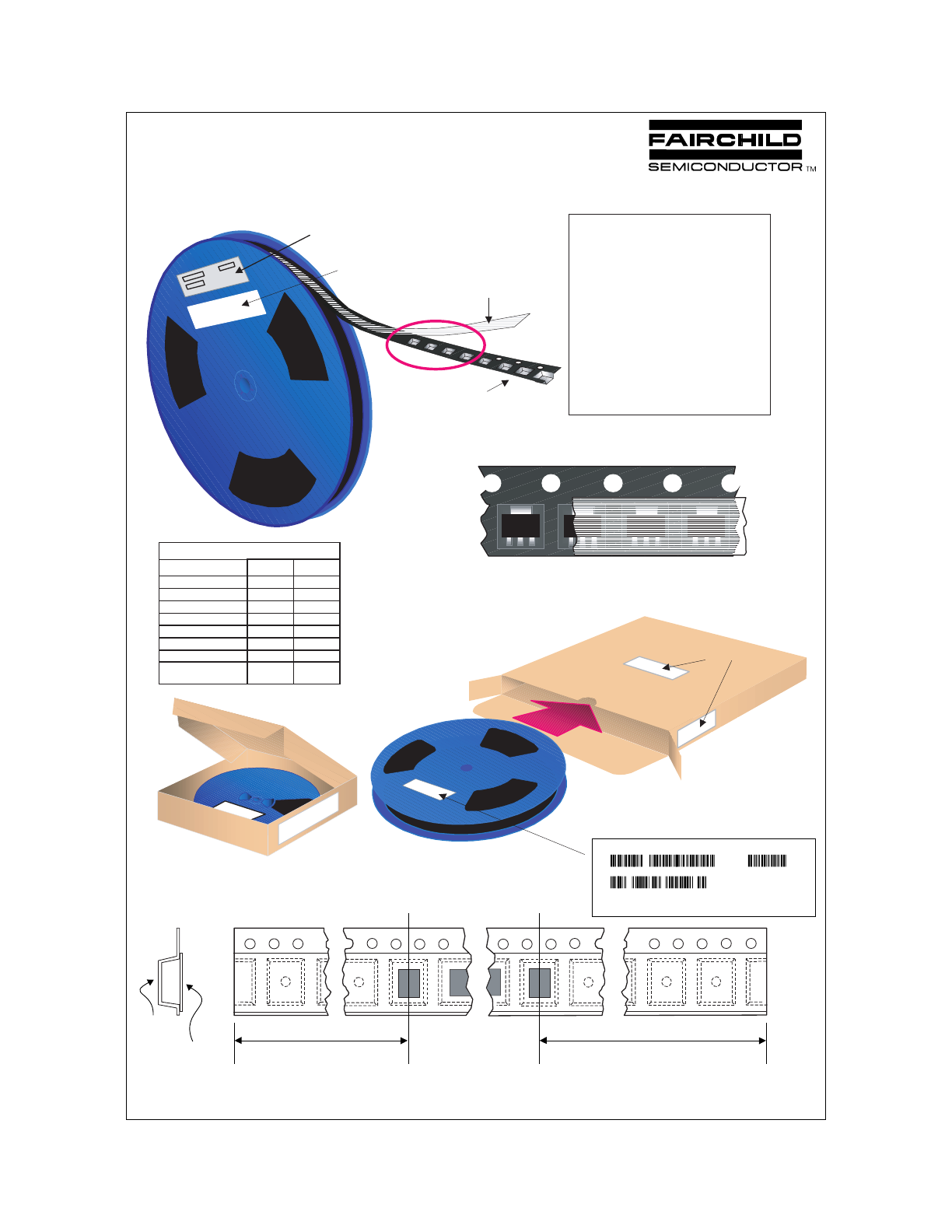

TO-92 Tape and Reel Data

March 2001, Rev. B1

©2001 Fairchild Semiconductor Corporation

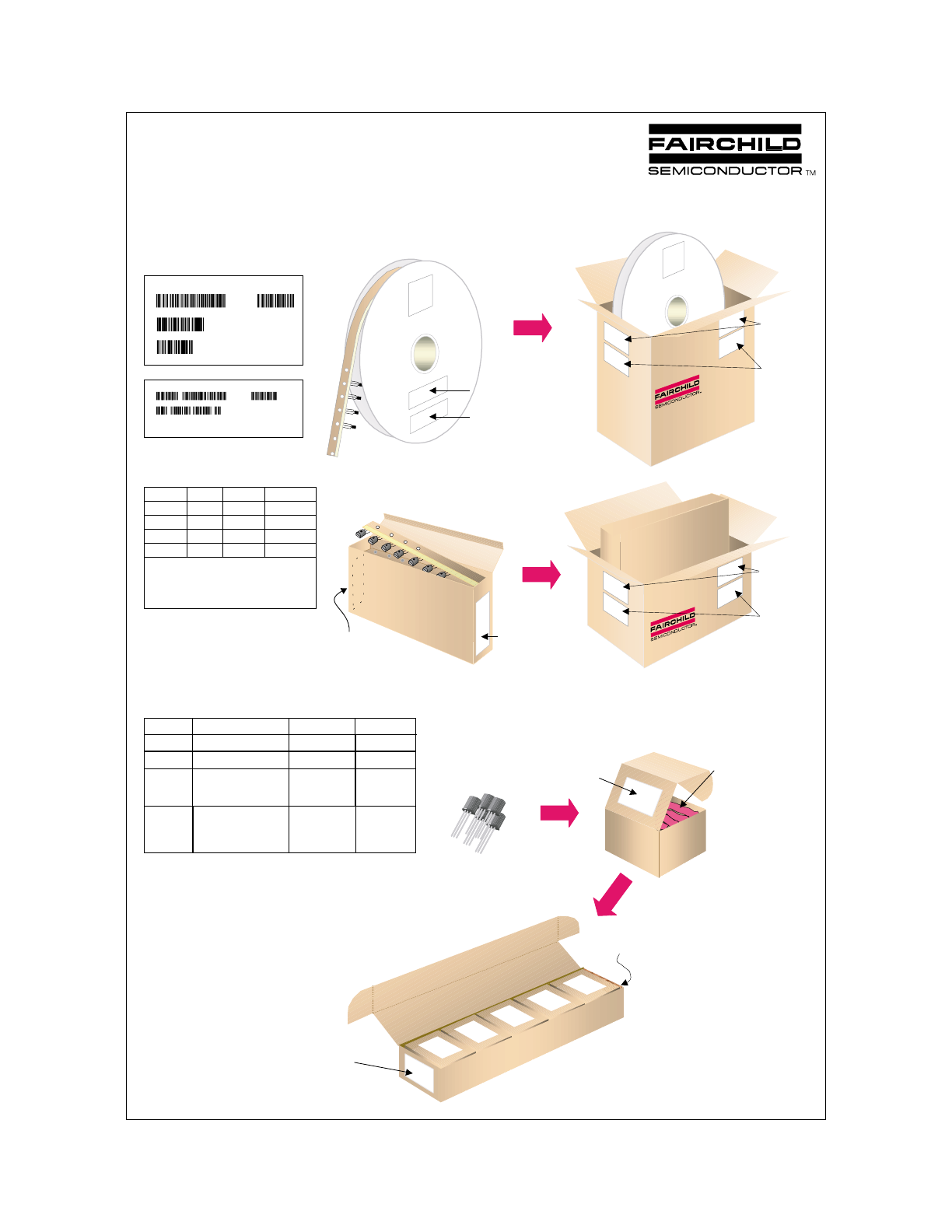

TO-92 Packaging

Configuration: Figure 1.0

AMMO PACK OPTION

See Fig 3.0 for 2 Ammo

Pack Options

2000 units per

EO70 box for

std option

FSCINT Label

530mm x 130mm x

83mm

Intermediate box

10,000 units maximum

per

intermediate box

for std option

FSCINT Label

114mm x 102mm x 51mm

Immediate Box

Anti-static

Bubble Sheets

(TO-92) BULK PACKING INFORMATION

EOL

CODE

DESCRIPTION

LEADCLIP

DIMENSION

QUANTITY

J18Z

TO-18 OPTION STD

NO LEAD CLIP

2.0 K / BOX

J05Z

TO-5 OPTION STD

NO LEAD CLIP

1.5 K / BOX

NO EOL

CODE

TO-92 STANDARD

STRAIGHT FOR: PKG 92,

NO LEADCLIP

2.0 K / BOX

BULK OPTION

See Bulk Packing

Information table

375mm x 267mm x 375mm

Intermediate Box

FSCINT

Label

Customized

Label

333mm x 231mm x 183mm

Intermediate Box

FSCINT

Label

Customized

Label

TO-92 TNR/AMMO PACKING INFROMATION

Packing

Style

Quantity

EOL code

Reel

A

2,000

D26Z

E

2,000

D27Z

Ammo

M

2,000

D74Z

P

2,000

D75Z

Unit weight = 0.22 gm

Reel weight with components = 1.04 kg

Ammo weight with components = 1.02 kg

Max quantity per intermediate box = 10,000 units

F63TNR

Label

5 Ammo boxes per

Intermediate Box

Customized

Label

327mm x 158mm x 135mm

Immediate Box

LOT:

CBVK741B019

NSID:

PN2222N

D/C1:

D9842

SPEC REV:

B2

SPEC:

QTY:

10000

QA REV:

FAIRCHILD SEMICONDUCTOR CORPORATION

HTB:B

(FSCINT)

F63TNR

Label

Customized

Label

5 Reels per

Intermediate Box

TAPE and REEL OPTION

See Fig 2.0 for various

Reeling Styles

LOT: CBVK741B019

FSID: PN222N

D/C1: D9842 QTY1:

SPEC REV:

SPEC:

QTY: 2000

D/C2:

QTY2:

CPN:

