a

Electrically Induced Damage to Standard Linear Integrated Circuits:

The Most Common Causes and the Associated Fixes to Prevent Reoccurrence

by Niall Lyne

AN-397

APPLICATION NOTE

ONE TECHNOLOGY WAY

•

P.O. BOX 9106

•

NORWOOD, MASSACHUSETTS 02062-9106

•

617/329-4700

INTRODUCTION

The sensitivity of electronic components to transient

electrical overstress events is a well-known problem,

exacerbated by the continuing evolution of integrated

circuits. Smaller geometries, increased circuit densities,

and the limited area allotted to on-chip protection all

tend to increase this sensitivity. In an effort to minimize

costs in each particular segment of system implementa-

tion, the burden of transient protection is often shifted to

other, less efficient means.

Techniques for protection from “zapping” depend on

the stage of manufacture. During the manufacturing of

integrated circuits and assembly of electronic equip-

ment, protection is achieved through the use of well-

known measures such as static dissipative table tops,

wrist straps, ionized air blowers, antistatic shipping

tubes, etc. These methods will be discussed only briefly

here in relation to Electrostatic Discharge (ESD) protec-

tion. Likewise this application note is not addressed to

precautionary measures employed during shipping, in-

stallation, or repair of equipment. Rather, the main

thrust will be limited to protection aspects called upon

during printed circuit board assembly, normal operation

of the equipment (often by operating personnel who are

untrained in preventative measures), and in service con-

ditions where the transient environment may not be well

characterized.

The transient environment varies widely. There are sub-

stantial differences among those experienced by, say,

automotive systems, airborne or shipborne equipment,

space systems, industrial equipment or consumer prod-

ucts. All types of electronic components can be

destroyed or degraded.

1

Even capacitors, relays, con-

nectors, printed circuit boards, etc., are susceptible,

although their threshold levels are much higher than

integrated circuits. Microwave diodes and transistors

are among the most sensitive components. However,

this application note will be restricted to standard linear

integrated circuits because of their wide usage, and to

limit the scope of coverage.

This application note will first review the nature of the

threat to integrated circuits in an operating environ-

ment, and then briefly discuss overall device protection

from the following: (1)

ESD events caused by human

handling, automatic board insertion equipment, etc., (2)

LATCH-UP generated from power-up/down sequencing

errors, floating ground(s) due to a loose edge connec-

tors, etc., and finally, (3)

HIGH VOLTAGE TRANSIENTS

generated from a power supply, a defective circuit

board, during circuit board troubleshooting, etc.

Electrostatic Discharge

Electrostatic discharge is a single, fast, high current

transfer of electrostatic charge that results from:

•

Direct contact transfer between two objects at differ-

ent potentials,

or

•

A high electrostatic field between two objects when

they are in close proximity.

The prime sources of static electricity are mostly insula-

tors and are typically synthetic materials, e.g., vinyl or

plastic work surfaces, insulated shoes, finished wood

chairs, Scotch tape, bubble pack, soldering irons with

ungrounded tips, etc. Voltage levels generated by these

sources can be extremely high since their charge is not

readily distributed over their surfaces or conducted to

other objects.

The generation of static electricity caused by rubbing

two substances together is called the triboelectric effect.

Examples of sources of triboelectric electrostatic charge

generation in a high RH (

≈

60%) environment include:

•

Walking across a carpet

⇒

1000 V–1500 V generated.

•

Walking across a vinyl floor

⇒

150 V–250 V generated.

•

Handling material protected by clear plastic covers

⇒

400 V–600 V generated.

•

Handling polyethylene bags

⇒

1000 V–1200 V generated.

•

Pouring polyurethane foam into a box

⇒

1200 V–

1500 V generated.

–2–

•

ICs sliding down an open antistatic shipping tube

⇒

25 V–250 V generated.

Note: For low RH (<30%) environments, generated volt-

ages can be >10

×

those listed above.

