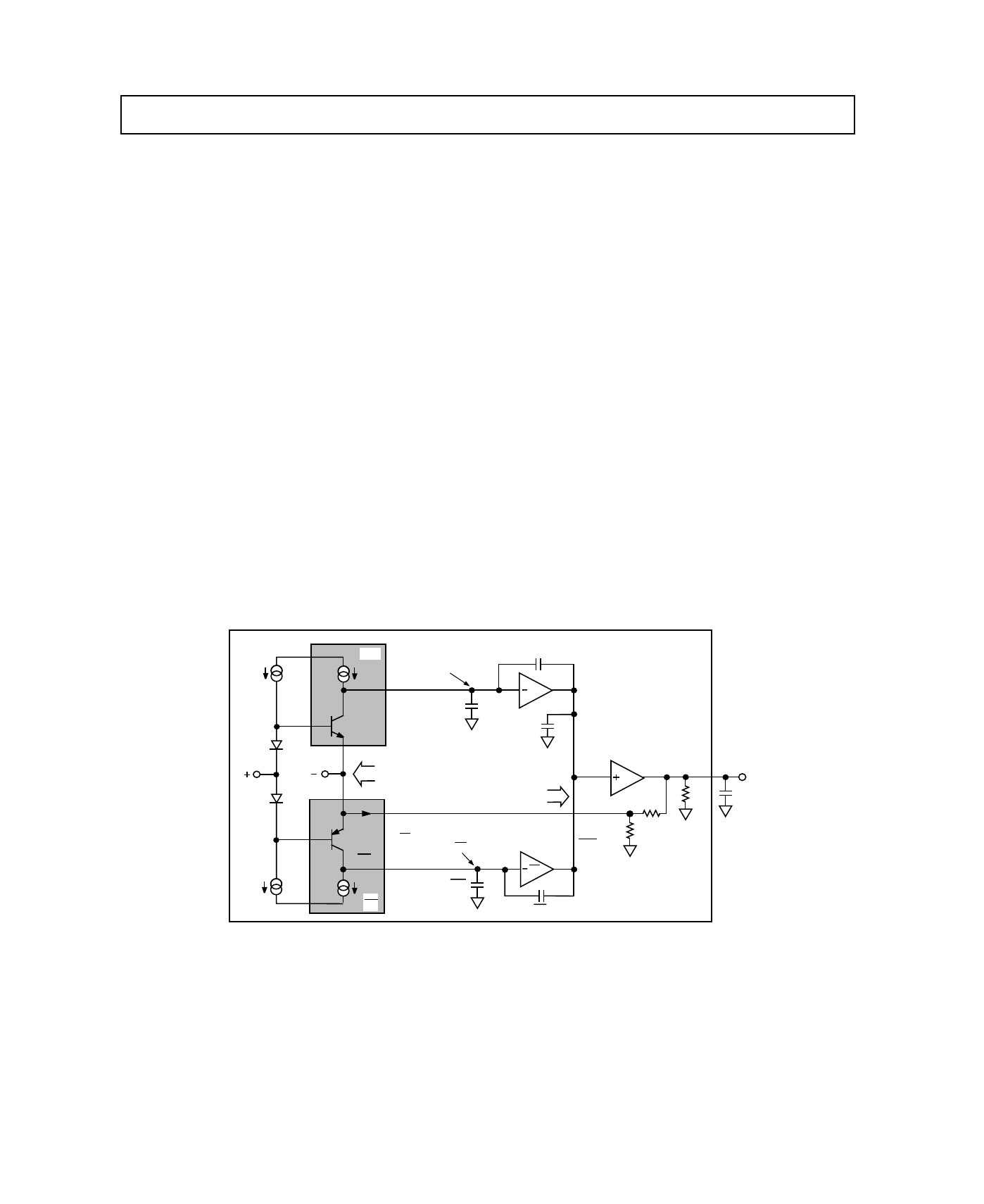

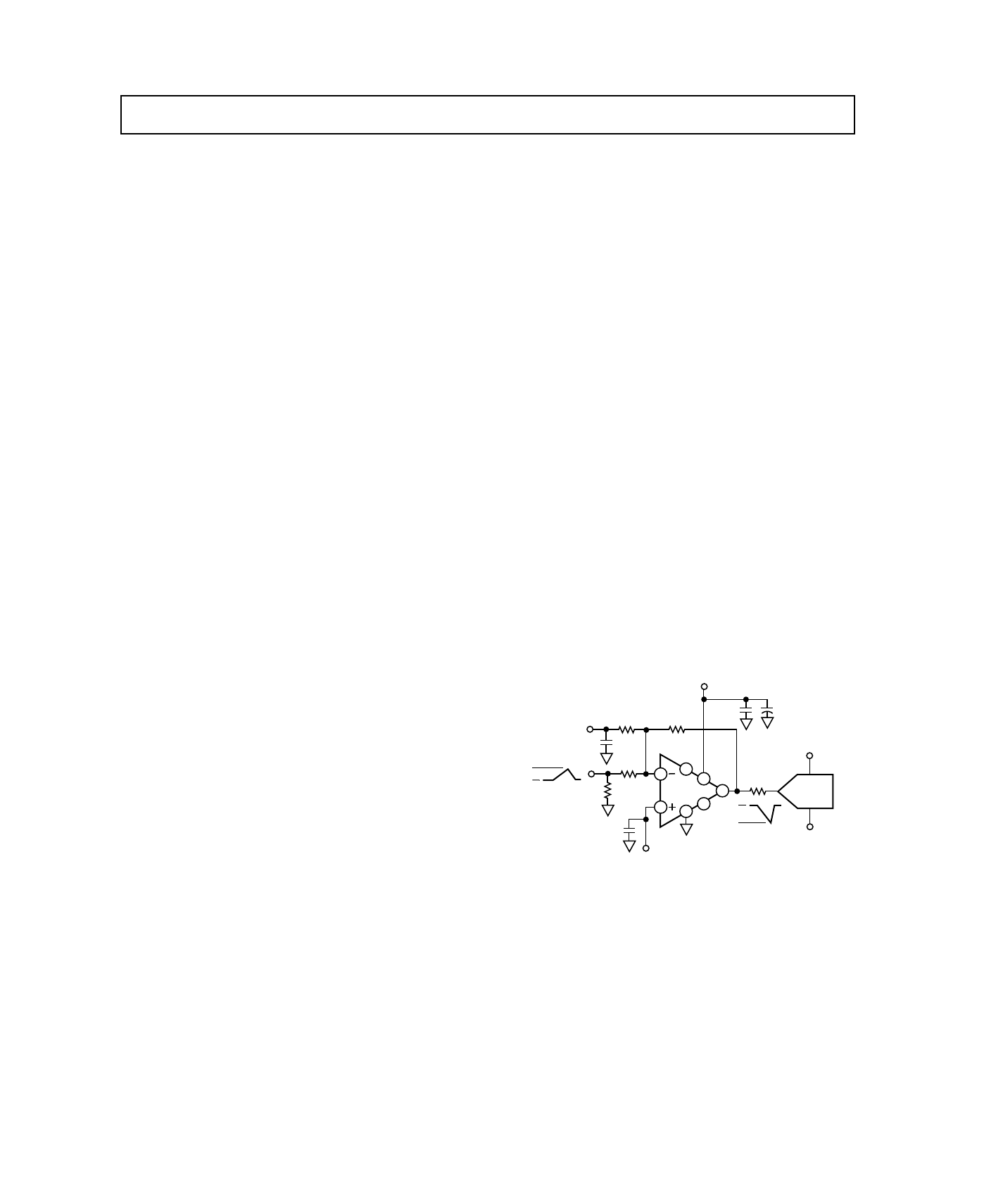

FUNCTIONAL BLOCK DIAGRAM

8-Pin Plastic Mini-DIP and SOIC

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

a

300 MHz, 1 mA

Current Feedback Amplifier

AD8011*

FEATURES

Easy to Use

Low Power

1 mA Power Supply Current (5 mW on +5 V

S

)

High Speed and Fast Settling on +5 V

300 MHz, –3 dB Bandwidth (G = +1)

180 MHz, –3 dB Bandwidth (G = +2)

2000 V/

µ

s Slew Rate

29 ns Settling Time to 0.1%

Good Video Specifications (R

L

= 1 k

Ω

, G = +2)

Gain Flatness 0.1 dB to 25 MHz

0.02% Differential Gain Error

0.06

°

Differential Phase Error

Low Distortion

–70 dBc Worst Harmonic @ 5 MHz

–62 dBc Worst Harmonic @ 20 MHz

Single Supply Operation

Fully Specified for +5 V Supply

APPLICATIONS

Power Sensitive, High Speed Systems

Video Switchers

Distribution Amplifiers

A-to-D Driver

Professional Cameras

CCD Imaging Systems

Ultrasound Equipment (Multichannel)

+4

+3

+2

+1

0

–2

–3

–4

1 10 100 500

FREQUENCY – MHz

–1

+5

–5

NORMALIZED GAIN – dB

G = +2

R

F

= 1k

Ω

V

S

= +5V OR

±

5V

V

OUT

= 200mV p-p

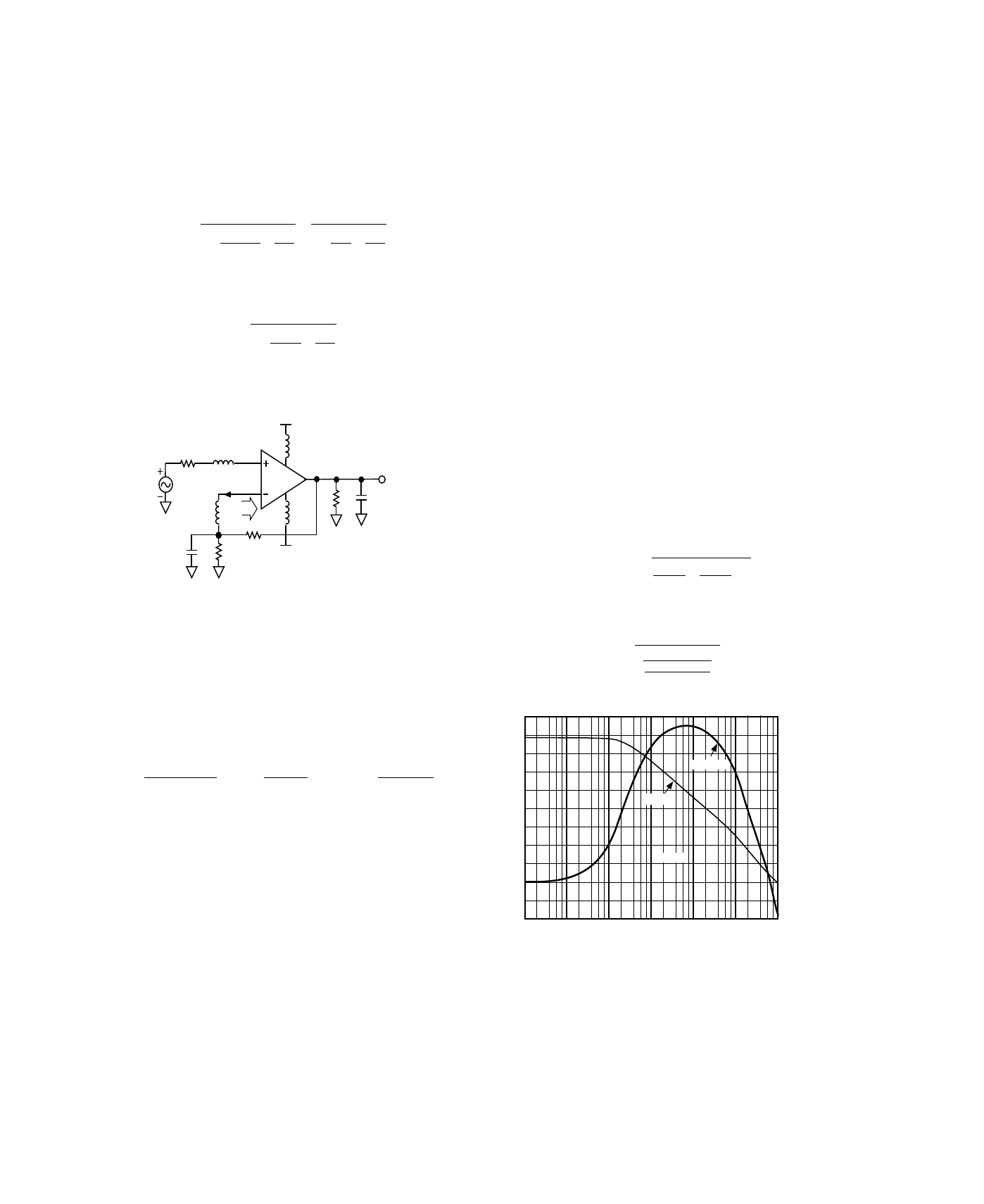

Figure 1. Frequency Response; G = +2, V

S

= +5 V or

±

5 V

*Patent pending.