N/F: F (F63TNR)3

F63TNR Label sample

FSCINT Label sample

C

5 EO70 boxes per

intermediate Box

ustomized

Label

94 (NON PROELECTRON

SERIES), 96

L34Z

TO-92 STANDARD

STRAIGHT FOR: PKG 94

NO LEADCLIP

2.0 K / BOX

(PROELECTRON SERIES

BCXXX, BFXXX, BSRXXX),

97, 98

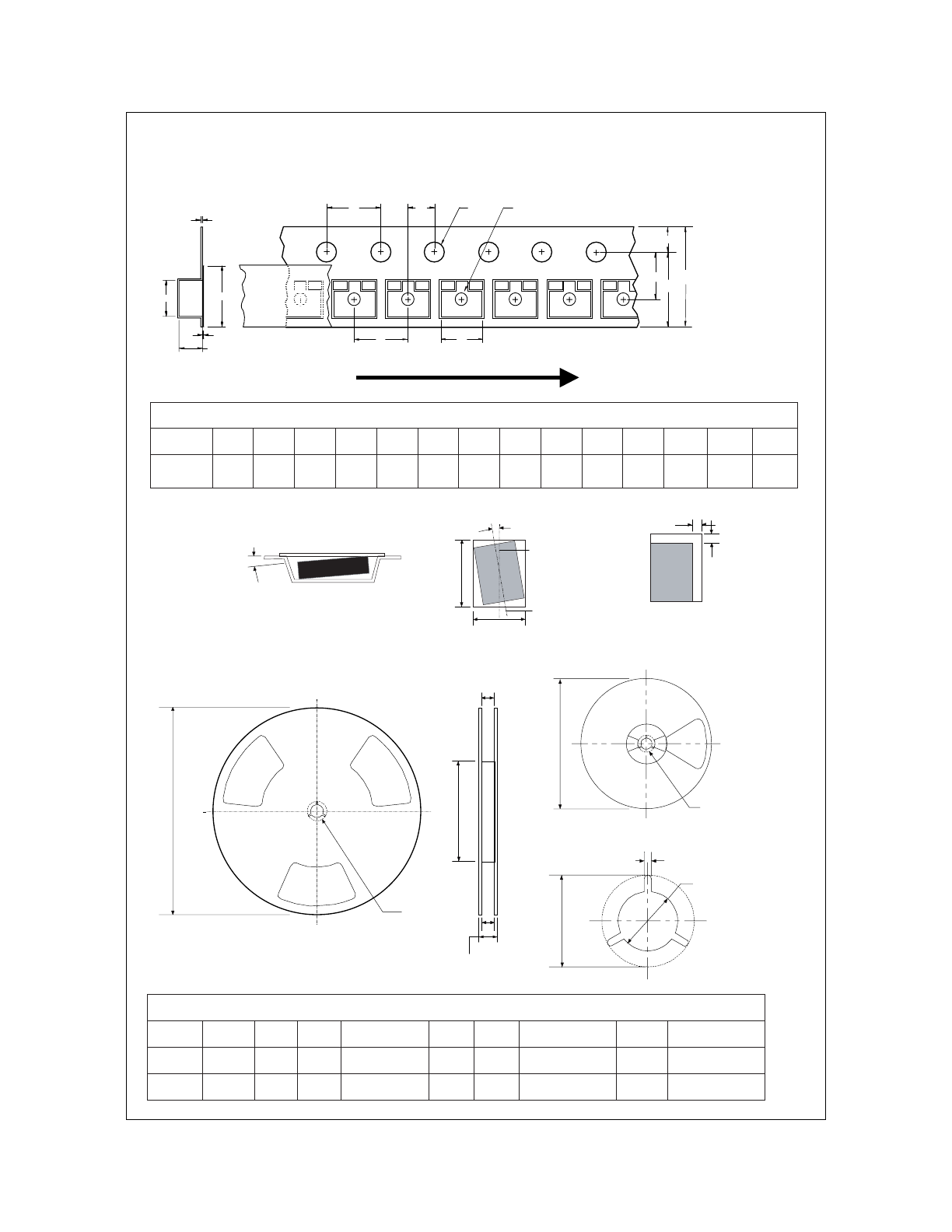

TO-92 Tape and Reel Data, continued

September 1999, Rev. B

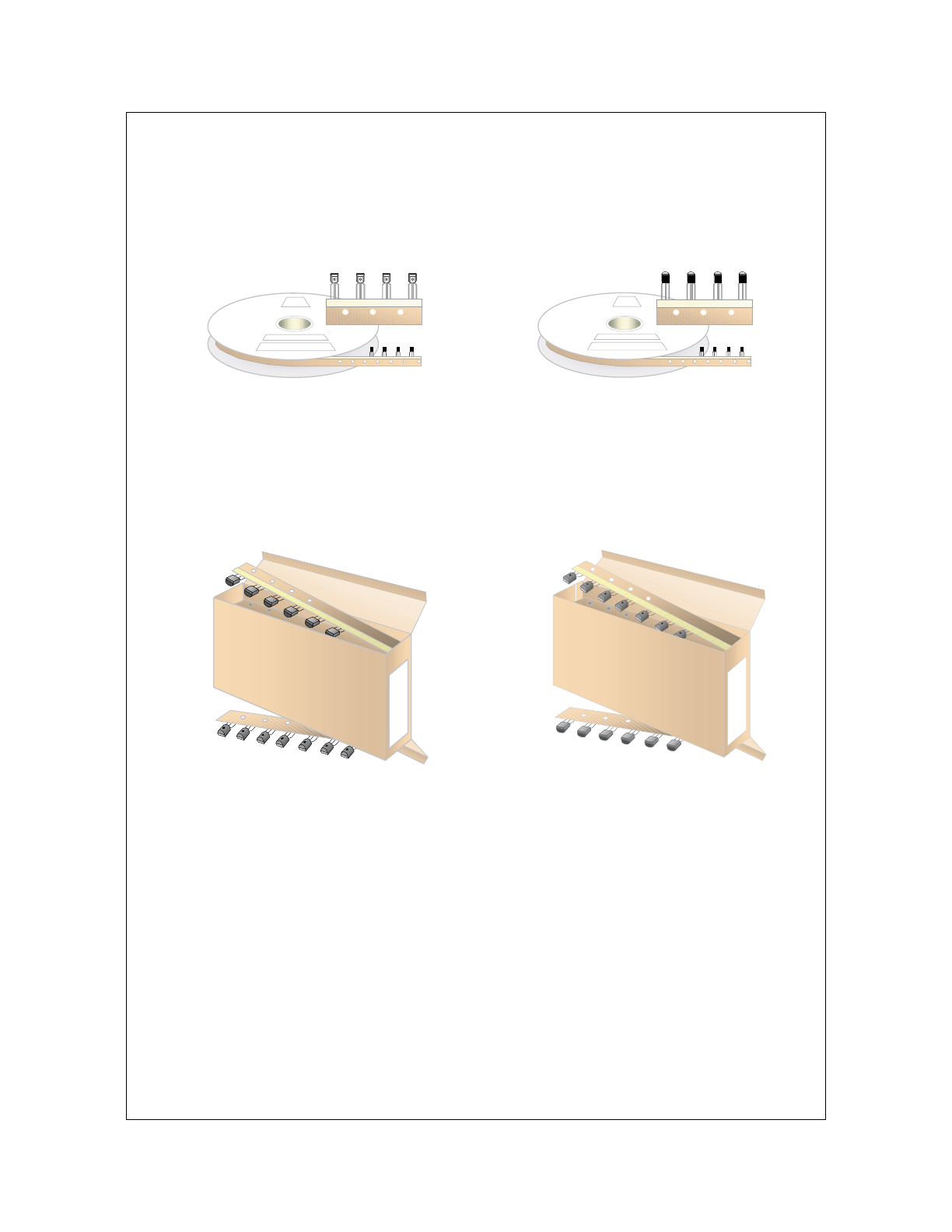