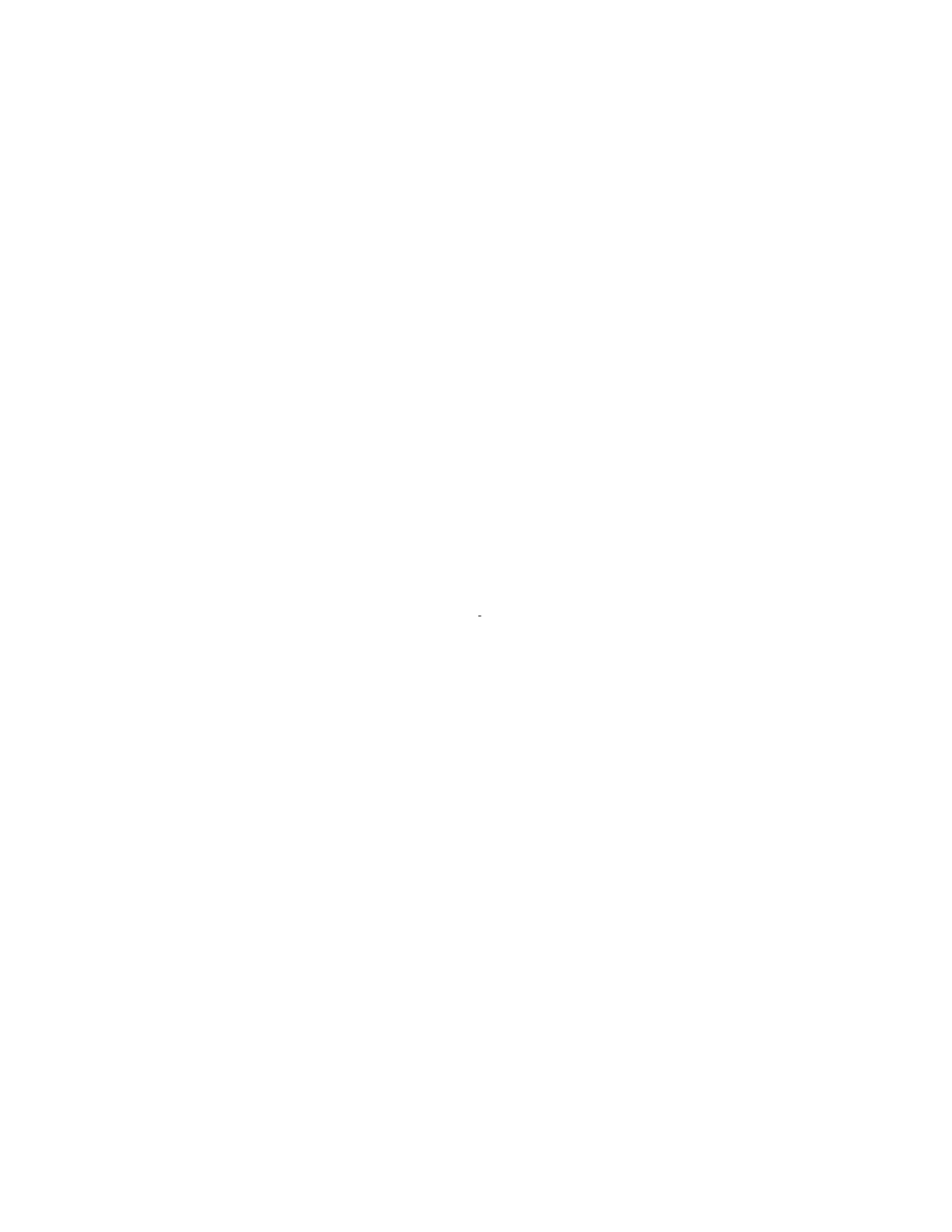

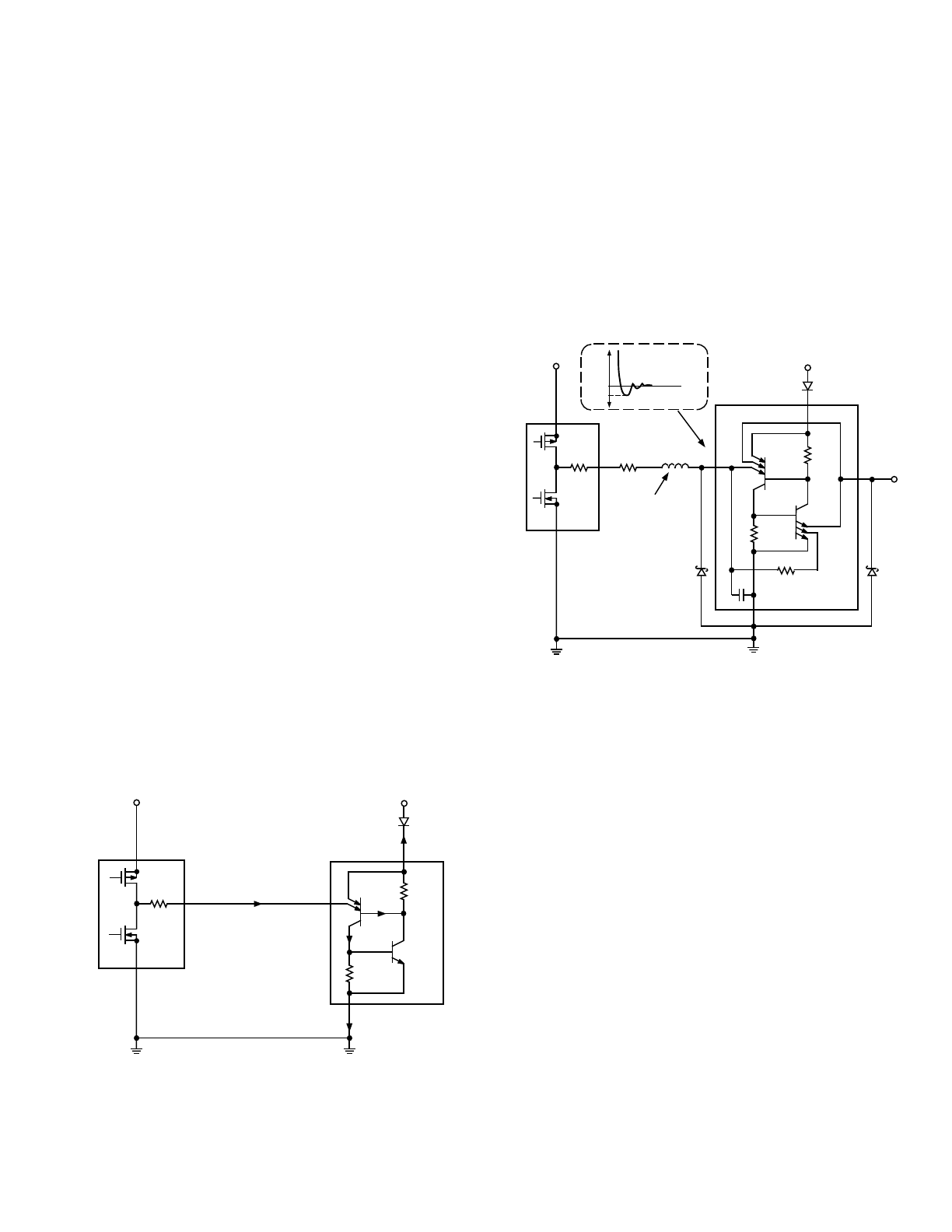

ESD Models

To evaluate the susceptibility of devices to simulated

stress environments a host of test waveforms have been

developed. The three most prominent of these wave-

forms currently in general use for simulating ESD events

in semiconductor or discrete devices are: The Human

Body Model (HBM), the Machine Model (MM), and the

Charged Device Model (CDM). The test circuits and cur-

rent waveform characteristics for these three models

are shown in Figures 1 to 3. Each of these models repre-

sents a fundamentally different ESD event. Conse-

quently, correlation between the test results for these

models is minimal.

Human Body Model:

2

Simulates the discharge event that occurs when a per-

son charged to either a positive or negative potential

touches an IC at a different potential.

RLC = 1.5 k

Ω

, ~0 nH, 100 pF.

HVPS

10M

Ω

0H

1.5k

Ω

100pF

S1

DUT

I

t

Figure 1. Human Body Model

Machine Model:

Japanese model based on a worst-case HBM.

RLC = 0

Ω

, 500 nH, 200 pF.

I

t

HVPS

10M

Ω

500nH

0k

Ω

200pF

S1

DUT

Figure 2. Machine Model

Charged Device Model:

Simulates the discharge that occurs when a pin on an IC

charged to either a positive or negative potential con-

tacts a conductive surface at a different (usually ground)

potential.

RLC = 0

Ω

, ~0 nH, 1 pF–20 pF.