1

2

3

4

8

7

6

5

AD8011

NC

V+

NC

–IN

V–

NC

+IN

NC = NO CONNECT

OUT

3rd

R

L

=1k

Ω

3rd

R

L

= 150

Ω

2nd

R

L

= 150

Ω

FREQUENCY – MHz

DISTORTION – dBc

–40

–100

1

10

20

2nd

R

L

= 1k

Ω

G = +2

–60

–80

Figure 2. Distortion vs. Frequency; V

S

=

±

5 V

© Analog Devices, Inc., 1995

One Technology Way, P.O. Box 9106, Norwood. MA 02062-9106, U.S.A.

Tel: 617/329-4700

pose amplifier. It also can be used to replace high speed am-

plifiers consuming more power. The AD8011 is a current feed-

back amplifier and features gain flatness of 0.1 dB to 25 MHz

while offering differential gain and phase error of 0.02% and

0.06

°

on a single +5 V supply. This makes the AD8011 ideal

for professional video electronics such as cameras, video switch-

ers or any high speed portable equipment. Additionally, the

AD8011’s low distortion and fast settling make it ideal for

buffering high speed 8-, 10-, 12-bit A-to-D converters.

The AD8011 offers very low power of 1 mA max and can run

on single +5 V to +12 V supplies. All this is offered in a small

8-pin DIP or 8-pin SOIC package. These features fit well with

portable and battery powered applications where size and power

are critical.

The AD8011 is available in the industrial temperature range of

–40

°

C to +85

°

C.

PRODUCT DESCRIPTION

The AD8011 is a very low power, high speed amplifier designed

to operate on +5 V or

±

5 V supplies. With wide bandwidth, low

distortion and low power, this device is ideal as a general pur-

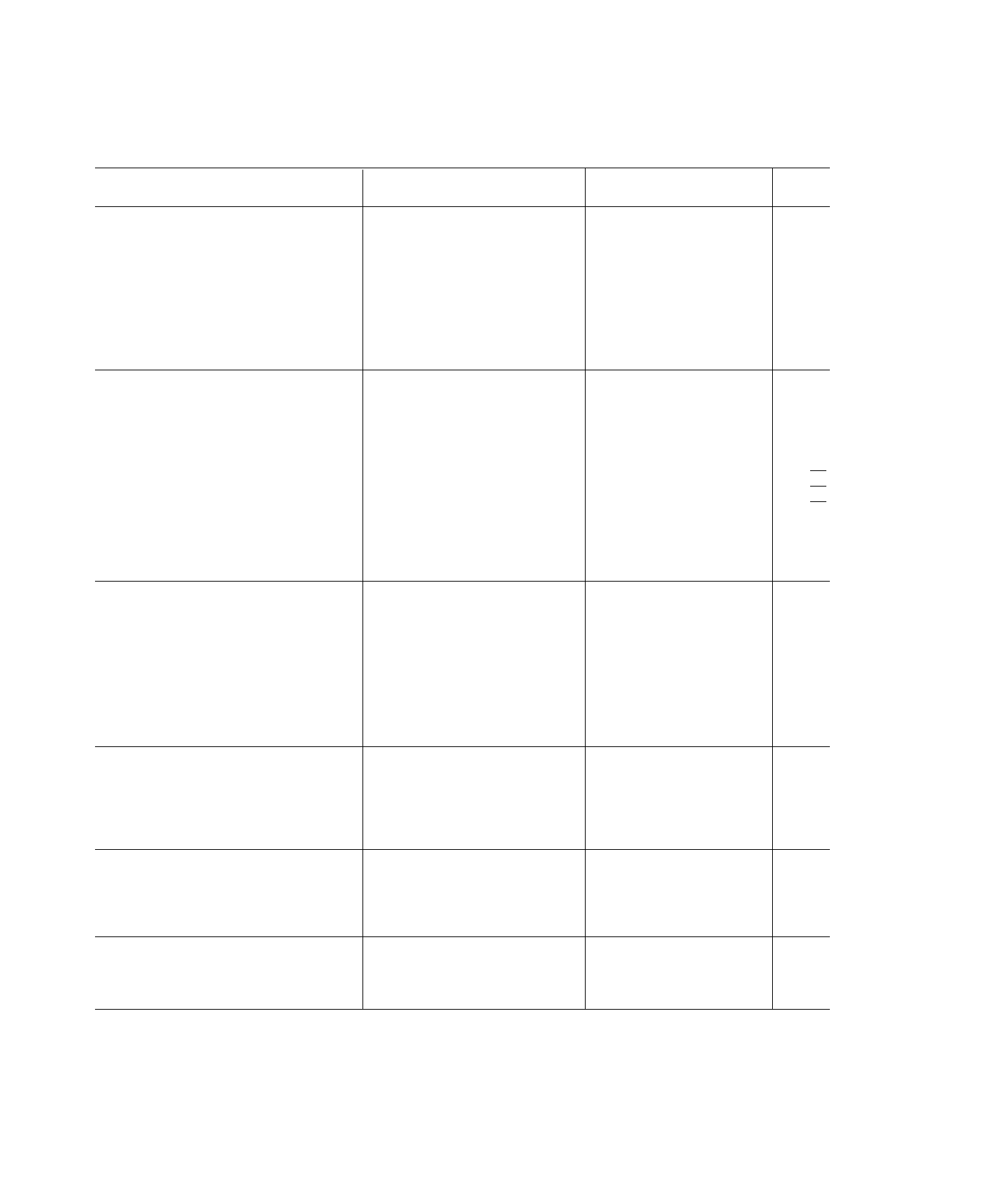

AD8011–SPECIFICATIONS

DUAL SUPPLY

Model

AD8011A

Conditions

Min

Typ

Max

Units

DYNAMIC PERFORMANCE

–3 dB Small Signal Bandwidth, V

O

< 1 V p-p

G = +1

340

400

MHz

–3 dB Small Signal Bandwidth, V

O

< 1 V p-p

G = +2

180

210

MHz

–3 dB Large Signal Bandwidth, V

O

= 5 V p-p

G = +10, R

F

= 500

Ω

57

MHz

Bandwidth for 0.1 dB Flatness

G = +2

20

25

MHz

Slew Rate

G = +2, V

O

= 4 V Step

3500

V/

µ

s

G = –1, V

O

= 4 V Step

1100

V/

µ

s

Settling Time to 0.1%

G = +2, V

O

= 2 V Step

25

ns

Rise and Fall Time

G = +2, V

O

= 2 V Step

0.4

ns

G = –1, V

O

= 2 V Step

3.7

ns

NOISE/HARMONIC PERFORMANCE

2nd Harmonic

f

C

= 5 MHz, V

O

= 2 V p-p, G = +2

R

L

= 1 k

Ω

–75

dB

R

L

= 150

Ω

–67

dB

3rd Harmonic

R

L

= 1 k

Ω

–70

dB

R

L

= 150

Ω

–54

dB

Input Voltage Noise

f = 10 kHz

2

nV/

√

Hz

Input Current Noise

f = 10 kHz, +In

5

pA/

√

Hz

–In

5

pA/

√

Hz

Differential Gain Error

NTSC, G = +2, R

L

= 1 k

Ω

0.02

%

R

L

= 150

Ω

0.02

%

Differential Phase Error

NTSC, G = +2, R

L

= 1 k

Ω

0.06

Degrees

R

L

= 150

Ω

0.3

Degrees

DC PERFORMANCE

Input Offset Voltage

2

5

±

mV

T

MIN

–T

MAX

2

6

±

mV

Offset Drift

10

µ

V/

°

C

–Input Bias Current

5

15

±µ

A

T

MIN

–T

MAX

20

±µ

A

+Input Bias Current

5

15

±µ

A

T

MIN

–T

MAX

20

±µ

A

Open-Loop Transresistance

800

1300

k

Ω

T

MIN

–T

MAX

550

k

Ω

INPUT CHARACTERISTICS

Input Resistance

+Input

450

k

Ω

Input Capacitance

+Input

2.3

pF

Input Common-Mode Voltage Range

3.8

4.1

±

V

Common-Mode Rejection Ratio

Offset Voltage

V

CM

=

±

2.5 V

–52

–57

dB

OUTPUT CHARACTERISTICS

Output Voltage Swing

3.9

4.1

±

V

Output Resistance

0.1

0.3

Ω

Output Current

T

MIN

–T

MAX

15

30

mA

Short Circuit Current

60

mA

POWER SUPPLY

Operating Range

±

1.5

±

6.0

V

Quiescent Current

T

MIN

–T

MAX

1.0

1.2

mA

Power Supply Rejection Ratio

Vs =

±

5 V

±

1 V

55

58

dB

Specifications subject to change without notice.

REV. 0

–2–

(@ T

A

= +25

°

C, V

S

=

±

5 V, G = +2, R

F

= 1 k

Ω

, R

L

= 1 k

Ω

, unless otherwise noted)