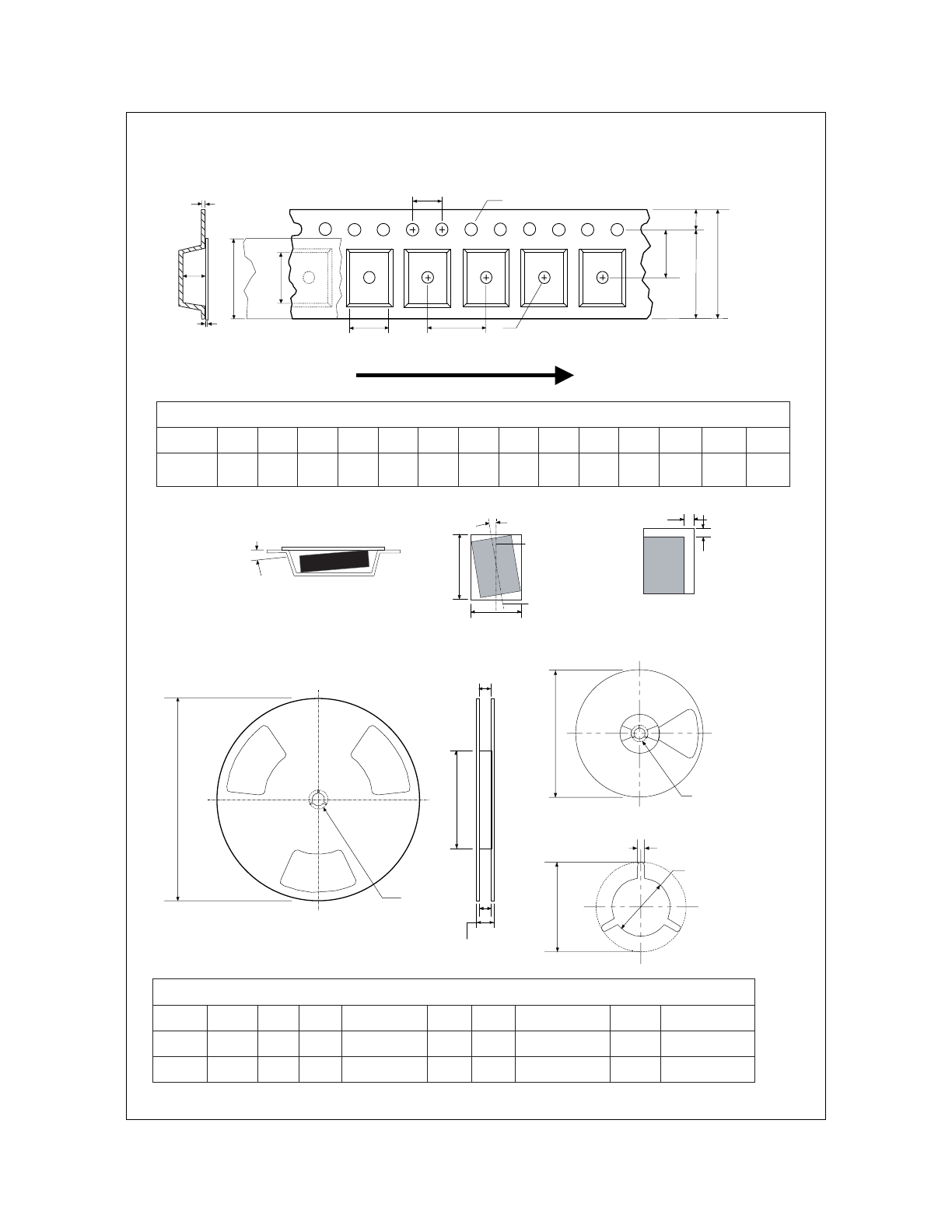

TO-92 Reeling Style

Configuration: Figure 2.0

Style “A”, D26Z, D70Z (s/h)

Machine Option “A” (H)

Style “E”, D27Z, D71Z (s/h)

Machine Option “E” (J)

FIRST WIRE OFF IS EMITTER

ADHESIVE TAPE IS ON THE TOP SIDE

FLAT OF TRANSISTOR IS ON BOTTOM

ORDER STYLE

D75Z (P)

FIRST WIRE OFF IS COLLECTOR

ADHESIVE TAPE IS ON THE TOP SIDE

FLAT OF TRANSISTOR IS ON TOP

ORDER STYLE

D74Z (M)

TO-92 Radial Ammo Packaging