HVPS

1G

Ω

1

Ω

DIELECTRIC

GROUND PLANE

DISCHARGE

CHARGE

I

t

Figure 3. Charged Device Model

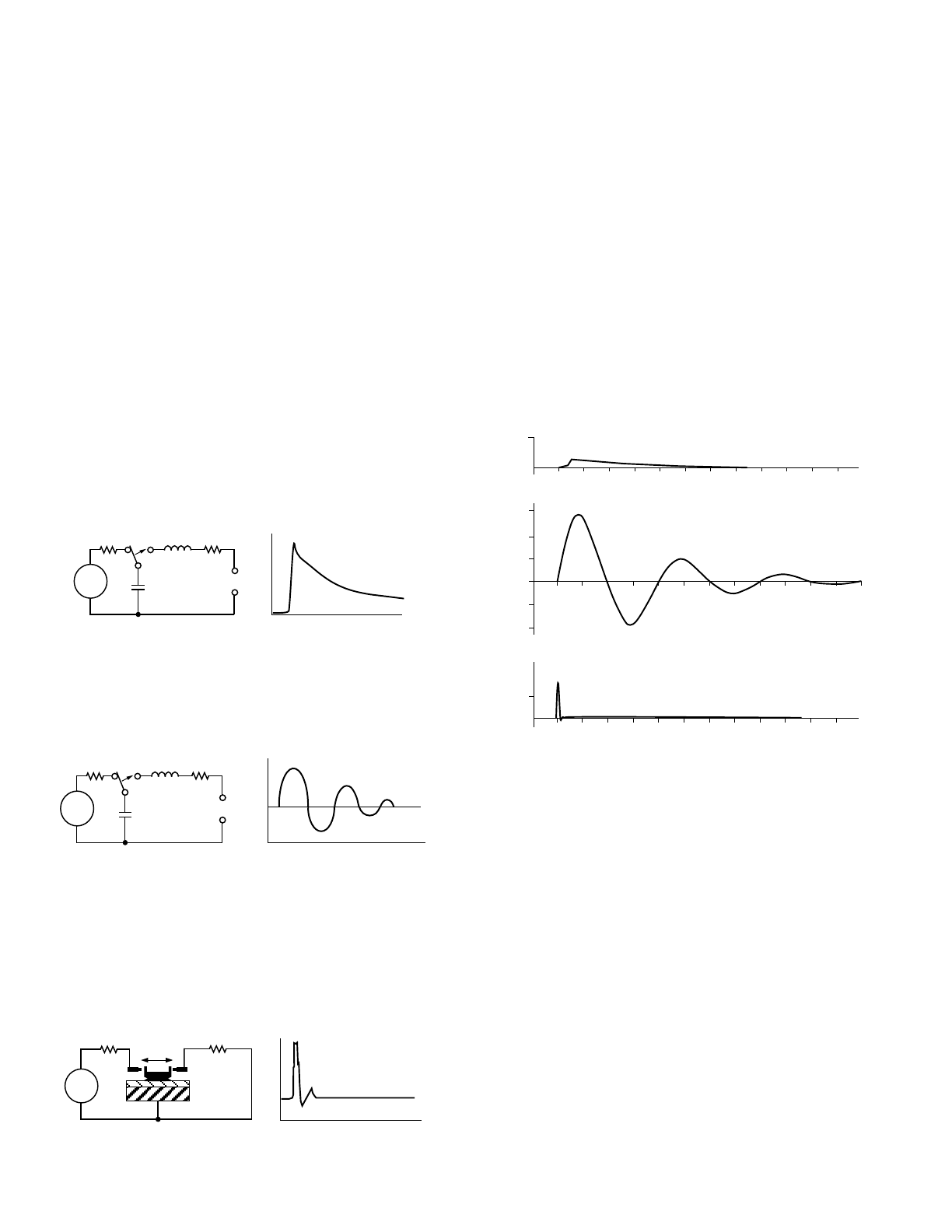

Comparison of HBM, MM, and CDM Waveforms

Figure 4 shows 400 V HBM, MM, and CDM discharge

waveforms on the same current vs. time scale. These

waveforms are of great use in predicting what failure

mechanism may result on a particular device type due to

ESD events simulated by one of these three models.

The rise time for the HBM waveform is <10 ns (typically

6 ns–9 ns), and this waveform decays exponentially to-

wards 0 V with a fall time of >150 ns. MIL-STD-883

3

Method 3015

Electrostatic Discharge Sensitivity Classifi-

cation requires a rise time of <10 ns and a delay time of

150

±

20 ns (Method 3015 defines delay time as the time

for the waveform to drop from 90% of the peak current

to 36.8% of the peak current). The peak current for the

HBM waveform is

≈

400 V/1500

Ω

or 0.267A. Although

this peak current is much lower than that for 400

V CDM

and MM events, the relatively long duration of the total

HBM event results in a discharge of relatively high

energy.

AMPS

2

HBM

20ns/DIV

t

6

4

2

0

–2

–4

AMPS

MM

20ns/DIV

t

2

AMPS

CDM

20ns/DIV

t

Figure 4. Relative Comparison of 400 V HBM, MM,

and CDM Discharges

The MM waveform consists of both positive-going and

negative-going sinusoidal peaks with peak magnitudes

that decay exponentially. The initial MM peak has a rise

time of

≈

14 ns, i.e., only slightly greater than that of the

single HBM peak. The total duration of the MM wave-

form is comparable to that for the HBM waveform. How-

ever, the peak current for the first peak of the 400

V MM

event is

≈

5.8 A

,

which is the highest of the three models.

The next four peaks, though decreasing in current, still

all have magnitudes of >1 A. These multiple high current

peaks of substantial duration result in an overall dis-

charge energy that is by far the highest of the three

models because there is no current limiting; R = 0

Ω

.

The CDM waveform corresponds to the shortest known

real-world ESD event. The socketed CDM waveform has

a rise time of 400 ps, with the total duration of the CDM

event of

≈

2 ns. The CDM waveform is essentially unipo-

lar, although some slight ringing occurs at the end of the

CDM event that results in some negative-going peaks.

–3–

With a 400 V charging voltage, a socketed CDM dis-

charge will have a peak current of 2.1 A. However, the

very short duration of the overall CDM event results in

an overall discharge of relatively low energy.

Summary of ESD Models

Table I is a reference table that compares the most

important characteristics of the three ESD simulation

models.

Table I.

Model

HBM

MM

Socketed CDM

Simulate

Human Body

Machine

Charged Device

Origin

US Military

Japan 1976

AT&T 1974

Late 1960s

Real World

Yes

Generally No

Yes

RC

1.5 k

Ω

, 100 pF

0

Ω

, 200 pF

1

Ω

, 1 pF–20 pF

Rise Time

<10 ns

14 ns*

400 ps**

I

PEAK

at 400 V

0.27 A

5.8 A*

2.1 A**

Package

Dependent

No

No

Yes

Leakage

Recovery

No

No

Yes

Standard

MIL-STD-883

ESD Assoc.

ESD Assoc. Draft

Method 3015

Standard S5.2;

Standard DS5.3

EIAJ Standard

ED-4701,

Method C-111

* These values are per ESD Association Standard S5.2. EIAJs stan-

dard ED-4701 Method C-111 includes no waveform specifications.

** These values are for the direct charging (socketed) method.

Prevention

When auditing a facility in which ESD protective mea-

sures will be taken, the following should be considered:

4

•

There must be a grounded workbench on which to

handle static sensitive devices incorporating:

a) Personal ground strap (wrist strap)

b) Conductive trays or shunts, etc.

c) Conductive work surface

d) Conductive floor or mat

e) A common ground point

•

All steel shelving or cabinets used to store devices

must be grounded.

•

The relative humidity should be controlled; the desir-

able range is 40 to 60 percent. Where high relative

humidity levels cannot be maintained, the use of ion-

ized air should be used to dissipate electrostatic

charges.

•

All electrical equipment used in the area must be

grounded.

•

Prohibit the use of prime static generators, e.g.,

Scotch tape.

•

Follow up with ESD audits at a minimum of three

month intervals.