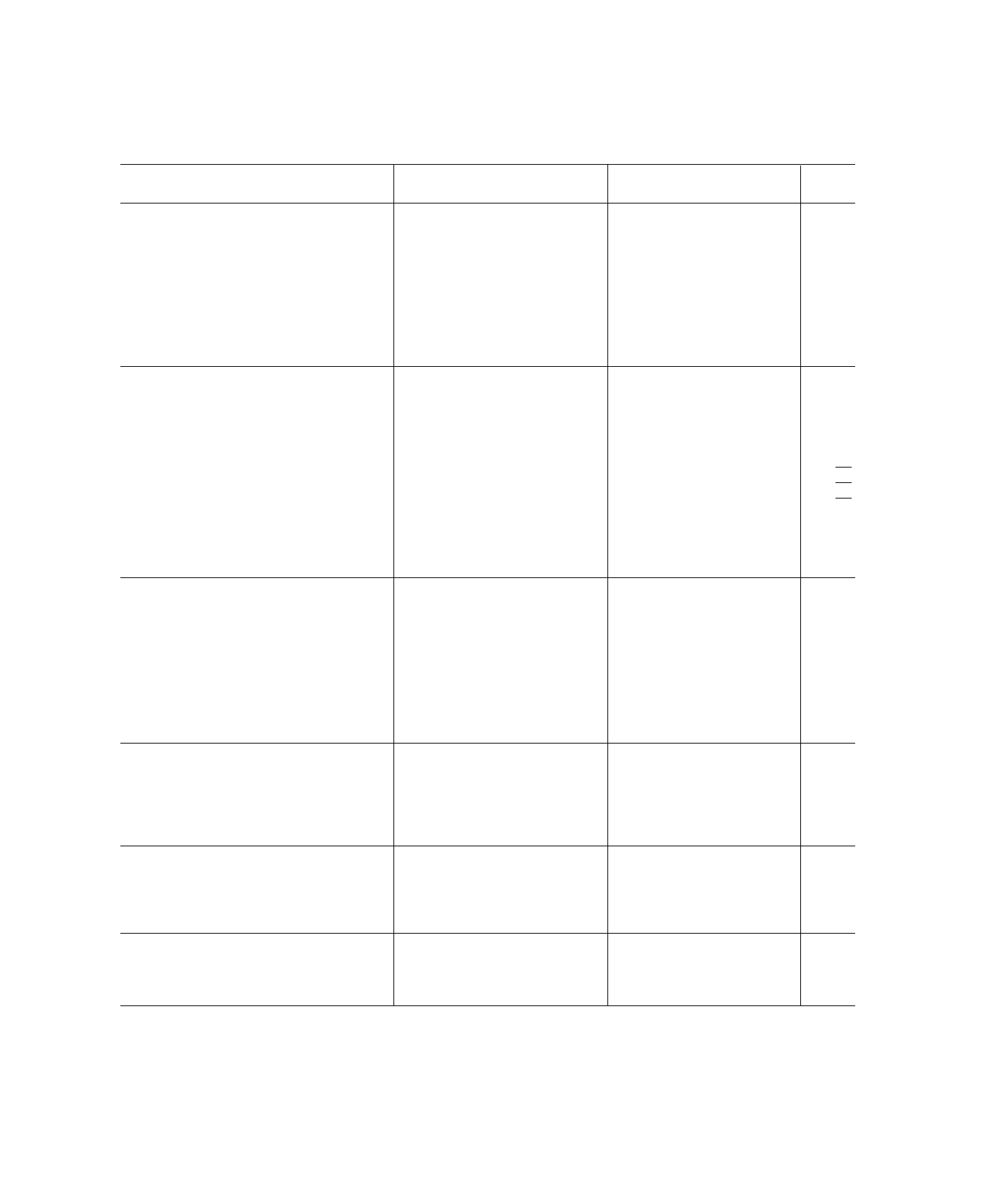

SINGLE SUPPLY

Model

AD8011A

Conditions

Min

Typ

Max

Units

DYNAMIC PERFORMANCE

–3 dB Small Signal Bandwidth, V

O

< 0.5 V p-p

G = +1

270

328

MHz

–3 dB Small Signal Bandwidth, V

O

< 0.5 V p-p

G = +2

150

180

MHz

–3 dB Large Signal Bandwidth, V

O

= 2.5 V p-p

G = +10, R

F

= 500

Ω

57

MHz

Bandwidth for 0.1 dB Flatness

G = +2

15

20

MHz

Slew Rate

G = +2, V

O

= 2 V Step

2000

V/

µ

s

G = –1, V

O

= 2 V Step

500

V/

µ

s

Settling Time to 0.1%

G = +2, V

O

= 2 V Step

29

ns

Rise and Fall Time

G = +2, V

O

= 2 V Step

0.6

ns

G = –1, V

O

= 2 V Step

4

ns

NOISE/HARMONIC PERFORMANCE

2nd Harmonic

f

C

= 5 MHz, V

O

= 2 V p-p, G = +2

R

L

= 1 k

Ω

–84

dB

R

L

= 150

Ω

–67

dB

3rd Harmonic

R

L

= 1 k

Ω

–76

dB

R

L

= 150

Ω

–54

dB

Input Voltage Noise

f = 10 kHz

2

nV/

√

Hz

Input Current Noise

f = 10 kHz, +In

5

pA/

√

Hz

–In

5

pA/

√

Hz

Differential Gain Error

NTSC, G = +2, R

L

= 1 k

Ω

0.02

%

R

L

= 150

Ω

0.6

%

Differential Phase Error

NTSC, G = +2, R

L

= 1 k

Ω

0.06

Degrees

R

L

= 150

Ω

0.8

Degrees

DC PERFORMANCE

Input Offset Voltage

2

5

mV

T

MIN

–T

MAX

2

6

mV

Offset Drift

10

µ

V/

°

C

–Input Bias Current

5

15

±µ

A

T

MIN

–T

MAX

20

±µ

A

+Input Bias Current

5

15

±µ

A

T

MIN

–T

MAX

20

±µ

A

Open-Loop Transresistance

800

1300

k

Ω

T

MIN

–T

MAX

550

k

Ω

INPUT CHARACTERISTICS

Input Resistance

+Input

450

k

Ω

Input Capacitance

+Input

2.3

pF

Input Common-Mode Voltage Range

1.5 to 3.5

1.2 to 3.8

V

Common-Mode Rejection Ratio

Offset Voltage

V

CM

= 1.5 V to 3.5 V

–52

–57

dB

OUTPUT CHARACTERISTICS

Output Voltage Swing

1.2 to 3.8

0.9 to 4.1

+V

Output Resistance

0.1

0.3

Ω

Output Current

T

MIN

–T

MAX

15

30

mA

Short Circuit Current

50

mA

POWER SUPPLY

Operating Range

+3

+12

V

Quiescent Current

T

MIN

–T

MAX

0.8

1.0

mA

Power Supply Rejection Ratio

∆

Vs =

±

1 V

55

58

dB

Specifications subject to change without notice.

REV. 0

–3–

AD8011

(@ T

A

= +25

°

C, V

S

= +5 V, G = +2, R

F

= 1 k

Ω

, V

CM

= 2.5 V, R

L

= 1 k

Ω

, unless otherwise noted)

REV. 0

–4–

AD8011

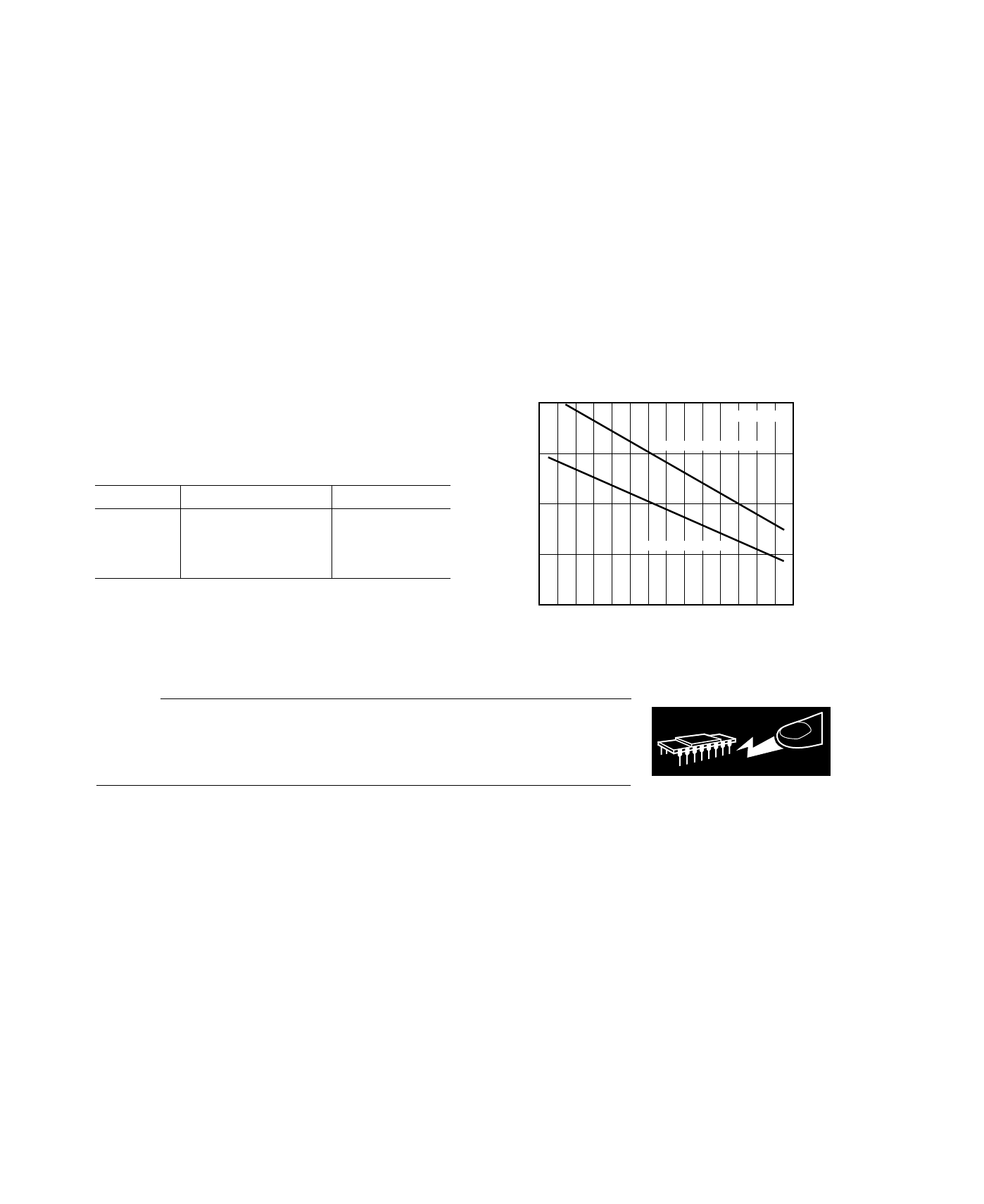

ABSOLUTE MAXIMUM RATINGS

1

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12.6 V

Internal Power Dissipation

2

Plastic Package (N) . . . . . . . . . . . . Observe Derating Curves

Small Outline Package (R) . . . . . . . Observe Derating Curves

Input Voltage (Common Mode) . . . . . . . . . . . . . . . . . . . .

±

V

S

Differential Input Voltage . . . . . . . . . . . . . . . . . . . . . . .

±

2.5 V

Output Short Circuit Duration

. . . . . . . . . . . . . . . . . . . . . . Observe Power Derating Curves

Storage Temperature Range (N, R) . . . . . . . . –65

°

C to +125

°

C

Operating Temperature Range (A Grade) . . . – 40

°

C to +85

°

C

Lead Temperature Range (Soldering 10 sec) . . . . . . . . +300

°

C

NOTES

1

Stresses above those listed under “Absolute Maximum Ratings” may cause

permanent damage to the device. This is a stress rating only and functional

operation of the device at these or any other conditions above those indicated in the

operational section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

2

Specification is for device in free air:

8-Pin Plastic Package:

θ

JA

= 90

°

C/Watt

8-Pin SOIC Package:

θ

JA

= 140

°

C/Watt

ORDERING GUIDE

Model

Temperature Range

Package Option

AD8011AN

– 40

°

C to +85

°

C

8-Pin Plastic DIP

AD8011AR

– 40

°

C to +85

°

C

8-Pin SOIC

AD8011-EB

Eval Board, SOIC,

G = +2

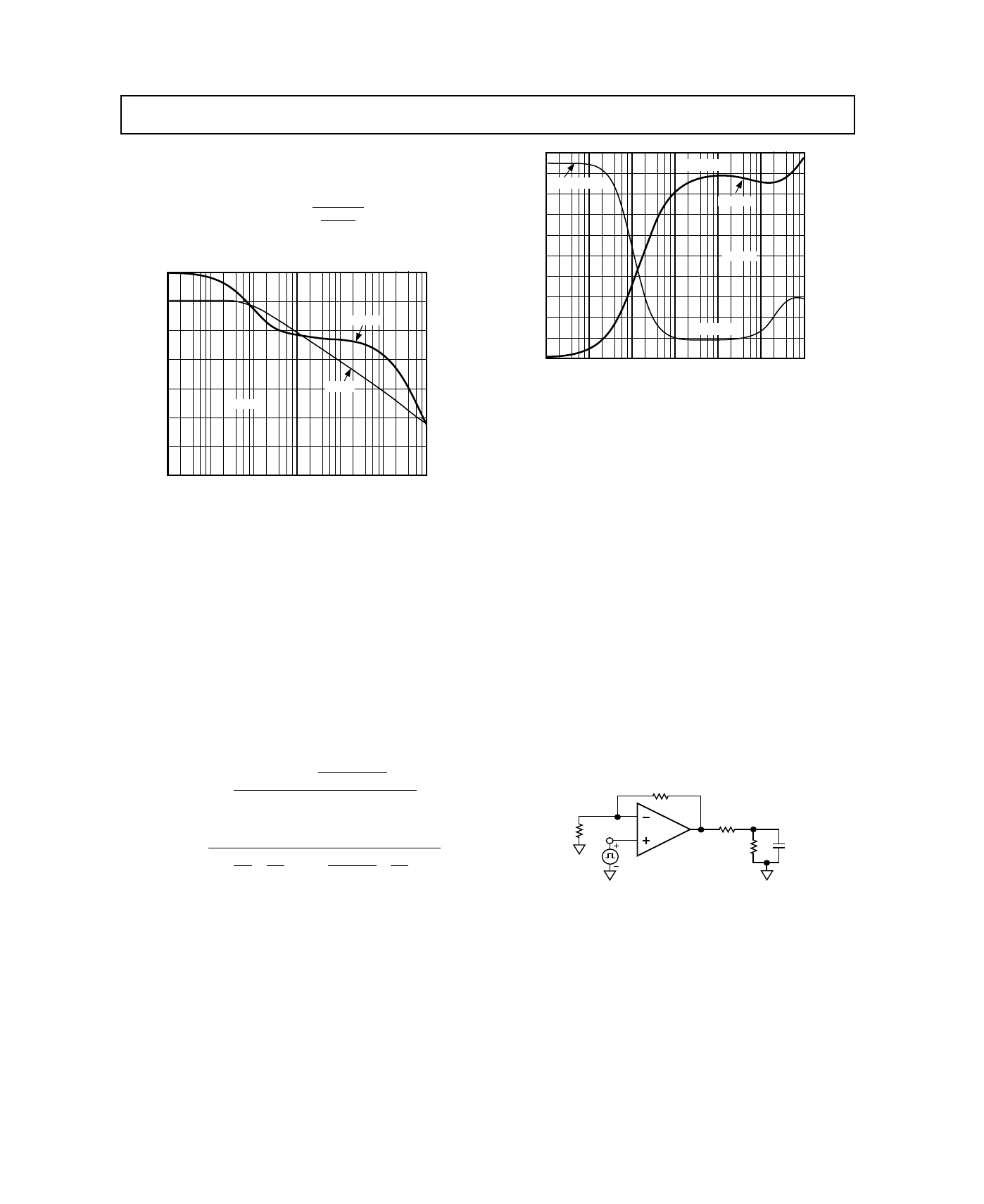

MAXIMUM POWER DISSIPATION

The maximum power that can be safely dissipated by the

AD8011 is limited by the associated rise in junction tempera-

ture. The maximum safe junction temperature for plastic

encapsulated devices is determined by the glass transition tem-

perature of the plastic, approximately +150

°

C. Exceeding this

limit temporarily may cause a shift in parametric performance

due to a change in the stresses exerted on the die by the package.