Configuration: Figure 3.0

FIRST WIRE OFF IS EMITTER (ON PKG. 92)

ADHESIVE TAPE IS ON BOTTOM SIDE

FLAT OF TRANSISTOR IS ON BOTTOM

FIRST WIRE OFF IS COLLECTOR (ON PKG. 92)

ADHESIVE TAPE IS ON BOTTOM SIDE

FLAT OF TRANSISTOR IS ON TOP

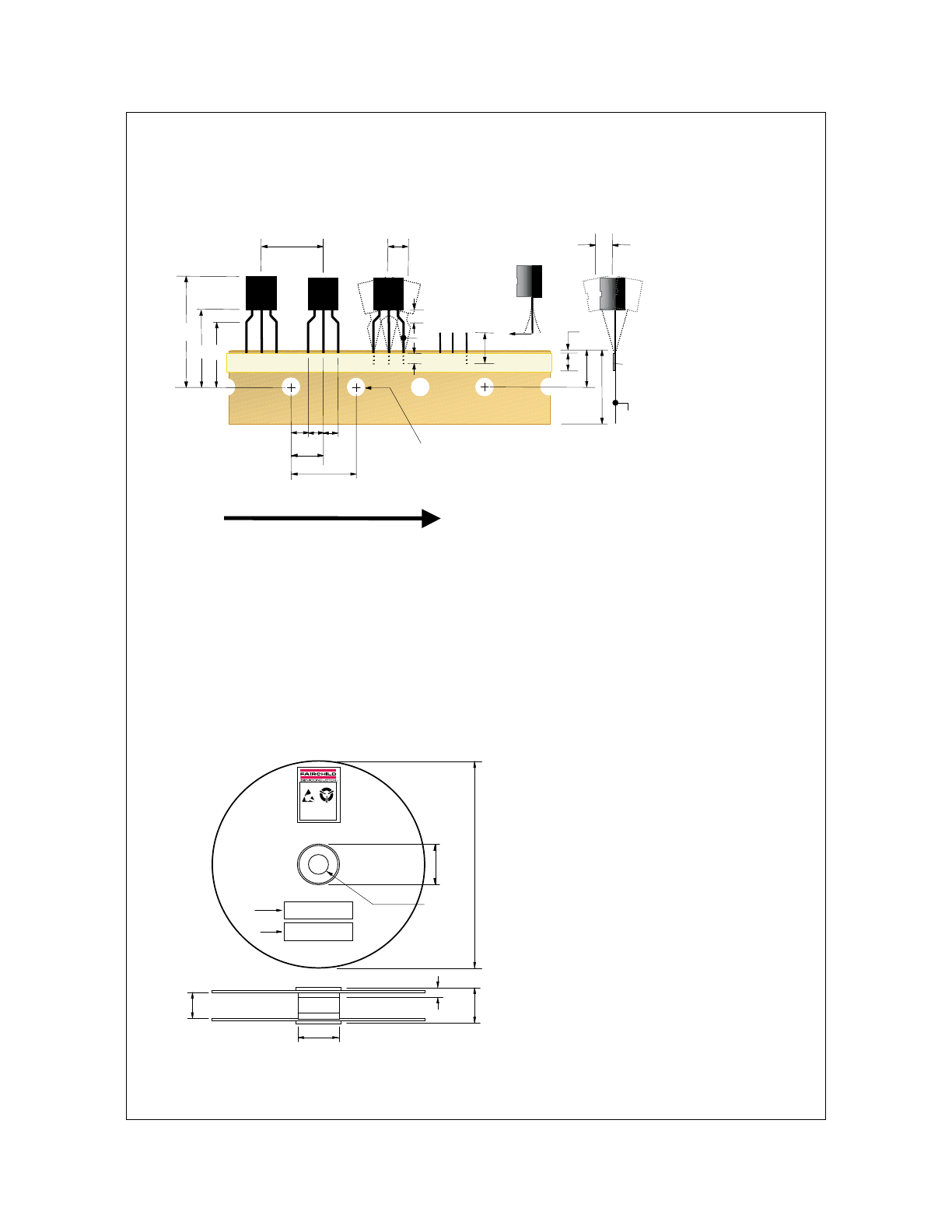

ITEM DESCRIPTION

Base of Package to Lead Bend

Component Height

Lead Clinch Height

Component Base Height

Component Alignment ( side/side )