•

Training: Keep in mind, the key to an effective ESD

control program is “TRAINING.” Training should be

given to all personnel who come in contact with inte-

grated circuits and should be documented for certifi-

cation purposes, e.g., ISO 9000 audits.

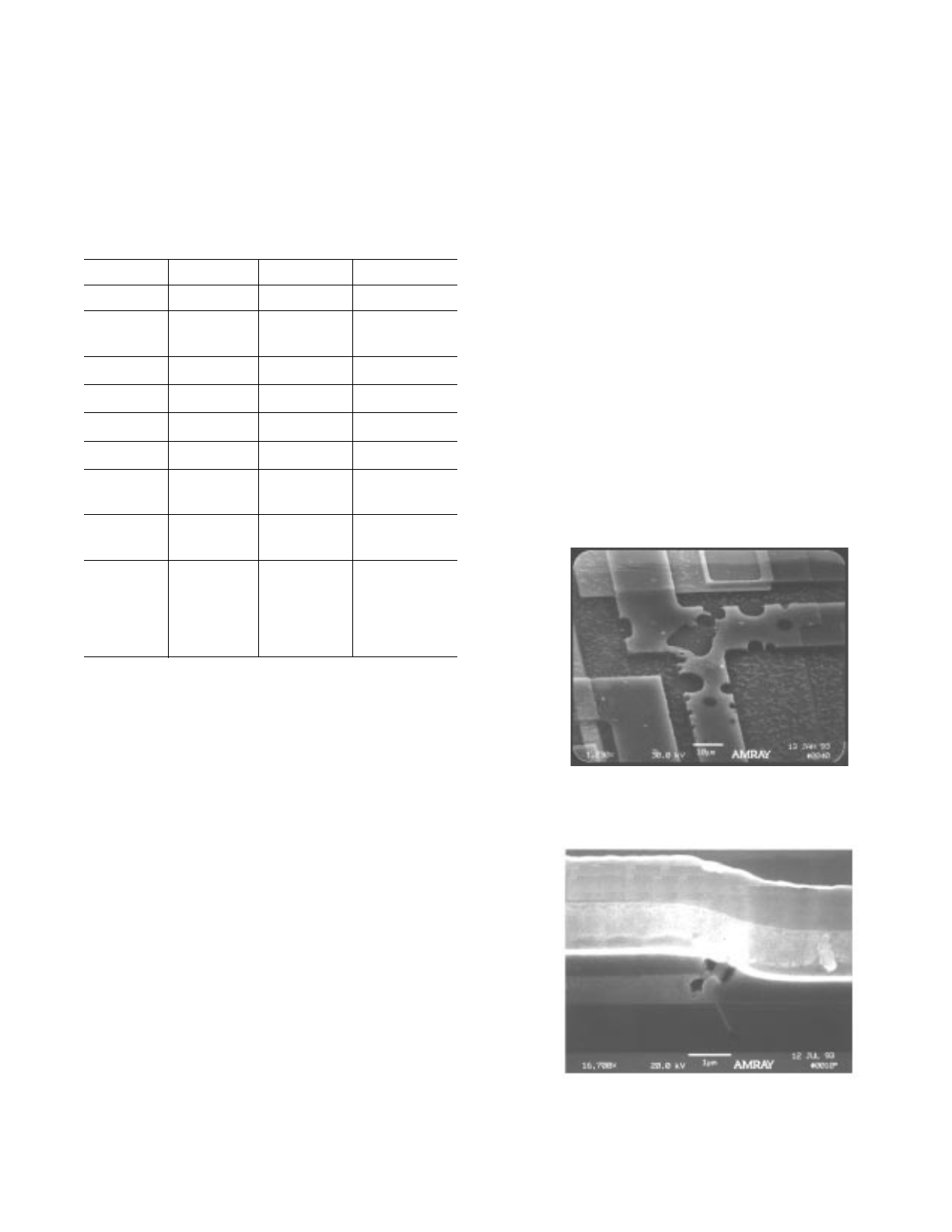

Determining whether a device failed as a result of ESD

or Electrical Overstress (EOS) can be difficult and is of-

ten best left to Failure Analysis Engineers.

Typically

ESD damage is less obvious than that of EOS when elec-

trical analysis and internal visual analysis are

performed. In the case of ESD, events of 1 kV or more

(depending on the ESD rating of the device) can rupture

oxides (inter layer dielectric of the die) and damage

junctions in less than 10 ns (see Figure 6).

Alternately,

EOS conditions leading to 1 to 3 amps of current for a

duration of

≥

1 ms can cause sufficient self-heating of

bond wires to fuse them. Such conditions can occur as a

result of latch-up. Lower currents can cause rapid melt-

ing of chip metallization and other interconnect layers

(see Figure 5).

Figure 5. Scanning Electron Microscope View of a

Fused Metallization Site, as a Result of Electrical

Overstress

Figure 6. Scanning Electron Microscope Cross-

Sectional View of a CDM ESD Site. This subsurface site

could not be viewed from the surface with an optical

microscope.

–4–

A quick analysis can be performed on site to evaluate if a

device may have been overstressed or may have been

subjected to an ESD event.

In order to perform this

analysis, to compare the pin-to-pin I/V results of the sus-

pect device to those of a known good device, a curve

tracer or similar equipment should be used. A typical

set of I/V traces for a short circuit, open circuit or ESD

leakage on a digital input pin (with reference to the V

SS

supply pin) of a 12-bit DAC is shown in Figure 7.

OPEN CIRCUIT

SHORT CIRCUIT

V/DIV. : 2V

I / DIV. : 50µA

GOOD TRACE

ESD LEAKAGE

Figure 7. Example of an Unpowered Curve Trace

Analysis of a Digital Pin versus a Supply Pin (V

SS

)