Exceeding a junction temperature of +175

°

C for an extended

period can result in device failure.

While the AD8011 is internally short circuit protected, this

may not be sufficient to guarantee that the maximum junction

temperature is not exceeded under all conditions. To ensure

proper operation, it is necessary to observe the maximum power

derating curves (shown below in Figure 3).

2.0

1.5

0.5

–50 –40 –30 –20 –10

0

10

20 30

40

50

60 70

80 90

AMBIENT TEMPERATURE –

°

C

1.0

0

MAXIMUM POWER DISSIPATION – Watts

T

J

= +150

°

C

8-PIN MINI-DIP PACKAGE

8-PIN SOIC PACKAGE

Figure 3. Maximum Power Dissipation vs. Temperature

WARNING!

ESD SENSITIVE DEVICE

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD8011 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

AD8011

REV. 0

–5–

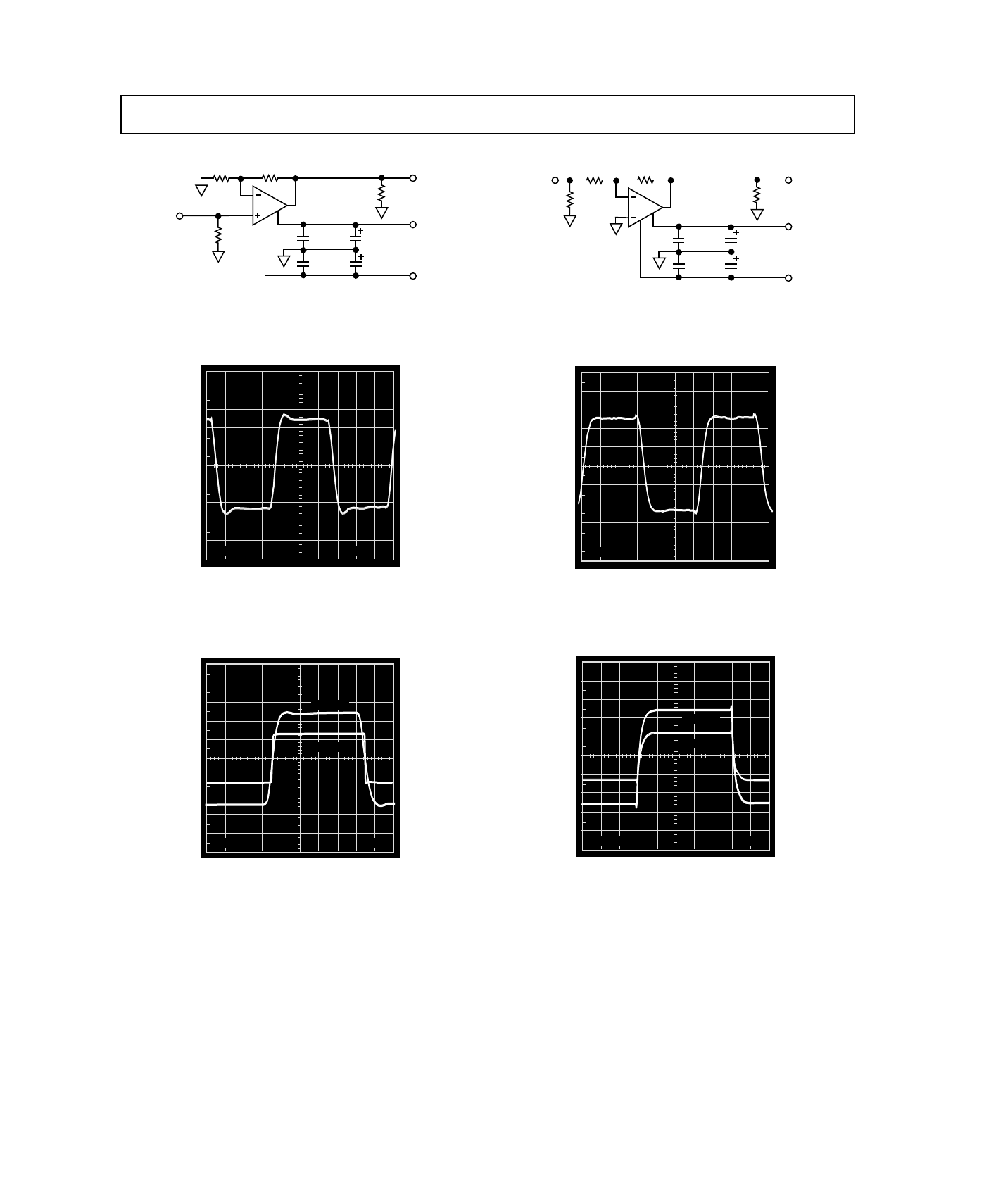

52.3

Ω

0.01µF

0.01µF

10µF

10µF

R

L

1k

Ω

1k

Ω

1k

Ω

V

IN

V

OUT

+V

S

–V

S

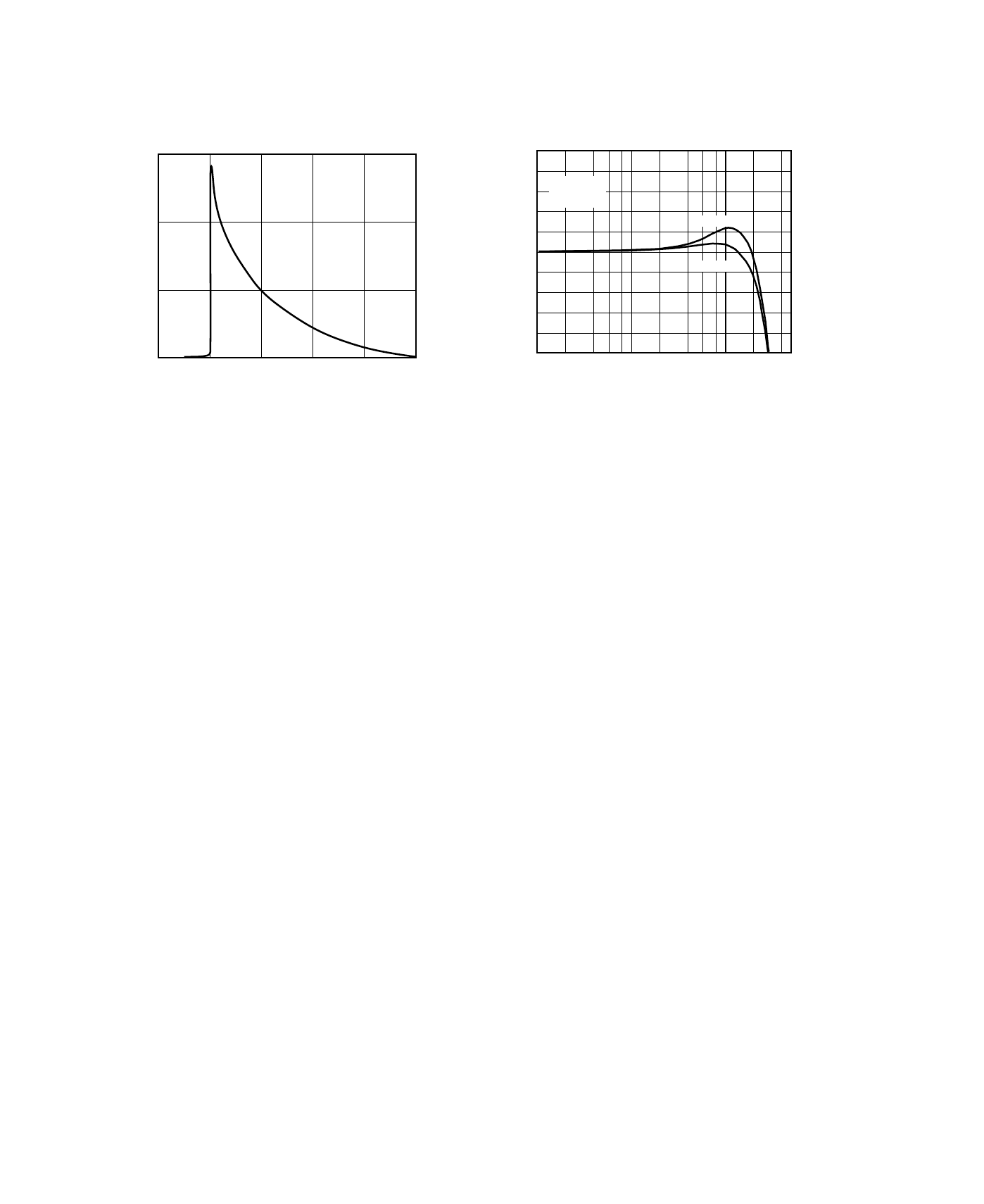

Figure 7. Test Circuit; Gain = –1

20mV

5ns

Figure 8.* 100 mV Step Response; G = –1, V

S

=

±

2.5 V or

±

5 V

800mV

10ns

4V STEP

2V STEP

Figure 9.* Step Response; G = –1, V

S

=

±

2.5 V (2 V

Step) and

±

5 V (4 V Step)

0.01µF

0.01µF

10µF

10µF

R

L

1k

Ω

1k

Ω

1k

Ω

50

Ω

V

IN

V

OUT

+V

S

–V

S

Figure 4. Test Circuit; Gain = +2

20mV

5ns

Figure 5.* 100 mV Step Response; G = +2, V

S

=

±

2.5 V or

±

5 V

800mV

10ns

4V STEP

2V STEP

Figure 6.* Step Response; G = +2, V

S

=

±

2.5 V (2 V

Step) and

±

5 V (4 V Step)

*NOTE: V

S

=

±

2.5 V operation is identical to V

S

= +5 V single supply operation.