Component Alignment ( front/back )

Component Pitch

Feed Hole Pitch

Hole Center to First Lead

Hole Center to Component Center

Lead Spread

Lead Thickness

Cut Lead Length

Taped Lead Length

Taped Lead Thickness

Carrier Tape Thickness

Carrier Tape Width

Hold - down Tape Width

Hold - down Tape position

Feed Hole Position

Sprocket Hole Diameter

Lead Spring Out

SYMBOL

b

Ha

HO

H1

Pd

Hd

P

PO

P1

P2

F1/F2

d

L

L1

t

t1

W

WO

W1

W2

DO

S

DIMENSION

0.098 (max)

0.928 (+/- 0.025)

0.630 (+/- 0.020)

0.748 (+/- 0.020)

0.040 (max)

0.031 (max)

0.500 (+/- 0.020)

0.500 (+/- 0.008)

0.150 (+0.009, -0.010)

0.247 (+/- 0.007)

0.104 (+/- 0 .010)

0.018 (+0.002, -0.003)

0.429 (max)

0.209 (+0.051, -0.052)

0.032 (+/- 0.006)

0.021 (+/- 0.006)

0.708 (+0.020, -0.019)

0.236 (+/- 0.012)

0.035 (max)

0.360 (+/- 0.025)

0.157 (+0.008, -0.007)

0.004 (max)

Note : All dimensions are in inches.

ITEM DESCRIPTION

SYSMBOL

MINIMUM

MAXIMUM

Reel Diameter

D1

13.975

14.025

Arbor Hole Diameter (Standard)

D2

1.160

1.200

(Small Hole)

D2

0.650

0.700

Core Diameter

D3

3.100

3.300

Hub Recess Inner Diameter

D4

2.700

3.100

Hub Recess Depth

W1

0.370

0.570

Flange to Flange Inner Width

W2

1.630

1.690

Hub to Hub Center Width

W3

2.090

Note: All dimensions are inches

TO-92 Tape and Reel Taping

Dimension Configuration: Figure 4.0

Ha

H1 HO

PO

P2

P1 F1

DO

P

Pd

b

d

L1

L

S

WO

W2

W

t

t1

Hd

W1

TO-92 Reel

Configuration: Figure 5.0

User Direction of Feed

SEN SI TIVE D EVICES

ELECT ROSTATIC

D1

D3

Customized Label

W2

W1

W3

F63TNR Label

D4

D2

TO-92 Tape and Reel Data, continued

July 1999, Rev. A

TO-92 (FS PKG Code 92, 94, 96)

TO-92 Package Dimensions

January 2000, Rev. B

1:1

Scale 1:1 on letter size paper

Dimensions shown below are in:

inches [millimeters]

Part Weight per unit (gram): 0.1977

©2000 Fairchild Semiconductor International

SOT-23 Packaging

Configuration: Figure 1.0

Components

Leader Tape

500mm minimum or

125 empty pockets

Trailer Tape

300mm minimum or

75 empt y poc kets

SOT-23 Tape Leader and Trailer

Configuration: Figure 2.0

Cover Tape

Carrier Tape

Note/Comments

Packaging Option

SOT-23 Packaging Information

Standard

(no flow code)

D87Z

Packaging type

Reel Size

TNR

7" Dia

TNR

13"

Qty per Reel/Tube/Bag

3,000

10,000

Box Dimension (mm)

187x107x183

343x343x64

Max qty per Box

24,000

30,000

Weight per unit (gm)

0.0082

0.0082

Weight per Reel (kg)

0.1175

0.4006

H uman readable

Label

Human Readable Label

Human Readable Label sample

343mm x 342mm x 64mm

Intermediate box for L87Z Option

187mm x 107mm x 183mm

Intermediate Box for Standard Option

SOT-23 Unit Orientation

3P

3P

3P

3P

Human Readable

Label

Customized Label

Embossed

Carrier Tape

Antistatic Cover Tape

Packaging Description:

SOT-23

made from a dissipative (carbon filled) polycarbonate

resin. The cover tape is a multilayer film (Heat Activated

Adhesive in nature) primarily composed of polyester film,

adhesive layer, sealant, and anti-static sprayed agent.

These reeled parts in standard option are shipped with

3,000 units per 7" or 177cm diameter reel. The reels are

dark blue in color and is made of polystyrene plastic (anti-

static coated). Other option comes in 10,000 units per 13"

or 330cm diameter reel. This and some other options are

described in the Packaging Information table.

These full reels are individually labeled and placed inside

a standard intermediate made of recyclable corrugated

brown paper with a Fairchil d logo printing. One pizza box

contains eight reels maximum. And these intermediate

boxes are placed inside a labeled shipping box which

comes in different sizes depending on the number of parts

shipped.

parts are shipped in tape. The carrier tape is

SOT-23 Tape and Reel Data

September 1999, Rev. C

©2000 Fairchild Semiconductor International

Dimensions are in millimeter

Pkg type

A0

B0

W

D0

D1

E1

E2

F

P1

P0

K0

T

Wc

Tc

SOT-23

(8mm)

3.15

+/-0.10

2.77

+/-0.10

8.0

+/-0.3

1.55

+/-0.05

1.125

+/-0.125

1.75

+/-0.10

6.25

min

3.50

+/-0.05

4.0

+/-0.1

4.0

+/-0.1

1.30

+/-0.10

0.228

+/-0.013

5.2

+/-0.3

0.06

+/-0.02

Dimensions are in inches and millimeters

Tape Size

Reel

Option

Dim A

Dim B

Dim C

Dim D

Dim N

Dim W1

Dim W2

Dim W3 (LSL-USL)

8mm

7" Dia

7.00

177.8

0.059

1.5

512 +0.020/-0.008

13 +0.5/-0.2

0.795

20.2

2.165

55

0.331 +0.059/-0.000

8.4 +1.5/0

0.567

14.4

0.311 – 0.429

7.9 – 10.9

8mm

13" Dia

13.00

330

0.059

1.5

512 +0.020/-0.008

13 +0.5/-0.2

0.795

20.2

4.00

100

0.331 +0.059/-0.000

8.4 +1.5/0

0.567

14.4

0.311 – 0.429

7.9 – 10.9

See detail AA

Dim A

max

13" Diameter Option

7" Diameter Option

Dim A

Max

See detail AA

W3

W2 max Measured at Hub

W1 Measured at Hub

Dim N

Dim D

min

Dim C

B Min

DETAIL AA

Notes: A0, B0, and K0 dimensions are determined with respect to the EIA/Jedec RS-481

rotational and lateral movement requirements (see sketches A, B, and C).