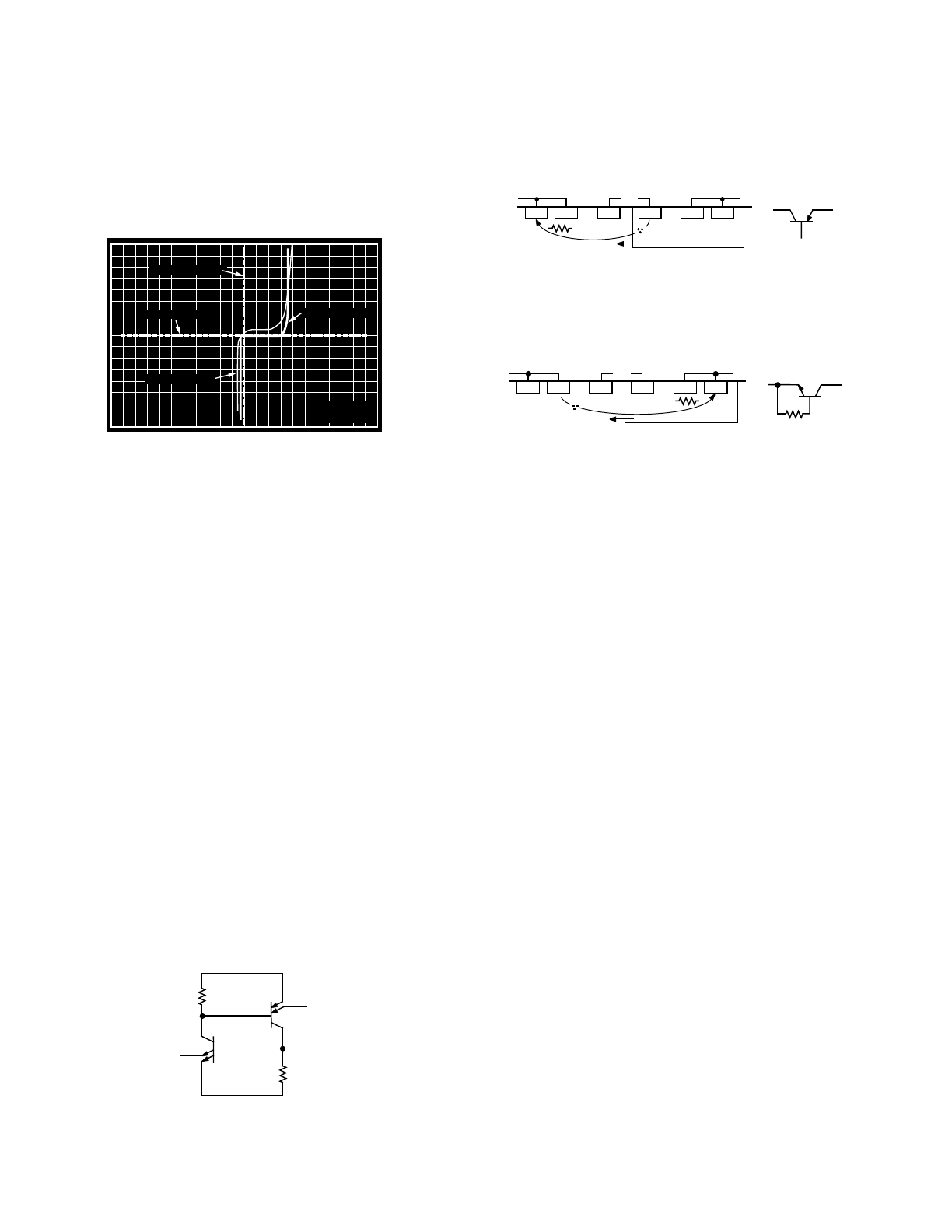

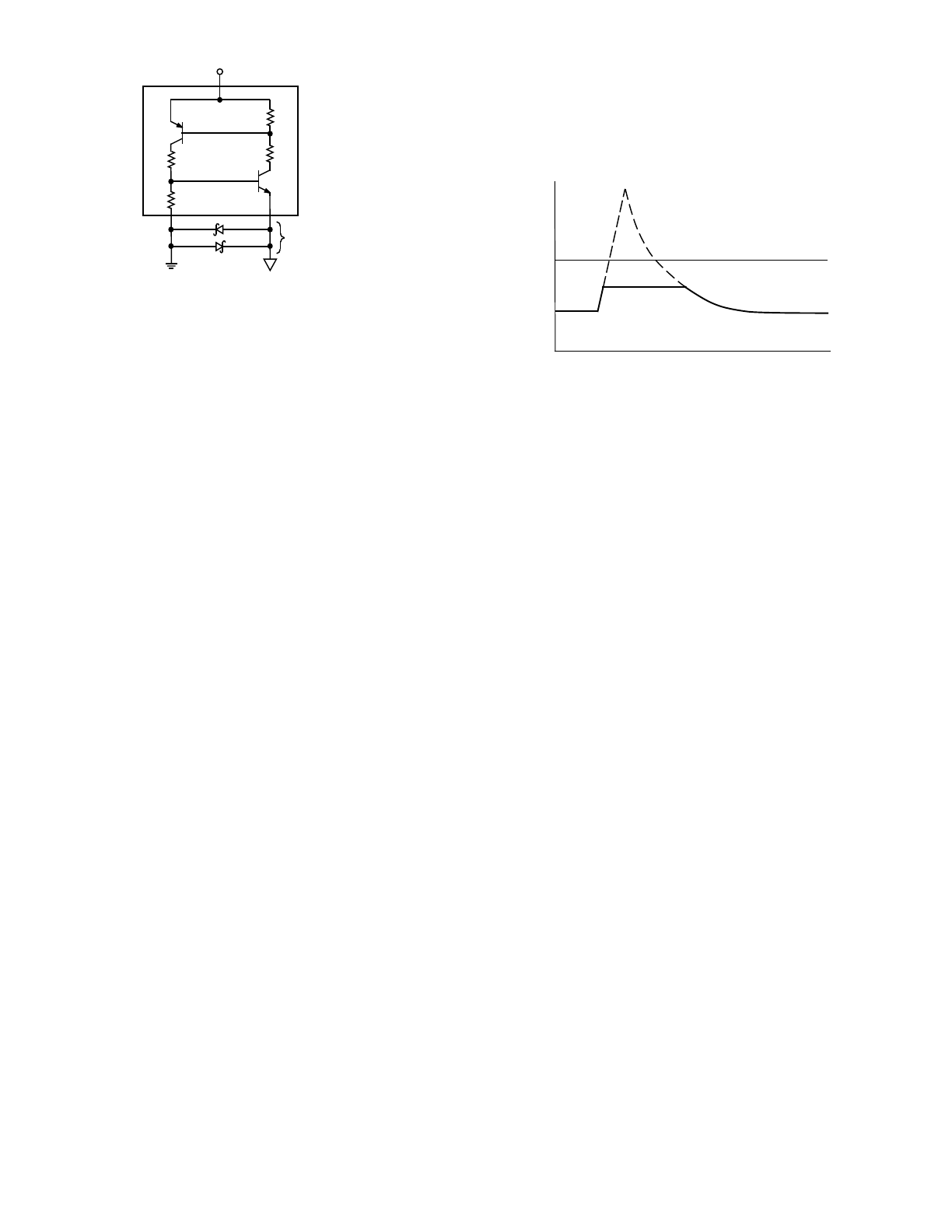

LATCH-UP

Latch-up is a potentially destructive situation in which a

parasitic active device is triggered, shorting the positive

and negative supplies together.

If current flow is not

limited, electrical overstress will occur.

The classic case

of latch-up occurs in CMOS output devices, in which the

driver transistors and wells form a

pnpn SCR structure

when one of the two parasitic base-emitter junctions is

momentarily forward biased during an overvoltage

event. The SCR turns on and essentially causes a short

between V

DD

and ground.

Triggering Mechanisms

There are two main triggering mechanisms.