REV. 0

–6–

AD8011

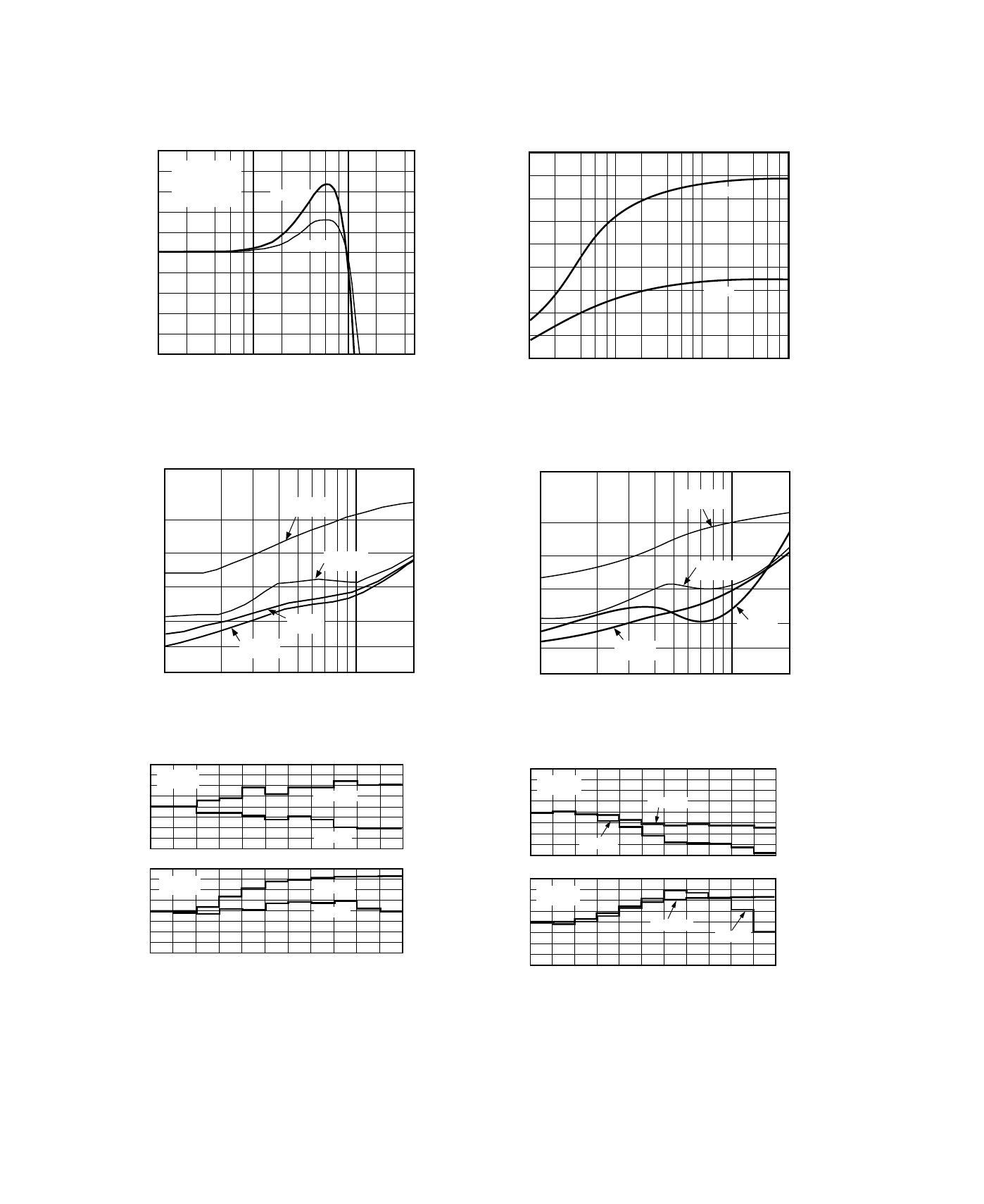

6.5

6.4

6.3

6.2

6.1

5.9

5.8

5.7

1 10 100 500

FREQUENCY – MHz

6.0

5.6

5.5

GAIN – dB

V

S

=

±

5V

V

S

= 5V

G = +2

V

IN

= 100mV p-p

R

L

= 1k

Ω

R

F

= 1k

Ω

Figure 10. Gain Flatness; G = +2

3rd

R

L

=1k

Ω

3rd

R

L

= 150

Ω

2nd

R

L

= 150

Ω

FREQUENCY – MHz

DISTORTION – dBc

–40

–100

1

10

20

2nd

R

L

= 1k

Ω

G = +2

–60

–80

Figure 11. Distortion vs. Frequency; V

S

=

±

5 V

1k

Ω

DIFF PHASE – Degrees

100

0

IRE

R

L

= 1k

Ω

DIFF GAIN – %

R

L

= 150

Ω

R

L

= 150

Ω

100

0

IRE

R

L

= 1k

Ω

0.04

–0.04

0.00

–0.02

0.02

0.01

–0.01

–0.03

0.03

0.04

–0.04

0.00

–0.02

0.02

0.01

–0.01

–0.03

0.03

V

S

=

±

5V

G = +2

V

S

=

±

5V

G = +2

0.4

–0.4

0.00

–0.2

0.2

150

Ω

DIFF PHASE – Degrees

0.1

–0.1

–0.3

0.3

Figure 12. Diff Phase and Diff Gain; V

S

=

±

5 V

9

8

7

6

5

3

2

10 100 1000 10000

LOAD RESISTANCE – Ohms

4

1

0

SWING – V p

-p

+5V

±

5V

Figure 13. Output Voltage Swing vs. Load

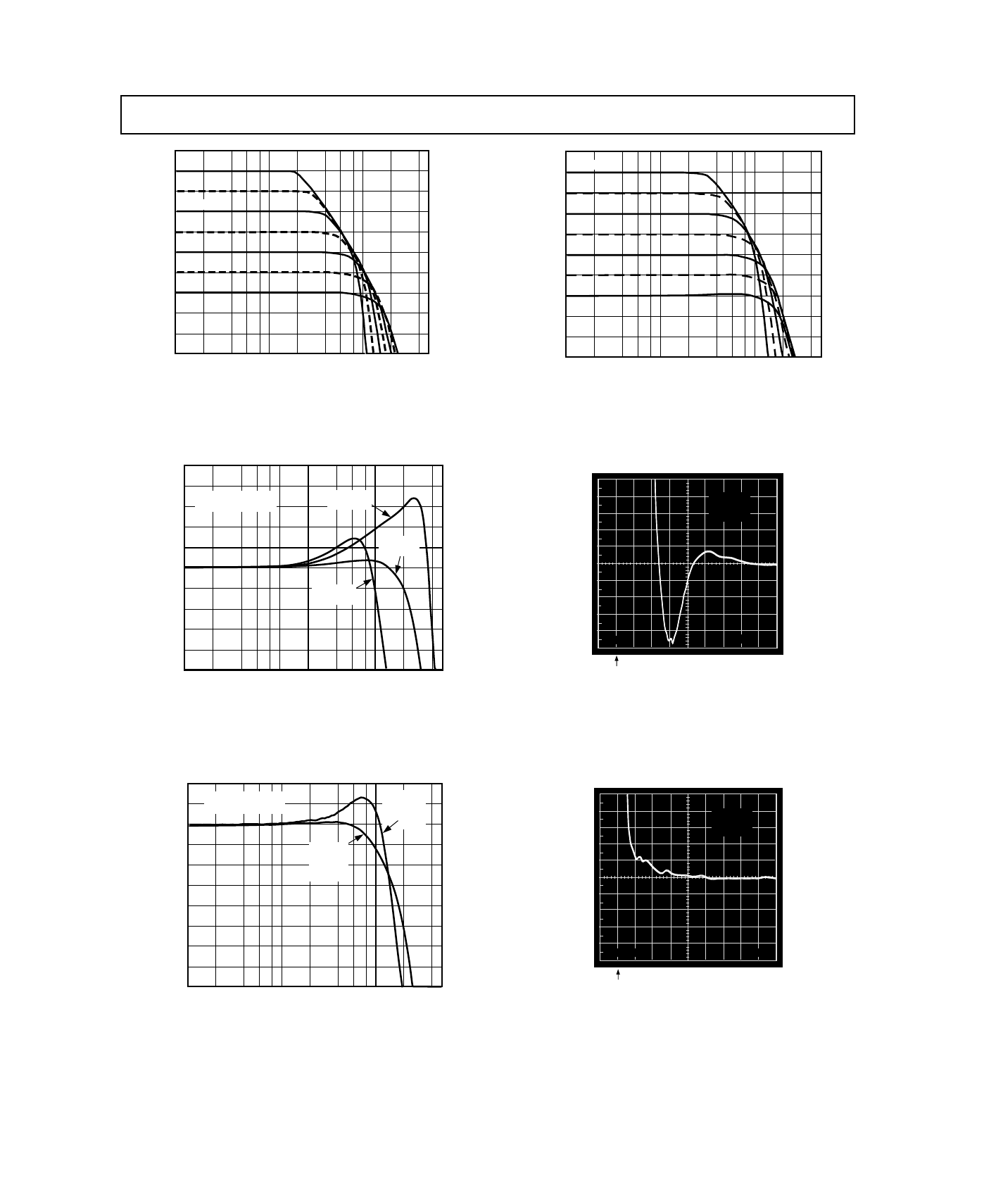

3rd

R

L

=1k

Ω

3rd

R

L

=150

Ω

FREQUENCY – MHz

DISTORTION – dBc

–40

–100

1

10

20

2nd

R

L

=150

Ω

2nd

R

L

=1k

Ω

G = +2

–60

–80

Figure 14. Distortion vs. Frequency; V

S

= +5 V

0.08

1k

Ω

DIFF GAIN – %

–0.08

0.00

–0.04

0.04

100

0

IRE

1k

Ω

DIFF PHASE – Degrees

150

Ω

DIFF PHASE – Degrees

100

0

IRE

0.02

–0.02

–0.06

0.06

0.8

–0.8

0.0

–0.4

0.4

0.2

–0.2

–0.6

0.6

0.08

–0.08

0.00

–0.04

0.04

0.02

–0.02

–0.06

0.06

R

L

=150

Ω

R

L

=1k

Ω

R

L

=1k

Ω

R

L

=150

Ω

V

S

= +5V

G = +2

V

S

= +5V

G = +2

150

Ω

DIFF GAIN – %

0.8

–0.8

0.0

–0.4

0.4

0.2

–0.2

–0.6

0.6

Figure 15. Diff Phase and Diff Gain; V

S

= +5 V

AD8011

REV. 0

–7–

0

–3

–6

–9

–12

–18

–21

–24

1 10 40 100 500

FREQUENCY – MHz

–15

+3

OUTPUT VOLTAGE – dBV

–27

1V rms

Figure 19. Large Signal Frequency Response;

V

S

= +5 V, G = +2

0.1%

5ns

G = +2

R

F

= 1k

Ω

2V STEP

t

= 0

OUTPUT VOLTAGE – 0.1%/DIV

Figure 20. Short-Term Settling Time; V

S

= +5 V or

±

5 V

0.1%

100ns

G = +2

R

F

= 1k

Ω

2V STEP

t

= 0

OUTPUT VOLTAGE – 0.1%/DIV

Figure 21. Long-Term Settling Time; V

S

= +5 V or

±

5 V

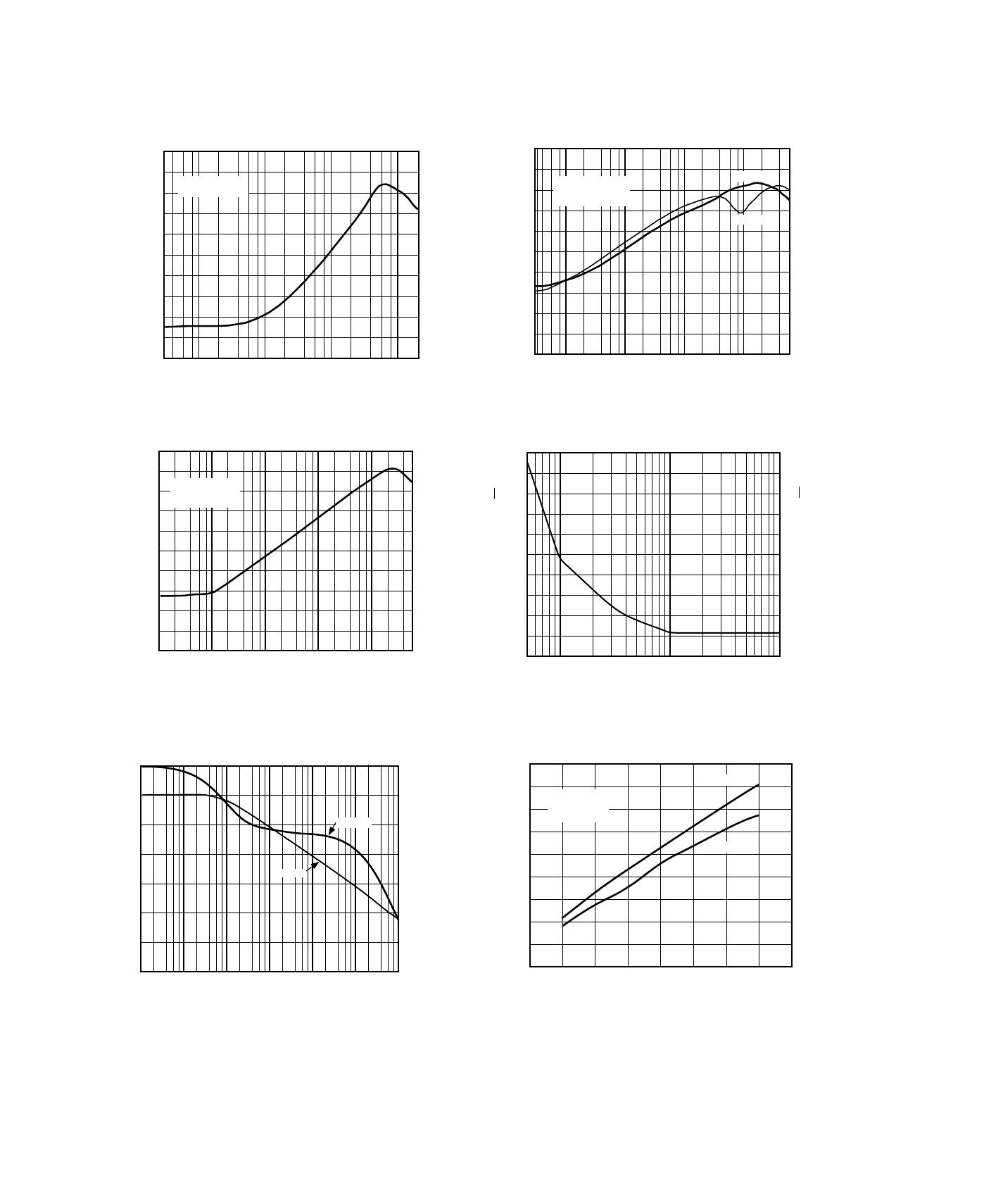

+6

+3

0

–3

–6

–12

–15

–18

1 10 40 100 500

FREQUENCY – MHz

–9

+9

OUTPUT VOLTAGE – dBV

–21

1V rms

Figure 16. Large Signal Frequency Response;