20 deg maximum component rotation

0.5mm

maximum

0.5mm

maximum

Sketch C (Top View)

Component lateral movement

Typical

component

cavity

center line

20 deg maximum

Typical

component

center line

B0

A0

Sketch B (Top View)

Component Rotation

Sketch A (Side or Front Sectional View)

Component Rotation

User Direction of Feed

SOT-23 Embossed Carrier Tape

Configuration: Figure 3.0

SOT-23 Reel Configuration: Figure 4.0

P1

A0

D1

F

W

E1

E2

Tc

Wc

K0

T

B0

D0

P0

P2

SOT-23 Tape and Reel Data, continued

September 1999, Rev. C

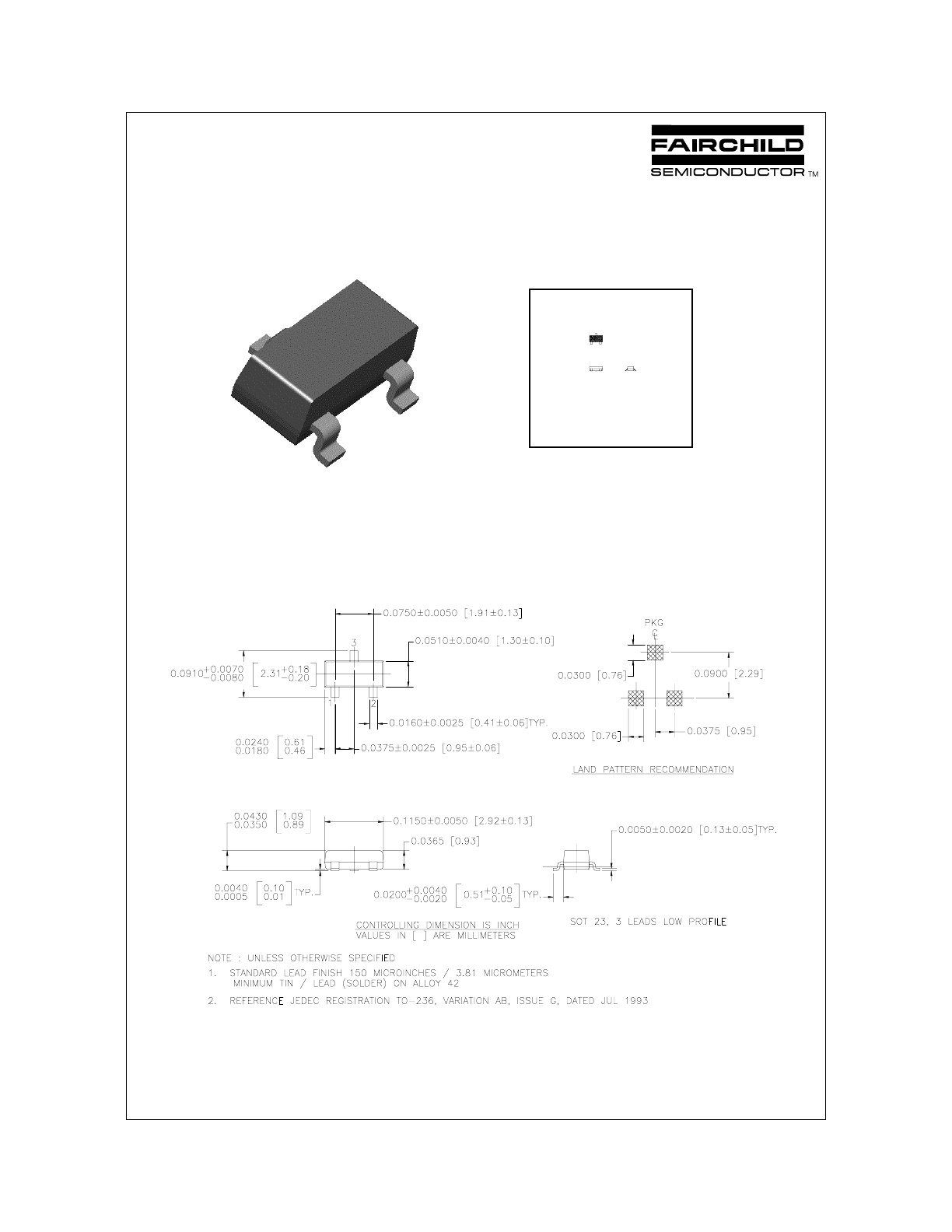

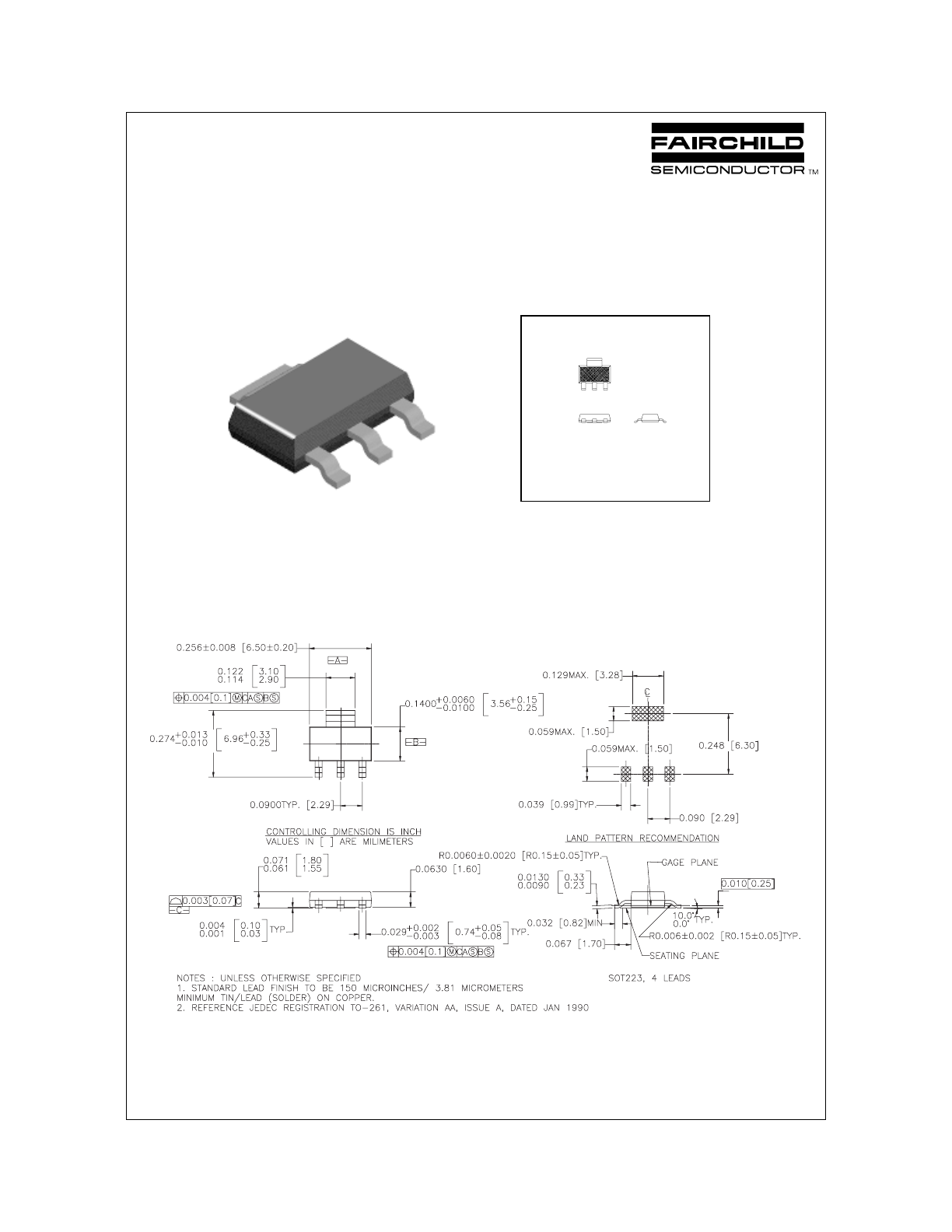

SOT-23 (FS PKG Code 49)

SOT-23 Package Dimensions

September 1998, Rev. A1

1:1

Scale 1:1 on letter size paper

Dimensions shown below are in:

inches [millimeters]

Part Weight per unit (gram): 0.0082

©2000 Fairchild Semiconductor International

SOT-223 Packaging

Configuration: Figure 1.0

Components

Leader Tape

500mm minimum or

62 empty pockets

Trailer Tape

300mm minimum or

38 empty pockets

SOT-223 Tape Leader and Trailer

Configuration: Figure 2.0

Cover Tape

Carrier Tape

Note/Comments

Packaging Option

SOT-223 Packaging Information

Standard

(no flow code)

D84Z

Packaging type

Reel Size

TNR

13" Dia

TNR

7" Dia

Qty per Reel/Tube/Bag

2,500

500

Box Dimension (mm)

343x64x343

184x187x47

Max qty per Box

5,000

1,000

Weight per unit (gm)

0.1246

0.1246

Weight per Reel (kg)

0.7250

0.1532

SOT-223 Unit Orientation

F

852

014

F

852

014

F

852

014

F

852

014

F63TNR Label

343mm x 342mm x 64mm

Intermediate box for Standard

184mm x 184mm x 47mm

Pizza Box for D84Z Option

F63TNR Label

LOT: CBVK741B019

FSID: PN2222A

D/C1: D9842 QTY1:

SPEC REV:

SPEC:

QTY: 3000

D/C2:

QTY2:

CPN:

N/F: F (F63TNR)3

F63TNR Label sample

F63TNR Label

Antistatic Cover Tape

Customized Label

Static Dissipative

Embossed Carrier Tape

Packaging Description:

SOT-223 parts are shipped in tape. The carrier tape is

made from a dissipative (carbon filled) polycarbonate

resin. The cover tape is a multilayer film (Heat Activated