First, if the

input/output (I/O) pin voltage is raised above the posi-

tive supply, or lowered below the negative supply, one

of the parasitic transistors is turned on. The current re-

turning to the supply through the collector causes a volt-

age drop across the base-emitter of the second parasitic

transistor. In turn, the collector current of the second

transistor maintains a forward bias on the base-emitter

of the first transistor. If the product of the two transistor

gains is greater than unity, the condition may be self-

sustaining and can persist even after the external volt-

age is removed.

OUTPUT

V

DD

R

SUB

GND

RWELL

OUTPUT

QP

QN

Figure 8. Parasitic SCR. The Diffusions in a CMOS

output form a parasitic SCR. The resistors are labeled

for an n-well process.

This triggering mechanism can occur if excessive volt-

age overshoot is present at the I/O pin, or if the signal

arrives at the input before the power supplies are ap-

plied to the device, or due to electrostatic discharge.

This latch-up is usually limited to the devices directly

connected to the pin.

p+

n+

n+

p+

p+

n+

n-well

p-sub

GND

OUTPUT

OUTPUT

GND

V

DD

ε

–

+

V

DD

Figure 9a. Output Overvoltage Triggering. Initial hole

current flows when the output voltage is raised above

V

DD

. This current causes a voltage rise in the substrate

under the NMOS device.

p+

n+

n+

p+

p+

n+

n-well

p-sub

GND

OUTPUT

V

DD

OUTPUT

GND

R

SUB

ε

–

+

Figure 9b. Current Multiplication. The substrate

voltage rise actively biases the second parasitic

transistor into conduction. The electron current

subsequently causes a voltage drop in the n-well,

further turning on the first transistor. If the product of

the current gains is larger than one, the final current

flow between the supplies can be self-sustaining,

limited only by internal resistance’s, i.e., an SCR.

Although triggering is by an overvoltage event (typically

of only a diode drop above or below the power sup-

plies), the industry practice is to classify the I/O suscepti-

bility in terms of the amount of excess current the pin

can source or sink in this overvoltage condition before

the internal parasitic resistance's develop enough volt-

age drop to sustain the latch-up condition. A value of

100 mA is generally considered adequate, with 200 mA

considered immune to latch-up.

The

second triggering mechanism occurs if a supply

voltage is raised enough to break down an internal junc-

tion, injecting current into the SCR previously described.

This triggering mechanism can occur due to supply tran-

sients, or electrostatic discharges shunted to a supply

rail. Unlike the case of I/O triggering, latch-up can occur

anywhere on the die and is not limited to the vicinity of

the external power connections or I/O pins.

The susceptibility to power supply overvoltage is usu-

ally limited by the fabrication process on which the de-

vice is manufactured, and can be found in the data sheet

under the Absolute Maximum Rating specification.

If

this rating is exceeded, permanent EOS damage may

occur. Operating a device near the maximum ratings

may degrade the long term reliability of the device. Also

the electrical specifications are applicable only at the

supply specified on the data sheet and will not be guar-

anteed above these ratings.

–5–

Design Rules

The following is a set of rules to be followed for all de-

signers using CMOS and Bipolar-CMOS ICs:

5

1. Digital inputs and outputs should not be allowed to

exceed V

DD

by more than 0.3 volts at any time. This

includes a power-down situation when V

DD

= 0 volts.

2. Digital inputs and outputs should also not be allowed

to go below DGND by more than –0.3 volts.

3. For mixed signal devices, DGND should not be al-

lowed to exceed AGND by 0.3 volts.

4. For a CMOS or Bipolar-CMOS DAC, I

OUT

should, in

general, not be allowed to drop below AGND by more

than 0.3 volts. Some DACs can tolerate significant

I

OUT

current flow, however, without any danger of

latch-up.

Latch-Up Prevention Techniques

The following recommendations should be imple-

mented in general, for all applications with CMOS and

Bipolar-CMOS ICs that violate one or more of the previ-

ously discussed rules:

1. If the digital inputs or outputs of a device can go be-

yond V

DD

at any time, a diode (such as a 1N914) con-

nected in series with V

DD

will prevent SCR action and

subsequent latch-up. This works because the diode

prevents the base current of the parasitic lateral-PNP

transistor from flowing out the V

DD

pin, thus prevent-

ing SCR triggering. This is shown in Figure 10.

Diodes are also a reliable solution if power-up se-

quencing is identified as the failure mechanism. In

such a case, the insertion of a Schottky diode be-

tween the logic inputs and the V

DD

supply rail (the

anode of the diode connected to the logic inputs), will

ensure that the logic inputs do not exceed the V

DD

supply by more than 0.3 volts, thus preventing latch-

up of the device.

Ib

≈

0

Ic

=

0

R

p-well

I

DGND

≈

0

DGND

R

SUB

V

DD

IC POWERED UP

IC#1

R

OUT

IC#2

I

DD

≈

0

1N914

0V

+5V

IC POWERED DOWN

DGND

COMMON GROUND

OUTPUT

INPUT

I

IN

≈

0

V

DD

Figure 10. Adding an inexpensive silicon diode in

series with the V

DD

pin of the unpowered IC effec-

tively prevents the parasitic lateral-PNP transistor’s

base current from flowing and inhibits SCR action.

However, the one

exception to this rule is when the

input range of a device exceeds the supply voltage

range of the device, e.g., by design the AD7893-10 12-

bit A/D subsystem, the input range is

±

10 V and the

supply is +5 V.

2. If the digital inputs and outputs of a device can go

below DGND at any time, a Schottky diode (such as

an HP5082-2835) connected from those inputs or out-

puts to DGND will effectively clamp negative excur-

sions at –0.3 volts to –0.4 volts. This prevents the

emitter-base junction of the parasitic NPN transistor

from being turned on, and also prevents SCR

triggering. Figure 11 shows the connections for the

Schottky diodes.

R

p-well

DGND

R

SUB

V

DD

IC#1

R

OUT

IC#2

1N914

+5V

DGND

COMMON GROUND

V

DD

R

IN

C

IN

HP5082-

2835

L

R

DAMPING

PARASITIC

TRACE

INDUCTANCE

I/P

HP5082-

2835

OUTPUT

+5V

0V

–0.3

INPUT CLAMPED

AND DAMPED

Figure 11. Adding Schottky diodes from the inputs

and outputs of a CMOS IC to DGND protects against

undervoltages causing conduction of the parasitic

NPN, thus inhibiting SCR action. The series damp-

ing resistor makes ringing due to long PC board

traces die out more quickly.

3. If the DGND potential can occasionally exceed AGND

by more than 0.3 volts, a Schottky diode placed be-

tween the two pins of the device will prevent conduc-

tion of the associated parasitic NPN transistor. This

provides additional protection against latch-up as

shown in Figure 12. An extra diode connected in in-

verse parallel with the one just mentioned provides

clamping of DGND to AGND in the other direction

and will help to minimize digital noise from being in-

jected into the IC.

To identify over- and under-voltage events as described

in points (2) and (3) above, the use of a storage oscillo-

scope is suggested, set at the maximum ratings specifi-

cation for each pin. Set the Time/Div. to the minimum

setting on the oscilloscope (preferably in the ns range).