V

S

=

±

5 V, G = +2

+4

+3

+2

+1

0

–2

–3

–4

1 10 100 500

FREQUENCY – MHz

–1

+5

NORMALIZED GAIN – dB

–5

G = +1

R

F

= 1k

Ω

G = +10

R

F

= 500

Ω

G = +2

R

F

= 1k

Ω

V

S

= +5V OR

±

5V

V

OUT

= 200mV p-p

Figure 17. Frequency Response; G = +1, +2, +10;

V

S

= +5 V or

±

5 V

+1

0

–2

–3

–4

1 10 100 500

FREQUENCY – MHz

–1

+2

NORMALIZED GAIN – dB

–5

–6

–7

–8

G = –10

R

F

= 500

Ω

R

L

= 1k

Ω

V

S

= +5V OR

±

5V

V

OUT

= 200mV p-p

G = –1

R

F

= 1k

Ω

R

L

= 1k

Ω

Figure 18. Frequency Response; G = –1, –10;

V

S

= +5 V or

±

5 V

REV. 0

–8–

AD8011

–10

–15

–20

–25

–30

–40

–45

–50

0.1 1 10 100

FREQUENCY – MHz

–35

–55

–60

CMRR – dB

V

S

= +5V OR

±

5V

G = +2

Figure 22. CMRR vs. Frequency; V

S

= +5 V or

±

5 V

100

10

0.1

10k 0.1M 1M 10M 100M 500M

FREQUENCY – Hz

1

0.01

OUTPUT RESISTANCE –

Ω

V

S

= +5V OR

±

5V

G = +2

R

F

= 1k

Ω

Figure 23. Output Resistance vs. Frequency; V

S

= +5 V

or

±

5 V

1k 10k 100k 1M 10M 100M 1G

140

120

100

80

60

20

0

FREQUENCY – Hz

40

GAIN – dB Ohms

0

PHASE – Degrees

–40

–80

–120

–160

–200

–240

–280

PHASE

GAIN

Figure 24. Transimpedance Gain and Phase vs. Frequency

+10

0

–10

–20

–30

–50

–60

–70

100k 1M 10M 100M 500M

FREQUENCY – Hz

–40

–80

–90

PSRR – dB

V

S

= +5V OR

±

5V

G = +2

R

F

= 1k

Ω

+PSRR

–PSRR

Figure 25. PSRR vs. Frequency; V

S

= +5 V or

±

5 V

12.5

10

5

2.5

500 1k 10k 100k

FREQUENCY – Hz

7.5

0

INPUT VOLTAGE NOISE – nV/

√

Hz

INPUT CURRENT NOISE – pA/

√

Hz

50

40

20

10

30

0

Figure 26. Noise vs. Frequency; V

S

= +5 V or

±

5 V

9

8

7

6

5

4

3

2

3 4 5 6 7 8 9 10 11

1

0

f = 5MHz

G = +2

R

F

= 1k

Ω

R

L

= 150

Ω

R

L

= 1k

Ω

TOTAL SUPPLY VOLTAGE – V

PEAK-TO-PEAK OUTPUT AT 5MHz (

≤

0.5% THD) – V

Figure 27. Output Swing vs. Supply

AD8011

REV. 0

–9–

THEORY OF OPERATION

The AD8011 is a revolutionary generic high speed CF amplifier

that attains new levels of BW, power, distortion, and signal

swing capability. If these key parameters were combined as a fig-

ure of ac merit performance or [(frequency

×

V

SIG

)/(distortion

×

power)], no IC amplifier today would come close to the merit

value of the AD8011 for frequencies above a few MHz. Its wide

dynamic performance (including noise) is the result of both a

new complementary high speed bipolar process and a new and

unique architectural design. The AD8011 uses basically a two

gain stage complementary design approach versus the traditional

“single stage” complementary mirror structure sometimes re-

ferred to as the Nelson amplifier. Though twin stages have been

tried before, they typically consumed high power since they

were of a folded cascade design much like the AD9617. This de-

sign allows for the standing or quiescent current to add to the

high signal or slew current induced stages much like the Nelson

or single stage design. Thus, in the time domain, the large signal

output rise/fall time and slew rate is controlled typically by the

small signal BW of the amplifier and the input signal step ampli-

tude respectively, not the dc quiescent current of the gain stages

(with the exception of input level shift diodes Q1/Q2). Using

two stages vs. one also allows for a higher overall gain band-

width product (GBWP) for the same power, thus lower signal

distortion and the ability to drive heavier external loads. In addi-

tion, the second gain stage also isolates (divides down) A3’s in-

put reflected load drive and the nonlinearities created resulting

in relatively lower distortion and higher open-loop gain.

Overall, when “high” external load drive and low ac distortion is

a requirement, a twin gain stage integrating amplifier like the

AD8011 will provide superior results for lower power over the

traditional single stage complementary devices. In addition, be-

ing a CF amplifier, closed-loop BW variations versus external

gain variations (varying RN) will be much lower compared to a

VF op amp, where the BW varies inversely with gain. Another

key attribute of this amplifier is its ability to run on a single 5 V

supply due in part to its wide common-mode input and output

voltage range capability. For 5 V supply operation, the device

obviously consumes half the quiescent power (vs. 10 V supply)

with little degradation in its ac and dc performance characteris-

tics. See data sheet comparisons.

DC GAIN CHARACTERISTICS

Gain stages A1/A1B and A2/A2B combined provide negative

feedforward transresistance gain. See Figure 28. Stage A3 is a

unity gain buffer which provides external load isolation to A2.

Each stage uses a symmetrical complementary design. (A3 is

also complementary though not explicitly shown). This is done

to both reduce second order signal distortion and overall quies-

cent power as discussed above. In the quasi dc to low frequency

region, the closed loop gain relationship can be approximated as:

G = 1+R

F

/R

N

noninverting operation

G = –R

F

/R

N

inverting operation

These basic relationships above are common to all traditional

operational amplifiers. Due to the inverting input error current

(I

E

) required to servo the output and the inverting I

E

×

R

I

drop

V

P

Q1

Q2

IPP

IPN

INP

IPN

V

N

A1

A1

Z

I

IQ1

Q3

Q4

IE

IR

–

IFC

IR +

I FC

C

P

1

C

P

1

Z2

A2

C

L

R

L

ICQ

–

IO

R

F

V

O

C

D

ICQ +

IO

–V

I

–V

I

V

O

´

IQ1

AD8011

A2

C

P

2

Z1

Z1 = R1 || C1

Z1

C

D

A3

R

L

Figure 28. Simplified Block Diagram

REV. 0

–10–

AD8011

This analysis assumes perfect current sources and infinite tran-

sistor V

A

s (Q3, Q4 output conductances are assumed zero).

These assumptions result in actual vs. model open loop voltage

gain and associated input referred error terms being less accurate

for low gain (G) noninverting operation at the frequencies below

the open loop pole of the AD8011. This is primarily a result of

the input signal (V

P

) modulating the output conductances of

Q3/Q4 resulting in R

I

less negative than derived here. For invert-

ing operation, the actual vs. model dc error terms are relatively

much less.

AC TRANSFER CHARACTERISTICS

The ac small signal transfer derivations below are based on a

simplified single-pole model. Though inaccurate at frequencies

approaching the closed-loop BW (CLBW) of the AD8011 at low

noninverting external gains, they still provide a fair approximation

and a intuitive understanding of its primary ac small signal

characteristics.

For inverting operation and high noninverting gains these trans-

fer equations provide a good approximation to the actual ac

performance of the device.

To accurately quantify the V

O

vs. V

P

relationship, both A

O

(s)

and T

O

(s) need to be derived. This can be seen by the following

nonexpanded noninverting gain relationship:

V

O

(s) /V

P

(s)

=

G

G

A

O

[s]

+

R

F

T

O

[s]

+

1

with

A

O

(s)

=

R1

×

g

mf

×

|A2|

1 – g

mc

×

R1

S

τ

1

1 – g

mc

×

R1

1E+03 1E+04 1E+05 1E+06 1E+07 1E+08 1E+09

80

70

60

50

40

20

10

FREQUENCY – Hz

30

GAIN – dB Ohms

–90

PHASE – Degrees

–100

–110

–120

–160

PHASE

GAIN

0

–10

–20

–30

–170

–180

–190

–200

–130

–140

–150

A

O

(s)

Figure 30. Open-Loop Voltage Gain and Phase

(error current times the open loop inverting input resistance)

that results (see Figure 29), a more exact low frequency closed

loop transfer functions can be described as:

A

V

=

G

1

+

G

×

R

I

T

O

+

R

F

T

O

=

G

1

+

G

A

O

+

R

F

T

O

for noninverting (G is positive)

A

V

=

G

1

+

1 – G

A

O

+

R

F

T

O

for inverting (G is negative)

R

S

L

N

T

O

(s)

A

O

(s)

V

P

Z

I

IE

L

I

R

N

C

P

R

F

+V

S

–V

S

L

S

R

L

C

L

V

O

L

S

Z

I

= OPEN LOOP INPUT IMPEDANCE = C

I

|| R

L

Figure 29. Z

I

= Open-Loop Input Impedance

where G is the ideal gain as previously described. With

R

I

= T

O

/A

O

(open-loop inverting input resistance), the second

expression (positive G) clearly relates to the classical voltage

feedback “op amp” equation with T

O

omitted do to its relatively

much higher value and thus insignificant effect. A

O

and T

O

are

the open-loop dc voltage and transresistance gains of the ampli-

fier respectively. These key transfer variables can be described as:

AO

=

R1

×

gmf

×

| A2|

(1 – gmc

×

R1)

and TO

=

R1

×

| A2|

2

; therefore RI

=

1

−

g

mc

×

R1

2

×

g

mf

Where g

mc

is the positive feedback transconductance (not

shown) and 1/g

mf

is the thermal emitter resistance of devices

D1/D2 and Q3/Q4. The g

mc

×

R1 product has a design value that

results in a negative dc open loop gain of typically –2500 V/V (see

Figure 30).

Though atypical of conventional CF or VF amps, this negative

open-loop voltage gain results in an input referred error term

(V

P

–V

O

/G = G/A

O

+ R

F

/T

O

) that will typically be negative for G

greater than +3/–4. As an example, for G = 10, A

O

= –2500 and

T

O

= 1.2 M

Ω

, results in a error of –3 mV using the A

V

deriva-

tion above.

AD8011

REV. 0

–11–

1E+03 1E+04 1E+05 1E+06 1E+07 1E+08 1E+09

400

370

340

310

280

220

190

FREQUENCY – Hz

250

RESISTANCE – Ohms

20

PHASE – Degrees

0

–20

–40

–120

PHASE

IMPEDANCE

160

130

100

–140

–160

–180

–60

–80

–100

SERIES 1

SERIES 2

Z

I

(s)

Figure 32. Open-Loop Inverting Input Impedance

Z

I

(s) goes positive real and approaches 1/2 g

mf

as

ω

approaches

(g

mc

×

R1 – 1)

/τ1

. This results in the input resistance for the

A

V

(s) complex term being 1/2 g

mf

; the parallel thermal emitter

resistances of Q3/Q4. Using the computed CLBW from A

V

(s)

above and the nominal design values for the other parameters,

results in a closed loop 3 dB BW equal to the open loop corner

frequency (1/2

πτ

1) times 1/[G/(2 g

mf

×

T

O

) + R

F

/T

O

]. For a

fixed R

F

, the 3 dB BW is controlled by the R

F

/T

O

term for low

gains and G/(2 g

mf

×

T

O

) for high gains. For example, using

nominal design parameters and R

1

= 1 k

Ω

(which results in a

nominal T

O

of 1.2 M

Ω

, the computed BW is 80 MHz for G = 0

(inverting I-V mode with R

N

removed) and 40 MHz for

G = +10/–9.

DRIVING CAPACITIVE LOADS

The AD8011 was designed primarily to drive nonreactive loads.

If driving loads with a capacitive component is desired, best set-

tling response is obtained by the addition of a small series resis-

tance as shown in Figure 33. The accompanying graph shows

the optimum value for R

SERIES

vs. capacitive load. It is worth

noting that the frequency response of the circuit when driving

large capacitive loads will be dominated by the passive roll-off of

R

SERIES

and C

L

.