Adhesive in nature) primarily composed of polyester film,

adhesive layer, sealant, and anti-static sprayed agent.

These reeled parts in standard option are shipped with

2,500 units per 13" or 330cm diameter reel. The reels are

dark blue in color and is made of polystyrene plastic (anti-

static coated). Other option comes in 500 units per 7" or

177cm diameter reel. This and some other options are

further described in the Packaging Information table.

These full reels are individually barcode labeled and

placed inside a standard intermediate box (illustrated in

figure 1.0) made of recyclable corrugated brown paper.

One box contains two reels maximum. And these boxes

are placed inside a barcode labeled shipping box which

comes in different sizes depending on the number of parts

shipped.

SOT-223 Tape and Reel Data

September 1999, Rev. B

©2000 Fairchild Semiconductor International

Dimensions are in millimeter

Pkg type

A0

B0

W

D0

D1

E1

E2

F

P1

P0

K0

T

Wc

Tc

SOT-223

(12mm)

6.83

+/-0.10

7.42

+/-0.10

12.0

+/-0.3

1.55

+/-0.05

1.50

+/-0.10

1.75

+/-0.10

10.25

min

5.50

+/-0.05

8.0

+/-0.1

4.0

+/-0.1

1.88

+/-0.10

0.292

+/-

0.0130

9.5

+/-0.025

0.06

+/-0.02

P1

A0

D1

P0

F

W

E1

D0

E2

B0

Tc

Wc

K0

T

Dimensions are in inches and millimeters

Tape Size

Reel

Option

Dim A

Dim B

Dim C

Dim D

Dim N

Dim W1

Dim W2

Dim W3 (LSL-USL)

12mm

7" Dia

7.00

177.8

0.059

1.5

512 +0.020/-0.008

13 +0.5/-0.2

0.795

20.2

5.906

150

0.488 +0.078/-0.000

12.4 +2/0

0.724

18.4

0.469 – 0.606

11.9 – 15.4

12mm

13" Dia

13.00

330

0.059

1.5

512 +0.020/-0.008

13 +0.5/-0.2

0.795

20.2

7.00

178

0.488 +0.078/-0.000

12.4 +2/0

0.724

18.4

0.469 – 0.606

11.9 – 15.4

See detail AA

Dim A

max

13" Diameter Option

7" Diameter Option

Dim A

Max

See detail AA

W3

W2 max Measured at Hub

W1 Measured at Hub

Dim N

Dim D

min

Dim C

B Min

DETAIL AA

Notes: A0, B0, and K0 dimensions are determined with respect to the EIA/Jedec RS-481

rotational and lateral movement requirements (see sketches A, B, and C).