This test should be conducted over a long period of

time, e.g., overnight.

4. In circuits where the I

OUT

pin of a CMOS IC can be

pulled below AGND, another Schottky diode clamp

between these two terminals will prevent sensitive

–6–

LATERAL

PNP

VERTICAL

NPN

R3

R1

R2

R4

+5V

HP5082-2835

SCHOTTKY

DIODES

DGND

AGND

Figure 12. Connecting Schottky diodes between

DGND and AGND prevents conduction of the

parasitic NPN transistor, and helps to minimize

injected noise from DGND to the analog output.

ICs from latching up. This condition sometimes oc-

curs with high speed bipolar operational amplifiers

that are used as current-to-voltage converters follow-

ing a DAC. During power-up or power-down transi-

tions, the op amp’s inverting input presents a low

impedance from I

OUT

to the negative supply rail. An

unprotected DAC may fail without the recommended

Schottky diode clamp to AGND.

5. In designs that have long digital PC board traces be-

tween components and are therefore prone to induc-

tive ringing problems, a series damping resistor of

10

Ω

–100

Ω

will be beneficial. This resistor increases

the damping factor of the equivalent series RLC net-

work and causes the ringing to decay more quickly.

This will help to prevent conduction of the input or

output protection diodes.

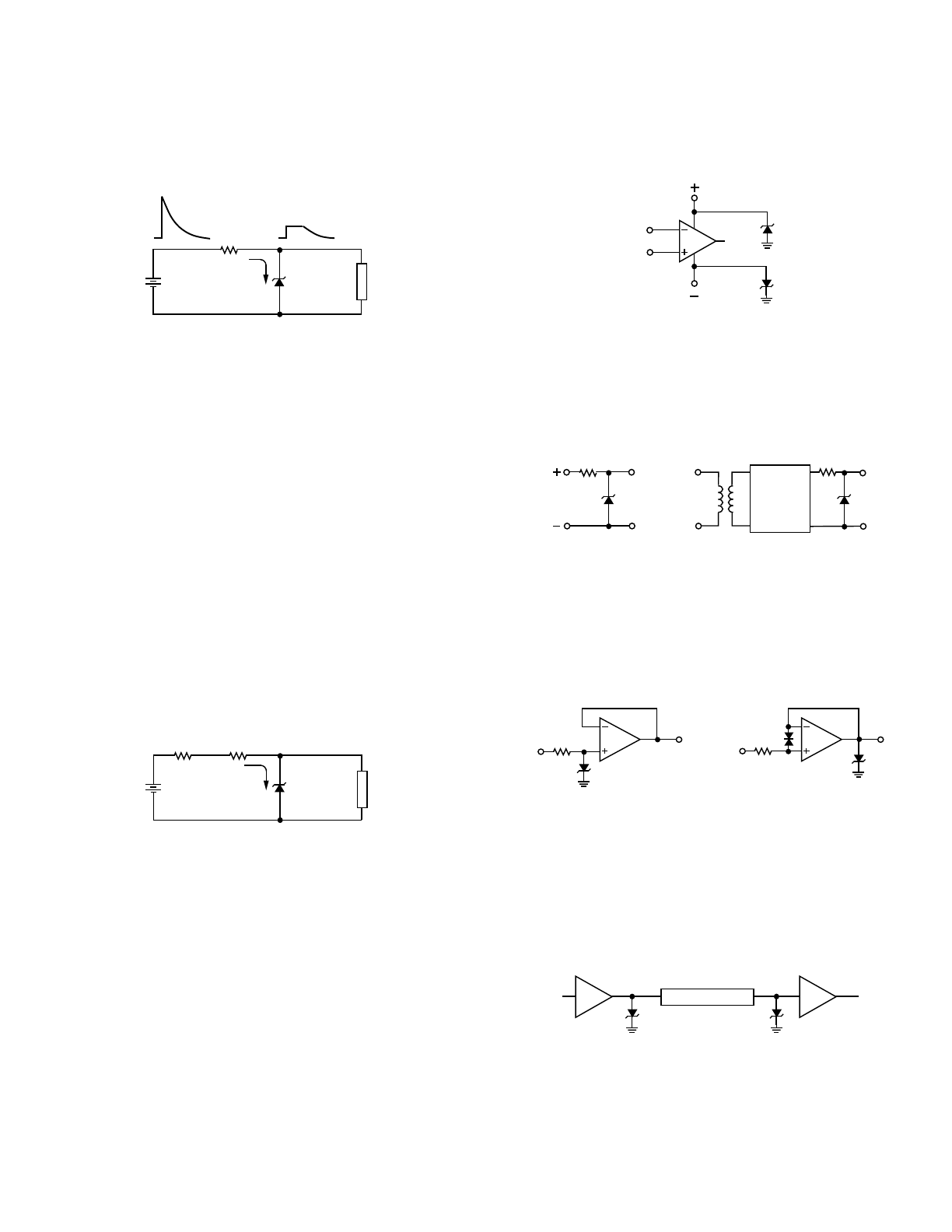

High Voltage Transients

If power supply overvoltaging is identified as the failure

mechanism, a reliable solution is the insertion of a

TransZorb* transient voltage suppressor (TVS). What is

a TVS and how does it work?

Transient voltage suppressors

6

(TVSs) are devices used

to protect vulnerable circuits from electrical overstress

such as that caused by ESD, inductive load switching

and lightning-induced line transients. Within the TVS,

damaging voltage spikes are limited by clamping or ava-

lanche action of a rugged silicon pn junction which re-

duces the amplitude of the transient to a nondestructive

level.

In a circuit, the TVS should be “invisible” until a

transient appears. Electrical parameters such as break-

down voltage (V

BR

), standby (leakage) current (I

D

), and

capacitance should have no effect on normal circuit

performance.

To limit standby current and to allow for variations in

V

BR

caused by the temperature coefficient of the TVS,

the TVS breakdown voltage is usually 10% above the

*TransZorb is a registered trademark of General Semiconductor

Industries, Inc.

reverse standoff voltage (V

R

), which approximates the

circuit absolute maximum operating voltage. When a

transient occurs, the TVS clamps instantly to limit the

spike voltage to a safe level, called the clamping voltage

(V

C

), while conducting potentially damaging current

away from the protected component.

TRANSIENT PEAK

IC FAILURE THRESHOLD

TVS CLAMPING

VOLTAGE (V

C

)

+30V

+20V

+12V

NORMAL OPERATING

VOLTAGE

TIME

Figure 13. Transients of several thousand volts can be

clamped to a safe level by the TVS.

TVSs are designed, specified and tested for transient

voltage protection, while a Zener diode is designed and

specified for voltage regulation.

Therefore, for transient

protection the TVS should be selected over the Zener.