1k

Ω

R

L

1k

Ω

C

L

AD8011

R

SERIES

1k

Ω

Figure 33. Driving Capacitive Load

where R1 is the input resistance to A2/A2B, and

τ1

(equal to

CD

×

R1

×

A2) is the open loop dominate time constant.

and T

O

(s)

=

|A2|

×

R1

2

s

τ

1

+

1

1E+03 1E+04 1E+05 1E+06 1E+07 1E+08 1E+09

140

120

100

80

60

20

0

FREQUENCY – Hz

40

GAIN – dB Ohms

0

PHASE – Degrees

–40

–80

–120

–160

–200

–240

–280

PHASE

GAIN

T

O

(s)

Figure 31. Open-Loop Transimpedance Gain

Note that the ac open-loop plots in Figures 31, 32 and 33 are

based on the full Spice AD8011 simulations and do not include

external parasitics (see below). Nevertheless, these ac loop equa-

tions still provide a good approximation to simulated and actual

performance up to the CLBW of the amplifier. Typically g

mc

×

R1 is –4, resulting in A

O

(s) having a right half plane pole. In the

time domain (inverse Laplace of A

O

) it appears as unstable,

causing V

O

to exponentially rail out of its linear region. When

the loop is closed however, the BW is greatly extended and the

transimpedance gain, T

O

(s) “overrides” and directly controls

the amplifiers stability behavior due to Z

I

approaching 1/2 g

mf

for s>>1/

τ

1. See Figure 32. This can be seen by the Z

I

(s) and A

V

(s) noninverting transfer equations below.

Z

I

(s)

=

(1 – g

mc

×

R1)

S

τ

1

1 – g

mc

×

R1

+

1

2

×

g

mf

( S

τ

1

+

1)

A

V

(s)

=

G

1

+

G

A

O

+

R

F

T

O

S

τ

1

G

2 g

mf

T

O

+

R

F

T

O

+

1

REV. 0

–12–

AD8011

11

10

9

8

7

5

4

3

6

2

1

1 10 100 500

FREQUENCY – MHz

GAIN – dB

R

F

= 1k

Ω

R

F

= 750

Ω

V

S

=

±

5V

G = +2

V

IN

= 200mV

Figure 35. Flatness vs. Feedback

Output pin and external component capacitance (designated

C

L

) will further extend the devices BW and can also cause peak-

ing below and above the CLBW if too high. In the time domain,

poor step settling characteristics (ringing up to about 2 GHz

and excessive overshoot) can result. For high C

L

values greater

than about 5 pF an external series “damping” resistor is recom-

mended. See section on Settling Time vs. C

L

. For light loads,

any output capacitance will reflect back on A2’s output (Z2 of

buffer A3) as both added capacitance near the CLBW (CLBW

> f

T

/B) and eventually negative resistance at much higher fre-

quencies. These added effects are proportional to the load C.

This reflected capacitance and negative resistance has the effect

of both reducing A2/s phase margin and causing high frequency

“L

×

C” peaking respectively. Using an external series resistor

(as specified above) reduces these unwanted effects by creating a

reflected zero to A2’s output which will reduce the peaking and

eliminate ringing. For heavy resistive loads, relatively more Load

C would be required to cause these same effects.

High inductive parasitics, especially on the supplies and inverting/

noninverting inputs, can cause modulated low level R

F

ringing

on the output in the transient domain. Again, proper R

F

compo-

nent and board layout practices need to be observed. Relatively

high parasitic lead inductance (roughly L >15 nh) can result in

L

×

C underdamped ringing. Here L/C means all associated in-

put pin, external component and leadframe strays including col-

lector to substrate device capacitance. In the ac domain, this L

×

C resonance effect would typically not appear in the passband of

the amplifier but would appear in the open loop response at fre-

quencies well above the CLBW of the amplifier.

40

30

20

0

10

15

20

25

C

L

– pF

10

R

SERIES

–

Ω

5

Figure 34. Recommended R

SERIES

vs. Capacitive Load for

≤

30 ns Settling to 0.1%

OPTIMIZING FLATNESS

As mentioned, the ac transfer equations above are based on

a simplified single pole model. Due to the devices internal

parasitics (primarily CP1/CP1B and CP2 in Figure 28) and

external package/board parasites (partially represented in Figure

34) the computed BW, using the V

O

(s) equation above, typi-

cally will be lower than the AD8011’s measured small signal

BW. See data sheet Bode plots.

With internal parasitics included only, the BW is extended do to

the complex pole pairs created primarily by CP1/CP2B and CP2

versus the single-pole assumption shown above. This results in a

“design controlled” closed-loop damping factor (

ζ)

of nominally

0.6 resulting in the CLBW increasing by approximately 1.3

×

higher than the computed single pole value above for optimized

external gains of +2/–1! As external noninverting gain (G) is

increased, the actual closed-loop bandwidth vs. the computed

single pole ac response is in closer agreement.

Inverting pin and external component capacitance (designated

C

P

) will further extend the CLBW do the closed loop zero cre-

ated by C

P

and R

N

iR

F

when operating in the noninverting mode.

Using proper R

F

component and layout techniques (see layout

section) this capacitance should be about 1.5 pF. This results in a

further incremental BW increase of almost 2

×

(versus the com-

puted value) for G = +1 decreasing and approaching its com-

plex pole pair BW for gains approaching +6 or higher. As

previously discussed, the single-pole response begins to correlate

well. Note that a pole is also created by 1/2 g

mf

and C

P

which

prevents the AD8011 from becoming unstable. This parasitic

has the greatest effect on BW and peaking for low positive gains

as the data sheet Bode plots clearly show. For inverting opera-

tion, C

P

has relatively much less effect on CLBW variation.

AD8011

REV. 0

–13–

INCREASING BW AT HIGH GAINS

As presented above, for a fixed R

F

(feedback gain setting resis-

tor) the AD8011 CLBW will decrease as R

N

is reduced (in-

creased G). This effect can be minimized by simply reducing R

F

and thus partially restoring the devices optimized BW for gains

greater than +2/–1. Note that the AD8011 is ac optimized (high

BW and low peaking) for A

V

=+2/–1 and R

F

equal to 1 k

Ω

.

Using this optimized G as a reference and the V

O

(s) equations

above, the following relationships results:

R

F

= 1k + 2 – G/2 gm for G = 1+ R

F

/R

N

(noninverting) or:

R

F

= 1k + G + 1/2 gm for G = –R

F

/R

N

(inverting)

Using 1/2 gm equal to 120

Ω

results in a R

F

of 500

Ω

for

G = 5/–4 and a corresponding R

N

of 125

Ω

. This will extend

the AD8011’s BW to near its optimum design value of typically

180 MHz at R

L

= 1 k

Ω

. In general, for gains greater than +7/–6,

R

F

should not be reduced to values much below 400

Ω

else ac

peaking can result. Using this R

F

value as the a lower limit, will

result in BW restoration near its optimized value to the upper G

values specified. Gains greater than about +7/–6 will result

in CLBW reduction. Again, the derivations above are just

approximations.

DRIVING A SINGLE-SUPPLY A/D CONVERTER

New CMOS A/D converters are placing greater demands on the

amplifiers that drive them. Higher resolutions, faster conversion

rates and input switching irregularities require superior settling

characteristics. In addition, these devices run off a single +5 V

supply and consume little power, so good single-supply operation

with low power consumption are very important. The AD8011

is well positioned for driving this new class of A/D converters.

Figure 36 shows a circuit that uses an AD8011 to drive an

AD876, a single supply, 10-bit, 20 MSPS A/D converter that

requires only 140 mW. Using the AD8011 for level shifting and

driving, the A/D exhibits no degradation in performance com-

pared to when it is driven from a signal generator.

The analog input of the AD876 spans 2 V centered at about

2.6 V. The resistor network and bias voltages provide the level

shifting and gain required to convert the 0 V to 1 V input signal

to a 3.6 V to 1.6 V range that the AD876 wants to see.

Biasing the noninverting input of the AD8011 at 1.6 V dc forces

the inverting input to be at 1.6 V dc for linear operation of the

amplifier. When the input is at 0 V, there is 3.2 mA flowing out

of the summing junction via R1 (1.6 V/499

Ω

). R3 has a current

of 1.2 mA flowing into the summing junction (3.6 V–1.6 V)/

1.65 k

Ω

. The difference of these two currents (2 mA) must flow

through R2. This current flows toward the summing junction

and requires that the output be 2 V higher than the summing

junction or at 3.6 V.

When the input is at 1 V, there is 1.2 mA flowing into the sum-

ming junction through R3 and 1.2 mA flowing out through R1.

These currents balance and leave no current to flow through

R2. Thus the output is at the same potential as the inverting in-

put or 1.6 V.

The input of the AD876 has a series MOSFET switch that turns

on and off at the sampling rate. This MOSFET is connected to

a hold capacitor internal to the device. The on impedance of the

MOSFET is about 50

Ω

, while the hold capacitor is about 5 pF.

In a worst case condition, the input voltage to the AD876 will

change by a full-scale value (2 V) in one sampling cycle. When

the input MOSFET turns on, the output of the op amp will be

connected to the charged hold capacitor through the series resis-

tance of the MOSFET. Without any other series resistance, the

instantaneous current that flows would be 40 mA. This would

cause settling problems for the op amp.

The series 100

Ω

resistor limits the current that flows instanta-

neously after the MOSFET turns on to about 13 mA. This

resistor cannot be made too large or the high frequency perfor-

mance will be affected.

The sampling MOSFET of the AD876 is closed for only half of

each cycle or for 25 ns. Approximately 7 time constants are

required for settling to 10 bits. The series 100

Ω

resistor along

with the 50

Ω

on resistance and the hold capacitor, create a

750 ps time constant. These values leave a comfortable margin

for settling. Obtaining the same results with the op amp A/D

combination as compared to driving with a signal generator in-

dicates that the op amp is settling fast enough.

Overall the AD8011 provides adequate buffering for the AD876

A/D converter without introducing distortion greater than that

of the A/D converter by itself.

3.6V

1.6V

AD8011

3

1

2

6

5

4

7

+5V

10µF

R2

1k

Ω

R3

1.65k

Ω

R1

499k

Ω

3.6V

V

IN

50

Ω

0.1µF

1.6V

1V

0V

100

Ω

AD876

+1.6V

+3.6V

REFT

REFB

0.1µF

0.1µF

Figure 36. AD8011 Driving the AD876

REV. 0

–14–

AD8011

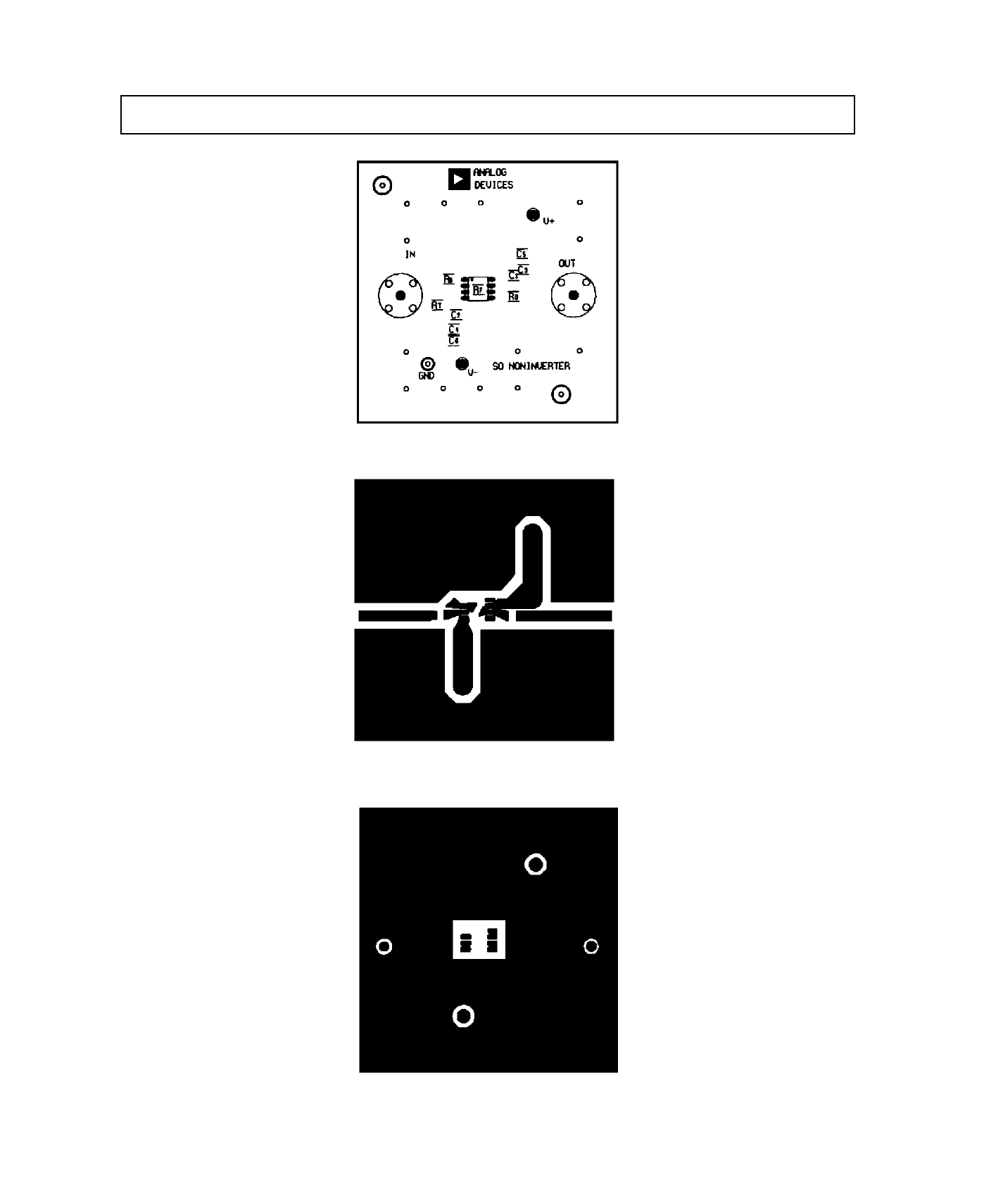

LAYOUT CONSIDERATIONS

The specified high speed performance of the AD8011 requires

careful attention to board layout and component selection.