20 deg maximum component rotation

0.5mm

maximum

0.5mm

maximum

Sketch C (Top View)

Component lateral movement

Typical

component

cavity

center line

20 deg maximum

Typical

component

center line

B0

A0

Sketch B (Top View)

Component Rotation

Sketch A (Side or Front Sectional View)

Component Rotation

User Direction of Feed

SOT-223 Embossed Carrier Tape

Configuration: Figure 3.0

SOT-223 Reel Configuration: Figure 4.0

SOT-223 Tape and Reel Data, continued

July 1999, Rev. B

SOT-223 (FS PKG Code 47)

SOT-223 Package Dimensions

1 : 1

Scale 1:1 on letter size paper

Part Weight per unit (gram): 0.1246

September 1999, Rev. C

©2000 Fairchild Semiconductor International

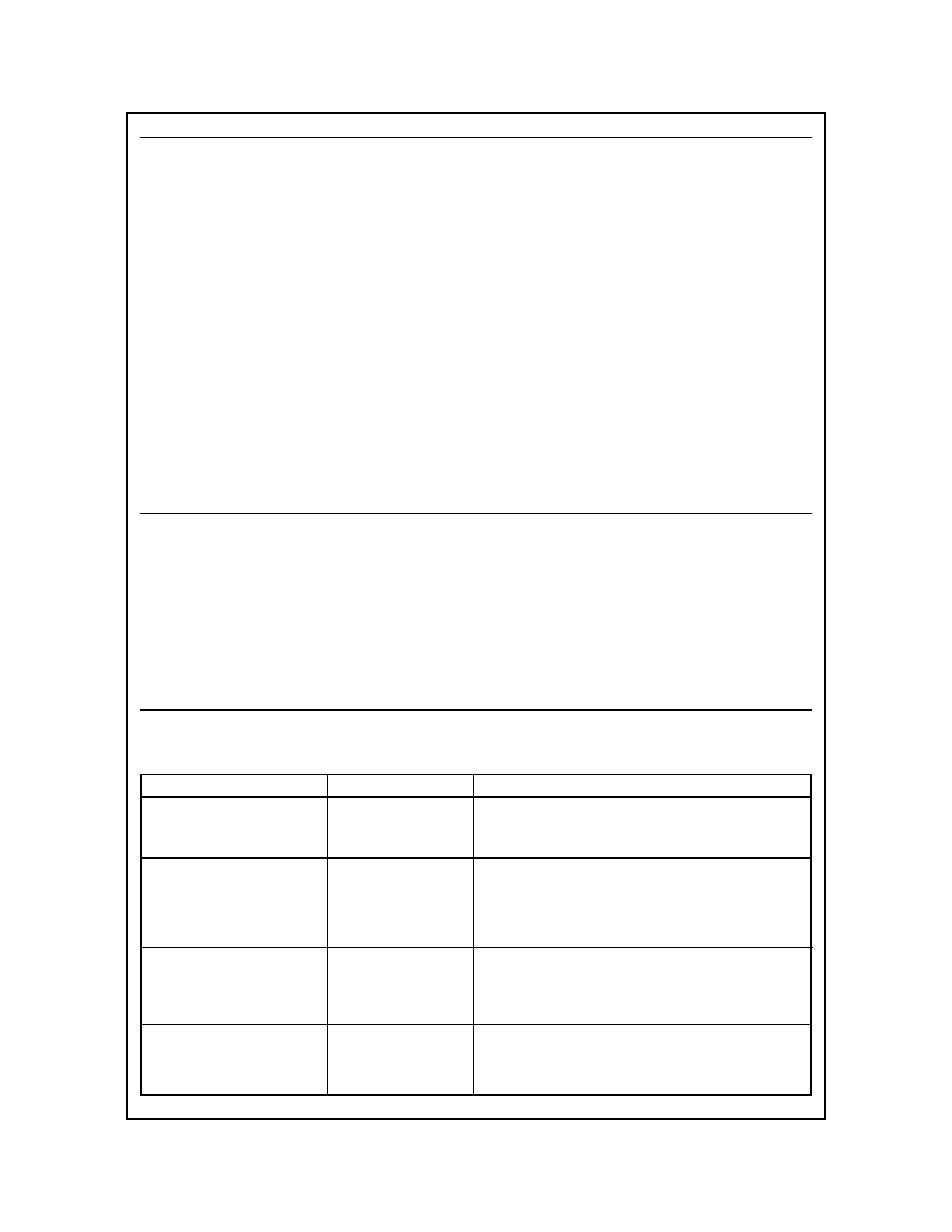

TRADEMARKS

The following are registered and unregistered trademarks Fairchild Semiconductor owns or is authorized to use and is

not intended to be an exhaustive list of all such trademarks.

LIFE SUPPORT POLICY

FAIRCHILD’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF FAIRCHILD SEMICONDUCTOR CORPORATION.

As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant into

the body, or (b) support or sustain life, or (c) whose

failure to perform when properly used in accordance

with instructions for use provided in the labeling, can be

reasonably expected to result in significant injury to the

user.

2. A critical component is any component of a life

support device or system whose failure to perform can

be reasonably expected to cause the failure of the life

support device or system, or to affect its safety or

effectiveness.

PRODUCT STATUS DEFINITIONS

Definition of Terms

Datasheet Identification

Product Status

Definition

Advance Information

Preliminary

No Identification Needed

Obsolete

This datasheet contains the design specifications for

product development. Specifications may change in

any manner without notice.

This datasheet contains preliminary data, and

supplementary data will be published at a later date.

Fairchild Semiconductor reserves the right to make

changes at any time without notice in order to improve

design.

This datasheet contains final specifications. Fairchild

Semiconductor reserves the right to make changes at

any time without notice in order to improve design.

This datasheet contains specifications on a product

that has been discontinued by Fairchild semiconductor.

The datasheet is printed for reference information only.

Formative or

In Design

First Production

Full Production

Not In Production

DISCLAIMER

FAIRCHILD SEMICONDUCTOR RESERVES THE RIGHT TO MAKE CHANGES WITHOUT FURTHER

NOTICE TO ANY PRODUCTS HEREIN TO IMPROVE RELIABILITY, FUNCTION OR DESIGN. FAIRCHILD

DOES NOT ASSUME ANY LIABILITY ARISING OUT OF THE APPLICATION OR USE OF ANY PRODUCT

OR CIRCUIT DESCRIBED HEREIN; NEITHER DOES IT CONVEY ANY LICENSE UNDER ITS PATENT

RIGHTS, NOR THE RIGHTS OF OTHERS.

PowerTrench

QFET™

QS™

QT Optoelectronics™

Quiet Series™

SILENT SWITCHER

SMART START™

SuperSOT™-3

SuperSOT™-6

SuperSOT™-8

FASTr™

GlobalOptoisolator™

GTO™

HiSeC™

ISOPLANAR™

MICROWIRE™

OPTOLOGIC™

OPTOPLANAR™

PACMAN™

POP™

Rev. G

ACEx™

Bottomless™

CoolFET™

CROSSVOLT™

DOME™

E

2

CMOS

TM

EnSigna

TM

FACT™

FACT Quiet Series™

FAST

SyncFET™

TinyLogic™

UHC™

VCX™