The surge power and surge current capability of the

TVS are proportional to its junction area. Surge ratings

for silicon TVS families are normally specified in kilo-

watts of peak pulse power (P

P

) during a given waveform.

Early devices were specified with a 10/1000

µ

s wave-

form (10

µ

s rise to peak and 1000

µ

s exponential decay

to one half peak), while more recent devices are rated

for an 8/20

µ

s test waveform. Power ratings range from

5 kW for 10/1000

µ

s, down to 400 W for 8/20

µ

s. This

power is derived from the product of the peak voltage

across the TVS and the peak current conducted through

the device.

TVSs have circuit operating voltages available in incre-

ments from 5 V up to 376 V for some families. Because

of the broad range of voltages and power ratings avail-

able (as well as the universal presence of transient volt-

ages), TVSs are used in a wide variety of circuits and

applications.

As an example, consider a pressure transducer which

operates at 28 V, placed in an environment in which it

encounters a transient voltage of 140 V peak, having a

source impedance of 2

Ω

and a duration of 10/1000

µ

s.

The failure threshold of the transducer is 40 V, therefore

the TVS must clamp at 40 V or less.

The current deliv-

ered by this transient is:

I = (140 V – 40 V)/2

Ω

= 50 A

Note that the voltage clamping action of the TVS results

in a voltage divider whereby the open circuit voltage of

the transient appears across the combination of the

source impedance and the TVS device.

Thus the TVS

–7–

TYPICAL TVS APPLICATIONS

DC Line Applications

TransZorb TVSs on power lines prevent IC failures

caused by transients, power supply reversals or during

switching of the power supply between on and off

(Figure 16).

Ic

Figure 16.

For power sources utilizing the TransZorb TVS, the

TransZorb TVS is chosen such that the reverse stand-off

voltage is equal to or greater than the dc output voltage.

For certain applications it may be more desirable to re-

place the series resistor (R) with an inductor (Figure 17).

RECTIFIER

NETWORK

R

TO

LOAD

AC

INPUT

TO

LOAD

15V

DC

INPUT

R

Figure 17.

Signal Line Applications

Input pins are vulnerable to low energy, high voltage

static discharges or crosstalk transmitted to the signal

wires. Limited protection is provided by the clamp

diode or an input network within the IC substrate

(Figure 18).

Ic

Ic

OR

Figure 18.

Transients generated on the line can vary from a few mi-

croseconds to several milliseconds in duration and up to

10,000 volts in magnitude.

Excess current passing

through the diode can cause an open circuit condition or

a slow degradation of the circuit performance.

TransZorb TVSs located on the signal line can absorb

this excess energy (Figure 19).

SIGNAL WIRE

OUT

IN

Figure 19.

A further reference on the subject of using TransZorbs

for circuit protection is Analog Devices Application Note

AN-311, entitled ”How to Reliably Protect CMOS Circuits

against Power Supply Overvoltaging.“

clamping voltage is subtracted from the transient volt-

age leaving a net source voltage of 100

V. When the

clamping voltage is high compared to the transient peak

voltage, the current is significantly reduced.

This circuit can be protected with a 5 kW rated TransZorb

TVS which will easily sustain the surge current.

TRANSIENT

VOLTAGE

CLAMPED

TRANSIENT

28V

2

Ω

5kW

TVS

LOAD

Z

S

Figure 14. A 5 kW TVS is required to handle the surge

current.

An alternate and more economical approach is to add a

series resistor to effectively increase the source imped-

ance thus limiting surge current as illustrated in Figure

15. Since the current drawn by the transducer under

normal operation is small (<20 mA typical), perfor-

mance is not adversely affected by a reduction in supply

current.

For a small load current, 10 mA, the voltage drop across

the added resistance is minimal, about 250

mV for a

25 ohm resistor. Adding this resistor reduces the surge

current to:

I = (140 V – 40 V)/(2

Ω

+ 25

Ω

) = 3.7 A

This is less than one-tenth the surge current without the

resistor. A TVS with lower power rating is able to

handle the resulting current.

In this case a 500 W sup-

pressor replaces the 5 kW device, saving board space

and cost.

28V

2

Ω

500W

TVS

LOAD

25

Ω

Z

S

Figure 15. The series resistor reduces transient current

allowing a much smaller TVS to be used.

Carbon composition resistors are recommended for this

application because of their energy dissipation capabil-

ity. Steady state power dissipated by the resistor (V

×

I) is

2.5 mW requiring the lowest rated resistor available for

adequate margin.

–8–

E2054–15–8/95

PRINTED IN U.S.A.

IN SUMMARY

Designing an application with maximum protection of

the integrated circuits is a challenging problem with a

solution that depends on many factors. The following is

a brief summary of the protection schemes discussed in

this application note:

1. Personnel should be trained in the proper handling

techniques for prevention of EOS/ESD damage.

2. A good facilities ground system including shielding

of equipment and data lines should be implemented.

3. Use transient suppressors judiciously, i.e., check if

there are spikes on the supply and the ground lines

which may exceed the maximum ratings of those

pins.

4. Review the proper power-up sequence of the

device(s). The correct order should normally be:

GND, Main supplies (if possible the substrate supply

being first), V

CC

, V

REF+/–

and finally all other pins.

5. Review the data sheet, in particular the maximum rat-

ings section.

Remaining devices from a lot that may have been

mistested or subjected to the same conditions as those

of any failing devices should be evaluated to determine

if latent damage may be present.

This analysis should

be performed due to the possibility that overstress con-

ditions existed which did not cause immediate failure

but induced subtle damage that could result in long-

term reliability problems.

Finally, the issue of input overvoltage protection for am-

plifiers is not discussed in this application note. How-

ever, it is exclusively discussed in two other Analog

Devices publications; (1) Joe Buxton, ”Simple Tech-

niques Protect Amplifiers from Input Overvoltage,“

Ana-

log Dialogue 28-3, 1994, and (2) Joe Buxton, ”Input

Overvoltage Protection,“

System Applications Guide,

Analog Devices, 1993, pp 1–56 to 1–74.

REFERENCES

1

Henry Domingos, ”Circuit Design for EOS/ESD Protec-

tion,” Proc. 1982 EOS/ESD Symp., pp. 1–17 to 1–21.

2

John A. Schmidt, Manager of Technical Services IMCS

Corporation, Santa Clara, CA, ”CDM–The Newest ESD

Test Model,“ 1991.

3

MIL-STD-883 Method 3015, ”Electrostatic Discharge

Sensitivity Classification,“ Military Standard Test

Methods and Procedures for Microelectronics.

4

ESD Prevention Manual, 1986. Norwood MA; Analog

Devices Inc., pp 9-11. Contains additional references.

5

Mark Alexander, ”Understanding and Preventing

Latch-Up in CMOS DACs,“ AN-109. Free from Analog

Devices, PMI Division.

6

General Instrument, Power Semiconductor Division

Data Book/11th edition, pp. 633, 696–703. Contains ad-

ditional references.

Andrew Olney, Analog Devices, Inc., personal communication