Table I shows the recommended component values for the

AD8011 and Figures 38–40 show the layout for the AD8011

evaluation board (8-pin SOIC, Gain = +2). Proper R

F

design tech-

niques and low parasitic component selection are mandatory.

The PCB should have a ground plane covering all unused por-

tions of the component side of the board to provide a low im-

pedance ground path. The ground plane should be removed

from the area near the input pins to reduce stray capacitance.

Chip capacitors should be used for supply bypassing (see Fig-

ure 37). One end should be connected to the ground plane

and the other within 1/8 in. of each power pin. An additional

(4.7

µ

F–10

µ

F) tantalum electrolytic capacitor should be con-

nected in parallel.

The feedback resistor should be located close to the inverting

input pin in order to keep the stray capacitance at this node to a

minimum. Capacitance greater than 1.5 pF at the inverting in-

put will significantly affect high speed performance when oper-

ating at low noninverting gains.

Stripline design techniques should be used for long signal traces

(greater than about 1 in.). These should be designed with the

proper system characteristic impedance and be properly termi-

nated at each end.

C1

0.01µF

C2

0.01µF

C4

10µF

C3

10µF

R

T

INVERTING CONFIGURATION

V

IN

V

OUT

+V

S

–V

S

R

G

R

F

R

O

C1

0.01µF

C2

0.01µF

C4

10µF

C3

10µF

R

T

NONINVERTING CONFIGURATION

V

IN

V

OUT

+V

S

–V

S

R

G

R

F

R

O

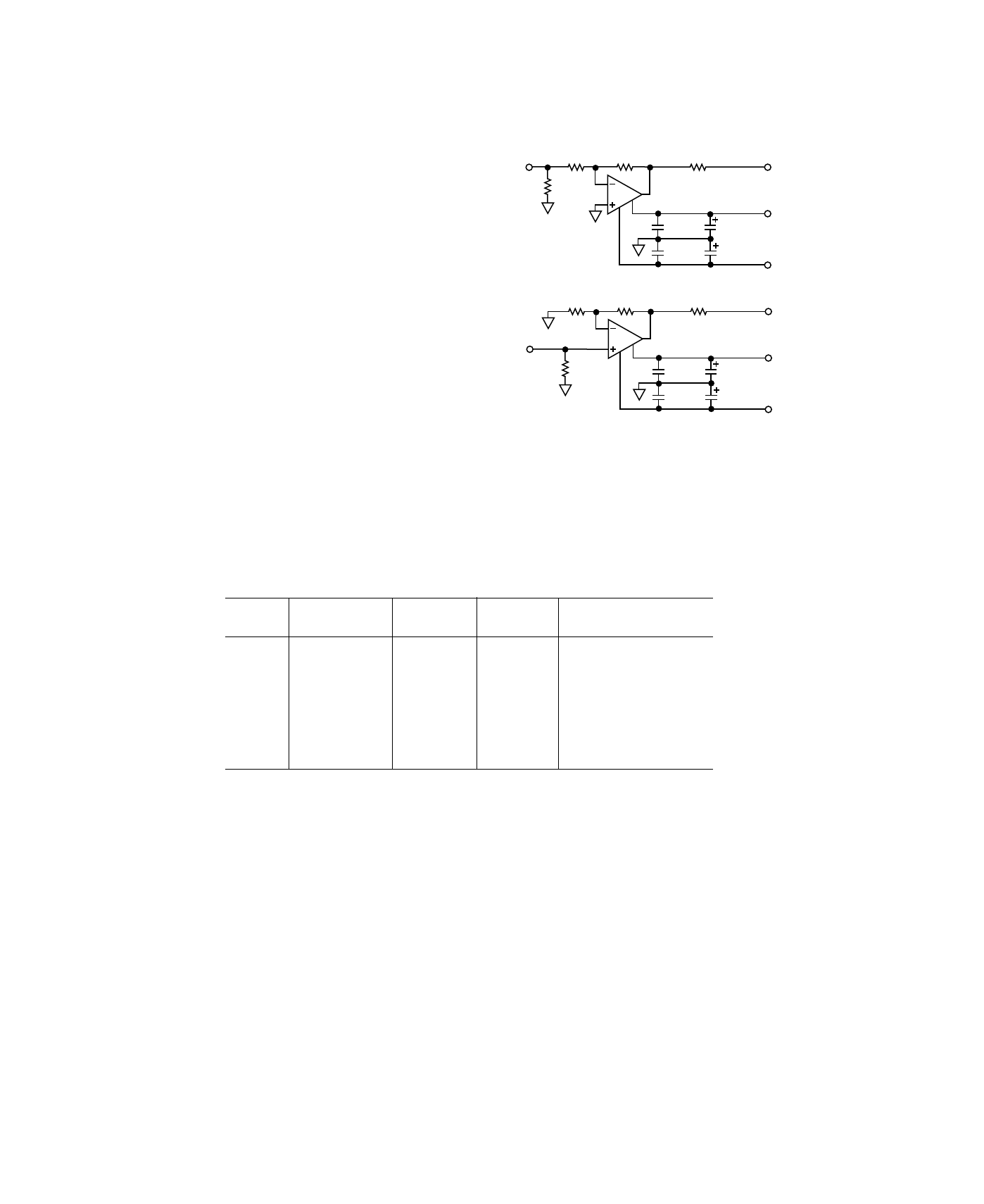

Figure 37. Inverting and Noninverting Configurations

Table I. Typical Bandwidth vs. Gain Setting Resistors

Small Signal –3 dB BW

Gain

R

F

R

G

R

T

(MHz), V

S

=

±

5 V

–1

1000

Ω

1000

Ω

52.3

Ω

150

–2

1000

Ω

499

Ω

54.9

Ω

130

–10

499

Ω

49.9

Ω

–

140

+1

1000

Ω

–

49.9

Ω

400

+2

1000

Ω

1000

Ω

49.9

Ω

250

+10

422

Ω

47.5

Ω

49.9

Ω

100

+6

1000

Ω

200

Ω

49.9

Ω

70

+6

500

Ω

100

Ω

49.9

Ω

170

R

T

chosen for 50

Ω

characteristic input impedance.

R

O

chosen for characteristic output impedance.

AD8011

REV. 0

–15–

Figure 39. Evaluation Board Layout (Solder Side)

Figure 38. Evaluation Board Silkscreen (Top)

Figure 40. Evaluation Board Layout (Component Side)

REV. 0

–16–

AD8011

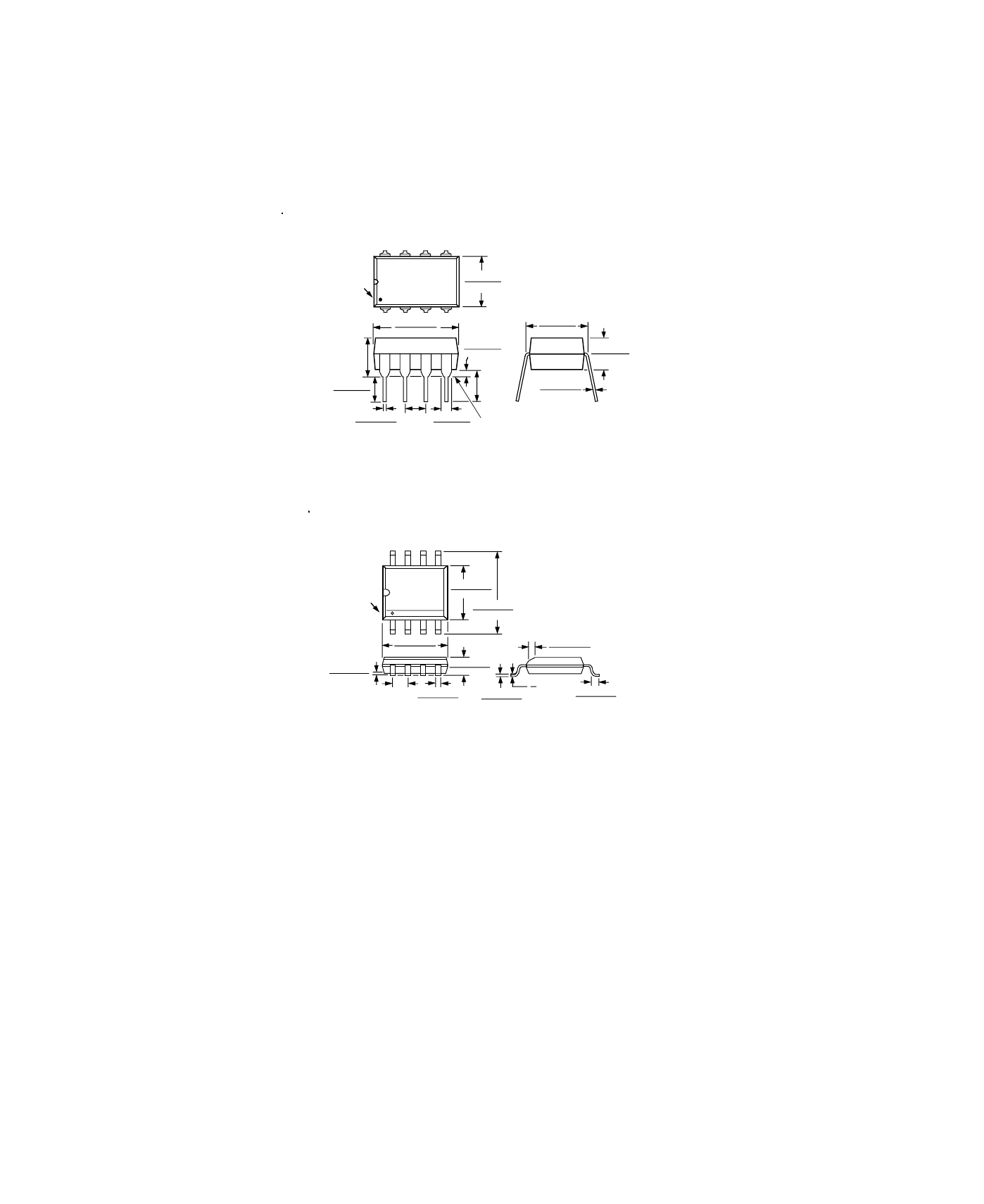

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

8-Pin Plastic DIP

(N Package)

8-Pin Plastic SOIC

(R Package)

PIN 1

0.1574 (4.00)

0.1497 (3.80)

0.2440 (6.20)

0.2284 (5.80)

4

5

1

8

0.0098 (0.25)

0.0075 (0.19)

0.0500 (1.27)

0.0160 (0.41)

8

°

0

°

0.0196 (0.50)

0.0099 (0.25)

x 45

°

0.0500

(1.27)

BSC

0.0688 (1.75)

0.0532 (1.35)

0.0098 (0.25)

0.0040 (0.10)

0.1968 (5.00)

0.1890 (4.80)

0.0192 (0.49)

0.0138 (0.35)

PIN 1

0.280 (7.11)

0.240 (6.10)

4

5

8

1

0.060 (1.52)

0.015 (0.38)

0.130

(3.30)

MIN

0.210

(5.33)

MAX

0.160 (4.06)

0.115 (2.93)

0.430 (10.92)

0.348 (8.84)

SEATING

PLANE

0.022 (0.558)

0.014 (0.356)

0.070 (1.77)

0.045 (1.15)

0.100

(2.54)

BSC

0.325 (8.25)

0.300 (7.62)

0.015 (0.381)

0.008 (0.204)

0.195 (4.95)

0.115 (2.93)

C2002–7.5–2/95

PRINTED IN U.S.A.